Granby 115, 118, 119, 215, 218 Installation Instructions Manual

...

ECONOPLUS ELECTRIC

FURNACE

SERIES 100

Models 115, 118 & 119

SERIES 200

Models 215, 218 & 219

SERIES 300

Model 315, 318, 319 & 323

Rev : June 2009

Econoplus Series 100, 200 and 300 ELECTRIC FURNACES

INSTALLATION INSTRUCTIONS – HOMEOWNER’S MANUAL

1.0 Scope and general instructions

1.1 Installer and service technician

Use this installation guide for the initial set-up of the furnace and for subsequent service and maintenance. Keep

this document near the unit for easy reference.

1.2 Homeowner

This guide details the different modes of operation of your unit. Please read this guide after the initial

installation by your installer and keep it handy afterward for future reference.

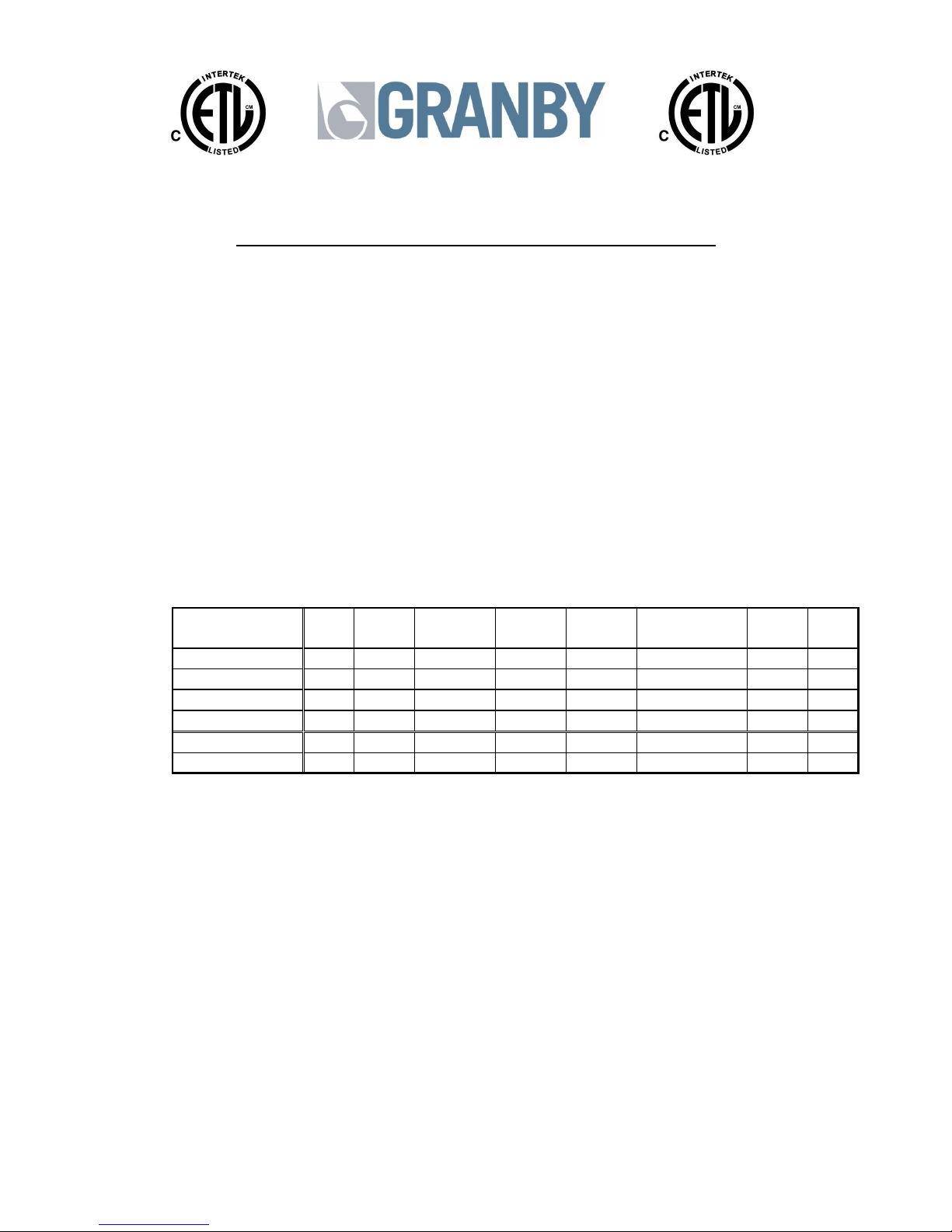

1.3 Models covered and description

• Series 100

The 100 series is the basic electric furnace. These furnaces are factory assembled for operation with a single

stage or standard thermostat. They also have a cooling relay factory installed to enable high speed operation

when coupled with an air conditioning unit at 0.5’’W.C. (Suffix C).

