Page 1

BIOBASIC

USER MANUAL

Models: 210, 310 & 410

Page 2

2 | BIOBASIC MANUAL

Before You proceed

Manufactured by Gram Commercial A/S

Aage Grams Vej 1

DK-6500 Vojens

Denmark

+45 7320 1300

www.gram-biobasic.com

Item number 765041746 Rev.: 180518

Language: English

Your feedback is much appreciated, feel free to email us at:

info@gram-bioline.com

This user manual is intended for the BIOBASIC product series.

We recommend that you read this user manual through thoroughly

before using the cabinet. Gram Commercial A/S does not guarantee

safety if the appliance is used for anything other than its intended

use. Contents of the manual can be subject to change without notice.

No part of this manual may be published or reproduced in any form

without expressed written consent of Gram Commercial A/S. Gram

Commercial A/S guarantees the appliance under certain warranty

conditions. Gram Commercial A/S is in no way responsible for any loss

or damage of content.

Page 3

BIOBASIC MANUAL

|

3

Contents

Before You proceed .................................................................................. 2

Contents .................................................................................................... 3

Intended use ............................................................................................. 4

Temperature setpoint range and ambient requirements ................................... 4

Symbols used ............................................................................................ 5

Installation ................................................................................................ 6

Initial setup steps ...................................................................................................6

Adjusting the base .................................................................................................. 7

Anti tilt bracket .......................................................................................................8

Wall mounting .........................................................................................................9

Surroundings ........................................................................................................10

Product inspection ...............................................................................................10

Voltage free contact .............................................................................................11

Connecting to electricity .....................................................................................12

Start up .................................................................................................... 14

The digital display controls .................................................................................. 15

General introduction to the controller interface ...............................................16

Alarm settings ....................................................................................................... 17

Buttons and useful shortcuts ..............................................................................17

Operation parameters .........................................................................................18

Error codes ............................................................................................................ 19

Sensor oset ......................................................................................................... 20

Ordinary use............................................................................................ 22

Regular maintenance ............................................................................ 23

Cleaning .................................................................................................................23

Door gaskets ......................................................................................................... 24

General info ............................................................................................. 25

Reversing of door .................................................................................... 26

IMPORTANT ............................................................................................. 27

Disposal ................................................................................................... 28

Declaration of Conformity ..................................................................... 29

Wiring diagrams ...................................................................................... 30

Piping diagram ........................................................................................ 32

Notes........................................................................................................ 33

Page 4

4 | BIOBASIC MANUAL

Intended use

The BIOBASIC range of refrigerators (RR) and freezers (RF),

are designed and manufactured to provide general purpose

storage solutions for laboratory items.

The BIOBASIC range complies with EN/IEC 60079-15,

covering electrical apparatus in Category 3, Zone 2 locations

where gas atmospheres may be present.

