Grand Aire WATPM Series Installation Instructions Manual

1

CONTENTS

INSTALLATION INSTRUCTIONS

These instructions are intended as an aid to qualified

licensed service personnel for proper installation, adjustment and operation of this unit. Read these instructions

thoroughly before attempting installation or operation.

Failure to follow these instruction may result in improper

installation,adjustment, service or maintenance possibly

resulting in fire, electrical shock, property damage,

personal injury or death.

1. SAFETY...............................................................................2

2. GENERAL..........................................................................3

3. APPLICATIONS.................................................................5

4. ELECTRICAL WIRING......................................................7

5. AIRFLOW PERFORMANCE.............................................9

6. DUCTWORK....................................................................10

7. REFRIGERANT CONNECTIONS.....................................10

8. AIR FILTER (not factory-installed)....................................11

9. FILTER INSTALLATION DIMENSIONS...........................12

10. WIRING..........................................................................13

PARTS

LIMITED

WARRANTY

5

YEAR

R-410A

REFRIGERANT

WATPM Series Air Handler

2-3-4-5 Ton Capacity

R410A

2

This document is customer property and is to remain with this unit.

These instructions do not cover all the different variations systems nor

does it provide for every possible contingency to be met in connection

with installtion.

All phases of this installation must comply with NATIONAL STATE

AND LOCAL CODES. If additional information is required please

contact your local distributor.

1. SAFETY

This is a safety alert symbol. When you see this symbol

on labels or in manuals, be alert to the potential for

personal injury.

This is an attention alert symbol. When you see this

symbol on labels or in manuals, be alert to the potential

for personal injury.

