Grand Canyon Gas Logs WBECS Owner's Operation And Installation Manual

Weather Beater Electronic

CALIFORNIA PROPOSITION 65

(For more information, go to: www.p65warnings.ca.gov)

Control System

Model: WBECS

Owner's Operation and

Installation Manual

WARNING: FOR OUTDOOR USE ONLY!

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause

injury or property damage. Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

WARNING: Do not store or use gasoline or other ammable vapors and liquids in the vicinity

of this or any other appliance.

WARNING: A propane cylinder not connected for use shall not be stored in the vicinity of

this or any other appliance.

WARNING: For use with Natural or Propane gas only. NO SOLID FUELS TO BE USED WITH

THIS SYSTEM.

If you smell gas:

1. Shut off gas to appliance.

2. Extinguish any open ame.

3. If odor continues, keep away from appliance and im-

mediately call your gas supplier or re department.

This product can expose you to Chromium, which is known to the state of

California to cause cancer and birth defects or other reproductive harm.

WEBCS-1 09/18

FOR YOUR SAFETY

WARNING

1

The Weather Beater Electronic Control System utilizes CSA certied components

to be added to an outdoor product.

Installation must conform with local codes or, in the absence of local codes, with the National

Fuel Gas Code, ANSI Z223.1 / NFPA, or International Fuel Gas Code.

The appliance, when installed, must be electrically grounded in accordance with local codes

or, in the absence of local codes, with the National Electric Code, ANSI/NFPA 70, if applicable.

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain the manual for future reference.

TABLE OF CONTENTS

System Overview............................................................... 2

Electronics ......................................................................... 2

Gas Valve and Pilot Components ...................................... 2

Gas Requirements............................................................. 3

Ignition Control Specications and Wiring Diagram .......... 3

Product Dimensions .......................................................... 5

Installation ......................................................................... 5

Gas Connection ................................................................. 6

Pilot Assembly Connections

Proper Venting ................................................................... 7

Acceptable Media .............................................................. 7

Operation ........................................................................... 7

Maintenance ...................................................................... 8

FAQ and Helpful Tips for proper operation ........................ 8

Troubleshooting ................................................................. 9

Parts List & Accessories ...................................................11

.............................................. 6

SYSTEM OVERVIEW

• Components are CSA Certied.

• 12 vac system to comply to NEC 2014 Article 680 require-

ments.

• -20° to 175° temperature range.

• Durable connections designed to resist outdoor conditions.

• 265,000 BTU’s at 1" pressure drop.

ELECTRONICS

• Certied ANSI Z21.20-2014

• 12 VAC for installation within 5 feet of water.

• Potted control module to protect against moisture and

damage.

• Hot Surface Ignition (HSI), provides stable burner ignition

in harsh conditions.

GAS VALVE AND PILOT COMPONENTS

• All connectors are water resistant.

• Certied CSA 229521-1656058.

• Coils are encapsulated to protect against moisture.

• Pilot has robust ame pattern, wind resistant.

• Pilot injectors are stainless steel.

• TC Flame-sense system.

• Hot Surface Ignitor (HSI).

• LED diagnostics.

• Electronics are ANSI Z21.20-2014 certied.

• I-Flame app is available as an option.

• Thermocouple Flame Sense, fast responding and resistant

to wind, moisture and corrosion.

• LED diagnostics for eld service and troubleshooting.

• Thermocouple is nickel plated for durability.

• Hot Surface Ignitor (HSI) with protective cage.

• Hot Surface Ignitor (HSI) connection is waterproof.

• The Power Wire connector is waterproof.

2

WEBCS-1 09/18

GAS REQUIREMENTS

FUEL TYPE

Prior to making gas connections, ensure appliance being

installed is compatible with the available gas type. Check

the label on the appliance to conrm appliance gas type

requirement.

Proper input gas pressures are required for optimum appliance performance.

Pressure Natural Gas Propane Gas

Minimum 3.5" W.C. 1/8 PSI 8" W.C. 1/3 PSI

Nominal 7" W.C. 1/4 PSI 11" W.C. 1/3 PSI

Maximum 14" W.C. 1/2 PSI 14" W.C. 1/2 PSI

GAS PRESSURE

Gas Pressure Requirements

IGNITION CONTROL SPECIFICATIONS AND WIRING DIAGRAM

RECOMMENDED WIRE SIZE

No less than 16 gauge wire for all installations

Note: There are numerous electrical devices that can be used to turn the re feature on and off. Devices such as wall

switches and remote control devices that are used should be UL listed and approved devices for turning high voltage (110

v electrical power) on and off.

WBECS IGNITION CONTROL TIMING

Pre-Purge 3.25 seconds

HSI Warm Up 5 seconds

Trial for Ignition 20 seconds

Flame Failure Response 10 seconds Max

Inter-Purge 5 seconds

Flame Loss Recycles 15 seconds

Flame Loss Recycles Delay None

ELECTRICAL REQUIREMENTS

WARNING: The Weather Beater Electronic Control

System operates on 12 Volts AC power.

DO NOT attempt to power using 110 Volts AC Power!

DAMAGE WILL RESULT!

Acceptable Input Voltages to Supplied 12 Volt AC Transformer

110 / 120 Volt AC

Read label on supplied transformer for

proper connection information.

Recommended Wire Size

16 gauge wire for all installations (30 feet maximum length)

ELECTRICAL CONNECTIONS

The WBECS is supplied with a 12 volt all weather sealed

transformer of minimum 60 watts. If another transformer is

used it must meet be a Class ll 12 VAC, 5 amp, 60 watt or

larger for the unit to operate properly. A minimum 16 gauge

WIRING OF MULTIPLE WBECS

The WBECS has a red and a black wire protruding from

it. These are the power wires. When multiple WBECS are

connected, the polarity between them must be the same. To

achieve this, all of the red wires must be connected to the

same wire from the transformer and all of the black wires

connected to the other wire from the transformer as shown

in this illustration.

