Grafik Eye 3000 Series, 3100, 3500 Installer's Manual

®

3000 Series

In stall er’s Guide

Control Unit Mod els 3100 and 3500

LUTRON

PLEASE READ

Section 1: Introduction

GRAFIK Eye® 3000 Series Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

System Communications and Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Section 2: Installing a GRAFIK Eye® Control Unit

Step 1: Test the Loads for Short Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Step 2: Turn the Power OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Step 3: Mount the Wallbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Step 4: Connect the Line Voltage/Mains Cables to the Control Unit . . . . . . . . . . . . . . . . . . . . 5

Step 5: Connect PELV (Class 2: USA) Cable to the Control Unit — Optional . . . . . . . . . . . . . 6

Step 6: Mount the Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Step 7: Test the Control Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Step 8: Connect the Wallstations — Optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Step 9: Connect Other Accessories — Optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Step 10: Connect Multiple Control Units — Optional. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Special Mounting Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installing an External Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Section 3: Programming a GRAFIK Eye® Control Unit

Control Unit Buttons and Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Entering and Exiting Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Identifying the Load Type for Each Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Programming Scenes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Adjusting High or Low End Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Selecting the Save Mode You Want to Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Section 4: Using the GRAFIK Eye® Control Unit

Selecting Scenes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Temporarily Adjusting Light Levels and Shade Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Setting Up System Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Appendix A: Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

English

Español Français Português NederlandsDeutsch

Chinese

This installer’s guide explains how to install and program a GRAFIK Eye 3000 Series control unit. Use this guide

in conjunction with installation instructions supplied separately with other GRAFIK Eye 3000 Series products.

R

LUTRON-Quality Systems

Reg is tered to ISO 9001

Italiano

R

Section 1:

M S

FADE TEMPORARY

MASTER

ZONES

ZONE 5 ZONE 6ZONE 3 ZONE 4ZONE 1 ZONE 2

Introduction

This section of the installer’s guide introduces the GRAFIK Eye 3000 Series lighting system

and control unit. This section also describes system communications and capacities. Read this

Introduction carefully before proceeding to the installation instructions beginning on page 4.

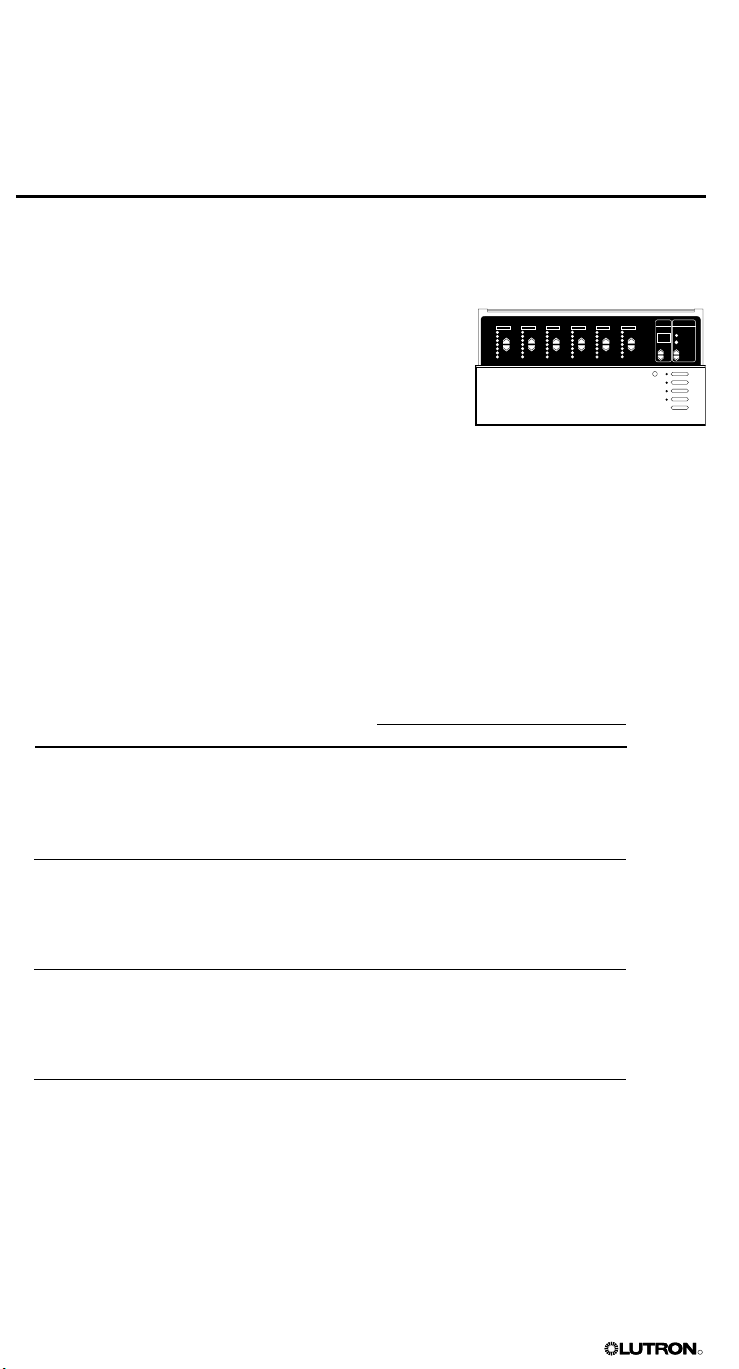

GRAFIK Eye® 3000 Series Control Unit

The GRAFIK Eye is part of a lighting control system that enables you to create customized

scenes and control lighting and shade zones.

The control unit is the centerpiece of the lighting control system. The control unit provides:

• Setup of lighting and shade control scenes using buttons on

the control unit.

• Pushbutton recall of four preset scenes, plus OFF.

• 12 additional scenes stored in the control unit, which are

accessible via optional wallstations and other control devices.

• Control of 2, 3, 4, or 6 zones.

• Smooth light level fading between scenes.

• Lockout options to prevent accidental changes.

• A built-in infrared receiver for operation with an optional remote control.

All of this can be accomplished on a single control unit. Up to 8 control units can be connected

together along with wallstations,

add additional control functions.

Additional features available with a 3500 model are accessed through PC control and include:

• Lighting level increments of 1%

• Virtual control through Liaison

• Shade control through RS232 interface

sensors, and other control interfaces to enlarge the system and

TM software

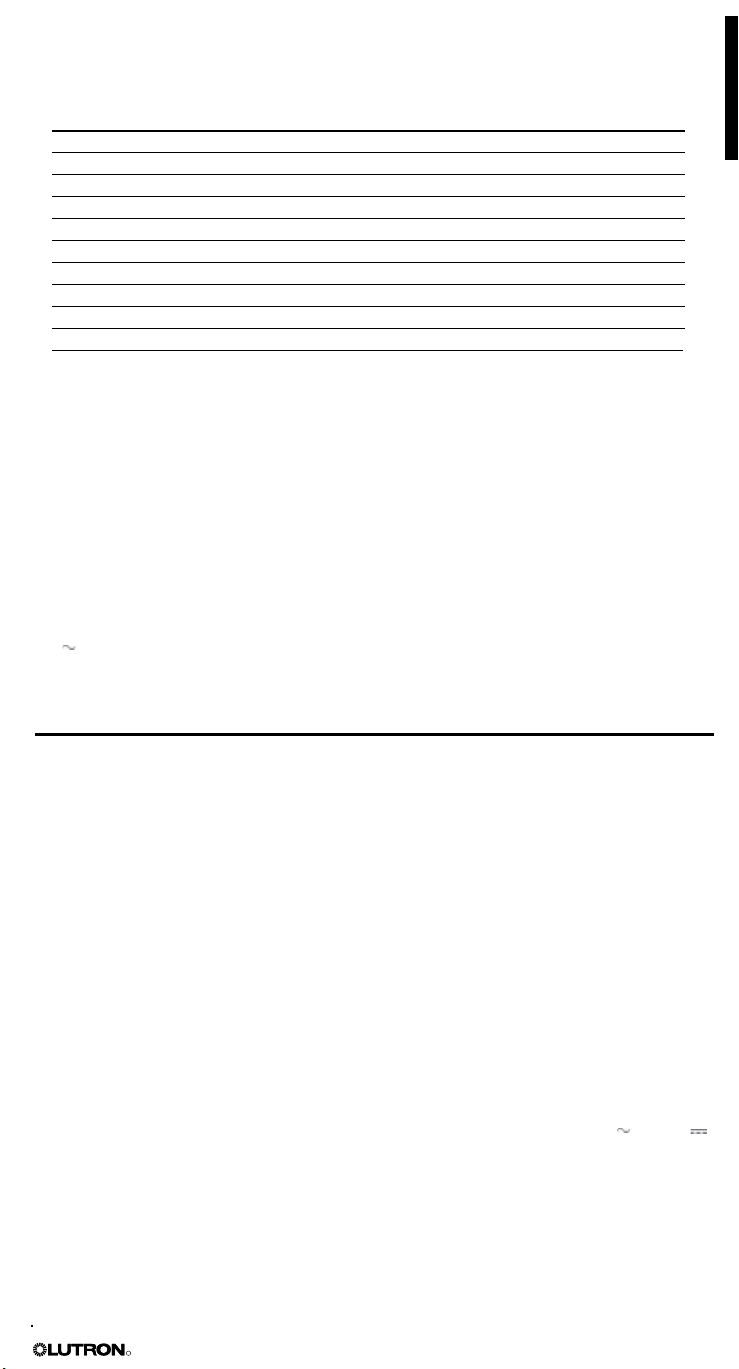

Model Numbers and Ratings

Model Number Voltage Ratings

50/60 Hz Unit Maximums Zone Ranges

2 Zones

GRX-3102, GRX-3502 120 V~ 1200 W/VA 25-800 W

GRX-3102-CE, GRX-3502-CE 230 V~ 1600 W/VA 40-800 W

GRX-3102-AU, GRX-3502-AU 220-240 V~ 1600 W/VA 40-1200 W

GRX-3102-JA, GRX-3502-JA 100 V~ 1050 W/VA 25-600 W

3 Zones

GRX-3103, GRX-3503 120 V~ 1500 W/VA 25-800 W

GRX-3103-CE, GRX-3503-CE 230 V~ 2300 W/VA 40-800 W

GRX-3103-AU, GRX-3503-AU 220-240 V~ 2400 W/VA 40-1200 W

GRX-3103-JA, GRX-3503-JA 100 V~ 1250 W/VA 25-600 W

4 Zones

GRX-3104, GRX-3504 120 V~ 2000 W/VA 25-800 W

GRX-3104-CE, GRX-3504-CE 230 V~ 2300 W/VA 40-800 W

GRX-3104-AU, GRX-3504-AU 220-240 V~ 3000 W/VA 40-1200 W

GRX-3104-JA, GRX-3504-JA 100 V~ 1600 W/VA 25-600 W

6 Zones

GRX-3106, GRX-3506 120 V~ 2000 W/VA 25-800 W

GRX-3106-CE, GRX-3506-CE 230 V~ 2300 W/VA 40-800 W

GRX-3106-AU, GRX-3506-AU 220-240 V~ 3000 W/VA 40-1200 W

GRX-3106-JA, GRX-3506-JA 100 V~ 1600 W/VA 25-600 W

Sources/Load Types

Control units can control incandescent, halogen (tungsten), magnetic low-voltage, and neon/

cold cathode load types. Electronic low-voltage and fluorescent load types, as well as shades,

can be controlled with appropriate interfaces.

2 GRAFIK Eye® 3000 Series Control Unit Installer’s Guide

R

Factory Presets

Lutron ships each control unit with the following factory presets (A- mode). In this mode,

control units and lighting wallstations communicate with no additional programming.

Setting Factory Preset

Address Not addressed (set to factory default A-)

Load type All zones set to incandescent

Scene 1 100% intensity for all zones

Scene 2 75% intensity for all zones

Scene 3 50% intensity for all zones

Scene 4 25% intensity for all zones

Scenes 5-16 100% intensity for all zones

OFF (scene 0) All zones OFF

Fade times 3 seconds between all scenes; 10-second fade time to OFF

Fade time from OFF 4 seconds to any scene (not adjustable)

Save mode Sd (save by default)

Note: Scene fade time affects lights but not shades; shades move immediately to their

programmed level.

Accessories

Depending on the size and requirements of the lighting system, control units can be configured

to work with a variety of optional accessories, including:

• Low-voltage wallstations. Wallstations, shade controllers, infrared (IR) sensors and receivers,

and door-jamb controls.

• Control interfaces. Contact closure devices, RS232 and Ethernet digital communications.

astronomic timeclock, and programming interface for GRAFIK Eye LiaisonTM software.

• Load interfaces. Required for any loads exceeding the maximum zone capacity (see page 2),

as well as Lutron 3-wire fluorescent dimming ballasts, electronic low-voltage lighting, and 277

V loads.

For part numbers and additional information on GRAFIK Eye 3000 Series accessories, visit

www.lutron.com.

System Communications and Capacities

PELV (Class 2: USA) cable can be used to connect GRAFIK Eye 3000 control units,

wallstations, and other accessories. You can link up to 8 control units to control up to 48

zones, and add up to 16 wallstations and 8 shade controllers (SG-SVC) for a total of 32 control

points. Note that wallstations control scenes (which can include light and shade settings);

shade controllers control only shades.

PELV (Class 2: USA) Cables

If your lighting system uses wallstations and/or multiple control units, PELV (Class 2: USA)

wiring is needed to supply power and carry communications between the control units and the

wallstations. PELV (Class 2: USA) wiring is also needed to connect other accessories.

Use properly certified PELV (Class 2: USA) cable. Each twisted pair in the PELV (Class 2: USA)

wiring link should consist of two #18 AWG (1.0 mm2 ) stranded conductors.

• One pair is for the low-voltage power wiring.

• The second pair is for a data link (up to 2000 ft/610 m long).

Note: Lutron offers a one-cable, low-voltage solution: P/N GRX-CBL-346S (non-plenum) or

GRX-PCBL-346S (plenum). Check availability and applicable electrical codes in your area.

In countries that abide by the IEC regulations, PELV is commonly referred to as Protective ExtraLow Voltage. A PELV circuit is a grounded circuit in which the voltage cannot exceed 50 V or 120 V

ripple-free. The power source must be supplied by a safety isolating transformer or equivalent.

Recommended unshielded cables include:

• For non-plenum installations, use (2) Belden 9470, (1) Belden 9156, or (2) Liberty 181P/2C-EX-

GRN, or equivalent.

• For plenum installations, use (2) Belden 82740, or equivalent.

In Europe, acceptable types of cable include HAR certified cable with insulated cores

enclosed in a sheath. This cable must bear the appropriate certification mark pertaining to

national wiring rules for fixed installations. If certified cable with insulated cores enclosed in a

sheath is used for the power cables, the PELV wiring can be any of the cables listed above.

GRAFIK Eye® 3000 Series Control Unit Installer’s Guide 3

R

Section 2:

Installing a GRAFIK Eye® Control Unit

This section explains how to install a GRAFIK Eye control unit and make sure it is properly

operating all connected loads.

DANGER! GRAFIK Eye 3000 Series control units

in accordance with all applicable regulations and building codes. Improper wiring can result

in personal injury or damage to control units or other equipment. Always turn off circuit

breaker or remove main fuse from power line before doing any work. To avoid overheating

and possible damage to equipment, do not install dimming devices to dim receptacles,

motor-operated appliances, or fluorescent lighting not equipped with Lutron Hi-lume®,

Eco-10TM, or Tu-Wire® electronic dimming ballasts, or devices approved for your location.

In dimmed magnetic low-voltage circuits, you can prevent transformer overheating and failure by avoiding excessively high current flow: Do not operate control units with any lamps

removed or burned out; replace any burned out lamps immediately; use only transformers

that incorporate thermal protection or fused primary windings. Control units are designed

for residential and commercial use, for indoor use only.

Important Information about Loads and Wallboxes

GRAFIK Eye 3000 Series control units can control incandescent, halogen (tungsten), magnetic

low-voltage, and neon/cold cathode load types. Many dimmable fluorescent, electronic lowvoltage, and shade loads can be controlled with appropriate interfaces.

• All electronic low-voltage (ELV) lighting used with the electronic low-voltage interface must be

rated for reverse phase-control dimming, also known as trailing edge dimming. Before

installing an ELV light source, verify with the manufacturer that their transformer can be dimmed.

When dimming, an electronic low-voltage interface MUST be used with the control unit.

• Contact Lutron or refer to your job drawings for information on other product interfaces.

• Not all zones on the control unit need to be connected; however, connected zones must have a

load of at least 25 W (40 W for AU and CE models).

• No zone may be loaded with more than 800 W (1200 W for AU models).

