Grafik Eye 3100, 3500 Installer's Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○

GRAFIK Eye 3000

Series Control Units

supply power to, and control

the brightness of two, three,

four, or six zones of lighting.

GRAFIK Eye Control Units

control the intensity of all the

light sources in a room. You

can adjust the lights for a

special event or activity with

the press of a button!

○○○

LIGHTING CONTROL

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

LUTRON

LUTRON

PLEASE LEAVE FOR OCCUPANT

3000 Series

Installer’s Guide

Models 3100 and 3500

IMPORTANT! GRAFIK Eye lighting controls must be installed by a qualified electrician in accordance with all applicable

regulations. Improper wiring can result in personal injury or damage to GRAFIK Eye lighting controls or other equipment.

Always turn off circuit breaker/MCB or remove main fuse from power line before doing any work. To avoid overheating and

possible damage to equipment, do not install dimming devices to dim receptacles, motor-operated appliances, or

fluorescent lighting not equipped with Lutron Hi-lume®, Eco-10™, or Tu-Wire™ Electronic Dimming Ballasts. In dimmed

magnetic low-voltage circuits, you can prevent transformer overheating and failure by avoiding excessively high current

flow: Do not operate GRAFIK Eye lighting controls with any lamps removed or burned out; Replace any burned out lamps

immediately; Use only transformers that incorporate thermal protection or fused primary windings. This lighting control is

designed for residential and commercial use. GRAFIK Eye Controls are designed for indoor use only.

Do you have: Then read this . . . . . . on page:

Control Unit only? STEP 1: Installing 3000 Series Control Units 3

Follow Step 1 and Step 3 How to wire and mount GRAFIK Eye 3000 Series Control Units.

Wallstations too? STEP 2: Installing Wallstations 4

DIP switch address settings, wiring, and mounting.

STEP 3: Setting Up Control Units 6

Identifying load types and setting up lighting scenes.

STEP 4: Setting Up System Communications 10

Assigning Wallstations to the Control Units they should operate.

Questions about Appendix A: More about Class 2/PELV Wiring 12

Class 2/PELV wiring?

Appendix B: Special Mounting Considerations 14

Appendix C: Power Boosters, 14

Electronic Low Voltage Interfaces,

and Fluorescent Dimming Ballast Interfaces

Appendix D: GRX-TVI 0-10 Volt Ballast Interface 15

Appendix E: HP 2•4•6 Dimming Modules 17

Appendix F: Infrared Controls 18

Problems? Appendix G: Troubleshooting 18

LUTRON-Quality Systems

Registered to ISO 9001

Page 2

Questions? Need technical assistance?

Phone Assistance . . . Worldwide!

■ In the U.S., Canada and the Caribbean:

1-800-523-9466

■ In Mexico, Central and South America:

1-610-282-3800

■ In Japan: 03-5405-7333

■ In Hong Kong: 2104-7733

■ In the U.K.: 0800-282-107

■ In Europe: 44-171-702-0657

■ All others: 1-610-282-3800

■ Website address: www.lutron.com

■ E-mail: product@lutron.com

Warranty

Lutron warrants each new unit to be free from defects in materials and workmanship and to perform under normal use and service. This

warranty shall run only for a period of one year from the date of purchase and Lutron's obligations under this warranty are limited to

remedying any defect or replacing any defective part and shall be effective only if the defective unit is shipped to Lutron postage prepaid within

12 months after purchase. Damage due to abuse, misuse, inadequate wiring or installation is not covered by this warranty. In no event shall

Lutron or any other seller be liable for any other loss or damage, including consequential or special damages that may arise through the use

by a purchaser or others of this device and the purchaser assumes and will hold harmless Lutron in respect of all such loss. Although every

attempt is made to ensure that catalogue information is accurate and up-to-date, please check with Lutron before specifying or purchasing this

equipment to confirm availability, exact specifications and suitability for your application. This product may be covered by one or more of the

following U.S. patents: 4,797,599; 4,803,380; 4,825,075; 4,893,062; 5,030,893; 5,191,265; 5,430,356; 5,463,286; 5,530,322; 5,808,417;

DES 308,647; DES 310,349; DES 311,170; DES 311,371; DES 311,382; DES 311,485; DES 311,678; DES 313,738; DES 335,867; DES

344,264; DES 370,663; DES 378,814 and corresponding foreign patents. U.S. and foreign patents pending. Lutron, GRAFIK Eye, and Hi-lume

are registered trademarks; Hi-Power, Eco-10, LIAISON, Designer, Tu-Wire, and Architrave are trademarks of Lutron Electronics Co., Inc. ©

1999 Lutron Electronics Co., Inc.

®

Safety standards listed above apply to one or more products in the GRAFIK Eye product line. Consult factory for specific information.

