Granby KHM SERIES, KHM-100, KHM-200 Nstallation, Operation And Service Manual

Installation, Operation and

Service Manual

KHM

SERIES

85% + EFFICIENCY

OIL FIRED HI-BOY FURNACE

KHM-100

KHM-200

KHM-100 Illustration

INSTALLATIONS MUST MEET ALL LOCAL AND FEDERAL

CODES THAT MAY DIFFER FROM THIS MANUAL

Please read the manual in its entirety before beginning installation.

This manual must be kept with the furnace for future reference.

GRANBY FURNACES INC.

PO Box 637

12118 Hwy 209

Parrsboro Nova Scotia Canada

B0M 1S0

902-254-2543

www.granbyindustries.com

01-30-2014 G2012-E2 Rev. F

1

TABLE OF CONTENTS

1.0 IMPORTANT SAFETY ADVICE 2

2.0 PRODUCT INFORMATION

3

3.0 FURNACE INSTALLATION

6

4.0 ACCESSORY INSTALLATION

9

5.0 BURNER INSTALLATION AND SPECIFICATIONS 13

5.1 ASSEMBLY & INSTALLATION OF BURNER 13

5.2 SET BURNER FOR EFFICIENT OPERATION 14

5.3 TECHNICAL INFORMATION 16

6.0 FURNACE OPERATION AND SETTINGS 17

6.1 BLOWER SETTING 17

6.2 FAN TIMER CONTROL BOARD (ST9103 A 1028) 18

6.3 ST9103 A 1028 CONTROL BOARD SEQUENCE 19

6.4 SERVICING – FAN TIMER (ST9103 A 1028) 20

7.0 SERVICE 22

8.0 ELECTRICAL / WIRING DIAGRAMS 25

HEATING / COOLING – RIELLO BURNER 25

HEATING / COOLING – BECKETT BURNER 26

HEATING ONLY (2 WIRES THERMOSTAT) 28

9.0 EXPLODED PARTS VIEW 29

KHM-100 29

KHM-200 31

10. START-UP TEST RESULTS 33

2

1.0 IMPORTANT SAFETY ADVICE

Please read and understand this manual before installing, operating or servicing the

furnace. To ensure you have a clear understanding of the operating procedures of the

appliance please take the time to read the IMPORTANT SAFETY ADVICE section of this

manual.

WARNINGS

NEVER burn garbage or paper in the unit.

NEVER store combustible material around it.

DO NOT attempt to start burner when excess oil has accumulated, when unit is full of vapour

or when heat exchanger is very hot.

DO NOT use gasoline, crankcase drainings or any oil containing gasoline.

CAUTION

DO NOT START THE BURNER UNTIL ALL FITTINGS, COVERS AND DOORS ARE IN

PLACE. DO NOT TAMPER WITH THE FURNACE OR CONTROLS, CALL A QUALIFIED

BURNER TECHNICIAN. DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPOURS AND LIQUIDS IN THE VICINITY OF THIS UNIT OR ANY OTHER APPLIANCE.

DANGER

Do not use this furnace as a construction heater. Use of this furnace as a construction

heater exposes it to abnormal conditions, contaminated combustion air and lack of air

filtering. Failure to follow this warning can lead to premature furnace failure which

could result in a fire hazard and/or bodily harm and/or materials damages.

IMPORTANT

This manual contains instructional and operational information

for the KHM OIL-FIRED FURNACE. Read the instructions

thoroughly before installing furnace or starting the burner.

Consult local authorities about your local FIRE SAFETY

REGULATIONS. All installations must be in accordance with

local state or provincial codes. Improper installation will result

in voiding of warranty.

3

2.0 PRODUCT INFORMATION

CLEARANCE (minimum) TO COMBUSTIBLES

UPFLOW POSITION

Top & Sides of Supply Plenum 1” (25 mm)

Front (Maintenance) 24” (610 mm)

Rear 0” (0 mm)

First Side 0” (0 mm)

Other Side 0” (0 mm)

Flue Pipe 9” (229 mm)

Floor Combustible

DOWNFLOW POSITION

Top 2” (51 mm)

Bottom and Sides - Plenum 1” (25 mm)

Rear 0” (0 mm)

First Side 0” (0 mm)

Other Side 0” (0 mm)

Front (Maintenance) 24” (610 mm)

Flue Pipe 9” (229 mm)

Floor (with Down flow base) Combustible

HORIZONTAL POSITION

Top 2” (51 mm)

Bottom and Sides - Plenum 1” (25 mm)

Rear 1” (25 mm)

First Side 1” (25 mm)

Other Side 1” (25 mm)

Front (Maintenance) 24” (610 mm)

