Grams Medical Aspirator S-300 Operating & Maintenance Instructions

Grams

Medical

Operatinu & Maintenance Instructions

For Grams Aspirator

Turnina The Aspirator On

The center position of the switch on the electrical panel is OFF. Placing switch in the UP position

bypasses the foot pedal and turns the aspirator on manually. To use the Pneumatic foot pedal, place the

switch in the DOWN position. The foot pedal is a "Push On

*

For best results using the foot pedal, press quickly and firmly.

*

The pilot light is illuminated when the aspirator is on.

"

In the event of electrical overload there is a circuit breaker on the electrical panel that

can be manually reset.

SP-320 Pump Module

The pump module is of a two stage rotary, oil type construction. This

type was chosen due to it's durability, low noise factor and it's

capability of producing vapor pressure vacuum. During high vacuum

procedures vaporization of moisture will occur. This vapor will pass

through the system (including the intake filter) and is collected by the oil.

*

You must service module every TEN HOURS OF OPERATION to

remove this moisture.

Service Pump Module

*

Hint: Module should be cool and allowed to stand 24 hours or

more after last use. The water and oil will separate and water will

collect on the bottom of the pump.

1.

Removing pump from chassis: Unplug from electrical panel,

remove the two hoses, and lift straight up

(the pump sits on springs and is not fastened).

2.

Place pump on drain counter with oil drain facing sink. Place container under pump to capture the

3.

Open

011,

*

You should make a total oil change every 50 hours of use, or when the oil does not

look reasonably clean.

4.

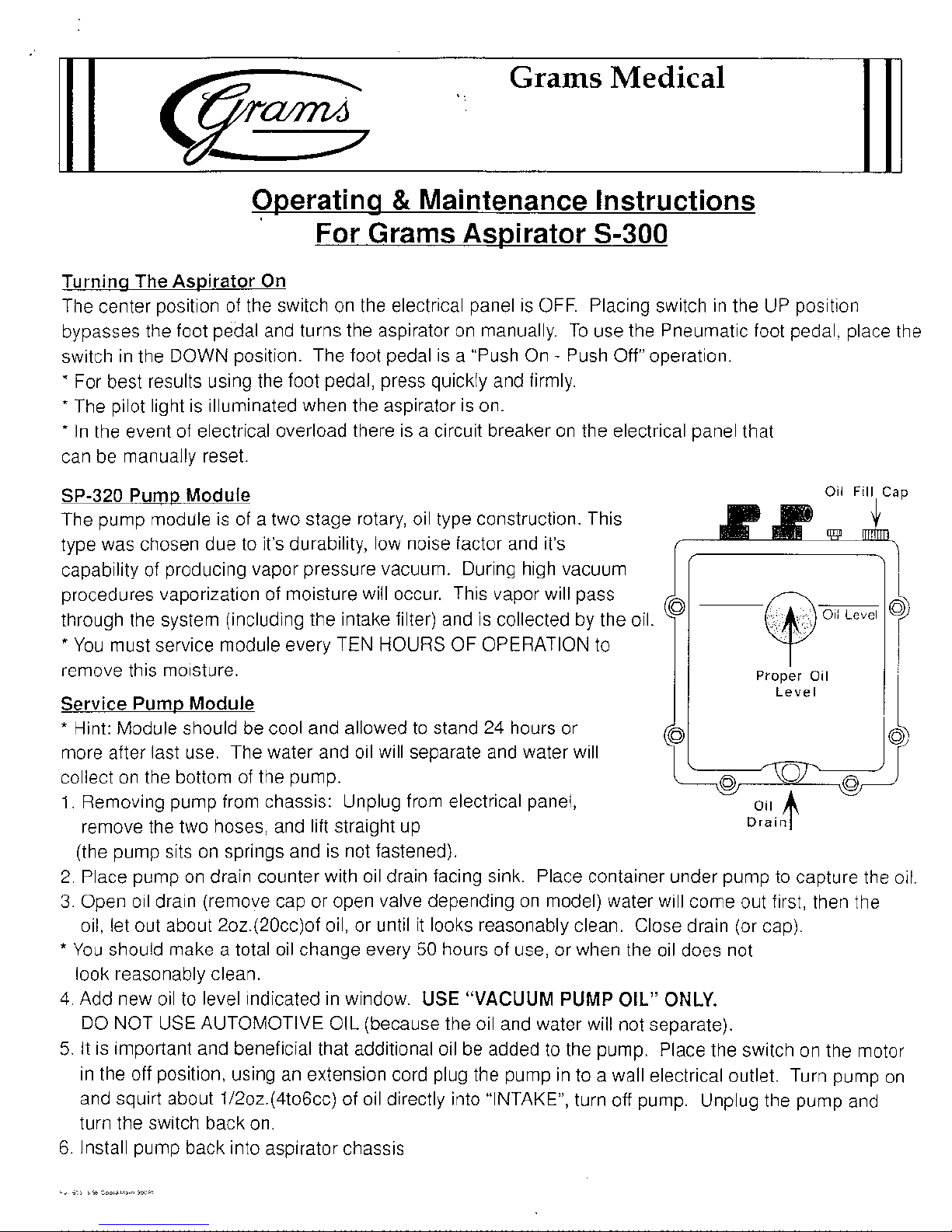

Add new oil to level indicated in window.