2

3

0

V

˜

LUTRON

5

0

/6

0

H

z

L

O

A

D

P

E

R

Z

O

N

E

: 4

0

- 8

0

0

W

M

A

X

U

N

IT

L

O

A

D

: 1

0

A

, 2

3

0

0

W

P

re

s

e

t L

ig

h

tin

g

C

o

n

tro

l

LIVE

TER

M

IN

A

LS A

T R

EA

R

D

O

N

O

T W

IR

E

LIV

E

U

. K

. 0

7

1

-7

0

2

-0

6

5

7

U

. S

. A

. (6

1

0

) 2

8

2

-3

8

0

0

C

O

O

P

E

R

S

B

U

R

G

, P

A

U

S

A

1

8

0

3

6

GRX-3104-CE

U

P

M

a

d

e

in

U

.S

.A

.

1

2

V

S

E

L

V

O

U

T

P

U

T

!

C

B

E

5

1

4

5

-0

4

9

G

R

X

-Z

Page 3

HOT/LIVE

SWITCH

LOAD

NEUTRAL

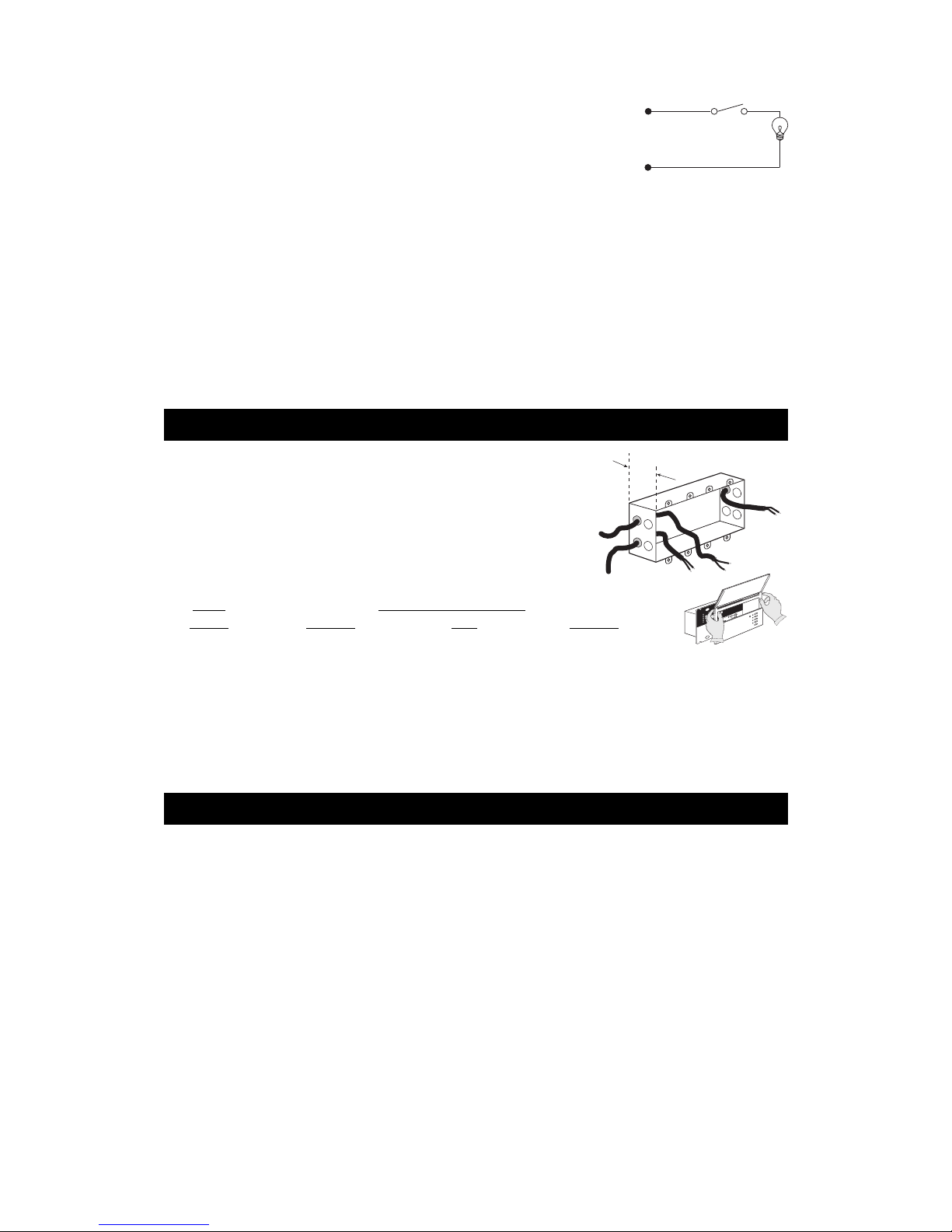

STEP 1: Installing Control Units

This section shows how to install Control Units and make sure they are properly operating all connected loads.

CAUTION!

First test loads for short circuits.

1. Turn power OFF at the breaker/MCB panel or fuse box.

2. Connect standard light switch between live lead and the load wire to test circuit.

3. Turn power on and check for short or open circuits: If load does not operate, circuit is open. If the

breaker/MCB trips (fuse blows or opens), circuit is shorted. Correct short or open circuits and test

again.

Load Types

The Control Units can control incandescent, halogen (tungsten), magnetic low-voltage, and neon/cold cathode load types. Electronic lowvoltage and fluorescent load types can be controlled with an appropriate interface.

■ Not all zones need to be connected; however, connected zones must have a load of at least 25W (40W for AU and CE models).

■ No zone may be loaded with more than 800 W (1200 for AU models).

■ Unit must not carry more than 16A of total lighting load (10A for CE models).

■ All Electronic Low-Voltage (ELV) lighting used with the Electronic Low-Voltage Interface must be rated for reverse phase-control

dimming. Before installing an ELV light source, verify with the manufacturer that their transformer can be dimmed. When dimming, an

Electronic Low-Voltage Interface MUST be used with the Series Control Unit.

Installation instructions. First, turn power off.

