Page 1

1 / 40

Instructions for

start-up, operation and maintenance

one2clean+

one2clean+ XXL

Small wastewater treatment

systems

Control unit version KL24plus

The points described in these instructions must be observed in all

cases. Failure to do so shall invalidate the warranty. For any additional items purchased through

GRAF, you will receive separate

installation instructions in the

transport packaging.

The components must be checked

for any damage before the system

is transferred to the pit.

You will receive separate instructions for installation of the system.

Be sure to read before starting

up!

Contents

1. General information 2

2. Safety 3

3. Description of function 6

4. Control unit 8

5. Start-up 18

6. Level measurement 19

7. Operation and maintenance 22

8. Fault messages and rectification 28

9. EC conformity declaration 31

10. Technical data 32

11. Template for weekly / monthly check notes 34

12. Maintenance log for GRAF small wastewater

treatment systems 37

13. Notes 39

Page 2

1. General information

2 / 40

1. General information

Below you will find some important information for safely operating your system for a long time to come.

• The SBR system is designed to receive all domestic wastewater. Other wastewater, e.g. from restau-

rants and / or commercial premises etc., may only be received if this was specified and taken into

account in the system's design.

• Biocides, toxic substances or substances which are not biocompatible must not enter this system

because they hinder bacteria important to wastewater cleaning and cause problems in the biological

process (detailed information is provided on the following pages).

To meet official cleaning requirements, it is essential that the system is operated in accordance

with our operating and maintenance instructions. You will find these instructions on the following

pages.

We also ask you to read the following information carefully:

The External control cabinets should be located as much in the shade as possible to prevent

them from overheating in the summer.

At all times ensure that the cabinet, especially its ventilation apertures, are not covered and are

freely accessible for maintenance work.

External control cabinet: Ventilation apertures on the rear

The power supply must be ensured at all times. Please ensure that the fuse on the control cabi-

net is sufficient (16 A). Additional electrical fixtures on the same fuse may disrupt operation.

Page 3

2. Safety

3 / 40

2. Safety

This chapter contains details relating to safety measures and residual risks. Read this chapter through

carefully before using the system to ensure that it is used as safely as possible.

Intended use 2.1

The control unit was specifically developed for use in SBR small wastewater treatment systems. The control unit must not be used in areas representing a danger to life and limb:

control of machinery, vehicles and safety processes,

research technology involving hazardous substances,

medical technology,

nuclear power technology,

etc.

Explanation of warning notices and prohibitions 2.2

Warning of danger

Warning of dangerous voltage

Warning of tripping risk

Warning of hot surface

Warning of hand injuries

Warning of explosive atmospheres

Fire, naked flames and smoking prohibited

Page 4

2. Safety

4 / 40

Danger notices 2.3

1. To ensure safety, everyone who comes into direct contact with the system must note the content of

this documentation.

2. The system must not be used for any purpose other than that described by the manufacturer.

3. Local operating and safety requirements and legislation must be followed at all times, even if they

are not explicitly mentioned in these instructions. The same applies to environmental requirements.

4. If the operator becomes aware of mistakes or dangers, the manufacturer or responsible maintenance company must be informed immediately.

5. Safety precautions must never be removed or bypassed during normal operation of the wastewater

treatment system. Safety precautions may only be temporarily bypassed or deactivated by the

maintenance fitter during repairs and maintenance.

6. When working with chemical substances, contact with the chemicals should be avoided Before these substances may be used, the instructions for use on the packaging must be read and followed.

7. If the use of personal protective equipment (safety shoes, protective glasses, gloves, ear defenders,

etc.) is prescribed, ensure that they are used. Defective or damaged protective equipment must be

immediately replaced with fully functional equipment.

8. Work on electrical equipment may only be undertaken by specialists.

9. All safety and danger notices on the machine should always be kept fully legible.

10. Hot parts must not come into contact with explosive or highly flammable chemicals.

11. Do not put vessels containing liquids on electric switch cabinets; short circuits may occur if the liquid

is spilled.

12. The system must not be operated by anyone under the influence of alcohol or medication which limits cognitive ability or ability to react.

13. The system must be de-energised before any maintenance or cleaning work takes place.

14. Other than for maintenance purposes, the system should always be left switched on, otherwise correct wastewater cleaning cannot be guaranteed.

Page 5

2. Safety

5 / 40

Warning notices 2.4

Be sure to observe this information. Failure to do so may result in personal injury or damage to property!

Installation loca-

tion

Ensure that the machine cabinet is not installed above or in the direct vicinity of water

vessels. There is a risk of electric shock if improperly installed.

Mains connection

Only connect the machine cabinet to a correctly installed 230 V socket or earth cable

which is fused with an upstream 16 A fuse.

Electrical equipment connected to the mains may be damaged during a storm. We

would recommend fitting surge protection in the building to protect against this.

The connection cable must be laid in a way it won’t represent a tripping hazard.

Explosive atmos-

pheres

The control unit must not be fitted or activated in environments with potential explosive atmospheres or in places where there are flammable materials. Sparks in such

environments may cause an explosion or fire and this may result in physical injuries

or even death.

Interferences

The control unit may cause medical equipment to malfunction. This device should

therefore not be used in close proximity to medical equipment.

Damage

The control unit must not be operated if the housing or cable insulation is damaged or

crushed.

Service work

Service work on the machine cabinet may only be undertaken by authorised specialists / electricians.

Voltage supply

The power supply must be ensured at all times. Please ensure that the fuse on the

control cabinet is sufficient (16 A). Additional electrical fixtures on the same fuse may

disrupt operation.

Page 6

3. Description of function

6 / 40

3. Description of function

Description of the wastewater treatment process 3.1

The one2clean+ wastewater treatment system is a fully biological system and functions on the principle of

the retention process with extended aeration (Sequencing Batch Reactor). The system basically consists

of an aerobic stage, which is split into a rest and an aeration zone, linked together in the lower section.

This process therefore subjects all the domestic wastewater directly to aerobic wastewater treatment.

Blowing in compressed air aerates the entire system and the resultant aerated sludge biologically cleans

the wastewater.

The coarse materials and floating solids in the wastewater are initially retained using a scum guard in the

rest zone. Then the wastewater passes into the aeration zone via an aperture under the scum guard.

The rest zone is aerated too, so the retained solids are also aerobically broken down over the course of

time. In the one2clean+, the wastewater is treated without pre-treatment so no anaerobic putrefaction

processes can occur.

