Granby KHM-100 GAS, KHM SERIES, KHM-200 GAS Installation, Operation And Service Manual

Installation, Operation and

Service Manual

KHM SERIES

80% + EFFICIENCY

GAS FIRED CATEGORY I HI-BOY FURNACE

KHM-100 GAS

KHM-200 GAS

KHM-100 Illustration

INSTALLATIONS MUST MEET ALL LOCAL AND FEDERAL

CODES THAT MAY DIFFER FROM THIS MANUAL

Please read the manual in its entirety before beginning installation.

This manual must be kept with the furnace for future reference.

GRANBY FURNACES INC.

PO Box 637

12118 Hwy 209

Parrsboro Nova Scotia Canada

B0M 1S0

902-254-2543

www.granbyindustries.com

04-07-2015 G2014-E2G-Rev.B

1

TABLE OF CONTENTS

KHM

Gas

1.0 IMPORTANT SAFETY ADVICE 3

2.0 PRODUCT INFORMATION 5

3.0

FURNACE INSTALLATION 8

4.0 ACCESSORY INSTALLATION 15

5.0 BURNER INSTALLATION AND SPECIFICATIONS 19

5.1 ASSEMBLY & INSTALLATION OF BURNER 19

5.2 GAS-FIRED FURNACE LIGHTING INSTRUCTIONS 20

5.2 TECHNICAL INFORMATION 21

6.0 FURNACE OPERATION AND SETTINGS 22

6.1 BLOWER SETTING 22

6.2 FAN TIMER CONTROL BOARD (ST9103 A 1028) 23

6.3 ST9103 A 1028 CONTROL BOARD SEQUENCE 24

6.4 SERVICING – FAN TIMER (ST9103 A 1028) 25

7.0

SERVICE 27

7.1 BURNER CLEANING NOTES 30

8.0 ELECTRICAL / WIRING DIAGRAMS 31

9.0 EXPLODED PARTS VIEW 32

KHM-100 32

KHM-200 34

10. START-UP TEST RESULTS 36

2

NOTE: THE BURNER INSTRUCTION MANUAL AND THE

B

URNER USER’S INFORMATION MANUAL ARE

CONSIDERED PART OF THIS MANUAL AND THEIR

INSTRUCTIONS MUST BE FOLLOWED EXCEPT WHEN

SPECIFICALLY MENTIONNED IN THIS MANUAL.

WARNING: If the information in this

manual is not followed exactly, a fire or

explosion may result, causing property

damage, personal injury or death.

- D

o not store or use gasoline or other

flammable vapors or liquid in the vicinity of

this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS

o Do not try to light the appliance,

o Do not touch any electrical switch; do not

use any phone in your building,

o Immediately call your gas supplier from an

outside phone. Follow the gas supplier’s

instructions,

o If you cannot reach your gas supplier, call

the fire department.

- I

nstallation and service must be performed

by a qualified installer, service agency or

the gas supplier.

3

1.0 IMPORTANT SAFETY ADVICE

Please read and understand this manual before installing, operating or servicing the

furnace. To ensure you have a clear understanding of the operating procedures of the

appliance please take the time to read the IMPORTANT SAFETY ADVICE section of this

manual.

• Use only with Natural gas or Propane gas. Refer to the furnace rating plate.

• Install this furnace only in a location and position as specified in Section 3 of

these instructions.

• Provide adequate combustion and ventilation air to the furnace space as

specified in Section 3 of these instructions.

WARNING

FIRE OR EXPLOSION HAZARD

Never test for gas leaks with an open flame. Use a commercially available soap

solution made specifically for the detection of leaks to check all connections, as

specified in Section 5 of these instructions.

• Always install furnace to operate within the furnace’s intended temperature-rise

range with a duct system that has an external static pressure within the allowable

range, as specified in Section 5 of these instructions. See furnace rating plate.

• When a furnace is installed so that supply ducts carry air circulated by the

furnace to areas outside the space containing the furnace, the return air shall also

be handled by duct(s) sealed to the furnace casing and terminating outside the

space containing the furnace.

• This gas-fired furnace is not intended for installation in a residential garage.

• This furnace is not factory approved for installation at altitude higher than 2000

feet.