IT IS NECESSARY TO USE A HIGHER OUTPUT

TRANSFORMER WHEN CONNECTING TWO UNITS.

wire must be used for installations up to 30 feet in total line

length, and 12 gauge for installs up to 100 feet. It is highly

recommended to use dielectric grease or silicon to ll any and

all wire nuts used in installation of the WBECS.

WEBCS-1 09/18

3

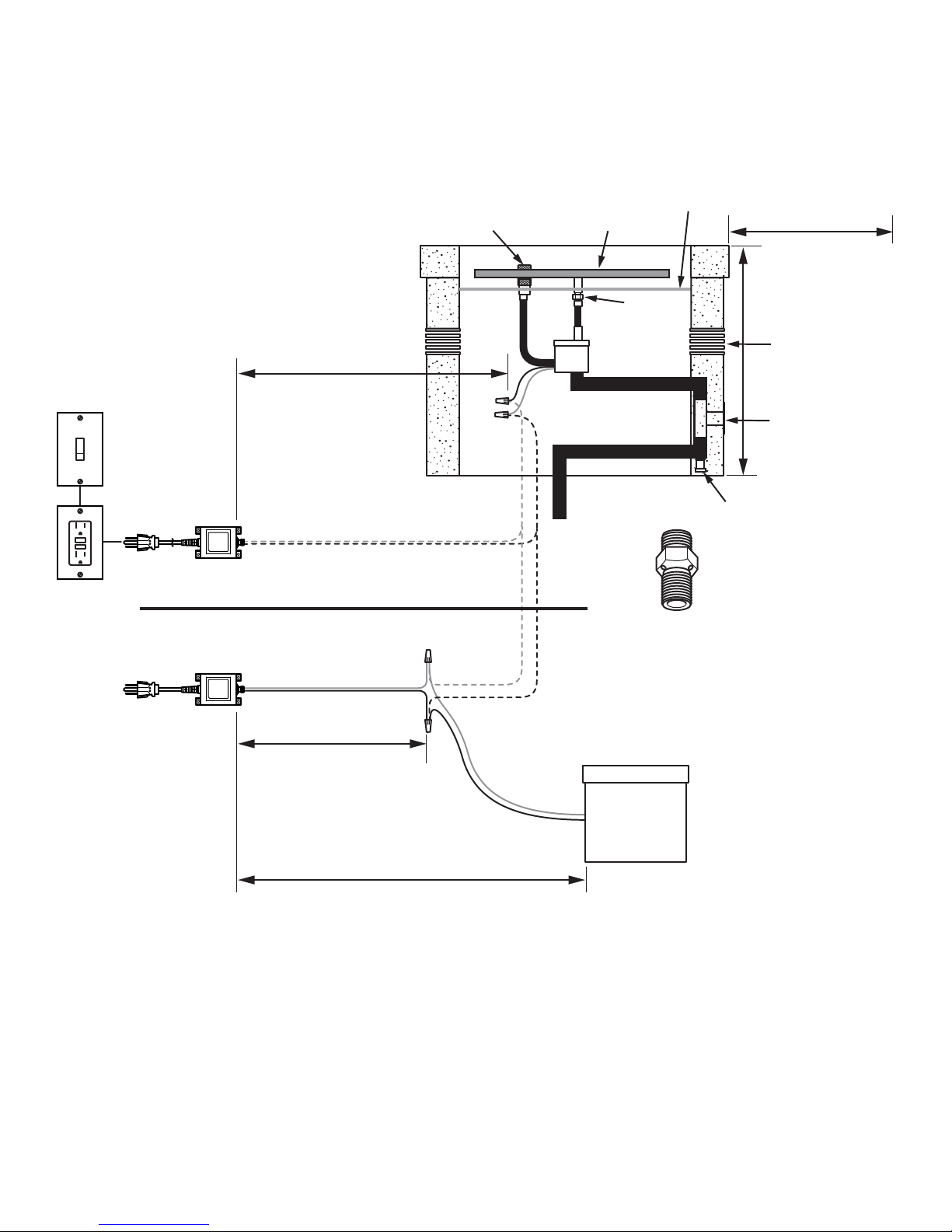

IGNITION CONTROL SPECIFICATIONS AND WIRING DIAGRAM

Appliance Manufacturer’s

Top, Sides and Bottom

Clearances to

Combustibles must

be maintained in

accordance with the

120 Volt AC Options

(Most common Shown)

Wall

Switch

Transformer

For Single Unit Installation

GFCI

Outlet

12 VAC

5 Amp Minimum

30' Maximum Wire Length

16 AWG

Pilot Burner Assembly

Red

Black

Burner

Ignition

Control Box

Gas

Line

Burner Pan

Orifice

Sediment Trap

Air Mixer for Propane is

Recommended for

Propane burners.

See instructions included

with the burner or

appliance.

specifications and

local codes.

Minimum

18 sq inches of

Cross Ventilation

on Each Side

of Enclosure

Manual Gas Shutoff

(Key Valve)

For 2 Unit

Installation

10 Amp Minimum

Wiring Two Units

5' Maximum

Wire length from transformer to splice

point must be less than 5' using

16 gauge wire

30' Maximum

Wire length from transformer to splice point

must be less than 30' using 16 gauge wire

Red

Black

2nd Unit

Red

Black

4

WEBCS-1 09/18

Loading...

Loading...