Mo

del

Econoplus

KW

Total

Amps

Volts

(V/Hz/Ph)

Motor

(HP)

Motor

Speed

Static

Pressure

(‘’W.C.)

CFM ΔT

(oF)

115 15 64.4 240

/60/1

¼ -

240 Med.

0.2 925 51

115-C 15 64.8 240

/60/1

¼ -

240 High 0.5 1050 45

118 18 76.9 240/60/1

¼ -

240 Med.

0.2 925 59

118-C 18 7

7.3 240/60/1

¼ -

240 High 0.5 1050

52

119 19 78.4 240

/60/1

¼ -

240 Med.

0.2 925 63

119-C 19 78.8 240

/60/1

¼ -

240 High 0.5 1050 65

Table 1 – Series 100 characteristics

• Series 200

The 200 series is the same basic electric furnace with more functional options. These furnaces are factory

assembled for operation with a 1, 2 or 3 stages thermostat. When used with a multi-stage thermostat the

unit will modulate its power depending on the stage calling for heat. The furnace is factory assembled with a

three positions switch to manually choose the level of heat if installed with a one stage thermostat. The

intermediate modes of heating are detailed in tables 2 and 3 and explained later in this guide. The Series 200

also comes with a low speed fan switch that enables operation of the lowest speed of the motor for

continuous ventilation when needed. The Series 200 also has a cooling relay to permit high speed operation

when matched with an air conditioning unit. Suffix C indicates operation at 0.5” W.C. at high speed.

• Series 300

Series 300 has the same functionality of series 200 while being equipped with a 120V motor-blower

combination. This series also comes with, as standard equipment, a 120V terminal strip enabling connection

of additional equipment such as electronic air filter and/or humidifier. Finally, this series has insulating wool

in the blower compartment. As in series 100 and 200, suffix C indicates operation at 0.5’’ W.C. at high speed.

Series 300 features an extended capacity with the addition of a 23 KWatt model. Please note that the 23

KWatt model is ONLY offered on Series 300. Finally, Series 300 is also offered with a 1/2HP ECM motor as

optional equipment. This motor is a high efficiency (up to 80%) motor that is fully compatible with the

standard control scheme of the furnace. ECM models are identified with the ECM suffix.

