Grand Canyon Gas Logs OTPB-24, OTPB-30, OTPB-48, OTPB-36, RTS-18 Installation And Operation Manual

...

1

Grand Canyon Gas Logs---3435 E. Atlanta Ave---Phoenix, AZ 85040

INSTALLATION AND OPERATIONS GUIDE FOR

GRAND CANYON GAS LOG FIRE PIT SERIES ONLY

Grand Canyon Gas Logs, logs are made of cement refractory material re-enforced with steel fibers. Each of the logs are hand painted and

hand finished to recreate the most realistic logs available on the market. The outdoor burner system is designed to recreate and burn like a

real wood burning camp fire with a natural looking flame. With this in mind the gas log sets MUST be burned in a fully vented, noncombustible fire pit with the. The fire pit must be designed and approved to burn wood.

Installation and service must be provided by a qualified installer, service agency or

gas supplier

WARNING: If the information in this

manual is not followed exactly, a fire or

explosion may result, causing property

damage, personal injury or loss of life

- Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any application

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance

• Do not touch any electrical switch;

do not use any phone in the building

• Immediately call the gas supplier

from a neighbor’s phone. Follow

the gas supplier’s instructions

• If you cannot reach the gas supplier,

call the fire department.

- Installation and service must be

performed by a qualified installer,

service agency or the gas supplier

This equipment is intended for use with an input of natural

or Propane gas only. Clothing or other flammable materials

should not be hung from the appliance, or placed on or near

the appliance.

Children and adults should be alerted to the hazards of high

surface temperatures and should stay away to avoid burns

or clothing ignition. Young children should be carefully

supervised when they are in the area of the appliance. Keep

the appliance area clear and free from combustible

materials, gasoline and other flammable vapors and liquids.

For installation on or over non-combustible floors only.

NEVER LEAVE THIS APPLIANCE BURNING WHILE

UNATTENDED

Installation and repair should be done by a qualified service

person. The appliance should be inspected before use and at

least annually by a qualified service person. More frequent

cleaning may be required as necessary. It is imperative that

the burner and circulating air passageways of the firepit be

kept clean. Storage of the appliance indoors is permissible

only if the gas cylinder is disconnected and removed from

the appliance.

To comply with certifications, listings, and building code

acceptances, and for safe operation and proper

performance of this log set, use only Grand Canyon Gas Logs

parts and accessories. Use of other controls, parts, and

accessories that are not designed for use with Grand Canyon

Gas Logs log set is prohibited and will void all the

warranties, certifications, listings and building code

WARRANTY

Grand Canyon Gas Logs burners and logs carry a

lifetime warranty against breakage and defects to the

original purchaser. ALL GCGL valves, pilot assemblies

and electrical components carry a 2 year warranty as

long as installed indoors and installed by a licensed

professional. Further warranty information can be

found in the warranty section of this guide.

INSTALLER: Leave this manual with the log set

CONSUMER: Retain this manual for future reference.

Fire Pit Series:

TEE-PEE Stack (TPS)

Round Tall Stack (RTS)

Round Flat Stack (RFS)

2

Grand Canyon Gas Logs---3435 E. Atlanta Ave---Phoenix, AZ 85040

IMPORTANT INFORMATION

WARNING: This appliance assembly contains burner orifices specifically for the input gas specified on the burner

and box, as well as the Btu rating specified in this manual. Modifying or failure to use the factory orifice may

cause property damage, personal injury or loss of life.

Read these instructions completely before installing and using Grand Canyon Gas Log system.

1. Gas type will be indicated on the burner and the box. Do not use a natural gas burner with propane or a

propane burner with natural gas.

2. The installation, provisions for combustion, and ventilation air must conform to the National Fuel Gas

Code, ANSI Z223.1/NFPA54, or the CSA B 149.1, National Gas and Propane Installation Code.

