Granby BKC Installation, Operation And Maintenance Manual

GRANBY CAST IRON SERIES

OIL-FIRED HOT WATER BOILER

BKC

Installation, Operation and

Maintenance Manual

INSTALLATIONS MUST MEET ALL LOCAL AND FEDERAL

CODES THAT MAY DIFFER FROM THIS MANUAL

Please read this complete manual before beginning installation. These instructions must be kept with

the boiler for future reference.

GRANBY FURNACES INC

PO Box 637

12118 Hwy 209

Parrsboro Nova Scotia Canada

B0M 1S0

www.GranbyIndustries.com

GRANBY CAST IRON SERIES – INSTALLATION/OPERATION MANUAL

TABLE OF CONTENTS

General Instructions 1

Receiving Shipment 2

Clearances for Service & Combustible Materials 2

Combustion Air and Ventilation 3

Air for Combustion 3

Air for Ventilation 3

Combustion Air Supply with No Barometric Damper 3

Boiler Location & Leveling Of Unit 3

Burner Tube Insertion 3

Jacket Assembly 4

Piping 6

General Requirements for Piping Circuits 6

Circulation Pump 7

Controls/General 7

Piping Install Diagrams 7

Wiring 9

General Instructions 10

Typical Wiring Diagrams 10

Venting Requirements 10

Natural Draft Applications 11

Condensation 11

Fuel System 11

Boiler Series Specifications 12

Burner Specifications 13

Start Up Procedure 13

Maintenance and Testing-Serviceman 14

Testing Safety and Control Devices 14

Cleaning Boiler Sections 14

Cleaning Fuel System and Burner 14

Perform Combustion Tests 14

Parts List and Boiler Diagram 15

THE INSTALLATION OF THE EQUIPMENT SHALL BE IN ACCORDANCE WITH THE REGULATION

OF AUTHORITIES HAVING JURISDICTION AND CSA STANDARD B139

THE INSTALLATION OF THE UNIT SHALL BE IN ACCORDANCE WITH THE AUTHORITIES

HAVING JURISDICTION.

READ AND SAVE THESE INSTRUCTIONS FOR REFERENCE.

NOTICE: All installations must conform to federal, state and local code.

5IM-OB-CAST-00 May/11

1

GRANBY CAST IRON SERIES – INSTALLATION/OPERATION MANUAL

CAUTION

DO NOT ATTEMPT TO START THE BURNER WHEN EXCESS OIL HAS ACCUMULATED,

WHEN THE UNIT IS FULL OF VAPOUR OR WHEN THE COMBUSTION CHAMBER IS

VERY HOT. NEVER BURN GARBAGE OR PAPER IN THE UNIT AND NEVER LEAVE

COMBUSTIBLE MATERIAL AROUND IT.

STEPS PRIOR TO INSTALLATION

Before beginning the installation process it is highly recommended that you read this manual

carefully. Your boiler must be installed by a qualified and where required licensed contractor in

accordance with all local codes. When local codes are not in effect the boiler must be installed

in accordance with NFPA 31 and NFPA 211, Standard for installation of Oil Burning Equipment

in the U.S. and CSA B139 in Canada. Failure to have the appliance installed by a qualified

technician in accordance with code may void your warranty.

Before installing the boiler inspect all items supplied by Granby for physical damage. Any

physical damage should be reported to your boiler wholesaler, not Granby. Your package will

include the boiler block, jacket assembly, burner and trim kit assembly including control.

To avoid injury and potential property damage, Granby has identified, in its opinion,

certain potential hazards to health and equipment, which are noted in Bold Face Large

Print announcements labeled CAUTION, WARNING, NOTICE or DANGER. You must pay

particular attention to these announcements.

This manual is presented in a sequence that allows for an orderly trouble free installation. We

suggest that you follow the instructions in order eliminate potential hazards.

Prior to system installation there should be an inspection of the chimney or proposed vent

system to determine that the condition is acceptable. Repair or replace any defects in the

chimney liner. The vent system and installation must be in compliance with all applicable

heating and building codes. Improperly sized vent systems can cause poor burner operation,

sooting, odour or condensation that might create chimney damage. Installation of Barometric

draft controls will insure adequate draft. A minimum draft required at the vent collar is -.01”

W.C.

CLEARANCES

Proper clearances must be maintained not only from combustible materials but also to provide

adequate access for servicing. All installations must comply with local codes and NFPA-31

and NFPA-211 and CSA B139. Consult local fire codes for required clearances. Connections

to chimney must be made with the proper gauge thickness and diameter of fluepipe as

required by NFPA-211 and CSA B139.