Preparation

1. Mount Wallbox. Use standard U.S. wallbox, 3 1/2 in. (87 mm) deep is strongly

recommended, 2 3/4 in. (68 mm) deep minimum. Always allow at least 4 1/2 in. (110 mm)

clearance above and below the faceplate to ensure proper heat dissipation.

2. Pull Wires. Use the rearmost knockouts when pulling wires into the wallbox. This will

provide the most clearance when mounting the Control Unit.

3. Remove Cover. Remove the Control Unit’s cover and hinged faceplate by pulling outward at

each corner.

Model Wallbox Size/Max. Unit Load

Number 100-127V 230V 220-240V

3102/3502 2-Gang U.S

†

/1200W/VA 4-Gang U.S†/10A 2-Gang U.S/1600W/VA

3103/3503 3-Gang U.S

†

/1500W/VA 4-Gang U.S†/10A 3-Gang U.S/2400W/VA

3104/3504 4-Gang U.S

†

/2000W/VA 4-Gang U.S†/10A 4-Gang U.S†/3000W/VA

3106/3506 4-Gang U.S†/2000W/VA 4-Gang U.S†/10A 4-Gang U.S†/300W/VA

† Lutron P/N 241-400.

Line Voltage/Mains Wiring

IMPORTANT WIRING NOTES!

■ Use properly certified cable for all line voltage/mains cables and

Class 2/PELV cables.

■ In Europe, acceptable types of cable include HAR certified cable

with insulated cores enclosed in a sheath. This cable must bear the

appropriate certification mark pertaining to national wiring rules for

fixed installations. If certified cable with insulated cores enclosed in

a sheath is used for the Power cables, the Class 2/PELV wiring can

be any of the specified cables in Appendix A: More about

Class 2/PELV Wiring.

■ Proper short-circuit and overload protection must be provided at

the distribution panel. You can use up to a 20A (16A for AU, and

10A for CE models) maximum circuit breaker/MCB or equivalent

(tripping curve C according to IEC60898/EN60898 is

recommended) with adequate short-circuit breaking capacity for

your installation.

■ Install in accordance with all local and national electrical codes.

■ CAUTION! Do not connect line voltage/mains cable to Class 2/

PELV terminals.

■ Earth/Ground terminal connection must be made as shown in

wiring diagrams.

■ Do not mix different load types on the same zone!