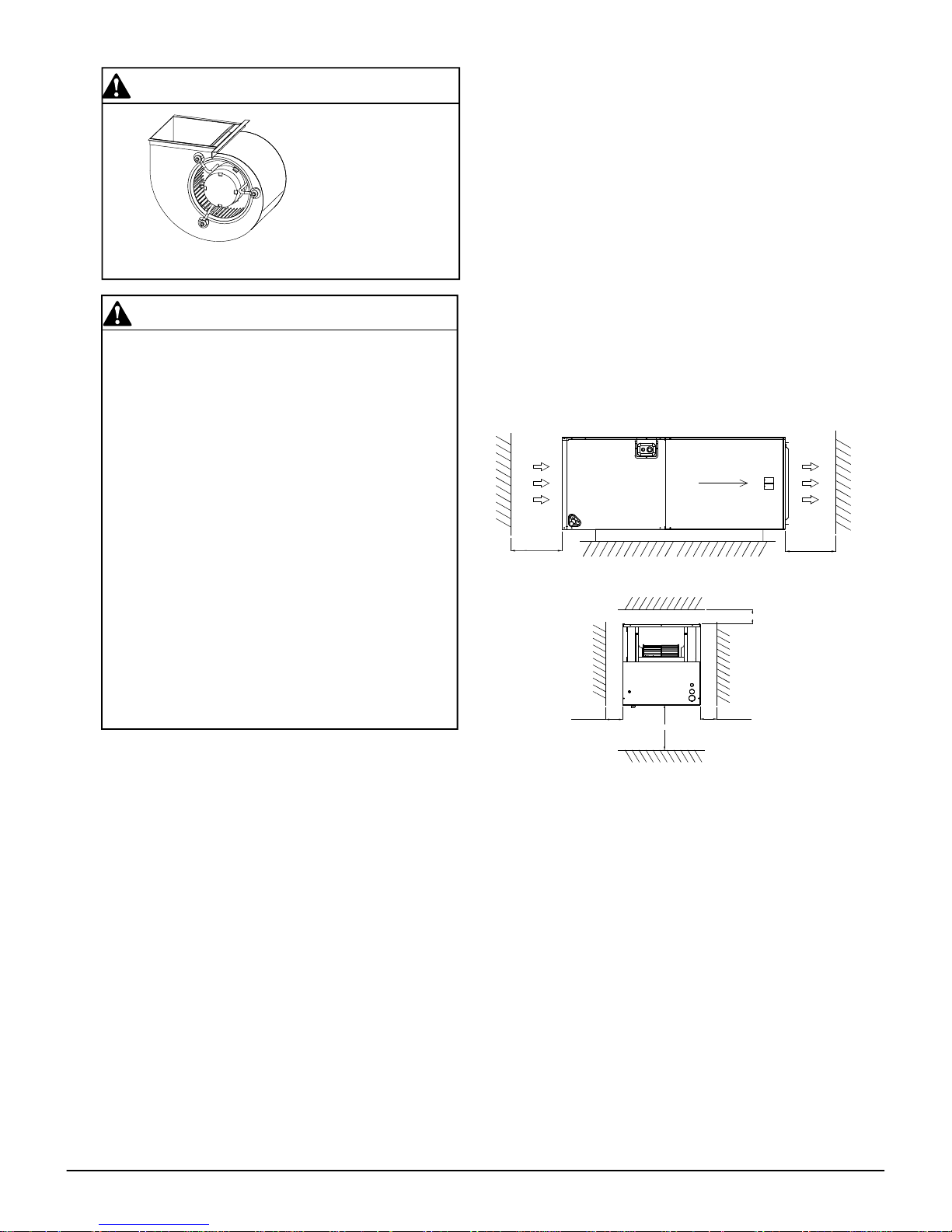

If removal of the blower assembly is required, all disconnect

switches supplying power to the equipment must be de-

energized and locked (if not in sight of unit ) so the field power

wires can be safely removed from the blower assembly. Failure

to do so can cause electrical shock resulting in personal injuring

or death.

WARNING

Disconnect all power to unit before installing or servicing.

More than one disconnect switch may be required to de-

energize the equipment. Hazardous voltage can cause server

personal injury or death.

WARNING

WARNING

WARNING

Because of possible damage to equipment or personal injury,

installation, service, and maintenance should be performed by a

trained, qualified service personnel. Consumer service is recom-

mended only for filter cleaning / replacement. Never operate the

unit with the acess panels removed.

WARNING

These instructions are intended as an aid to qualified, licensed

service personnel for proper installation, adjustment and opera-

tion of this unit. Read these instructions thoroughly before

attempting installation or operation. failure to follow these instruc-

tions may result in improper installation, adjustment, service or

maintenance possibly resulting in fire, electrical shock, property

damage, personal injury or death.

The unit must be permanently grounded. Failure to do so can

result in electrical shock causing personal injury or death.

WARNING

PROPOSITION 65: This appliance contains fiberglass insula-

tion. Respirable particles of fiberglass are known to State of

California to cause cancer.

All manufacturer products meet current federal OSHA Guide-

lines for safety. California Proposition 65 warnings are required

for certain products, which are not covered by the OSHA

standards.

California’s Proposition 65 requires warnings for products sold in

California that contain or produce any of over 600 listed chemi-

cals known to the State of California to cause cancer or birth

defects such as fiberglass insulation, lead in brass, and combus-

tion products from natural gas.

All “new equipment” shipped for sale in California will have

labels stating that the product contains and /or produces Propo-

sition 65 chemicals. Although we have not changed our

processes, having the same label on all our products facilitates

manufacturing and shipping. We cannot always know “when, or

if” products will be sold in the California market.

You may receive inquiries from customers about chemicals

found in, or produced by, some of our heating and air-

conditioning equipment, or found in natural gas used with some

of our products. Listed below are those chemicals and

substances commonly associated with similar equipment in our

industry and other manufacturers.

Glass Wool (Fiberglass) Insulation

Carbon Monoxide (CO).

Formaldehyde

Benzene

More details are available at the websites for OSHA

(Occupational Safety and Health Administration), at

www.osha.gov and the State of California’s OEHHA (Office of

Environmental Health Hazard Assessment), at www.oehha.org.

Consumer education is important since the chemicals and

substances on the list are found in our daily lives. Most consum-

ers are aware that products present safety and health risks,

when improperly used, handled and maintained.

3

WARNING

The first 6 inches of supply air plenum and ductwork must be

constructed of sheet metal as required by NFPA 90B. The supply

air plenum or duct must have a solid sheet metal bottom directly

under the unit with no openings, registers or flexible air ducts

located in it. If flexible supply air ducts are used they may be

located only in the vertical walls of rectangular plenum, a

minimum of 6 inches from the solid bottom. Metal plenum of duct

may be connected to the combustible floor base, if not, it must be

connected to the unit supply duct exposed to the supply air

opening from the downflow unit. Exposing combustible (non-

metal. material to the supply opening of a downflow unit can

cause a fire resulting in property damage, personal injury or

death.

Exception warning to downflow:

Installations on concrete floor slab with supply air plenum and

ductwork completely encased must be not less than 2 inches of

concrete (See NFPA 90A).

The unit can be positioned for upflow, left and right downflow

position.

This Air Handler provides the flexibility for installation in any upflow or

downflow horizontal application. The direct drive motors provides a

selection of air volume to match any application. 5-Speed motors

provide selections of air flow to meet desired applications.