Flue Pipe 9” (229 mm)

Floor 2” (51 mm)

DRAFT PRESSURE

Breech draft pressure -0.01” wc minimum

AIR/BLOWER DATA

External static – Non A/C 0.2” wc

External static – A/C 0.5” wc

Maximum cooling 3.0 tons… KHM-100

5.0 tons… KHM-200

Maximum air temperature rise See page 16 and 34

High Limit, max design outlet temp 185°F

Thermostat anticipator 0.2 amps

MOTOR/BLOWER

KHM-100: 1/2 hp 4 Speed / G10-8 DD or 1/2 hp ECM / G10-8

KHM-200: 3/4 hp 4 Speed / GT12-10DD or 3/4 hp ECM / GT12-10

4

FAN/HIGH LIMIT CONTROL

Honeywell ST9103 Fan Center & Thermo-Disk (7” stem)

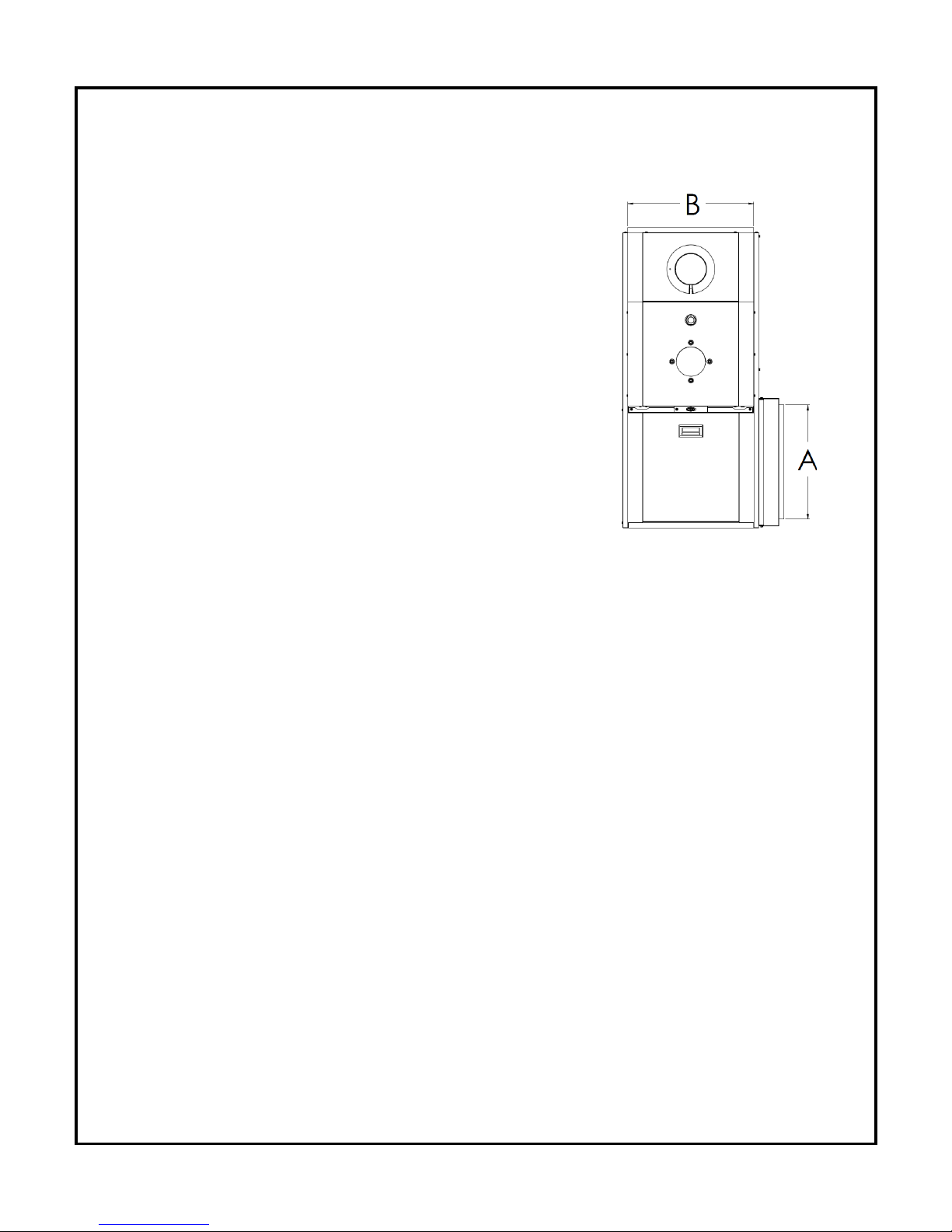

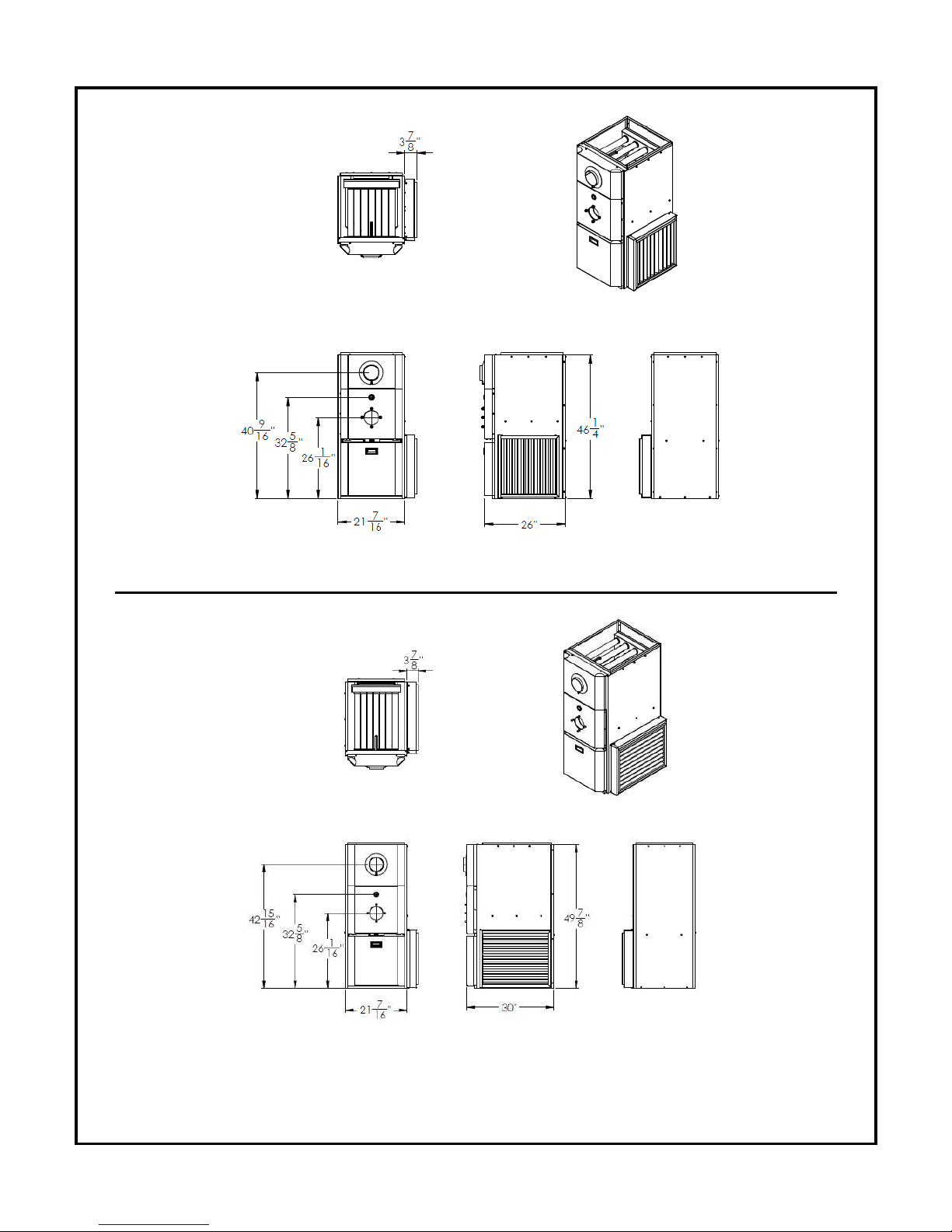

DIMENSIONS (KHM-100)

Depth 26” (660 mm)

Height 46 1/4” (1175 mm)

Width 21 7/16” (545 mm)

DIMENSIONS (KHM-200)

Depth 30” (762 mm)

Height 49 7/8” (1267 mm)

Width 21 7/16” (545 mm)

PLENUM DIMENSIONS (KHM-100)

Cold air return (A) 18” x 18” (457 x 457 mm)

Hot air supply (B) 20” x 20” (508 x 508 mm)

PLENUM DIMENSIONS (KHM-200)

Cold air return (A) 23” x 18” (584 x 457 mm)

Hot air supply (B) 24” x 20” (610 x 508 mm)

AIR FILTERS

KHM-100 20” x 20” x 2” non-pleated UL approved

KHM-2 00 25” x 20” x 2” non-pleated UL approved

A/C COIL LOCATION

Minimum height above the heat exchanger 6” (152 mm)

See A/C Coil Manufactures Requirements

SMOKE-PIPE CONNECTION

5” Chimney or direct vent DVS Granby kit

CLEANOUTS

Front Cover & Burner Opening

THERMOSTAT

Any thermostat

FUEL

Not heavier than No. 2 furnace oil.

