Grand Banks GB-36-127, 36 Operation Manual

OPERATIONS MANUAL

Welcome aboard

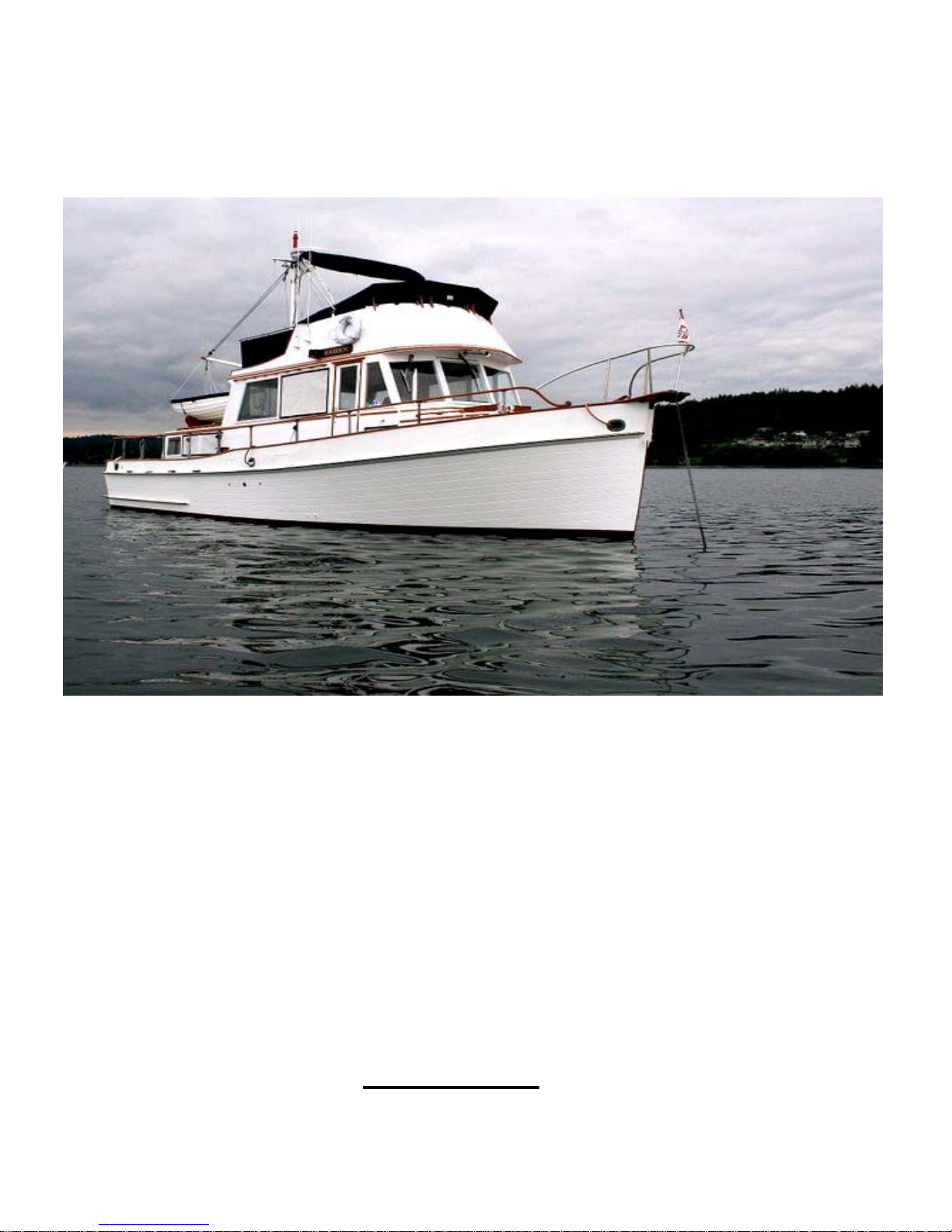

Kaizen

改善

GB-36-127

Owners: Michael Barrett and Holly Marold

425-750-1583

Specifications:

Hull ID WIDLC36-353 1973

VHF Call Number WdA9944

LOA 36’ 4”

Beam 12’ 2”

Draft 3’ 11”