• See page 2 for maximum unit ratings.

must be installed by a qualified electrician

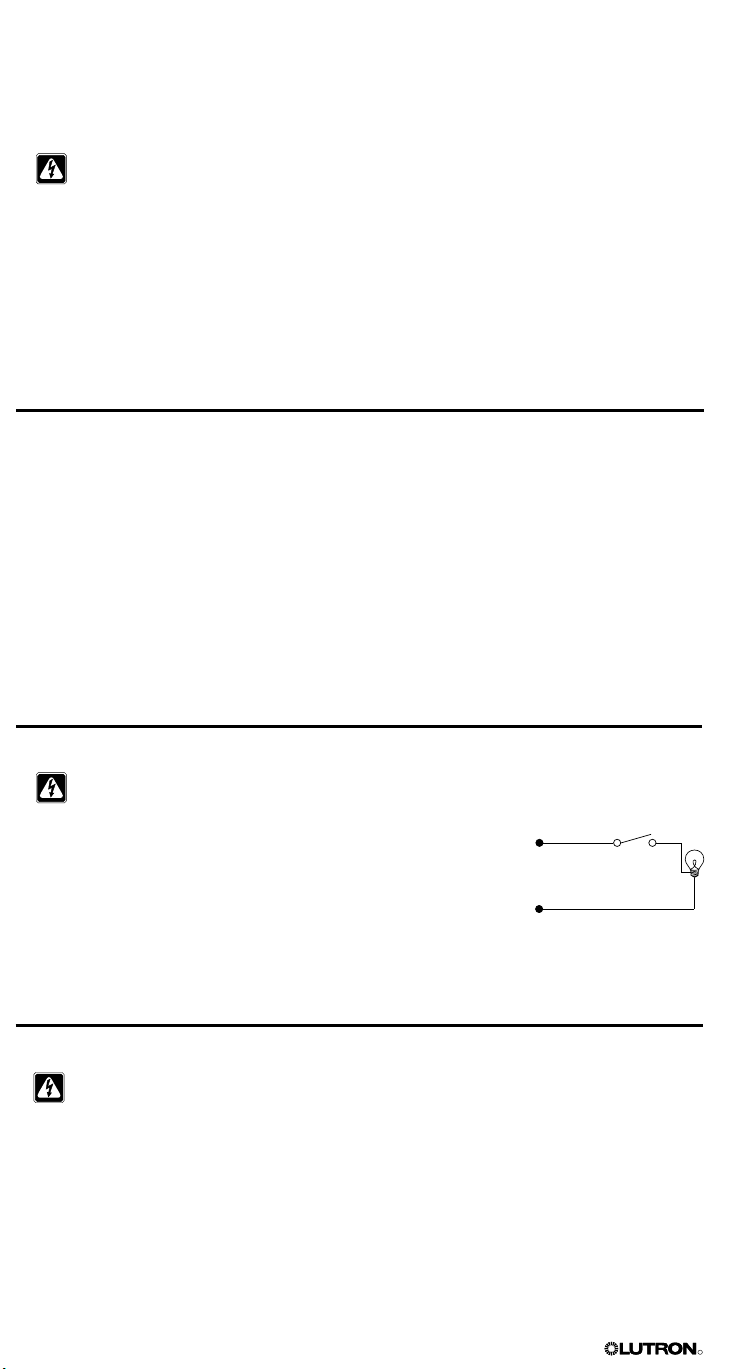

Step 1: Test the Loads for Short Circuits

CAUTION! Before connecting the loads to the control unit, test the loads for short-circuits.

1. Turn power OFF at the circuit breaker or fuse box.

2. Connect a standard light switch between the live lead and load wire to

test the circuit.

3. Turn power ON and check for short or open circuits. If load does not

operate, the circuit is open. If the breaker/MCB trips (fuse blows or

opens), a load short may exist. Correct short or open circuits and test

again.

Hot/Live

Neutral

Step 2: Turn the Power OFF

CAUTION! Before continuing with the installation, make sure the power is turned OFF at

the circuit breaker or fuse box. Do not perform any wiring with the power ON.

Switch

Load

4 GRAFIK Eye® 3000 Series Control Unit Installer’s Guide

R

Step 3: Mount the Wallbox

230V

˜

LUTRON

5

0/6

0H

z

LO

AD

P

E

R

ZONE:

40 - 80

0

W

M

AX

UNIT LO

A

D: 1

0

A, 2300W

P

rese

t

Ligh

ting C

o

ntro

l

LIVE TERMINALS

AT

RE

AR

DO NOT WIRE LIVE

U.

K. 0

71

-70

2

-0657

U

.

S.

A

. (610) 282

-3

800

CO

O

PERS

B

UR

G

,

PA U

SA 18

0

36

GR

X-3104-

CE

UP

Ma

d

e in U

.S.A.

1

2V

S

E

LV

O

UTPU

T

!

CB

E

5

145-0

49

G

R

X

-Z

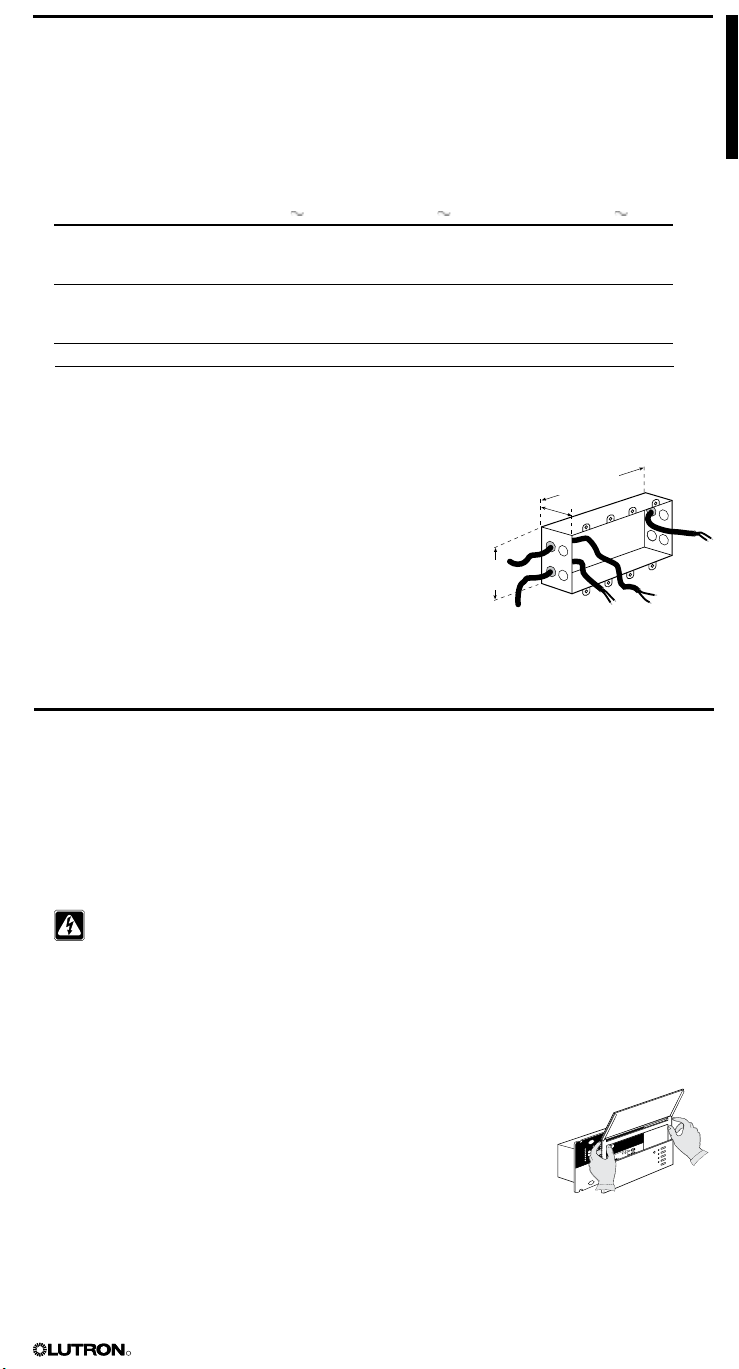

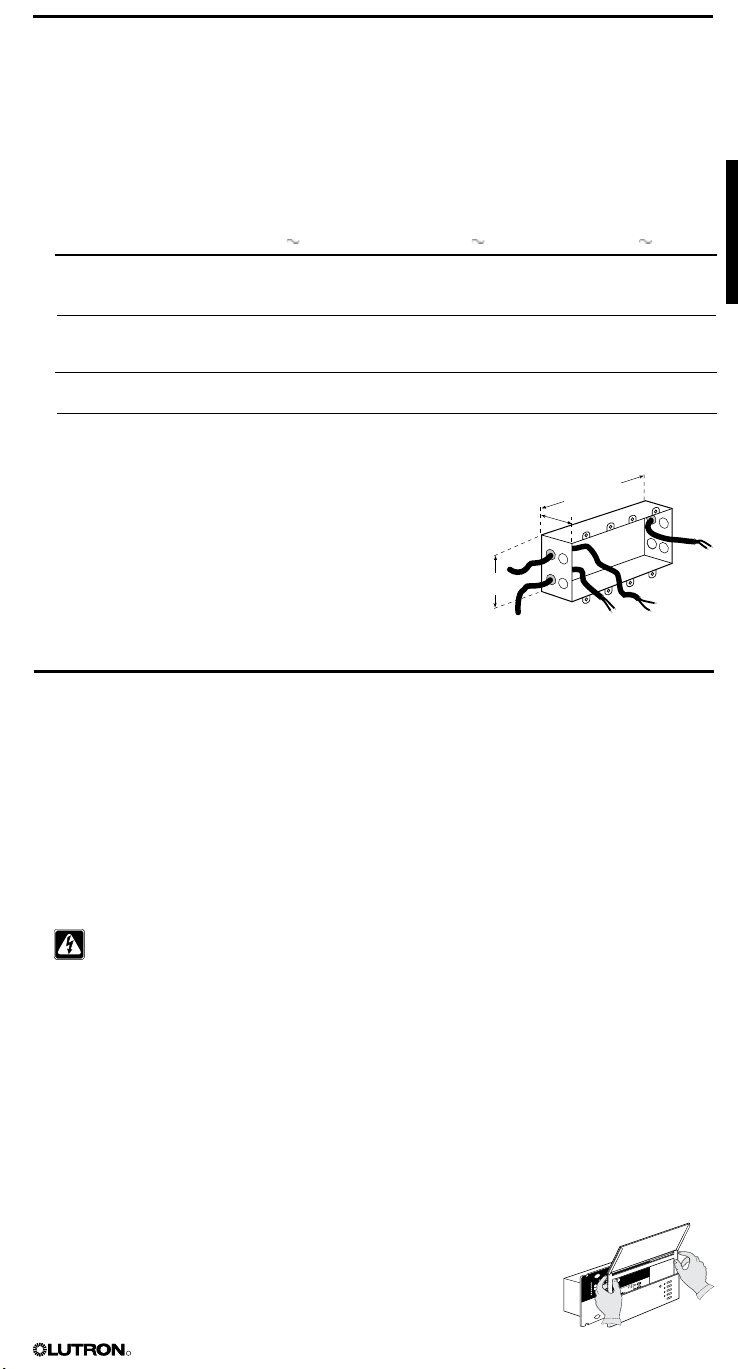

1. Mount a standard U.S. wallbox on a dry, flat indoor surface that is accessible and allows for

system programming and operation. See the table below for the recommended wallbox for

each model.

Use a minimum depth of 2 3/4 in. (68 mm), preferably 3 1/2 in. (87 mm). Allow at least 4 1/2 in.

(110 mm) clearance above and below the faceplate to ensure proper heat dissipation. Allow

1 in. (25

NOTE: For mounting in a panel, refer to page 10.

2. Pull the line voltage/mains cables into the wallbox using

If the control unit will be connected to wallstations and/

mm) for faceplate overhang on all sides.

Control Unit Model 100-120 V 230 V (CE) 220-240 V (AU)

GRX-3102/3502 2-gang wallbox 4-gang wallbox 2-gang wallbox

or two single-gang or two single-gang

wallboxes wallboxes

GRX-3103/3503 3-gang wallbox 4-gang wallbox 3-gang wallbox

or three single-gang or three single-gang

wallboxes wallboxes

GRX-3104/3504 4-gang wallbox 4-gang wallbox 4-gang wallbox

GRX-3106/3506 4-gang wallbox 4-gang wallbox 4-gang wallbox

NOTE: Single-gang wallbox P/N 241218; 4-gang wallbox P/N 241400.

7.9 in.

the rearmost knockouts. This will provide the most

clearance when mounting the control unit.

(87 mm)

(200 mm)

3.5 in.

or additional control units, also pull the PELV (Class 2:

USA) cabling into the wallbox using the remaining

rearmost knockout (refer to page 7). Use recommended

3.75 in.

(95 mm)

cable as specified in “PELV (Class 2: USA) Cables” on

page 3.

Step 4: Connect the Line Voltage/Mains Cables to the Control Unit

Important Wiring Information

• Use properly certified cable for all line voltage/mains cables.

• Proper short-circuit and overload protection must be provided at the distribution panel. You

can use up to a 20 A (16 A for AU, and 10 A for CE models) maximum circuit breaker/MCB or

equivalent (tripping curve C according to IEC60898/EN60898 is recommended) with adequate

short-circuit breaking capacity for your installation.

• Install in accordance with all local and national electrical codes.

CAUTION! Do not connect line voltage/mains cable to PELV (Class 2: USA) terminals.

• Earth/ground terminal connection must be made as shown in wiring diagrams on page 6.

• Do not mix different load types on the same zone!

• See page 3 for devices that require interfaces. Wire as specified in the interface documentation.

• The line voltage/mains cables should be separated from the PELV (Class 2: USA) cable and

terminal block by at least 1/4 in. (7 mm).

To connect the line voltage/mains cables to the control unit:

1. Remove the control unit’s cover and hinged faceplate by pulling

outward at each corner.

2. Strip 1/2 in. (12 mm) of insulation off the line voltage/mains cables in

the wallbox.

3. Connect the line voltage, ground, and load wires to the appropriate

terminals on the back of the control unit, as shown on page 6 for

GRX, GRX-AU and GRX-CE models.

The recommended installation torque is 9.0 in.-lbs. (1.0 N•m) for line voltage connections and

10 in.-lbs. (1.3 N•m) for the earth/ground connection. Each power terminal can accept up to

two #12 AWG (2.5 mm2 ) wires. This does not apply to the PELV (Class 2: USA) terminal block.

GRAFIK Eye® 3000 Series Control Unit Installer’s Guide 5

R

N

L

SSA

GRX-3106-CE

ZONE: 40 - 800 W/VA

10 A 2300 W/VA

Coopersburg, PA 18036 USA

:

