Page 1

User information

„SILENTIO“ system control

Fill level measuring device and drinking

water supply

Item no.: 351022

Otto Graf GmbH Carl-Zeiss-Str. 2-6 Tel .: 07641-5890

Kunststofferzeugnisse D-79 331 Teningen Fax: 07641-58950

Page 1

Page 2

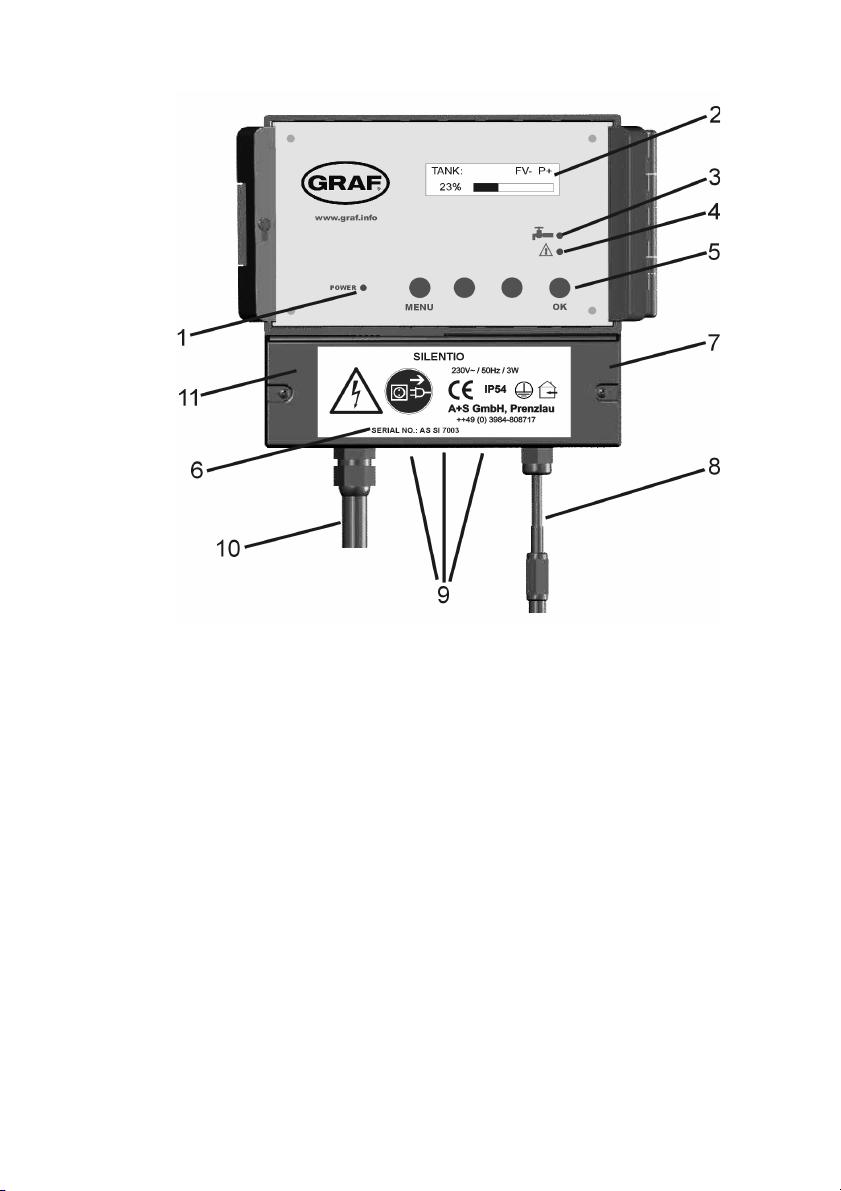

Figure 1: View of equipment

1: LED for power supply display

2: Display

3: LED for drinking water operation

4: LED for faults and malfunction

5: Operating buttons

6: Serial number

7: Lower cover of the System Control

8: Main connection cable with power coupling for data lead

9: Pre-stamped breakthrough for upgrading features

10: Mains power coupling for data lead supply cable

11: The mains circuit breaker of the system controls are under this

cover.