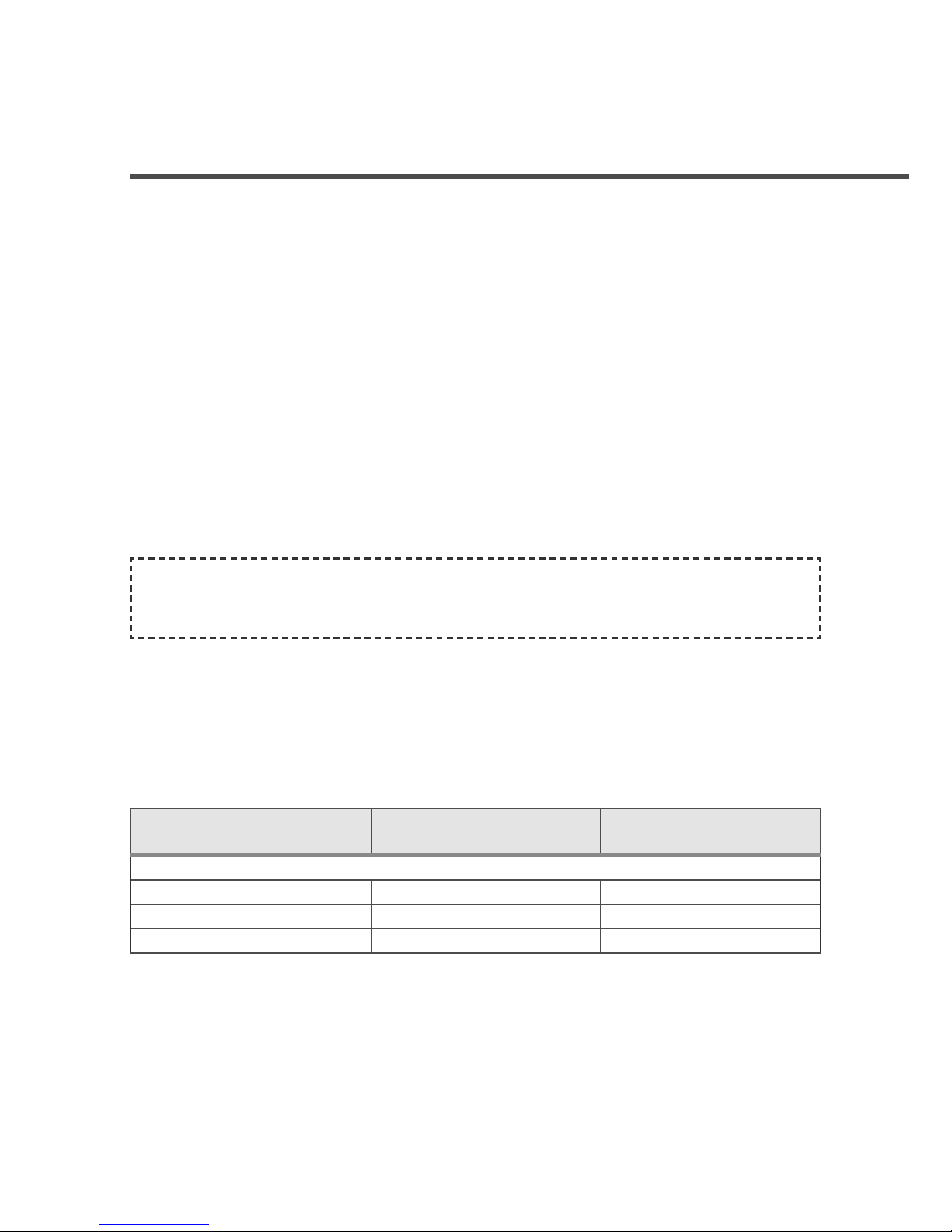

Temperature setpoint range and

ambient requirements

model + temperature

setpoint range

Minimum ambient

operating temperature

Maximum ambient

operating temperature

BIOBASIC 210, 310, 410

RR with solid door: +2/+15 ºC +10 ºC +35 ºC

RR with glass door: +2/+15 ºC +10 ºC +32 ºC

RF: -25/-5 ºC +10 ºC +35 ºC

Enabling placement of BIOBASIC refrigerators and freezers, in

Zone 2 areas categorised according to EN/IEC 60079-15.

Page 5

BIOBASIC MANUAL

|

5

Symbols used

Hazard

Risk of electric shock

Risk of material damage

Risk of personal injury

Risk of burning / freezing

Info

Page 6

6 | BIOBASIC MANUAL

Installation

Due to safety and operating reasons, the cabinet must not be used

outdoors. The cabinet should be installed in a dry and suciently

ventilated area. To ensure ecient operation, the cabinet should not be

installed in direct sunlight or close to heat sources.

Avoid placement of the cabinet in a chloric/acidic environment due to

risk of corrosion.

Clean the cabinet with a mild soap solution prior to use.

If the cabinet has been laying down (e.g. during transport.).

The cabinet must stand up-right for 24 hours prior to being turned on.

Initial setup steps

Certain cabinets are shipped

with a protective lm that

should be removed prior to

putting the cabinet into service.

Page 7

BIOBASIC MANUAL

|

7

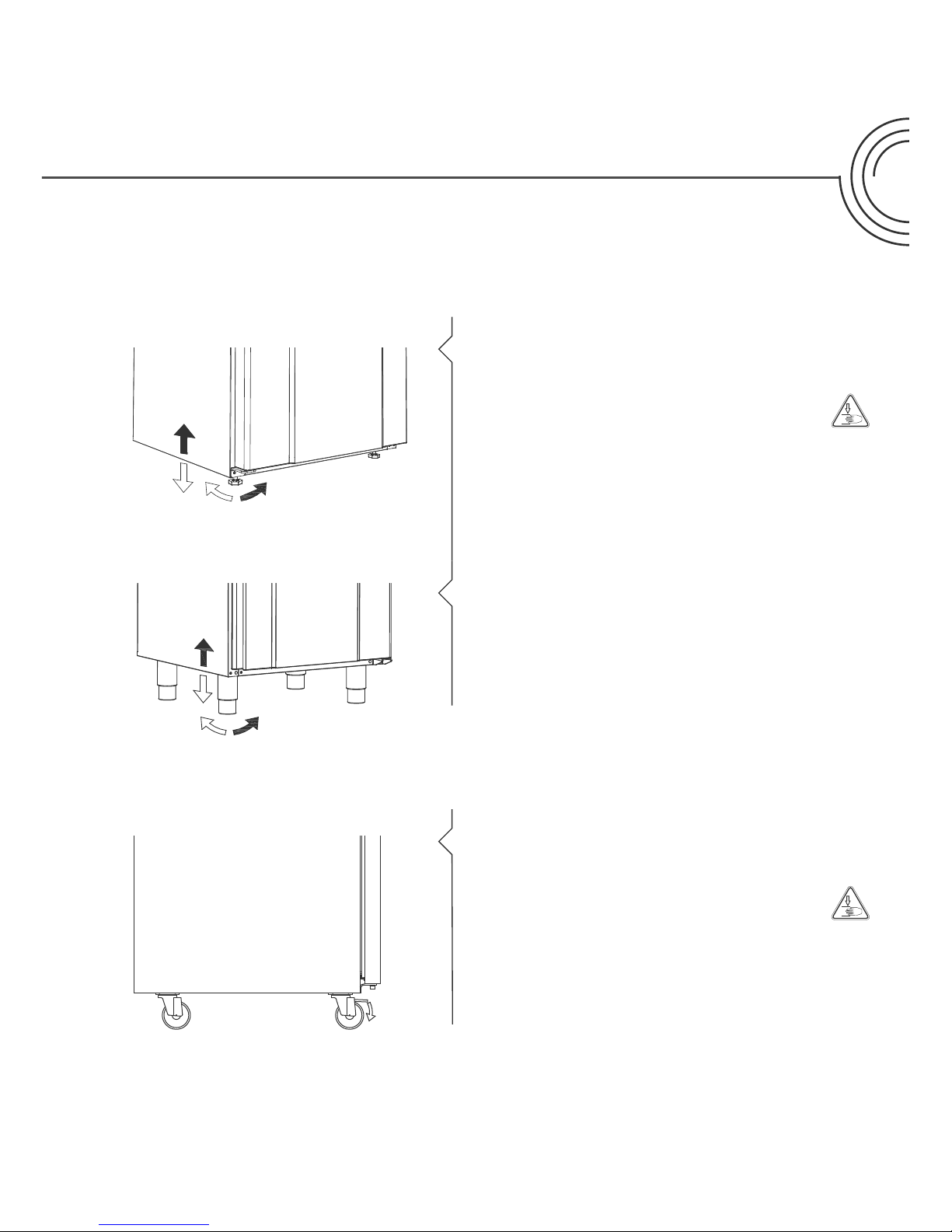

Cabinets equipped with legs

should be levelled as shown in the

illustrations to the left.