ZONE 4

ZONE 6

HOT/LIVE

SSA

CU WIRE ONLY

ZONE 2

Class 2

1 2 3 4

ZONE 3

ZONE 5

NEUTRAL

ZONE 1

USA

CLASS 2

IEC

PELV

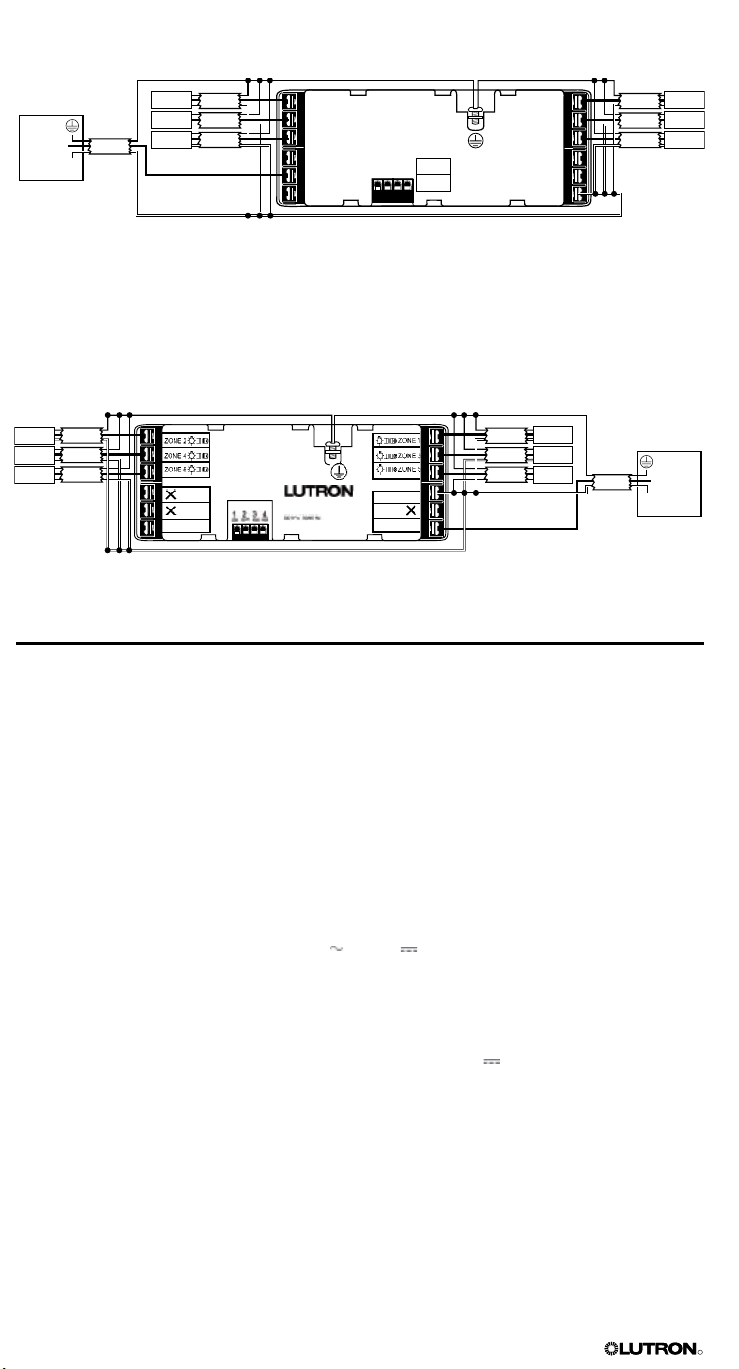

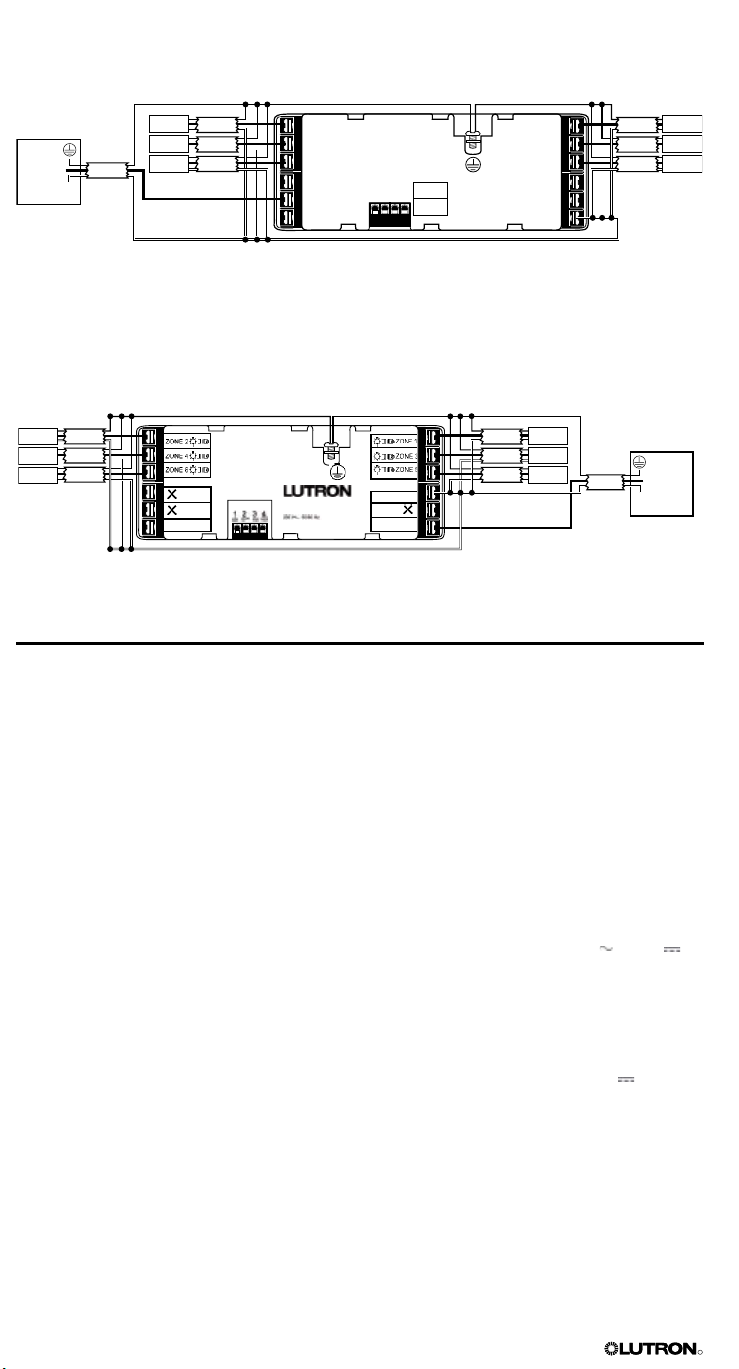

Line Voltage/Mains Connections for GRX* and GRX-AU* Models (6-Zone Unit Shown)

Earth/ground from distribution panel

Distribution

panel

Hot/

Live

N

2 #12 AWG

Input power from

distribution panel

Load 2

Load 4

Load 6

2 #12 AWG

2 #12 AWG

2 #12 AWG

2 #12 AWG

2 #12 AWG

2 #12 AWG

Neutral from distribution panel

Line Voltage/Mains Connections for GRX-CE Models* (6-Zone Unit Shown)

Earth/ground from distribution panel

Load 1

Load 3

Load 5

Load 2

Load 4

Load 6

2 2.5 mm

2 2.5 mm

2

2

2

2 2.5 mm

* For phase-to-phase and delta-feed wiring, contact Lutron.

2

2 2.5 mm

Load 1

2

2 2.5 mm

Load 3

2

2 2.5 mm

Load 5

Neutral from

distribution panel

Input power from

distribution panel

Distribution panel

Hot/

2

2 2.5 mm

Live

N

Step 5: Connect PELV (Class 2: USA) Cable to the

Control Unit — Optional

If your lighting system uses wallstations and/or multiple control units, PELV (Class 2: USA)

wiring is needed to supply power and carry communications between the control units and the

wallstations.

Important Wiring Information

• Lutron requires that you connect (daisy-chain) control units and wallstations with two twisted

pairs for operation. Each twisted pair in the PELV (Class 2: USA) wiring link should consist of

two #18 AWG (1.0 mm2) stranded conductors.

• Use properly certified PELV (Class 2: USA) cable. For a description of recommended cable

types, refer to “PELV (Class 2: USA) Cables” on page 3.

• Install in accordance with all local and national electrical codes.

• Wallstation circuits are classified as Class 2 (USA) and PELV (IEC) circuits. Unless otherwise

specified, the voltages do not exceed 24 V or 15 V . As Class 2 circuits, they comply

with the requirements of NFPA 70®, National Electrical Code® (NEC®). As PELV circuits, they

comply with the requirements of IEC 60364-4-41, VDE 0100 Part 410, BS7671:1992, and other

equivalent standards. External circuits connected to input, output, RS232, Ethernet, DMX512,

and other communication terminals or wallstations, must be supplied from a Listed Class 2

source or comply with the requirements for PELV circuits as applicable in your country.

• The control unit’s low-voltage PELV (Class 2: USA) circuit is 12 V .

• The PELV (Class 2: USA) cable and terminal block should be separated from the line voltage/

mains cables by at least 1/4 in. (7 mm).

6 GRAFIK Eye® 3000 Series Control Unit Installer’s Guide

R

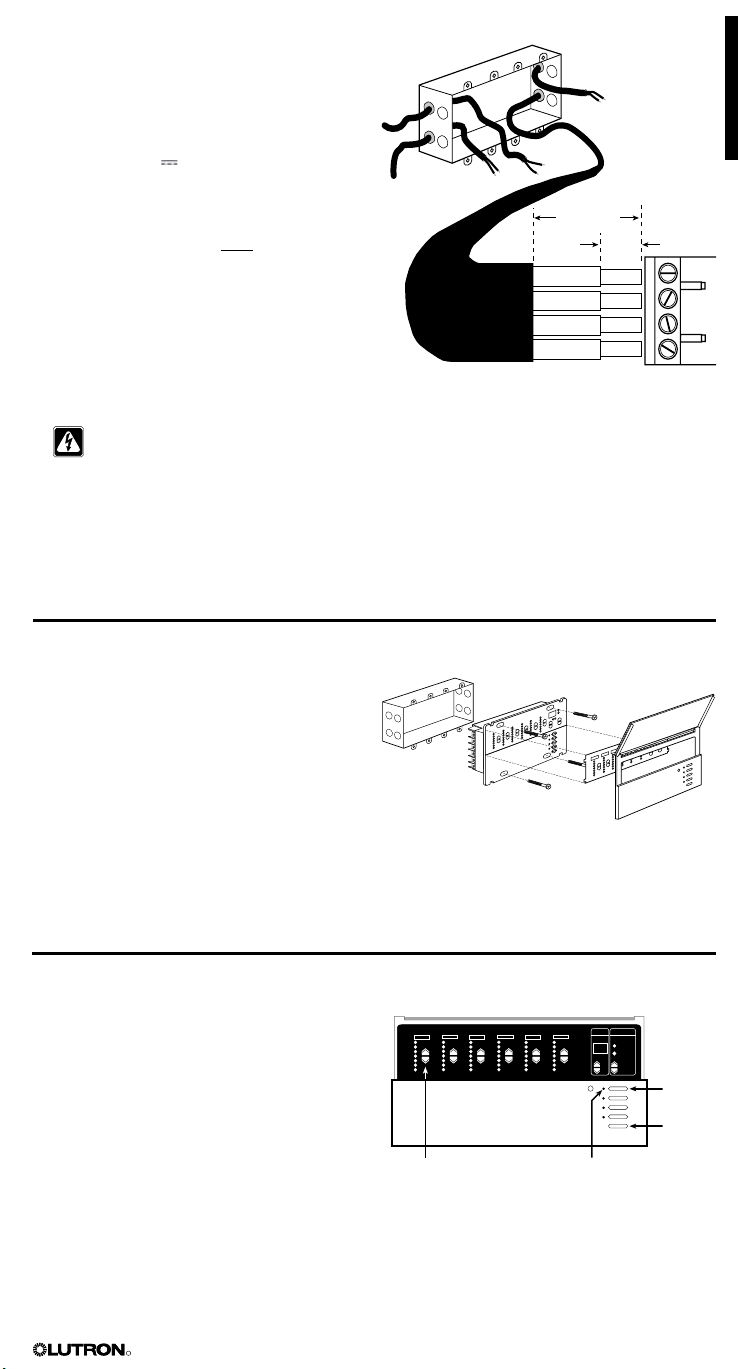

To connect the PELV (Class 2: USA) wires to the control unit:

1

2

3

4

M S

FADE TEMPORAR Y

MASTER

ZONES

ZONE 5 ZONE 6ZONE 3 ZONE 4ZONE 1 ZONE 2

1. Strip 1 in. (25 mm) of insulation from the

PELV (Class 2: USA) cable in the wallbox.

2. Strip 3/8 in. (9.5 mm) of insulation from each

wire.

3. Connect the twisted pair for low-voltage

power wiring to terminal 1 (common) and

terminal 2 (12 V ) on the control unit.

NOTE: You will daisy-chain this low-voltage

power wiring to wallstations and/or other

Line voltage/mains

cable

control units. Refer to pages 8 and 9.

4. Connect the twiste

d pair data link to terminal

3 (MUX) and terminal 4 (MUX) of the control

unit.

NOTE: You will daisy-chain this data link to

wallstations and/or other control units. Refer

to pages 8 and 9.

5. If shielded wire is used, connect the drain

wires to each other or to terminal D on the

wallstation, if present. Do NOT connect drain

2 pair #18 AWG

(1.0 mm2)

wires to earth/ground.

WARNING! Make sure no bare wire

is exposed after making connections.

The recommended installation torque is

3.5 in.-lbs. (0.4 N•m) for PELV (Class

2: USA) connections.

Line voltage/mains

cable

PELV (Class 2:

USA) cable

1.0 in.

(25 mm)

3/8 in.

(9.5 mm)

PELV (Class 2:

USA) terminals

Step 6: Mount the Control Unit

1. Mount the control unit in the wallbox as shown

using the four screws provided.

NOTE: Make sure the PELV (Class 2: USA)

cable and terminal block remain separated

from the line voltage/mains cables when the

control unit is mounted in the wallbox.

2. Reattach the cover and faceplate to the

control unit by pushing inward at each corner.

Step 7: Test the Control Unit

1. Turn the power ON.

2. Press the SCENE 1 button on the front of the

control unit. The Scene 1 LED will light.

3. Press the 5 or 6 button for each zone and

verify that the control unit is controlling all

connected loads. If not, refer to Appendix

A: Troubleshooting, or call Lutron Technical

Support.

ZONE intensity

raise

and lower

buttons

Scene 1 LED

SCENE 1

button

OFF

GRAFIK Eye® 3000 Series Control Unit Installer’s Guide 7

R

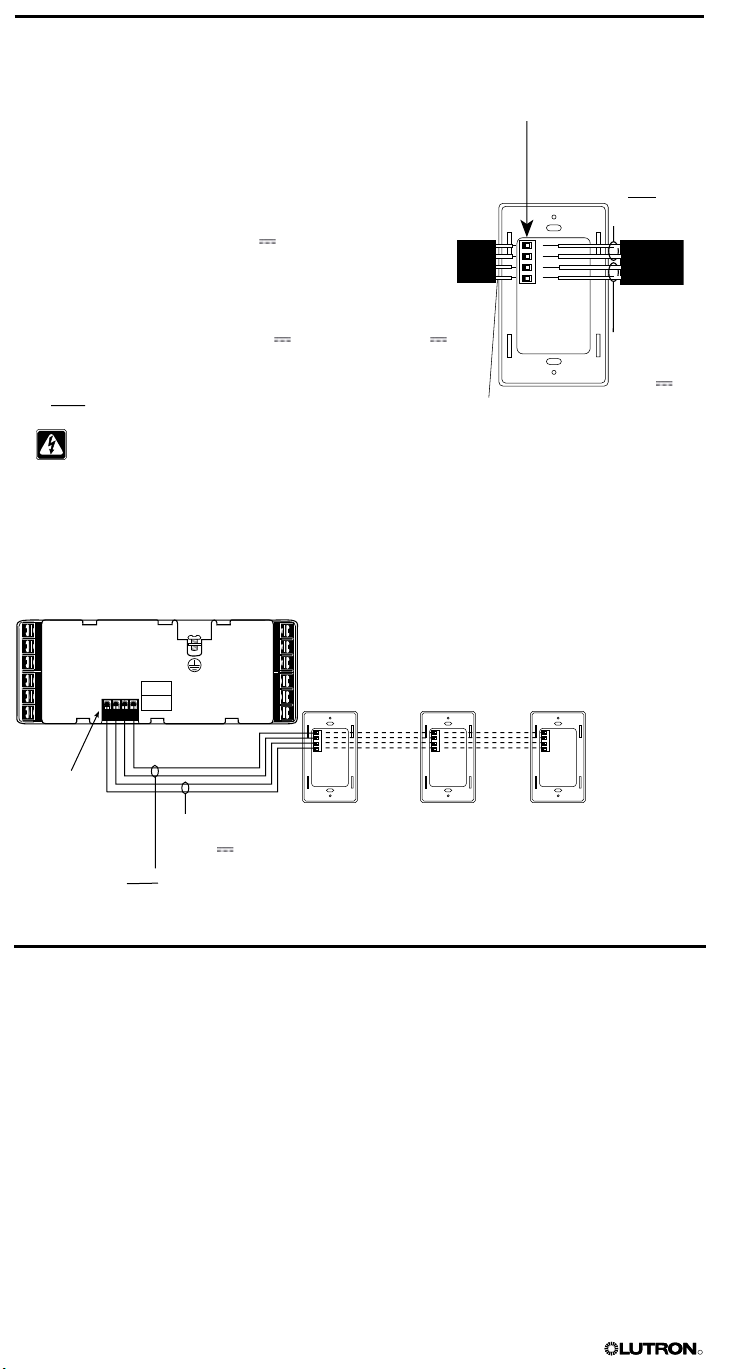

Step 8: Connect the Wallstations — Optional

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

ZONE 4

ZONE 6

HOT/LIVE

SSA

CU WIRE ONLY

ZONE 2

Class 2

1 2 3 4

ZONE 3

ZONE 5

NEUTRAL

ZONE 1

USA

CLASS 2

IEC

PELV

If your lighting system uses wallstations, make the appropriate connections at the wallstation

using PELV (Class 2: USA) cabling.

NOTE: For procedures on how to install and address

wallstations, refer to the separate instructions included with

each device. Wallstations must be installed by a qualified

electrician in accordance with all local and national electrical

codes.

1. Daisy-chain the PELV (Class 2: USA) twisted pair for low-

voltage power wiring from the control unit to terminal

1 (common) and terminal 2 (12 V ) on up to three

wallstations.

2. Terminate the terminal 2 connection so that the control unit

supplies power to a maximum of three wallstations.

NOTE: To power more than three wallstations from one

control unit, install an external 12 V power supply (15 V

for CE/AU models). Refer to page 10 for instructions.

3. Daisy-chain the PELV (Class 2: USA) twisted pair data

link from the control unit to terminal 3 (MUX) and terminal

4 (MUX) on each wallstation.

WARNING! Make sure no bare wire is exposed after

making connections. The recommended installation

torque is 3.5 in.-lbs. (0.4 N•m) for PELV (Class 2: USA)

connections.

Control Unit Connected to Three Wallstations

GRAFIK Eye

3000 control unit

Each terminal can accept

2 #18 AWG (1.0 mm2) wires

2 twisted pairs

#18 AWG

(1.0 mm2)

Data link:

4: MUX

3: MUX

PELV

(Class 2: USA)

power

2: 12 V

1: common

wiring:

Wallstation Wallstation Wallstation

Each

terminal

can accept

2 #18 AWG

(1.0 mm2)

wires

Data link:

4: MUX

3: MUX

PELV (Class 2: USA)

power wiring:

2: 12 V

1: common

Maximum of 1000 ft. (300 m) between the

GRAFIK Eye control unit

and the third wallstation.

For longer distances or to power more than three

wallstations, see page 10.

Step 9: Connect Other Accessories — Optional

If your lighting system uses accessories other than wallstations (shade controllers, interface

devices, and power boosters), make the connections at the accessory using the appropriate

wiring.

