Granby KHE-00-G023-03, KHE-00-G015-03, KHE-00-G018-03, KHE-00-G020-03, KHE-00-G027-05 Installation, Operation And Service Manual

...

Installation, Operation and Service

Manual

Conforto

Electric

Furnace

HE 10 TO 27kW

K

INSTALLATIONS MUST MEET ALL LOCAL AND FEDERAL CODES THAT MAY

DIFFER FROM THIS MANUAL

Please read the complete manual before beginning installation. This

manual must be kept with the furnace for future reference. For

maintenance or question, please refer to your installer – contractor directly.

02-13-2018 G2018-A1 Rev. A

TABLE OF CONTENTS

1.0 IMPORTANT SAFETY ADVICE 3

2.0 PRODUCT INFORMATION 3

3.0 INSTALLATION 4

4.0 HIGH VOLTAGE CONNECTIONS 6

5.0 PANEL DISPLAY, SWITCHES AND CUICUIT BREAKER 7

6.0 TECHNICAL INFORMATION 10

7.0 HEATING OUTPUT RATES BY STAGES 11

8.0 COMMISIONING CHECKLIST 11

9.0 KHE SERIES ELECTRICAL FURNACE 12

10. WIRING DIAGRAM – PSC & ECOTECH RESCUE MOTORS 13

11 EXPLODED VIEW KHE 14

2

1.0 IMPORTANT SAFETY ADVICE

Please read and understand this manual before installing, operating or servicing the

furnace. To ensure you have a clear understanding of the operation of the unit please take the

time to read the IMPORTANT SAFETY ADVICE section of this manual.

WARNING – BASIC SAFETY WARNINGS

KNOW the location of the emergency disconnect switch for the unit.

EXAMINE the package before installation to ensure it did not get damaged during shipping.

ENSURE that the unit is connected to a properly sized duct system before controller is powered.

Failure to do so will result in damage to the heating elements, voiding the warranty.

WARNING – BEST PRACTICES FOR OPTIMAL OPERATION

DO NOT ATEMPT DO INSTALL YOURSELF OR MAKE ANY REPAIRS IF YOU ARE NOT A

QUALIFIED TECHNICIAN, CALL A QUALIFIED HEATING TECHNICIAN.

DANGER

Do not use this furnace as a construction heater. Use

heater exposes it to abnormal conditions, contaminated circulating air and air filtering.

Failure to follow this warning can lead to premature furnace failure which could result in

a fire hazard and/or bodily harm and/or material damage and will void its manufacturer’s

warranty.

of this furnace as a construction

IMPORTANT

This manual is intended to inform the installer of installation, operation and maintenance

procedures for trouble free operation of the Conforto KHE electric furnace. It is essential that

the service technician carefully reads this manual to fully understand the furnace and its

installation, operation and maintenance procedures before servicing the furnace or the heating

system as operating procedures may vary depending on furnaces manufacturers. The Conforto

KHE electric furnace is designed and manufactured with quality components for maximum life

expectancy, durability and requires minimum maintenance and service. To insure a satisfactory

installation, it is imperative that the instructions in this manual be followed carefully before

operating the heating system. Failure to do so may result in breach of warranty.

2.0 PRODUCT INFORMATION

The Conforto KHE warm air electric furnace is a multi-po

installation in the up flow, down flow or horizontal

with a central heat-pump or central cooling system.

sitional design allowing for an

fl

ow positions. This appliance may be used

3

INSTALLATION OVERVIEW

Install this appliance in accordance with these instructions and all national and local

building/safety codes and requirements.

Only connect this furnace to a duct system with a maximum

pressures in excess will result in reduced air flow and potential elevated discharge air

temperatures during heating cycles and reduced discharge air temperatures during cooling

cycles.

Do not operate this furnace without both supply and retu

place or with less than 0.20” W.C, external static pressure.

INSPECTION

As soon as you receive this unit un package and inspe

damage has resulted during the shipping process.

static pressure of 0.60” W.C. Static

rn air ducts installed with air filters in

ct it thoroughly to ensure that no

3.0 INSTALLATION

General

These furnaces must be properly installed in compliance

standard codes. This appliance requires 240Vac single phase, 60Hz voltage.

The supply power lead shall enter the control enclosure of the furnace through the knockout

provided on the right-hand side of the furnace. This will ensure the required separation between

the low voltage and high voltage leads.

Knockouts are provided for 115Vac and 24Vac connectio

cleaners on both sides of the furnace.

Always ensure that the installation protects all electric

Attention must be given to the placement of A/C coils and drains.

fl

A non-combustible base is needed for counter

Adequate access must be provided at the front of this furnace for service.

ow installations on combustibles floors.

with all national and local safety

ns for humidifiers and electronic air

al components from exposure to water.

ATTENTION: the front of the appliance must always remain accessible to allow maintenance

and service.