For cabinets equipped with

castors, the oor must be level

to ensure stable positioning and

safe use. When the cabinet is

positioned, the 2 front castors

should be locked.

Adjusting the base

Page 8

8 | BIOBASIC MANUAL

Installation

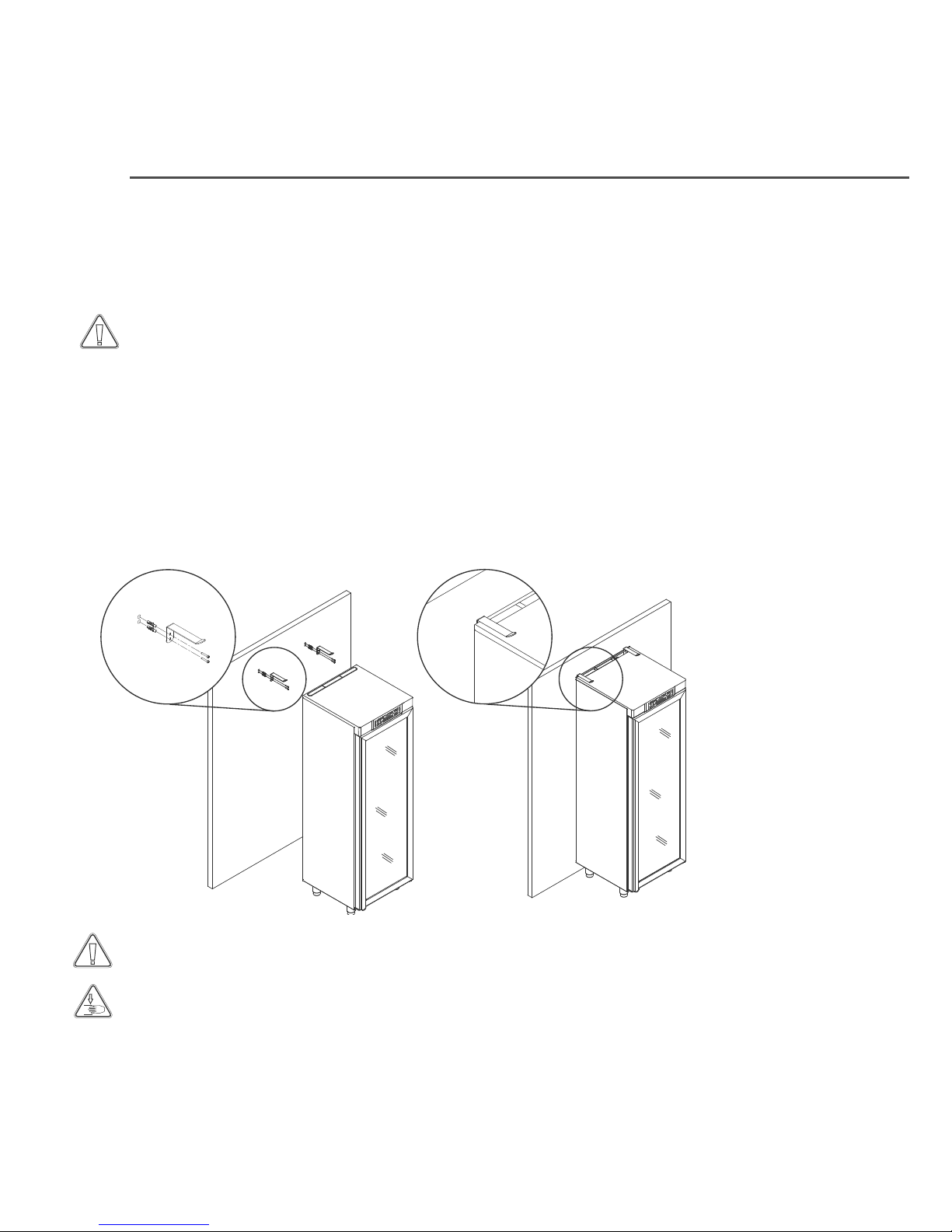

Cabinets with drawers and/or glass door must be secured to a stable

vertical surface, ensuring that the cabinet can not tip over when the

drawers are drawn to the outermost position, or the door is open.

Brackets for securing the cabinet are included from the factory.

Find the instructions for the tilt bracket below.

The anti-tilt brackets must be tted when installing the cabinet,

ensuring that the users, surroundings and stored items are not

damaged.