For procedures on how to install and connect accessories, refer to the separate instructions

provided with each accessory.

Important Wiring Information

• Accessories must be installed by a qualified electrician in accordance with all local and national

• Use properly certified cable as described in the instructions shipped with the accessory.

electrical codes.

8 GRAFIK Eye® 3000 Series Control Unit Installer’s Guide

R

4

3

2

1

4 3 2 1

1 2 3 4

1 2 3 4

4 3 2 1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

Step 10: Connect Multiple Control Units — Optional

If your lighting system has multiple control units, connect them using PELV (Class 2: USA)

cabling as described here.

1. Daisy-chain the PELV (Class 2: USA) cabling to terminal 1, terminal 2, terminal 3, and terminal 4

on all control units and wallstations.

NOTE: To power more than three wallstations from one control unit, install an external 12 V

or 15 V power supply. Refer to page 10 for instructions.

2. Since each control unit has its own power supply, terminate the terminal 2 connection so that:

• Each control unit supplies power to a maximum of three wallstations.

• Each wallstation receives power from only one control unit.

WARNING! Make sure no bare

mended installation torque is 3.5 in.-lbs. (0.4 N•m) for PELV (Class 2: USA) connections.

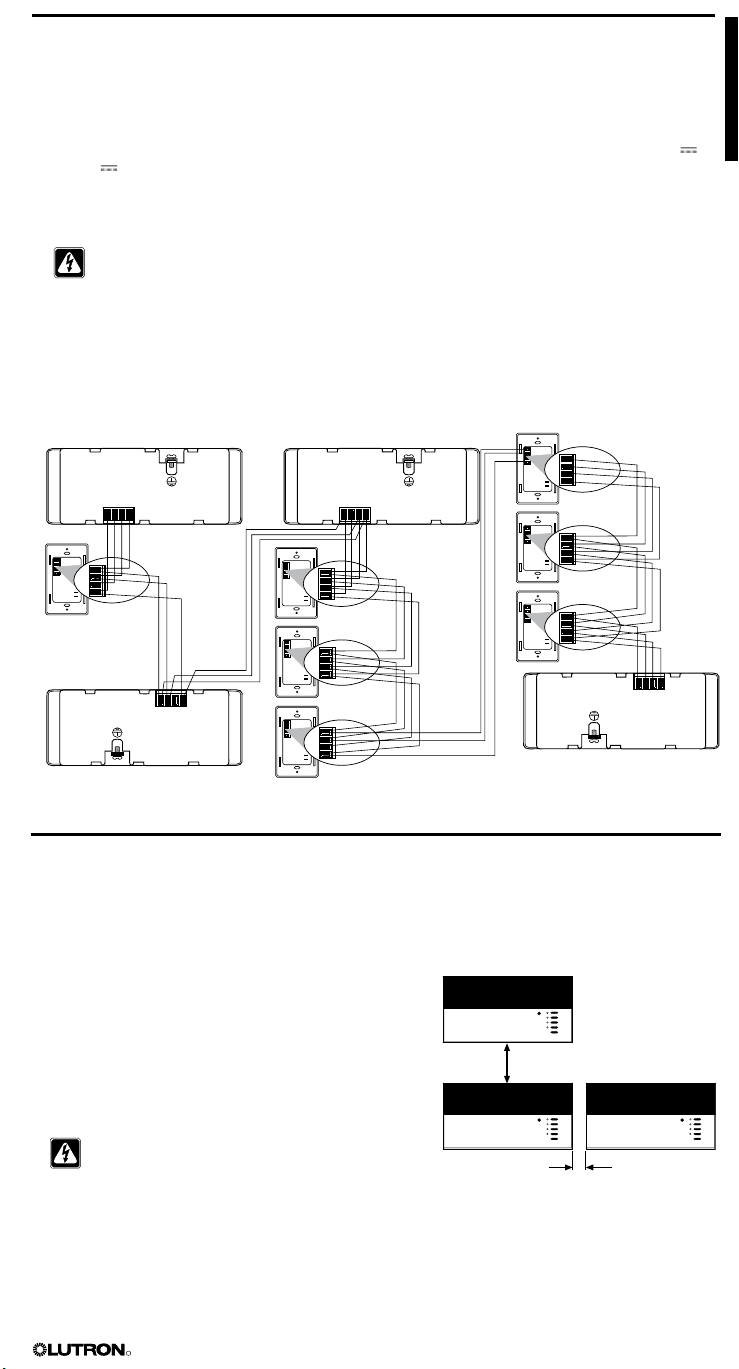

System Maximums: Up to 8 Control Units and 16 Wallstations

and 8 Shade Controllers

A1

a

A2 and A3

have their

own power

supplies—no

inal 2

A1 powers a only—

terminal 2 connection

terminates at a.

term

connection.

wire is exposed after making connections. The recom-

Total PELV (Class 2: USA)

A3

b

c

e

f

A3 powers b, c and d.

g

ing length is 2000 ft.

wir

(600 m).

A4 powers

e, f, and

g—

no

terminal 2

connection

between d

and e.

A2

d

Special Mounting Considerations

Wallbox Mounting and Spacing

When mounting multiple control units or interface devices, be sure to follow spacing and

ventilation requirements to ensure proper operation.

• All control units MUST be mounted in a standard

U.S. wallbox. (For mounting procedures, refer to

A4

page 5.)

• All control units, power boosters, fluorescent

interfaces, and electronic low-voltage interfaces MUST

have 4 1/2 in. (110 mm) of space above and below

the faceplate to dissipate the heat caused by normal

operation. Allow 1 in. (25 mm) for faceplate overhang

on all sides.

CAUTION! GRAFIK Eye 3000 Series control

units and interface devices, such as NGRX-PB,

dissipate heat when operating. Obstructing

these units can cause malfunction to both the

control unit and the interface device if ambient

temperature does not remain between 32–104 °F

(0–40 °C).

GRAFIK Eye® 3000 Series Control Unit Installer’s Guide 9

4 1/2 in. (110 mm) minimum

Limited by physical size of unit.

Must be able to open front cover.

R

4

3

2

1

4

3

2

1

3

2

1

4

Mounting in a Panel

• The enclosure must be in accordance with all local

and national electrical codes.

• Lutron does not recommend using a door to enclose

the front of a panel, since this restricts airflow to the

ELV

interface

control units and interface devices.

• If mounting multiple control units or interface devices

4 1/2 in. (110 mm) minimum

in an enclosure:

– Ambient temperature within an

enclosure MUST

remain between 32–104 °F (0–40 °C).

– If not mounting in a metal enclosure, all units

MUST be mounted in a wallbox. Refer to

4 1/2 in. (110 mm) minimum

FDB

interface

“Wallbox Mounting and Spacing” on page 9.

• To improve heat dissipation of interface units, (i.e.,

NGRX-PB, GRX-ELVI, etc.), remove the faceplate

Power

booster

from the unit.

CAUTION! GRAFIK Eye 3000 Series control

d interface devices, such as NGRX-PB,

units an

dissipate heat when operating. Obstructing

these units can cause malfunction to both the

control unit and the interface device if ambient

temperature does not remain between 32–

104 °F (0–40 °C).

Installing an External Power Supply

Install an external PELV (Class 2: USA) rated 12 V (15 V for CE/AU models) power supply if

you need to power 4 to 16 wallstations from a single control unit or if your wire lengths exceed

maximums. The power must be a regulated supply rated for at least 50 mA per wallstation on

the link.

Power supplies do not boost data line signals. The distance limitation for the data line is 2000 ft.

(610 m).

Make sure you review the manufacturer’s instructions before installing.

Lutron offers a 12 V

15 V power supply is approved for CE and AU models; 12 V is approved for all other

models.

Important Wiring Information

1. Connect the Common and Power wires from the power supply to Terminals 1 and 2 on all

wallstations. Do not connect this wire to any control units on the link. Be sure that the terminal 1

connection is made to all wallstations and control units.

2. Lutron recommends these maximum distances from the external 12 V power supply to the

sixteenth wallstation:

• #18 AWG (1.0 mm

• #12 AWG (2.5 mm

Note that the allowable maximum distance depends on the number of wallstations in the system.

Refer to separate Application Note W14 or contact Lutron Technical Support for additional

information.

transformer for 120 V applications. Please ask for P/N GRX-12VDC.

2

) wire: 300 ft. (90 m).

2

) wire: 1000 ft. (300 m).

PELV (Class 2: USA) terminals

on back of unit

To power source

10 GRAFIK Eye® 3000 Series Control Unit Installer’s Guide

1 twisted pair

#18 AWG (1.0

or larger

1 #18 AWG

(1.0 mm2)

External PELV (Class 2:

Lutron P/N GRX-12VDC for 120 V applications

UK plug style TU-240-15DC-9-BL

European plug style

mm2)

Common

12 V

USA) rated power supply

TE240-15DC-9-BL

2 twisted pairs

#18 AWG (1.0

mm2) or larger

Wallstation Wallstation

16 wallstations

(maximum)

R

Section 3:

FADE TEMPORARY

MASTER

ZONES

ZONE 5 ZONE 6

M S

FADE TEMPORARY

MASTER

ZONES

ZONE 1 ZONE 2

M S

00

Programming a GRAFIK Eye® Control Unit

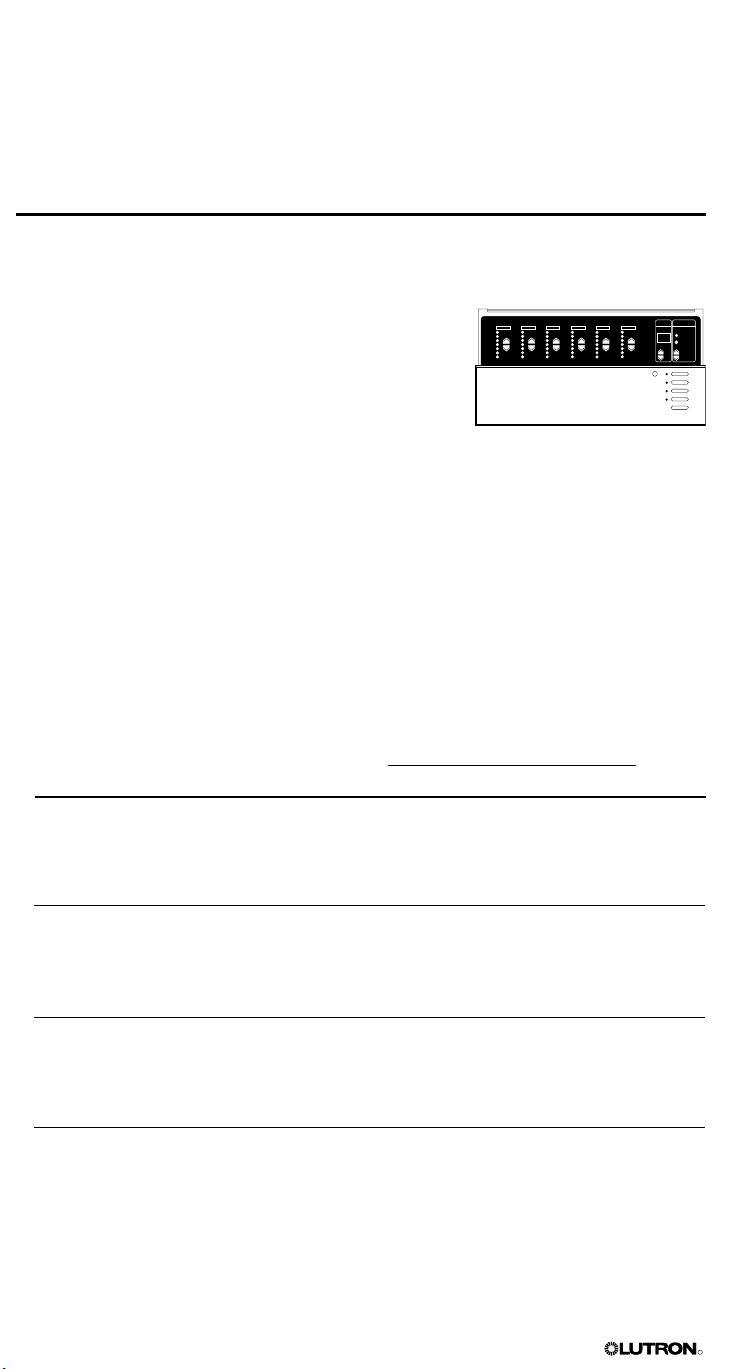

This section identifies buttons and indicators on a GRAFIK Eye 3000 Series control unit. This

section also explains how to enter setup mode, program a control unit, adjust the high and low

end trim, and select a save mode. Most programming operations are typically performed only

once, when the control unit is installed. Other operations, such as selecting scenes and making

temporary adjustments, are performed as needed to achieve the right lighting and shade effects.

For systems with multiple control units, refer to page 20 for addressing.

NOTE: Lutron ships each control unit with factory-set programming. For a description of the

factory presets, refer to page 3

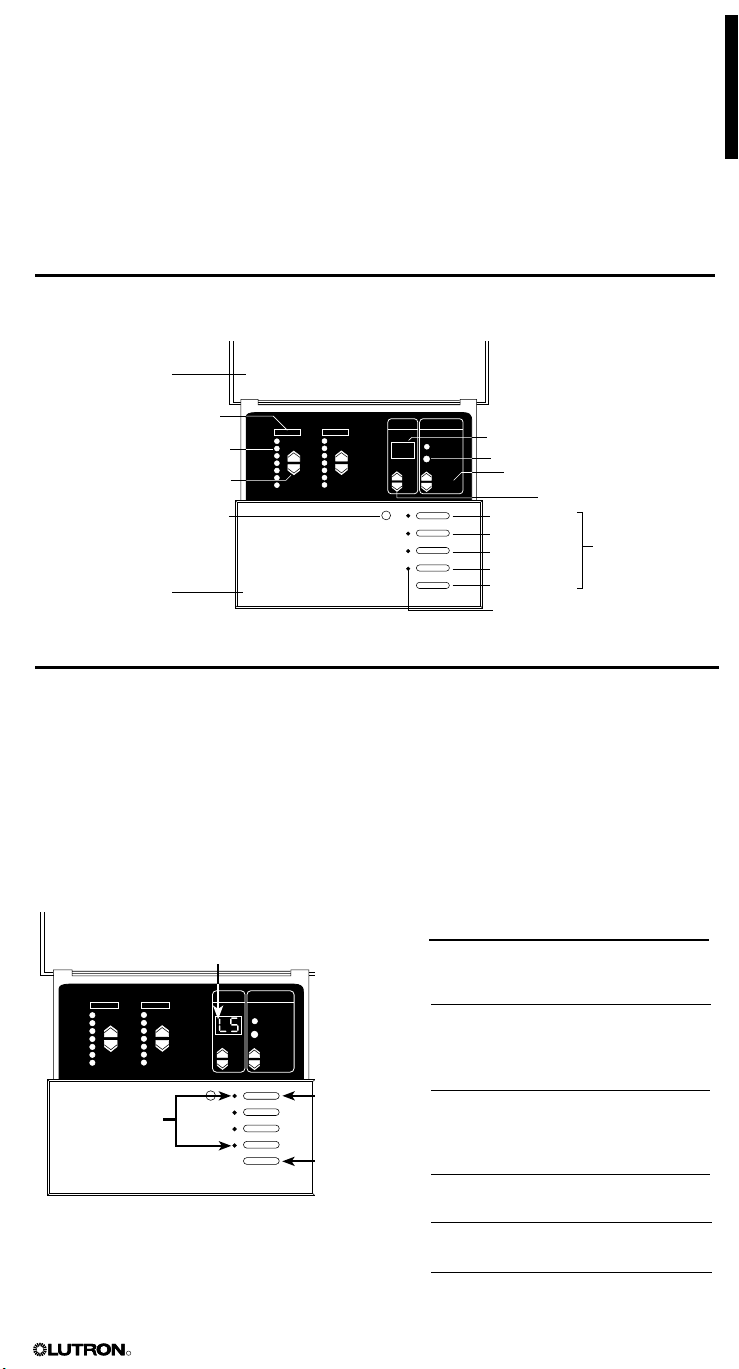

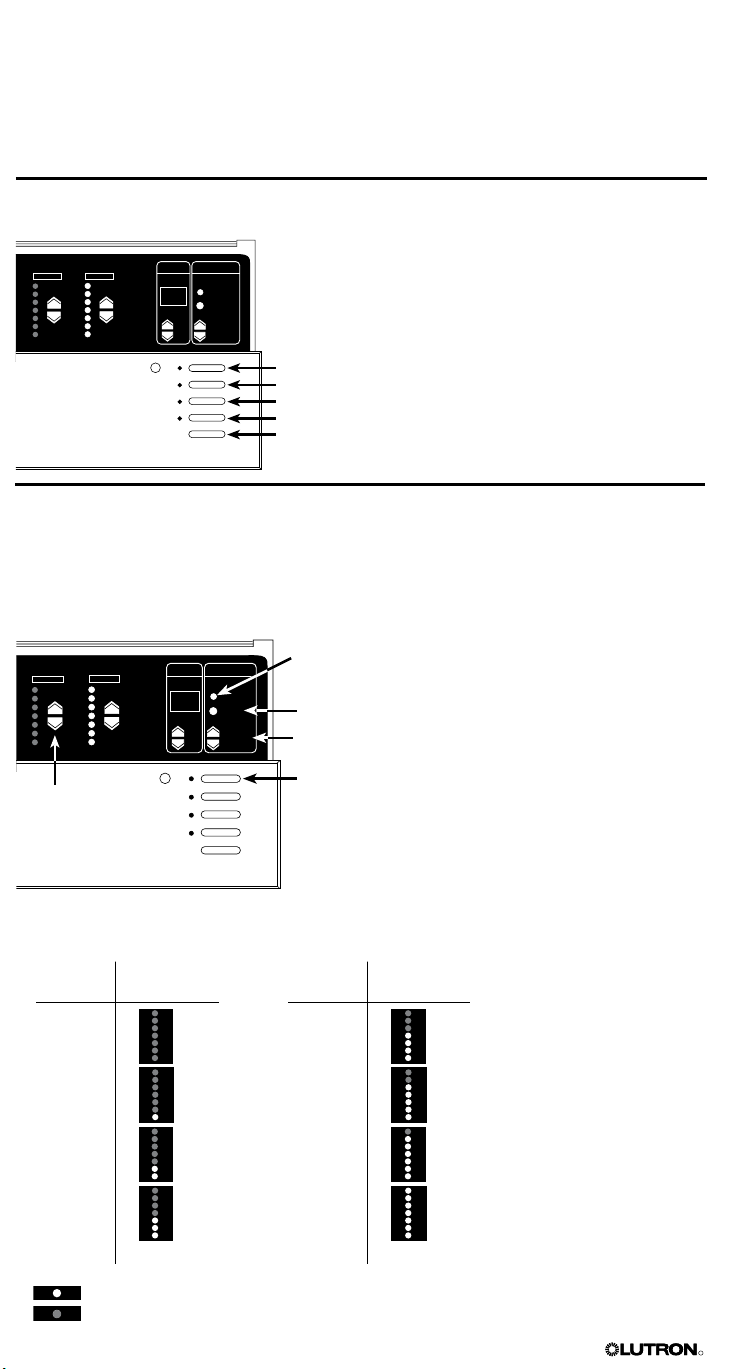

Control Unit Buttons and Indicators

Hinged cover

Zone label

Light level/shad

ZONE raise/lower buttons

remote

Faceplate

e position

LED bar graph

Infrared wireless

control receiver

Scene

FADE window (if

in seconds, if ‘M’ is lit, time is in

minutes)