• Excessive exposure to contaminated combustion air will result in safety and

performance related problems.

o Sample List of Contaminants to be Avoided

The recommended source of combustion air is to use the outdoor air

supply. However, the use of indoor air in most applications is

acceptable except as follows:

• 1. If the furnace is installed in a confined space it is

recommended that the necessary combustion air come from

the outdoors by way of attic, crawl space, air duct, or direct

opening.

• 2. If outdoor combustion air is used, there must be no

exposure to the installations or substances listed in “3” below.

4

• 3. The following types of installation may require

OUTDOOR AIR for combustion, due to chemical

exposures:

o - Commercial buildings

o - Buildings with indoor pools

o - Furnaces installed in laundry rooms

o - Furnaces installed in hobby or craft rooms

o - Furnaces installed near chemical storage areas

o Exposure to the following substances in the

combustion air supply may also require OUTDOOR

AIR for combustion:

- Permanent wave solutions

- Chlorinated waxes and cleaners

- Chlorine based swimming pool chemicals

- Water softening chemicals

- De-icing salts or chemicals

- Carbon tetrachloride

- Halogen type refrigerants

- Cleaning solvents (such as

perchloroethylene)

- Printing inks, paint removers, varnishes, etc.

- Hydrochloric acid

- Cements and glues

- Antistatic fabric softeners for clothes dryers

- Masonry acid washing materials

WARNINGS

NEVER b

urn garbage or paper in the unit.

NEVER store combustible material around it.

CAUTION

DO NOT START THE BURNER UNTIL ALL FITTINGS, COVERS AND DOORS ARE IN

PLACE. DO NOT TAMPER WITH THE FURNACE OR CONTROLS, CALL A QUALIFIED

BURNER TECHNICIAN. DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPOURS AND LIQUIDS IN THE VICINITY OF THIS UNIT OR ANY OTHER APPLIANCE.

DANGER

Do not use this furnace as a construction heater. Use of this furnace as a construction

heater exposes it to abnormal conditions, contaminated combustion air and lack of air

filtering. Failure to follow this warning can lead to premature furnace failure which

could result in a fire hazard and/or bodily harm and/or materials damages.

5

IMPORTANT

This manual contains instructional and operational information

for the KHM GAS FIRED FURNACE. Read the instructions

thoroughly before installing furnace or starting the burner.

Consult local authorities about your local FIRE SAFETY

REGULATIONS. All installations must be in accordance with

local state or provincial codes. Improper installation will result

in voiding of warranty.

THE INSTALLATION OF YOUR GAS-FIRED FURNACE MUST CONFORM TO

T

HE REQUIREMENT OF THE AUTHORITY HAVING JURISDICTION OR IN

THE ABSENCE OF SUCH REQUIREMENTS, TO THE NATIONAL FUEL GAS

CODE ANDSI Z223.1/NFPA 54 AND/OR NATIONAL GAS AND PROPANE

INSTALLATION CODE CAN/CSA B149.1.

2.0 PRODUCT INFORMATION

CLEARANCE (minimum) TO COMBUSTIBLES (Operation and Service Clearances)

Top & Sides of Supply Plenum 1” (25 mm)

Front (Maintenance) 24” (610 mm)

Rear 0” (0 mm)

First Side 0” (0 mm)

Other Side 0” (0 mm)

Flue Pipe 9” (229 mm)

Floor Combustible

Furnaces for indoor installation on combustible flooring shall not be installed directly

on carpeting, tile or other combustible material other than wood flooring.

DRAFT PRESSURE

B

reech draft pressure -0.01” wc minimum

AIR/BLOWER DATA

Maximum External static – Non A/C 0.5” wc

Maximum External static – A/C 0.5” wc

Maximum cooling 3.0 tons… KHM-100

5.0 tons… KHM-200

Maximum air temperature rise 75 Degrees F

High Limit, max design outlet temp 185°F

Thermostat anticipator 0.2 amps

6

MOTOR/BLOWER

KHM-100: 1/2 hp 4 Speed / G10-8 DD or 1/2 hp ECM / G10-8

KHM-200: 3/4 hp 4 Speed / GT12-10DD or 3/4 hp ECM / GT12-10

FAN/HIGH LIMIT CONTROL

Honeywell ST9103 Fan Center & Thermo-Disk (7” stem)