■ Fluorescent and electronic low voltage loads require

interfaces. Zone loads that exceed 800W/VA (1200W/VA for

AU models) and total unit loads that exceed the unit capacity

require power boosters. Refer to Appendices C, D, E, and F.

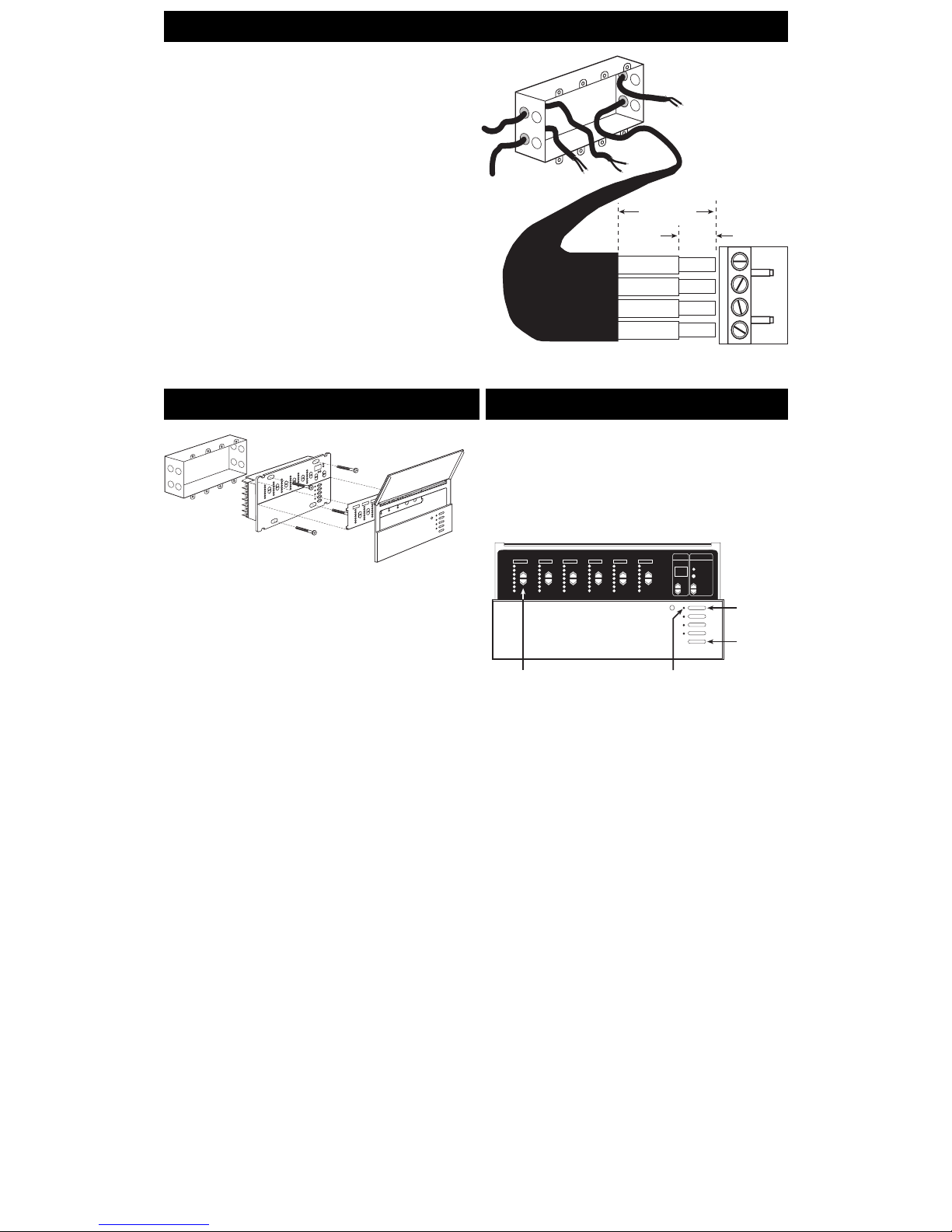

Wire the Control Unit (see Page 16)

1. Strip 1/2 in. (12 mm) insulation from all wires in wallbox and

connect them to appropriate terminals on the back of the

Control Units. The recommended installation torque is 9.0

in.

●

lbs. (1.0 N●m) for line voltage connections and 10 in.●lbs.

(1.3 N

●

m) for the earth/ground connection. Each power

terminal can accept up to two #12 AWG (2.5 mm

2

) wires. (Does

not apply to Class 2/PELV terminal block.)

