GRAND EFFECTS Model 100 Owner's Manual

For your safety:

If you smell gas:

1. Shut off gas to the appliance

2. Extinguish any open flame

near unit.

3. If odor continues, immediately

call your gas supplier

For your safety:

Do not store or use any gasoline or

other flammable vapors and / or

liquids in the vicinity of this or any

other appliance.

GRAND EFFECTS

360 Fire-Water Bowls and

Fire-Water Inserts

Model 100

OWNER’S MANUAL /

OPERATING AND MAINTENANCE INSTRUCTIONS

This manual should remain with the homeowner or parties responsible for operation.

(Rev A)

2

Table of Contents

Gas and Electrical Requirements Page 3

Installation of Fire Water Insert Page 3

Burner Setup and Adjustment Page 8

Maintenance Page 9

Operation Page 10

Troubleshooting Page 11

Control Panel Wiring Diagram Page 12

Burner Assembly Wiring Diagram Page 13

3

1.0 Gas and Electrical requirements:

1.1 Input Voltage: 120 Vac / 60 Hz to Grand Effects Control Panel

1.2 Gas type: Natural Gas Propane

1.3 Gas Pressure: Nominal: 7” wc 11”wc

1.4 Gas flow: 1 Burner System: 60,000-80,000 Btu/Hr

1.5 Water flow: 25-50 gpm (Flow will vary depending on bowl size and flow

preference)

Note: Check with your gas supplier to verify gas flows and pressures available at the location

of your installation. In many cases utility companies will install larger meters at no charge to

accommodate larger flows.

2.0 Installation for 360 Water Fire Bowl/ Water Fire Bowl Insert

Warning: This unit is for outdoor use only

Recommended CSA/AGA Clearances: Sides 4ft/Top 6ft

2.1 Do not install near any combustibles such as wood structures, fuels, clothing, fabrics

or dry vegetation.

2.2 Install Burner Assy well out of the way of pedestrian traffic.

2.3 Installation shall be performed by a licensed contractor. All aspects of installation

must conform to local or National codes, or in the absence of codes, with National Fuel

Gas Code ANZI Z223.1.

2.4 The Control Panel and approved manual gas valve shall be located where they can be

easily accessible so that the gas can be shut off quickly in case of an emergency.