CLEARANCE FOR SERVICING Front 24”

Back 24”

Left Side 24”

Right Side 2”

Top 10”

5IM-OB-CAST-00 May/11

2

GRANBY CAST IRON SERIES – INSTALLATION/OPERATION MANUAL

CLEARANCE TO COMBUSTIBLES Front 24”

Back 24”

Left 24”

Right 2”

Chimney Connector 9”

Top 10”

CAUTION: Adequate air supply for both combustion and ventilation must be available.

COMBUSTION AND VENTILATION AIR

Installations taking place in traditional unconfined settings such as basements generally have

an adequate supply of both combustion and ventilation air.

In situations where the boiler is to be located in a confined space with all combustion and

ventilation air coming from within the building two openings must be made with an adjoining

room with one being near the floor and the other being near the ceiling of the boiler room.

These openings must be clear and free of obstacles and measure at least 140 sq. in. per

gallon of oil burned per hour.

In instances where the air supply for both combustion and ventilation is to come from outside

the building two air openings, one near the floor and one near the ceiling, measuring at least

35 sq. in. for each gallon of oil burned per hour.

If there is no accessible source of air for combustion and ventilation available within the

building, combustion air ducts may be installed to convey the air. Those ducts used to convey

air must have areas of at least 35 sq. in per gallon of oil burned per hour for vertical ducts and

70 sq. in per gallon of oil burned per hour for horizontal ducts. The area of the ducts and

corresponding openings of connected free areas must be equal. The duct must have direct

outside access and be installed with a rain hood and insect screen installed at the outside wall.

This dedicated supply of ducted air should be installed within 5 feet of the boiler.

ALL VENTILLATION REQUIREMENTS SHOULD CONFORM TO LOCAL CODE AND OR

NFPA-31 AND CSA B139.

*NFPA or OEM burner specifications take precedence where required.

PLACEMENT & LEVELING OF THE UNIT

The boiler should be located on a firm foundation in an easily accessible area that meets the

previously discussed clearances and air requirements. In situations where the floor may be

uneven the GC may be leveled by using the leg levelers provided on the boiler or through the

insertion of shims under the legs.

BURNER TUBE INSERTION AND BURNER ATTACHMENT

The insertion of the burner air tube must be back 3” for the Riello burner and 2 ¾” for the

Beckett burner. Attach the burner in accordance with the burner manufacturer’s instructions

provided. Make sure that the burner is level and that all nuts are fully tightened.

5IM-OB-CAST-00 May/11

3

GRANBY CAST IRON SERIES – INSTALLATION/OPERATION MANUAL

JACKET ASSEMBLY AND CONTROL INSTALLATION

The boiler jacket has been designed for ease of assembly and removal. The following step by

step process will ease installation. A screw driver, 17 mm socket and ratchet or a 17 mm

wrench or adjustable wrench are needed.