3. For warranty to be valid gas log sets must be installed by a NFI certified or other qualified professional.

4. This appliance must be installed only in a solid-fuel burning fireplace with a working flue and constructed

of non-combustible materials. Solid fuels are not to be burned in a fireplace where a decorative appliance

has been installed.

5. A permanent free opening must be provided by either the fireplace chimney or chimney damper to vent

carbon monoxide and other flue gases. Any chimney damper must be fixed in a manner, which will

maintain the permanent free opening at all times. Use the table at the bottom of this page to determine

the minimum permanent free opening based on chimney height and the appliance Btu rating.

6. A fireplace screen must be in place when the appliance is operating and, unless other provisions for

combustion air are provided, the screen shall have an opening(s) for introduction of combustion air. With

use of glass doors, doors must be open while the appliance is burning to assure proper ventilation.

7. The minimum inlet supply pressure for the purpose of input adjustment is 5.0 inches (natural gas) 8.0

inches (propane) in water column. The maximum inlet supply pressure is 10.5 inches (natural gas) 13.0

inches (propane) in water column.

8. The appliance and its individual shut-off valve must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures in excess of ½ psig (3.5kPa). The appliance

must be isolated from the gas supply piping system by closing its individual manual valve during pressure

testing equal to or less than ½ psig (3.5kPa).

9. The appliance area is to be clear and free from combustible materials, gasoline and other flammable

vapors and liquids.

10. Do not use this appliance if any part has been under water. Immediately call a qualified service technician

to inspect the appliance and to replace any gas control which has been under water.

11. The fire pit should be examined prior to use and inspected by a qualified agency. The burner should be

cleaned annually by a qualified agency

12. To clean the burner shut off and disconnect the gas supply, use a pipe cleaner to clean out burner ports

and vacuum the inside of the burner by removing the orifice/air mixer fitting from the inlet of the burner.

After the burner is cleaned, attach the orifice/air mixer fitting onto the inlet of the burner and reconnect

the gas supply. Light according to the “Lighting Instructions”.

13. If burning a log set, use a soft dry paintbrush for periodic dusting of the gas fire logs. Special care must be

taken to clean the logs because rubbing will remove soot but will also remove the color.

14. If the fire pit has a cover allow the fire pit to completely cool prior to covering.

15. The top of the fire pit must be fully open and clear of any obstruction prior to igniting the burner system.

All covers, caps and lids must be removed before the burner system is in operation