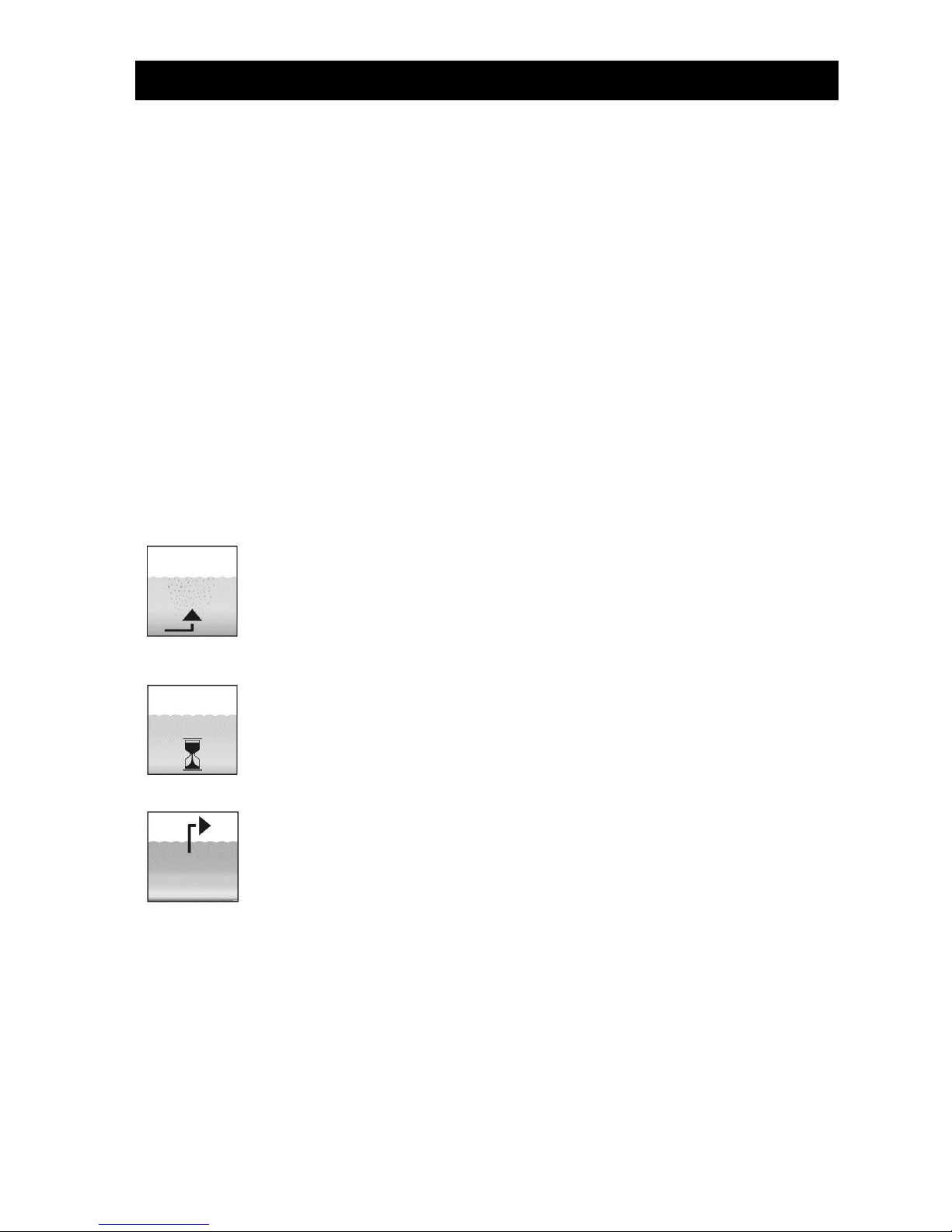

The SBR procedure is a series of different steps, undertaken one after another and at least once a day.

Step 1: Aeration

In the first phase, the wastewater is put straight through aerobic treatment for a fixed

time. As a result, the microorganisms (aerated sludge) are supplied with the oxygen

needed for the breakdown and then pressure aeration causes mixing. The system's

aeration equipment is supplied with ambient air by a compressor. Aeration is intermittent so that targeted wastewater cleaning is possible. Different ambient conditions can

thereby be achieved.

Step 2: Settle

There is no aeration in the second phase. The aerated sludge and the remaining settleable solids can now settle with the aid of gravity. A clear water zone forms at the top

and a sludge layer at the bottom. Any floating sludge is on top of the clear water zone.

Step 3: Clear water extraction

In this phase, the biologically cleaned wastewater (clear water) is drawn out of the SBR

stage. It is pumped out by an air lift (or mammoth) pump, which uses compressed air.

The air lift pump is designed not to pump out any floating sludge on top of the clear

water layer. A minimum water level is maintained in the system without any further

components.

In multi-tank systems, there is also a phase in which the sludge is returned to the system.

Once step is complete, the cleaning process starts again with step 1.

Two cycles are undertaken a day. The maintenance company can individually adapt the switching times.

Page 7

3. Description of function

7 / 40

Structure of one-tank systems 3.2

Figure 1: One-tank system

Structure of multi-tank systems 3.3

Figure 2: Two-tank system

Sampling point

Clear water lifter

Scum baffle

Pipediffusors

Sampling point

Clear water lifter

Pipe Diffusors

Pipediffusors

Sludge return

Connection pipe

Page 8

4. Control unit

8 / 40

4. Control unit

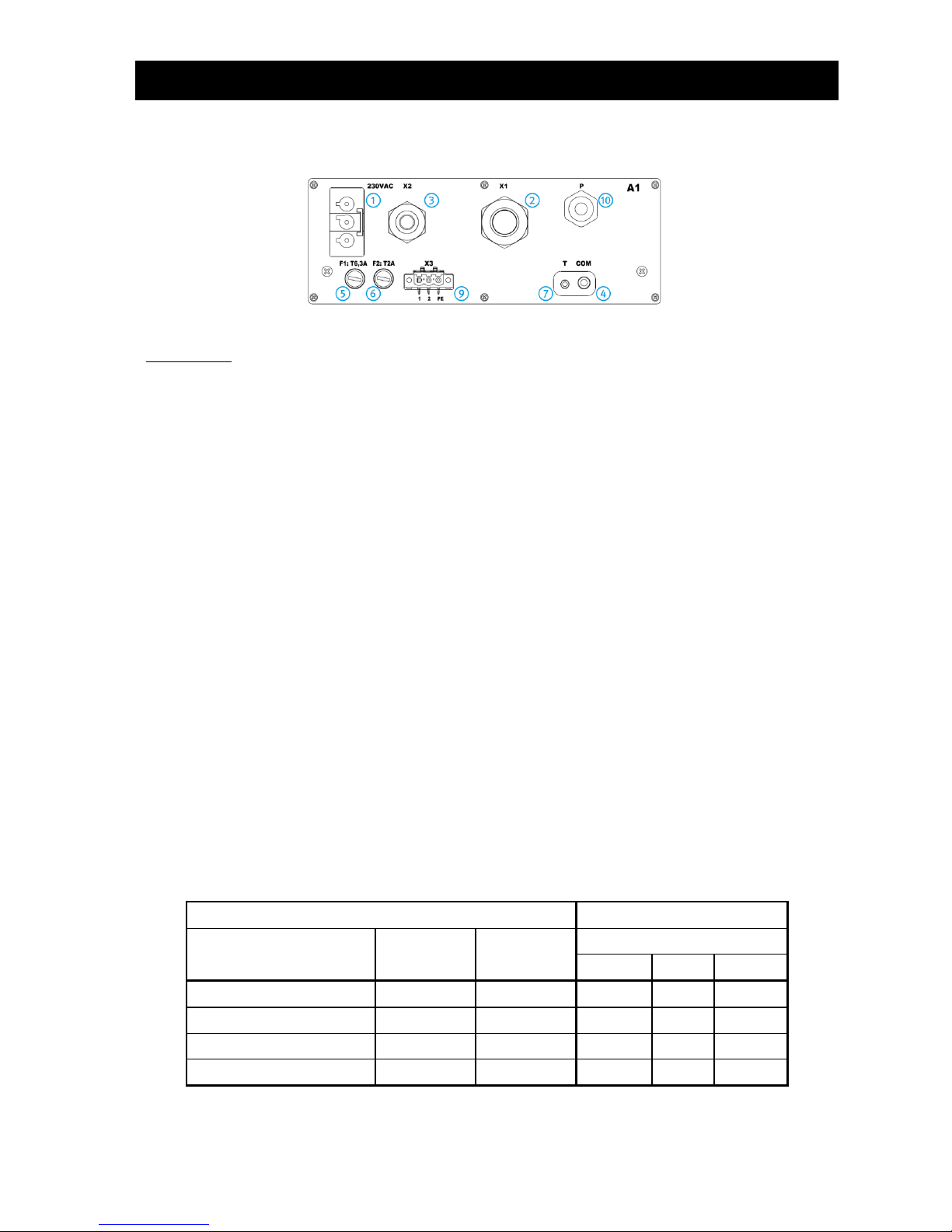

Connections to the KL24plus control unit 4.1

The figures below show the basic structure of the switch cabinet of a two-tank system.

