Grand Hall Yn663ng, Yn663lp Owner's Manual

Owner’s Manual

Customer Service Helpline: If you have questions about assembly or grill operation, or if there are damaged or

missing parts when you unpack this unit from the shipping box, call us Monday through Friday at 1-800-752-3085

n

W

ARNING:

All barbecues and carts are designed for outdoor use only!

All barbecues are not intended for commercial use.

n

W

ARNING:

Read this Owner’s Manual carefully and

be sure your gas grill is properly

assembled, installed and maintained.

Failure to follow these instructions

could result in serious bodily injury

and/or property damage. This gas grill

is intended for outdoor use only and is

not intended to be installed in or on

recreational vehicles or boats.

Note to Installer: Leave this Owner’s

Manual with the consumer after delivery

and/or installation.

Note to Consumer: Leave this

Owner’s Manual in a convenient place

for future reference.

P80151009A

RV 041205

America's Barbecue Grill Superstores

Design Certified

Unit approved by

CSA Laboratories under standard

ANSI Z21-58b-2002/CGA 1.6b-2002

52” All Grill BBQ

YN662AGLP

YN662AGNG

YN662CT

(Cart Only)

38”

All Grill BBQ

YN663LP

YN663NG

YN663CT

(Cart Only)

52” BBQ with Side Burner

YN662LP

YN662NG

YN662CT (Cart Only)

READ THESE SAFETY INSTRUCTIONS

n

WARNING

Fuels used in gas or oil-fired appliances and the products of

combustion of such fuels, contain chemicals known to the

State of California to cause cancer, birth defects and/ or

other reproductive harm.

This warning is issued pursuant to California Health &

Safety Code Sec. 25249.6.

n

WARNING

Failure to comply with these instructions could result in a

fire or explosion that could cause serious bodily injury,

death, or property damage.

n

WARNING

Your grill will get very hot. Never lean over the cooking

area while using your grill. Do not touch cooking surfaces,

grill housing, grill lid or any other grill parts while the grill is

in operation, or until the grill has cooled down after use.

Failure to comply with these instructions may result in

serious bodily injury.

Grill lnst

allation Codes

This gas grill must be installed in accordance with all

local codes. In areas without local codes, follow the latest

edition of the National Fuel Gas Code ANSI Z223.1. In

Canada, installation must conform to standard CAN/CGA

1b149.1 or 1-b149. 2 (Installation Code for Gas Burning

Appliances and Equipment) and all local codes.

Proper Placement and Clearance of Grill

Never use your gas grill in a garage, porch, shed,

breeze way or any other enclosed area. Your gas grill is to

be used outdoors only, at least 24 inches from the back

and 18 inches to the side of any combustible surface.

Your gas grill should not be placed under any surface that

will burn. Do not obstruct the flow of ventilation air around

the gas grill housing.

This outdoor gas grill is not intended to be installed

in or on recreational vehicles and/or boats.

PROPANE MODELS:

Correct LP Gas Tank Use

LP gas grill models are designed for use with a standard

20 lb. Liquid Propane Gas (LP gas) tank, not included with

grill box. Never connect your gas grill to an LP gas tank that

exceeds this capacity. A tank of approximately 12 inches in

diameter by 18-1/2 inches high is the maximum size LP gas

tank to use. A Propane tank with an OPD (Overfill Prevention

Device) must be used. This safety feature prevents the tank

from being over-filled which can cause malfunction of the LP

gas tank, regulator and/or grill.

The LP gas tank must be constructed and marked in

accordance with specifications of the U.S. Dpt. of

Transportation (DOT). In Canada, the LP gas tank must

meet the Canadian Transportation and Communications

(CTC) specifications. Also be sure to read and follow all LP

instructions on the following page.

If the outdoor cooking gas appliance is not in use, the

gas must be turned off at the supply cylinder.

(a) Do not store a spare LP-gas cylinder under or near

this appliance;

(b) Never fill the cylinder beyond 80 percent full; and

(c) If the information in (a) and (b) is not followed

exactly, a fire causing death or serious injury may

occur.

1. The LP gas tank has a shutoff valve, terminating in an

LP gas supply tank valve outlet, that is compatible with

a Type 1 tank connection device. The LP gas tank must

also have a safety relief device that has a direct communication with the vapor space of the tank.

2. The tank supply system must be arranged for vapor

withdrawal.

3. The LP gas tank used must have a collar to protect the

tank valve.

! Never connect an unregulated LP gas tank to your gas

grill. The gas regulator assembly supplied with your gas

grill is adjusted to have an outlet pressure of 11" water

column (W.C.) for connection to an LP gas tank.

! Only use the regulator and hose assembly supplied with

your gas grill. Replacement regulators and hose assemblies must be those specified by manufacture.

! Have your LP gas tank filled by a reputable propane gas

dealer and visually inspected and re-qualified at each

filling.

! Never fill the gas tank beyond 80% full. Have your

propane gas dealer check the release valve after every

filling to ensure that it remains free of defects.

! Always keep LP gas tanks in an upright position.

! Do not store (or use) gasoline or other flammable

vapors and liquids in the vicinity of this gas grill.

! An LP gas tank that is not connected for use must NOT

be stored on bottom shelf or in the vicinity of this or any

other gas grill.

! Do not subject the LP gas tank to excessive heat.