3.5 in. (87 mm) DEEP RECOMMENDED

Class 2/PELV Wiring

M S

FADE TEMPORARY

MASTER

ZONES

ZONE 5 ZONE 6ZONE 3 ZONE 4ZONE 1 ZONE 2

Scene 1

button

OFF

Zone intensity raise and lower

buttons

Scene 1 LED

Page 4

1

2

3

4

LINE VOLTAGE/MAINS CABLE

CLASS 2/PELV

TERMINAL

CLASS 2/PELV CABLE

1.0 in. (25 mm)

3/8 in.

(9.5 mm)

LINE VOLTAGE/MAINS CABLE

1. Mount as shown using the four screws provided. (When mounted in

the wallbox, the Class 2/PELV cable and terminal block should

remain separated from the line voltage/mains cables.)

2. Reattach the faceplate to the Control Unit by pushing inward at each

corner.

Testing: Do the lights work?

IMPORTANT WIRING NOTES!

Review Appendix A BEFORE wiring!

■ Wallstations must be installed by a qualified electrician.

■ Wallstations use Class 2 or PELV wiring methods as applicable in your

locale.

— Using Class 2 wiring methods: Wallstations must be connected in

accordance with the 1996 National Electrical Code, Article 725-54(a),

(1) Exception No. 3 or the Canadian 1994 CE Code Handbook, Rule

16-212, Subrule (4). Check with your local electrical inspector to

comply with local codes and wiring practices.

— Using PELV wiring methods: Wallstations that are connected to

terminals 1—4 must always meet the requirements of DIN VDE 0100

Part 410 and IEC 60364-4-41 for PELV circuits. See “What is PELV?”

in Appendix A.

■ Wallstations must be mounted in a wallbox. Please refer to instruction sheet

included with each Wallstation to determine wallbox requirements.

■ Note that the NTGRX-1S can use line voltage/mains branch circuit wiring.

Refer to the installation instructions packaged with the Wallstation.

Connect Class 2/PELV wiring

only if your project has Wallstations

and/or more than one Control Unit

.

Use recommended cable as specified in Appendix A: More About

Class 2/PELV Wiring.

Wiring Note

■ Use the rearmost knockouts when pulling wires into the wallbox.

This will provide the most clearance when mounting the Control

Unit.

1. Strip 1 in. (25 mm) of insulation from the Class 2/PELV cable.

2. Strip 3/8 in. (8 mm) of insulation from each wire.

3. Connect the Class2/PELV wires to the Class 2/PELV

terminal block. Make sure no bare wire is exposed after

making connections. The recommended installation torque is

3.5 in.

●

lbs. (0.4 N●m) for Class 2/PELV connections.

4. The Class 2/PELV cable and terminal block should be separated

from line voltage/mains cables by at least 1/4 in. (7 mm).

Mounting

1. Restore Power.

2. Press Scene 1 button on front of the GRAFIK Eye Control

Unit. The Scene 1 LED will light.

3. Press zone

55

55

5 or

66

66

6 to raise or lower the light levels. Make

sure that the Control Unit is dimming all connected loads. Refer

to Appendix G: Troubleshooting, or call Lutron.

STEP 2: Installing Wallstations

Examples of Wallstations

NTGRX-2B-SL Entrance/Special Function Control

NTGRX-4S Scene Selection Control with Raise/

Lower

NTGRX-4S-IR Scene Selection Control/Infrared

Receiver

NTGRX-4B Scene Selection Control

NTGRX-4M Master Control

NTGRX-4PS Partition Control

GRX-CIR* Infrared Ceiling Receiver

GRX-4S-DW* ArchitraveTM Door Jamb Control

GRX-AV* Interface Control

GRX-RS232* RS-232 Interface Control

GRX-PRG* Personal Computer Interface

GRX-IT/GRX-8IT Infrared Handheld Transmitter

(see Appendix C)

EGRX-4S* European Style 4S Control

EGRX-4S-IR* European Style 4S Control/Infrared

Receiver

. . . and more!

Page 5

56

56

56

56

56

56

1234

1

2

3

4

5

6

7

8

1234

9

10

11

12

13

14

15

16

*

FOR THIS ADDRESS . . .