Anti tilt bracket

Page 9

BIOBASIC MANUAL

|

9

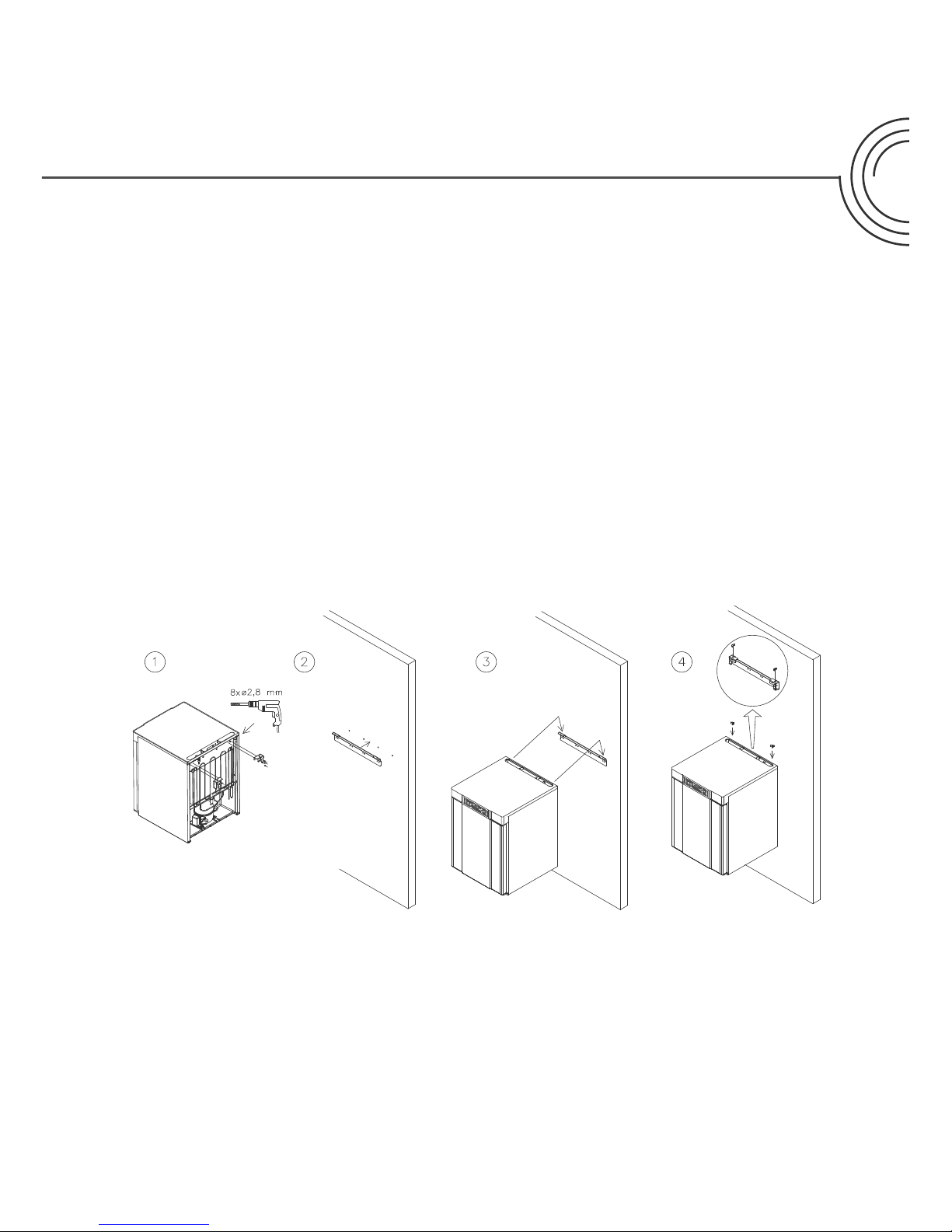

Wall mounting

Wall mounting brackets can be supplied if specied. Allowing the

cabinet to be lifted from the oor. Find instructions on wall mounting

of a BIOBASIC 210 below, the same procedure applies for mounting 310

and 410.