! Never store an LP gas tank indoors. If you store your

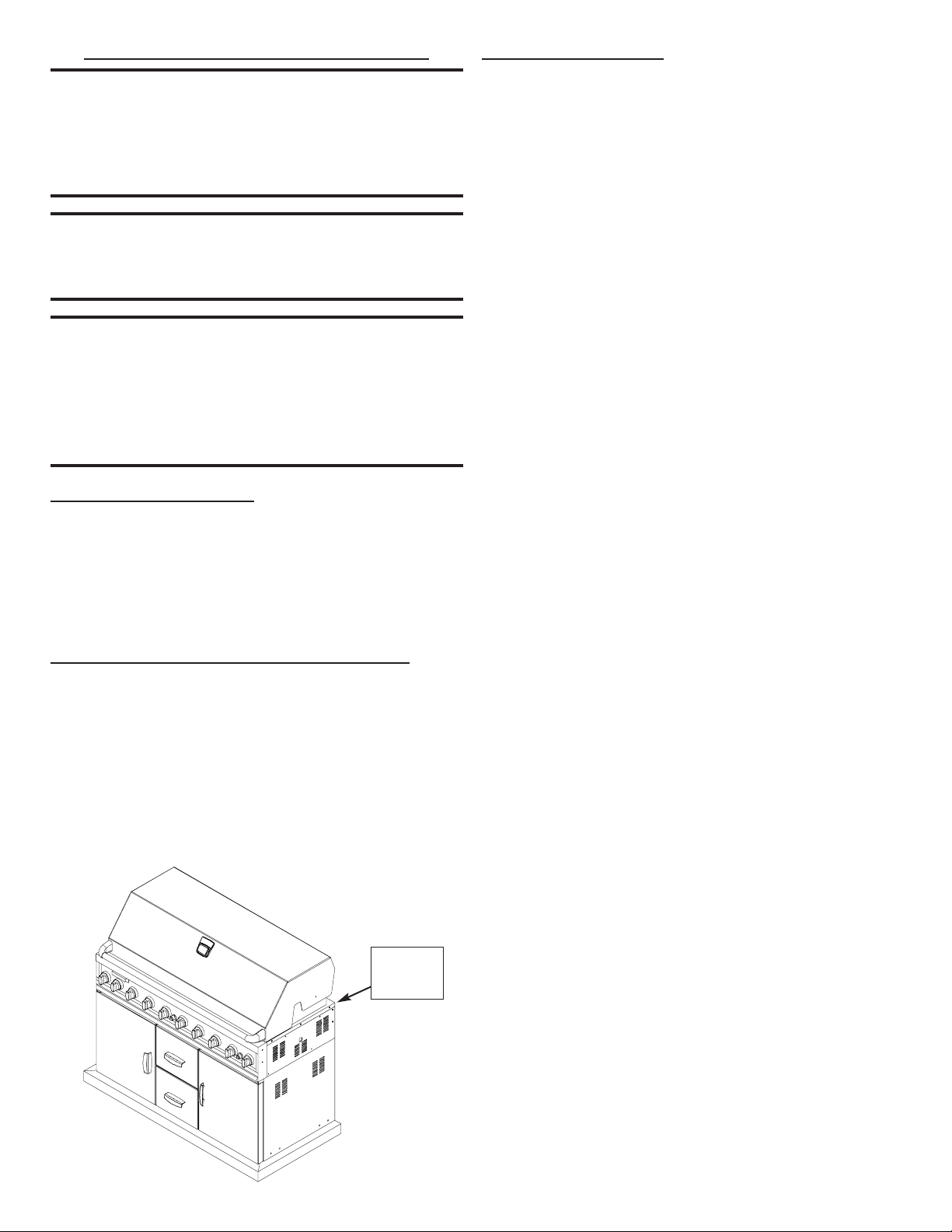

CSA label

located at

rear of unit

- 2 -

gas grill in the garage or other indoor location, always

disconnect the LP gas tank first and store it safely outside and out of reach of children.

! LP gas tanks must be stored outdoors in a well-ventilat-

ed area. Disconnected LP gas tanks must not be stored

in a building, garage or any other enclosed area.

! When your gas grill is not in use the gas must be turned

off at the LP gas tank.

! The regulator and hose assembly must be inspected

before each use of the grill. If there is excessive abrasion or wear or if the hose is cut, it must be replaced

prior to the grill being used again.

! Keep the gas regulator hose away from hot grill surfaces

and dripping grease. Avoid unnecessary twisting of

hose. Visually inspect hose prior to each use for cuts,

cracks, excessive wear or other damage. If the hose

appears damaged do not use the gas grill. Call our serv-

ice center at 1-800-752-3085.

! Never light your gas grill with the lid closed or before

checking to insure the burner tubes are fully seated over

the gas valve orifices.

! Never allow children to operate your grill. Do not allow

children to play near your grill.

n

WARNING

A strong gas smell, or the hissing sound of gas indicates a

serious problem with your gas grill or the LP gas tank.

Failure to immediately follow the steps listed below could

result in a fire or explosion that could cause serious bodily

injury, death, or property damage.

! Shut off gas supply to the grill.

! Turn the Control Knobs to the OFF position.

! Open grill lid.

! Get away from the LP gas tank.

! Do not try to fix the problem yourself..

! If odor continues or you have a fire you cannot extin-

guish, call your fire department.

Do not call near the LP gas tank because your telephone is

an electrical device and could create a spark resulting in

fire and/or explosion.

NOTE: The normal flow of gas through the regulator and

hose assembly can create a humming noise. A low volume

of noise is perfectly normal and will not interfere with operation of the grill. If humming noise is loud and excessive you

may need to purge air from the gas line or reset the regulator excess gas flow device. This purging procedure should

be done every time a new LP gas tank is connected to your

grill. For help call the Customer Service Helpline for assistance.

Built-in Units Utilizing Natural Gas

When connecting a built-in unit to the natural gas supply in your home, please ensure the pipe joint compound is

resistant to the action of natural gas. In addition, please

observe the following:

The barbecue and its individual shut-off valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess

of ½ psi (3.5 kPa).

The barbecue must be isolated from the gas supply

piping system by closing its individual

manual shut-off valve

during any pressure testing of the gas supply piping system

at test pressures equal to or less than ½ psi (3.5 kPa)

The units are supplied from the factory equipped for

use with natural gas and includes a natural gas regulator.

If operation with propane gas is desired, you must pur-

chase a Propane Model. In addition, a Propane Gas

Regulator MUST

be installed in the gas supply line from

the propane gas tank.

Please remember to check all gas connections for

leaks after the piping is completed. Follow the procedure

under the heading "CAUTION: LEAK CHECKING."