SET SWITCHES

LIKE THIS:

RECORD LOCATION

AND TYPE OF

CONTROL HERE

SET SWITCHES

LIKE THIS:

RECORD LOCATION

AND TYPE OF

CONTROL HERE

123456

1234

DIP SWITCHES 1—4

SET ADDRESS

567

567

567

567

567

567

567

567

Class 2/PELV

Terminal

Class 2/PELV Cable

123456

1

4

3

2

4

3

2

1

CU WIRE ONLY

USA: Class 2

IEC: PELV

CONTROL UNIT

WALLSTATION

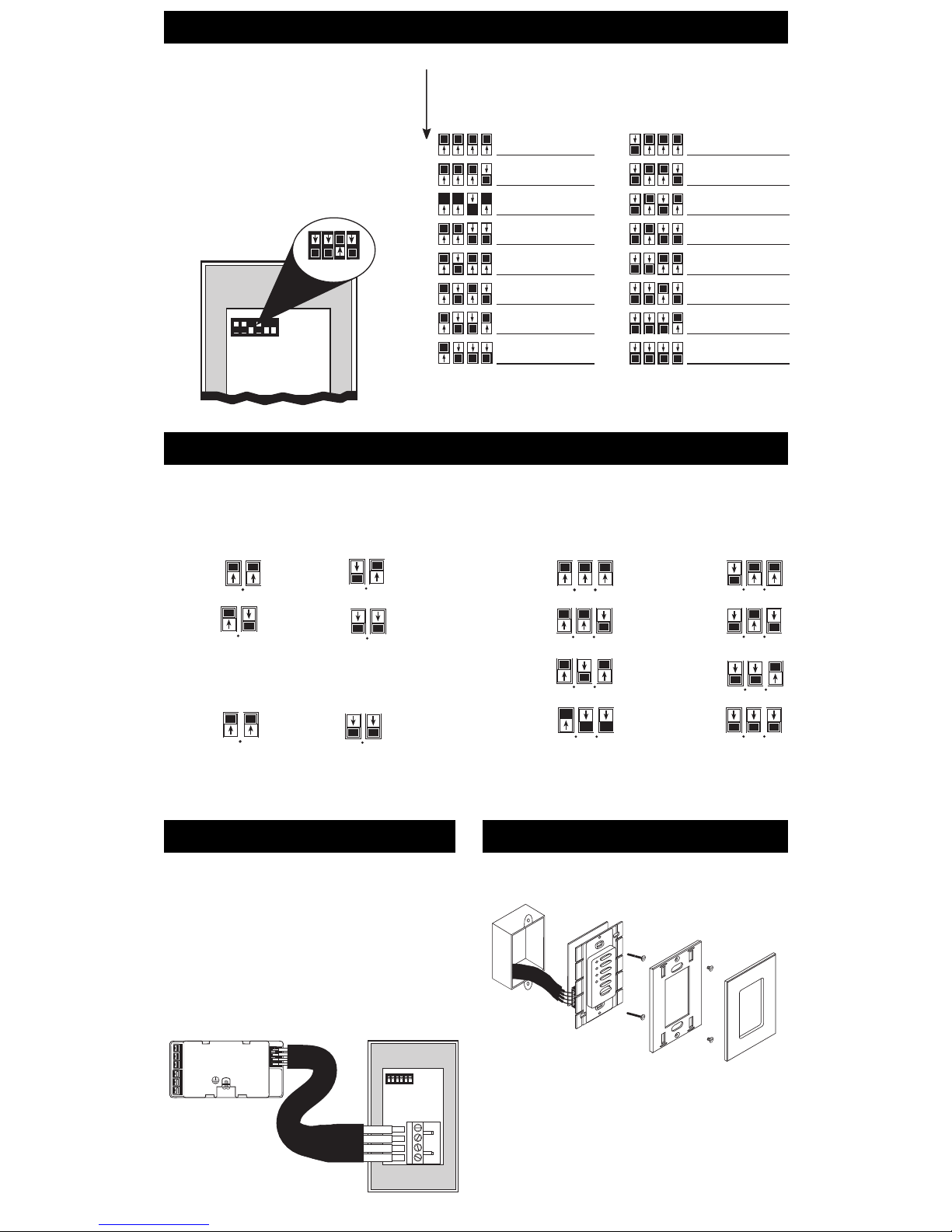

Set DIP switches 1—4 with unique system address

Each Wallstation must have a

unique

system address

(1—16) to identify the Wallstation and enable it to

communicate with the Control Unit(s).

To set its address, set DIP switches 1—4 to one of

the configurations shown at right (GRX-PRG

automatically assumes address 16). Document your

assignments by noting each Wallstation’s address.