Top and side power and control wiring, accessible screw terminals for

control wiring all combine to make the installation easy, and minimize

installation cost. See fig.1.

2. GENERAL

CAUTION

Make sure the blower

morot support is tight(3-

motor mount bolts) then

check to see if wheel is

secured to motor shaft

before operating unit.

To ensure the proper installation, select a solid and level site.

Ensure enough space maintained for installation and maintenance.

≥40’’

≥

25’’

≥40’’

≥0

≥0

≥0

AIRF LOW

Front of unit

Clearances in the Horizontal Position

Clearances in the Vertical Position

4

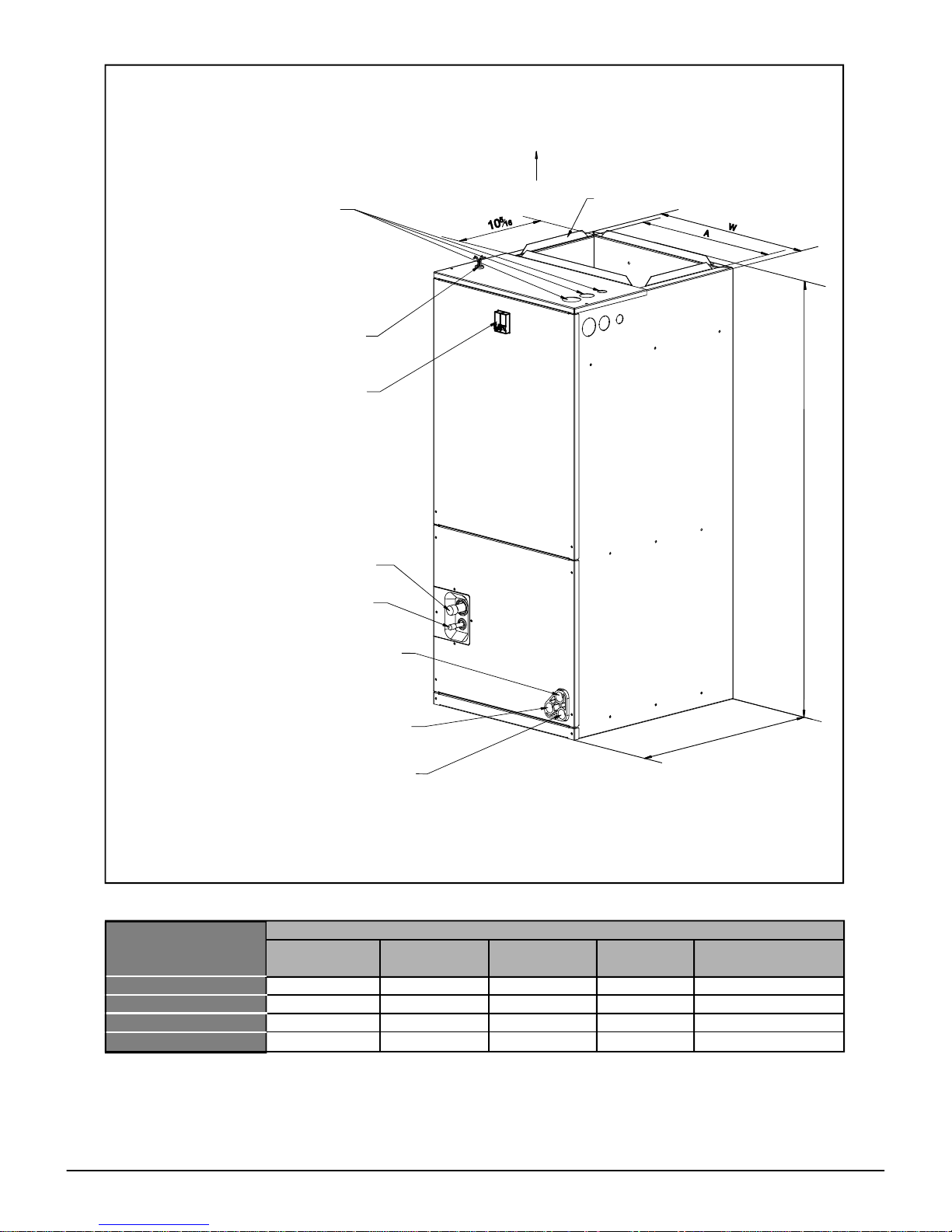

2.1 UNIT DIMENSIONS

UPFLOW UNIT SHOWN;

UNIT MAY BE INSTALLED UPFLOW, DOWNFLOW,

HORIZONTAL RIGHT, OR LEFT AIR SUPPLY.