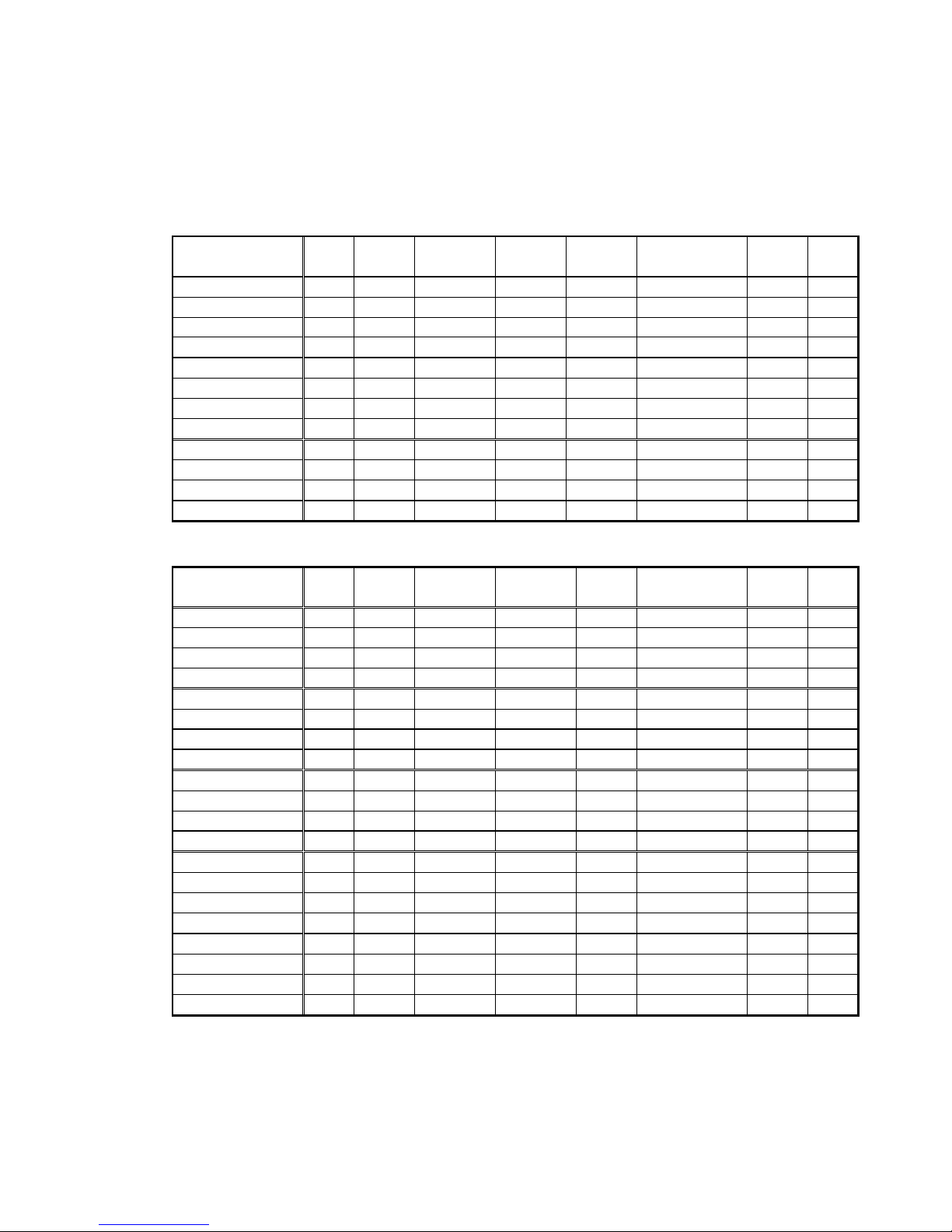

Model

Econoplus

KW Total

Amps

Volts

(V/Hz/Ph)

Motor

(HP)

Motor

Speed

Static

Pressure

(“ W.C.)

CFM ΔT

(oF)

215 @ 5KW 5 22.6 240

/60/1

¼ -

240 Lo 0.2 750 21

215 @ 10KW 10 43.5 240

/60/1

¼ -

240 Lo 0.2 750 42

215 15 64.4 240

/60/1

¼ -

240 Med.

0.2 925 51

215-C 15

64.8 240

/60/1

¼ -

240 High 0.5 1050 45

218 @ 9KW

9

39.3 240/60/1

¼ -

240 Lo 0.2 750 38

218 @ 13KW

13 56

240/60/1

¼ -

240 Med.

0.2 925 44

218 18 76.9 240/60/1

¼ -

240 Med.

0.2 925 59

218-C 18 77.3 240/60/1

¼ -

240 High 0.5 1050

52

219 @ 9KW 9 39.3 240

/60/1

¼ -

240 Lo 0.2 750 38

219 @ 14KW 14 60.1 240

/60/1

¼ -

240 Med.

0.2 925 48

219 19 78.4

240

/60/1

¼ -

240 Med.

0.2 925 63

219-C 19 78.8 240

/60/1

¼ -

240 High 0.5 1050 55

Table 2 – Series 200 characteristics

Model

Econoplus

KW Total

Amps

Volts

(V/Hz/Ph)

Motor

(HP)

Motor

Speed

Static

Pressure

(“ W.C.)