* Reserved for GRX-PRG, if present on link.

Set DIP switches 5, 6 and/or 7 to specify function

For most Wallstations, you must also set DIP switches to specify exactly how the Wallstation is to function. Please refer to the Instructions

shipped with each Wallstation for more detailed information.

NTGRX-4S, -4S-DW, -4S-IR, -CIR, -4B

Scene Selection Control

Switches 5 and 6 determine which scenes the unit will select:

Scenes Scenes

1 to 4 9 to 12*

Scenes Scenes

5 to 8* 13 to 16*

NTGRX-4M

Master Control

Switches 5 and 6 determine whether bottom button turns lights on

or off:

ON OFF

only only

NTGRX-2B-SL

Multi-Control

Switches 5, 6 and 7 determine the function of the unit’s two buttons:

Scene 1 Fine Tuning

and Off Control

Scene 9/ Partition

Scene 10* Status

Scene 13/ Zone

Scene 14* Lockout

Panic Sequencing

Control Scenes 5—16*

* When using a Wallstation to access scenes 5—16, the scene LEDs will illuminate only on the Wallstation—not on the GRAFIK Eye

Control Unit.

Turn off power and wire

Review Appendix A: More About Class 2/PELV Wiring

before proceeding!

1. Mount 1-gang U.S. wallbox*, 2 3/4 in. deep (68 mm)

minimum.

2. Strip 3/8 in. (9 mm) insulation from both twisted pairs in the

wallbox.

3. Connect two #18 AWG (1.0 mm

2

) twisted pairs for Class 2/

PELV wiring (daisy-chain between stations)

†

.

4. Confirm all connections.

Mounting

Place twisted pairs in wallbox and mount as shown. Restore power.

* Some Wallstations have special mounting considerations. Please

refer to the detailed instructions supplied with each Wallstation.

† If shielded wire is used, the drain wire must also be daisy-

chained. Do not connect drain wire to earth/ground or

Wallstation (unless a “D” terminal is present).