Mast Height 18’4 From Waterline

Displacement 28,000 LBS

Fuel Capacity 400 Gallons in two tanks

Navigation Range (Approx) 1000 Miles

Water Capacity 240 Gallons in two tanks

Engine and Transmission Oil Chevron Delo 400 30W

Amp hours/House Batteries- Full Charge 400 Amp hours

TABLE OF CONTENTS

2

GRAND BANKS 36 SPECIFICATIONS 2

WELCOME ABOARD! 5

SAFETY GUIDELINES 6

BEFORE EMBARKING: 6

CRUISING CHEKLISTS 7

• General Preparation Checklist 8

• Navigation Preparation Checklist 8

• Engine Preparation Checklist 9

STARTING ENGINES 10

GETTING UNDERWAY 11

APPROACH AND DOCKING

AT THE DOCK 12

ENGINE SHUT DOWN 13

FUELING 14

ELECTRICAL SYSTEM 15

SHORE POWER (110 VOLT) 15

ELECTRICAL EFFICIENCIES: Helpful Hints 16

ELECTRICAL SYSTEM (D.C. Panel) 17-18

LINK 1000 19

A.C. PANEL AND INVERTER 20

ELECTRONICS 21-24

WATER SYSTEM 25

SANITATION & WASTE 26

SHOWER and DRAIN 26

3

PROPANE STOVE/OVEN 27

CRABBING and FISHING 28

CRAB COOKING 29

CABIN HEAT 30

STEREO SPEAKERS 30

TV/DVD PLAYER 31

BARBECUE 31

CANVAS and BIMINI 32

ANCHOR and WINDLASS 32

ANCHORAGE 32

LOWERING the ANCHOR 33

RAISING the ANCHOR 34

MOORING CANS 35

DINGYS 36-37

THROUGH-HULL LOCATIONS 38

WHERE IS IT? 39

HOW DO I? 40

NAUTICAL LIBRARY 41

Welcome aboard!

4

We are happy you have chosen “Kaizen“for your vacation. We are sure you will enjoy

cruising the lovely islands of the Pacific Northwest.

Kaizen was originally built in 1969, completely refurbished in 1993, and again from 2003-

2007.

Kaizen (改善)

Japanese for "change for the better" or "improvement"; the English translation is "continuous

improvement".

We hope you will enjoy the many extra amenities that have been added to make Kaizen

a comfortable cruiser.

• Upgraded decor, including oriental rugs, upholstery, miniblinds, and refrigeration. She

has a refurbished bridge including seats and canvas.

• Upgraded electrical system: 1000 watt Heart Inverter has been added, coupled with six

deep cycle golf cart batteries provides ample load capacity and ease of use. This

superior arrangement allows you to run small AC (110 volt) systems “on demand” in

peace and quiet. Chart plotter, TV & VCR, microwave, and coffee pot all work well (one

at a time).

• For cooking using the propane stove and the Magma propane grill doubles as a single

burner stove as well.

• Updated electronics package, July 2007

• Upgraded stereo sound system: Bose weather-resistant speakers in the Main Salon

and bridge accompany the stereo CD player and AM/FM radio.

• Kaizen is also equipped with a 9 foot Ranger rowing dinghy, and, the Avon ridged

inflatable dingy. A 3 hp outboard is also available, or you can row if you prefer.

• There is an Espar diesel heater with a thermostat mounted at the lower pilot’s station

for those cool summer mornings and to extend the chartering season.

Other features of “Kaizen” have been designed to enhance your overall enjoyment of

this special yacht, such as:

• Nautical Library: for your safety and reading enjoyment, you will appreciate the

comprehensive collection of reference literature and guidebooks, charts, instructional

videos, repair & maintenance manuals, etc.

Kaizen is well equipped to provide many of the comforts of home, while you explore the

spectacular cruising waters of the Great Northwest. Enjoy!

We hope this manual will help you become familiar with the Kaizen If you have questions

about the boat or about places to visit, please do not hesitate to ask the AYC staff.

SAFETY GUIDELINES

5

Kaizen is equipped with safety as a priority. Buy a safe and enjoyable charter can only

happen when the yacht and the skipper both function properly. The following information is

intended to assist you in the proper operation of the boats systems and to note some of the

most important safety precautions. A thorough understanding of the equipment and

procedures is your best assurance of having the best possible charter experience. Some

pointers:

• Familiarize yourself with boat systems – complete manuals are organized in binders,

located beneath the starboard seat, main salon.

• Familiarize yourself with the charts you will depend upon. Use the charts to keep track

of your position at all times – stay clear of rocks, shoals, old pilings, and kelp beds.

• Be on constant watch for logs and debris while underway – it is recommended that

lines of floating debris be crossed very slowly to avoid propeller and drive shaft

damage.

• Know the status of tides, currents, and weather forecasts. Conditions change fast!

• Do not cruise after dark or in low visibility conditions.

• All members of the crew should be familiar with the VHF Radio operation -

emergencies are no time to learn.

• Keep hands away from anchor windlass when operating.

BEFORE EMBARKING

1. Locate life jackets (May West type under bridge controls in large locker, and jacket

type in the aft hanging locker) and wear as necessary.