DO

5.

It is important and beneficial that additional oil be added to the pump. Place the switch on the motor

in the off position, using an extension cord plug the pump in to a wall electrical outlet. Turn pump on

and squirt about

turn the switch back on.

6.

Install pump back into aspirator chassis

011

drain (remove cap or open valve depending on model) water will come out f~rst, then the

let out about 2oz.(20cc)of oil, or until it looks reasonably clean. Close drain (or cap).

USE "VACUUM PUMP OIL" ONLY.

NOT USE AUTOMOTIVE OIL (because the oil and water will not separate).

1/2oz.(4to6cc) of oil directly into "INTAKE", turn off pump. Unplug the pump and

S-300

-

Push Off" operation.

1-JI

Level

oil

+

Drain

011

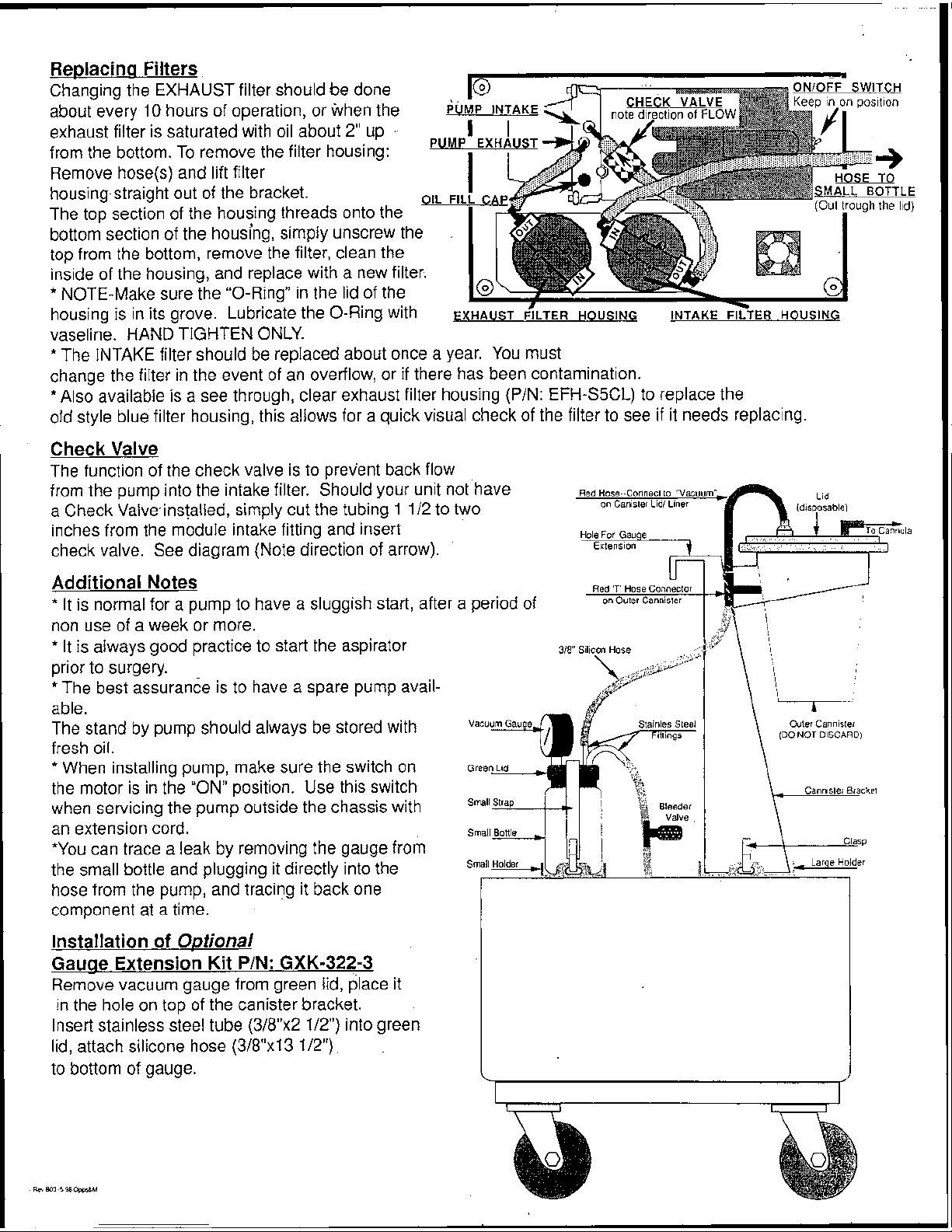

Replacina Filters

Changing the EXHAUST filter should be done

about every

10

hours of operation, or when the

exhaust filter is saturated with oil about

2"

up

from the bottom. To remove the filter housing:

Remove

hose(s) and lift filter

housing-straight out of the bracket.