Page 10

10 | BIOBASIC MANUAL

Installation

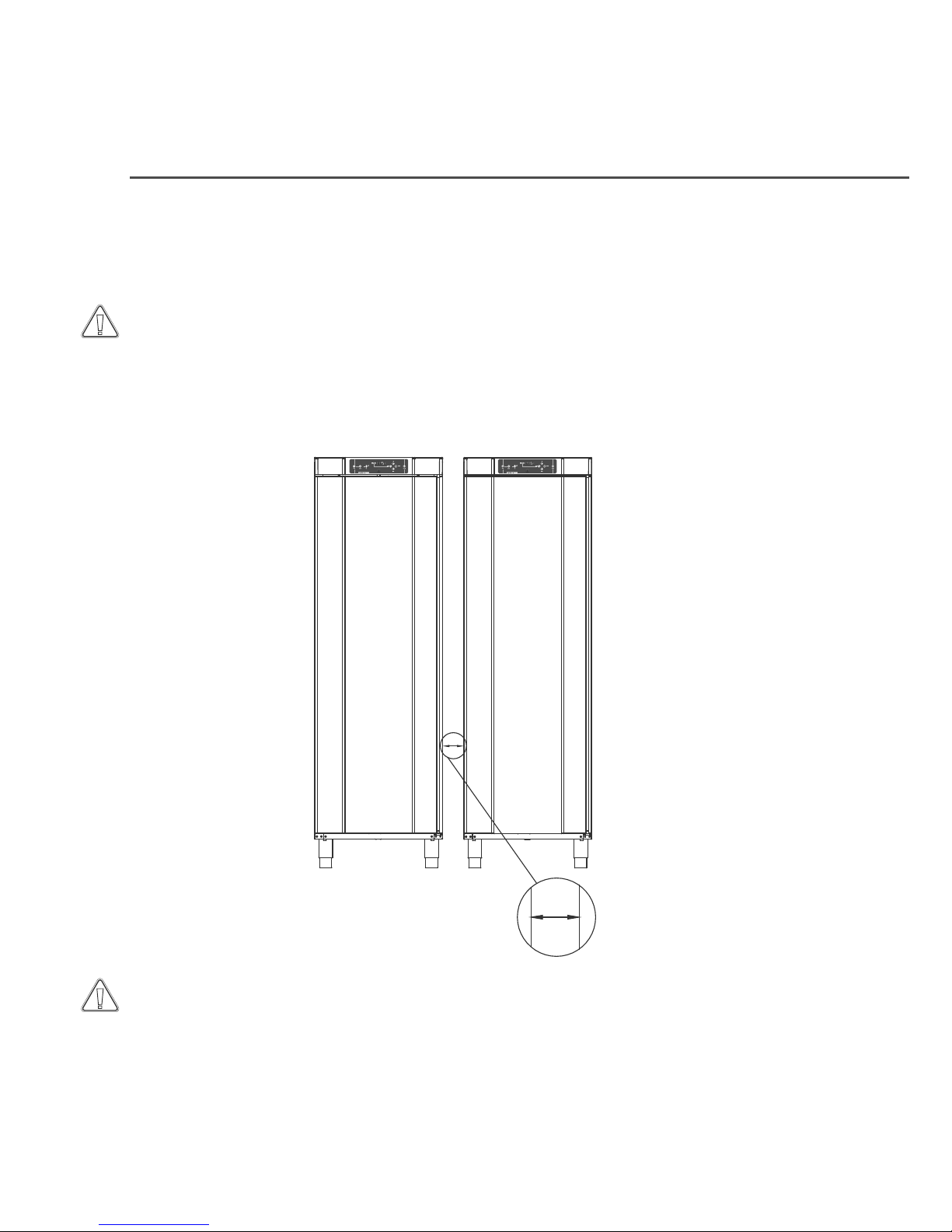

There must be at least a 30mm gap between cabinets and/or walls.

A visual inspection of the cabinet must be conducted prior to putting

the cabinet into service. Check the cabinets structural integrity, that

door frames and doors don’t have deformities, gaskets seal properly

and the doors sit ush up against the door frame.

Surroundings

Product inspection

Min. 30mm

Page 11

NC

Common

NO

Common

NC

Common

NO

Common

NC

Common

NO

Common

+

+

NC

NO

NC

BIOBASIC MANUAL

|

11

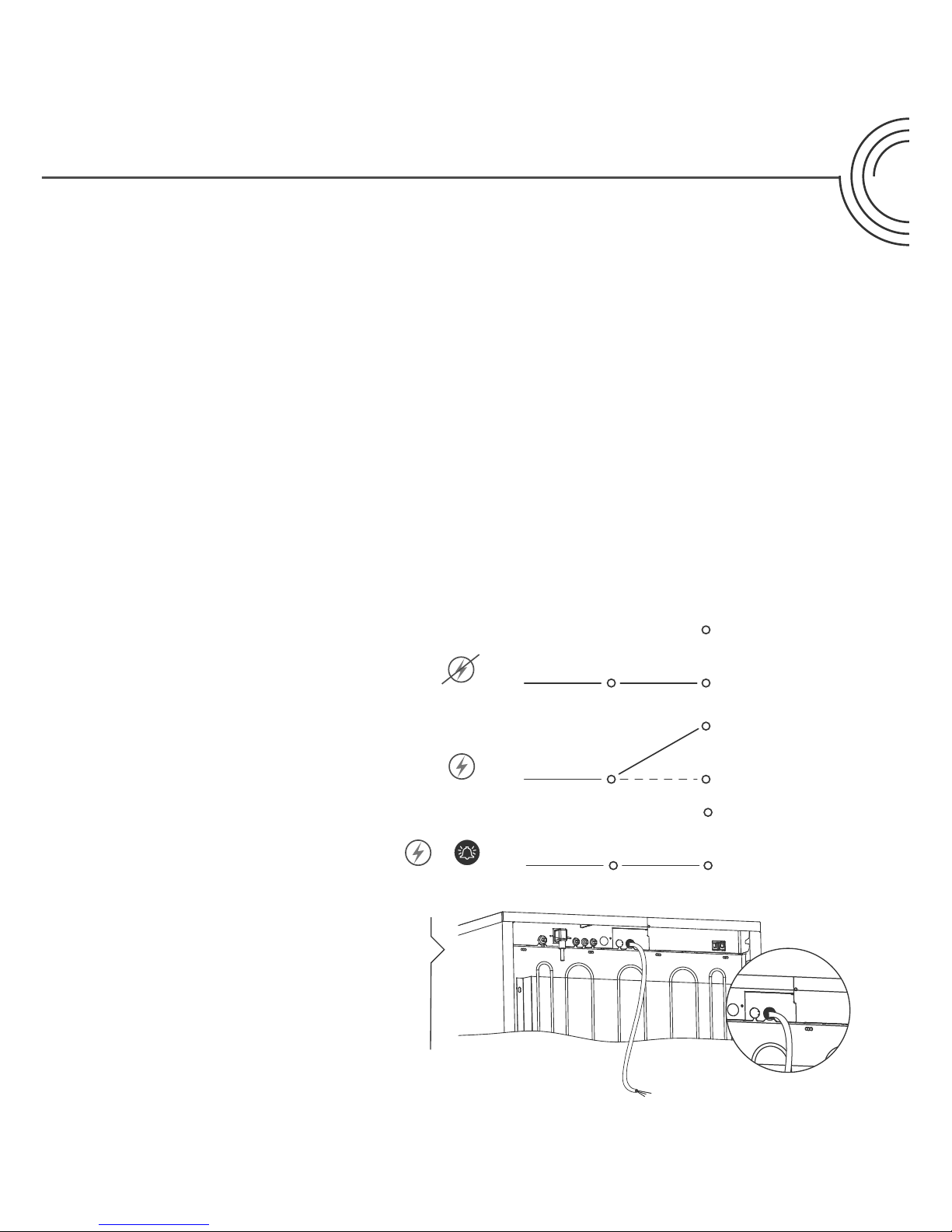

The illustration below shows the three connectors for the relay (e.g..

in connecting to CTS or other external monitoring systems). The three

connections, are respectively Common, NO (Normally Open) and NC

(Normally Closed).

The moment voltage is applied, the controller draws the relay, this

makes it possible for the controller to respond to both high and low

temperature alarms, door alarms and power failures. Find instructions

on setting the alarms in the controller settings section.