CFM ΔT

(oF)

315 @ 5KW 5

25.8 240

/60/1

1/3 -

120 Lo 0.2 750 21

315 @ 10KW 10

46.7 240

/60/1

1/3 -

120 Lo 0.2 750 42

315 15

67.6 240

/60/1

1/3 -

120 Med.

0.2 1020

47

315-C 15

68.6 240

/60/1

1/3 -

120 High 0.5 1150

41

3

18 @ 9KW

9

42.5 240/60/1

1/3 -

120 Lo 0.2 750 38

3

18 @ 13KW

13

59.2 240/60/1

1/3 -

120 Med.

0.2 1020

41

318 18

77.5 240/60/1

1/3 -

120 Med.

0.2 1020

54

318-C 18

78.5 240/60/1

1/3 -

120 High 0.5 1150

48

319 @ 9KW 9

42.5 240

/60/1

1/3 -

120 Lo 0.2 750 38

319 @ 14KW 14

63.3 240

/60/1

1/3 -

120 Med.

0.2 1020

43

319 19

82.1 240

/60/1

1/3 -

120 Med.

0.2 1020

58

319-C 19

83.1 240

/60/1

1/3 -

120 High 0.5 1150

51

323 @ 10KW

10

46.7 240/60/1

1/3 -

120 Lo 0.2 750 42

323 @ 18KW

18

77.5 240/60/1

1/3 -

120 Med.

0.2 1020

54

323 23 99.0 240/60/1

1/3 -

120 M

ed. 0.2 1020

70

323-C 23 100.0

240/60/1

1/3 -

120 High 0.5 1150

62

323ECM @ 10KW

10

46.7 240/60/1

½ - 120 E

Lo

0.2 650 49

323ECM @ 18KW

18

77.5 240/60/1

½ - 120 E

Med.

0.2 1230

47

323ECM

23

96.2 240/60/1

½ - 120 E

Med.

0.2 1230

58

323ECM

-C 23

96.9 240

/60/1

½ - 120 E

High 0.5 1280

56

Table 3 – Series 300 characteristics

2.0 Important safety information

• WARNING – BASIC SAFETY WARNINGS

The initial electrical connection and subsequent service MUST be done by a qualified electrician in

accordance with this manual AND ELECTRICAL CODES HAVING JURISDICTION IN YOUR AREA.

This unit is intended and approved for use with heating ducts. Use without ducts will result in untested

operation that could result in property damage, accident or DEATH.

Disconnect power to the unit before doing any service on the unit. The type of voltage and current used in

this furnace are enough to cause serious injury and/or DEATH.

This furnace is not approved or intended for use outside. Use outside voids the warranty.

Do not store gasoline, fuel or any flammable substances near the furnace.

Ask the installer to show you the location of the main disconnect breaker of the furnace.

WARNING – BEST PRACTICES FOR OPTIMAL OPERATION

Make sure that the air filter is always clean and in good working condition and not overly obstructed. An

obstructed air filter will result in reduced air flow and higher outlet temperature. Continued operation WITH

THE FILTER CLOGGED will drastically reduce the life of the heating elements.

The unit must be inspected once a year by a qualified technician.

Make sure that you have enough clearance in the front and the rear of the unit for service and maintenance.

Although the unit is approved for zero clearance on these panels, it is definitely NOT a good practice to do it.