TEMPORARY

MASTER raise/lower buttons

Scene 1

Scene 2

Scene 3

Scene 4

OFF

indicator LEDs

‘S’ is lit, time is

ZONES button

FADE buttons

SCENE buttons

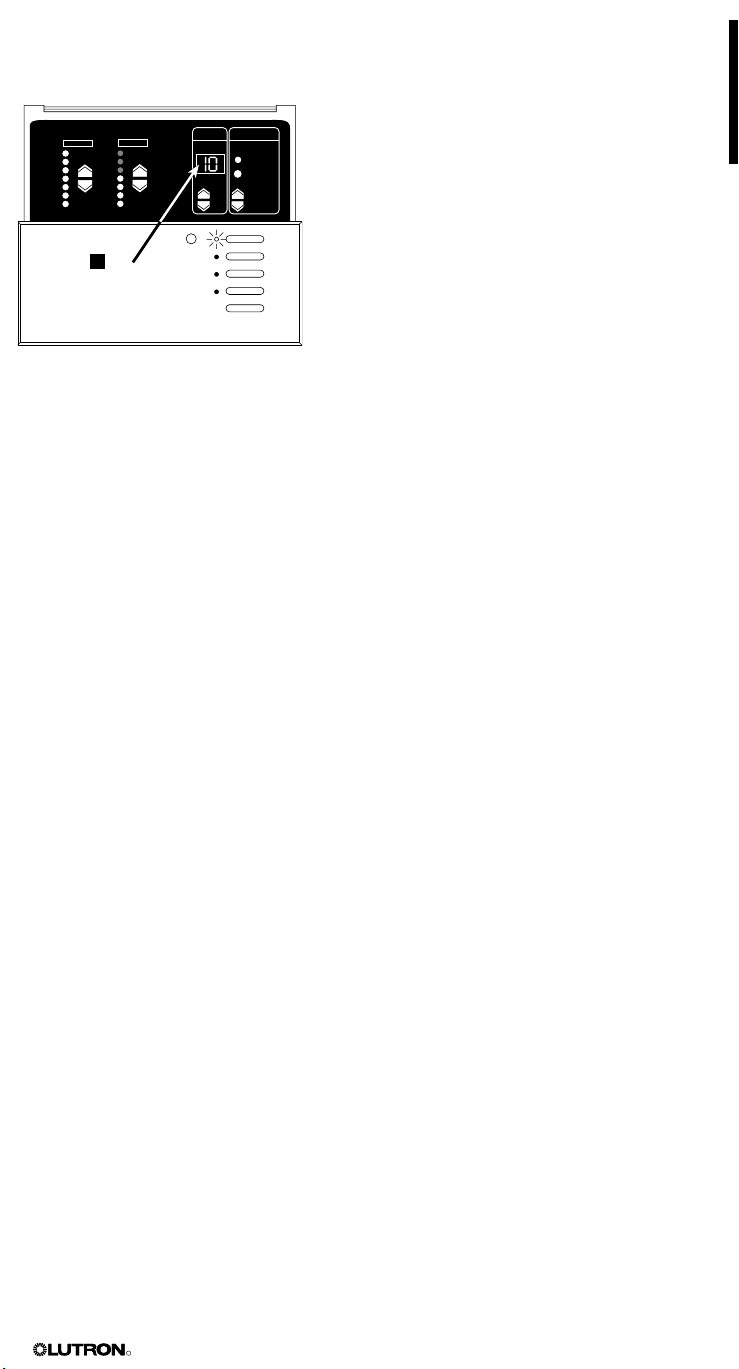

Entering and Exiting Setup Mode

You must enter setup mode to access the programming functions on the control unit.

To enter setup mode: Press and hold the SCENE 1 and OFF buttons for about three sec-

onds, until the scene LEDs start cycling. When the buttons are released, the LEDs should

continue to cycle.

In setup mode, the FADE window displays the first setup code available for programming. To

scroll up and down through the menu of setup codes, press the FADE 5 or 6buttons.

To exit setup mode: Press and hold the SCENE 1 and OFF buttons for about three seconds,

until the scene LEDs stop cycling. The control unit returns to normal operating mode.

The setup codes include:

Use 5

codes (LS is the first code to display)

Scene LEDs

to scroll through setup

and 6

To enter (exit)

setup mode:

Press and

hold for

about three

seconds until

LEDs cycle

(stop cycling)

Code Stands for Description

Sd Save modes Select from

several save

options (page 17).

Sc Scene Set up any of the

scenes, including

unaffected zones

(page 16).

A- Address Identify control

units for system

communications

(page 20).

LS Load Select Identify load types

(page 12).

HE High End Set high end trim

(page 17).

LE Low End Set low end trim

(page 17).

GRAFIK Eye® 3000 Series Control Unit Installer’s Guide 11

R

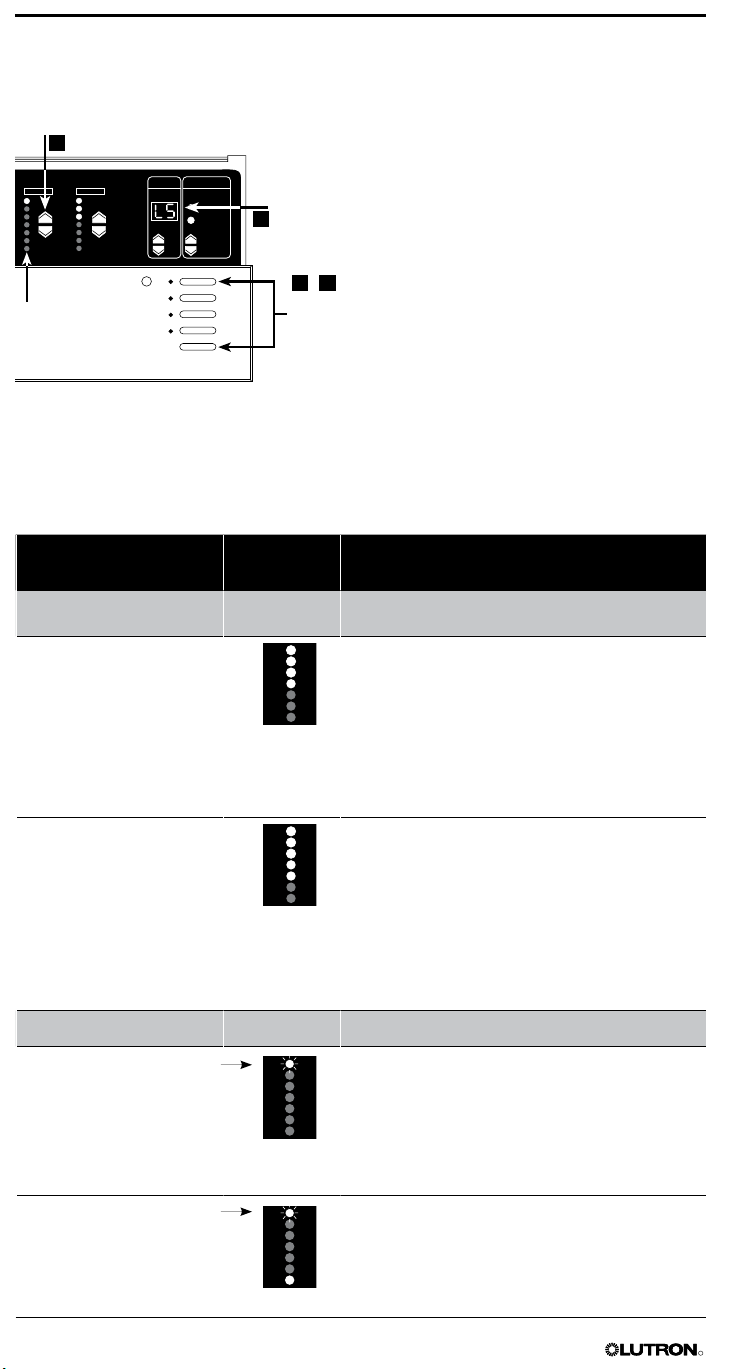

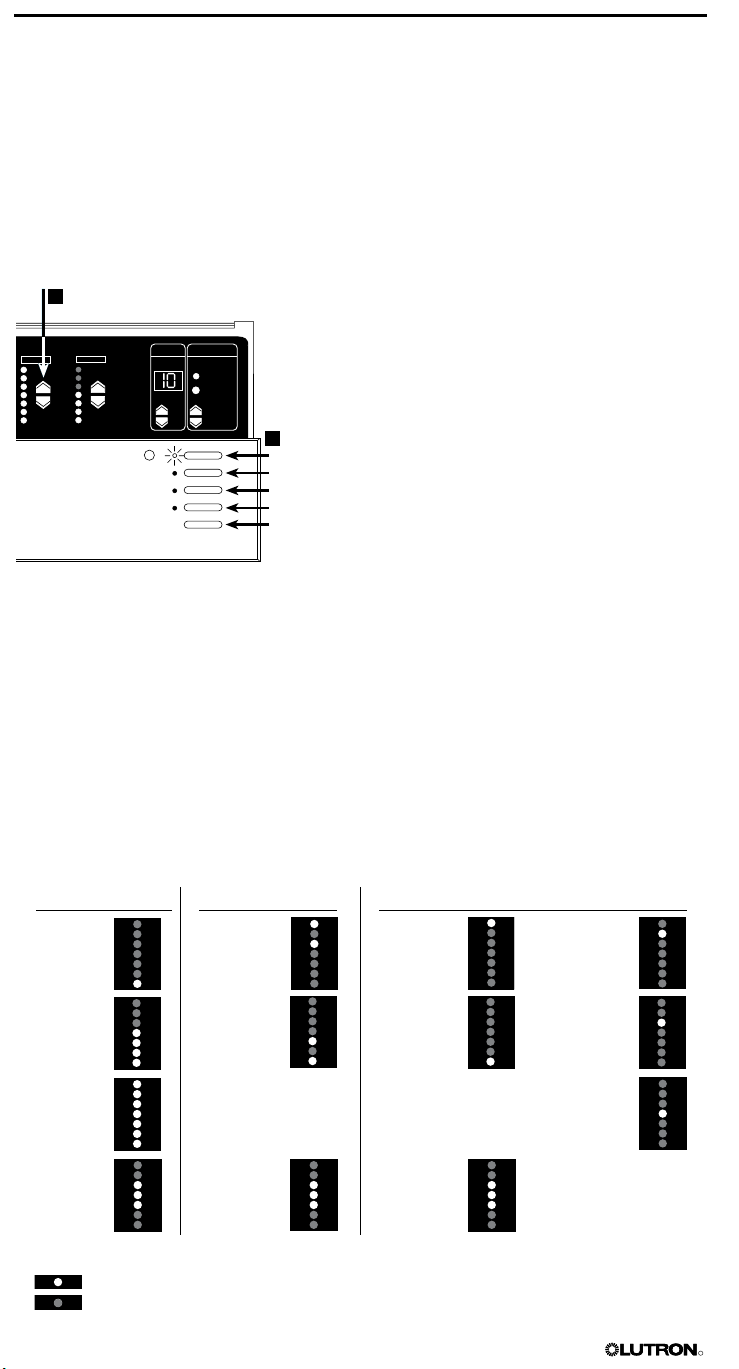

Identifying the Load Type for Each Zone

FADE TEMPORARY

MASTER

ZONES

ZONE 5 ZONE 6

M S

3

2

1 4

,

A load refers to the type of lighting, shade, or interface device connected to the control unit.

Lutron ships control units with all zones set for incandescent/halogen (tungsten) lighting. If your

lighting system has non-incandescent loads, change each of those zones to the correct load type.

Set the load type for each zone

Check for

LS

Zone LEDs

To set this load type...

Enter

(exit)

setup

mode

Select this

LED display Important Notes

Switching (non-dim)

Loads

Non-dim

*

(last on, first off)

Non-dim

* Use non-dim for

(first on, first off)

Motorized Shades

AC shade* * AC

Sivoia

® QED

shade*

Blinking

LED

Blinking

LED

* Sivoia QED shade zones are factory set to

To identify the load type for each zone:

1. Enter setup mode. Press and hold the

SCENE 1 and OFF buttons for about three

seconds, until the scene LEDs cycle.

2. Check for LS in FADE window. LS is the

first code to display when you enter setup

mode. In LS mode, ZONE LEDs turn on from

top to bottom.

3. Set the load type for each zone. Press the

ZONE 5 or 6 button until the ZONE LEDs

match the load type connected to each zone.

Refer to the following table for each load type

and its corresponding LEDs.

4. Exit setup mode. Press and hold the SCENE

1 and OFF buttons for about three seconds,

until scene LEDs stop cycling.

In the sample 6-zone control unit shown here:

• Zone 5 is set for incandescent, magnetic

low-voltage, or HP dimming module.

• Zone 6 is set for neon/cold cathode.

Use non-dim for any lights to be switched ON and

OFF only—not dimmed (unless using HP dimming

module) when fading between scenes. This load will

be the last to switch on and the first to switch off.

Fluorescent non-dim loads with electronic or magnetic ballasts must use a GRX-TVI Interface and

be set for non-dim mode, or use an HP 2•4•6TM

dimming module and be set for HP 2•4•6

dimming module loads. Contact closure outputs.

any lights to be switched ON

and OFF only—not dimmed (unless using HP

dimming module) when fading between scenes.

This load will be the first to switch on and the first

to switch off.

Fluorescent non-dim loads with electronic or magnetic ballasts must use a GRX-TVI Interface and

be set for non-dim mode, or use an HP 2•4•6

dimming module and be set for HP 2•4•6

dimming module loads. Contact closure outputs.

shades zones

are factory set to unaffected

in each scene. To program shade positions for a

scene, refer to pages 14 and 15.

GRAFIK Eye 3000 control units must be

addressed to control shades. To assign

addresses, refer to page 20.

unaffected in each scene. To program shade

positions for a scene, refer to pages 14-16.

GRAFIK Eye 3000 control units must be

addressed to control shades. To assign

addresses, refer to page 20.