Page 2

Page 3

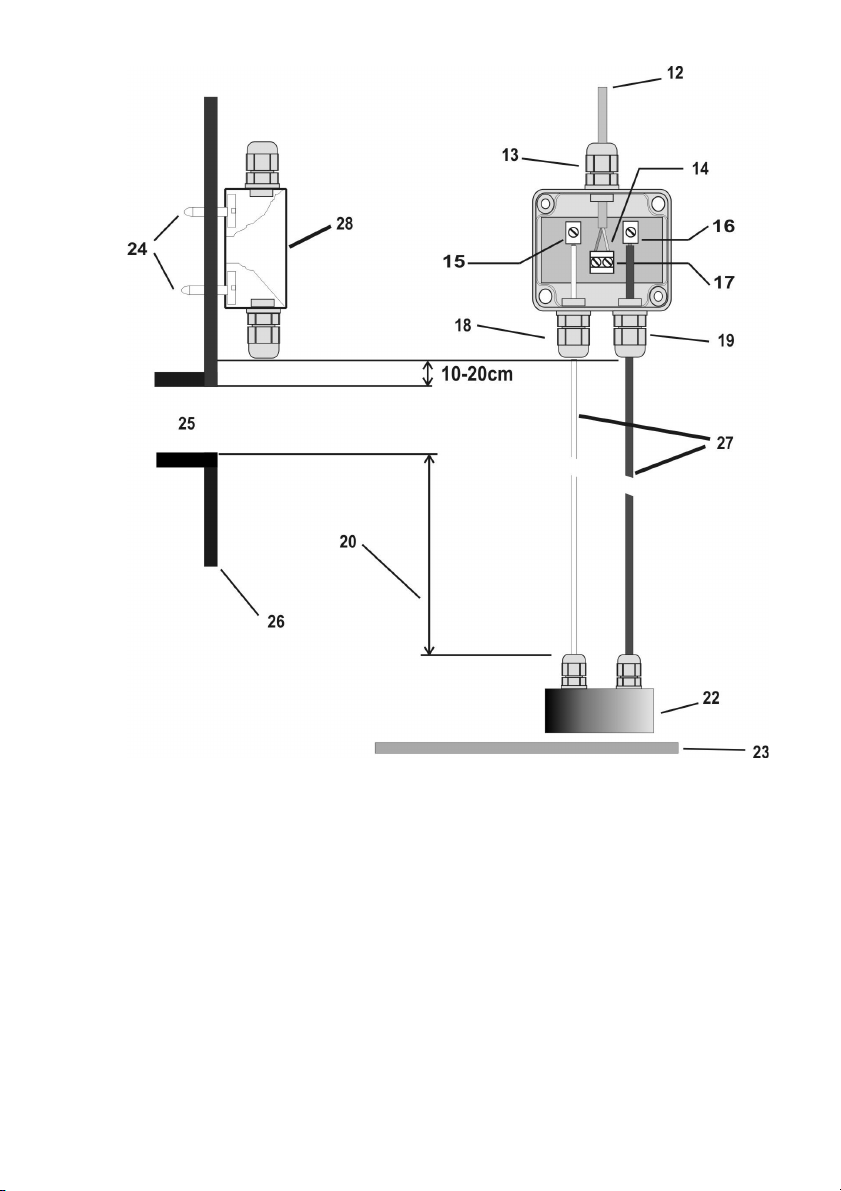

Figure 2: Sensor assembly

12: Data cable

13: screw cap 3

14: Connection of the data cable is reverse protected.

15: connect white cable here

16: connect red cable here

Page 3

Page 4

17: data cable terminal

18: screw cap 2

19: screw cap 1

20: active measuring length

22: Stainless steel probe

23: Tank floor

24: Screws must be blunted ! (danger of injury)

25: overflow

26: Tank side in dome

27: Sensor

28: Sensor control box ( measurement pick-up )

1. Safety Instructions

Please read carefully the safety and instruction manual before using this

device! Follow all instructions that are in the User Guide (Manual) to achieve

the optimal performance. Please keep these safety and operating instructions

safe for further use.

General Safety Instructions

Symbol Explanation

- refers to an information

- means warning and indicates a special situation

- indicates a hazardous situation which may cause to heavy or

serious injury or even death

1.1 Personnel

The installation, commissioning and dismantling of the device

must be done only by trained and authorized personnel. During

installation, it is necessary to pay attention to the safety

regulations defined by the user and local laws and rules.

Page 4

Page 5

1.2 Proper Use of the Device

The equipment is designed exclusively for the intended purpose specified in

the manual. Any other use and / or misuse of the device can lead to unpredictable risks including death and causes the loss of all the claims against the

manufacturer.

1.3 Limitation of Liability

The manufacturer would not take over any liability for damages resulting from:

- the usage of the device by untrained and unauthorized personnel,

- use of device for not intended purpose

- opening and/or manipulation of the device

- not following the manual and safety instructions

1.4 Electric Current

!!Danger of life from electric current!!

Direct contact to the parts of the device will cause an electric shock. In

case of damage to the insulation, the device must be switched off

immediately and the damaged area must be de-energized.

While maintaining on the device, ensure that the power supply is off at

all times and make sure the device is de-energized.

1.5 Electric Shock

If objects (e.g. hairpins, needles or coins) or liquids fall into the device,

it can cause life threatening electrical short-circuits, which can lead to

fire. The user has to make sure that above mentioned objects, especially

made of metal and/ or liquid things, will not fall in to the device

intentionally or unintentionally.

1.6 Safety Operations

The operation and use of the device is to be done by instructed and

authorized personnel only.

Page 5

Page 6

1.7 Power Supply

The equipment exclusively operates with the operating voltage indicated in the

manual.

1.8 Cable Connection

When installing the cable connections, the user needs to pay attention to

the safety regulations. Always pay attention to the connection to the

protective earth ground! Pay attention when connecting with other

devices, that those have to be of the same earth potential (same heavy

current/voltage side).

1.9 Ventilation

The equipment must be installed in so that good ventilation to the device is

ensured. Do not put any covering objects on the device, such as newspapers, books

or towels.

1.10 Water and Moisture

The device is not allowed to operate in close vicinity of electrical

conductive liquids or moist areas. It is not allowed to place any liquid

things on the device or in the nearby area of the device.

Attention: Danger of Electric Shocks!

1.11 Temperature and Heat

The operating temperature of the device is defined in the specifications. The device

must not be placed near things which produce heat such as to blowers, heaters,

furnaces or other devices.

1.12 Opening the Device

Disconnect the mains plug before opening the device!

There is a risk of electrical shock when touching the parts inside the

device. It is not permitted to make any changes in the device.

Page 6

Page 7

1.13 Cleaning

Do not use any volatile solvents such as alcohol, diluents, gasoline etc.

to clean the device. Only use a dry, clean cloth.

1.14 Unusual Smell

If any unusual smoke or smell occurs, immediately switch off of the

device and remove it from the main power supply! Contact your dealer

or the manufacturer.

1.15 Fuses

The replacement of the fuses in the device is only permitted by

trained and authorized technical staff.

The change of the fuses is only allowed when the device is switched off

and is removed from the main power supply. Otherwise there is a risk of

electric shocks. The security functions and safety values are mentioned

in the manual. The guarantee for this equipment will expire in case of

using other fuses than those specified in the manual.

1.16 Repairing

The user is not allowed to perform the maintenance work by himself, except for

those specified in the manual. All maintenance and repair work must be done by

trained and authorized technical personnel.

1.17 Important notes on safety

Special Safety Instruction

Please, read and follow safety instructions carefully before assembly or using

the device!

During installation and when working with 230 V ~ mains supply the VDE

regulations must be followed. Equipment using a 230 V ~ supply may only be

installed and commissioned by a qualified tradesman. The assembly place must

allow all possible safety precautions when laying the attached cables.

Page 7

Page 8

Power supply cables and data cables may not be damaged or squeezed for any

reasons. Plan the assembly place so that you can reach the mains plug easily and

unplug it from the electrical outlet in dangerous situations.

Choose the assembly place so that children cannot play or be near to the device and

at its connections without supervision.

Before opening the device disconnect it from the mains supply (unplug) otherwise

there is a serious danger of an electrical shock.

Fuses may only be replaced with standard-compliant parts with the same nominal

value.