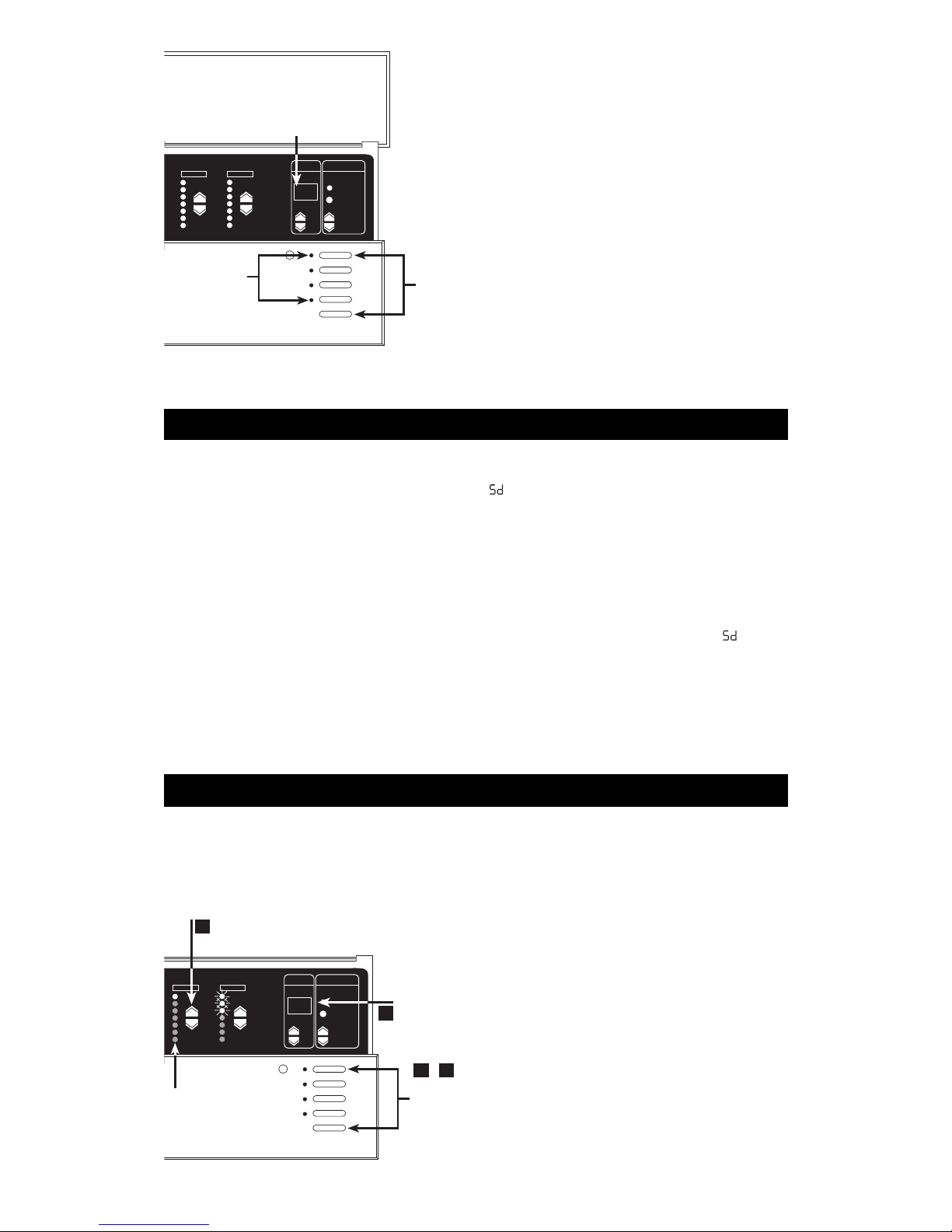

STEP 3: Setting Up GRAFIK Eye Control Units

Page 6

To enter setup mode: Press and hold the Scene 1 and OFF

button for about three seconds, until the scene LEDs start cycling.

To exit setup mode: Exit setup mode the same way you entered

it. Press and hold the Scene 1 and OFF button for about 3

seconds, until scene LEDs stop cycling. The Control Unit is out of

setup mode; back in normal operating mode.

In setup mode, the FADE window displays the setup codes. To

scroll through the menu of setup codes, press the FADE

5 or

5 buttons.

Identifying the load type for each zone

1. Enter setup mode. Press and hold Scene 1 and OFF buttons for

about 3 seconds, until scene LEDs cycle.

2. Check for LS in FADE window. (LS is the first code to appear

when you enter setup mode. For the LS mode, ZONE LEDs turn on

from top to bottom.)

3. Set each zone’s load type. Press ZONE

5 and 5 until

ZONE LEDs match the load type connected to each zone. Refer to

chart on next page.

4. Exit setup mode. Press and hold Scene 1 and OFF buttons for

about 3 seconds, until scene LEDs stop cycling.

In the 6-Zone Control Unit shown here:

■ Zone 5 is set for incandescent or magnetic low-voltage.

■ Zone 6 is set for neon/cold cathode.

This section shows how to set up a GRAFIK Eye Control Unit,

including:

■ Identifying the load type for each zone of lighting

connected to the Control Unit.

■ Setting up the scenes to create the desired lighting

effects, and make sure the Control Unit is working

correctly.

To set up the GRAFIK Eye Control Unit, enter the “setup

mode” and use the menu of setup codes that appear in the

FADE window. Step-by-step instructions for using the setup

codes are on the following pages.

How to enter and exit setup mode

The following is a list of the setup codes and their descriptions:

Code Stands for Description

Save Options Select from several save options (p.

9)

Sc Scene Set unaffected zones and set any of

the 16 scenes (p. 9)

A- Address Identify Control Units when setting

up system communications (p. 10)

LS* Load Select Identify load type (p. 7)

LE Low End Set low end trim (p. 8)

*When you enter setup mode, this code appears first.

■ If you press FADE 5, you will see A-, Sc, then .

■ If you press FADE 6, you will see LE.

Lutron ships GRAFIK Eye Control Units with all zones set for

incandescent/halogen (tungsten) lighting. If your project has nonincandescent loads, change all non-incandescent zones to the

correct load type.

FADE TEMPORARY

MASTER

ZONES

ZONE 5 ZONE 6

M S

LS

3

2

1 4

,

SET EACH ZONE’S LOAD TYPE

CHECK FOR LS

ENTER (EXIT)

SETUP MODE

ZONE LEDs

FADE TEMPORARY

MASTER

ZONES

ZONE 5 ZONE 6

M S

LS

TO ENTER (EXIT)

SETUP MODE:

PRESS AND HOLD FOR

ABOUT 3 SECONDS

UNTIL LEDs CYCLE

(STOP CYCLING)

LEDs

SCROLL THROUGH SETUP CODES

Loading...

Loading...