Figure 3: EPP cabinet with 3-way air distributor

The following connections can be found on the switch cabinet:

1. 230V AV ~ 50 Hz mains connection, for connecting the control unit to a socket

2. Compressor connection, for connecting the

compressor to the control unit via an integrated two pin plug

3. Compressor's air connection. This is used to

connect the strip of valves integrated in the

switch box to the compressor

4. Hose connection (19 mm) for connecting the

aeration unit

5. Hose connection (13 mm) for connecting the

discharge lifter

6. Hose connection (13 mm) for connecting the

sludge lifter

7. One unused hose connection

Figure 4: Air distributor with stepped motors

Y4

Y3 Y2

Compressor

Compressor connection

Connection for power supply

Connection 6 mm

for level sensor

aeration

sludge lifter

discharge lifter

(two tank systems)

Control unit

Page 9

4. Control unit

9 / 40

Connections on the rear of the control unit 4.2

Figure 5: Rear of KL24plus control unit

Connections:

1 Connection for mains cable

230 V AC ~ 50 Hz

2 X1: Pre-assembled valve cable

3 X2: two pin plugs for the air compressor connection

4 COM: Connection for communication module (optional) and/or port for PC

5 F1: T6.3A main fuse, slow blow

6 F2: T2A fuse for UV module, slow blow

7 Connection for temperature sensor, "must be plugged in!"

9 X3: Connection for UV module

10 P: Connection for pressure measuring hose

Connections on the air distributor/valve block 4.3

When delivered, the control unit is already correctly connected to the corresponding connection on the air

distributor/valve block.

A distinction is made between three different air distributor variants:

1. 4-way air distributor (4 separate valves Y1 …Y4)

2. 3-way air distributor (3 separate valves Y2 …Y4) and

3. 2-way air distributor (2 separate valves Y3 and Y4)

To allow you to correctly connect up at a later date, the connectors of the control unit (X1.1 …X1.4), their

function (aeration, clear water extraction or sludge extraction) and the connections on the air distributor in

a matrix are shown in detail in the table below.

Control unit

Air distributor connections

Functions

Valves

Connectors

3-way

Y2

Y3

Y4

Aeration

Valve 1

X1.1

X

Clear water extraction

Valve 2

X1.2

X

Sludge Return

Valve 3

X1.3

X

-----

Valve 4

X1.4

Page 10

4. Control unit

10 / 40

Starting up the control unit 4.4

Once the system has been connected to the power supply, perform a brief system test. The system test

takes a few seconds and checks the real-time buffering. During this time, the LED lights up red. Then the

LED switches to green and the start phase is complete. During the system test the words "SYSTEM TEST

... OK" appear. The program version and the control unit's serial number are displayed briefly. The system's current operating mode is then displayed in the liquid crystal display. Once the system test is complete, the date and current time should be checked and adjusted if necessary.

After checking the date/time, the function of the installed parts should be checked. The check can only

take place as soon as the installed parts are connected to the control cabinet via the air hoses needed.

The check should be carried out via the "Manual operation" menu item in the control unit. The individual

installed parts should be activated and checked in turn.

The system should be reset to automatic mode once the check is completed successfully.

PLEASE NOTE: The clear water lifter will only work if the tanks are filled.

If the time and date are not set correctly, operating faults are saved with the wrong times.

Page 11

4. Control unit

11 / 40

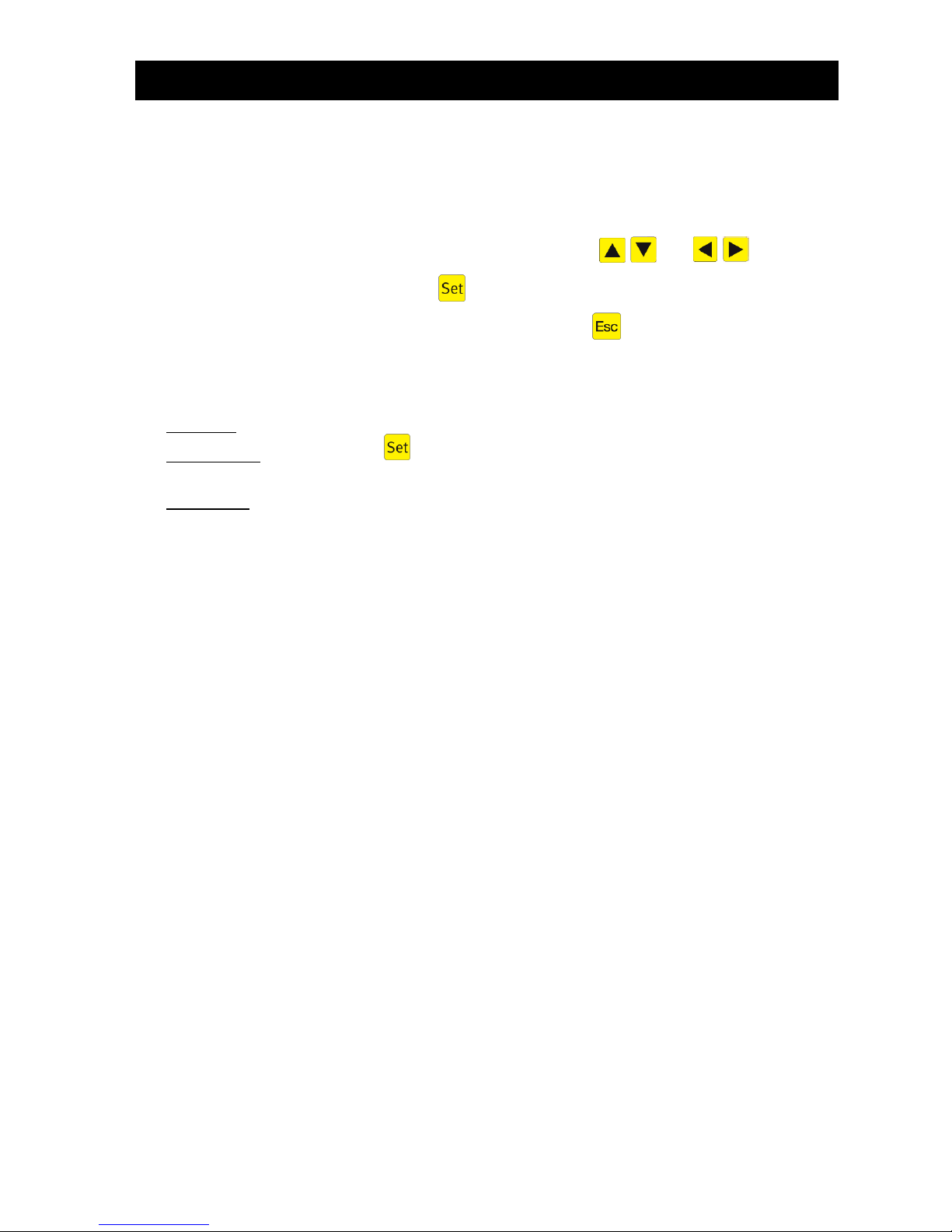

Instructions for operating the wastewater treatment system 4.5

The system is operated using a microprocessor in the control unit. The microprocessor allows operating

parameters to be set, operating statuses to be displayed, system parameters to be queried and operating

times to be programmed by a specialist.