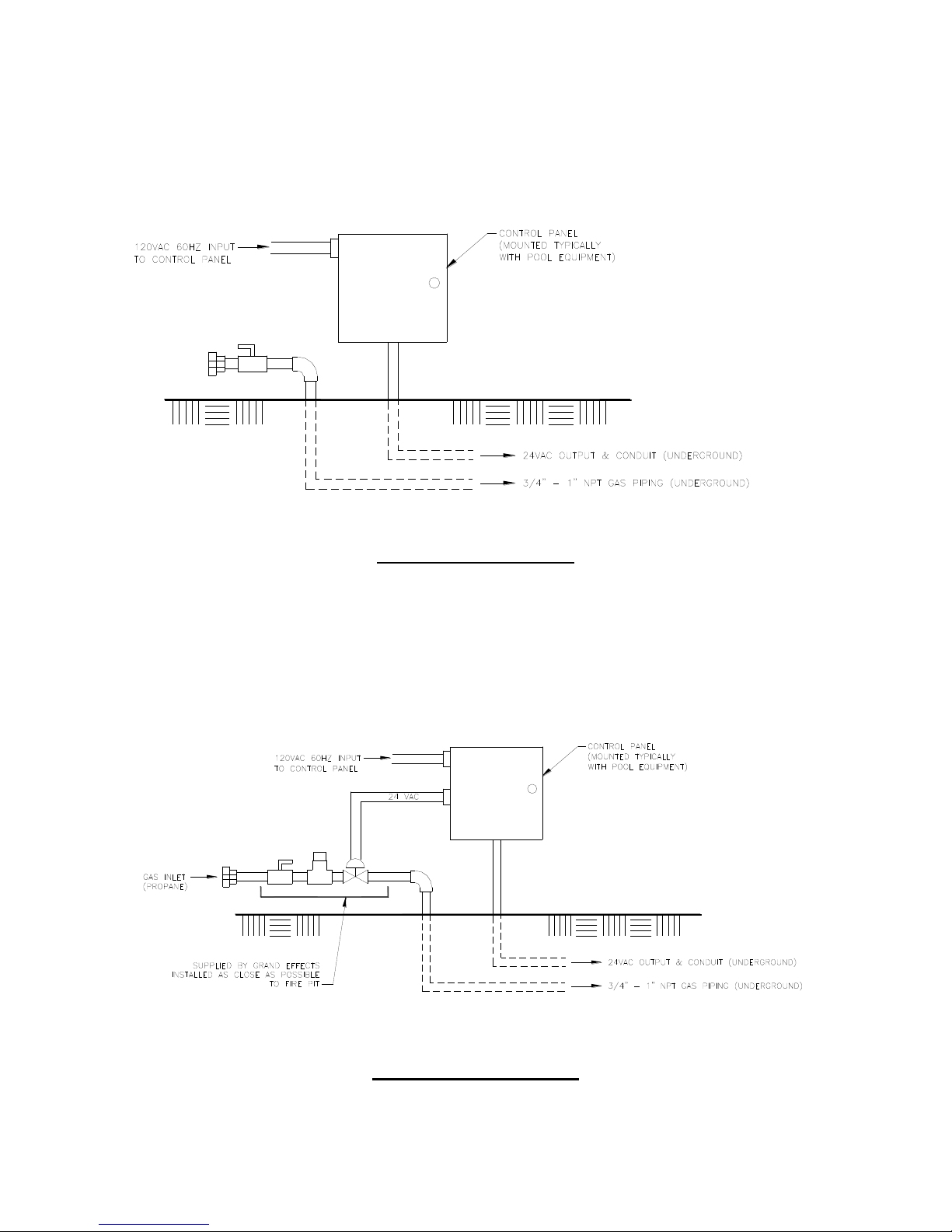

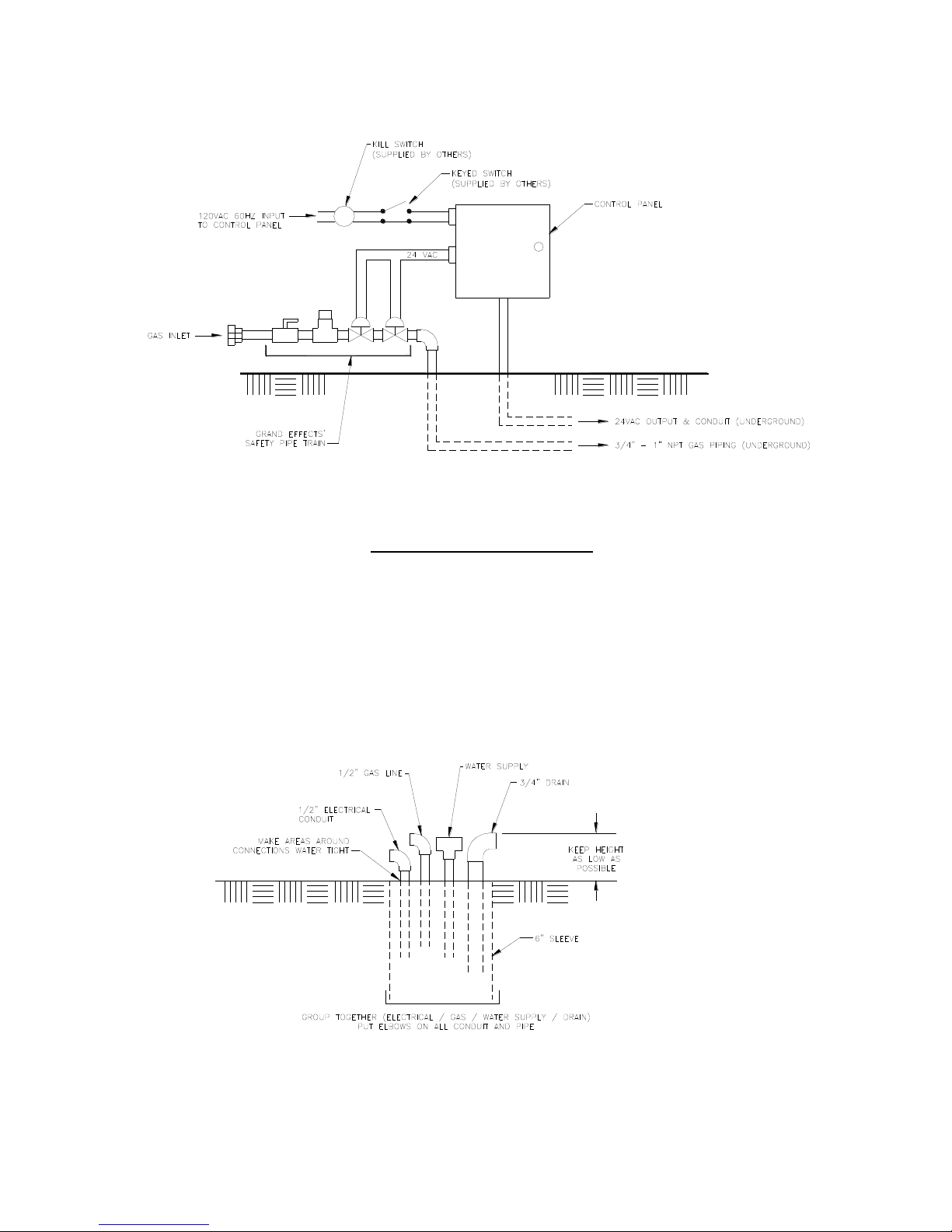

2.5 Install the Control Panel and gas piping as shown in Fig. 1(Natural Gas) or

Fig. 2 (Propane Gas) or Fig. 3 (Commercial Installation).

2.6 Note that piping is different for propane than natural gas as shown in Fig. 1 and Fig. 2

2.7 Low voltage 14 or 16ga wiring (24Vac) shall be installed underground between the

Control Panel and the Burner Assembly. Wire per Grand Effects Wiring Diagram. 120v

source into Control Typically, the pool controller is the device that turns the unit on/off.

If a pool controller is not available, Grand Effects can provide a hand held remote

system or an electrician can wire a decorative switch for on/off control up stream of the

Grand Effects Control Panel. Panel can come from any 120v source, including pool

controller or home system.

2.75 Control Panel should be installed at higher elevation than water bowl.

2.8 Maintain good piping practice by keeping pipe length and elbows to a minimum to

eliminate unnecessary pressure drops. (Do not use any corrugated flexible gas line).

2.9 On commercial installations, it is recommended to install a keyed switch and kill switch

located in close proximity and in visible sight of feature or features. The keyed and kill

switches are supplied by others.

2.91 Gas/electrical and drain connections must be located to fit in a 6” sleeve. Make area

around connections water tight as shown in Fig. 4. Elbows need to be installed on

gas/electrical and drain for hoses to be positioned properly as shown in Fig. 4

4

Note: Control Panel should be installed at higher elevation

than Fire-Water Feature

Set up for Natural Gas

Fig. 1

Set up for Propane Gas

Fig. 2

5

(Commercial Installation)

Fig. 3

Fig. 4

Loading...

Loading...