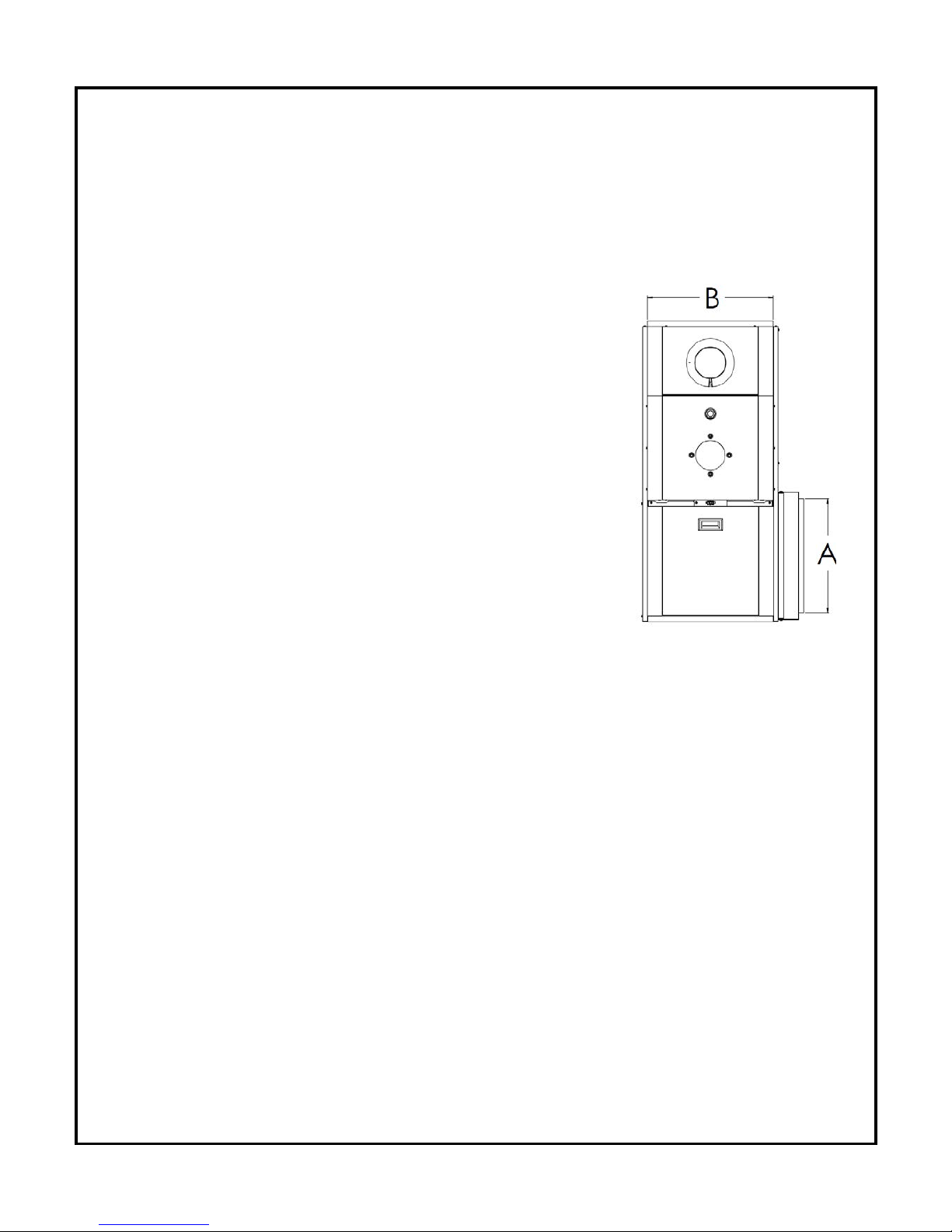

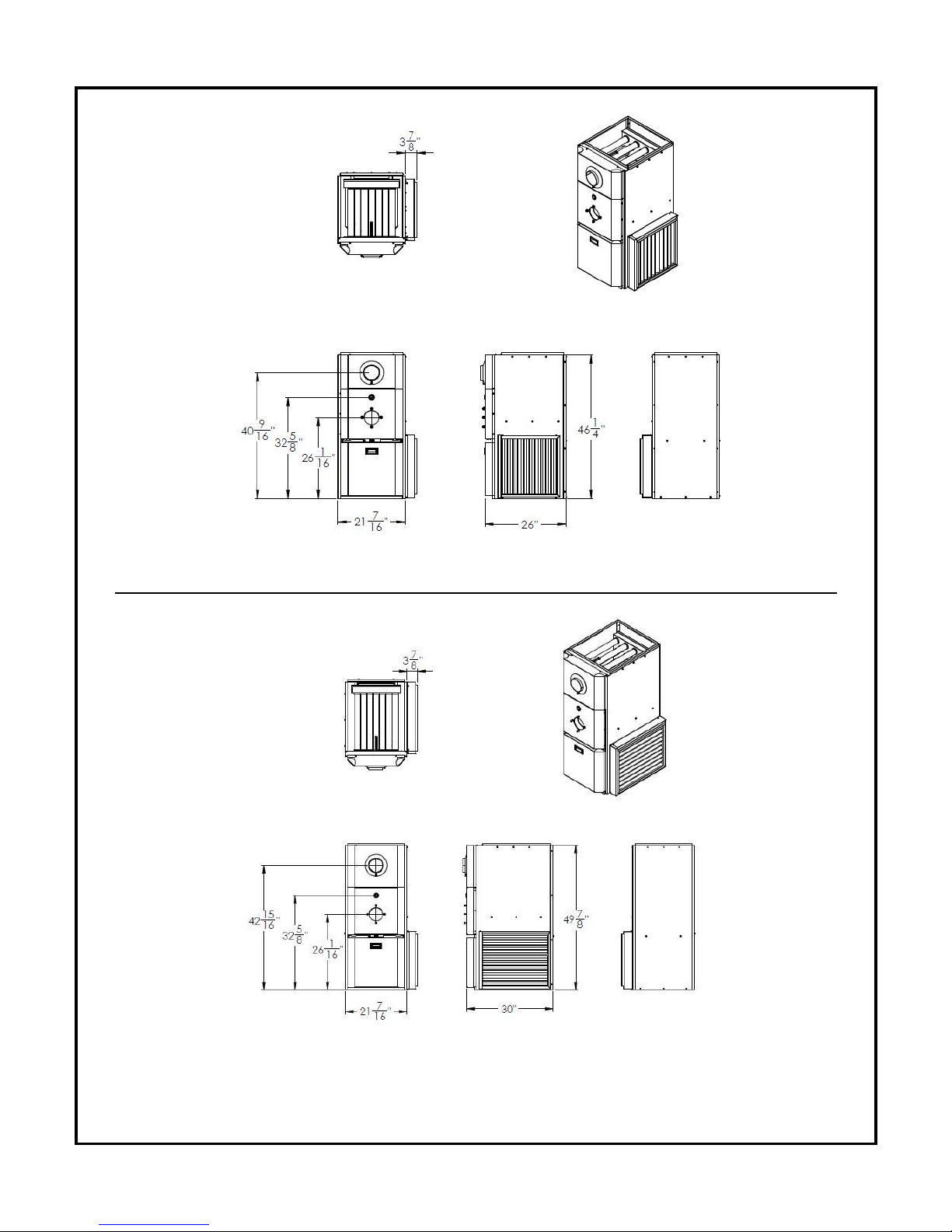

DIMENSIONS (KHM-100)

Depth 26” (660 mm)

Height 46 1/4” (1175 mm)

Width 21 7/16” (545 mm)

DIMENSIONS (KHM-200)

D

epth 30” (762 mm)

Height 49 7/8” (1267 mm)

Width 21 7/16” (545 mm)

PLENUM DIMENSIONS (KHM-100)

Cold air return (A) 18” x 18” (457 x 457 mm)

Hot air supply (B) 20” x 20” (508 x 508 mm)

PLENUM DIMENSIONS (KHM-200)

Cold air return (A) 23” x 18” (584 x 457 mm)

Hot air supply (B) 24” x 20” (610 x 508 mm)

AIR FILTERS

KHM-100 20” x 20” x 2” Pleated UL approved

KHM-2 00 25” x 20” x 2” Pleated UL approved

A/C COIL LOCATION

Mi

nimum height above the heat exchanger 4” (152 mm)

See A/C Coil Manufactures Requirements

SMOKE-PIPE CONNECTION

5” Chimney

CLEANOUTS

Front Cover & Burner Opening

THERMOSTAT

Any thermostat

FUEL

Natural Gas or Propane Gas

ELECTRICAL – CANADA:120 Volts, 60 Hz. Less than 12 amps, circuit protection 15 amps.

