Page 1

765041938 Rev. 002 1

GRAM BAKER GA 950 / GA 550

User manual

Page 2

765041938 Rev. 002 2

Gram Commercial A/S

Aage Grams Vej 1

6500 Vojens

+45 73 20 12 00

www.gram-commercial.com

Page 3

765041938 Rev. 002 3

Contents

Application ............................................................................................................................................... 5

Safety information ................................................................................................................................... 6

Location ................................................................................................................................................... 7

Placement of multiple units next to each other ................................................................................... 9

General description ............................................................................................................................... 10

Electrical connection ............................................................................................................................. 11

Humidifier .............................................................................................................................................. 12

Water drain ............................................................................................................................................ 12

Water connection .................................................................................................................................. 13

General use ........................................................................................................................................... 14

Commissioning, functional description .............................................................................................. 15

Connection and disconnection of the main circuit breaker .............................................................. 16

User interface to the unit (touchscreen) ............................................................................................ 17

Settings for the unit: date, time and language .................................................................................. 17

Selection of language .......................................................................................................................... 18

Setting of clock (time).......................................................................................................................... 19

Setting the date .................................................................................................................................... 19

Setting of date format .......................................................................................................................... 20

Season: summer time/winter time ...................................................................................................... 20

Temperature measurement, units of Celsius or Fahrenheit. ........................................................... 20

Setting of ending times for programs for each weekday .................................................................. 21

Preconfigured programs ...................................................................................................................... 22

Selection and start of a program ........................................................................................................ 22

Selection of ending time for the program .......................................................................................... 23

Changing of established date and ending time for the program...................................................... 24

Changing of further settings before program start ............................................................................ 25

Display during program execution (fig. 32) ....................................................................................... 27

Changing a running program .............................................................................................................. 28

Interruption of the currently running program ................................................................................... 29

Storage of user-defined (own) programs ........................................................................................... 29

Manual programs ................................................................................................................................. 33

Deletion of a specially created program ............................................................................................ 33

Alarms/error messages ....................................................................................................................... 34

Temperature alarms ............................................................................................................................ 34

Sensor alarms ...................................................................................................................................... 35

Vapour system alarms ......................................................................................................................... 35

Other alarms ........................................................................................................................................ 35

Door closing mechanism ....................................................................................................................... 36

Page 4

765041938 Rev. 002 4

Power failure ......................................................................................................................................... 36

Cleaning ................................................................................................................................................ 36

Door gaskets ......................................................................................................................................... 37

Long term storage ................................................................................................................................. 37

Service .................................................................................................................................................. 38

Disposal ................................................................................................................................................. 39

EC-Declaration of conformity ................................................................................................................ 40

Wiring diagram ...................................................................................................................................... 41

Piping diagram ...................................................................................................................................... 42

Page 5

765041938 Rev. 002 5

ENGLISH

Thank you for choosing a quality product from Gram Commercial.

This manual will advise you how to install, use and maintain your new product.

Before our products leave the factory, they undergo a full function and quality test. Should

you nevertheless experience problems with the product, then contact your local dealer.

Gram Commercial subsidiaries and dealers placed all over the world are ready to help you.

Gram Commercial supplies warranty on all products.

This warranty is subject to correct use according to specifications, where e.g. common

maintenance and eventual repairs are carried out by Gram Commercial techicians or

technicians approved by Gram Commercial.

Changes in installation and other use of the procuct than prescribed in this manual, might

affect the operation and durability of the product.

The manual is written according to our current technical knowledge. We constantly work on

updating this information, and we reserve the right to make technical changes.

Application

This product is designed for storage of foodstuff at a constant temperature. The product may

not be used for chilling or freezing of foodstuff.

The product is only to be used for the purpose for which it has been expressly designed

(storage of cooled or frozen items). Any other use could cause that the products stored in the

product are not kept at the right temperature.

The manufacturer will not be held liable or responsible for any damage caused by improper,

incorrect or unreasonable use.

Page 6

765041938 Rev. 002 6

Safety information

Important

Description of symbols used in this manual.

Warning

Lacking observation to these instrucions might result in accidents with

personal injury.

Important

If these instructions are not observed, the product might be damaged or

destroyed.

Be aware that Gram Commercial has taken precautions to ensure that the safety of the

product is in order.

Please read carefully the following information regarding safety.

It is important, that everyone who are to use or install the product, to have access to

this manual.

This appliance is not intended for use by persons with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been

given supervison or instruction concerning use of the appliance by a person

responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

The appliance might contain parts with sharp edges in the compressor

compartment, and in the inside compartment.

The appliance is not to be transported on a sack truck, there is a danger of loosing

the balance, causing danger to persons.

Do not pull the power cord to dicconnect the appliance, or when moving the

appliance.

Page 7

765041938 Rev. 002 7

Location

When receiving the product, check the packaging material for damage.

If any damage occurs at the packaging material, it should be considered if the product might

have been damaged too. If the damage is substantial, please contact your dealer.