ELECTRICAL – 120 Volts, 60 Hz

Canada Less than 12 amps, circuit protection 15 amps.

USA 13.3 amps, circuit protection 20 amps.

5

KHM-100 - DIMENSIONS

Dimensions are in inches

KHM-200 - DIMENSIONS

Dimensions are in inches

6

3.0 FURNACE INSTALLATION

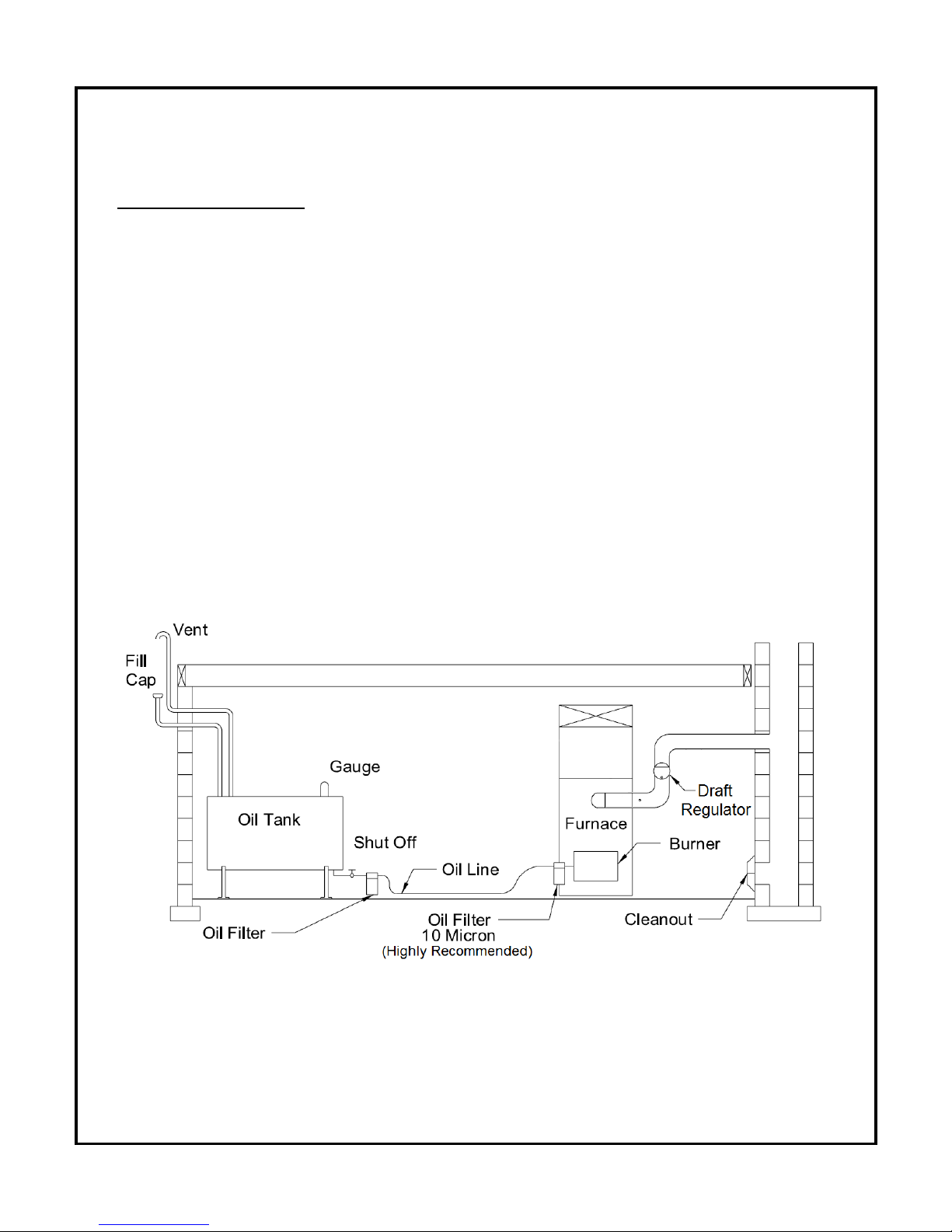

OIL TANK & PIPING

Tank installation must conform to local requirements.