The top section of the housing threads onto the

bottom section of the housing, simply unscrew the

top from the bottom, remove the filter, clean the

inside of the housing, and replace with a new filter.

*

NOTE-Make sure the "0-Ring" in the lid of the

housing is in its grove. Lubricate the 0-Ring with

EXHAUST

FILTER

HOUSING INTAKE

FILTER

HOUSING

vaseline. HAND TIGHTEN ONLY.

*

The INTAKE filter should be replaced about once a year. You must

change the filter in the event of an overflow, or

if

there has been contamination.

*Also available is a see through, clear exhaust filter housing (PIN:

EFH-S5CL) to replace the

old style blue filter housing, this allows for a quick visual check of the filter to see if it needs replacing.

Check Valve

The function of the check valve is to prevent back flow

from the pump into the intake filter. Should your unit not'have

a Check Valveinstalled, simply cut the tubing 1 112 to two

inches from the module intake fitting and insert

!la

check valve. See diagram (Note direction of arrow).

Additional Notes

*

It is normal for a pump to have a sluggish start, after a period of

non use of a week or more.

*

It is always good practice to start the aspirator

prior to surgery.

*

The best assurance is to have a spare pump avail-

able.

The stand by pump should always be stored with

(DO

NOT

DISCARD)

fresh oil.

*

When installing pump, make sure the switch on

the motor is in the "ON" position. Use this switch

when servicing the pump outside the chassis with

an extension cord.

*You can trace a leak by removing the gauge from

the small bottle and plugging it directly into the

hose from the pump, and tracing it back one

component at a time.

Installation of

O~tional

Gauae Extension Kit

PIN:

GXK-322-3

Remove vacuum gauge from green lid, place it

in the hole on top of the canister bracket.

Insert stainless steel tube

(3/8"x2 112") into green

lid, attach silicone hose

(31811x1 3

112")

to bottom of gauge.

J

S-300

Assembly Instructions

Unpacking

Unpack all three boxes.

wrapping and packing. Discard packing, except the pump

box (box

pump. You might need this later to

service.