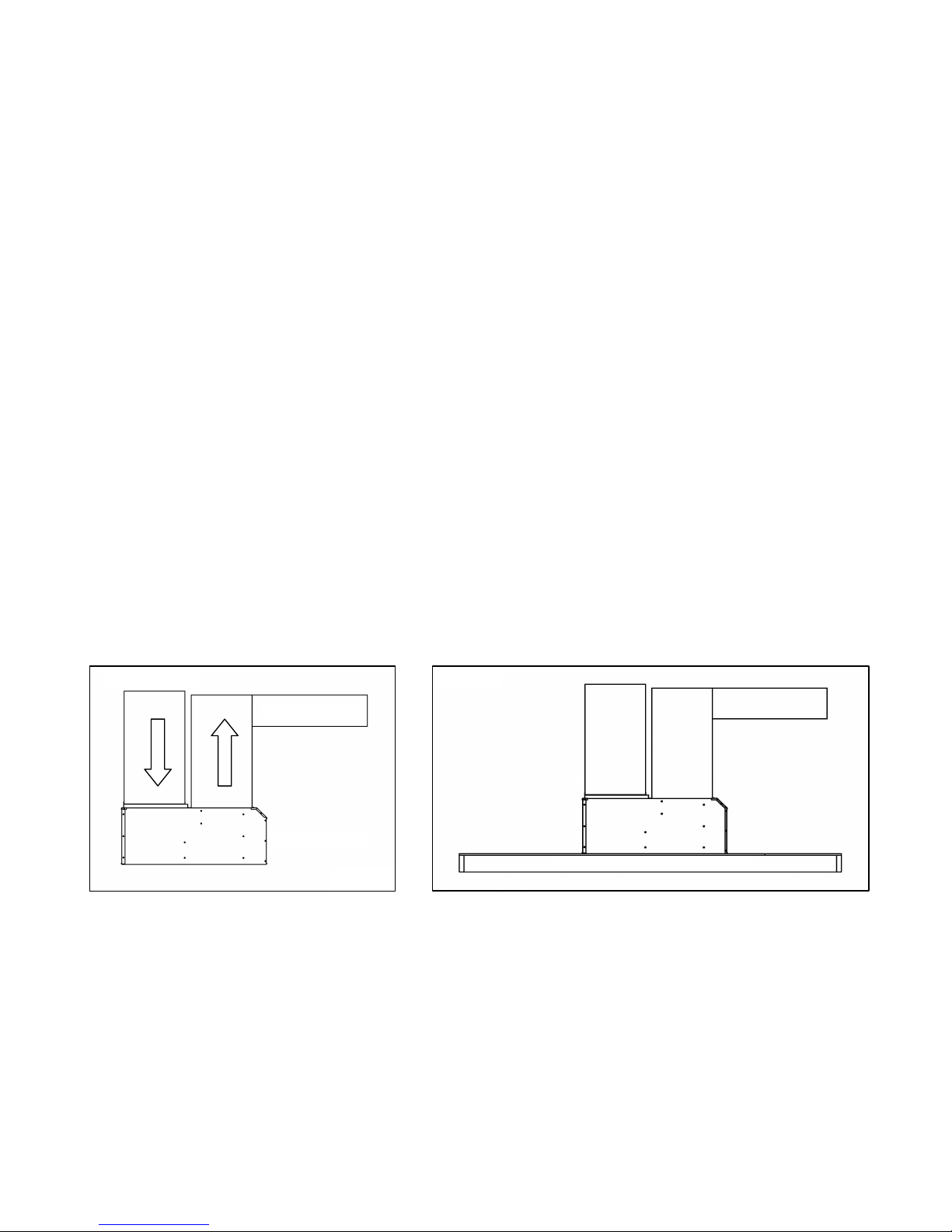

3.0 Installation of the furnace

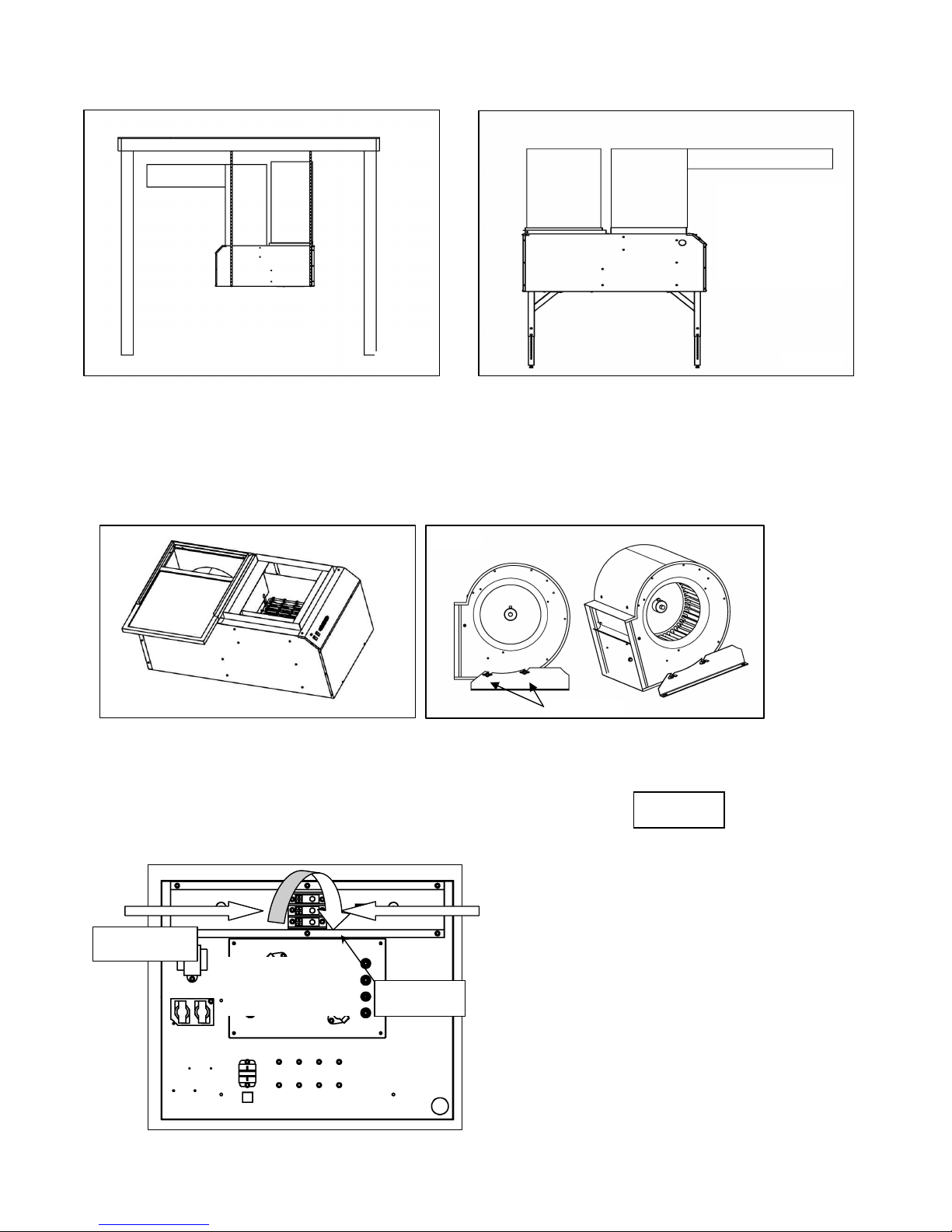

The return air/ inlet connection is made on the rear of the unit and the supply plenum is connected in the front of the

unit. The flanges supplied with the cabinet are 19” X 19” and can accommodate plenums of that size. The cabinet is also

large enough so 20” X 20” supply plenums could be attached directly on the furnace. See Figure 1 for details. The unit is

approved for installation with zero clearance on all parts of the cabinet including the floor (combustible floor) and also

with zero clearance on the walls of the supply plenum. The unit can be installed directly on the floor, on the adjustable

legs (included) or suspended to the ceiling with “plumber” straps. Please see figure 2A, 2B and 2C for the different

installation configurations. Make sure to leave sufficient clearance in the front of the unit for the electrical connections

and electrical service and in the rear of the unit for blower and motor maintenance and service. Please note that the air

filter rack can be installed on the right or left side of the unit in addition to the rear (factory position). To change the

filter rack position, refer to fig. 3.

Supply Air Plenum

Return Air Plenum

Front of furnace

Floor (Combustible floor approved)

Figure 1

Figure 2A

Also note that the blower in the rear compartment can be removed by loosening the 4 wing nuts (figure 3) that hold it to

the blower supports. The wire is long enough so you can remove the blower from the unit without disconnecting it.

CAUTION: when removing the blower, DO NOT remove the blower legs. Loosen the 4 wing nuts and slide the blower