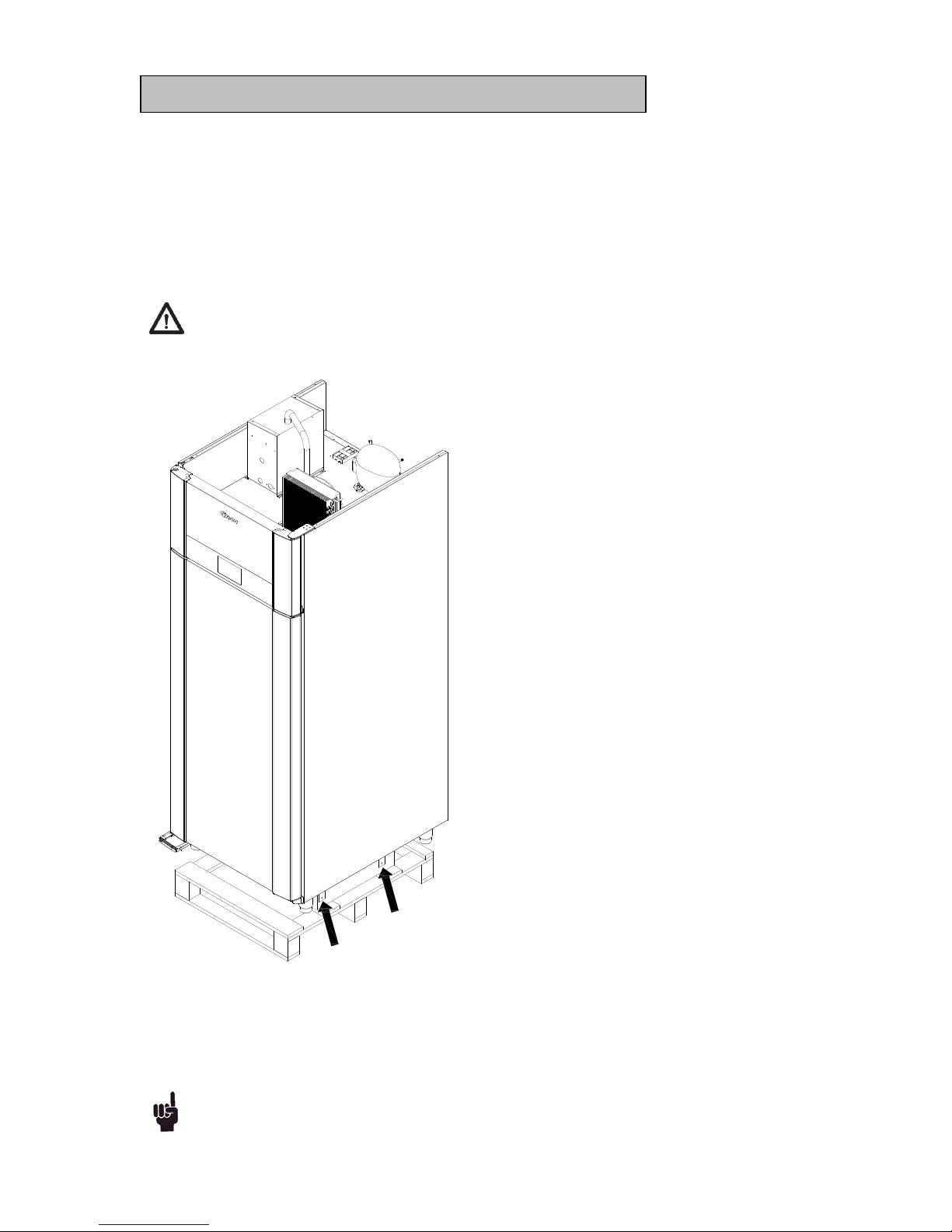

The transport pallet can be removed by loosening the screws that fasten the pallet to the

product.

This task requires at least 2 persons.The heaviest part of the product is at the top.

Be aware of this, when removing the transport pallet.

If the cabinet has been transported in horizontal position it must stand upright at

least 2 hours before it is started to allow the oil from the compressor to run back.

Page 8

765041938 Rev. 002 8

Because of the heavy weight of the product, the floor might be damaged or

scratched when moving the product.

Correct set up gives the most effective operation.

The product should be located in a dry and adequately ventilated room.

To ensure efficient operation, it may not be placed in direct sunlight or against

heat-emitting surfaces. The product is designed to operate in an ambient

temperature between +16C and +40°C.

Avoid placement of the product in a chlorine/acid-containing environment

(swimming bath etc.) due to risk of corrosion.

The product and parts of the interior is equipped with a protecting film, which

should be removed before use.

Clean the product with a mild soap solution before use.

The set up place must be level and horizontal.

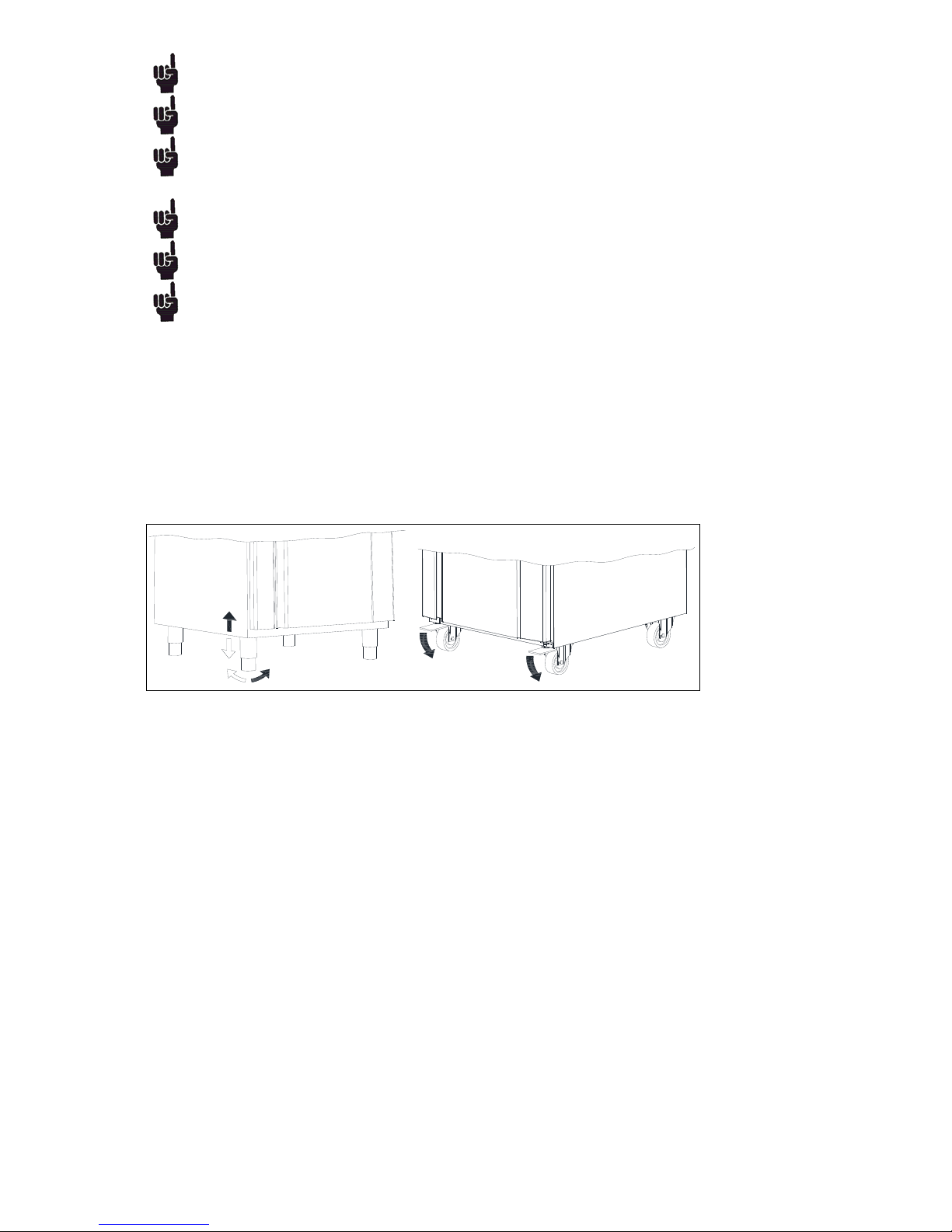

For versions with legs, use the adjustable legs to make sure that the product stands

level and upright.

For versions with castors, the locking devices of the two front castors must be activated,

when the product is in place. The base must be level, and the product may not be placed on

frames or the like.