USA: 13.3 amps, circuit protection 20 amps.

7

KHM-100 - DIMENSIONS

Dimensions are in inches

KHM-200 - DIMENSIONS

Dimensions are in inches

8

3.0 FURNACE INSTALLATION

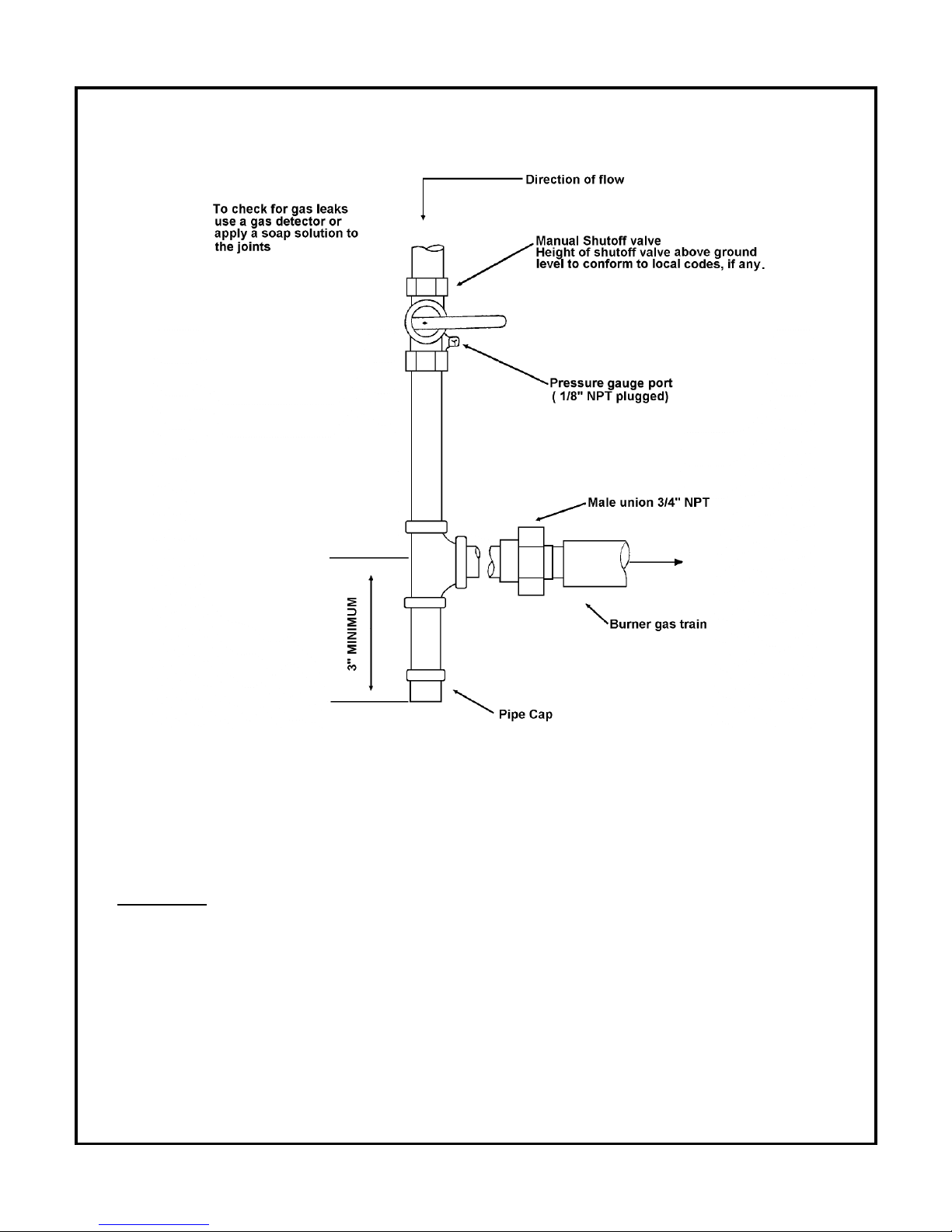

GAS PIPING

Gas piping must conform to local requirements.

Install according to the applicable code such as NATIONAL FUEL GAS CODE ANDSI

Z223.1/NFPA 54 AND/OR NATIONAL GAS AND PROPANE INSTALLATION CODE

CAN/CSA B149.1.