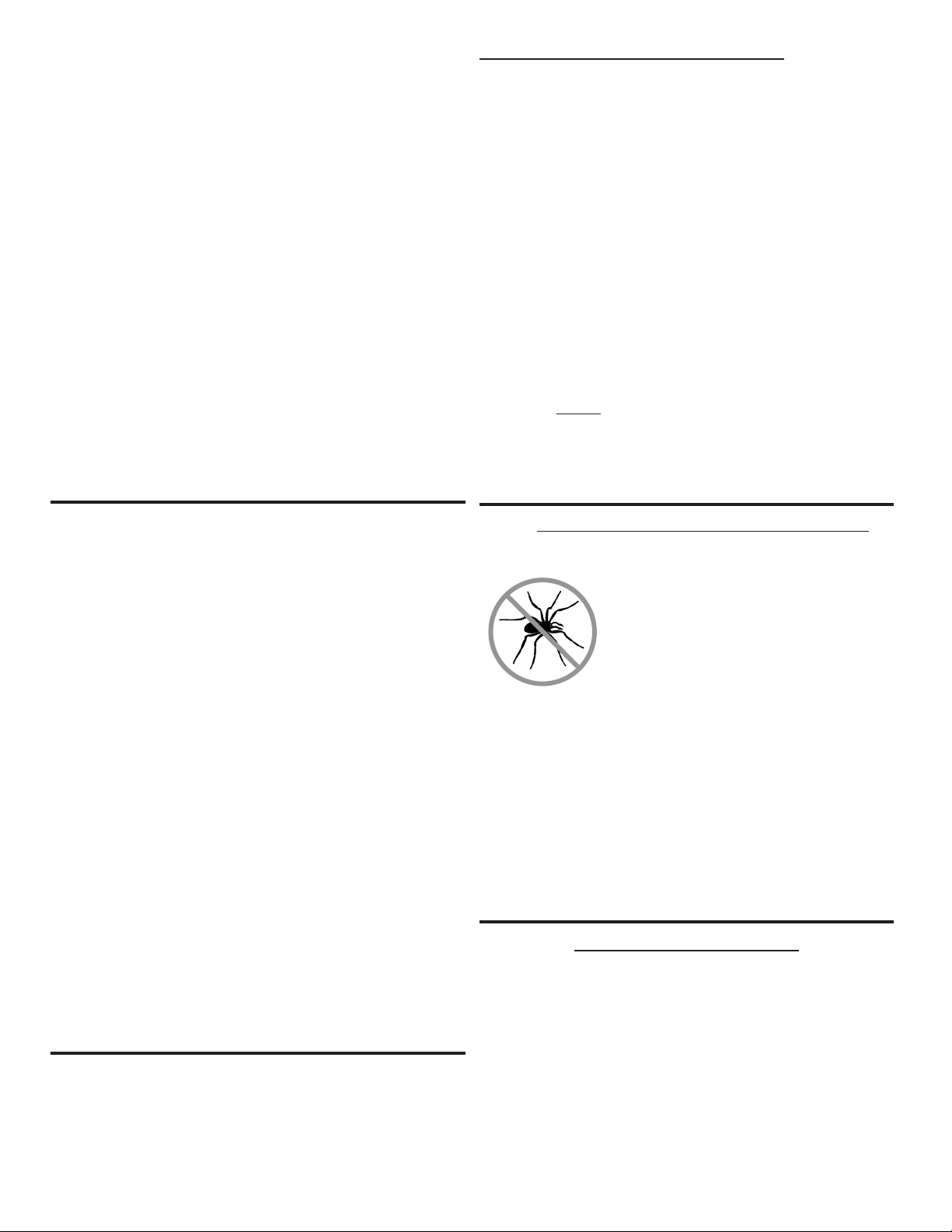

n CAUTION: BEWARE OF FLASHBACK

CAUTION: Spiders and small insects occasionally spin

webs or make nests in the

grill burner tubes during

transit and warehousing.

These webs can lead to a

gas flow obstruction which

could result in a fire in and

around the burner tubes.

This type of fire is known as a ”FLASHBACK” and can

cause serious damage to your grill and create an unsafe

operating condition for the user.

Although an obstructed burner tube is not the only cause of

”FLASHBACK”, it is the most common cause.

To reduce the chance of ”FLASHBACK”, you must clean the

burner tubes before assembling your grill, and at least once

a month in late summer or early fall when spiders are most

active. Also perform this burner tube cleaning procedure if

your grill has not been used for an extended period of time.

BEFORE USING YOUR GRILL

To reduce the chance of ”FLASHBACK” clean the burner tubes and burners before fully assembling your grill.

Unscrew the bolt at the rear of the burner using a screwdriver. Carefully lift each burner up and away from the gas

valve orifice, then refer to Fig1 and perform one of these

three cleaning methods:

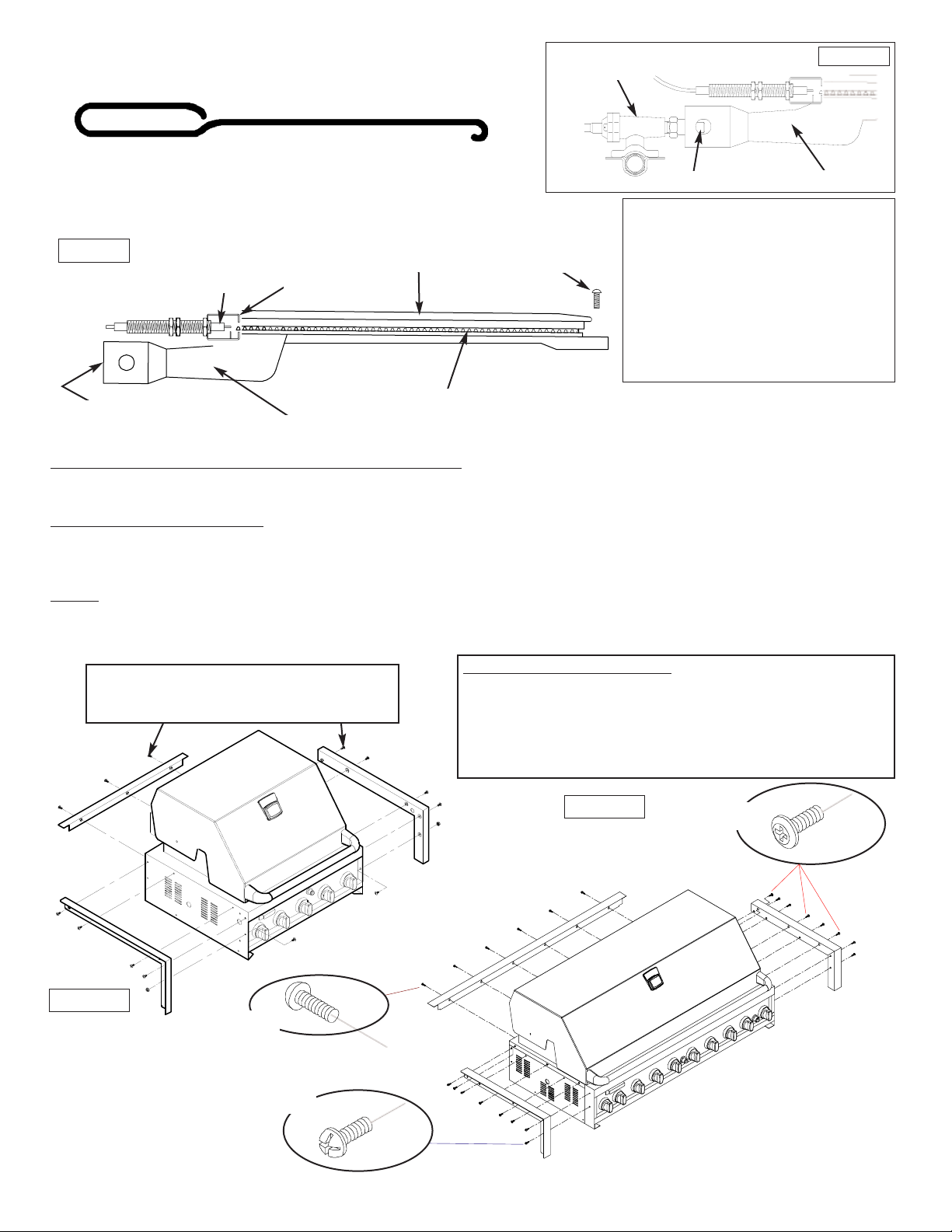

1. Bend a stiff wire, (a lightweight coat hanger works well)

into a small hook as shown below. Run the hook through

the burner tube and inside the burner several times to

remove any debris.