Fig. 2

Page 9

765041938 Rev. 002 9

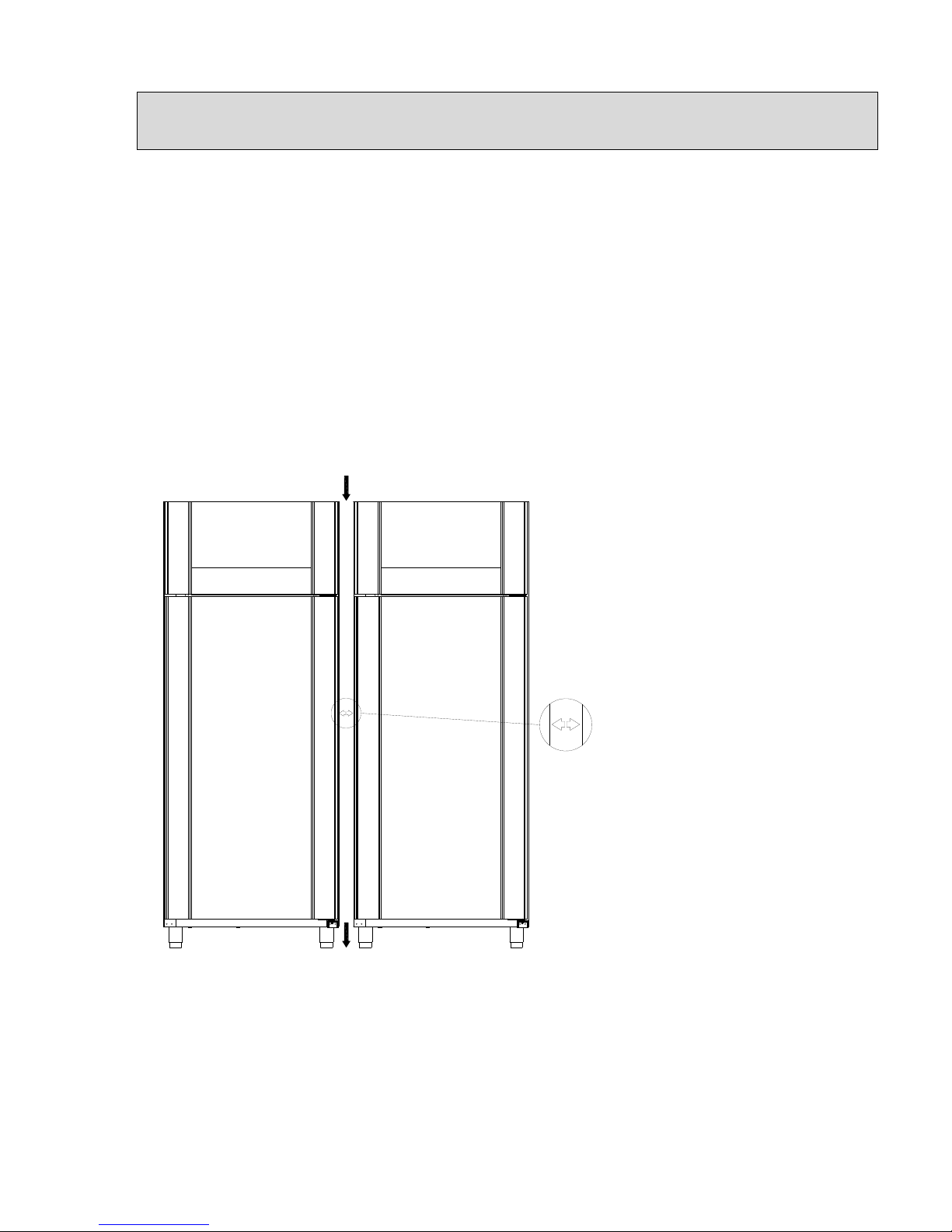

Placement of multiple units next to each other

Depending upon the temperature and humidity at the installation location as well as the

correct values being set, water contained in the surrounding air may condense on the surface

of a refrigerator (condensation formation) due to the design.

If multiple refrigerators or freezers are placed next to each other, then this condensation

effect is stronger, plus a smaller amount of air would then circulate between the units.

Hence, the minimum distance between the units must be 40 mm.

This space must not be closed off at its top or bottom, however due to aesthetical

considerations it may be covered in the front by, for example, a stainless steel panel. In order

to be able to clean this space, the panel must be detachable.

If it is not possible to establish free air circulation at the bottom via, for example, installation

on a pedestal, then the space must not be fully sealed at the front.