Settings are entered by scrolling through numerical values using the and arrow keys.

The setting is then confirmed by pressing the key.

The individual dialogues can be closed prematurely by pressing or close automatically after 2

minutes.

The control unit is divided into the following display screens:

1. Basic level: Status of cycle process with remaining time elapsing and fault message display.

2. Operator level: By pressing the key, the operator can enter the operator level and undertake

operator-specific settings.

3. Service level: A password-protected service level is accessed from the operator level via an additional

code. This level is reserved for trained staff. Settings and/or changes can be undertaken here and diagnosis data called up.

4.5.1 Control programs

The control unit switches the outputs for air compressors and valves at specific times.

The times are defined by the set sequence tables.

In accordance with the sequence table selected, a complete cleaning cycle is started at each start time.

Setting holiday times at operator level enables all cleaning cycles to be suppressed for the set time period. Only a holiday cycle with greatly reduced activity occurs during this time. No treated wastewater is

extracted during this time because no water should be fed in.

The current sequence table can be modified by trained staff in the service level. Depending on the size of

the wastewater treatment system, another sequence table can be selected. The current sequence table

and other settings are stored resistant to zero voltage. The current sequence table is only modified or a

new sequence table selected in the cycle pause. This ensures that the current extraction is always undertaken at the end of a complete cleaning cycle.

If this is not necessary, the user can perform a "Cycle restart" to immediately adopt the modified parameters.

A sequence table consists of:

• table name - comprising max. 16 characters, e.g. one2clean+ 4PE C

• number of start times (cycles) - max. 24

• cycles - with cycle times and the consumers to be switched

Page 12

4. Control unit

12 / 40

4.5.2 Operating status display

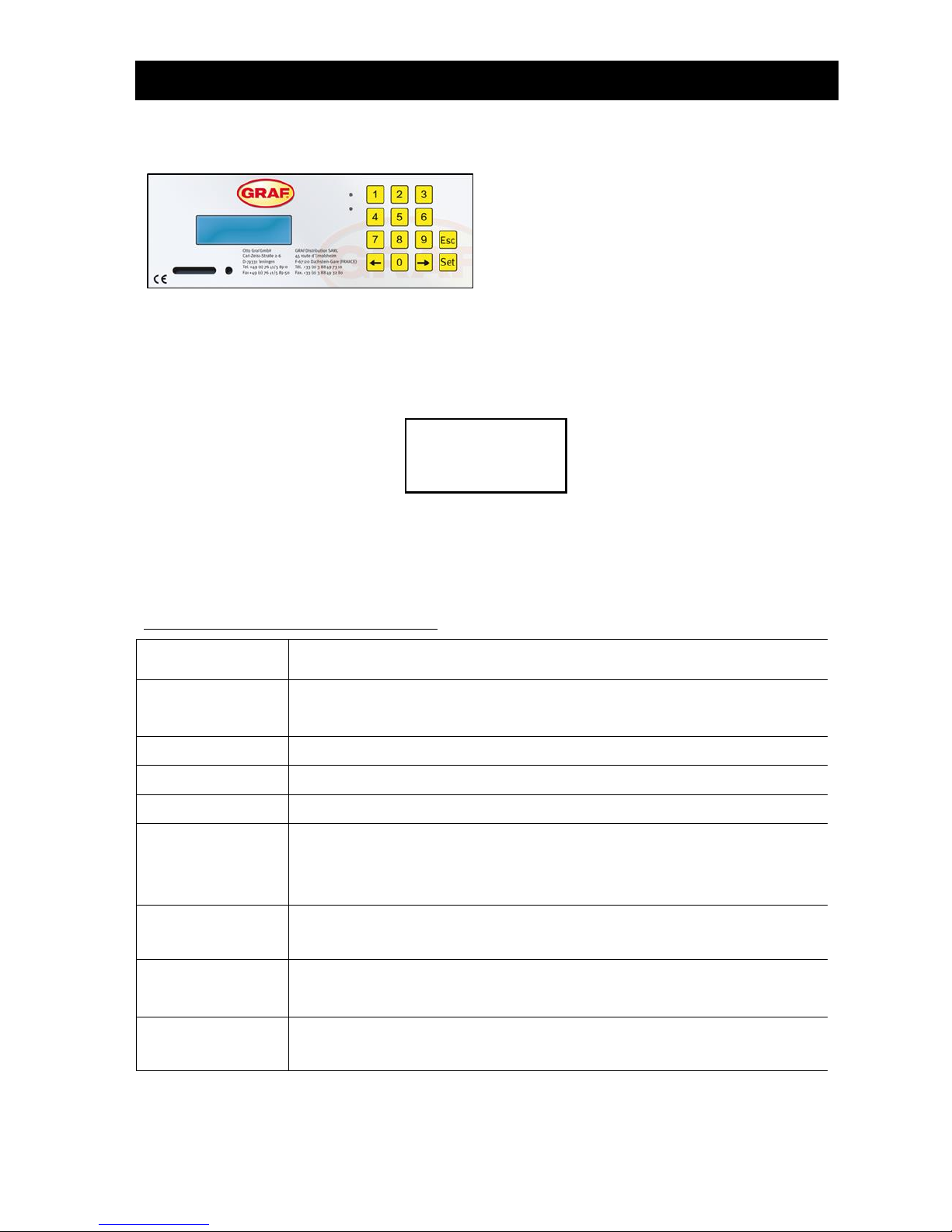

Figure 6 View of KL24plus operating unit

The system's operating status is indicated by the LEDs (Green = Operation / Red = Fault) and by text on

the screen.

In normal operating mode (aeration mode), the display looks like this:

In automatic mode, the liquid crystal display shows the current operating phase and time remaining in this

stage of operation.

If a fault occurs, the red LED switches on. A message appears in the liquid crystal display indicating

which component is faulty (e.g. compressor 0.0A fault).

The following operating phases are displayed:

KL24plus

Control unit

Process undertaken

Denitrification

Aeration is activated intermittently, the aerated sludge is briefly mixed. There are

long pauses in between (reaction times).

Aeration

Aeration is activated, the system is aerated at intervals.

Settling phase

Rest phase; the aerated sludge settles.

Discharge phase

Discharge lifter is activated, the clear water is pumped into the discharge.

Sludge removal

Sludge lifter is activated, the excess sludge is pumped out of the last tank back

into the first one.

ONLY with multi-tank systems

Cycle pause

Aeration is activated, the system is aerated at intervals (considerably less than in

the "aeration" phase).

Holiday mode

Aeration is activated, the system is aerated at intervals, no cleaning cycles are

undertaken.

Remaining: XXX.XX

min

Display showing time remaining.

Aeration

Remaining:

120:10min

Page 13

4. Control unit

13 / 40

Operating the control unit 4.6

You can start various queries when in automatic mode.

Pressing takes you to the first operating level. Now you can call up the individual queries by pressing

the two arrow keys and followed by :

Display

KL24plus

Meaning

Operating mode

Remaining time

Time remaining in current operating phase

Operating hours

counter reading

Operating hours display for individual valves and compressor

Manual mode

function

Manual activation of valves

Date

time

Current time, day and date. Can be set by pressing SET

Holiday mode

set date

Set holiday mode (max. 90 days)

Read out old

faults

Operational faults are saved here and can be read out. Press to switch between the error message and the associated date

Display

settings

The current settings can be viewed using the arrow keys

Action code

For specialists

Enter service

menu code

For specialists

4.6.1 Operating hours query

Press the key. Screen shows:

By again pressing , the operating hours can be called up for valves, compressor and house pump in

turn using the arrow keys and .