All liability is excluded for damages which result from non-compliance of these

instructions or from an improper handling of the device. At chosen intervals in this

hand book we will give directions for safety precautions. These safety precautions

have been specially marked.

2. Description and intended use

The “SILENTIO” is an electronic water management control system. It has been

developed especially for rain water usage systems. It can be used with a wide

variety of tank systems. Tanks made from metal or steel reinforced cement may

only be used when the following conditions have been correctly followed.

Metal tanks lead to faulty readings. Helpful is to assemble the device so that the

sensor is as far as possible from the metal sides so for example, in the centre of a

cylindrical tank. The system controls offer an easy to use guide for the switch

programming.

Using an LCD display the fill measurement is shown in 1 % stages (in relation to

the height of the tank).The sensor operates with a 12 volt supply. All programmed

values such as the tank height are retained after disconnection of the power supply

or after a power-cut.

3. Description

Performance features:

– Fill level measurement readout in 1% steps and with

an additional bar type indicator

– In 1% steps freely variable choice of the switching

points for the drinking water refill

– Automatic flushing of the system (choice of intervals

in day and time are possible)

– Dialogue oriented user guidance (choice of language)

– Equipment indication using 3 additional LED

– Supervision of the measurement pick-up and the

sensor

– Error indications in plain text

Page 8

Page 9

Technical data:

Control electronics Measurement sensors

Operating current :230VAC Measurement voltage :12DC

Fused :T50mA Measuring frequency :(0,2-20)kHz

Power consumption :3VA Data cable length :20m

Tank height :3m (optional 6m)

Measurements [mm] :155x165x90 Measurements [mm] :90x80x50

Additional pumps connection Filter cleaning valve connection

Operating voltage :230V AC Operating voltage :230V AC

Pump capacity :max. 850VA Valve effective performance : max. 1A

Notes:

Only the control electronics in the device are protected by the fuse. Valves

and pump connections are not protected. These are protected only by the

mains supply via the mains fuse.

The yellow LED indicating “Drinking water operation” is lit as soon as the

valve switches over to the mains supply. The user is made aware that the

system now uses water from the mains supply. The red LED for “Faults

and malfunctions” is lit as soon as the system identifies a fault. The display will

then show a warning that describes the cause of the fault in plain text.

4 . Assembly:

4.1 Control system

The electric mains supply plug acts also as the ON/OFF switch.

Before opening the equipment pull the plug out from the mains

socket!

The system control is integrated as standard in the basic „SILENTIO“ device from

the company Graf. Caution: Always remove the plug from the mains socket before

opening the lower cover [7] of the system control housing!

Page 9

Page 10

4 .2 Connection sensors and data cable:

The sensor electronics comprise of a stainless steel probe [22] with a red and a

white connecting cable [27] and the sensor measurement pick-up [28].

Figure 3: Sensor technology

1. Now the sensor measurement pick-up [28] (cover removed) should be

installed on the tank wall (preferably in the man hole shaft of the Graf

synthetic tank). The location of the mounted sensor pick-up should be

between 10 and 15 cm above the overflow [25]. The enclosed screws

should be used to secure the device. After fully tightening the screws, the

points that are showing themselves on the outside of the tank must be

blunted to avoid injury [24].

2. Measure the height from the bottom of the tank [23] to the end of the

terminals [15] and [16] on the measurement pick-up [28].

3. Shorten the connection cable to suit the measured height.

4. Connect the sensor cable to the sensor as described in the following

instructions: Remove between 5-7 mm of the insulation from both of the

cables. Next, pass the red cable through the screw mounting 1 [19] and

tighten this lightly, then connect the red cable to the terminal [16]. The

free white cable is now passed through the screw mounting 2 [18] and

tightened lightly, then connect the white cable to the terminal [15].

5. Now pass the end of the data cable that has no plug connector [12]

through the screw mounting 3 [13]. Lightly tighten the screw mounting

and connect the cable wire cores of the data cable [12] to the double

terminal [14]. The connection of the data cable is reverse polarity

protected. Attention! The screws should be tightened with care to

ensure that they are not damaged through over tightening.

6. Now recheck that all the screwed items and the sensor components have

Page 10

Page 11

been fitted correctly. Replace the cover of the measurement pick-up and

secure this with the appropriate fastening screws.

7. The installation of the data cable [12] to the system control must be

according to good professional practice to constitute a correct completion

of the sensor technology: A protective cable conduit must be used. (The

data cable is not suitable for installing directly in the earth).

The end of the data cable that is still unconnected is fitted with a plug

connector. This is to be plugged into the appropriate socket [8] of the

system control. Diagram 2 on page 3 makes clear the interrelation:

Note:

The red and the white cable going down to the probe should be straight and

smooth to be drawn taught by the weight of the stainless steel probe. The

stainless steel probe must hang just above the tank floor.

4 .3 Electrical connection of the filter flushing valve:

Before opening the equipment pull the plug out from the mains socket!

The connection of the valve for cleaning the rainwater filter is optional. If running

the system without the rainwater filter please read on from point 3 (Putting into operation).

Before connecting the Rainwater usage system, please ensure there is no over

straining or tension on any of the connections.

The plug of the system control unit must not be connected to the socket of the

electrical supply.

Pass the end of the cable from the solenoid valve for the rainwater cleaning filter

through the threaded grommet holder provided with the housing of the SILENTIO

system control. Now open the lower housing cover [7] of the system control (see

Figure 1). The openings for the threaded grommet holders are pre-stamped to ease

breaking out. Break out the opening for the threaded grommet holder with an

appropriate tool such as a small screw driver. Fit the supplied threaded grommet

holder into the opening and secure with the locking nut from the inside. Isolate the

wire cores of the cable in the proper manner. Pass the cable through the grommet

opening in the system control unit housing. Connect the protective earthing

conductor (green - yellow wire core) to a free terminal with the designation “PE /

Ground”.

Connect the neutral wire core (blue) to a free terminal with the designation “5”.

Connect the live electrical supply wire core (brown or black) to a free terminal with

Page 11

Page 12

the designation “3” (power supply to the filter flushing valve). The following figure

depicts the connections described above:

1: Pump

2: Power supply to additional pump

3: Power supply to filter flushing valve

4: Power supply to switch-over valve

5: Neutral conductor

P: 230V AC

PE / Ground : Earth

Figure 4: Electrical diagram for filter flushing valve

After connecting the wires, close the lower cover [7] of the system control housing.