Min. 40 mm

Page 10

765041938 Rev. 002 10

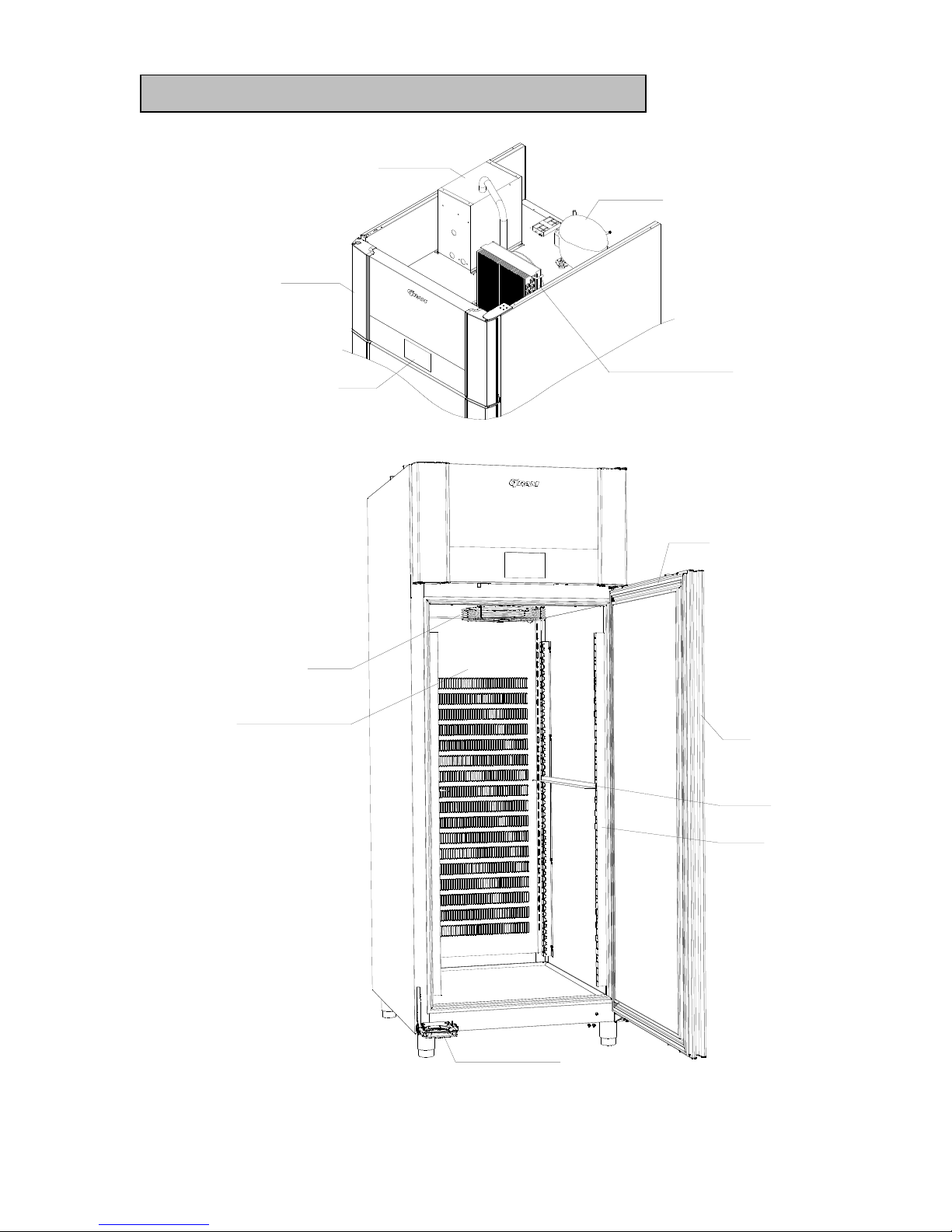

General description

Condenser with air filter

Compressor

Display

Front panel

Vapor system

Door

Gasket

Air inlet

Air distribution plate

Foot pedal opener

Wall rail

Supports

Page 11

765041938 Rev. 002 11

Electrical connection

Read the text below thoroughly before electrical connection.

The product is intended for connection to alternating current. The connection

voltage (V) and frequency (Hz) are shown on the name plate in the cabinet. Only

the supplied cord is to be used.

Never use an extension cord for this appliance!

If a wall socket is placed in a longer distance than the length of the supplied power

cord, contact an electrician to establish a wall socket within the range of the

supplied power cord.

If the product is defective, it must be examined by a service electrician advised by

Gram Commercial during the guarantee period, if it is a product with built-in

compressor.

If it is a product connected to an external compressor unit, it must be examined

by the company who has connected the product to the unit.

Outside the guarantee period, it is advisable to use the service advised by Gram

Commercial, if possible. If this is not the case, assistance is required from

a refrigeration company with knowledge of Gram’s products.

Page 12

765041938 Rev. 002 12

Always disconnect the power if interruptions in power supply occur, and when electrical parts

are removed/put on, and before cleaning and maintenance of the product.

Repairing of electrical/technical parts may only be performed by a service electrician from

Gram Commercial or an authorised refrigeration company with knowledge of Gram’s

products.

Do not use the product before all coverings are installed, so that live or rotating machine

parts can not be touched.

The product is not to be used outdoor.

All earthing requirements stipulated by the local electricity authorities must be observed. The

plug and wall socket should then give correct earthing. If necessary, contact an electrician.

Make sure the product is switched off at the socket before service is

performed on electrical parts. It is not sufficient to switch off the product

by the START/STOP key as there will still be voltage to some electrical

parts of the product.

Humidifier

The cabinet is equipped with a humidifier that provides steam during proving. The humidifier

consists of a water tank heated by electrodes. From the tank, steam is led into the cabinet

through a pipe. The tank is automatically filled from the water supply.

The tank can be flushed by switching the cabinet off at the main switch and then switching it

on again. In addition, the system is automatically flushed regularly depending on water

quality.

For further information on servicing and maintaining the humidifier, please

consult the "Service and operation manual". For maintenance of the humidifier,

request service assistance.

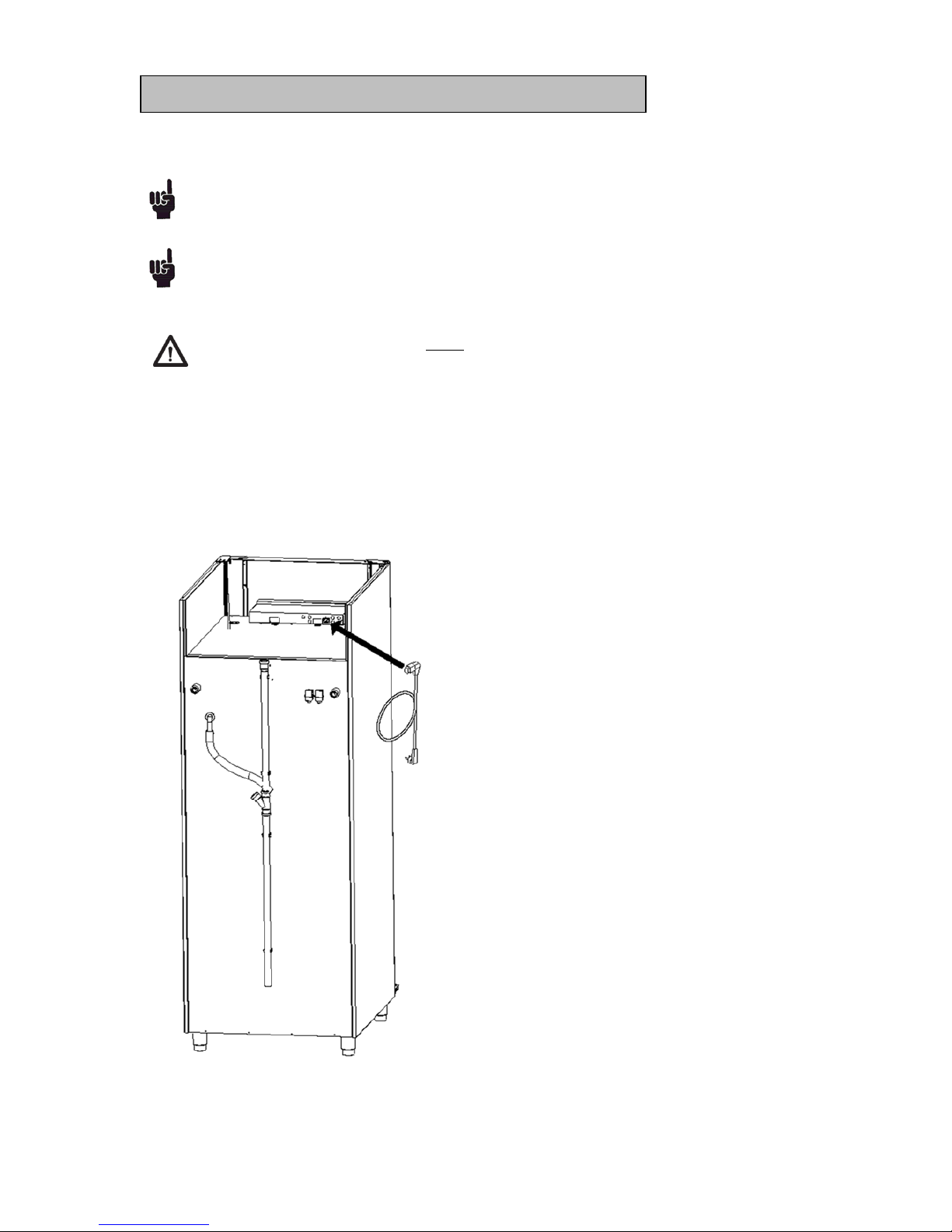

Water drain

Defrost water and water flushed from the humidifier

are led away through a pipe on the rear of the

cabinet. A water seal must be installed between

cabinet and drain.