Install according to the applicable code such as CSA B139 and NFPA 31. Minimize the

number of connections in suction line and make all connections as tight as possible. Use a

pipe joint compound suitable for oil on all pipe threads. To reduce possibility of air leaks,

tighten stem packing gland nut on any valves installed in the suction line. Also, be sure the oil

filter is tight, as filter gaskets often shrink. Check for kinks in the oil lines as well as for

possible air pockets and for loose connections. Two filters as shown below are recommended.

Optional tank gauge protectors and outlet protectors are available at your local dealer.

ONE PIPE SYSTEM Where the tank is above the burner and when the oil flows by

gravity to the oil pump, a single-stage fuel unit with a single oil line

to the pump may be used.

TWO PIPES SYSTEM When a single line is unsuitable, use a double line system or see

your dealer for special oil line fittings. Install by-pass plug on burner

fuel unit as specified in the burner manual.

Oil Tank and Piping

7

PLACEMENT & VENTING

Furnace installation shall conform to the required installation code for oil-fired equipment (USA:

NFPA 31, Canada: CSA B139).

FLOOR SUPPORT COMBUSTIBLE – If required, support furnace on five (5) concrete

blocks. Make sure the center of the furnace base is supported.

Approved for installation on combustible floors in the upflow position and

downflow position (with the optional sub-base). Not approved for

installation on combustible floor in horizontal applications. For horizontal

applications, use railing type support (not supplied) to keep the furnace

in position. Make sure that all clearances are respected.

CHIMNEY/VENT Connect the furnace to a chimney/vent system of size and condition

required by the NFPA 31 (USA) or CSA B139 (Canada) code. Furnace

is approved for factory built chimney type “L” vents. Breech is certified

for 5” vent pipe. Keep vent/flue pipe as short as possible with a

minimum upward slope of ¼’’ per foot. Vent/flue pipes MUST NOT pass

through a ceiling. Maximum flue gas temperature is 575°F.

CONDENSATION If you have condensation in your chimney, make sure that the

chimney size is according to the tables in CSA B139 / NFPA 31.

The temperature at the entrance of the chimney can be increased

by insulating the flue-pipe between the furnace and the chimney

base. If this is not sufficient, consider cutting or removing some

flue baffles in the furnace. BE AWARE THAT REMOVING BAFFLES

REDUCES THE UNIT EFFICIENCY AND A MODIFIED UNIT IS NO

LONGER ENERGY STAR APPROVED.

COMBUSTION &

Install openings and ductwork to the furnace room providing fresh

VENTILATION AIR outside combustion and circulation air for cooling the furnace casing, as

installation code requires (USA NFPA 31, Canada CSA B139). If

installed in a closed room, provide two free air ventilation openings of at

least 8” x 12” (96 sq. in.) free flow area near ceiling and floor. Oil burners

must have sufficient air to allow vent systems to operate properly.

DRAFT Use approved draft control supplied for 5” pipe. Set specified draft

minimum pressure of -0.01” wc.

ELECTRICAL Wire according to the National Electrical Code (Canadian Electrical

Code in Canada) or local codes. Use a separately fused #12 electrical

line directly from the service panel to the furnace junction box. Install a

manual shut-off switch at the door or stairway to furnace room so

furnace can be shut off remotely.

CLEARANCES Before placing unit, review installation clearances as shown on furnace

operating decal or section PRODUCT INFORMATIONS.

LOCATION Install the furnace close to chimney and central to ductwork.