4.4 Electrical connection of the additional pump:

Connection of the additional pump is optional. If running the system without the

additional pump please read from point 3 (putting into operation).

Before opening the equipment pull the plug out from the mains socket!

Page 12

Page 13

The plug of the system control unit must not be connected to the socket of the

electrical supply. An earth cable is absolutely necessary for connection of the

additional pump. We advise that this cable should be protected by a pipe running

from the holding tank to the rainwater usage system. Pass the end of the cable

through the threaded grommet holder provided with the housing to the SILENTIO

system control. Now open the lower cover of the system control housing (see

Figure 1). Remove the blind screw and replace this with the supplied threaded

grommet holder. Isolate the wire cores of the cable in the proper manner. Pass the

cable through the grommet opening in the system control unit housing. Connect the

protective earthing conductor (green - yellow wire core) on a free terminal with the

designation “PE / Ground”. Connect the neutral wire core (blue) on a free

terminal with the designation “5”.

Connect the live electrical supply wire core (brown or black) on a free terminal

with the designation “2” (power supply to the additional pump). The following

figure depicts the connections described above:

1: Pump

2: Power supply to additional pump

3: Power supply to filter flushing valve

4: Power supply to switch-over valve

5: Neutral conductor

P: 230V AC

PE / Ground : Earth

Figure 5: Connection diagram for additional pump

After connecting the wires, close the lower cover [7] of the system control housing.

Page 13

Page 14

5. Putting into operation:

Before putting into operation, please be absolutely sure that all the live wires and

electrical terminals are correctly insulated and that the protective covers are in

position throughout the system. Now open the transparent cover of the system

control. Now plug in the system to the appropriately fused socket for the system.

The system will now independently run through a systems check. For the duration

of the systems check (approximately 10 seconds) the display will read as follows.

Instead of “xx” the software position will be shown.

Figure 6: Display for the duration of the systems check

In the first line the system type will be shown and in the second line the software

position will be shown. After the correct initialisation of the system installation has

been acknowledged the LCD display will show the fill level as a percent (%).

The first running of the unit will show the fill level reference point that

is according to the standard factory setting tank height Standard

factory setting values:

- Tank height to overflow : 200cm (+/- 1cm)

- Drinking water switching point : ON at 10%

OFF at 12%

- Flushing the drinking water system : after 14 days for 30 seconds

- Cleaning the rainwater filter : after 14 days for 5 seconds

with rainwater

- Language : English

Figure 7 shows the LCD display in operation mode. Except for the fill level and the

switch positions “FV” and “P” the display should correspond with the intended

default.

Page 14

Page 15

29: Status of valve for rain water filter FV+ : Filter valve open

30: Status of house water system (Pump) FV- : Filter valve closed

31: Visual representation of fill level P+ : House water pump

running

32: Fill level % P- : No water being

with drawn

Figure 7: Display in operation

6. Set up of the system control:

After putting into operation, the system control must be adjusted and programmed

according to the conditions and requirements of the individual users system. The

required settings are easily programmed. There are four buttons for this purpose.

All necessary programming data entries follow a menu displayed by the LCD. For

the set up follow all the points listed in table 1 in the sequence as shown. Should

any error in the sequence occur then it is necessary to begin the set up again from

the beginning starting with the tank height. Begin the programming of the settings

by pressing the button marked “MENU”.

With the buttons “+” or “-” the menu may be scrolled backwards and forwards.

With the respective menu point shown the values may be altered. For this the

button “ENTER” must be used. The “?” displayed in the LCD will now change to a

“>”graphic character. With the “+” or “-” the desired value may now be entered

according to individual requirements. When the desired value has been entered this

must be confirmed by pressing the “ENTER” button. The value is only then taken

over and stored in the programming of the unit.

Page 15

Page 16

Through pressing the “MENU” button again the display changes back to the

operation mode.

It is possible to reset the unit to the factory setting standard values at any time.

The resetting can only be carried out in the operation mode (Display see Figure 6):

To do this press the “ENTER” button and hold it pressed. Now simultaneously in

addition press the “MENU” button. After a short wait the following display will be

shown:

Figure 8: Message reset to standard factory settings

As soon as this message is displayed the buttons may be released

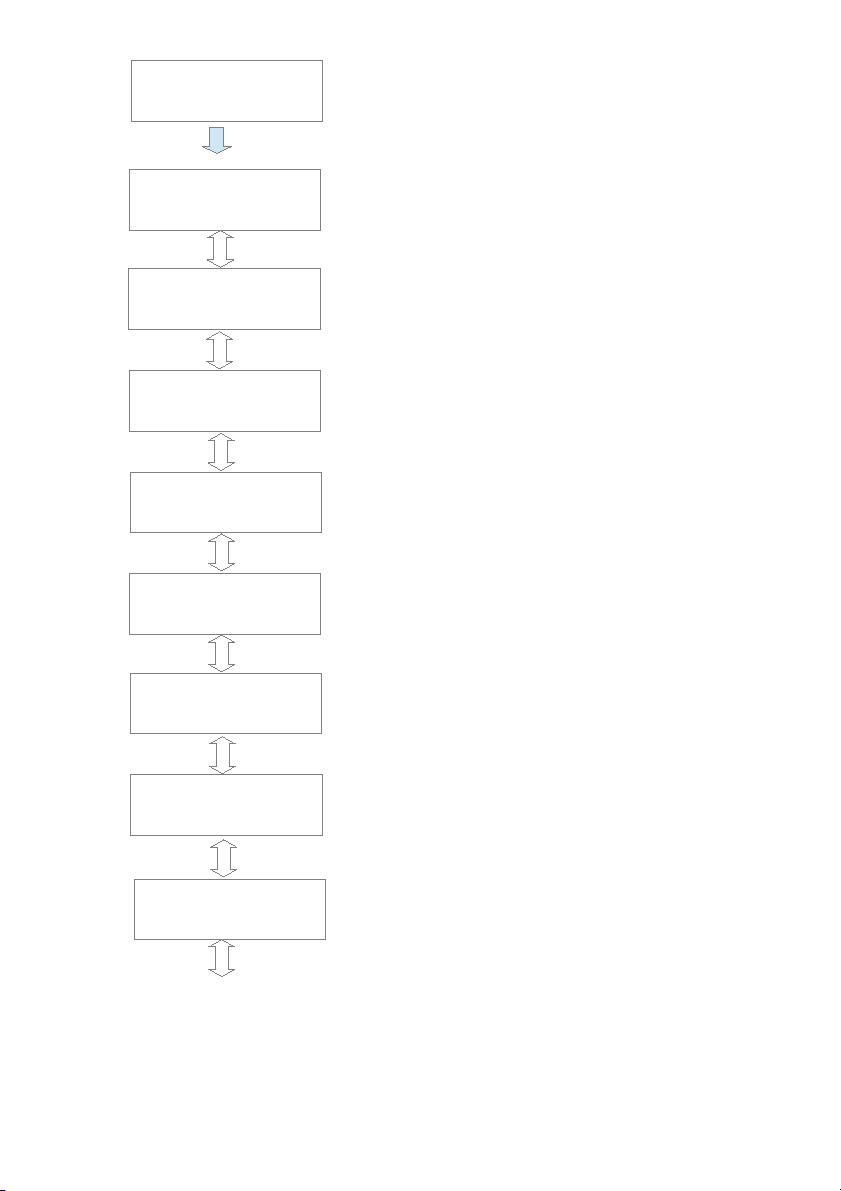

The menu structure integrated in the system control is introduced to familiarise the

user in diagram 9. To bring up the menu, press and hold the „MENU“ button for

longer than 5 seconds. All outlets are inactive when the menu level has been activated. The operation of the device is suspended. The system control switches automatically back to the operating mode when no entries have been received for approximately 30 seconds.

key „MENU“ (>5s)

+/- +/-

Depiction 9: Main menu level

Press the “ENTER” button to arrive at each of the listed sub-menu functions.

Through pressing the “MENU” button again the display changes back to the operation mode.

Page 16

DEFAULT VALUES

23%

SWITCHING POINTS

DEVICE

ADJUSTMENT

MANUAL OPERATION

TANK: FV- P+

23%

Page 17

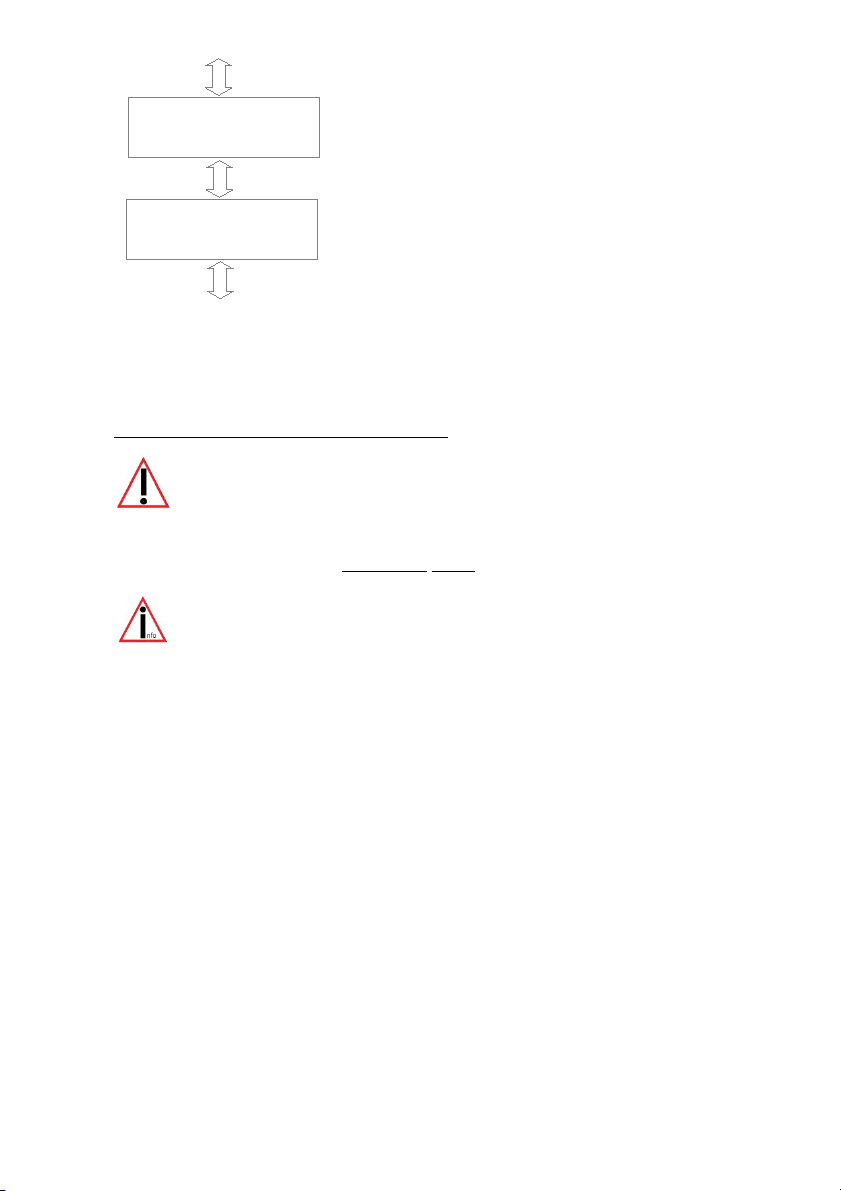

Depiction 10: Sub-menu “Switching points”

Page 17

SWITCHING POINTS

key „ENTER“

VALVE ON

0-100% 10%

VALVE OFF

0-100% 12%

Supply with mains drinking water – OFF

+ / -

Supply with mains drinking water – ON (The

numerical value is always smaller than with valve

OFF)

DW INTERVAL

0-14 DAYS 14

Flush the drinking water supply piping every 14

days. The value „0“ switches the flushing off.

+ / -

+ / -

Flushing the drinking water supply pipes for 30

seconds.

+ / -

DW DURATION

0-60 SEC 30

Cleaning the rainwater filter every 14 days

The value 0 switches the cleaning process off.