Page 13

765041938 Rev. 002 13

Water connection

To provide proper steam production, the humidifier must be connected to a water supply. To

assure ideal steam production, it is important that the electrical conductivity of the inlet water

is measured by the installer, to assure it is within standard range. See Below Box!

Please note the following:

The electrical conductivity of the water must be in the range: 200-800 µS/cm.*

The temperature of the inlet water must not exceed 40°C.

The water pressure must be in the range 1-10 bar.

A shut-off valve, a check valve, and a filter if necessary, must be fitted to the supply pipe.

*If the electrical conductivity of the water is outside the above mentioned standard range (200

– 800 µS/cm) some controller settings, might need adjustment in order to maintain proper

steam production. These adjustments must be done by a service technician, and are

described in the service manual.

Indications that water conductivity is outside of standard range are:

Too poor steam production

Frequently having boiler overfilled alarm

Page 14

765041938 Rev. 002 14

General use

Do not block vent holes in the front panel.

Do not damage the refrigeration system parts.

During normal operation, some parts of the refrigeration system in the

compressor compartment might reach high temperatures, and could therefore

cause burns if touching these components.

Do not use electrical devices inside the product.

To ensure correct and efficient air flow in the cabinet, the shaded areas must be

kept free of items.

All items to be stored, that are not wrapped or packed, must be covered in order

to avoid unnecessary corrosion of the inner parts of the cabinet.

If any controller parameters are changed from default, this could cause that the

product is not functioning normally, and harmful temperatures could damage

items that are kept inside the product.

If the product is turned off, wait minimum 3 minutes before turning it on again.

This is to protect the compressor from damage

Maximum loading of wire shelf: 40 kg

Do not store explosive substances such as aerosol cans with flammable

propellant in this appliance.

Page 15

765041938 Rev. 002 15

Commissioning, functional description

In order to ensure reliable processes for Freezing, Storage, Thawing, Proving and Holding

the cabinet must be furnished with controls to regulate the air temperature, ventilation and

relative humidity.

The operating modes of Storage, Thawing, Proving and Holding can be connected up

manually.

This means that the unit can also be used as a normal refrigerator or freezer in a storage

program with a constant temperature. With the thawing and proving operating modes, the

relative humidity is instead kept constant while the temperature varies.

Correct programming of the controls establishes the desired combination of the operating

modes:

time-controlled freezing with subsequent storage for an arbitrary length of time

time-controlled freezing with subsequent storage and time-controlled thawing as well

as subsequent maintenance of the climate upon conclusion of the thawing program

complete program with freezing, storage, thawing and proving until being taken out or

holding when the roux time is exceeded.

Page 16

765041938 Rev. 002 16

Connection and disconnection of the main circuit breaker

The unit is furnished with a two-pole main breaker, which is located behind the tiltable control

panel. When it has been disconnected, the controls and all components that are accessible

without opening the control panel are disconnected from the power supply. If the main

breaker is connected, then the controls and the other components are connected to the

power supply.

Warning

When working on the electrical equipment, the unit must

always have its power from the grid shut off by disconnecting

it and then pulling the plug out of the power socket. It is NOT

sufficient to disconnect the unit with the ON/OFF button

because certain parts of the unit will still have an applied

voltage.

Page 17

765041938 Rev. 002 17

User interface to the unit (touchscreen)

All operating functions are performed by touching the respective buttons displayed on the

touchscreen, for example changing values and starting and stopping programs. In connection

with this, the function is "touch and release", which in other words is that the controls react to

being touched once you let go of the keyboard.

When the unit is connected with the lighting mains, and the main breaker switched on, then

the standby display is shown on the screen: (fig. 1). The Gram logo and the unit type "GA

950" as well as the date and time are shown on a field with a blue background. Please check

that the correct date and time are displayed.

Fig. 1

If the date, time or selected language are not displayed correctly (date format), go to the

section entitled "Settings for the unit: date, time and language" (see below) in order to

change the settings.

When the display is touched, the controls change from standby to the first on-screen menu

(fig. 2):

Fig. 2

This menu is the start menu for all further functionality. If the unit is in the process of running

an active program, and you do not touch the screen for 30 minutes, then the controls will

switch back to the standby display (fig. 1)

Settings for the unit: date, time and language

Page 18

765041938 Rev. 002 18

In order to change the settings for the date, time, formats, units or menu language, you need

to press the button on the keyboard (machine symbol) in the lower right corner of the

screen (fig. 3). The factory setting for the language is English.

When you press the button , the menu for settings for the unit opens (fig. 4):

Fig. 3 Fig. 4

To set the date, time or language, press the button . The settings menu then opens

with the associated fields (fig. 5):

Selection of language

Fig. 5 Fig. 6

When you touch the fields, the pull-down menus are opened and the possible values

displayed. Fig. 6 shows the language selections. The desired language can be selected by

touching it.

It is important to restart the controls to ensure that this change has been performed for all

areas.

Page 19

765041938 Rev. 002 19

Setting of clock (time)

The clock is set by touching the field with the time under the text "Time" (fig. 7):

Fig. 7 Fig. 8

Enter the desired time directly using the numerical keypad and confirm with the "OK" button

(fig. 8). The clock works with days in 24-hour format. It is not possible to use a 12-hour

format ("am"/"pm"). After pressing the "OK" button, the time is saved and the display returns

to the previous menu (fig. 5). Exit the menu without making any changes by selecting "<".

Setting the date

The date is set by pressing on the date field under the text "Date"

(Fig. 9)

Fig. 9 Fig. 10

A calendar menu will be displayed (fig.10). Here, you must select the month, year and day,

and then confirm with "OK". Exit the menu without making any changes by selecting "<". The

previous menu is then displayed (fig. 5).

Page 20

765041938 Rev. 002 20

Setting of date format

Set the date format by pressing the "DD/MM/YYYY" field (fig. 11).

Fig. 11 Fig. 12

The choice between the sequence day/month/year and month/day/year is now shown (fig.

12): Select by pressing.

Season: summer time/winter time

Setting of the season, i.e. the setting of winter/summer time is done by pressing on the field

under the text "Summer time" (fig. 13):

Fig. 13 Fig. 14

Possible choices:

"NO"

= manual selection of winter time (system time)

"YES"

= manual selection of summer time (system time + 1 hour)

"AUTO"

= automatic switching to Central European Summer Time, CEST:

Start on summer time: last Sunday in March

End of summer time: last Sunday in October

The factory setting is "AUTO". Select by pressing.

Temperature measurement, units of Celsius or Fahrenheit.

Setting the unit to display temperatures in Celsius or Fahrenheit is done by pressing the field

under "Units" (fig. 15):

Page 21

765041938 Rev. 002 21

Fig. 15 Fig. 16

Here, you can choose to display temperatures in Celsius or Fahrenheit for all displays in the

controls (fig. 16).

When you have made all the changes to the settings, then return to the Settings menu (fig. 4)

for the unit by pressing the "OK" button (fig. 16).