2. Review emergency procedures

3. Secure loose objects on deck and below.

CRUSING CHECKLIST

6

Bilge Main bilge access. In Grand Banks trawlers, bilge water tends

forward, so water level in the bilge is checked here.

Anchor Ready for use. Electric Windlass is controlled by remote switching

device.

Fresh Water Tanks Full. Capacity gauge is located in the aft head

Dockside Power Circuit breaker off. Power cord detached and secured.

Battery Power Circuit breaker set on “ALL” Position

Rowing Dingy Covered, Oars Secured

Inflatable Secured on stern with oars in place. Outboard secured to bracket

on bridge.

Mast Boom Down tight and secured

Decks Cleared

Galley and Heads Countertops cleared

Stove Countertop In Down position

Fenders On board and secured (once underway).

Lines On board and secured (once underway).

GENERAL PREPARATION CHECKLIST

Oil Level Dipstick on inboard side of each main engine

7

• DO NOT OVERFILL

• DO NOT OPERATE BELOW “ADD” MARK

Transmission

Fluid Level Dipsticks on inboard side of each transmission,

Remover, Wipe Dry and re-install dipstick

• DO NOT OVERFILL

• DO NOT OPERATE BELOW “ADD” MARK

• Should be checked immediately after operation. Check at

beginning of charter, once mid-way, and at completion of

charter.

Racor Fuel Filters Check for water or dirt in bowl. Drain into empty oil container or

bucket if needed. Container of clean diesel fuel can be used to

clean bowl. If bad fuel necessitates changing of filters, spares

located in spare part box (to port of engine room).

Fresh Water Coolant Check levels in expansion tanks. (Top of each Engine).

Cooling Water Valves should be open (handles upward parallel to valve).

Thru-hull Valves To check sea strainers, first close thru-hull valve. Do not over-

tighten sea strainer, as brass bolts can slip easily. Open thru-hull

valve when done, and check for leakage.

DO NOT OPEN UNLESS OBSTRUCTED OR NEEDS CLEANING.

Bilge Pumps Two automatic bilge pumps, fore under fwd ladder and aft under

floor of engine room vicinity of sea strainer, keep the bilges dry as

necessary. Test by switching from automatic to manual mode then

return to automatic setting – pump manually until flow stops – look

on STBD side.

(On/Off switches located portside of lower helm station).

ALWAYS LEAVE IN AUTO POSITION!

NAVIGATION PREPARATION CHECKLIST

Weather Forecast reviewed

8

Currents and Tides Reviewed

Cruise Plan and Charts At helm

Binoculars At helm

VHF Radios Power turned on with toggle switch on instrument panel on; set to

Channel 16

Chartplotters Power to all turned units on with toggle switch on the instrument

panel

Turn on Bridge Chartplotter first. It is the master.

DO NOT CHANGE THE MASTER

Depth Gages Displayed on Chartplotter both Helms

Radar Turned on (if needed) displayed on Chartplotter

Engine Preparation Checklist

1. Do daily check first (Remember your “WOBBS” every morning: Water

(Coolant), Oil, Bilges (Inspect and Pump-out), Belts and Sea Strainer.

2. Engines should be started with the Battery Switch in the ALL position. This is the

correct switch setting underway and when charging using the inverter when AC

3. Shore Power is on.

STARTING ENGINES

1. When on shore power, turn on the engine block heaters for about 3 hours prior to

starting.

9

2. DC Panel: Run exhaust fan for at least 60 seconds. REMEMBER TO TURN OFF.

3. Lower helm: Ensure both engine cut-off plungers are in the down position.

Ensure that the engine transmission controls (black knob handles) are in neutral

position (straight up and down).

4. Begin with the Port (left) Engine. For the first start of the day, use cold start procedure,

i.e., pull up cold start plunger and hold it as you advance the throttle all the way

forward, depress plunger, return throttle to idle position, then set engine throttle to

approximately one third (about 1000 RPM), set engine switch to “ON” position, alarm

will sound, press and hold start button until engine starts or for a maximum of ten

seconds. Engine should start immediately. Return throttle to idle position. If engine

does not start, repeat this step. If engine still does not start after repeated

attempts, GET PROFESSIONAL HELP.

5. Check for oil pressure (gauge), and check for cooling water flowing out (beneath swim

step)

6. If low oil pressure, or no cooling water, or if engine alarms continue to sound, shut

down immediately and correct the problem.

7. Repeat steps #3- #5 above, for starboard (right) engine.

8. IMPORTANT: Engine temperature should exceed 150 degrees before

accelerating beyond 1500 RPM.