16. A manual gas valve and 11.0” W.C pressure regulator must be installed prior to the use of the propane

cylinder

3

Grand Canyon Gas Logs---3435 E. Atlanta Ave---Phoenix, AZ 85040

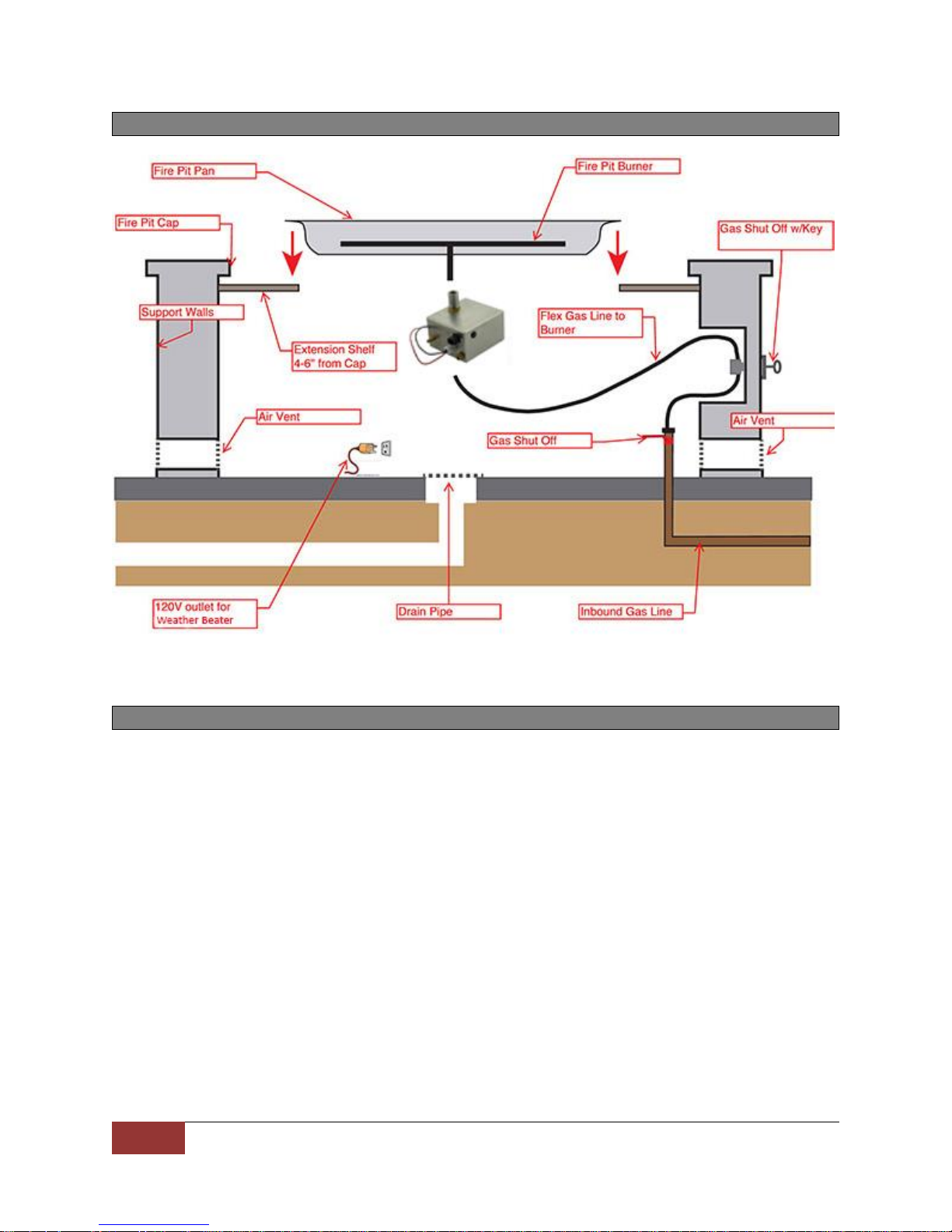

Typical Fire-Pit Installation

The above diagram is an illustration of a typical fire-pit installation with Hot Surface Electronic ignition system.

Some parts may not be applicable for match lite models.

GAS CYLINDERS

1. This appliance shall be used with NATURAL and LP inlet gas supply only. The LP or CNG gas supply cylinder

must be constructed and marked in accordance with the specifications for LP-gas cylinders or CNG-gas cylinders

of the U.S. Department of Transportation (DOT).

2. The use or storage of the LP or CNG cylinder may not be used in a building, garage or any other enclosed area.

3. Cylinders must be stored outdoors in a well-ventilated area out of the reach of children. Disconnected cylinders

must have threaded valve plugs tightly installed.

4. If the appliance in not in use, the gas must be turned off at the supply cylinder

5. Inspect the hose before each use of the appliance. The hose assemble must be replaced prior to the appliance

being put into operation if there is evidence of excessive abrasion or wear, or if hose is damaged. The hose

assembly must be replaced with a replacement hose assembly equivalent to, or greater than, rating specified

on the original hose.

6. The gas hose shall be located out of the pathways where people may trip over it or in areas where the hose

may be subject to accidental damage.

7. Never use matches or open flame to test for leaks. Use soapy water or a leak detector.

8. Don not store or use LP-gas supply cylinder around excessive heat; the cylinder may get too hot or cause the

pressure to rise. Store the cylinder in a secure upright position.

9. Cylinder must be fully opened and the pressure controlled by reducing pressure regulator to operate properly.

Loading...

Loading...