12 GRAFIK Eye® 3000 Series Control Unit Installer’s Guide

R

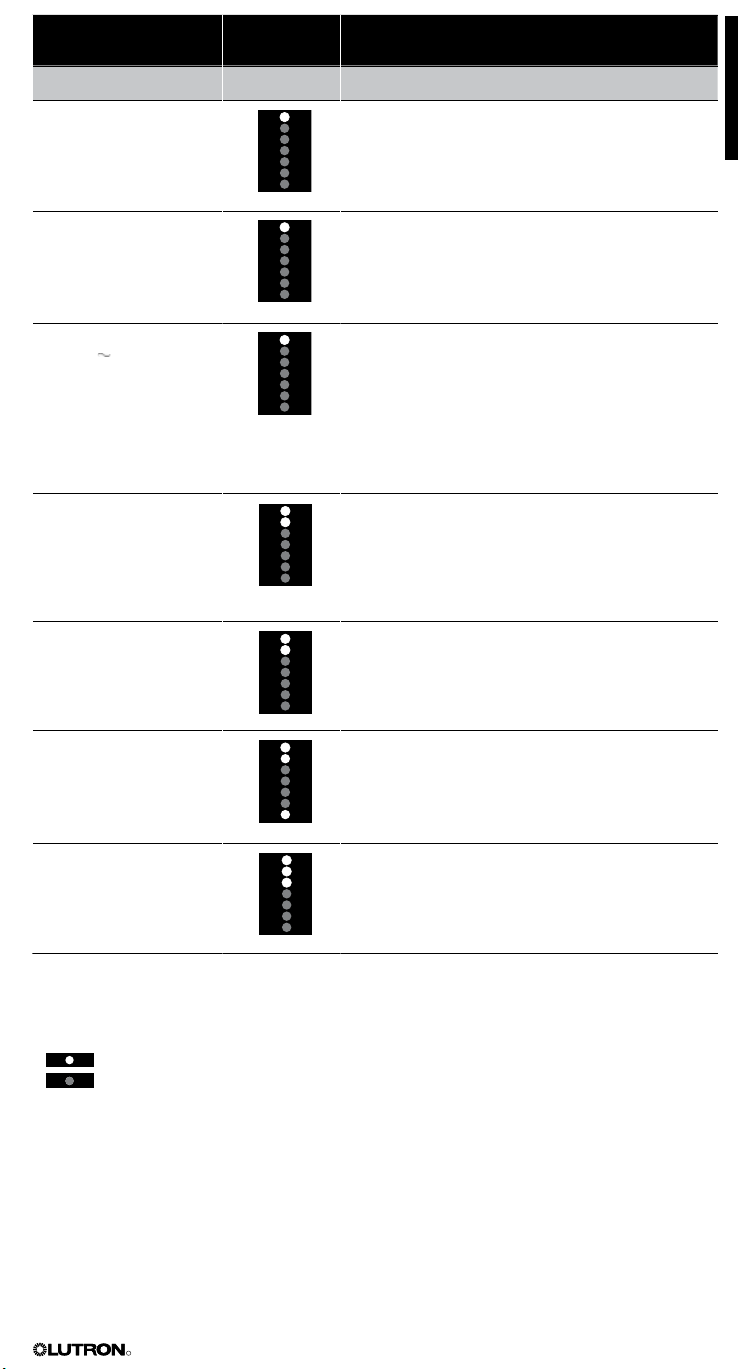

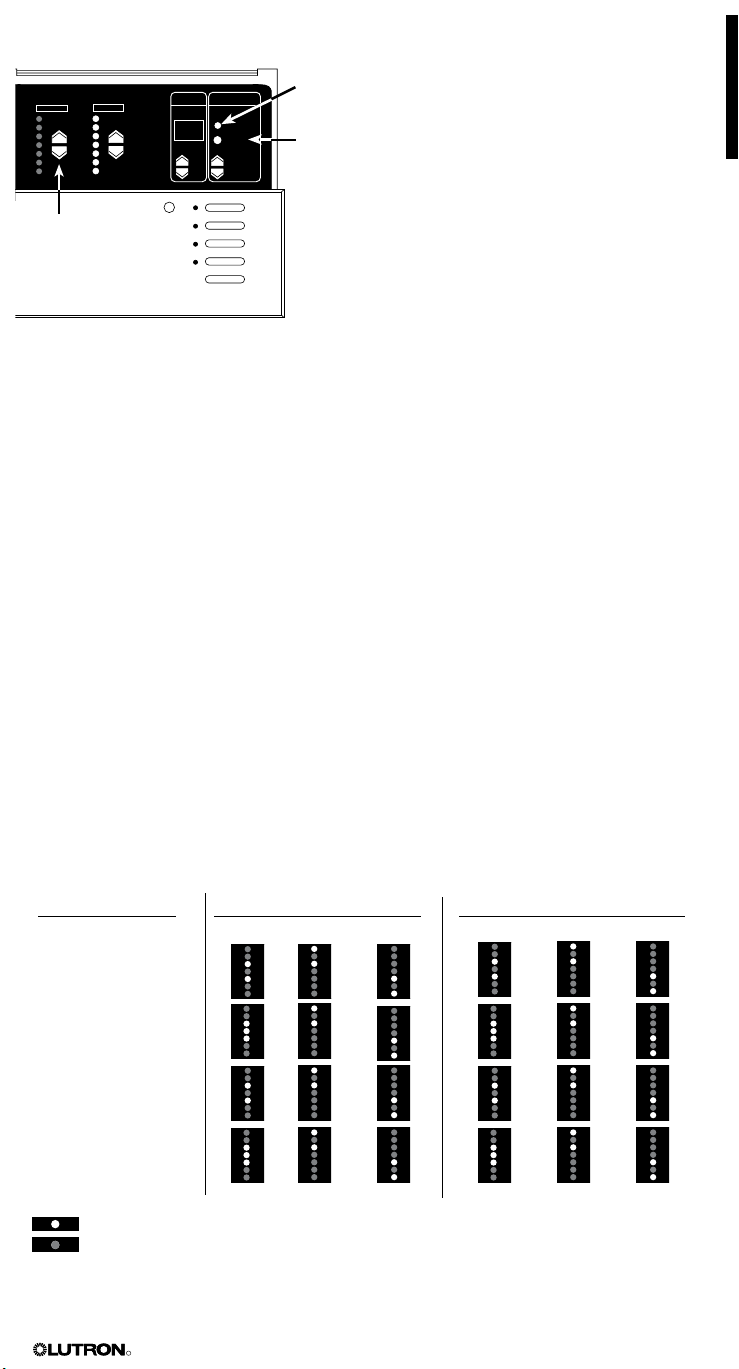

To set this load type...

Dimming Loads

Incandescent/halogen

(tungsten)

Select this

LED display Important Notes

* Use for tungsten

NOTE: This is the factory preset load type for each

zone.

filament lamps.

Magnetic low-voltage * Use for magnetic

•4•6TM loads

HP 2

(120 V supply only)

* Set all zones connected to HP dimming modules

as shown—no matter what load type they are

(including non-dim or switching). The HP can be

used to switch non-capacitive ballasts. To finetune the dimming of these “HP-powered” zones,

you must adjust high and low end trim on the HPs

as described in the instructions supplied with the

unit. Do NOT use HPs with generator-supplied

line/mains voltage.

GRX-ELVI loads

(Electronic

low-

voltage)*

* All electronic low-voltage (ELV) lighting used with

an electronic low-voltage interface (ELVI) must

be rated for reverse phase control/trailing edge

dimming. Refer to the documentation for your

interface.

GRX-FDBI or

GRX-TVI loads

(Lutron 3-wire

fluorescent)*

* Zones

fluorescent lighting must have GRX-FDBI or

GRX-TVI fluorescent interfaces. Contact Lutron

for more information. Refer to the documentation

set for Lutron Hi-lume or Eco-10

for your interface.

Tu-Wire® compact

fluorescent

* Tu-Wire compact fluorescent does not require a

fluorescent dimming ballast interface (FDBI). This

load type is not available in GRX-CE models.

transformer low-voltage lighting.

Neon/cold cathode * Use for neon or cold cathode lighting.

*Interface required; contact Lutron Technical Support for details.

Legend:

LED lit

LED off

GRAFIK Eye® 3000 Series Control Unit Installer’s Guide 13

R

Programming Scenes

FADE TEMPORARY

MASTER

ZONES

ZONE 5 ZONE 6

ZONE

M S

2

1

Scenes are preset lighting levels, fade times, and shade positions stored in the control unit. (Note

that AC shades can be programmed in a scene as only fully open, fully closed, or unaffected;

Sivoia QED shades can be programmed at any preset level or unaffected.) You can program up

to 16 scenes, plus OFF (scene 0). Any time a scene button is pressed or input from an optional

control interface is received, the system activates the desired scene.

Programming Scenes 1 through 4 (Save Mode)

If the control unit is set to the factory default Sd save mode (adjustments to zone settings are

saved for the current scene), you can program scenes 1 through 4 without entering setup mode.

NOTE: To program scenes using setup mode, refer to page 16. To select a save mode, refer to

page 17.

Set the scene settings for each zone

To program scenes 1 through 4 using

save mode:

1. Select a scen

scene you want to pro

e. Press the SCENE button for the

gram.

2. Set the scene settings for each zone.

For lighting zones, press the ZONE 5 or 6

Select a

scene

Scene 1

Scene 2

Scene 3

Scene 4

OFF

button to set the right visual intensity for this

scene.

For AC shade zones, press the ZONE 5 or 6

button until the ZONE LEDs match the right

shade position for this scene. See the illustration

below.

For Sivoia QED shade zones, press the

ZONE 5 or 6 button until the ZONE LEDs

match the right shade position for this scene.

See the illustration below.

NOTE: To quickly set a shade zone to fully open

or fully closed, press and hold the ZONE 5 or 6

button for about three seconds.

unaffected zones, press and hold the

For

ZONE 6 button until all its LEDs go out and

the middle three LEDs light (this may take up

to 10 seconds). This zone’s settings will not be

affected when this scene is selected.

To reprogram an unaffected zone as

affected, follow the steps above. Then press the

ZONE 5 button for about three seconds until

the middle three ZONE LEDs are no longer lit.

Program the zone’s settings.

LED Displays for Programming Scene Settings

Lighting Zones AC Shade Zones Sivoia QED Shade Zones

Off Fully open Fully open Preset 1

On 50% Fully closed Fully closed Preset 2

On 100% Preset 3

Unaffected Unaffected Unaffected

Legend:

LED lit

LED off

14 GRAFIK Eye® 3000 Series Control Unit Installer’s Guide

R

FADE TEMPORARY

MASTER

ZONES

ZONE 5 ZONE 6

ZONE

M S

3

Set scene’s

fade-in time

3. Set the fade-in time for this scene (does not

apply to shades). Press the FADE 5 or 6 button

to make the fade-in time anything from 0–59

seconds or 1–60 minutes.

The M and S indicators under the FADE window

show whether fade is “M”inutes or “S”econds.

To set the fade in minutes, press the FADE 5

button to scroll through 1–59 seconds to 1 to 60

minutes, then M lights. Fade is now expressed

in minutes. To get back to seconds, press

the FADE 6 button until the window shows

“S”econds.

4. Repeat steps 1 through 3 to set up each of the

remaining scenes.

To set a Fade-to-OFF time, press the OFF

scene button, then set the seconds or minutes to

fade to OFF from this scene.

GRAFIK Eye® 3000 Series Control Unit Installer’s Guide 15

ZONE 1 ZONE 2

M S

2

3

4

1

FADE TEMPORAR Y

MASTER

ZONES

5

6

,

Programming Scenes 1 through 16 (Setup Mode)

ZONE 5 ZONE 6

M S

FADE TEMPORAR Y

MASTER

ZONES

4

R

You can program any scene using setup mode. If your lighting system requires more than 4

scenes, scenes 5 through 16 must be programmed using setup mode.

NOTE: To program scenes 1 through 4 using Sd save mode, refer to page 14.

Select flashing Sc/1

Program

lighting or

shade scene

settings for

each zone

To set unaffected zone,

press ZONE 6 twice

and then hold until middle three LEDs light

Set scene’s

fade-in time

Select

scene

Enter

(exit)

setup

mode

To program scenes using setup mode:

1. Enter setup mode. Press and hold the

SCENE 1 and OFF buttons for about

three seconds until the scene LEDs start

cycling.

2. Select Sc (scene setup) by pressing the

FADE 5 button twice. Sc and 1 (scene 1)

will alternately flash in the FADE window.

3. Select scene. Press the MASTER 5

or 6 button to select the number of the

scene to be programmed (1 through 15;

0 is the OFF scene).

4. Program scene settings for each zone.

For lighting zones, press the ZONE 5

or 6 button to set the zone intensity.

(GRX-3500 units will display exact percentage light output; press again to adjust

light levels in 1% increments.)

For AC shade zones, press the

ZONE 5 or 6 button until the ZONE

LEDs match the right shade position for

this scene. See the illustration on page 14.

For Sivoia QED shade zones, press

the ZONE

5 or 6 button until the ZONE

LEDs match the right shade position for

this scene. See the illustration on page 14.

For unaffected zones, press and hold

the ZONE 6 button until all its LEDs go

out and the middle three LEDs light (this

may take up to 10 seconds). This zone’s

settings will not be affected when this

scene is selected.

To reprogram an unaffected zone as

affected, follow the steps above. Then

press the ZONE 5 button for about three

seconds until the middle three ZONE

LEDs are no longer lit. Program the

zone’s settings.

5. Set the scene’s fade-in time. Press

and hold the TEMPORARY ZONES

button. The current fade-in time will be

displayed. Adjust using the FADE 5 or 6

button while still holding the TEMPORARY

ZONES button. (Fade time does not apply

to shade zones.)

6. Exit setup mode. Press and hold the

SCENE 1 and OFF buttons until the LEDs

stop cycling.