9. NOTE: Engines can be restarted at the upper helm in an emergency as long as the

engine switches are in the ON position. Start buttons are located to the starboard of

depth gauge plunger/switch. To port of this plunger is the ship’s horn button. (Horn

circuit breaker on DC panel must be ON for the Horn to work).

GETTING UNDERWAY

1. Shore power switch to off. Remove shore power. Please instruct your crew in this

procedure. Not every one is aware of the locking tangs, power breakers at dockside,

10

or the bezel ring attachment on the fittings. Store the power cords on the bridge.

Refer to the A.C. section below.

2. While still at dock and idling (approximately 700 RPM), shift gears to test response

while tied to dock. Shift gears ONLY with throttle in idle. Pause in neutral when shifting

to forward or reverse.

3. Monitor engine instruments. A buzzer warning may sound for low oil pressure or high

temperatures, but your most reliable source to determine health of the engines is to

constantly monitor engine gauges. SHUT DOWN IF BUZZER SOUNDS WHILE

RUNNING. CHECK OIL PRESSURE & ENGINE TEMPERATURE.

4. Normal cruising RPM is 1800-1900, which will yield approximately 9 knots (10+ mph)

and 4 gph fuel consumption. The theoretical maximum RPM of 2200 might add 10%

increase in speed while also adding 50% increase in fuel consumption. NEVER

EXCEED 2400 RPM!

5. Note: knot meters read “speed through water” which includes the affect of currents and

tides, rather than true “speed over ground” (actual forward progress) as measured by

GPS. (Also, note the difference between the two should indicate the positive or

negative speed of current impacting the boat.)

6. Once again, watch out for logs and other floating debris, as well as crab pots and

fishing nets.

7. Check local wind and current and establish a maneuvering plan. Decide how to keep

clear of conflicting traffic. Direct the specific order or the removal of individual lines.

Recover the dock step and direct crew to walk or push the boat as appropriate.

8. Shift gears at idle RPM. A pause in neutral is appropriate.

9. Please do not remove lines or fenders until clear of the marina. Leaving them in place

will afford vital protection and options if circumstances go sour.

10. Once clear of the marina, store lines and fenders.

APPROACH AND DOCKING

During docking, use the FLYBRIDGE HELM for greater visibility to the stern. Have your

crew make ready the lines and fenders and give clear instructions on how you will be docking.

11

Often times your crew will need to step off from the swim step with the stern line. Another

crew member will need to be at the bow or mid-ships to hand over the next lines.

1. Check all gauges for proper reading and normal water volume at the exhaust.

2. Place dock lines on at all cleats, and fenders deployed on both sides (touching the

water, please) BEFORE YOU GO INTO THE MARINA.

3. Check local winds and currents.

4. Brief crew/line handlers on intentions, critical lines to be applied first.

5. “Kaizen” has a modest amount of momentum. Use neutral a lot, go easy, reverse, and

stop the boat if the dock is on the fenders. Continuing will only roll the fenders out of

the way and hull scratches will result. Do not allow your crew to jump off the gunwales.

Do not let them carry dock lines while they disembark. Both hands free for line

handlers until they get safely to the dock. Don’t force your crew to muscle the boat off

from a poor or fast approach. With as much weight as “Kaizen” displaces, injuries are

likely of desperation pushing is attempted. GO SLOW.

AT THE DOCK

1. Tie up the boat at least twice, once for nominal control then for position and security.

Check your line handlers’ cleatings. Reset fenders as appropriate.

2. If applying shore power, ensure that the boat end is installed first, turn the circuit

breaker off at the dock power box, and then plug it in. Turn the power back on and

verify good polarity and acceptance at the electrical panel by turning on the white main

master switch on the AC panel.

3. Secure unnecessary switches, turn on those circuit breakers necessary for the stay,

and ensure that the battery charger is on and operating properly.

4. Ensure that the inverter is charging.

ENGINE SHUT DOWN

1. Idle engines in neutral for at least five (5) minutes to cool down. By the time you finish

tying up or anchoring this time will have passed.

12

2. Stop engines one at a time, by lifting the engine cut-off plungers located between

controls, and turning the switch off after each engine has stopped. This will disengage

the alarm buzzers.

3. NOTE: DO NOT TURN THE IGNITION CIRCUIT BREAKERS OFF WHILE THE

ENGINE IS RUNNING AS YOU WILL LIKELY BURN OUT THE DIODES WHICH

ENABLE ALTERNATOR CHARGING CIRCIUTS.

4. Return cut-off plungers to down position.

FUELING

1. MAKE SURE YOU HAVE THE RIGHT FUEL! DIESEL! DIESEL! DIESEL! MAKE

SURE IT IS GOING INTO THE CORRECT DECK FILL!

13

Loading...

Loading...