Pressing once takes you back to the "Operating hours" display.

Note: If no key is pressed for 10 minutes, normal mode engages automatically.

Operating hours

Page 14

4. Control unit

14 / 40

4.6.2 Manually controlling the valves and cabinet fan using "Manual mode"

Press , then press the arrow key until the following appears on screen:

Manual mode can now be set for all functions by again pressing and using the arrow keys to

make the relevant selection.

Taking the example of valve 1, the screen now shows:

By selecting "1" for "ON" and "0" for "OFF", valve 1 can be activated and deactivated in manual mode.

You can proceed in the same way with the other valves. The valves are selected with the arrow keys

as described above.

Pressing the key once takes you back to the maintenance level. And pressing again restores automatic mode.

Note: Each valve should run for at least 5 seconds when testing because it takes some time to

monitor the power consumption of valves before any faults are detected. After the valves,

the cabinet fan (if fitted) can also be activated and checked.

Manual mode

function

Manual mode

Valve1: OFF

Page 15

4. Control unit

15 / 40

4.6.3 Setting date/time

Press , then press the arrow keys until the following appears on screen (example):

By pressing you can set the time and date using the arrow keys . To confirm each change,

you must press .

Pressing once takes you back on to holiday mode. Pressing takes you back to manual mode.

Note: The system's time and date MUST be set correctly to ensure accurate recording of operat-

ing hours and any malfunctions that may occur. The built-in clock has a maximum deviation

of 5 minutes per year. There is no automatic switchover from summer to winter time.

If no key is pressed for 10 minutes, normal mode engages automatically.

4.6.4 Setting holiday mode

Note: The wastewater treatment system has a reduced operation when in holiday mode. This

mode should only be used if no wastewater will be fed into the wastewater treatment system

during the selected period. Wastewater which does enter the system during holiday mode is

not cleaned. Holiday mode is automatically activated and deactivated on the dates entered.

Press , then press the arrow keys until the following appears on screen:

The input of holiday data is released by again pressing :

Start of holiday:

Pressing enters the year, month and day in the format YY-MM-DD. should be pressed each

time a year, month of day is entered.

End of holiday:

Press the key again and enter the end date for holiday mode using the numerical keys:

20:15:56

2014-12-19 Mo

Holiday

set date

Holiday

Beg.: 21-05-2007

Holiday

end.: 21-05-2007

Page 16

4. Control unit

16 / 40

Pressing the key saves the input of data for holiday mode and exits this function.

Note: Holiday mode can be set for a maximum of 90 days.

If no key is pressed for 2 minutes, normal mode engages automatically without the date just

entered being saved.

4.6.5 Reading out errors – old faults

The control unit saves fault messages and the operation of valves using "Manual mode" in what is known

as a logbook. This function can be used to call up previous fault messages with time and date. The indi-

vidual messages can be called up using the arrow keys. The menu item can be exited using .

Note: 128 fault messages can be saved. Once this figure is reached, each new message overwrites

the oldest one. The memory can be cleared by a maintenance specialist in the service level using the

"Clear logbook" command.

4.6.6 Displaying settings

The current control unit settings can be viewed under this menu item. These settings cannot be changed.

This menu item is used to analyse the settings without changing them.

4.6.7 Service menu

Operating parameters can be changed in the Service menu. Access is protected by a code. This second

maintenance level is reserved for qualified staff!

Changing fuses 4.7

The control unit has two interchangeable fuses. These are located on the rear of the control unit.

De-energise the control unit before changing the fuses.

Fuses used:

Microfuse

KL24plus control unit

F1 supply

6.3 A, slow blow

Consumer F2

2 A, slow blow

Function of the power cut detector 4.8

The control unit is equipped with a power cut detector, which is powered via an integrated emergency

power supply (buffer). Upon delivery, the emergency power supply is flat. It charges when the control unit

is switched on. In the event of a power cut, the charge of one emergency power supply for indicating the

power cut will last around 12 hours. If the emergency power supply is not required in response to power

cuts, it is prevented from discharging by a switching circuit.

Important: In the event of mains failure, the time / date setting is powered for around 10 days by an extra

buffer. All saved data, such as operating hours, program settings etc., is retained. If the time and date are

not set, weekly operating hours for the units are no longer saved. Error messages occurring in the future

are saved with the wrong date.

Page 17

4. Control unit

17 / 40

If the system is disconnected from the mains (e.g. due to a power cut, should the internal fuse blow or by

disconnecting from the socket), the indicator issues an acoustic and optical signal in turn regardless of

the cause. There is a 5-second delay before the device responds to a mains failure. This prevents brief

interrupts, which often occur e.g. during a storm but do not impact on the wastewater treatment system's

overall function, from being indicated unnecessarily.

After the 5-second delay, there is an intermittent beep with a red flashing signal. Five flashing

signals and one beep repeat at intervals of 5 seconds for around 12 hours (if the emergency

power supply is fully charged).

The device cannot be switched off when in this state.

When the mains voltage is restored, the device is returned to the monitoring status and the control unit

continues from where it left off without any keys having to be pressed. The fault message disappears

automatically. If the emergency power supply is flat, the device restarts with a cycle pause.

Power cut

Please note: If the system is disconnected from the mains for more than 24 hours,

the system will be unable to clean the wastewater properly if at all. Never switch off

system (the only exceptions are if maintaining system parts and in the case of system faults restricting function)

Page 18

5. Start-up

18 / 40

5. Start-up

When starting up, the functionality of the small wastewater treatment system is checked by means of a

test run. The start-up also includes setting the control unit and instructing the operator.

Preparations 5.1

Before starting up, the following should be ensured for correct operation:

The switch cabinet and installed parts must not be damaged in any way.

The connections (inlet and outlet) should be established correctly (no mistakes).

Lines (air hoses) must be routed and used in the empty pipe as specified.

The aeration and ventilation function must be checked (smoke cartridge test)

All installed parts (aeration, lifter and sampling tank) must be checked.

The switch cabinet must be installed and the electrical connection established.

The tank's seal integrity should be checked.

Test run 5.2

The system must be filled with water for the test run. The system must be filled to at least 10 cm above

the minimum water level so that the lifter's intake connection is covered with water.

The test run is undertaken by the system's control unit. This requires the system to be switched on after

filling via the two pin plug.

The system is now ready and runs fully automatically.

System test

When the control unit is switched on, a system test is performed automatically. The system is powered up and the serial number displayed.

System test

set time

A note indicating that the time should be set then appears. This note only

appears during the first system test. If the control unit was previously

switched on before the first start-up, this note does not appear.

HH:MM:SS

2013-31-01 Mo

Press , then press the arrow keys until the "Time / date" screen

appears. Again pressing allows the time and date to now be set in turn

using the arrow keys . To confirm each change, you must press .

Pressing takes you back to the menu.

Page 19

6. Level measurement

19 / 40

6. Level measurement

The control units are fitted with an integrated pressure sensor as standard. This can establish the level by

means of the aeration unit (membrane aerator) secured to the base of the tank.

This level measurement is mainly used:

1. to save power when the wastewater infeed is low (underload detection)

2. to prevent sludge from leaking in the event of overflows (overload detection)

When supplied, this function is deactivated so during your start-up the system runs in automatic mode

regardless of utilisation - the amount of wastewater flowing in.