16 GRAFIK Eye® 3000 Series Control Unit Installer’s Guide

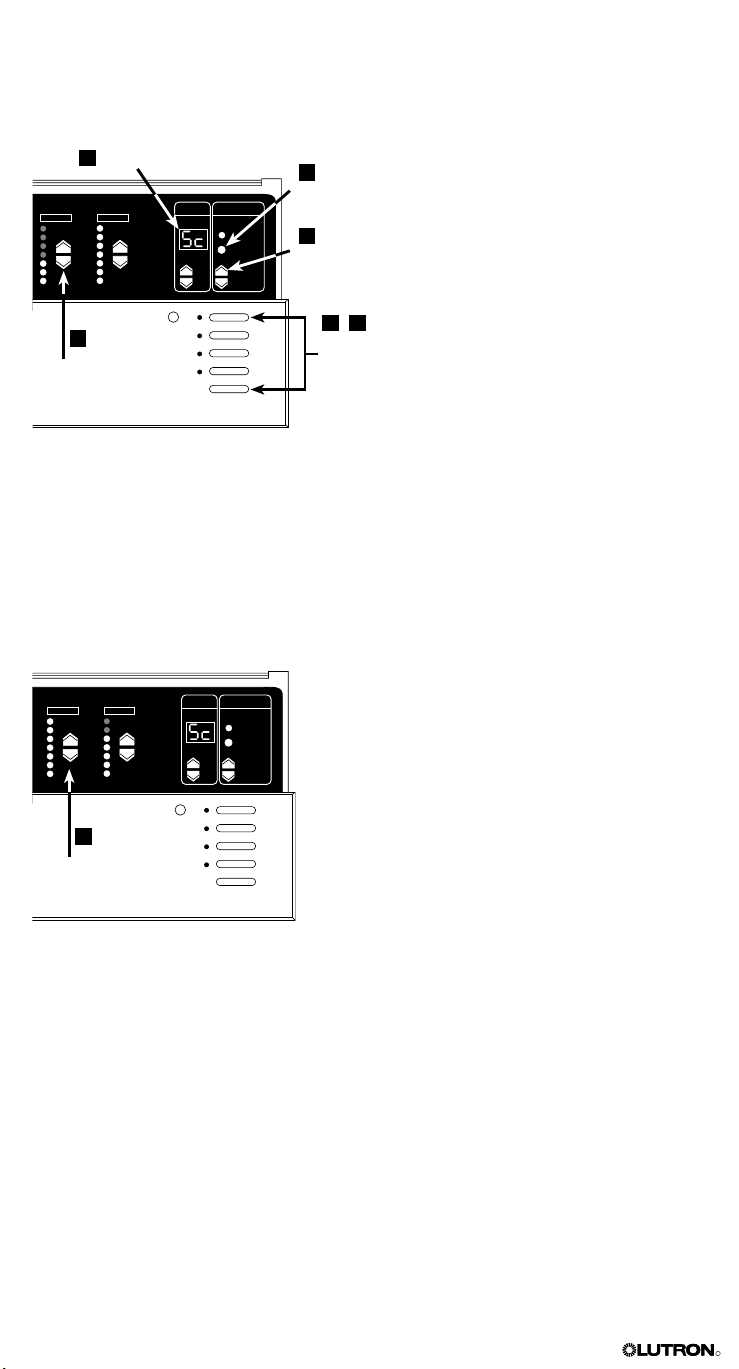

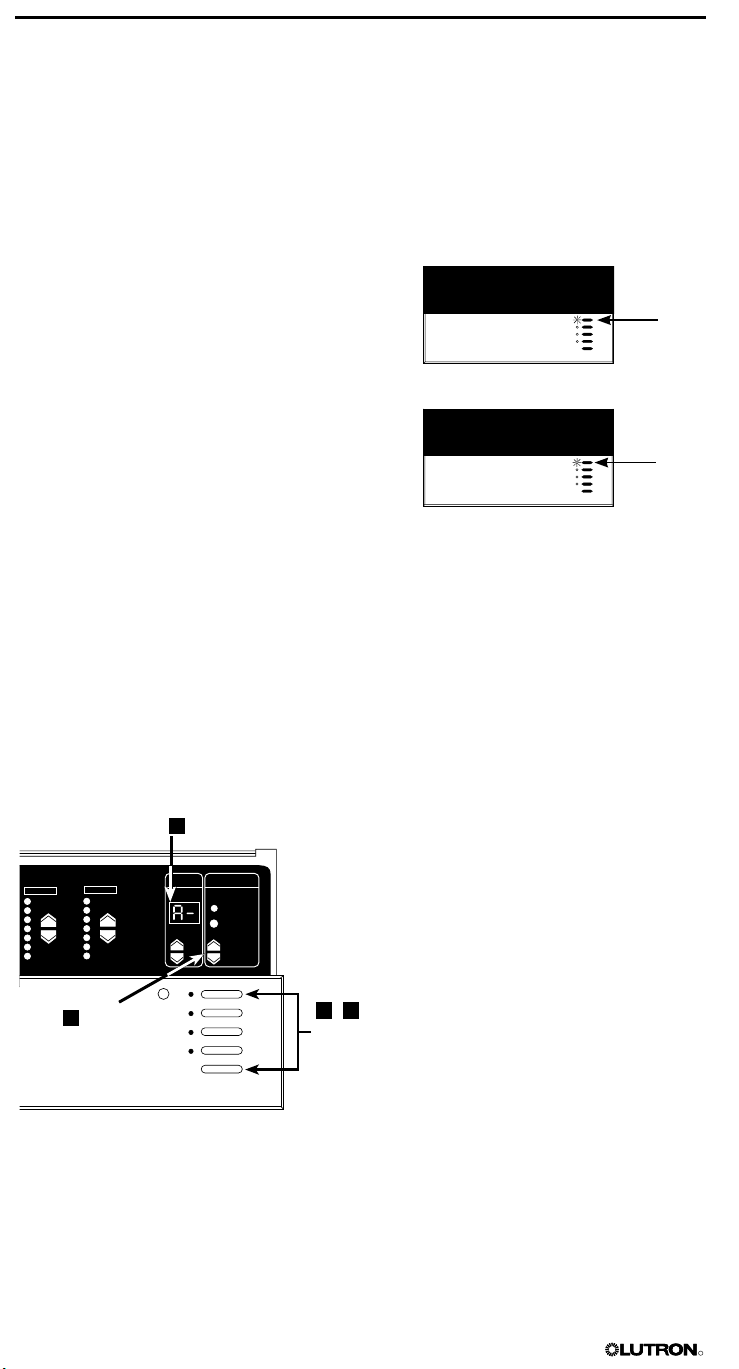

Adjusting High or Low End Trim

FADE TEMPORARY

MASTER

ZONES

ZONE 5 ZONE 6

M S

3

2

1

4

,

FADE TEMPORARY

MASTER

ZONES

ZONE 5 ZONE 6

M S

2

3

1

4

,

R

High and low end trim settings limit the maximum and minimum output of a dimming zone. Trim

levels are set automatically when the load type is programmed. Change the high or low end trim

for a zone only if the default setting needs to be adjusted.

Adjust zone’s trim setting

The zone’s LED bar graph does

not change while you make trim

adjustments. The bar graph

remains set to its highest/lowest

level in this mode.

Select HE

or LE

Enter

(exit)

setup

mode

To adjust high or low end trim:

1. Enter setup mode. Press and hold the

SCENE 1 and OFF buttons for about three

seconds, until the scene LEDs start cycling.

2. Select HE (high end) or LE (low end).

Press the FADE 6 button until HE or LE is

displayed in the FADE window.

For high end, all zones go to their highest

possible dim levels and all their LEDs are lit.

For low end, all zones go to their lowest possible

dim levels and only their bottom LED is lit.

NOTE: For shade zones, the middle three LEDs

are lit to indicate that they are unaffected. For

non-dim lighting zones, all LEDs are lit (for

high end) or OFF (for low end) and you cannot

adjust the high or low end trim.

3. Adjust zone’s trim setting. Press the

ZONE 5 or 6 button to raise or lower the

trim. Repeat this process for other zones that

require trim adjustments.

4. Exit setup mode. Press and hold SCENE 1

and OFF buttons until the scene LEDs stop

cycling.

Note: Setting low-end trim below the factory

default may cause some load types to flicker.

Selecting the Save Mode You Want to Use

Save modes enable you to specify how buttons on the control unit work. For example,

adjustments to a zone’s settings can be temporary or saved for the current scene. Buttons can

also be disabled to prevent accidental changes.

Select Sd

Code Stands for Description

Sd

Sb

Sn

4S

bd

Save by Default

Save by Button TEMPORARY ZONES LED is normally ON and all intensity/shade position and

Save Never

Four Scenes

Button Disable

Changes to a zone’s intensity/shade position or fade time are saved for

Allows only the four SCENE buttons, OFF button, IR receiver, and

All buttons on the control unit are disabled. IR receiver and wallstations are

Select

save mode

Enter

(exit)

setup

mode

the current scene. To make temporary adjustments in Sd mode, refer to

page 18. Typical user: Home theater owner.

fade changes are temporary unless the TEMPORARY ZONES LED is turned

OFF with the TEMPORARY ZONES button. Typical user: Restaurant manager.

TEMPORARY ZONES LED is permanently ON and cannot be turned OFF. In

this mode, all intensity changes are temporary. Typical user: Lighting designer.

MASTER 5 or 6 buttons to operate. All other buttons on the control unit

are disabled. Typical use: Rented meeting space.

still functional. (Setup mode is still accessible by repeating Step 1.) Typical

use: Public space.

To select the save mode you want to use:

1. Enter setup mode. Press and hold the

SCENE 1 and OFF buttons for about three

seconds until scene LEDs start cycling.

2. Select Sd. Press the FADE 5 button until

Sd is displayed in the FADE window.

3. Select save mode. Press the MASTER 5

or 6 button to scroll through the save

modes and select one. Refer to the save

mode descriptions in the table below.

4. Exit setup mode. Press and hold the

SCENE 1 and OFF buttons until scene LEDs

stop cycling.

GRAFIK Eye® 3000 Series Control Unit Installer’s Guide 17

FADE TEMPORARY

MASTER

ZONES

ZONE 5 ZONE 6

M S

Section 4:

FADE TEMPORAR Y

MASTER

ZONES

ZONE 5 ZONE 6

M S

R

Using the GRAFIK Eye® Control Unit

This section describes how to use your GRAFIK Eye control unit, including selecting scenes,

making temporary changes, and setting up system communications.

Selecting Scenes

To select a scene, press the corresponding

SCENE button on the control unit. The first

button calls up scene 1; the second button,

scene 2; and so on. The last button is the OFF

scene.

Scenes 1 through 4 (and OFF) can be selected

Scene 1

Scene 2

Scene 3

Scene 4

OFF

Temporarily Adjusting Light Levels and Shade Positions

You can temporarily adjust the light level or shade position of a zone. Temporary adjustments

remain in effect only until a new scene selection occurs.

NOTE: For control units set to bd save mode (refer to page 17), temporary adjustments can be

made only using a wallstation, shade controller, or IR control.

on the control unit.

Scenes 5 through 16 are selected only

using wallstations and other optional control

interfaces. (For installation and setup

procedures, refer to the separate instructions

provided with the wallstation or interface.)

To temporarily adjust all lighting

zones:

1. Press the appropriate scene button.

2. To raise or lower the intensity of all lighting

zones in the scene, press the MASTER

5 or 6 button. (This will not affect shade

zones or unaffected

To temporarily adjust a lighting zone:

1. Press the TEMPORARY ZONES button

so the TEMPORARY LED above the

ZONE

raise/lower

buttons

TEMPORARY

LED

TEMPORARY

ZONES

MASTER

raise/

lower

SCENE

buttons

TEMPORARY ZONES button lights.

2. Press the ZONE 5 or 6 button to adjust

any zone’s light level.

LED Displays for Temporarily Changing Lighting Settings

Lighting

Level (%) LED DIsplay

0

1-13

14-28

29-42

Lighting

Level (%) LED DIsplay

43-56

57-70

71-85

86-100

lighting zones.)

Legend:

LED lit

LED off

18 GRAFIK Eye® 3000 Series Control Unit Installer’s Guide

R

FADE TEMPORARY

MASTER

ZONES

ZONE 5 ZONE 6

M S

ZONE

raise/lower

buttons

TEMPORARY

LED

TEMPORARY

ZONES

To temporarily adjust a Sivoia QED

shade zone:

1. Press the TEMPORARY ZONES button

so the TEMPORARY LED above the

TEMPORARY ZONES button lights.

2. Press the ZONE 5 or 6 button to adjust

any zone’s shade position to a preset

position.

3. Use the raise/lower buttons on the

wallstation that controls the shade zone to

adjust it to a position that is not a preset.

To temporarily adjust an AC shade

zone:

1. If fully open, press the ZONE 6 button.

At the desired position, press the ZONE 6

button again to stop the AC shade.

2. If fully closed, press the ZONE 5 button.

At the desired position, press the ZONE 5

button again to stop the AC shade.

LED Displays for Temporarily Changing Shade Settings

Scene Status/Control AC Shade Zones Sivoia QED Shade Zones

Stopped Raising Lowering Stopped Raising Lowering

Affected/Control unit

Unaffected/Control unit

Affected/Wallstation

Unaffected/Wallstation

Legend:

LED lit

LED off

GRAFIK Eye® 3000 Series Control Unit Installer’s Guide 19

R

Setting Up System Communications

FADE TEMPORARY

MASTER

ZONES

ZONE 5 ZONE 6

M S

2

3

1

4

,

If your GRAFIK Eye 3000 Series lighting system has more than one control unit, you need

to address the control units and then set up communications between the control units,

wallstations, and other optional accessories.

NOTE: A single control unit operating shade zones must also be addressed.

Checking System Interconnections

Before you address and set up communications between control units, make sure your system

interconnections are working.

To check system interconnections:

1. Select scene 1 (press the top SCENE button) on

one of the control units.

2. Is scene 1 selected on all other control units?

• If yes, the PELV (Class 2: USA) wiring is

correct and you can begin addressing the

control units.

• If no, the GRAFIK Eye control unit has been

addressed to other than A- (factory default).

See below for more information on addressing

control units.

-or-

PELV (Class 2: USA) is miswired. Check for

loose connections, shorted or crossed links.

Press SCENE 1 button . . .

. . . all other SCENE 1 LEDs light

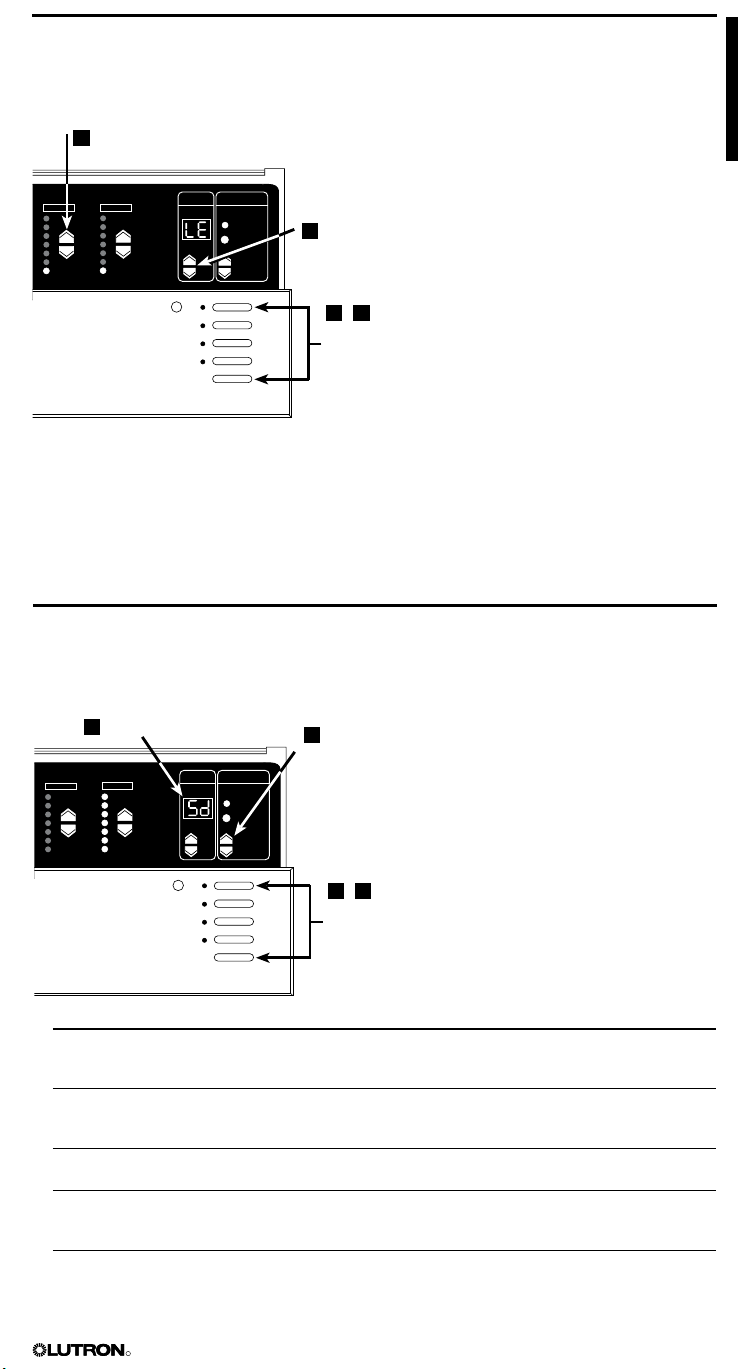

Assigning an Address to Each Control Unit

If your lighting system has multiple control units, assign a unique system address (A1 through

A8) to each control unit. Once any control unit has been addressed, communication is lost

between all other components until each control unit has been addressed. To program a

wallstation, refer to its documentation.

NOTE: A single control unit operating shade zones must also be addressed.

To address each control unit:

1. Enter setup mode. Press and hold the

SCENE 1 and OFF buttons for about

three seconds, until the scene LEDs

cycle.

2. Select A-. Press the FADE button

until A- (the factory default address)

displays in the FADE window.

3. Assign a unique address. Press the

MASTER button once; the next “free”

(unassigned) address automatically

displays in the FADE window. This will

be the control unit’s address. (If you are

working on the first control unit in the

lighting system, A1 will display.)

4. Exit setup mode. Press and hold the

SCENE 1 and OFF buttons for about

three seconds, until the LEDs stop

cycling.

5. Repeat steps 1 through 4 for each

control unit.

Assign a

unique address

Select A-

Enter (exit)

setup mode

20 GRAFIK Eye® 3000 Series Control Unit Installer’s Guide

R

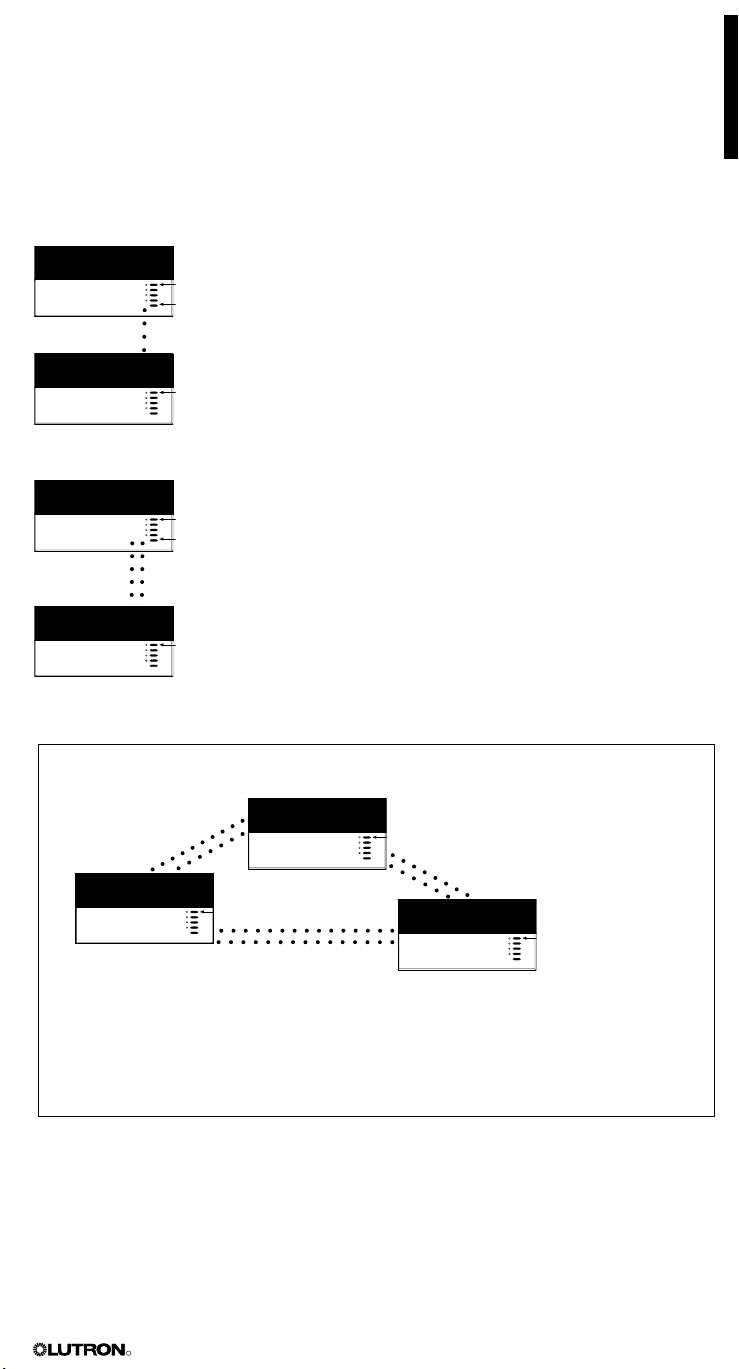

Setting Up Communications between Two or More Control Units

Two-way communications between control units enables you to set up lighting and shade effects

for more than six zones (the maximum number of zones any one control unit can operate).