+ / -

CLEANER INTERVAL

0-14 DAYS 14

Cleaning the rainwater filter for 5 seconds

CLEANER DURATION

0-60 SEC 5

CLEANER RINSE AT

INCREMENT 2%

Cleaning the rainwater filter when the fill level

has increased by 2% after rainfall. If the fill level

continues to increase, the rinsing will be repeated

every 3 hours. The value 0 switches the cleaning

process off.

+ / -

+ / -

Main menu level

CLEANER RINSE

WITH DW NO

Permit the cleaning of the rainwater filter with

mains drinking water (standard: “NO”)

+ / -

Page 18

Press the „ENTER“ button to alter the respective switching points The value to be

altered will begin to blink. The value may then be adjusted by using the „+“ and the

„-“ buttons. Press the “ENTER” button again when the displayed value should be

accepted.

Note:

In the depiction 10 the standard factory settings have been displayed.

The following is an introduction to the general device settings:

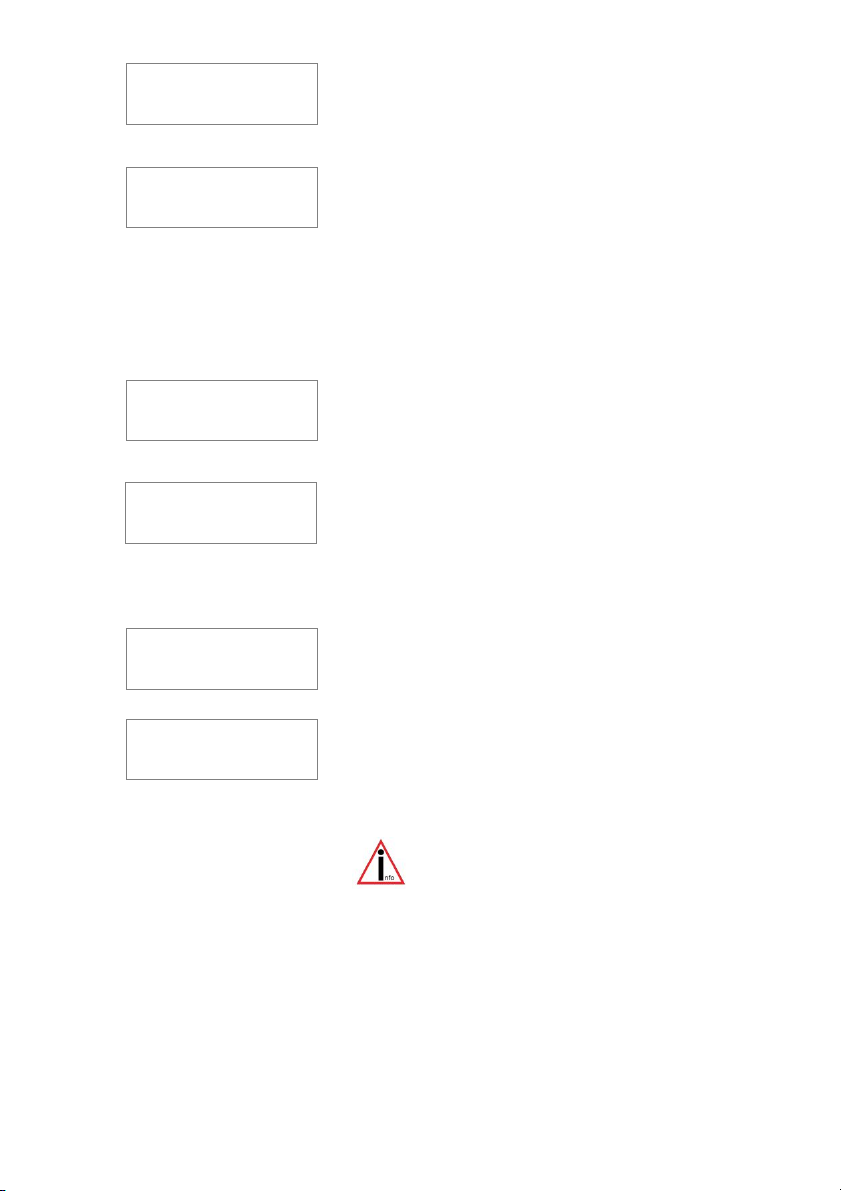

Depiction 11: Sub-menu “General device description”

The last part of the operation level covers the manual functions:

Page 18

DEVICE

ADJUSTMENT

LANGUAGE

ENGLISH

key „ENTER“

+ / -

[20] in Figure 2

(A 6m Sensor may be ordered.)

MEASURING LENGHT

30-600cm 200

+ / -

MANUAL OPERATION

LAST FLUSH

DW 0

key „ENTER“

+ / -

HAND FLUSH

DW NO

Time scale in days; the time elapsed since the

last flush using mains drinking water

Activation of the flushing process for the mains

drinking water inlet pipe. The switch-over valve

remains permanently switched on. The yellow LED

blinks. The system is using mains drinking water !

Main menu level

Main menu level

Page 19

Depiction 12: Sub-menu “Manual functions”

7. Error messages and fault correction:

The operation of the system control is to be checked at regular intervals

(at the latest every 4 weeks).

The read out reports always represent only probabilities; e.g. no clear localization

by the device is possible for overlaying faults.

Please also take note that the system control device cannot identify any

malfunction of the house water system. (No malfunction signal is supplied

by the house water system to the system control device).

If faults are recognized by the sensors the system control cannot continue to work

independently.

The particular faults are shown on the plain text in the display:

Page 19

LAST RINSE

CLEANER 1

+ / -

HAND RINSE

CLEANER NO

Time scale in days; the time elapsed since the

last filter rinse

+ / -

+ / -

Activation of the filter rinse

Page 20

Depiction 13: Error messages

Page 20

ERROR

SENSOR

The reason for this error is that the white

sensor cable has been damaged.

ERROR

DL SHORT CIRCUIT

Error possibilities:

The data cable of the measurement pick-up

is not connected to the data cable terminal

[14] but has been connected to the sensor

terminal [15/16] -

- Cinch plug or the cinch connector has a short

circuit

- Wires of the data cable have been damaged

ERROR

SENSOR CONTROL

The measurement sensor delivers no signal

and must be replaced.