Function 6.1

The water level is measured at adjustable intervals at the start of a cleaning cycle by means of the pressure in the membrane aerator. If the level in the tank exceeds a previously set level ("Level measurement"

in service level), the system starts a cleaning cycle. If the set level is not reached, the system automatically goes into cycle pause for the set interval. Only enough oxygen to maintain the biological components is

then pumped into the system. The water level continues to be measured during the cycle pause at set

intervals. Should sufficient wastewater have again flowed into the system after a certain time, the control

unit switches to the normal cleaning cycle once the set level is reached.

Activation of level measurement 6.2

The tank must be filled with water up to the level at which a cleaning cycle is triggered. This level depends

on the geometry of the tank and the number of connected inhabitants.

The recommended levels above the minimum water level are stated in the table below for the plastic

tanks of the Carat.

Note Calibration has to be run in order to activate the level measurement. Calibration should be under-

taken at least once a year during all maintenance interventions because the pressure at the

aeration's membrane may change during operation.

Table 1: Recommended setting for levels:

Carat

Type

2700

3750

4800

6500

H [cm]

100

115

130

155

Page 20

6. Level measurement

20 / 40

1st step: Calibrating the pressure sensor

It is absolutely essential that the sensor is calibrated for first starting up. Please carefully work through

the following points in order:

Service menu

Go to "Service code", press the key and enter the following code when

prompted to do so: 9 9 9 9

Calibrate?

No

Use the arrow keys to select "Calibrate Yes" and confirm with the

key. Calibration then starts automatically.

Measurement un-

derway

3 measurement processes are undertaken automatically

Current

level input: 000 cm

Enter the current level as measured with rule (measured from base of tank to

surface of water) and confirm with .

Save?

xxx cm No

The measurement now entered is displayed again. Use the arrow keys

to select "Save yes" and confirm with the key. The calibration is

complete and you can exit this menu with the key.

2nd step: Setting the control parameters

It is absolutely essential that the control parameters for the level measurement are set for the system to

function correctly. Please carefully work through the following points in order:

Service menu

Go to "Service menu", press the key and enter the general service code

X.X.X. when prompted to do so.

Level measurement

Use the arrow keys to select "Level measurement" and confirm with

the key.

Level

start from: 000 cm

Enter the water level from which a cleaning cycle is to start. Confirm this with

the key.

Overflow warning

from: 000 cm

If 000 cm is saved, this warning message remains deactivated.

Measurement interval

04 h

The measurement interval of the level measurement is changed hourly using

the arrow keys . The set measurement interval can be confirmed

using the key. This menu item has a default setting which can usually be

retained.

To activate the overflow warning, you need to measure the height between the tank base and the bottom edge of the emergency overflow on the sampling tank. The level of the overflow warning should be

around 5 to 10 cm below the emergency discharge.

This level then has to be entered under "Warning overflow" using the arrow keys and confirmed

with the key.

If 000 cm is saved, the overflow warning message is deactivated.

Page 21

6. Level measurement

21 / 40

3rd step: Function check

The level measurement can now also be manually activated in manual operation for checking purposes.

This requires the level measurement to be activated under Manual mode using the key. The control

unit automatically takes a measurement once switched on. After the measurement is complete, the measured level appears in the display.

Page 22

7. Operation and maintenance

22 / 40

7. Operation and maintenance

This wastewater treatment system is a fully aerated system without an anaerobic pre-treatment stage. It is

therefore absolutely essential that the control unit and compressor are not switched off – other than for

maintenance purposes by specialist staff.

Operating instructions 7.1

Basically only substances with the characteristics of domestic wastewater may enter the system.

Biocides, toxic substances or substances which are not biocompatible or biodegradable must not enter

the system because they cause biological process problems. The following are not permitted:

- rainwater from roofs and yards

- infiltration water (e.g. drainage water)

- liquid or solid residue from keeping animals

- commercial or agricultural wastewater, unless it is comparable to domestic wastewater

- chemicals, pharmaceuticals, mineral oils, solvents

- cooling water

- solids in the form of food waste, plastics and hygiene articles, coffee filters, bottle tops and

other domestic items

- milk and milk products

- water discharged from swimming pools

- large volumes of blood

If discharging larger volumes of grease or plant-based oils, we would recommend pre-cleaning the

wastewater containing the greases/oils in a grease separator upstream of the wastewater treatment system (caution: faeces must not be allowed to enter the grease separator!).

The table below contains a list of substances which must not be disposed of in the wastewater treatment

system:

Solids or liquids which

should not be disposed of

via the sink or toilet:

Why not:

Correct disposal:

Ash

Does not break down

Dustbin

Chemicals

Contaminate the wastewater

Collection points

Disinfectants

Kill bacteria

Do not use

Paints

Contaminate the wastewater

Local collection point

Chip fat

Is deposited in pipes and causes blockages

Dustbin

Adhesive plaster

Blocks the pipes

Dustbin

Cigarette butts

Are deposited in the system

Dustbin

Condoms

Blockages

Dustbin

Corks

Are deposited in the system

Dustbin

Medicines

Contaminate the wastewater

Collection points, pharmacies

Engine oil

Contaminate the wastewater

Collection points, service stations

Waste containing oil

Contaminate the wastewater

Collection points, service stations

Plant protection agents

Contaminate the wastewater

Local collection point

Page 23

7. Operation and maintenance

23 / 40

Solids or liquids which

should not be disposed of

via the sink or toilet:

Why not:

Correct disposal:

Paintbrush cleaners

Contaminate the wastewater

Local collection point

Cleaning agents, except chlorine-free products (environmentally sound)

Contaminate the wastewater, corrode piping and

seals

Local collection point

Razor blades

Risk of injury to staff in the sewage system and

treatment plant

Dustbin

Pipe cleaners

Corrode piping and seals, contaminate the

wastewater

Local collection point

Pesticides

Contaminate the wastewater

Local collection point

Panty liners

Cause blockages, non-degradable plastic films

blight watercourses

Dustbin

Cooking oil

Cause deposits and pipe blockages

Local collection points

Food waste

Cause blockages, attract rats

Dustbin

Wallpaper paste

Causes blockages

Local collection point

Textiles (e.g. nylon tights,

cleaning cloths, handkerchiefs

etc.)

Block pipes, may paralyse a pump station

Used textiles collection point

Thinner

Contaminates the wastewater

Local collection point

Bird sand, cat litter

Cause deposits and pipe blockages

Dustbin

Cotton buds

Block the system

Dustbin

Toilet blocks

Contaminate the wastewater

Do not use

Nappies

Block the pipes

Dustbin

Cement water

Is deposited, results in production of concrete

Contact specialist company

Page 24

7. Operation and maintenance

24 / 40

Maintenance by a maintenance specialist 7.2

The maintenance should be undertaken by a specialist company (experts)1 at regular intervals (every 6

months). The intervals and work defined by the local water authority in the licence issued under water law

also apply. The system owner should take out a maintenance contract with a qualified specialist for this

work.

Note During retrofitting or any work related to maintenance on the electrical parts of the system, the

control cabinet must be de-energised.

Maintenance should include the following:

- Inspection of the operating log to check for correct operation (nominal/actual comparison)

- Check the air filter of the air compressor and the supply/exhaust air openings on the con-

trol cabinet

- Air compressor maintenance according to details provided by manufacturer.