8

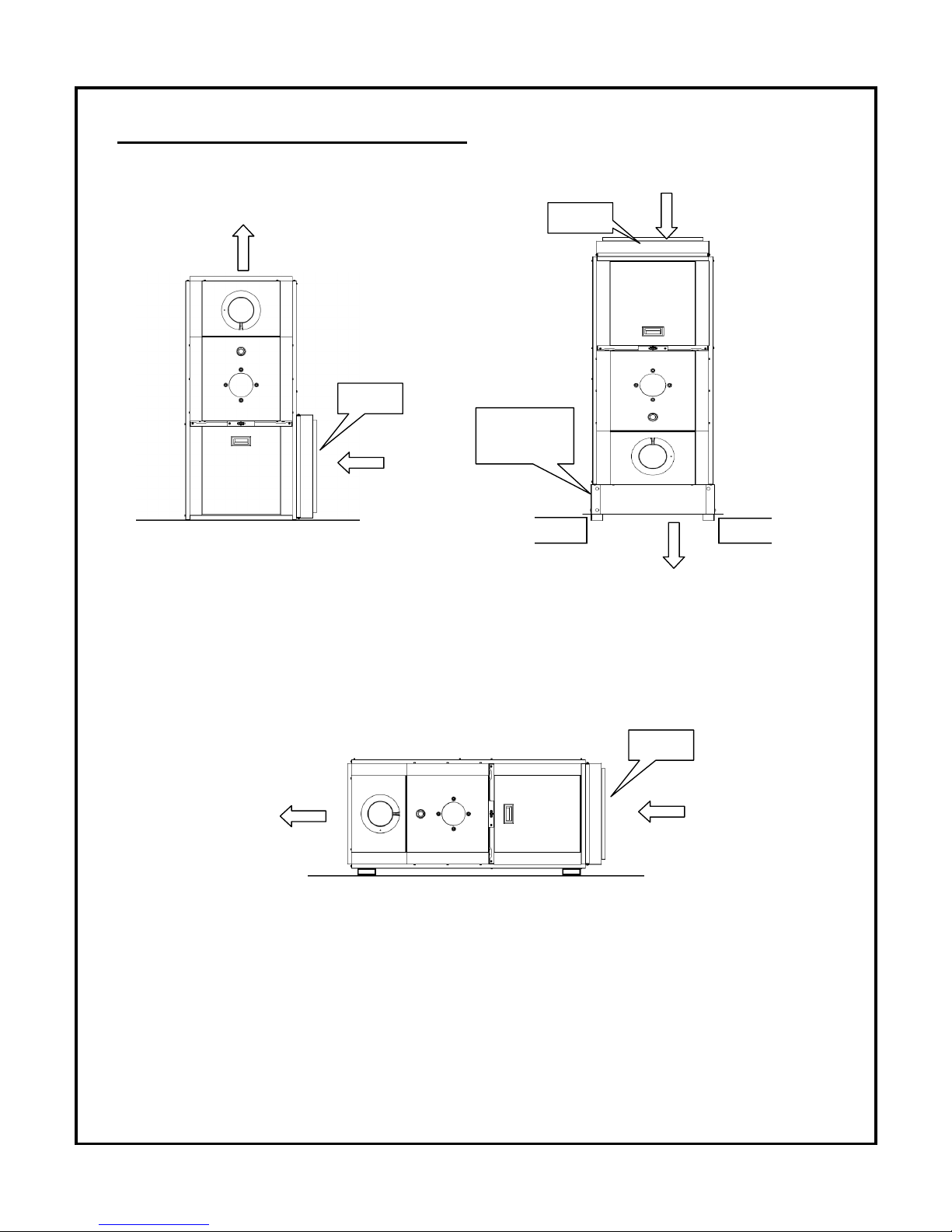

MULTI-POSITION CONFIGURATIONS

UPFLOW INSTALLATION DOWNFLOW INSTALLATION

The return air opening can be located

on left side or on the right side of the

unit. After installing the filter rack

supplied with the unit we recommend

installing the blower door before

handling the unit.

HORIZONTAL INSTALLATION

When the unit is installed in the horizontal configuration on a combustible floor with a choice of

right or left air outlet, the clearance of (2’’) from combustible material must be taken into

consideration.

The burner must always be installed facing upwards regardless of the

configuration installation.

For complete clearance information to combustibles, see PRODUCT

INFORMATION, page 3.

WARM AIR

AIR RETURN

WARM AIR

AIR RETURN

WARM AIR

AIR RETURN

Filter

Filter

Downflow

Sub-base

Filter

When the unit is installed in downflow

configuration on a combustible floor, the

clearance from combustible material must be

respected. The downflow sub-base

CAB-A0-0045-00 (for KHM-100) or

CAB-A0-0046-00 (for KHM-200) can be used

to ensure these clearances.