Voltage free contact

Normally closed

circuit (NC)

Connection of the voltage-free contact should be done by a qualied installer.

Location of the voltage

free contact

Page 12

12 | BIOBASIC MANUAL

Installation

When setting up in an ordinary scenario that is not subject to

regulations for EN 60079-15 zone 2:

The appliance may be connected in accordance with applicable local

heavy current regulations.

Note that there are special regulations for products that are in

accordance with EN 60079-15 zone 2.

The appliance has been manufactured in accordance with EN 6007915: Electrical apparatus for explosive gas atmospheres - Part 15: Type

of protection “n”. Zone 2 is the applicable zone. If the appliance is to be

installed in a zone 2 environment, specialist personnel should perform

the installation, or be consulted beforehand, in order to ensure that

the appliance is installed in compliance with the guidelines currently

contained in the standard.

The cabinet is intended for connection to alternating current. The

connection values for voltage (V) and frequency (Hz) are given on the

type/number-plate.

The power cord from the mains is plugged in

the terminal box on the back of the cabinet.

The plug is then xated in place by the

hanger that is built into the terminal box.

Please note that the hanger should be tted

tightly around the plug, as shown.

Connecting to electricity

Page 13

BIOBASIC MANUAL

|

13

The appliance must be connected to the external power supply using a

suitable device which mechanically prevents the plug and socket from

being separated unintentionally. The connection must be labelled:

”DO NOT SEPARATE WHEN ENERGIZED” .

Fuses and similar must never be removed or replaced while the

appliance is connected to a power source. The electrical terminal box

must never be opened while the appliance is connected to a power

source. The compressor starting equipment must never be dismantled

while the appliance is connected to a power source. The LED lighting

must never be dismantled while the appliance is connected to a power

source. Whenever electrical components are dismantled or replaced,

the appliance must be moved to an area in which there is no risk of

ignition caused by the electrical components or gases contained in the

appliance. Never use the cabinet if the plug is damaged. The cabinet

should be examined by a Gram Commercial A/S authorised service

technician in such cases.

In both cases:

Use a three-wire plug, if the power outlet is intended for a three-wire

plug, the lead in green / yellow insulation should be connected to the

ground terminal. Power must be connected via a wall socket. The wall

socket should be easily accessible. All earthing requirements stipulated

by the local electricity authorities must be observed. The cabinet plug

and wall socket should then give correct earthing. If in doubt, contact

your local supplier or authorized electrician.

In case of technical diculties or breakdowns, always

contact authorized service personnel. Never dismantle the

terminal box or any other electrical component.

Page 14

14 | BIOBASIC MANUAL

Start up

BIOBASIC +5º

MENU/

BACK

ALARM SET

MUTE

2ºC

15 ºC

7 1112

13

6

8

14

1

On/O

2

Select or conrm a menu

parameter

3

Navigate upwards in a given

menu / raise a given value

4

Navigate downwards in a

given menu / lower a given

value

5

Parameter settings menu / go

a menu-step back

6

Setpoint temperature setting

7

Temperature alarm settings

8

Acknowledge alarm, mute for

5 minutes

Page 15

BIOBASIC MANUAL

|

15

The digital display controls

ON/OFF

MENU/

BACK

UP

DOWN

SELECT

10 9 5 3 2

1

15 4

9

Key pad lock engaged

10

Display

11

Temperature- and/or door-

alarm registered

12

Parameter settings menu is

open

13

Defrost in progress

14

Visual distinction between

refrigerator or freezer

15

Door lock

Page 16

16 | BIOBASIC MANUAL

Start up

Turn On/O:

Press shortly to turn the cabinet on and press for 6 seconds to turn

the cabinet o.

Initiation procedure:

Readout of the software version and variant will occur shortly after

turning the cabinet on. The cabinet will then automatically start a

defrost-cycle, and terminate it again after a system check.

The cabinet is ready when the temperature is displayed.

The cabinet will always commence operation when initially connected

to a power supply. For instance after a power outage or when plugging

the cabinet in for the rst time.

Setpoint temperature adjustments:

Temperature adjustments are done by pressing for 3 seconds,

prompting the set point temperature. Adjust the set point temperature

by either pressing or . Conrm the settings by pressing .

Servicing:

Make sure the appliance is switched o at the socket before service is

performed on the cabinet. It is not sucient to switch o the cabinet on

the On/O button, as current will persist in some electrical parts of

the cabinet.

If fuses or similar are to be replaced, the appliance must be moved to a

no-risk area for safe replacement.

General introduction to the controller interface

Page 17

BIOBASIC MANUAL

|

17

Press

for 3 seconds to enter the alarm settings

Alarm settings

Unit

HL [° C]

High temperature alarm limit.

Code for activated alarm [A2]

LL [° C]

Low temperature alarm limit.

Code for activated alarm [A3]

Hd [Min.] Delay of high temperature alarm

Ld [Min.] Delay of low temperature alarm

dA On/o

Door alarm.

Code for activated alarm [ A1]. [1=on / 0=o]

dAd [Min.] Delay of door alarm

bU On/o

Acoustic signal for alarm codes

[ A1], [ A2] and [ A3]. [1=on / 0=o]

Alarm settings

Buttons and useful shortcuts

Buttons: Press for: Function:

- Acknowledge alarm, mute for 5 minutes

> 3 seconds Access the alarm settings

> 5 seconds Access the parameter settings

> 3 seconds Adjust/show setpoint temperature value

+

> 3 seconds Manually start or stop a defrost

+

> 6 seconds Activating / deactivating the keypad lock

-

Show highest registered temperature spike (since

the last reset of alarm and temperature history)

-

Show lowest registered temperature spike (since

the last reset of alarm and temperature history)

+

> 3 seconds Clear and reset alarm and temperature history

+ +

+

> 6 seconds Restores factory settings

+

Page 18

18 | BIOBASIC MANUAL

Operation parameters

Operation parameters

Unit

CA

[° K]

Oset of A-sensor. Reference sensor

for refrigeration and alarm system

d1

Number of defrosts per 24 hours (4

is factory setting)

d2

[° C]

Termination temperature in the

evaporator during a defrost

Li

On/o

*Only for glass door models* -

Turn light on or o

tEr

Relay test / Component test

tC [° C] Test compressor relay

tF [Min.] Test evaporator fan

td [Min.]