The gas piping must be installed between the gas meter and the combination gas valve

(located upstream of the Riello gas burner on the furnace. The gas valve has a knob acting as

a shut-off valve to stop gas flow. It is recommended to install a manual shut-off valve upstream

of the gas valve to facilitate service of the gas valve. The gas valve also has pressure tapping

for inlet pressure as well as outlet pressure. The outlet pressure of the gas valve is also

referred as manifold pressure in this manual.

If local codes allow the use of a flexible gas appliance connector, always use a new

listed connector. Do not use a connector which has previously serviced another gas

appliance

WARNING:

• Connect from the gas supply to the burner combination gas valve inlet using new, clean

black iron pipe and malleable iron fittings only. Do not use copper, brass, cast iron or

galvanized pipe or fittings.

• Provide support for gas piping. Do not rest weight of piping on burner gas valve.

• Apply pipe dope sparingly at all joints. Use only pipe dope listed for use with propane

gas. Do not use pipe sealing tape. In doubt consult CSA B149.1 or NFPA 54 or the

authorities having jurisdiction.

• Do not hold gas valve with a pipe wrench. Use crescent wrench or other smooth jawed

device. Do not over-tighten.

• Failure to comply with above could result in severe personal injury, death or

substantial property damage.

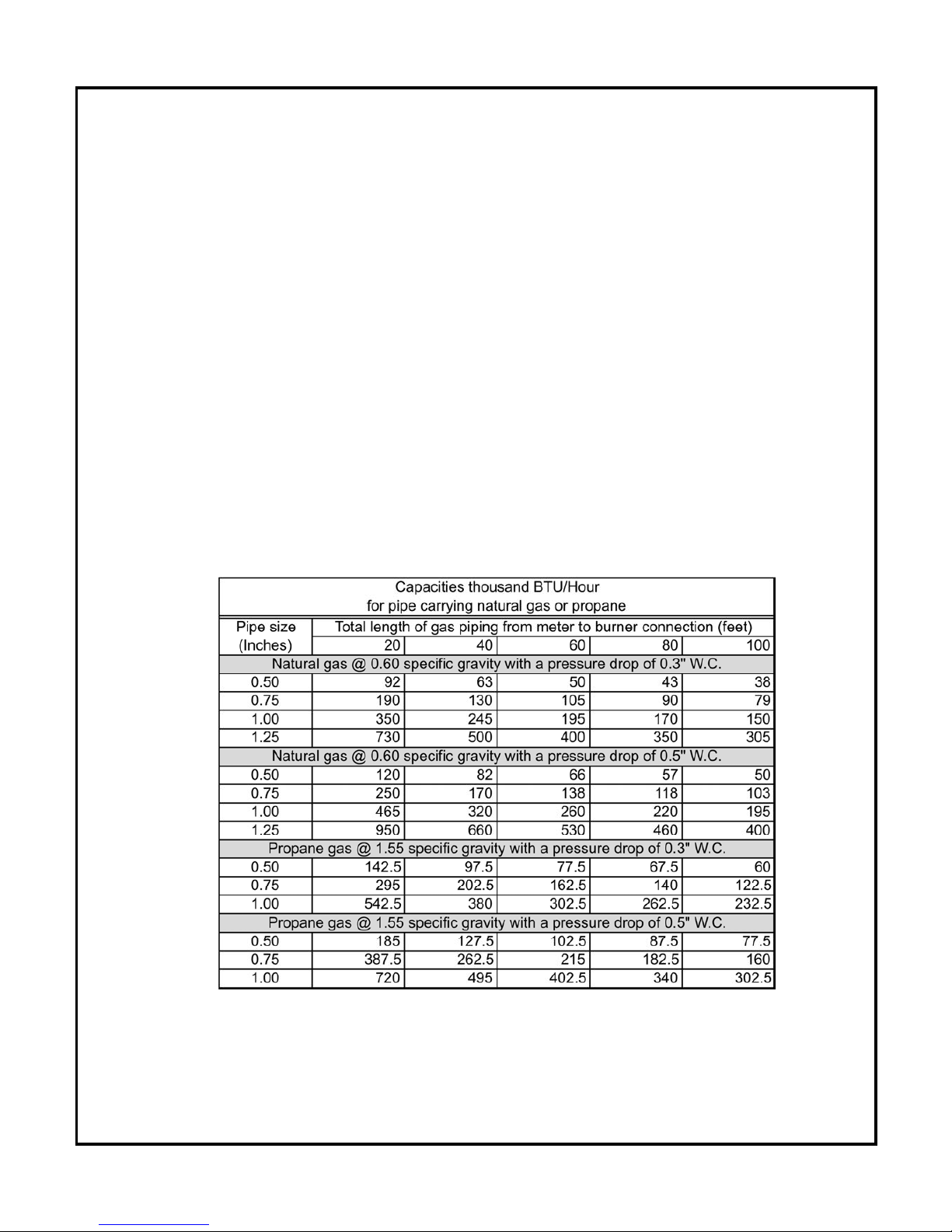

1. If possible, install a new gas line directly from the gas meter. If you are using an existing

gas line, verify it is clean and in good condition and verify it is large enough to handle the

load of all connected appliances. See the table below for guidance on pipe sizes.

2. When branching from a common gas line, do not tap from the bottom or horizontal sections,

only from the side or top.

3. Install a main manual shutoff valve, sediment trap and ground joint union near the burner

combination gas valve connection as shown below.

9

GAS SUPPLY PRESSURE

•

Maximum supply pressure: 13 inches W.C.

• Minimum supply pressure: 7” inches W.C.

WARNING:

• Do not expose the combination gas valve to gas pressures in excess of 14” W.C. The

valve has a safety mechanism that interrupt the flow of gas over 14” W.C. In any event

higher pressure could damage the valve seat, resulting in potentially hazardous

conditions. When pressure testing at higher pressures, disconnect burner from gas line

before testing.

10

• If the gas supply pressure can exceed 14 inches of water column at any time, you must

i

nstall a lockup type gas pressure regulator in the gas supply piping, ahead of the main

manual gas valve on the burner.