out. To replace the blower, position the studs in the slots on the blower legs and fully insert the blower. Be sure to

RETIGHTEN the wings nuts after reinstalling the blower. Consult figure 4 for details.

4.0 Electrical connection to the furnace

4.1 240VAC – High voltage

You only need to bring a 2 conductors wire + ground to the furnace for the series 100 and 200 and a 3

conductors wire + ground for the series 300. The only electrical “installation” to the furnace is this connection.

All other wiring is factory installed/connected. Consult the local electrical codes for the size of the conductors

needed between the distribution panel and the furnace and

the grounding of the unit. The use of copper wires is

recommended. If aluminum wire is used, make sure to

respect all applicable codes.

Also note that it is possible to change the orientation of the

main terminal block in the furnace to accommodate a

supply wire coming from the left or right. The factory

installed position is on the right side. Knock-outs are

provided on the left and right side panels. If you choose to

reorient the main supply block, you will have to disconnect

and reconnect the internal wires to the block. To do this,

Wing Nuts

Installed with the

mounting legs supplied

as standard equipment.

See the mounting

procedure at the end of

this manual

Alternate filter rack position

Factory designed

240V connection

Alternate 240V

Wiring connection

Rotate the connection

Block for alternate

wiring direction

Figure 2B

Figure 2C

Figure 3

Figure 4

Figure 5 ( model 115 shown)

Rotation of

Supply block

Loading...

Loading...