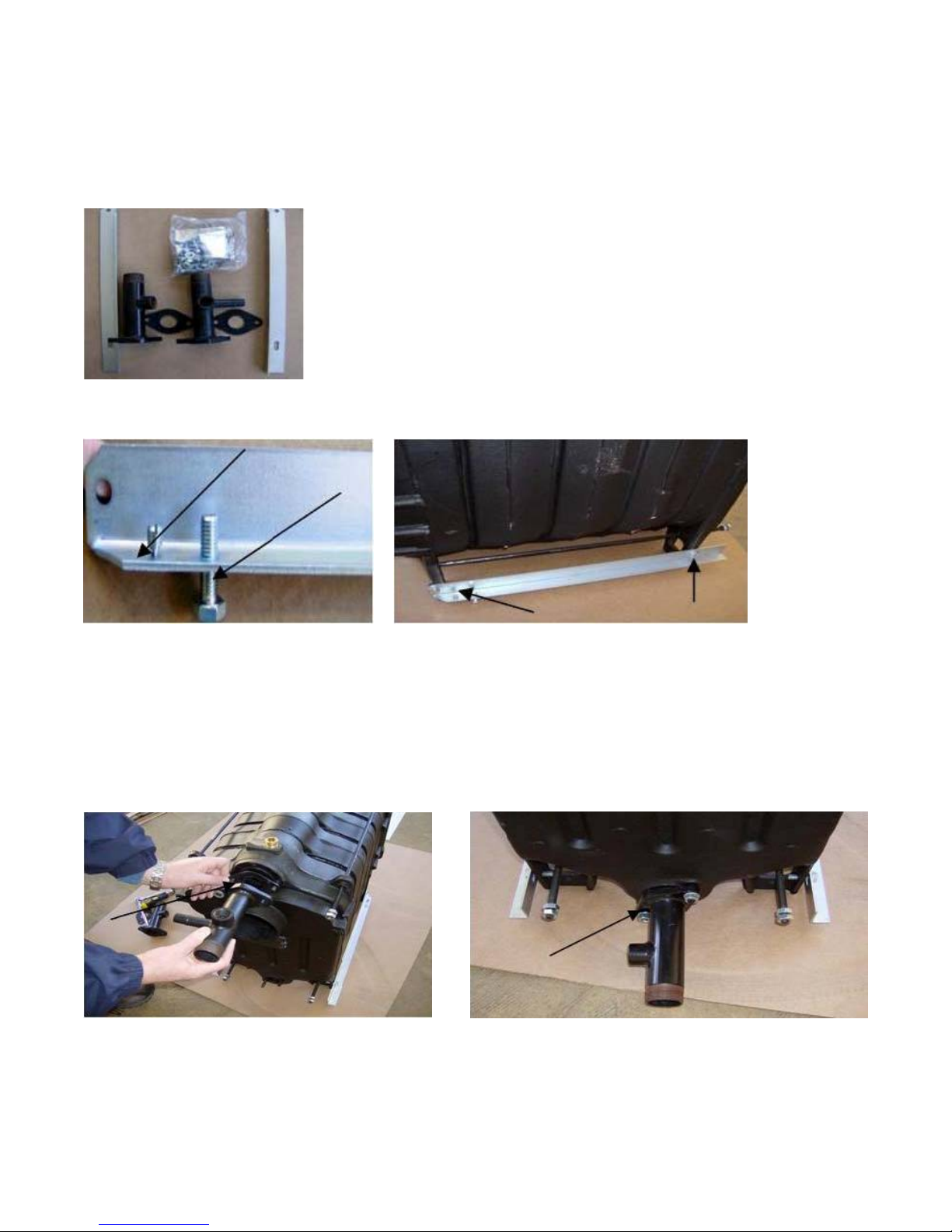

STEP 1 VERIFY CONTENTS OF JACKET ASSEMBLY PACKAGE.

Your jacket assembly will contain two (2) manifolds with gaskets, a

fastening package which includes all necessary bolts, screws, nuts

and washers for assembly along with burner studs, nuts and

washers, block insulation, rear of block insulation, aluminum faced

tape, leveling frame rails, two (2) side panels, a rear panel top

panel and re-insulated top and bottom front panels.

STEP 2 FRAME RAIL CONNECTION

Attach 10 mm bolts to the underside of the frame rails. These will be used to level the boiler.

Screw the 4 mm jacket affixing screw to the frame rail from the top down. Both the bolt and

affixing screw will be located on the same end of the frame rail. The frame rail will then be

bolted to the legs of the boiler with the frame rail and containing the affixing screw facing in the

direction of the front end of the boiler.

STEP 3 MANIFOLD INSTALLATION

Using the gaskets and bolts supplied connect the manifolds directly to the boiler block. The

top supply manifold will have a 3/4” npt tapping for a relief valve and 1/4” npt tapping for a

gauge. The bottom return manifold has 3/4” npt tapping for a drain vlave. Both manifolds

have 1-1/4” male npt threads for system connection.

5IM-OB-CAST-00 May/11

4

GRANBY CAST IRON SERIES – INSTALLATION/OPERATION MANUAL

STEP 4 INSULATION INSTALLATION

Drape the large piece of block insulation directly over the block taking care to provide

adequate clearance from frame rails. Using the aluminum faced tape attach the preshaped

rear inslulation to the block insulation. The process is simply taping the two pieces together.

The front panels come pre-insulated.

STEP 5 SIDE AND BACK PANEL ATTACHMENT

Affix panel mounting nuts to the rear of the tie rods. Mount the side panels by placing the

panel over the frame rail so that the hole in the bottom lip of the panel fits directly over the

jacket affixing screw on the rail. You can then lock the panel in place by sliding it slightly

forward. The slot on the rear of the panel will now be in position to slide over the tie rod at the

rear of the boiler. Tighten the nuts on the tie rod end to firmly secure the panel. Repeat on the

other side. Screw the back panel to the side panels.

STEP 6 CONTROL SENSOR ATTACHMENT

Prior to jacket top and front panel installation the control sensor must be inserted into the brass

well located at the back of the boiler and secured by a clip. Feed the sensor through the hole

on the front of the right side panel from the outside. Penetrate the block insulation to insert the

sensor. The sensor must be fully inserted to the bottom of the well.

5IM-OB-CAST-00 May/11

5

Loading...

Loading...