"20f3") its foam and two little red vinyl caps from the

Remove everything out of its

send.the pump in for

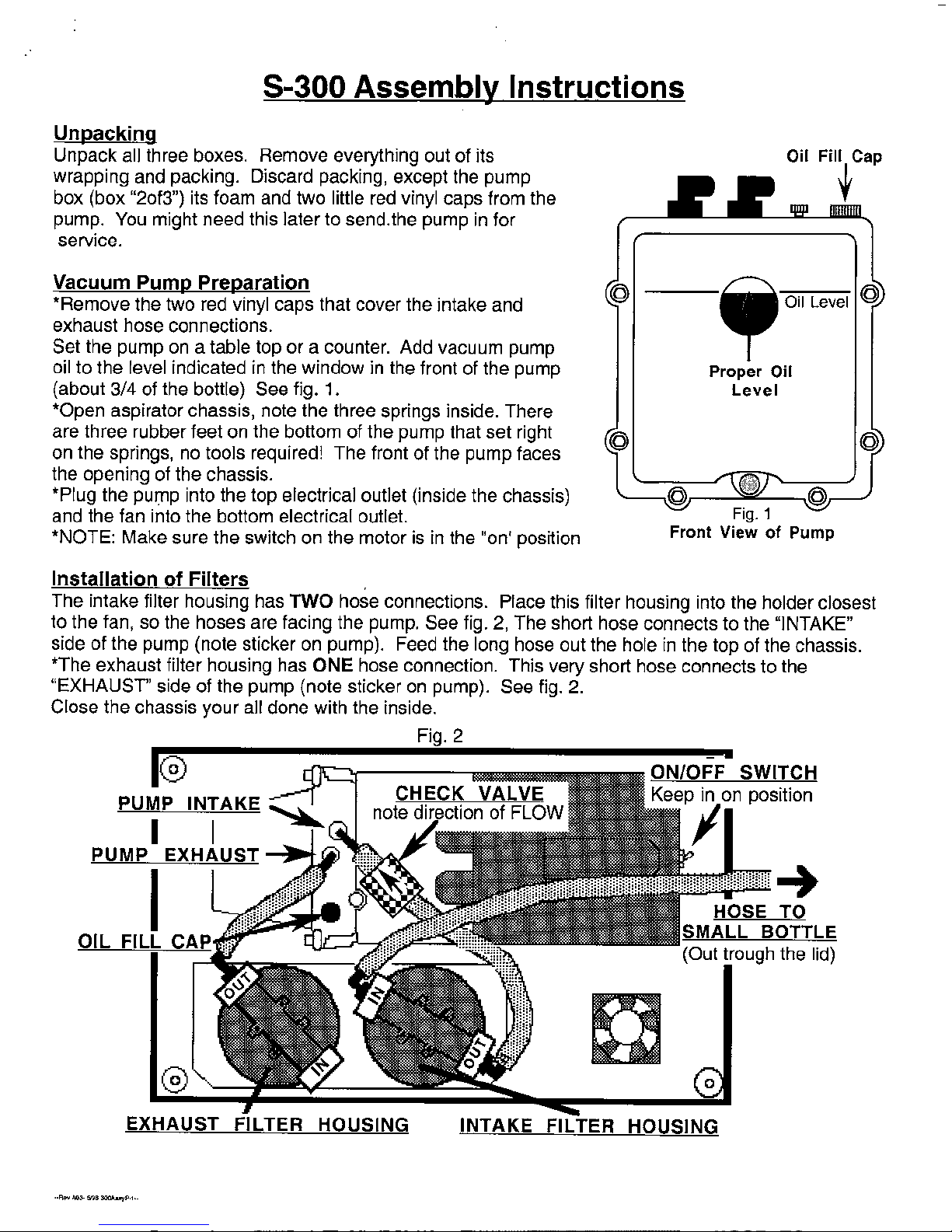

Vacuum Pump Preparation

*Remove the two red vinyl caps that cover the intake and

exhaust hose connections.

Set the pump on a table top or a counter. Add vacuum pump

oil to the level indicated in the window in the front of the pump

(about 314 of the bottle) See fig.

*Open aspirator chassis, note the three springs inside. There

are three rubber feet on the bottom of the pump that set right

on the springs, no tools required! The front of the pump faces

the opening of the chassis.

*Plug the pump into the top electrical outlet (inside the chassis)

and the fan into the bottom electrical outlet.

*NOTE: Make sure the switch on the motor is in the "on' position

1.

@

Front

Proper

Level

View

Oil Level

Oil

of Pump

Installation of Filters

The intake filter housing has

to the fan, so the hoses are facing the pump. See fig. 2, The short hose connects to the "INTAKE"

side of the pump (note sticker on pump). Feed the long hose out the hole in the top of the chassis.

*The exhaust filter housing has

"EXHAUST" side of the pump (note sticker on pump). See fig. 2.

Close the chassis your all done with the inside.

TWO

ONE

hose connections. Place this filter housing into the holder closest

hose connection. This very short hose connects to the

Fia. 2

EXHAUST FILTER HOUSING INTAKE

FILTER

HOUSING

Installation of Canister Bracket & Vacuum Jar

Place the canister bracket in the large holder on top of the chassis, so the loop faces the end

of the chassis with the electrical panel, then snap the clasps into place.

*Place green lid on top of small bottle, set the jar in the small holder, so that the two stainless

steel hose connections face towards the canister bracket. Use the 'small' strap to fasten the

jar to the chassis.

*Connect the vacuum hose sticking out of the lid

(from the inside) to the bleeder

hose connection that is attached to the small

bottle).

*Insert vacuum gauge into green lid.

valve (a black plastic

*Place

318"~ 12" silicon hose onto the red plastic

hose tee on the outer canister. Set the outer

canister in the loop so the hose faces the

bracket, then thread the hose through the slot

in the bracket and attach to strait stainless

steel fitting in small jar. For complete

&

instructions on the disposable lids

liners

(CL-340) see separate instructions in the lids

&

liners box.

Installation of Foot Pedal

Push hose (from foot pedal) onto tube on

the electrical panel marked

"pneumatic foot pedal".

(if it does not fit snugly trim about 1" off the

hose) That's it your done!

Installation of

Gauae Extension Kit

Remove vacuum gauge from green lid, place it

in the hole on top of the canister bracket.

Insert stainless steel tube (318x2

silicone hose attached into green lid, attach

silicone hose

gauge.

Optional

PIN:

GXK-322-3

112") with

(3/8"x13 112") to bottom of

P/ease don Y hesitate to ca// the factoy forpersona//hsfruction

Grams

design and production of medical instrumentation

Medical

- - - - -

-

-

-

-

Loading...

Loading...