9

4.0 ACCESSORY INSTALLATION

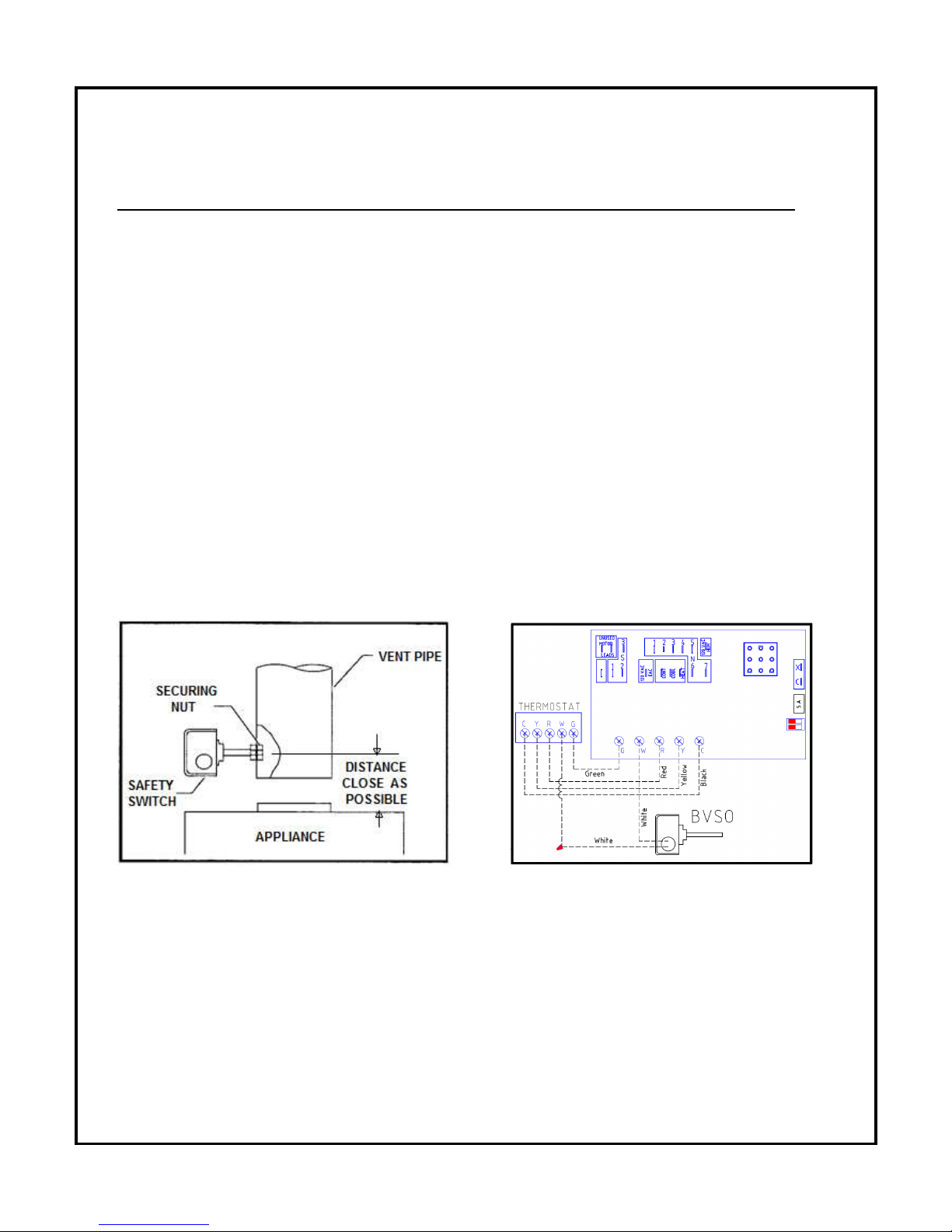

BLOCKED VENT SWITCH (BVSO) FOR CANADIAN APPLICATION ONLY

Oil-fired appliances installed in Canada require a blocked vent switch system when installed on

a chimney. A safety switch is included with the furnace to perform this function. It is the

installer’s responsibility to install the switch in accordance with the instructions provided. Not

applicable for Direct Vent systems. Field Controls Model: WMO-1 (Manual Reset)

Switch Operation

Blocked vent switches are flue gas safety devices for detecting spillage of flue gases due to a

blocked flue or inadequate draft. After detecting a problem, the switch de-energizes the

system’s burner control.

NEVER reset the switch unless the cause of the blockage has been corrected.

Installation (Figure 1)

1) Drill a 5/8” hole in to the flue vent pipe near the appliance breech connection.

2) This hole must be before the draft regulator, vertically or horizontally.

3) Remove one of the securing nuts from the threaded tube of the safety switch.

4) Tighten the other securing nut onto the pipe as far as possible.

5) Insert the threaded tube end into the pierced hole of the flue vent pipe.

6) Install the securing nut on the safety switch tube, which protrudes into the flue vent pipe.

Tighten the nut securely.

Figure 1-

Illustration from the instruction

Figure 2- BVSO wiring diagram

manual of Field Controls

Wiring Instructions (BVSO)

Caution: Disconnect the electrical power when wiring the unit.

Wire the blocked vent switch in accordance with The National Electrical Code and applicable

local codes. Wire the safety switch (BVSO) in series with the thermostat and the fan timer

relay control (Figure 2).

10

System Test Procedure (BVSO)

1) With the power re-established, block the chimney or vent pipe downstream of the switch.

2) Adjust the thermostat to call for heat.

3) Once the heating system has started the blocked vent switch should shut down the burner

within 10 minutes or sooner.

4) Once the system has cooled, the blocked vent switch can manually be reset.