- 3 -

2. Use a bottle brush with a flexible handle. Run the brush through

the burner tube and inside the burner several times, removing any

debris.

3. Preferably, an air hose should be used to force air through each

burner tube. The forced air should pass debris or obstructions

through the burner and out the ports.

Figure 1

GAS VALVE

ASSEMBLY

BURNER TUBE

ORIFICE

Figure 2

SPARK

ELECTRODE

ASSEMBLY

BURNER TUBE

PHILLIPS HEAD

SCREW

BURNER PORTS

BURNER

GAS

COLLECTOR

BOX

n

WARNING

The location of the burner tube with

respect to the orifice is vital for safe

operation. Check to ensure the orifice

is inside of the burner tube before

using your gas grill (Figure 1).

If the burner tube does not fit over the

valve orifice, lighting the burner may

cause explosion and/or fire.

- 4 -

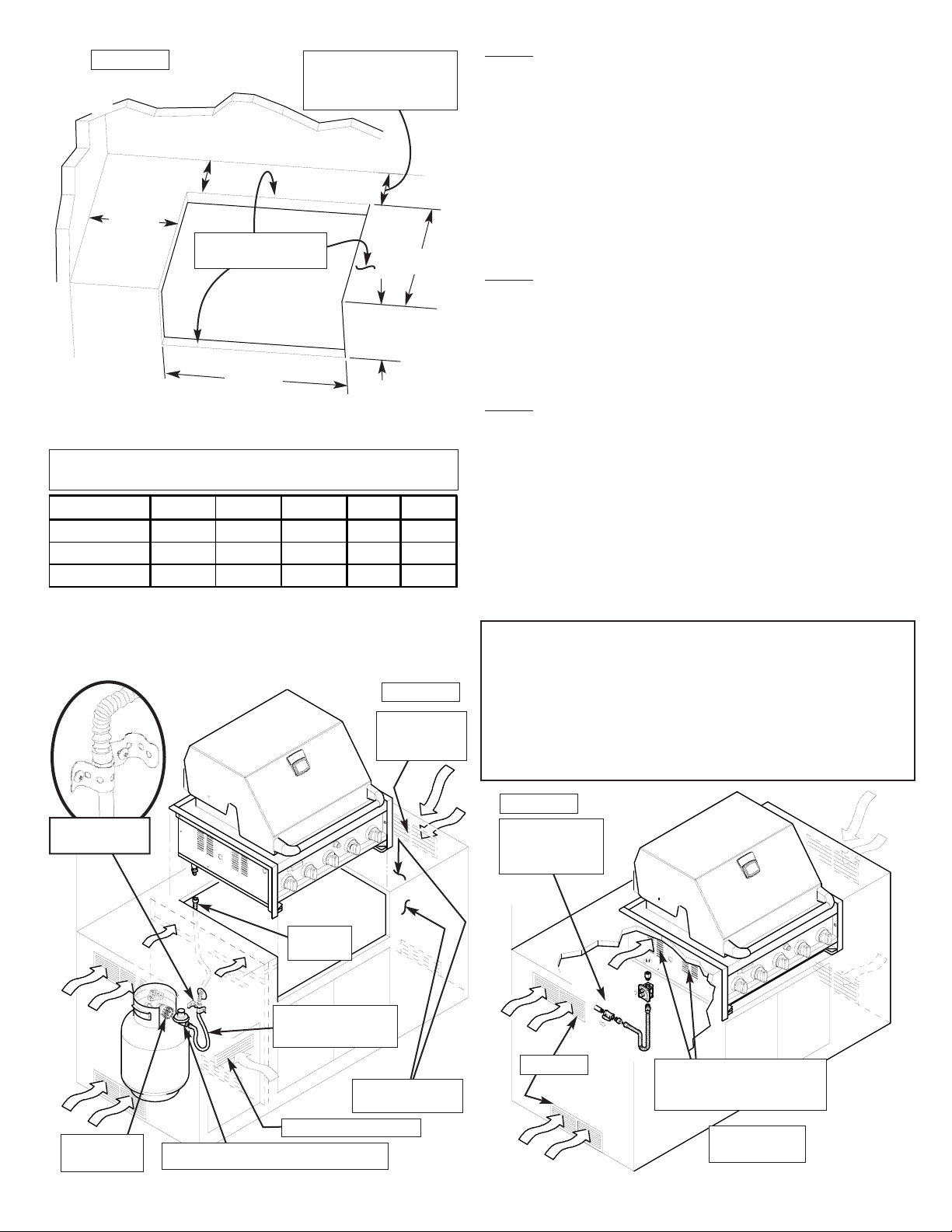

Outdoor BBQ Built-in Installation Specifications

Prior to installing unit, side and rear trims must be installed to fully support the unit.

Built-in T

rim Kit Installation:

Carefully remove the stainless steel trim pieces from the carton and attach Left, Right & Rear stainless trims to left, right &

rear sides of barbecue using 10 bolts & 2 nuts. Check to make sure they are aligned flush with the side barbecue face

and top before fully tightening the bolts.

NOTE:

When choosing a location for your Gas grill, keep in mind that it should not be located under any overhead com-

bustible construction. The side and bottom of the grill should not be any closer than 18 inches to combustible construction,

and the back of the grill should not be any closer than 24 inches to combustible construction.

TO CLEAN BURNER TUBE

INSERT HOOK HERE

Figure 3a

Rear Trim:

52" BBQ uses 4 bolts

38" BBQ uses 3 bolts and Wok uses 2 bolts

YN662AGLP , YN662AGNG

Rear Trim:

(A) - (6X) 3/16” x 3/8” Phillips Head Screws

Left & Right Trim:

(B) -(6X) 3/16” x 3/8” Pan Head with Cross Recess Screw

(C) -(10X) 1/4” x 1/2” Phillips Head Screw

Figure 3b

6X (A)

10X (C)

6X (B)

NOTE: When using Propane, EXTREME CAUTION should be

used to provide ample ventilation of vapor from the enclosure.

LP Gas vapor is heavier than air and SERIOUS INJURY from

a DANGEROUS EXPLOSION could occur if LP Gas is allowed

to accumulate in an enclosure and then ignited. Both the

Barbecue enclosure and LP cylinder enclosure require venting

that must be provided at the floor level of the enclosure to allow

any leaking LP Gas vapor to escape. Upper & lower groundlevel vents (20 sq. in. minimum each) MUST BE PROVIDED

on both sides of built-in construction. Please ask a Barbeques

Galore associate for full details.

NOTE:

When installing a barbecue equipped for liquid propane

in an island, the propane tank must be in a separate enclosure

that is completely isolated from the barbecue. It must be crossventilated in accordance with the current standard. The

propane tank MUST NEVER be installed directly under the barbecue.