Test defrost element relay (RF

models)

tA [Min.]

Test alarm relay (will trip voltage

free)

tdP On/o Test display

Sensor read-out P-A

[° C] Test output of A-sensor

P-B

[° C] Test output of B-sensor

Please note - changing operation parameters without the expressed

consent from Gram Commercial A/S can have unintended implications

on performance and potentially void warranty.

Press for 5 seconds to enter operation parameters.

Page 19

BIOBASIC MANUAL

|

19

Error codes

Display code Explanation

- 0 - Door is open

A1 Door alarm “dAd” has been activated

A2 High temperature alarm “HL” is or has been activated

A3 Low temperature alarm “LL” is or has been activated

F1 Error on the main cabinet sensor. The refrigeration system will use an

emergency program to make the cabinet run. Temperature stability will be

aected. Service is required

F2 Error on the evaporator sensor. Service is required

Please nd instructions for connecting the “voltage-free contact” in the

“Installation” section.

In order to assure the safety of the stored items, the alarms

should be supported by external alarms. This can be done by

utilizing the possibility of the voltage-free contact.

Page 20

20 | BIOBASIC MANUAL

Sensor oset is used in cases where there are deviations in the

cabinet’s actual operation compared to control measurements by

independent temperature measuring systems.

The A-sensor is used to manage the cabinets refrigeration system, and

is also the reference sensor for the display and alarms.

The A-sensor is oset if the actual temperature in the cabinet does not

match the setpoint, despite taking the hysteresis into consideration.

Oset of A sensor is named “CA”.

Osetting the A-sensor

Press and hold for more than 5 seconds

Press to select “CA”

Press + to oset the A-sensor

Press to conrm the set value

The A-sensor is now oset, proceed to other parameters by pressing

, and then navigate by using or

Leave the user menu by pressing several times until

the cabinet temperature is shown in the display.

Sensor oset

Page 21

BIOBASIC MANUAL

|

21

Practical example of osetting:

Example 1 - The temperature in the cabinet is operating colder than

the actual setpoint.

With a setpoint of +4°C, the actual temperature inside the cabinet is

between +2 and +4°C. The desired temperature range is between +3

and +5°C. This means that “CA”, in this case, should be -1,0K, so that the

refrigeration system stops 1,0K before and starts 1,0K later than the

setpoint normally otherwise would dictate.

Example 2 - The temperature in the cabinet is operating warmer than

the actual setpoint.

With a setpoint of +4°C, the actual temperature inside the cabinet is

between +4 and +6°C. The desired temperature range is between +3

and +5°C. This means that “CA”, in this case, should be 1,0K, so that the

refrigeration system stops 1,0K later and starts 1,0K earlier than the

setpoint normally otherwise would dictate.

Page 22

100mm

20mm

22 | BIOBASIC MANUAL

Ordinary use

The cabinet is not suited for storing items that emit vapours, as they

might corrode the cabinet and its components.

All the items stored in the cabinet that are not sealed, or wrapped,

should be covered to reduce the risk of corrosion of the cabinet and its

components.

Items placed on the bottom of the cabinet will cause the air circulation

to be impeded, reducing the cabinets performance.

Items should be evenly distributed in the cabinet, with minimum layerthickness / maximum surface. And at the same time, the air should be

able to circulate freely between the items.

Keep the marked areas in the cabinet

(shown on this page) clear of all items,

ensuring adequate air circulation, and

therein cooling.

Do not place items beneath the lowest

shelf bracket.

Page 23

BIOBASIC MANUAL

|

23

Regular maintenance

Always disconnect the cabinet before cleaning.

The cabinet should be cleaned internally with a mild soap solution

(Max. 85°C) at suitable intervals and checked thoroughly before it is put

into operation again.

It is recommended that the re-evaporation tray is cleaned at least once

a year. This shall only be done while the cabinet is turned o.

Be careful not to damage the defrost water tube and heating element

(located in the tray) when cleaning.

Cleaning agents containing chlorine or compounds of chlorine as

well as other corrosive agents, may not be used, as they might cause

corrosion to the stainless panels of the cabinet and the evaporator

system.

Cleaning

The compressor compartment and in

particular the condenser must be kept free

from dust and dirt. This is best done with a

vacuum cleaner and a brush. Do not ush

compressor compartment or evaporator

with water as this may cause short-circuits

in the electrical system.

Page 24

24 | BIOBASIC MANUAL

Door gaskets

Door gaskets are an important part of a cabinet, door gaskets

with impaired functionality reduces a cabinets seal with the door.

Impaired seals can lead to increased humidity in the storage chamber,

iced evaporator (and thus reduced cooling capacity), and in some

cases, decreased lifetime expectancy of the cabinet. It is therefore

very important to be aware of the door gaskets condition. Regular

inspections are recommended.

The door gasket should be

cleaned regularly with a mild

soap solution.

If a gasket is to be replaced,

please contact your local Gram

BioLine distributor.

Page 25

BIOBASIC MANUAL

|

25

General info

Is the cabinet being used for purposes other than its intended use, or

use of the cabinet is not in accordance with guidelines specied in the

user manual, the user bears full responsibility for any consequences

thereof.