5) This procedure should be tested a second time.

6) After testing the blocked vent switch the chimney should be cleared of obstruction and the

heating system should be tested over a long run cycle.

If the block vent switch shuts down the system, check to ensure there is enough draft in the

chimney and venting pipes.

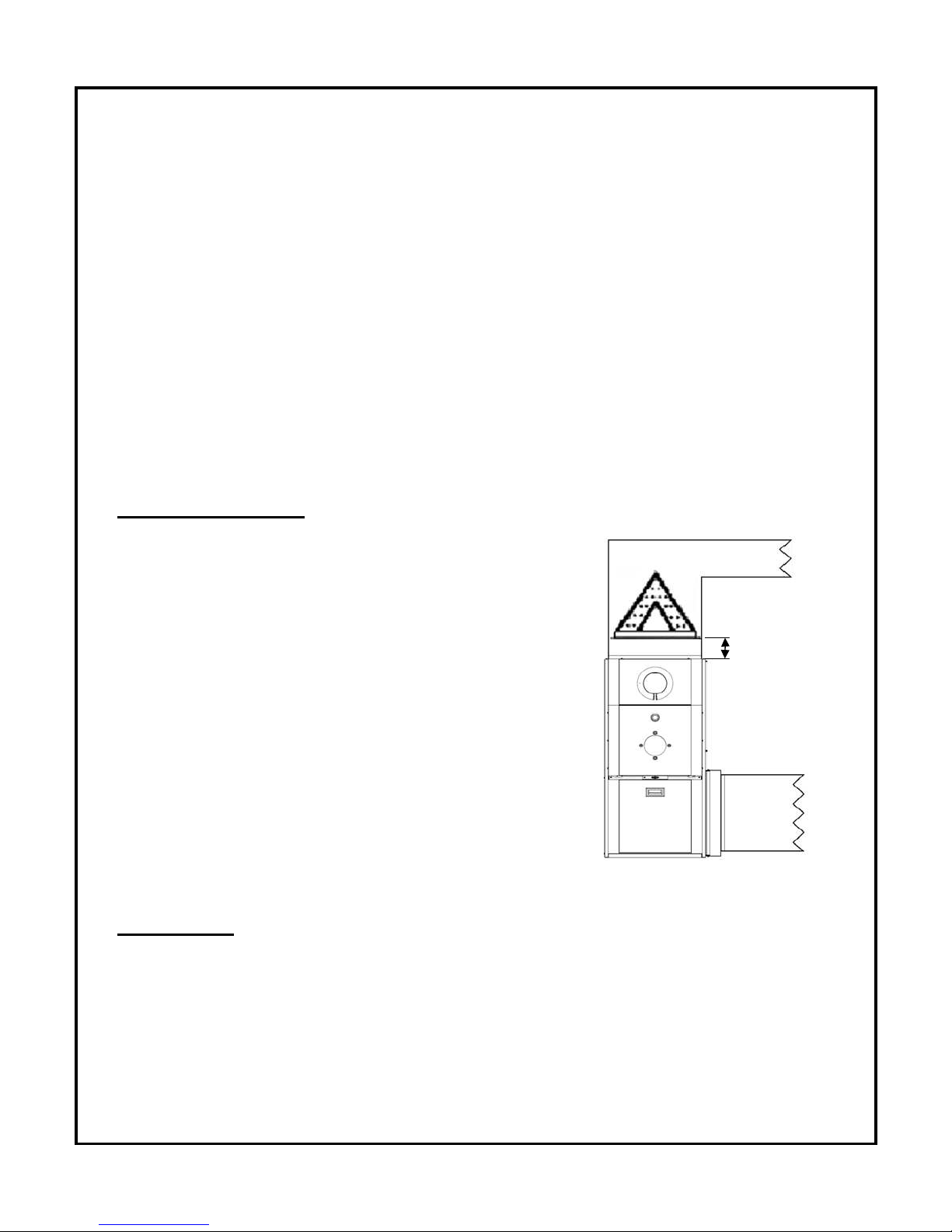

AIR CONDITIONING

An air conditioning coil may be installed on the supply side

only. Coils installed on the return side will cause

condensation on the heat exchanger; this will shorten the heat

exchanger life and may cause products of combustion to enter

the house. Wire as per wiring label and diagram. Height of

the coil above the unit supply shall be at least 4” (102

mm).

See A/C coil Manufacturers Requirements.

To check the AC coil total air flow resistance,

see procedure at page 34.

HUMIDIFIER

If a humidifier is installed ensure that no water can drip or run from it into the furnace. This

would cause deterioration and void the furnace warranty.

4 inch

minimum

Loading...

Loading...