Fig. 17 Fig. 2

Return to the start menu (fig. 2) by pressing the field (arrow back) in the lower right

corner (fig. 17).

Setting of ending times for programs for each weekday

In order to take weekends and holidays into consideration, an ending point in time can be

established for programs for each weekday as a default. This is then shown upon later

program selection, and you only need to confirm it by choosing "morning".

Press the button in the keyboard (machine symbol) in the start menu (fig. 3, page 16).

The menu for settings for the unit now opens (fig. 18).

Fig. 18 Fig. 19

Press on the "Calendar page" (fig. 18) in order to open the ending time menu for the program

(fig. 19). When you press on the white fields with the times for the day, a settings menu

opens, where you can enter the time (fig. 20).

Page 22

765041938 Rev. 002 22

Fig. 20 Fig. 20a

Enter a time. In order to jump over a day, the symbol „---„ (fig. 20a) needs to be inserted on

the desired day. With "OK", you save what you entered for this weekday, or you can return

to the weekly overview (fig. 19) without saving.

Once all the changes have been made, you return to the start menu by pressing twice,

(fig. 20a).

Preconfigured programs

There are five preconfigured programs stored in the controls, which can be selected directly

in the start menu under the overview (fig. 21). These programs cannot be deleted or

overwritten.

Fig. 21

Selection and start of a program

In order to start a preconfigured program without changing the settings, you press on the

button on the keyboard with the symbol Master. The selected symbol is shown with a blue

edge, and the "Settings" button (symbol for the sliding button) is shown in blue, which means

that it has been activated (fig. 22).

Fig. 22

Page 23

765041938 Rev. 002 23

Further touching of the Master symbol opens a window with an ending time for the program

(ready at) on the following day.

Selection of ending time for the program

A menu is opened in which the ending time for the program is selected, and the default setting of "Weekday" must be confirmed (fig. 23).

The usual ending time for programs can be established in the menu Settings for the unit

as a default value for each weekday (see the section entitled "Default ending times for

programs for each weekday", page 21).

If the ending time established for the program is

correct, then the program can be started by

choosing "Weekday" (Monday, Tuesday, etc.).

The program only starts if there is sufficient time

remaining between the time for the starting and

ending times for the program for the sum of the

programmed program sections (phases).

Otherwise, the earliest possible ending time for

the program is shown (fig. 23).

To switch out of the display, press on "Ready at".

Page 24

765041938 Rev. 002 24

Changing of established date and ending time for the program

To do this, press on the "Calendar" field (fig. 26)

Fig. 26 Fig. 27

The calendar menu (fig. 27) will be displayed. Here, the date

can be changed by touching the date fields. Selections for

changing the time can be opened by touching the time window.

Here, the time can be entered and then saved with "OK". By

selecting you exit the menu without making any changes.

With "OK" you exit the menu and start execution of the

program.

Fig. 20

Page 25

765041938 Rev. 002 25

Changing of further settings before program start

In order to adjust a preconfigured program, touch the button on the keyboard with the Master

symbol. The selected symbol is displayed with a blue edge, and the "Settings" button

(symbol with sliding button) is shown in

blue, which means that it has been

activated (fig. 28).

Touching the "Settings" button (symbol

with sliding button) displays the settings

menu with five program phases:

Freezing, Storage, Thawing, Proving,

Holding (fig. 29).

Fig. 28

Fields are shown below that contain the values for duration, temperature and relative

humidity for the respective program phase.

By touching the field for the respective

program phase, for example , you

select it to have its values set. The fields are

then opened, for example

, by touching

them (white fields). The data entry menu is

shown, for example time, "Duration" (fig. 30).

Fig. 29

Fig. 30

In order to deactivate a program phase, the symbol must be selected, after which you press

on it until the field "GREY" has been saved. In order to reactivate the program phase, you

must press on it again, until the symbol has its original colour. If goods are placed in the unit

that have been refrigerated in advance, and the program is started with storage, then under

Page 26

765041938 Rev. 002 26

you must choose selection, see the first section. For example, to disconnect holding

you must make the same selection under .

With "OK" the values are accepted and the menu closed. The selection menu "Save recipe

?" is then shown (fig. 31)

Saves the entered values

temporarily and accordingly runs the execution of

the program activated below only once.

Enables storage of the changes in a

special user-defined program (see the section

"User-defined programs", page 27).

Fig. 31

Means that the menu will be exited without changes, i.e. the changes will be

rejected.

Page 27

765041938 Rev. 002 27

Display during program execution (fig. 32)

Thetoplineshowsthephaseoftheprogramexecutioncurrentlyrunningdependingupontheprogram

selected:

Freezing,Storage,Thawing,Proving,Holding

Thefieldintheupperright

rectangleshowsthe

currentlyrunningprogram

phaseandtheassociated

remaining(residual)time.

Aredtriangleisshownas

analarmsymbolinthe

eventofanalarm.

Thecurrentvalueforthe

temperatureortherelative

humidityisshowninthe

lowerrightcorner

dependinguponthe

programphase.

Thegreenbaratthe

bottomofthedisplay

showsthetotalprogram

executioninproportion

totheduration.

Inthewindowinthemiddle,the

symbolforthecurrently

runningprogramisshownatthe

left,inthecentretheendingtime

fortheprogramandattherighta

buttontointerrupttheprogram.

Page 28

765041938 Rev. 002 28

Changing a running program

Fig. 33 Fig. 34

Touching the program symbol (fig. 33) opens the settings menu (fig. 34), where you can

change the specifications for program phases that have not been run yet.

Touching the field with the ending time for the program (fig. 35) opens the settings menus for

date and time (fig. 36) for purposes of changing the ending time for the program, see the

above for the descriptive section "Changing the ending time for the program" (page 22) /

"Changing the date of the ending time for the program" (page 23).

Fig. 35 Fig. 36

Here, the date can be changed by touching the

date fields. Selection of the time can be opened

by touching the time window, fig. 20. Here, the

time can be entered and saved with "OK". Exit

the menu without making changes with "<".

The ending time for the program may only be

changed before the start of the thawing phase!

Fig. 20

Page 29

765041938 Rev. 002 29

Interruption of the currently running program

Touching the button causes the currently running program to be interrupted (fig. 36).

Fig. 36 Fig. 37

A window opens where for verification purposes you are asked whether the program should

really be halted (fig. 37). If ("YES") is selected, the program is stopped. If

("Back") is selected then interruption of the program is interrupted, i.e. you

return to the currently running program without any action being taken.

Storage of user-defined (own) programs

In order to change a predefined program and save it as your own program, touch the button

on the keyboard with the symbol (here, for example, Master). The selected symbol is

displayed with a blue edge, and the

"Settings" button (symbol with sliding button)

is shown in blue, which means that it has

been activated (fig. 38). Touching the

"Settings" button (symbol with sliding button)

displays the settings menu with the five

program phases (fig. 39).