• The furnace and its gas connections must be leak tested before placing the boiler in

operation.

• Enough combustion air should be provided to the gas-fired furnace in accordance with

the section “Air for combustion and ventilation” of the National Fuel Gas Code ANSI

Z223.1/NFPA 54 or clause 8,2, 8,3 or 8.4 of Natural gas and Propane installation code

CAN/CSA B149.1, or applicable provisions of the local building codes.

TEST AND PURGE GAS LINE

1. Read warning above.

2. Pressure test and purge the line. Pressure testing should be done by the gas supplier or

utility, following all applicable codes.

11

PLACEMENT & VENTING

THE INSTALLATION OF YOUR GAS-FIRED FURNACE MUST CONFORM TO

THE REQUIREMENT OF THE AUTHORITY HAVING JURISDICTION OR IN

THE ABSENCE OF SUCH REQUIREMENTS, TO THE NATIONAL FUEL GAS

CODE ANDSI Z223.1/NFPA 54 AND/OR NATIONAL GAS AND PROPANE

INSTALLATION CODE CAN/CSA B149.1.

FLOOR SUPPORT COMBUSTIBLE – If required, support furnace on five (5) concrete

blocks. Make sure the center of the furnace base is supported.

Approved for installation on combustible floors. Make sure that all

clearances are respected.

CHIMNEY/VENT

Breech is certified for 5” vent pipe. Keep vent/flue pipe as short as

possible with a minimum upward slope of ¼’’ per foot. Vent/flue pipes

MUST NOT pass through a ceiling. Maximum flue gas temperature is

480°F.

ADDITIONAL CHIMNEY INFORMATIONS

WARNING

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each appliance connected to the venting

system being placed into operation could result in carbon monoxide poisoning or

death.

When an existing furnace is removed from a common venting system, the common venting

system is likely to be too large for proper venting of the appliances connected to it. At the time

of removal of the existing furnace, the following steps shall be followed with EACH appliance

remaining connected to the common venting system, while the other appliances remaining

connected to the common venting system are not in operation:

1. Seal any unused openings in the venting system.

2. Visually inspect the venting system for proper size and horizontal pitch and determine

there is no blockage or restriction, leakage, corrosion and other deficiencies which could

cause an unsafe operation.

3. Insofar as is practical, close all building doors and windows and all doors between the

space in which the appliances remaining connected to the common venting system are

located and other spaces of the building. Turn on clothes dryer and any appliance not

connected to the common venting system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they will operate at maximum speed. Do not operate

a summer exhaust fan. Close fireplace dampers.

Loading...

Loading...