- Function check on mechanical, electro-technical and other system parts key to operation, such

as aerator, lifter, control unit, valves

- Calibration of the level measurement

- Inspection of sludge height If necessary, the operator must arrange for the sludge to be removed

- Carry out general cleaning work, e.g. remove deposits

- Check the structural condition of the system

- Check sufficient aeration and ventilation

- Analysis of the aeration basin:

Even aeration pattern (bubbles)

Oxygen concentration (O2/l > 2 mg), if necessary adapt the compressor operating times

Sludge as proportion of volume SV30 (if the sludge makes up more than 900 ml/l, sludge

removal is required)

The maintenance work undertaken, any damage found, repairs undertaken and other information should

be summarised in a maintenance report by the maintenance company. A suitable template is provided in

the Annex. Anything established during the analyses should also be documented in this report. The system operator should be given the maintenance report so that it can be passed to the responsible authorities if demanded. The maintenance report should be attached to the operating manual. Please keep the

operating log in a place where it can be easily accessed.

Note: System failures resulting from insufficient maintenance (e.g. of the compressor) will not be

covered by free replacement under warranty.

1

Specialist companies are those not affiliated to an operator, whose staff (specialists) are suitably

qualified to operate and maintain small wastewater treatment systems through their professional training and from having received relevant qualification measures.

Page 25

7. Operation and maintenance

25 / 40

Determination of the sludge removal 7.3

Definition:

A settlement sample should be taken at the maintenance intervals to determine whether the wastewater

treatment system requires sludge removal. The SV30 (VS) is measured for this settlement sample. The

SV30 is the volume of sludge that 1000 ml of aerated sludge absorbs after a settlement period of 30

minutes. It is a measurement of the amount of sludge present in the wastewater treatment system.

Determination of the sludge volume is regulated in DIN EN 14702-1.

If the sludge volume is high (> 250 ml/l), the values of an undiluted SV30 measurement according to the

standard are not representative.

Reason: The settlement process in the comparatively narrow measuring cylinder is different because the

walls of the vessel and interactions of individual flakes interfere with one another.

A diluted sample should therefore be measured for higher volumes of sludge (> 250 ml/l). Another sample

with discharge water must be diluted for this purpose, taking water from the sample or clear water excess.

The volume ratio may be 1+1, 1+2 or 1+3 and may be multiplied by the dilution factor of 2, 3 or 4. The

diluted sample in which the value first falls below 250 ml/l is used to determine the sludge volume.

Implementation (recommendation):

1. Series of measurements:

The 1st measurement cylinder is filled up to the 1000 ml mark with the sludge sample. This sam-

ple is the undiluted sludge volume. If SV30 < 250 ml/l, this value is representative.

At the same time, a diluted sample in placed in the 2nd measurement cylinder. We recommend

diluting to a ratio of 1+2 (330 ml sludge and 670 ml discharge). The value read off is then multiplied by the dilution factor of 3 (see table below).

2. Series of measurements:

If the sludge volumes in the two measurement cylinders of the 1st series of measurements > 250

ml/l, the measurement should be repeated with the 1+3 dilution.

Sludge removal is needed as soon as the results of both the diluted and undiluted measurement produce

a SV30 of > 700 ml/l.

The table below can be used to assess the SV30 measurement.

Vers.

no.

Measurement cylinder

filled with

Reading,

diluted

ml/l

E V A L U A T I O N

Aerated

sludge

ml/l

Discharge

ml/l

Dilution

Dil.

factor f

SV30

ml/l

SV30 entry

ml/l

e.g.

500

500

225

500 + 500 = 1+1

2

225 x 2 = 450

450 (225 x 2)

e.g.

330

670

210

330 + 670 = 1+2

3

210 x 3 = 630

630 (210 x 3)

Table: Evaluation for undiluted SV30 > 250 ml/l

Page 26

7. Operation and maintenance

26 / 40

Figure 7: Sludge volume measurement with undiluted aerated sludge sample

Figure 8: Sludge volume measurement with 1+2 diluted aerated sludge sample

1000 ml

< 250 ml

30 min

670 ml water

from PN

330 ml

aerated sludge

< 233 ml (dilution factor of 3)

30 min

Page 27

7. Operation and maintenance

27 / 40

Sludge removal instructions 7.4

Removing sludge from the wastewater treatment system should be carried out according to the following

points:

1. Remove the cover

2. Remove the deposits on the water surface and on all visible surfaces (baffle, sample container,

siphon)

3. Wash down the visible surfaces

4. Insert the suction hose into the wastewater treatment tank until it reaches the floor

(CAUTION: air admittance valves on the ground must not be damaged!)

Aspirate until about 30 cm of wastewater and sludge remain in the wastewater treatment system

Page 28

8. Fault messages and rectification

28 / 40

8. Fault messages and rectification

Technical system operation faults (failure of a unit) are indicated on the control unit display.

Fault message on display 8.1

- Fault message as text on the LCD,

- Operating control light flashes red.

Display LCD

Possible cause

Corrective action

KL24plus

No display, no light

Power is disconnected

Check the power supply to the plant and

controller

Check the microfuse F1 on the supply line

Check the position of the maintenance

switch (position 1)

if the buffer is empty, a power failure will be

indicated neither acoustically nor visually.

No display, light is green

Switch off the plant and turn it back on

after 10 second.

No/weak display

Contrast is set

incorrectly

Hold down ESC key and adjust contrast,

using the arrow keys.

Set the clock

Internal clock/date not

set

Make settings in the menu item Date and

Time

**Fault** Com. Fault

Compressor is not work-

ing/will not power on

Check the main fuse F1

Check the compressor in manual mode

**Fault** Valve 1

Valve does not operate

Blown fuse

Winding defective

Valve jammed due to

obstruction

Cable break

Check the valve in manual mode

Check the microfuse of the consumers F2

Check the valve for possible smoke resi-

due

Unscrew the valve from the metal bar,

check it for dirt, and remove dirt (see

Maintenance Instructions in the Appen-

dix).

**Fault** Valve 2

**Fault** Valve 3

**Fault** Valve 4

**Fault** UV module

UV module does not

work

Check the UV module and the remaining

lamp life

**Fault** min fill level

Compressed air line

leak between controller

and charging lifter, e.g.,

due to loose hose

Check hose for leaks

Warning Backwater

Water level is too high in

chamber 1

Compressed air line

clogged, e.g. due to

kinked hose

See Point -

Check hose for kinks

Temperature max

Temperature sensor not

plugged in

Cabinet fan is not work-

ing

Filters dirty in the cabi-

net and the compressor

Direct sunlight on the

cabinet

Temperatures for turn-

ing on the cooling fan

and the maximum tem-

perature that are en-

Plug in temperature sensor on back of

controller

Check the function of the cabinet fan

Check air filter in the cabinet

Shade location

Provide cool ventilation

Check air filter in the air compressor

Check air compressor in manual mode

Have maintenance company check set

temperatures

Replace temperature sensor

Page 29

8. Fault messages and rectification

29 / 40

Display LCD

Possible cause

Corrective action

KL24plus

tered in the Service

menu are too high

Air compressor defec-

tive

Temperature sensor

defective

**Fault** Temp Sensor

Temperature sensor is

missing

Temperature sensor is

not fully plugged into the

socket

Temperature sensor

defective

Replace sensor

Ensure secure connection between con-

troller and temperature sensor. Then

power off controller for 10 sec. and switch

it back on. Check whether a temp sensor

fault message is displayed.

**Fault** Power failure

Power failure

Plant switched off via

maintenance switch

No voltage on the switch

cabinet

FI fuse has blown

Wait for power to return

Switch plant on via maintenance switch

Check supply to the switch cabinet

Locate cause for triggering the RCCB and

correct it (possible cause: solenoid valve

defective).

**Fault** Modem

Batteries in the module

are not yet fully charged

Modem has no mains

voltage

No SIM card inserted in

the modem

SIM card is not regis-

tered to the network

Wait 5 minutes until batteries are fully

charged

Connect modem to power

Insert SIM card in the modem

Wait until the card is registered. Other-

wise relocate antenna so that reception is

possible.