NOTE:

Upper & lower ground-level vents (20 sq. in. minimum

each) MUST BE PROVIDED for combustion air on both sides

of built-in construction. Please ask a Barbeques Galore associate for full details.

Barbecues must be installed in accordance with CSA

specifications and all local building codes.

Air Vents

Louvers on BBQ must

remain unobstructed to

allow for combustion air.

Figure 6

Natural Gas

Installation

Access must

be provided to

Shut-off Valve

- 5 -

Depth

Width

Height

Side*

Rear*

6” minimum clear-

ance from cutout

(for hood)

Model Height Width Depth Side* Rear*

52" YN662 10" 52-3/4" 24-1/2" 18" 24"

38" YN663 10" 38-3/4" 24-1/2" 18" 24"

Side Burner 10" 17-1/2" 24-1/2" 18" 24"

non-combustible

construction

Built-in Model Cutout Dimensions &

Clearance to Combustibles

* Rear & Side Clearances indicated are to combustible

construction

Figure 4

nWARNING

Vapors from products containing Chlorine and other caustic

chemicals can cause Stainless Steel flexible connectors to

corrode. THESE PRODUCTS SHOULD NOT BE STORED IN

AN ISLAND OR NEAR THE connector. Cleaning solutions,

Household Chemicals and Solder fluxes can also cause pinholes if they come in contact with these connectors and

MUST be washed off immediately with water.

Stainless

Flexline

Non-combustible

Construction

Vented on

BOTH SIDES

of Island

Vented Access Door

CSA Approved Propane Regulator

CSA Approved

Rubber Gas Hose

QCC-1/OPD

Tank

Figure 5

Clamp down

flexline

- 6 -

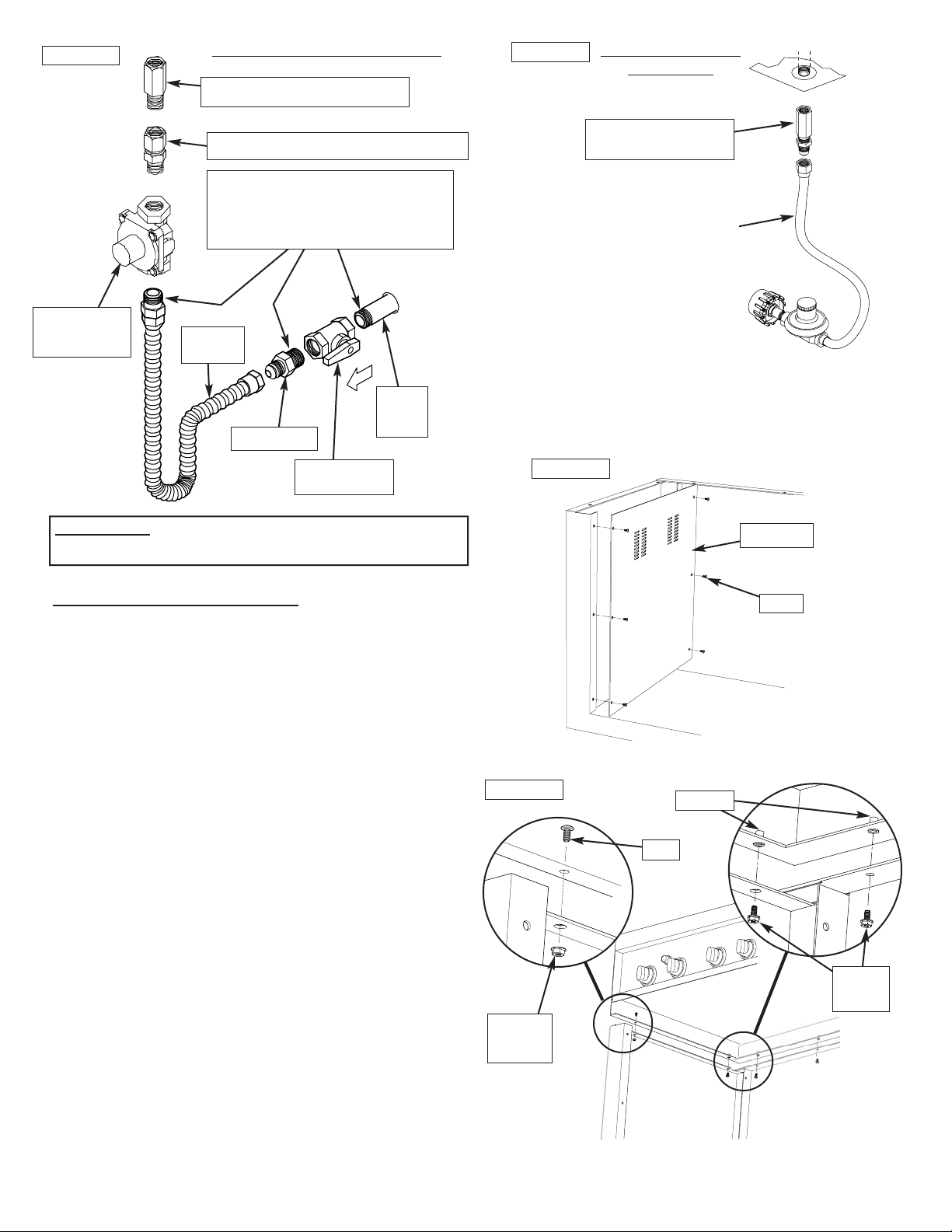

Cart & Barbecue Assembly (requires an assistant)

1. Unpack Cart.

2. Unpack Barbecue.

3. Position barbecue on top of Cart.

4. Remove Left & Right Side Panels on both sides of cart

as shown in Figure 9.

5. With the help of your assistant, position barbecue on

top of Cart and align mounting holes as shown in Figure

10.

6. Secure with two Mushroom Head bolts and nuts at both

front sides. Do not tighten until all fasteners are in

place.

7. Secure with Washer Head bolts (no nuts required) as follows:

YN662 (52” BBQ’s) 6 bolts at rear & side

YN663 (38” BBQ) 5 bolts at rear & side

You may need your assistant to adjust the position of the

barbecue so that the holes are all aligned.

8. Once barbecue & cart are aligned, tighten all bolts.

9. Replace Left & Right Side Panels.

Figure 9

Figure 7

NATURAL GAS MODELS ONLY

Side Panel

Bolts

CSA Approved

Rubber Gas Hose

Cart model LP Gas

Connection

3/8 FF x 3/8 MF

on Propane models

Figure 10

Nutserts

Washer

Head

Bolts

Nuts at

front only

(2)

Bolts

Figure 8

IN

OUT

CSA Approved

Natural Gas

Regulator

Yellow Teflon Pipe Thread Sealant

is recommended for use on all

pipe thread connections EXCEPT

flared threads.

Stainless

Flexline

Natural

Gas

Supply

Close Nipple

Shut-off Valve

1/2-1/2” NPT

IMPORTANT: Regulator must be on the Barbecue or your

warranty is void.