ERROR

SENSOR SYSTEM

For further diagnosis, remove the stainless steel

weight [22] out of the water. If the error indication

has now stopped, then the sensor it self was the

cause of the fault. If the error indication should

continue, this implies that the measurement pick-up

is defect.

ERROR

NO SIGNAL

The communication between the system

control to the measurement pick-up is

interrupted.

ERROR

MEMORY

First try re-setting the system control to the

factory default settings . If the error message

continues to be displayed then it is necessary

to contact your service partner.

Note: After re-setting to the factory

default settings all the newly

programmed setting values will

have been overwritten and must be

re-programmed!

Page 21

Before opening the equipment pull the plug out from the mains

socket!

If the device shows no function at all then check whether the main electrical supply

provides current and also check the house fuses.

If the electrical outlet is under current, then unplug the mains plug from the system

control. Without connection to current open the lower cover of the system control

(see Figure 1) and check the equipments mains fuse.

If your efforts are unsuccessful, please consult the manufacturer by E-Mail:

GmbH

Niederlassung Prenzlau

Franz Wienholz Str. 40

17291 Prenzlau

Tel. : +49 (3984)- 80 87 17

Fax : +49 (3984)- 80 69 61

Internet : http:// www.aktuatorikundsensorik.com/

E-Mail : info@AS-Prenzlau.de

We prefer to receive an E-Mail, if you must contact us then be sure to enter

the serial number of your controller that begins with “AS”.( The serial number

is found on the name/type label. )

8. Upgrade options:

The SILENTIO control device can also be equipped with a number of additional

special functions.

1. Optional pressure sensor

Using a pressure sensor, alternative mediums or depths

may be adapted to the use of the device. The sensor must

be matched the required specifications of the device.

2. Optional drain pump

If the fill level of the tank reaches a specified value, then

a valve or a pump can be activated. This is to prevent the

fill level of the tank from exceeding a specified

maximum level.

Page 21

Page 22

3. Optional refill

If the fill level in the main tank sinks below a specified

level, then a second tank is employed to back up and re

fill the main tank. The pump used in this process must

also be equipped with a mechanism to prevent it from

running dry.

If this system is required, then the device must be sent to the manufacturer. There

follows an additional calculation.

Note:

The standard system control device may be equipped with a maximum of

one additional switch output point.

9 . General installation and assembly regulations:

It is necessary to these instructions when installing a rain water usage equipment:

EN 806:

- Drinking water installation

- Planning and implementation

- Calculation of the pipe diameters

- Using the equipment

EN 1717:

- free outlet between drinking and rainwater

- Notification sign to inform that a rainwater usage system is installed

in the locality

- Notification signs marking the rainwater outlets

- Notification signs marking the rainwater installations network

- Backflow prevention (e.g. a non-return/check valve)

- Frost free installation

- Reservoir/tank with air bleeding/ventilation

Page 22

Page 23

- No diameter reduction in the drainage system according to EN 1256

- Technical regulations in relation to groundwater drainage according

to EN 752

- Drainage systems outside of buildings according to the regulations of

the local services authorities

- When required: Obligatory registration of the system and other mandatory stipulations

10. Disposal of the equipment:

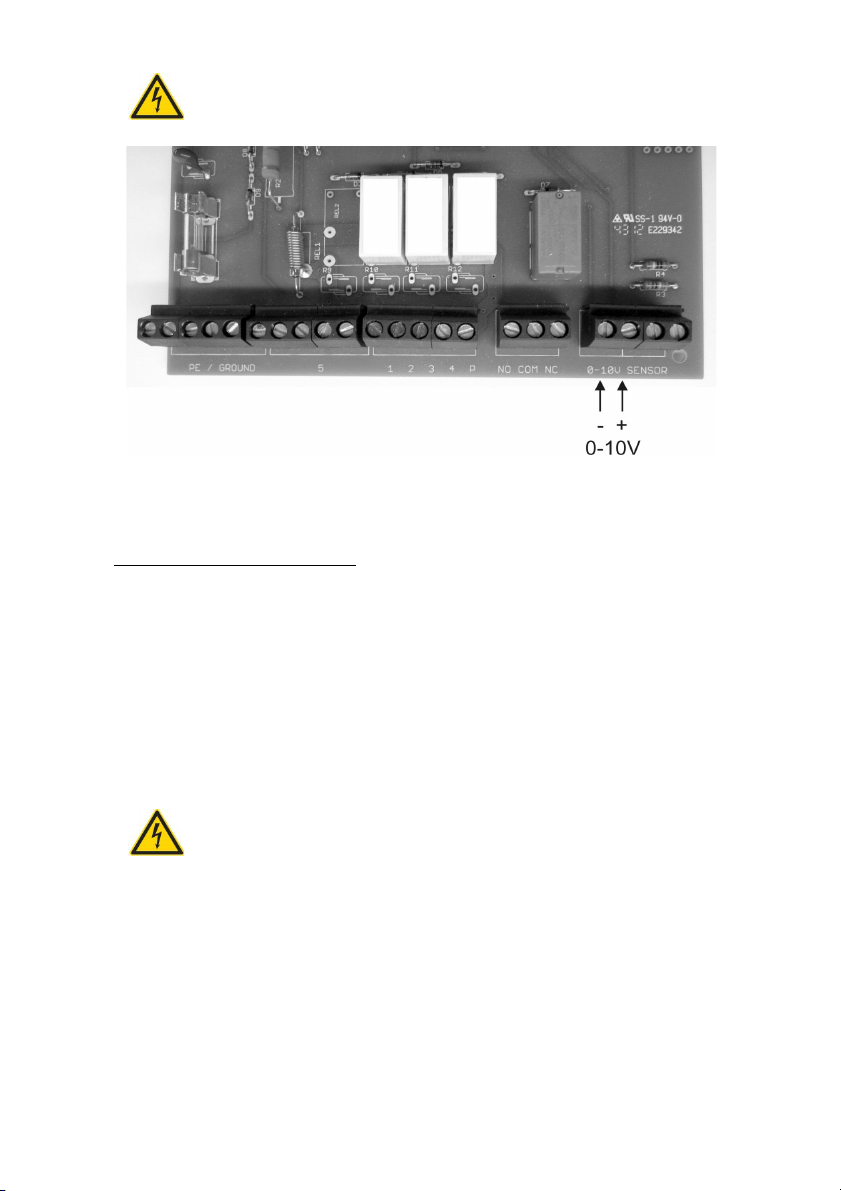

11. Analogue outlet:

Your device has been fitted with an additional analogue port. This port shows the

percent values from the system control (0% – 100%) by a voltage range from 0V to

10V. The following connection values apply:

Minimal apparent ohmic resistance : 20K Ohm

Short circuit protection : Yes

Short circuit current : Approx 15mA

Cable length : maximum 200m

(shielded)

Note:

The system control is only capable of displaying whole percent values (no

fractions). These are shown on the analogue signal display. A maximum of

one digit behind the point is to be considered for the evaluation of the

pro-cent value.