Page 30

8. Fault messages and rectification

30 / 40

Unusual water levels - troubleshooting 8.2

Observation

Possible cause

Corrective action

The water level in the

aeration tank is unusually high.

Plant is running in holiday mode.

Plant is constantly running in cycle

pause.

Control settings are incorrect.

The outflow lifter is congested.

The air hose to the outflow lifter is

leaking.

Flooding in the receiving water

course doesn't allow water to drain

from plant.

Controller is defective.

Ending of holiday mode

Have the controller settings

checked by service technician

Have SBR reactor pumped out

and clean lifter

Have SBR reactor pumped out

and seal hose connections

Wait until flooding subsides,

Contact maintenance company

The plant emits

odours, the treated

wastewater is cloudy

or discoloured

Too little air is supplied to the plant

One-sided aeration due to defective

membrane unit

Have aeration time increased by

service company

Verify aeration diagram, contact

maintenance company

Aeration diagram is

one-sided and large,

isolated bubbles are

rising

Membrane unit defective

Aerator unit is leaking

Aerator unit is not positioned correctly

on the bottom

Contact maintenance company

Contact maintenance company

Possible faults at the air distributor (valve block) 8.3

Observation

Possible cause

Anchor does not pick up.

Supply voltage is interrupted or insufficient.

Motor defective!

Anchor blocked in polluted tube space.

Valve does not close.

Anchor blocked!

No power supply

Valve does not open.

Nominal voltage is not present

Status: 12 / 2017

Specifications subject to change without notice!

Page 31

9. EC conformity declaration

31 / 40

9. EC conformity declaration

Manufacturer: Otto Graf GmbH

Carl-Zeiss-Straße 2-6

DE-79331 Teningen

hereby declares that the one2clean+ small wastewater treatment system meets the requirements of the

following directives:

2006/42/EC Directive of the European Parliament and of the Council of 17 May 2006 on machines

and changes to Directive 95/16/EC.

2006/95/EC "Directive of the Council relating to electrical equipment designed for use within cer-

tain voltage limits"

The following harmonised standards were applied:

EN 60204-1 Electrical equipment of machines. Part 1: General requirements

EN ISO 13849-1 Safety of machinery – Safety-related parts of control systems. – Part 1:

General principles for design

This EC declaration of conformity ceases to apply if the product is modified without consent.

Teningen, 13/01/2014

Arne Schröder

(Product management team leader)

Page 32

10. Technical data

32 / 40

10. Technical data

Technical data for control units 10.1

Programmable logic microcontroller

o T3,15A fuse (internal)

o Wide-range 100-240 VAC/ 50-60 Hz power supply

o Real-time clock with deviation of 5 min./a, with battery buffer

o Log book, resistant to zero voltage

o Cable failure monitoring compressor by measuring the output currents

o Operating/error message display with LED (green/ red)

o Operating temperature range 0°C …+55°C

o Permissible temperature range without operation -20°C … +85°C

o Relative air humidity 10...95 %, no condensation

o Degree of protection IP54

o 14 keys control unit

o Display: Graphic display with 128x32 pixels

Outputs:

o 230 VAC 50 Hz compressor (standard)

o 4 x 24 VDC stepped motors for compressed air flow

o 24 VDC/ < 250 mA metering pump for phosphate precipitation or metering of carbon

o External 24 VDC/ < 26 mA warning light

Page 33

10. Technical data

33 / 40

Circuit diagrams 10.2

10.2.1 Circuit diagram for KL24plus control unit in EPP cabinet

Page 34

11. Template for weekly / monthly check notes

34 / 40

11. Template for weekly / monthly check notes

for systems requiring maintenance twice a year, the parameters should be noted monthly

Date of

check

Sludge -

leaking?

Cloudi-

ness/discol

ouration?

Sup-

ply/discharg

e blocked?

Air filter

checked?

Operating hours counter

Yes

No

Yes

No

Yes

No

Yes

No

Valve 1

Valve 2

Valve 3

Total

Page 35

11. Template for weekly / monthly check notes

35 / 40

for systems requiring maintenance twice a year, the parameters should be noted monthly

Date of

check

Sludge -

leaking?

Cloudi-

ness/discol

ouration?

Sup-

ply/discharg

e blocked?

Air filter

checked?

Operating hours counter

Yes

No

Yes

No

Yes

No

Yes

No

Valve 1

Valve 2

Valve 3

Total

Page 36

11. Template for weekly / monthly check notes

36 / 40

for systems requiring maintenance twice a year, the parameters should be noted monthly

Date of

check

Sludge -

leaking?

Cloudi-

ness/discol

ouration?

Sup-

ply/discharg

e blocked?

Air filter

checked?

Operating hours counter

Yes

No

Yes

No

Yes

No

Yes

No

Valve 1

Valve 2

Valve 3

Total

Page 37

12. Maintenance log for GRAF small wastewater treatment systems

37 / 40

12. Maintenance log for GRAF small wastewater treatment systems

Location (address):

Maintenance company:

Date of maintenance:

Serial number:

Order no.:

System size:

PE

Actual connection

PE

Operator's name:

Customer no.:

1st line of address:

Tel. no.:

Town/city, postcode:

Fax no.:

Installed by:

Start-up:

Will the system process commercial wastewater too?

No

Restaurant without kitchen

Restaurant with kitchen

Other

Grease separator present, NG

Emptying needed

Function check of system parts important to operation:

Aeration / valve 1 (blue)

Discharge lifter / valve 2 (black)

Excess sludge lifter / valve 3 (white)

Power cut indicator

Air inlet / aeration:

moderate

intensive, circulation clearly visible

Aerator pattern / aeration:

fine bubbles

even

Comments:

Sludge accumulator + buffer:

Sludge height:

cm

Floating sludge height:

cm

The operator should arrange for the cesspit to be emptied.

SBR reactor:

Oxygen concentration:

mg/l (normally approx. 4-6 mg/l, at least 2 mg/l)

Sludge as proportion of

volume:

ml/l (maximum 700 ml/l)

Comments:

Control unit:

Control unit type:

Σ- operating hours:

Aeration (valve 1):

Discharge (valve 2):

Excess sludge reservoir

(valve 3):

Page 38

12. Maintenance log for GRAF small wastewater treatment systems

38 / 40

Comments:

Blower:

Blower type:

Blower OK

Change the slats (slat length: mm):

Change the membranes

Filter change

Cooling fan OK

Comments:

Time of sampling:

Date:

Time:

Sampling site:

Sampling shaft

SBR chamber

Sample

transport:

cooled 4°C

frozen

Air temperature:

°C

Water temperature:

°C

Odour

none

weak

strong

rotten

earthy

Colouring

none

weak

strong

beige

brown

Cloudiness

none

weak

strong

opaque

Floating matter

none

a little

a lot

Dry substance

Activated sludge

kg SOL / m³

P

total

ml / l

Substances that can

settle

ml / l

pH BOD5

ml / l

COD

ml / l

NH4-N

ml / l

N

tot

ml / l

Additional comments:

Operating log available.

Maintenance noted in the log.

Programming modified:

Fault rectified:

Additional comments:

To be arranged by the operator:

The operator is asked to note the substances which must not enter the system (see operating manual).

Pit is overflowing, operator must discharge content.

Sludge removal

Date and signature

Page 39

13. Notes

39 / 40

13. Notes

Page 40

13. Notes

40 / 40

www.graf.info

2017-10

Loading...

Loading...