Fig. 38

Page 30

765041938 Rev. 002 30

Fig. 39

Under these, there are fields containing the values for duration, temperature and relative

humidity for the respective program phase. By touching the field for the respective program

phase, for example, it is selected for the setting of its values. Then the fields, for

example , are opened when touched. The value entered for a

value, for example the length of time "Duration", is shown (fig. 40).

Fig. 40

In order to deactivate a program phase, the symbol must be selected, after which you press

on it until the "GREY" field has been saved. To reactivate the program phase, you must

press on it again until the symbol has its original colour. If goods are placed in the unit that

have been refrigerated in advance, and the program is started with storage, then under

you must choose selection, see the first section. For example, to disconnect holding, you

have to make the same selection under .

FreezingStorageThawingProvingHolding

Page 31

765041938 Rev. 002 31

With "OK" the values are accepted and the menu closed. The selection menu "Save recipe

?" is then shown (fig. 41)

Saves the entered values

temporarily and runs in a corresponding

manner the commenced program sequence

1 x.

Means that the menu is exited

without changes.

Fig. 41

With the settings made are saved in a special user-defined program. The

storage menu is displayed.

Fig. 42 Fig. 43

When touching the field with the program name (fig. 42), a window with an alphanumeric

keyboard is displayed for entry of a special program name (fig. 43). Enter a name for the

program, and press "OK", or exit the window without changes with .

The storage menu is then displayed again.

Fig. 43 Fig. 44

Page 32

765041938 Rev. 002 32

Touching the program symbol (fig. 43) shows a selection of symbols for your own programs

(fig. 44). Choose a symbol by touching it, and navigate back and forth between further

symbols with "<" or ">". Change for example the picture from to or exit the

menu without changes with "<".

The storage menus will be displayed.

Fig. 45 Fig. 46

Touching the field selects the memory location in one of the folders in the

start menu.

Fig. 47

Select a folder, or exit the menu without changes with "<".

Bear in mind that the preconfigured programs themselves in the folder cannot be

overwritten.

When all settings have been adjusted, you can save your program with "OK".

Page 33

765041938 Rev. 002 33

Manual programs

The display start page (fig. 48) will save up to

four different symbols. You can activate each

one of these program phases separately to

for example use the unit as a storage freezer

or solely as a proving machine.

Fig. 48

Procedure at the start of the phases:

Select the desired program, and press once, until a blue frame is displayed.

Then press the symbol at the bottom to the right, and set the settings accordingly

(white fields).

Exit the menu with the symbol OK. For further steps in connection with execution, storage

and interruption, please see page 29.

Exit the menu without saving with the button "<".

Deletion of a specially created program

Select program, blue frame is displayed, after which you continue to press until a new menu

item is displayed, (fig. 49).

Fig. 49

You can now select "YES" or "NO" for deletion. The program is deleted by selecting "YES",

whereas it continues to be available by selecting "NO".

Page 34

765041938 Rev. 002 34

Alarms/error messages

If an error arises, an error message window

is displayed on the screen, for example a

room sensor error, and an acoustic alarm is

issued.

In order to acknowledge this alarm, you

must touch the alarm window (the area with

the black background).

Then a red triangle is shown on the display

for the currently executing program until the

error is remedied.

Depending upon the priority of the error, the

program will continue with an emergency

program, or it will be interrupted.

Temperature alarms

Error message Description System reaction

Alarm high temperature

The temperature around the room sensor

has been above the alarm value for longer

than the alarm delay time

none

Alarm low temperature

The temperature around the room sensor

has been below the alarm value for longer

than the alarm delay time

none

Condenser temperature high

The temperature around the evaporator

sensor has been above the alarm value

for longer than the alarm delay time

none

Too many consecutive evaporator

temperature alarms

The evaporator temperature alarm is

occurring more frequently than the setting

for repetition counts

The compressor is disconnected, and

the evaporator fan runs with 100%

power.

Page 35

765041938 Rev. 002 35

Sensor alarms

Error message Description System reaction

Room sensor error

Sensor defective, not connected or shortcircuited.

Compressor runs for 5 min. ON and

5 min. OFF.

Evaporator sensor error

Sensor defective, not connected or shortcircuited.

Defrosting will be 45 min., and the

evaporator fan will start 10 min. after

the defrosting.

Condenser sensor error

Sensor defective, not connected or shortcircuited

None

RF sensor error

Sensor defective, not connected or shortcircuited

Vapour system will be shut off until the

error has been remedied

Vapour system alarms

Error message Description System reaction

Boiler overfilled – summon service

Too much water in boiler, defective water

valve.

Vapour system will be shut off until the

error has been remedied.

Water connection error

No water connection to boiler, no power to

water valve.

No steam production

Test water connection

No water connection to boiler, no power to

water valve.

No steam production

Boiler discharge error Defective water valve.

Vapour system will be shut off until the

error has been remedied.

Boiler overfilled Defective water valve

Vapour system will be shut off until the

error has been remedied.

Other alarms

Error message Description System reaction

Door open

Door open longer than 45 min. or defective

door contact.

Compressor disconnected until the

error has been remedied.

Power connection error Loss of power for more than 5 min.

Program is shut down when the power

comes back on again.