Page 23

Old equipment may not be disposed of in

the house refuse. It must be brought to the

recognised professional recycling depot.

Please help – ensure your old electronics

come to a separate recycling.

Page 24

Before opening the equipment pull the plug out from the mains

socket!

Depiction 14: Location of the analogue port

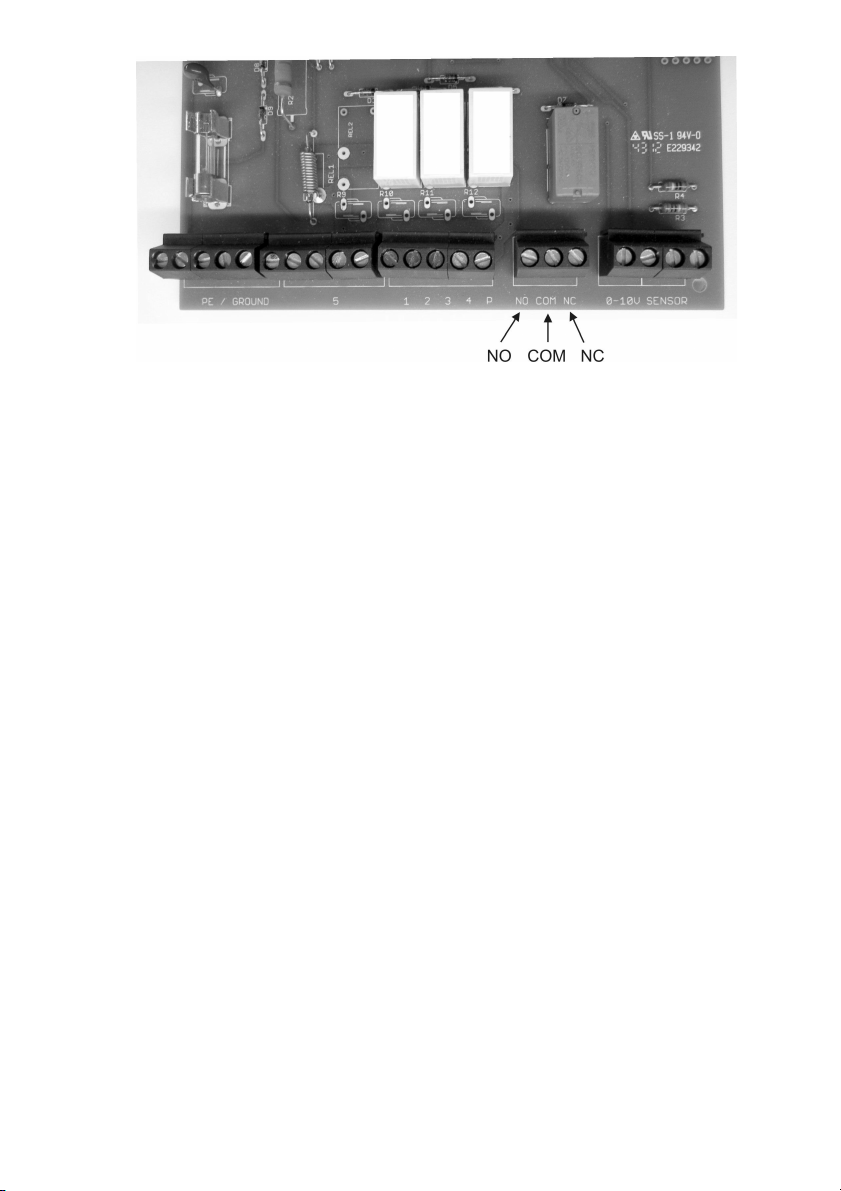

12. Alarm indicator contact:

As an additional function, your unit is equipted with a potential-free alarm indicator

contact. This contact is designed as a changeover contact element. A maximum of

230V AC is approved when a current of 1A is switched. The activation of this contact occurs as soon as one of the malfunctions listed under Point 6 appears. The

picture on the following page shows the location of the connections. These become

available as soon as the lower cover of the system control unit is opened (see [7] in

diagram 1).

Before opening this cover, it is important to disconnect the device from the

mains electricity supply!

Before opening the equipment pull the plug out from the mains

socket!

Explanation of terms:

- COM is the common port

- NC is coupled to the COM port when there is no current.

- NO is connected to the COM port when there is a malfunction

Page 24

Page 25

Depiction 15: Location of the fault indicator

The M 12/M16 opening on the underside of the system control device must be

opened and the cable drawn through. Place the supplied grommet into the opening

and pass the cable through into the system control.

Page 25

Page 26

Attachment A – Symbols used:

Attention! Pull out the mains plug from the socket before

opening the device.

Warning of dangerous electrical voltage

Attention! An error has occurred.

Mains drinking water operation

Page down

Page up

Protection classification I

Only for use in a dry areas.

Page 26

Page 27

Room for your notes:

Page 27

Page 28

Revision history:

Revision Date Description Author

Silentio 3.4 12.02.18 Formatting SU

Room for your notes:

Purchase date : ...................................

Device serial number / Type : AS SI .......................

Active measuring length : ...................................

Software level SILENTIO REV : .......

Design and specifications are subject to change without notice

Dated: February 2018 ; Version: SI 3.4

man_Silentio_3-4_eng.odt

Page 28

Loading...

Loading...