24

36

48

54-1/2"[1385] 22"[560] 24"[610]

19-1/2"[496]

54-1/2"[1385] 22"[560] 24"[610]

19-1/2"[496]

60 54-1/2"[1385] 22"[560] 24"[610] 19-1/2"[496]

MODEL SIZE

Dimensions inch [mm]

SUPPLY

DUCT "A"

UNIT HEIGHT

"H" IN. [mm]

UNIT WIDTH

"W" IN.[mm]

UNIT LENGHT

"D" IN.[mm]

LIQUID LINE /

VAPOR LINE

4

6-1/2"[1180] 19-5/8"[500] 21-5/8"[550] 18"[456]

Fig.1 DIMENSIONS

W

A

1

0

5

1

6

NOTE: 25” CLEARANCE IS REQUIRED IN THE FRONT

OF THE UNIT FOR FILTER AND COIL MAINTENANCE.

SUPPLY AIR

FLANGES ARE PROVIDED

FOR FIELD INSTALLATION

ELECTRICAL CONNECTIOS

MAY EXIT TOP OR EITHER SIDE

HIGH VOLTAGE CONNECTION 7/8”,

1-3/8”, 1-3/4” DIA KNOCK OUTS

LOW VOLTAGE CONNECTION

BREAKER SWITCH

(FOR ELECTRIC HEATER ONLY)

VAPOR LINE CONNECTION COPPER (SWEAT)

LIQUID LINE CONNECTION COPPER (SWEAT)

AUXILIARY DRAIN CONNCECTION 3/4”

FEMALE PIPE THREAD (NPT)

AUXILIARY DRAIN CONNECTION 3/4”

FEMALE PIPE THREAD (NPT)

PRIMARY DRAIN CONNCETION 3/4”

FEMALE PIPE THREAD (NPT)

DIMENSIONAL DATA

H

D

3/8" / 3/4"

[9.5]/[19]

3/8" / 3/4"

[9.5]/[19]

3/8" / 7/8"

[9.5]/[22]

3/8" / 7/8"

[9.5]/[22]