Page 36

765041938 Rev. 002 36

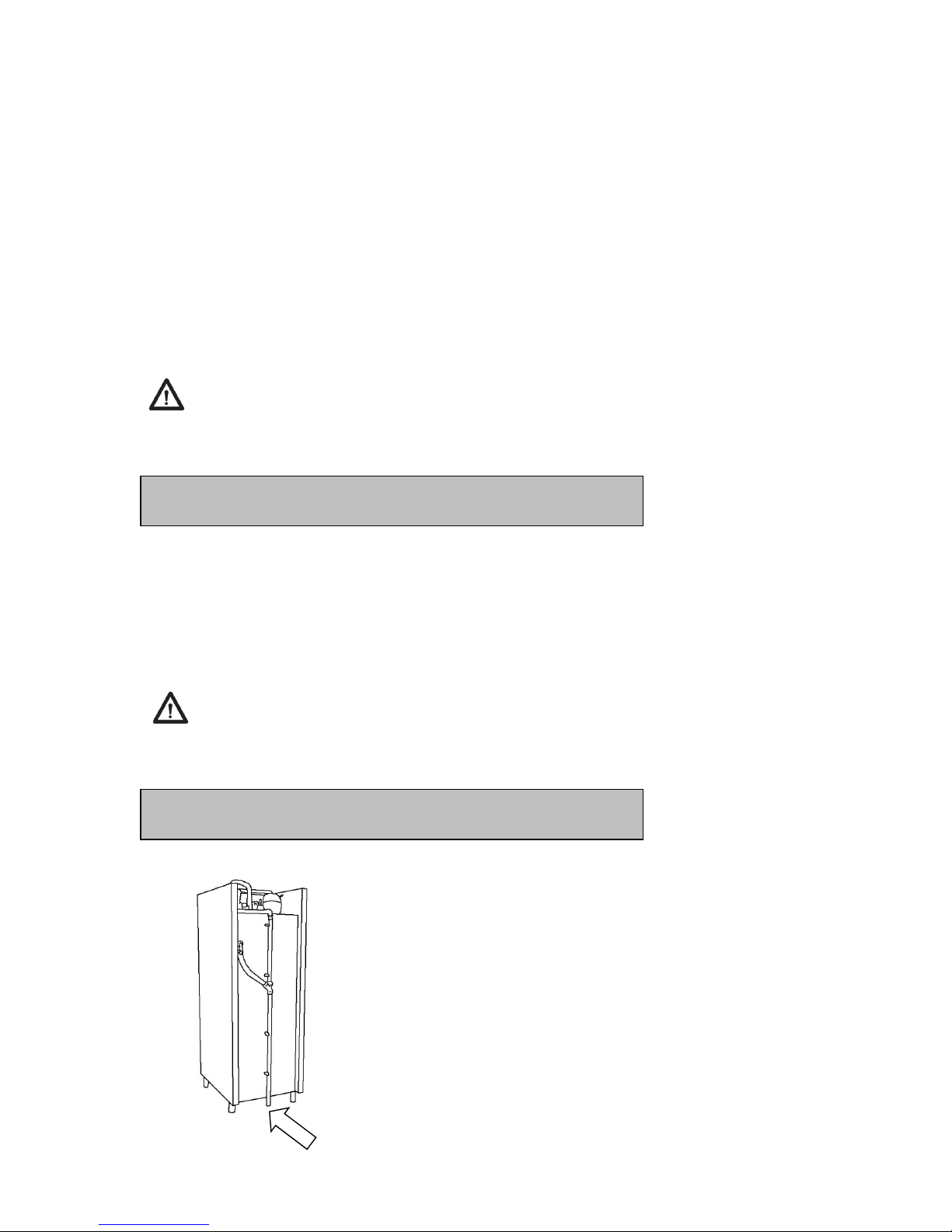

Door closing mechanism

The door is equipped with a self-closing system. If the door is opened less than 90, it will

close by itself. If the door is opened more than 90, it will stay open.

The door can be opened by using the foot pedal. This leaves both hands free when placing

foodstuffs the cabinet.

Power failure

In the event of a power failure, the control remembers the temperature setting and restarts

the product when power is restored. If the power failure persists for some time, the control

might revert to the factory setting.

Cleaning

Insufficient cleaning will cause that the product will not work at optimum perfomance, or

eventually it will be defective.

Before cleaning, the product should always be disconnected.

Do not flush the product with water, do not use water jet or steam hose

as this may cause short-circuits in the electrical system.

Cleansing agents containing chlorine or compounds of chlorine as well

as other corrosive means, are not to be used, as they might cause

corrosion to the stainless panels of the cabinet and the evaporator.

The compressor compartment and in particular the condenser must be kept free

from dust and dirt. This is best done by cleaning the compressor compartment

and the condenser air filter with a vacuum cleaner, if dust/flour is the matter.

The air filters on the condenser and the front panel can be removed and cleaned

in hot water (at max. 50°C).

For the external maintenance – use stainless steel polish.

The product should be cleaned internally with a mild soap solution at suitable

intervals and checked thoroughly before it is put into operation again.

Page 37

765041938 Rev. 002 37

Door gaskets

This chapter deals with the importance of a well-functioning door gasket.

Gaskets are an important part of a refrigerator/freezer. Gaskets with reduced functionality,

reduces the tightness of the cabinet. Reduced tightness might cause increased humidity,

internal icing, an iced up evaporator (leading to reduced refrigeration capacity), and in worst

case reduced lifecycle of the cabinet.

Therefore it is important to be aware of the condition of the gasket. Regular

inspection is recommended.

The gasket should be cleaned regularly with a mild soap solution.

If a gasket needs replacement, contact your supplier.

Long term storage

If the product is taken out of operation, and need to be prepared for long-term storage,

clean the inside compartment, the door and door gasket thorougly with a hot soapy damp

cloth.

Eventual remnants of food could create mould.

Page 38

765041938 Rev. 002 38

Service

The refrigerating system and the hermetically sealed compressor require no

maintainance - they merely have to be kept clean.

If refrigeration fails, first investigate whether the unit has been unintentionally disconnected or

switched off at the socket, or whether a fuse has blown.

If it is not possible to find the cause of the refrigeration failure, please contact Gram

service department.

When contacting us please tell us the name and serial number (S/N) / (WWYY) of the

cabinet. This information is stated on the name plate.

Location of the name plate:

Type

REF

PO No

S/N

Input: V Hz W A

Defrost: W

Refrigerant: g

Climate class:

Isolation class:

Foam propellant Cyclopent ane

Permissible operation over-pressure:

Suction side: 10 bar

Discharge side: 25 bar

Gram Commercial A/S

Aage Grams Vej 1, 6500 Vojens

Denmark CVR nr. 12 00 66 32

Page 39

765041938 Rev. 002 39

Disposal

The below only concerns the United Kingdom.

Disposal of an old cabinet is only available when we are delivering a new one at the same

time. Cabinets must be fully defrosted and emptied prior to collection.

Gram recognises that our products for the catering market are considered as WEEE when

they become obsolete. To ensure that Gram’s responsibilities are handled correctly and

environmentally friendly, we are signed up the largest Business to Business compliance

scheme in the UK – B2B Compliance

http://www.b2bcompliance.org.uk

B2B Compliance will on our behalf deal with all areas of our responsibilities when

collecting and disposing of equipment which fall under the UK WEEE regulations.

B2B Compliance can be contacted on telephone number 01691 676124.

Page 40

765041938 Rev. 002 40

EC-Declaration of conformity

Producer

Name: Gram Commercial A/S

Adress: Aage Grams Vej 1, 6500 Vojens

Tel.: +45 73 20 12 00

Product

Model: Baker GA 950, Baker GA 550

Refrigerant: R134a, R404A, R290

Year: 2016

Directives

The product is in compliance with all the essential health- and safety requirements

and provisons in:

Directive for Machinery 2006/42/EF

The product is where relevant in compliance with the following other directives:

Regulation 2015/1095

FCM regulation 10/2011

Regulation 1935/2004

RoHS - 2011/65/EU

Standards

The following standards are used to the extent necessary to comply with the relevant

directives:

DS/EN 12100:2011 - Safety of machinery -- General principles for design -- Risk

assessment and risk reduction

DS/EN 60335-1:2012 – Household and similar electrical appliances. Safety. General

requirements

DS/EN 60335-2-89:2010 – Household and similar electrical appliances. Safety.

Particular requirements for commercial refrigerating appliances with an incorporated

or remote refrigerant condensing unit or compressor

Person

responsible for

technical dossier

Company: Gram Commercial A/S

Adress: Aage Grams Vej 1

Name: John Lund

Signature

Vojens 18/11-2016 R&D Manager

Page 41

765041938 Rev. 002 41

Wiring diagram

Page 42

765041938 Rev. 002 42

Piping diagram

Page 43

765041938 Rev. 002 43

Loading...

Loading...