Extension Fitting for manifold

Extension Fitting for outlet (NG only)

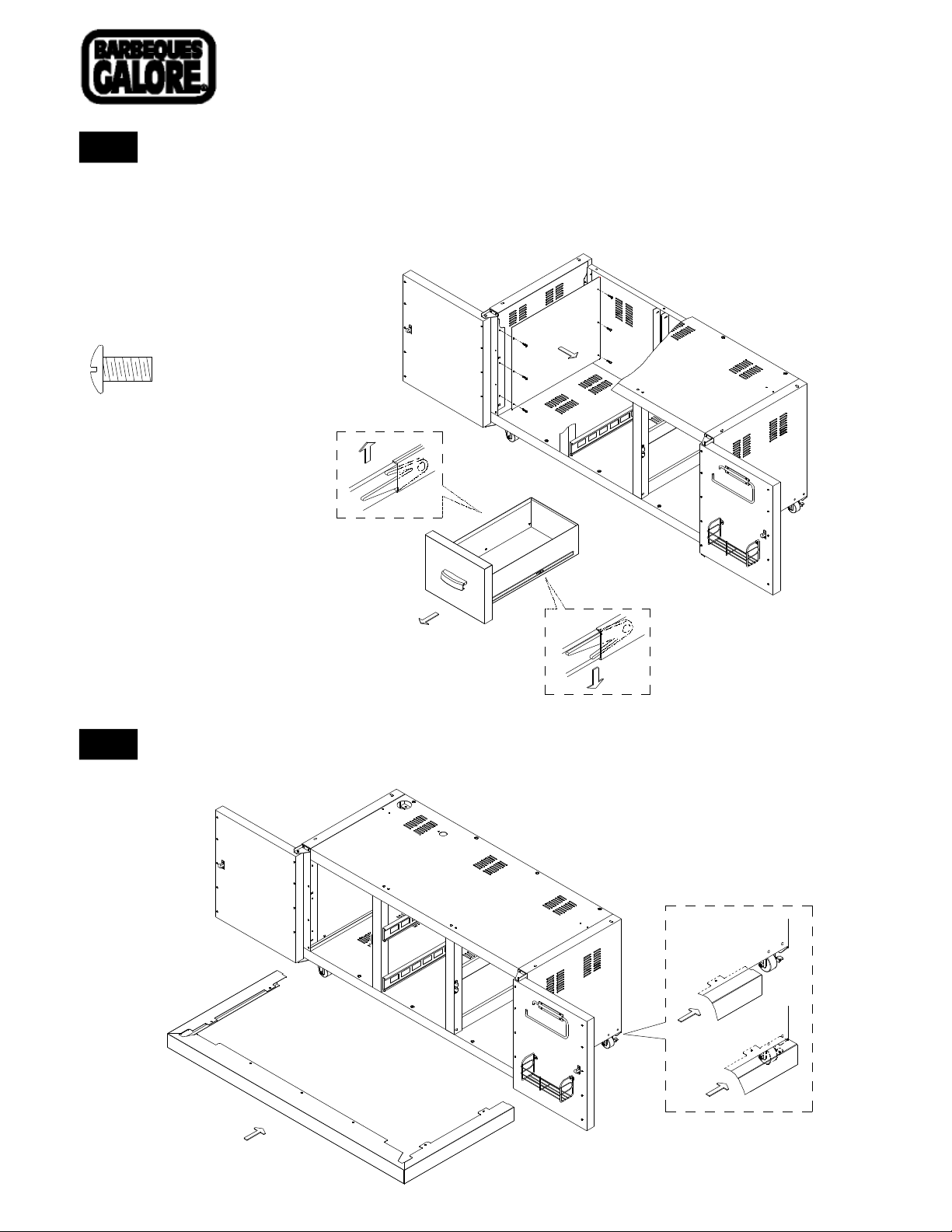

Grand Turbo YN662CT, YN663CT Models

P81201013A

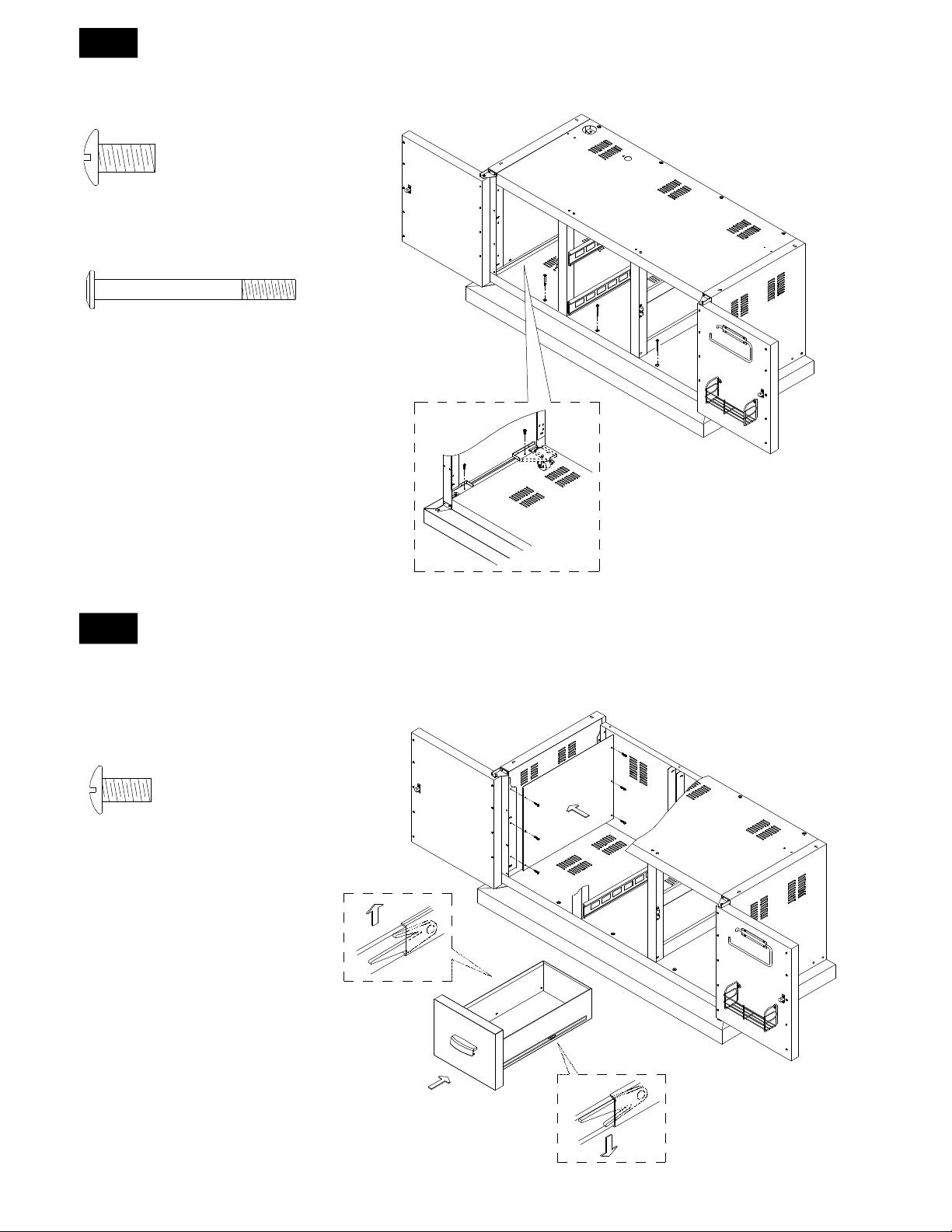

Cart & Cart Trim Plate Assembly Instructions

1

3/16"x1/2” Phillips Head Screw

Qty. 12

(from left & right cart side panel

trim plate)