Depending on the room or facility, you can set up two-way communications so that all control

units “talk” and “listen” to each other. In this configuration, selecting a scene at any one of the

control units automatically activates the same scene in the others. Optionally, you set up some

control units to share two-way communications while others do not. This configuration enables

you to specify which control units activate the same scenes and which work independently.

NOTE: The control units must be addressed (as described on page 20) before setting up twoway communications.

A1 “talks” . . .

LEDs cycle

. . . A2 “listens”

LEDs flash

A1 “listens” . . .

LEDs cycle

. . . when A2 “talks”

LEDs flash

Example: Three Control Units All Communicating for 16-Zone Control

To set up communications between control units:

1. Put A1 in setup mode. Press and hold the SCENE 1 and OFF

buttons for about three seconds, until the LEDs cycle.

2. Identify the control units that should “listen” to A1 (A2 and

up to six others). At each of the other control units, press and

hold the SCENE 1 button for about three seconds until the LEDs

flash in unison, showing that these control unit(s) are “listening” to

A1 and will respond to its commands.

To make a “listening” control unit not listen to A1: Put A1 in

setup mode, then press the “listening” control unit’s OFF button

until the LEDs stop flashing.

3. Take A1 out of setup mode. Press and hold the SCENE 1 and

OFF buttons for about three seconds, until the LEDs on A1 and

all other linked control units stop cycling.

You have set up communications in one direction between A1

and all “listening” control units.

4. To complete the two-way communication, reverse the

process described above. Put A2 in setup mode; then make

A1 (and any other control units) “listen”; then take A2 out of

setup mode. Continue for each control unit.

A1

6 zo

nes

Selecting a

scene on

A1 . . .

A2

6 zones

A3

4 zones

All three control units are programmed to communicate with one another and act like a 16zone control unit. Note that communications are set up both ways among all control units:

• A1 “talks” and “listens” to A2 and A3.

• A2 “talks” and “listens” to A1 and A3.

• A3 “talks” and “listens” to A1 and A2.

Setting Up Communications between Control Units, Wallstations, and Other Accessories

Wallstations and other optional accessories (refer to page 3) must be set up to communicate

with control units on the GRAFIK Eye link. For procedures on how to set up communications

with wallstations and accessories, refer to the separate instructions included with the device.

GRAFIK Eye® 3000 Series Control Unit Installer’s Guide 21

. . . Activates the

same scene on A2

and A3.

R

Appendix A

Troubleshooting

Problem Possible Cause Remedy

Unit does not turn lights on

Long fade time Set FADE time to 0 seconds.

Low zone settings Use ZONE

Miswire Check wirin

on page 5)

System short circuit Find and correct shorts in fixtures

and/or wallbox.

System

Wrong load type Check load type setting.

Breaker/MCB is off Switch breaker/MCB on.

5 button for each scene.

g (refer to wiring details

.

overload Make sure lighting loads don’t exceed unit’s

maximum rated load.

Unit does not control load

or ZONE control does not work

Disconnected wires Connect zone wires to loads (refer to page 5).

Burned-out lamps Replace bad lamps.

1 or more zones are “full-on”

when any scene is on and

zone intensity is not a

(and zone is

Shorted triac Replace control unit.

A ZONE control affects

more than one zone Miswire

Wallstation does not

function properly

Incorrect programming Check wallstation programming.

Faceplate is warm Normal operation Solid-state controls dissipate about 2% of the

Unit does not allow scene

changes or zone

adjustments Wrong

Unit does not allow shade

changes or a

not a non-dim)

djustments Incorrect programming Check programming. Control unit must be correctly

Miswire Check wiring (refer to wiring details on page 5).

djustable

Miswire Make sure loads are connected to the right zones

Check wiring (refer to wiring details on page 5).

Miswire or loose connection

save mode Refer to page 17 for a description of save modes.

(refer to wiring details on page 5).

Tighten loose connections at PELV (Class 2: USA)

terminals on unit and wallstations (refer to page 6).

connected load as heat. For spacing and ventilation

considerations, refer to pages 9 and 10.

addressed; see page 20.

NOTE: Contact Lutron Technical Support for additional troubleshooting assistance.

22 GRAFIK Eye® 3000 Series Control Unit Installer’s Guide

Warranty

R

Lutron Electronics Co., Inc.

One Year Limited Warranty

For a period of one year from the date of purchase, and subject to the exclusions and restrictions described below,

Lutron warrants each new unit to be free from manufacturing defects. Lutron will, at its option, either repair the

defective unit or issue a credit equal to the purchase price of the defective unit to the Customer against the purchase

price of comparable replacement part purchased from Lutron. Replacements for the unit provided by Lutron or,

at its sole discretion, an approved vendor may be new, used, repaired, reconditioned, and/or made by a different

manufacturer.

If the unit is commissioned by Lutron or a Lutron approved third party as part of a Lutron commissioned lighting

control system, the term of this warranty will be extended, and any credits against the cost of replacement parts will

be prorated, in accordance with the warranty issued with the commissioned system, except that the term of the unit’s

warranty term will be measured from the date of its commissioning.

EXCLUSIONS AND RESTRICTIONS

This Warranty does

1. Damage, malfunction or inoperability diagnosed by Lutron or a Lutron approved third party as caused by normal

wear and tear, abuse, misuse, incorrect installation, neglect, accident, interference or environmental factors, such

as (a) use of incorrect line voltages, fuses or circuit breakers; (b) failure to install, maintain and operate the unit

pursuant to the operating instructions provided by Lutron and the applicable provisions of the National Electrical

Code and of the Safety Standards of Underwriter’s Laboratories; (c) use of incompatible devices or accessories; (d)

improper or insufficient ventilation; (e) unauthorized repairs or adjustments; (f) vandalism; or (g) an act of God, such

as fire, lightning, flooding, tornado, earthquake, hurricane or other problems beyond Lutron’s control.

2. On-site labor costs to diagnose issues with, and to remove, repair, replace, adjust, reinstall and/or reprogram the

unit or any of its components.

3. Equipment and parts external to the unit, including those sold or supplied by Lutron (which may be covered by a

separate warranty).

4. The cost of repairing or replacing other property that is damaged when the unit does not work properly, even if the

damage was caused by the unit.

EXCEPT AS EXPRESSLY PROVIDED IN THIS WARRANTY, THERE ARE NO EXPRESS OR IMPLIED

WARRANTIES OF ANY TYPE, INCLUDING ANY IMPLIED WARRANTIES OF FITNESS FOR A PARTICULAR

PURPOSE OR MERCHANTABILITY. LUTRON DOES NOT WARRANT THAT THE UNIT WILL OPERATE WITHOUT

INTERRUPTION OR BE ERROR FREE.

NO LUTRON AGENT, EMPLOYEE OR REPRESENTATIVE HAS ANY AUTHORITY TO BIND LUTRON TO ANY

AFFIRMATION, REPRESENTATION OR WARRANTY CONCERNING THE UNIT. UNLESS AN AFFIRMATION,

REPRESENTATION OR WARRANTY MADE BY AN AGENT, EMPLOYEE OR REPRESENTATIVE IS SPECIFICALLY

INCLUDED HEREIN, OR IN STANDARD PRINTED MATERIALS PROVIDED BY LUTRON, IT DOES NOT FORM A

PART OF THE BASIS OF ANY BARGAIN BETWEEN LUTRON AND CUSTOMER AND WILL NOT IN ANY WAY BE

ENFORCEABLE BY CUSTOMER.

IN NO EVENT WILL LUTRON OR ANY OTHER PARTY BE LIABLE FOR EXEMPLARY, CONSEQUENTIAL,

INCIDENTAL OR SPECIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO, DAMAGES FOR LOSS OF PROFITS,

CONFIDENTIAL OR OTHER INFORMATION, OR PRIVACY;

FAILURE TO MEET

ANY OTHER PECUNIARY OR OTHER LOSS WHATSOEVER), NOR FOR ANY REPAIR WORK UNDERTAKEN

WITHOUT LUTRON’S WRITTEN CONSENT ARISING OUT OF OR IN ANY WAY RELATED TO THE INSTALLATION,

DEINSTALLATION, USE OF OR INABILITY TO USE THE UNIT OR OTHERWISE UNDER OR IN CONNECTION WITH

ANY PROVISION OF THIS WARRANTY, OR ANY AGREEMENT INCORPORATING THIS WARRANTY, EVEN IN

THE EVENT OF THE FAULT, TORT (INCLUDING NEGLIGENCE), STRICT LIABILITY, BREACH OF CONTRACT OR

BREACH OF WARRANTY OF LUTRON OR ANY SUPPLIER, AND EVEN IF LUTRON OR ANY OTHER PARTY WAS

ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

NOTWITHSTANDING ANY DAMAGES THAT CUSTOMER MIGHT INCUR FOR ANY REASON WHATSOEVER

(INCLUDING, WITHOUT LIMITATION, ALL DIRECT DAMAGES AND ALL DAMAGES LISTED ABOVE), THE ENTIRE

LIABILITY OF LUTRON AND OF ALL OTHER PARTIES UNDER THIS WARRANTY ON ANY CLAIM FOR DAMAGES

ARISING OUT OF OR IN CONNECTION WITH THE MANUFACTURE, SALE, INSTALLATION, DELIVERY, USE,

REPAIR, OR REPLACEMENT OF THE UNIT, OR ANY AGREEMENT INCORPORATING THIS WARRANTY, AND

CUSTOMER’S SOLE REMEDY FOR THE FOREGOING, WILL BE LIMITED TO THE AMOUNT PAID TO LUTRON

BY CUSTOMER FOR THE UNIT. THE FOREGOING LIMITATIONS, EXCLUSIONS AND DISCLAIMERS

TO THE MAXIMUM EXTENT ALLOWED

PURPOSE.

TO MAKE A WARRANTY CLAIM

To make a warranty claim, promptly notify Lutron within the warranty period described above by calling the Lutron

Technical Support Center at (800) 523-9466. Lutron, in its sole discretion, will determine what action, if any, is

required under this warranty. To better enable Lutron to address a warranty claim, have the unit’s serial and model

numbers available when making the call. If Lutron, in its sole discretion, determines that an on-site visit or other

remedial action is necessary, Lutron may send a Lutron Services Co. representative or coordinate the dispatch of a

representative from a Lutron approved vendor to Customer’s site, and/or coordinate a warranty service call between

Customer and a Lutron approved vendor.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply

to you. Some

limitation or exclusion may not

National Electrical Code (NEC) is a registered trademark of the National Fire Protection Association, Inc., Quincy,

Massachusetts.

Lutron, the sunburst logo, Hi-Lume, Tu-Wire, Sivoia, Eco-10 and GRAFIK Eye are registered trademarks, and

•4•6 is a trademark of Lutron Electronics Co., Inc.

HP 2

© 2011 Lutron Electronics Co., Inc.

not cover, and Lutron and its suppliers are not responsible for:

ANY DUTY, INCLUDING OF GOOD FAITH OR OF REASONABLE CARE; NEGLIGENCE, OR

BY APPLICABLE LAW, EVEN IF ANY REMEDY FAILS ITS ESSENTIAL

states do not allow the exclusion or limitation of incidental or consequential damages, so the above

apply to you.

BUSINESS INTERRUPTION; PERSONAL INJURY;

WILL APPLY

GRAFIK Eye® 3000 Series Control Unit Installer’s Guide 23

R

Contact Information

Internet: www.lutron.com

E-mail: product@lutron.com

WORLD HEADQUARTERS

USA

Lutron Electronics Co., Inc.

7200 Suter Road, Coopersburg, PA 18036-1299

TEL +1.610.282.3800

FAX +1.610.282.1243

Toll-Free 1.888.LUTRON1

Technical Support 1.800.523.9466

Brazil

Lutron BZ do Brasil Ltda.

AV, Brasil, 239, Jardim America

Sao Paulo-SP, CEP: 01431-000, Brazil

TEL +55.11.3885.5152

FAX +55.11.3887.7138

North and South America Technical Hotlines

USA, Canada, Caribbean: 1.800.523.9466

Mexico: +1.888.235.2910

Central/South America: +1.610.282.6701

EUROPEAN HEADQUARTERS

United Kingdom

Lutron EA Ltd.

6 Sovereign Close, London, E1W 3JF United Kingdom

TEL +44.(0)20.7702.0657

FAX +44.(0)20.7480.6899

FREEPHONE (UK) 0800.282.107

Technical support +44.(0)20.7680.4481

WORLDWIDE OFFICES

France

Lutron LTC, S.A.R.L.

90 rue de Villiers, 92300 Levallois-Perret France

TEL +33.(0)1.41.05.42.80

FAX +33.(0)1.41.05.01.80

FREEPHONE 0800.90.12.18

Germany

Lutron Electronics GmbH, Landsberger Allee 201,

13055 Berlin, Germany

TEL +49.(0)30.9710.4590

FAX +49.(0)30.9710.4591

FREEPHONE 00800.5887.6635

Italy

Lutron LDV, S.r.l.

FREEPHONE 800.979.208

Spain, Barcelona

Lutron CC, S.R.L.

Gran Via del Carlos III, 84, planta 3

08028, Barcelona, Spain

TEL +34.93.496.57.42

FAX +34.93.496.57.01

FREEPHONE 0900.948.944

Spain, Madrid

Lutron CC, S.R.L.

Calle Orense, 85, 28020 Madrid, Spain

TEL +34.91.567.84.79

FAX +34.91.567.84.78

FREEPHONE 0900.948.944

a

,

ASIAN HEADQUARTERS

Singapore

Lutron GL Ltd.

15 Hoe Chiang Road, #07-03 Euro Asia Centre,

Singapore 089316

TEL +65.6220.4666

FAX +65.6220.4333

China, Beijing

Lutron GL Ltd. Beijing Representative Office

5th Floor, China Life Tower

No. 16 Chaowai Street, Chaoyang District, Beijing

100020 China

TEL +86.10.5877.1817

FAX +86.10.5877.1816

China, Shanghai

Lutron GL Ltd., Shanghai Representative Office

Suite 07, 39th Floor, Plaza 66

1266 Nan Jing West Road, Shanghai, 200040 China

TEL +86.21.6288.1473

FAX +86.21.6288.1751

China, Hong Kong

Lutron GL Ltd.

Unit 2808, 28/F, 248 Queen’s Road East

Wanchai, Hong Kong

TEL +852.2104.7733

FAX +852.2104.7633

Japan

Lutron Asuka Co. Ltd.

No. 16 Kowa Building, 4F, 1-9-20

Akasaka, Minato-ku, Tokyo 107-0052 Japan

TEL +81.3.5575.8411

FAX +81.3.5575.8420

FREEPHONE 0120.083.417

Asia Technical Hotlines

Northern China: 10.800.712.1536

Southern China: 10.800.120.1536

Hong Kong: 800.901.849

Japan: +81.3.5575.8411

Singapore: 800.120.4491

Taiwan: 00.801.137.737

Thailand: 001.800.120.665853

Other countries: +800.120.4491

Lutron Electronics Co., Inc.

P/N 032-379 Rev. A 5/2011

LUTRON

®

Serie 3000 Guía

R

del instalador

Unidades de Control Modelos 3100 y 3500

POR FAVOR LEA

Sección 1: Introducción

Unidad de Control GRAFIK Eye® Serie 3000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Comunicaciones del Sistema y Capacidades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Sección 2: Instalación de una Unidad de Control GRAFIK Eye®

Paso 1: verifique las Caras para que no haya cortocircuitos . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Paso 2: DESCONECTE la alimentación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Paso 3: Monte la Caja de pared . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Paso 4: Conecte los cables de línea/alimentación a la Unidad de Control. . . . . . . . . . . . . . . . 5

Paso 5: Conecte Cable PELV (Clase 2: EE.UU.) a la Unidad de control – Opcional. . . . . . . . . 6

Paso 6: Monte la Unidad de control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Paso 7: Pruebe la Unidad de control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Paso 8: Conecte las Estaciones – Opcionales. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Paso 9: Conecte Otros Accesorios – Opcional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Paso 10: Conecte Múltiples Unidades de control – Opcional . . . . . . . . . . . . . . . . . . . . . . . . . 9

Consideraciones de Montajes Especiales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Instalación de una fuente de alimentación externa. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Sección 3: Programación de una unidad de Control GRAFIK Eye®.

Botones e indicadores de la unidad de control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Entrar y Salir del Modo Configuración . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Identificación del tipo de carga de cada zona . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Programación de las Escenas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Ajuste del extremo alto o bajo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Selección del Modo Guardar que quiere usar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Sección 4: Uso de la Unidad de Control GRAFIK Eye®

Selección de escenas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Ajuste Temporal de los Niveles de luz y las Posiciones de las Cortinas. . . . . . . . . . . . . . . . . . 18