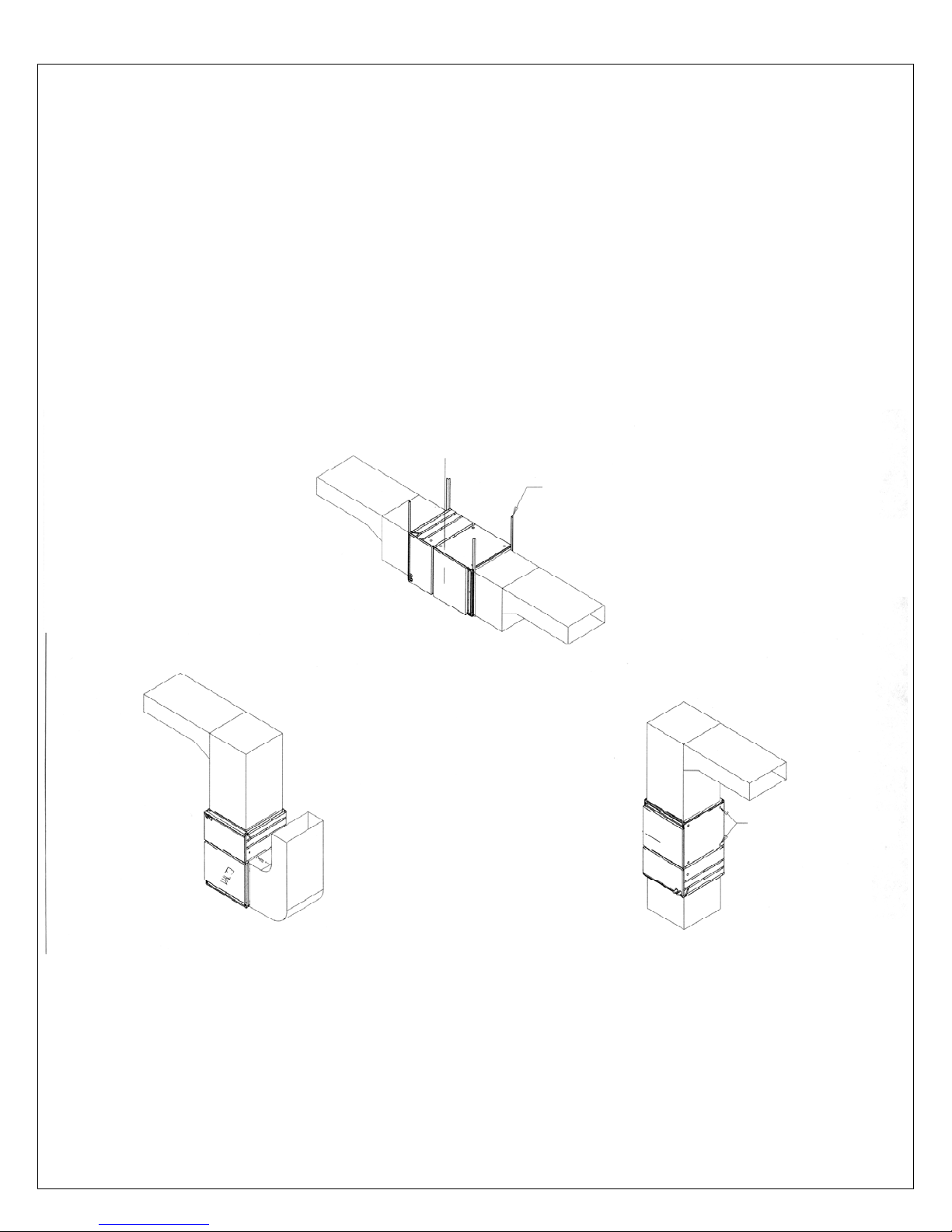

For horizontal installations, it is recommended to use s

rods supporting the unit from the bottom. Refer to Figure 1.

teel angle support brackets with threaded

4

Due to the hazardous nature of electrical and mechanical requirements only trained and

materials

.

Return air knock out.

qualified personnel should install and service heating and cooling equipment.

WARNING

It is important to check airflow and make sure that the furnace does not operate above

the temperature rise specified in the specifications, Section 6. This is particularly

important if a cooling or heat pump coil has been installed. High limit thermal protectors

should never engage during normal operation of the furnace. The high limit protectors

are designed to engage during the improper functioning of the blower or when the air

has not been kept clean.

Fig 1

Horizontal Installation

Note : Return air opening must be cut out

to knockouts provided. Minimum return air

opening size, 18’’ X 18’’

Caution : Return air openings shall not be

installed in back panel.

Supply air plenum must be constructed of

suitable materials and sized by installing

contractor so as to be of sufficient strength

to support furnace and accessory fittings

and materials.

Minimum 1’’ x 1’’ x 1/8’’ angle

Note : Field selected suspension

materials must be sized by the installing

contractor and be of sufficient strength to

support air handler weight of 100 lbs and

connected accessory fittings and

fi

lter

Upflow Installation

Counterflow Installation

electing a location

S

This furnace shall be centrally located in relation to

the outlet registers. All ductwork shall be

suitably sized with external static pressure in mind to ensure adequate air distribution.

These furnaces are suited for vertical up flow, down flow an

d horizontal installations. This furnace

shall not be installed on its front or back. To install this unit on its front or back would result in

inadequate access for servicing. Always ensure that when suspending this furnace that suitable

structural support is available and provides adequate access to the control and fan

compartments for service.

5

Loading...

Loading...