Cart & Cart Trim Plate Assembly (requires an assistant)

1. Open the left door from cabinet cart. Unscrew the left cart side panel trim plate from the left cart side

panel.

2. Repeat for right cart side panel trim plate.

3. Pull out the upper drawer, Push up black tenon on the left slide and push down black tenon on the right

slide to remove the upper drawer.

4. Repeat for lower drawer.

2

1. Place the cart trim plate under the cart.

2. Be sure the rear of cart trim plate are inserted into the cart trim plate bracket.

- 7 -

3

Align the holes on the cart bottom shelf

and the caster seats

with the threaded holes on the cart trim plate.

Tighten securely using 4 screws and 3 bolt provided.

1/4”x1/2”Phillips Head Screw

Qty. 4

1/4"x2-1/2" Pan Head with Cross

Recess Bolt

Qty. 3 (for YN662CT Model)

Qty. 2 (for YN663CT Model)

4

2. Repeat for right cart side panel trim plate.

3. Install the upper drawer, Push up black tenon on the left slide and push down black tenon on the right

slide to install the upper drawer to cart.

4. Repeat for lower drawer.

3/16"x1/2” Phillips Head Screw

Qty. 12

(from left & right cart side panel

trim plate)

1. Install the left cart side panel trim plate to the left cart side panel.

- 8 -

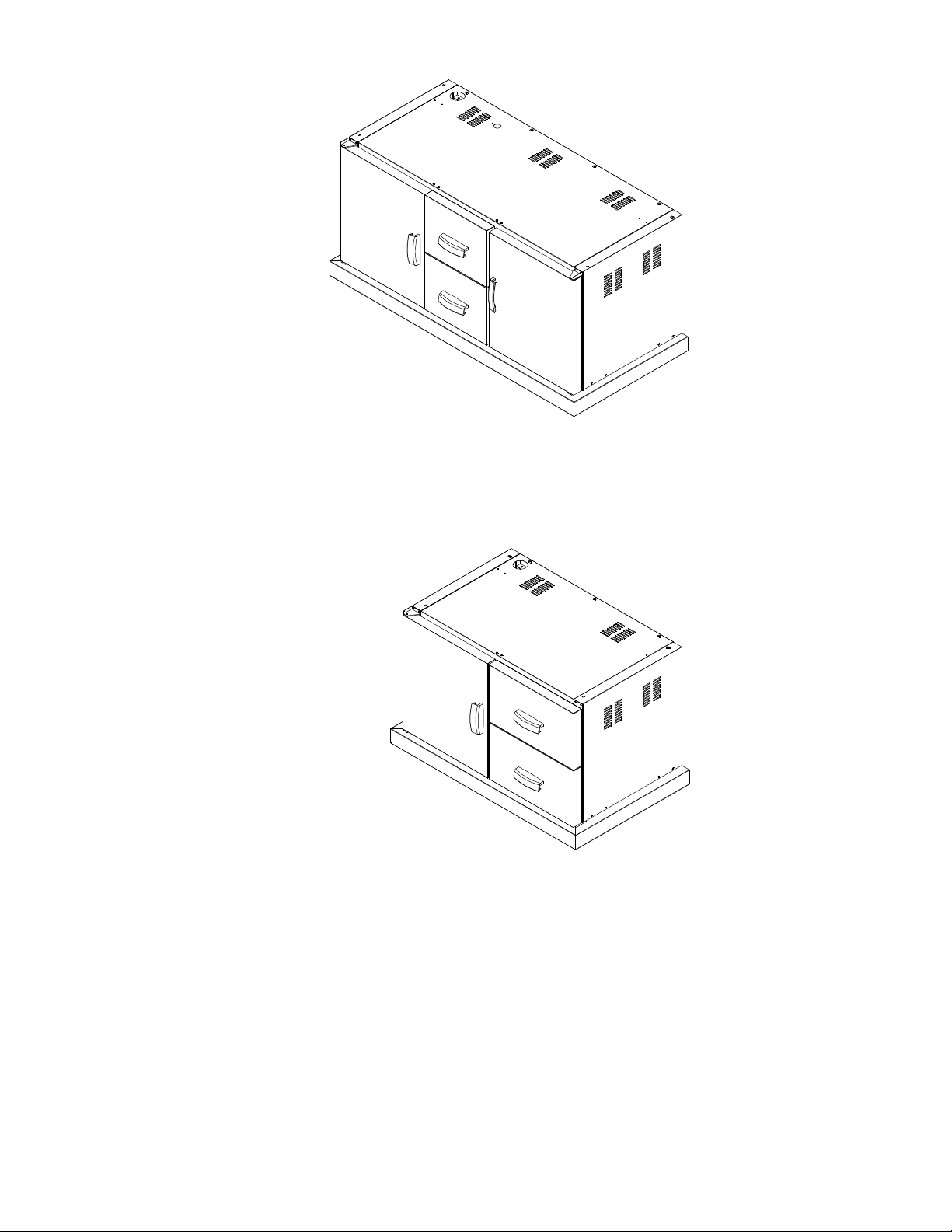

YN662CT Model

YN663CT Model

- 9 -

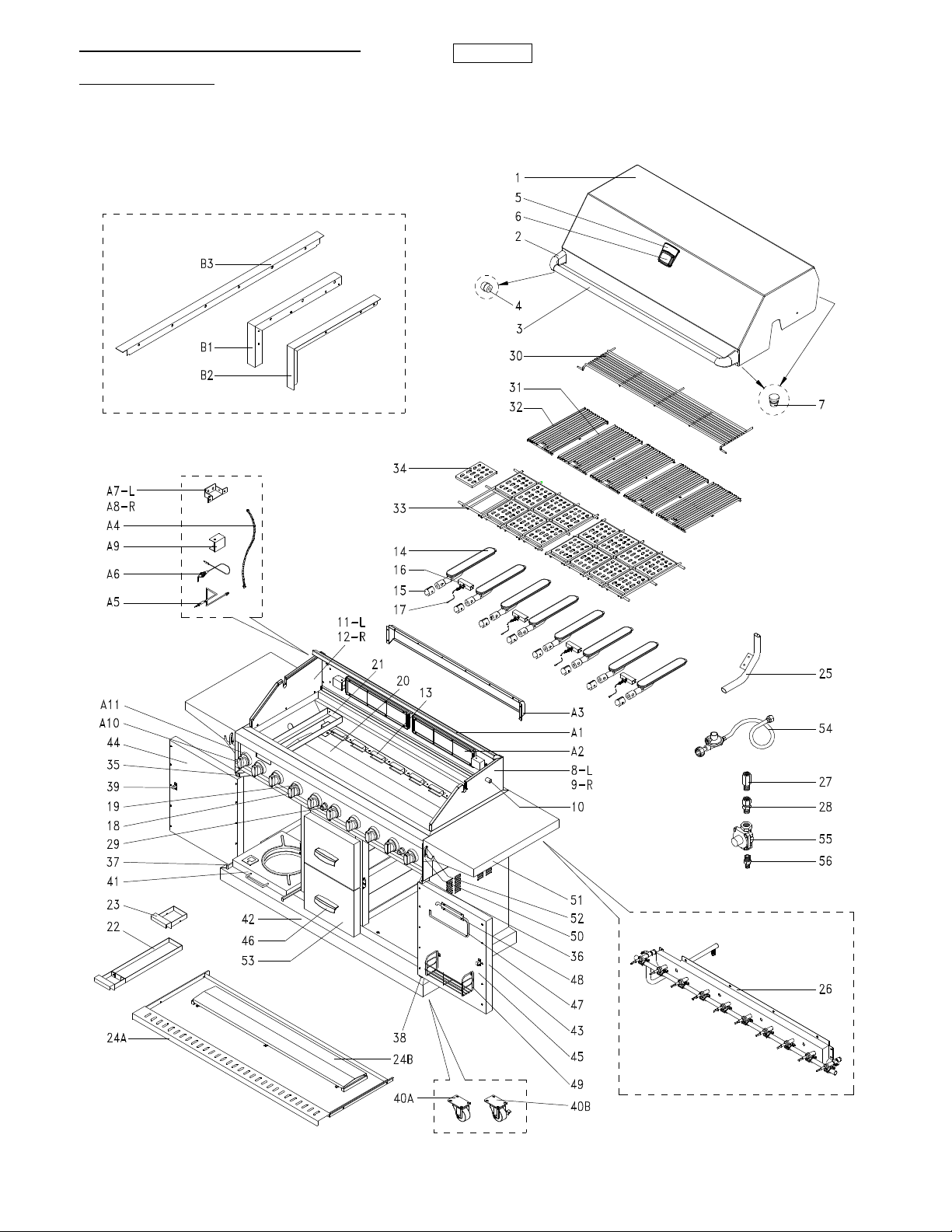

YN662AGLP , YN662AGNG

Parts Diagram

Figure 11

- 10 -

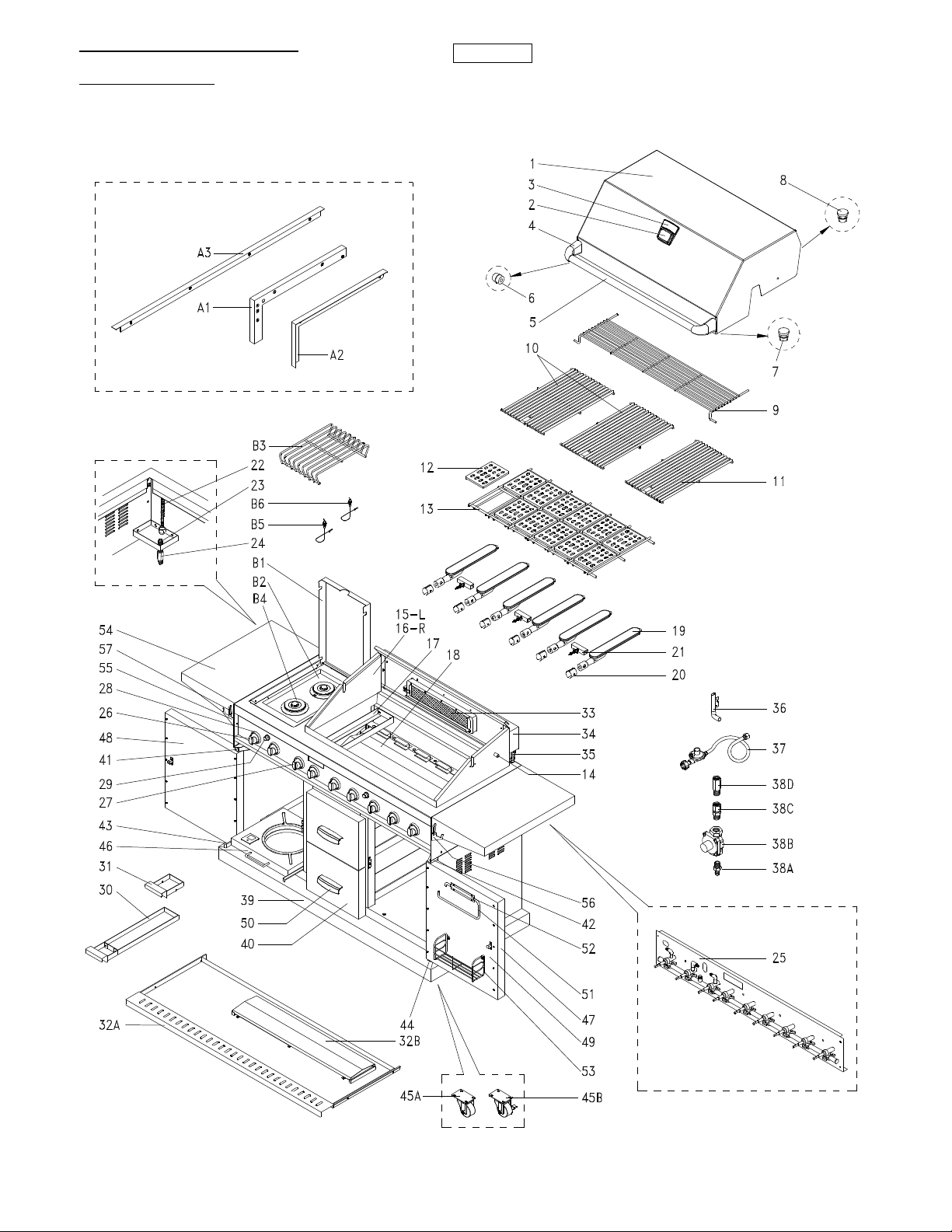

YN662LP , YN662NG

Parts Diagram

Figure 12

- 11 -

Loading...

Loading...