1-9/16

2-15/16

5/16

2-15/16

1-3/8

1-1/4

5/16

2-13/16

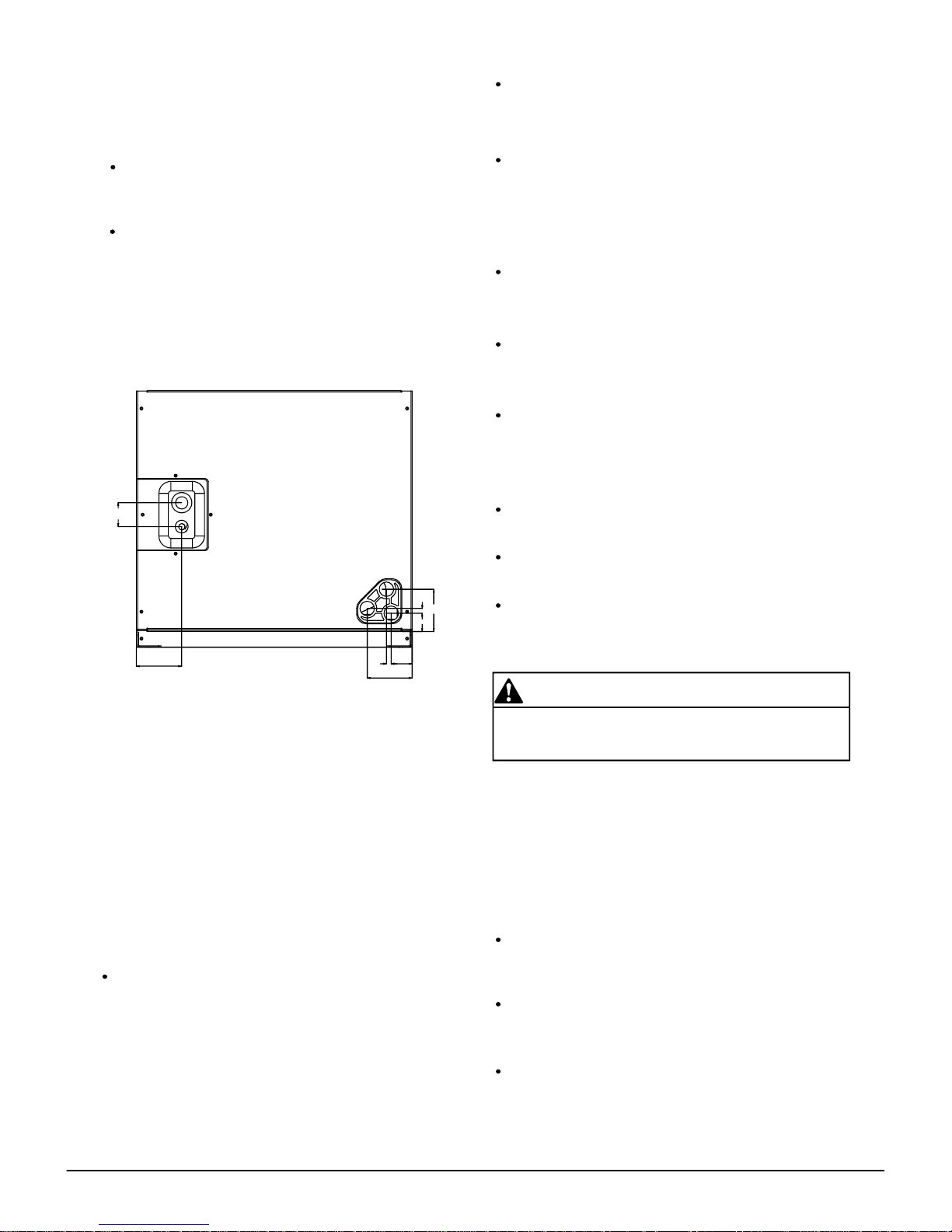

3.2 VERTICAL DOWNFLOW

Conversion to Vertical Downflow: A vertical upflow unit may be

converted to vertical downflow. Remove the door and indoor coil and

reinstall 180

°

from original position. See Fig 3.

IMPORTANT: To comply with certification agencies and the National

Electric Code for downflow application, the circuit breaker(s) on field-

installed electric heater kits must be re-installed per procedure below

so that the breaker switch “on” position and marking is up and, “off”

position and marking is down.

To rotate breaker(s): Rotate one breaker set (circuit) at a time

starting with the one on the right. Loosen both lugs on the load

side of the breaker. (Make sure that wires are identified and are

reinstalled into proper breaker).Wires are bundles with wire ties,

one bundle going to the right lug and one bundle going to the left

lug.

Using a screwdriver or pencil, lift white plastic tab with hole

away from breaker until breaker releases from mounting

opening.

With breaker held in hand, rotate breaker so that “on” position

is up, “off” position is down with unit in planned vertical mount-

ing position. insert right wire bundle into top right breaker lug,

ensuring all strands of all wires are inserted fully into lug, and

no wire insulation is in lug.

Tighten lug as tight as possible while holding circuit breaker.

Check wires and make sure each wire is secure and none are

loose. Repeat for left wire bundle in left top circuit breaker lug.

Replace breaker by inserting breaker mounting tab opposite

white pull tab in opening, hook mounting tab over edge in

opening.

With screwdriver or pencil, pull blue tab with hole away from

breaker while setting that side of breaker into opening. When

breaker is in place, release tab, locking circuit breaker into

location in opening.

Repeat above operation for remaining breaker(s) (if more than

one is provided).

Replace single point wiring jumper bar, if it is used, on line side

of breaker and tighten securely.

Double check wires and lugs to make sure all are secure and

tight. Check to make sure unit wiring to circuit breaker load lugs

match that shown on the unit wiring diagram.

5

3 APPLICATIONS

3.1 VERTICAL UPFLOW

Vertical Upflow configuration is the factory set on all models (see

Fig 1).

If return air is to be ducted, install duct flush with floor.

Use fireproof resilient gasket 1/8 to 1/4 in. thick between the

ducts, unit and floor. Set unit on floor over opening.

Horizontal right is the default factory configuration for the units.

Conversion to Horizontal left: A vertical upflow unit may be

converted to horizontal left by removing indoor coil assembly and

reinstalling coil as shown for left hand air supply.

Rotate unit into the downflow position, with the coil compartment

on top and the blower compartment on bottom. See Fig. 3

Reinstall the indoor coil 180° from original position. Ensure the

retaining channel is fully engaged with the coil rail. See Fig. 3.

Secondary drain pan kits are recommended when the unit is

configured for the horizontal position over a finished ceiling

and/or living space.

Fig.2 DIMENSIONS FOR FRONT CONNECT COIL

CAUTION

When using the unit with electrical heater, the switch on the front

of panel is used only for electrical heater.

IMPORTANT NOTE

Torque applied to drain connections should not

exceed 15.ft.lbs.(see Fig.1&2)

3.3 HORIZONTAL

Loading...

Loading...