Defective parts must be replaced with original parts from Gram

Commercial A/S. Gram Commercial A/S can only guarantee functional

and safety requirements on the cabinets, if above-mentioned is

adhered to.

The cabinets refrigeration components should at least be checked once

a year by a Gram Commercial A/S technician or a similar professional.

Quote the serial number (SN) of

a cabinet when referring to it.

This information can be found

on the type/number-plate

located on the inside of the

storage chamber.

Page 26

26 | BIOBASIC MANUAL

Reversing of door

1. Switch o the power at the mains socket.

2. Dismantle the two screws that hold the control panel at front

and back, pull the panel a little forward, and then tilt it upwards.

3. Dismantle the hinge at pos. A, and lift o the door.

4. Dismantle the hinge at pos. B, and mount it at pos. F.

5. Turn the door 180°, and x it at the hinge pos. F.

6. Mount the hinge from pos. A in pos. D, and move bracket from

pos. C to pos. E.

7. Fasten the control panel again. Apply power to the cabinet.

Applicable to cabinets without self close device and glass door

C A

B

D

E

F

Left hinged Right hinged

Page 27

BIOBASIC MANUAL

|

27

IMPORTANT

There may occur sharp edges on the cabinet housing, compressor

room, and interior furnishings. Show due diligence when handling the

cabinet, neglect of these precautions can lead to injuries.

Danger of wedging in the frame slot between the door and the cabinet,

show due diligence when opening and closing the cabinet door.

Negligence of these precautions can lead to injuries.

Danger of wedging in the drawer column between the drawers and

interior of the cabinet, show due diligence when using the drawers.

Negligence of these precautions can lead to injuries.

Unlocked castors can lead to unexpected movements of the cabinet.

Lock the castors after installation. Negligence of these precautions can

lead to injuries.

The re-evaporation tray, re-evaporation tray heating element, pressure

pipes and compressors develops considerable heat during operation.

Assure that these components are suciently tempered before

touching. Negligence of these precautions can lead to injuries.

The evaporator develops considerable cold during operation.

Assure that the evaporator is suciently tempered before touching.

Negligence of this precaution may lead to injuries.

The fan may cause injury during operation, avoiding touching the

fans while the cabinet is connected to the mains. Negligence of these

precautions can lead to injuries.

Do not use electrical appliances inside the cabinet.

Notice

Page 28

28 | BIOBASIC MANUAL

Electrical and electronic equipment (EEE) contains materials,

components and substances that can be dangerous and harmful to

human health and the environment if the waste (WEEE) is not disposed

of properly.

Products that are labelled with a “crossed-out wheelie bin ‘is electric

and electronic equipment. The crossed out wheelie bin symbolizes

that waste of this type can not be disposed of with unsorted municipal

waste, but must be collected separately.

Contact you local BioLine distributor when the cabinet needs to be

disposed of.

For additional information, see our website:

www.gram-biobasic.com

Disposal

Page 29

Rev. 002 - 17.05.2018

BIOBASIC MANUAL

|

29

Declaration of Conformity

English EC Declaration of Conformity

W e, Gram Co mmercial A/S declare under sole responsibility that the following products:

Nam e: GRAM BIOBASIC

Model: 210, 310 & 410

Refrigerant: R134a & R600a

To which this declaration relates, is in c ompliance with all the applicabl e essential requirements, and ot her provisions of t he European

Council Directive.

Directive of the European Parliament and of the Council:

- ATE X Directive 2014/34/EU

- Pressure Equipment Directive 2014/68/EU

- Directive for Machinery 2006/42/EU

- Low Voltage Directive 2014/35/EU

- EMC Directive 2014/30/EU

- RoHS 2011/65/EU

Product c ompliance has been demonstrated on the basis of:

Harmonized Standards:

Text:

DS/EN 61010-1: 2010

Safety requirements for electr ical equipment for measurement, control, and

laboratory use - Part 1: G eneral requirements .

DS/EN 61326-1: 2013

Electric al equipment for meas urement, control an d laboratory use. EMC

requirements. General requirements.

DS/EN 60079-0: 2012

Electric al apparatus for explosive atmospheres.

DS/EN 60079-11: 2012

Explosive atmospheres - Part 11: Equipment protection by intrinsic safety "i".

DS/EN 60079-15: 2010

Explosive atmospheres - par t 15: T ype og pr otection “n” .

DS/EN 60079-25: 2010

Explosive atmospheres - part 25: Intrinsically safe systems.

DS/EN 60704-1: 2010

Household and similar electrical appli ances - T est cod e for the det erminat ion of

airborne acoustical noise - Part 1: Gen eral requirements.

DS/EN ISO 3744: 2010

Acoustics - Determination of sound power levels of noise s ources using sound

pressure - Engineering method in an essentially free field over a reflecting plane.

DS/EN ISO 9001: 2008

Quality management systems.

DS/EN 50581: 2012

Technical documentation for the assesment of electrical and eletronic products with

respect to the restriction of hazardous substances.

Gram Commercial A/S

Aage Grams Vej 1

DK-6500 Vojens

Telephone: + 45 73 20 13 00

Vojens, 17.05.2018

John B. S. Petersen

Approval Manager

Page 30

30 | BIOBASIC MANUAL

Wiring diagrams

Page 31

BIOBASIC MANUAL

|

31

Page 32

32 | BIOBASIC MANUAL

Piping diagram

Page 33

BIOBASIC MANUAL

|

33

Notes

Page 34

34 | BIOBASIC MANUAL

Notes

Page 35

BIOBASIC MANUAL

|

35

Page 36

Gram Commercial A/S

Aage Grams Vej 1

DK-6500 Vojens

Tel. +45 7320 1300

Info@gram-bioline.com

Item number 765041746 Rev.: 180518

Language: English

Loading...

Loading...