Page 1

one2clean / one2clean plus installation

one2clean

Item no.

106850 Set-up kit 3 inhabitants

106851 Set-up kit 5 inhabitants

106852 Set-up kit 7 inhabitants

106853 Set-up kit 9 inhabitants

one2clean plus

em no.

It

106417 / 106413 Set-up kit 3 inhabitants

106418 / 106414 Set-up kit 5 inhabitants

106419 / 106415 Set-up kit 7 inhabitants

106420 / 106416 Set-up kit 9 inhabitants

mail@graf.info

www.graf.info

instructions

It is essential that you observe the

points described in these instructions. Failure to do so will invalidate all warranty claims. For all

additional items ordered from

GRAF, separate installation instructions will be provided in the

transport packaging.

It is essential that you check the

components for possible damage

before installation.

You will receive separate instructions for assembling the system.

Contents

1. SCOPE OF DELIVERY

2. NOTES

2.1 Safety

2.2 Ventilation and bleeding

3. CONSTRUCTION AND FUNCTIONAL PRINCIPLE

4. ASSEMBLING THE SET-UP KIT

5. ASSEMBLING CONTROL UNIT IN THE INTERIOR

6. ASSEMBLING CONTROL UNIT IN THE EXTERNAL

CABINET

7. TECHNICAL DATA

13

14

14

14

15

16

20

21

22

Page 2

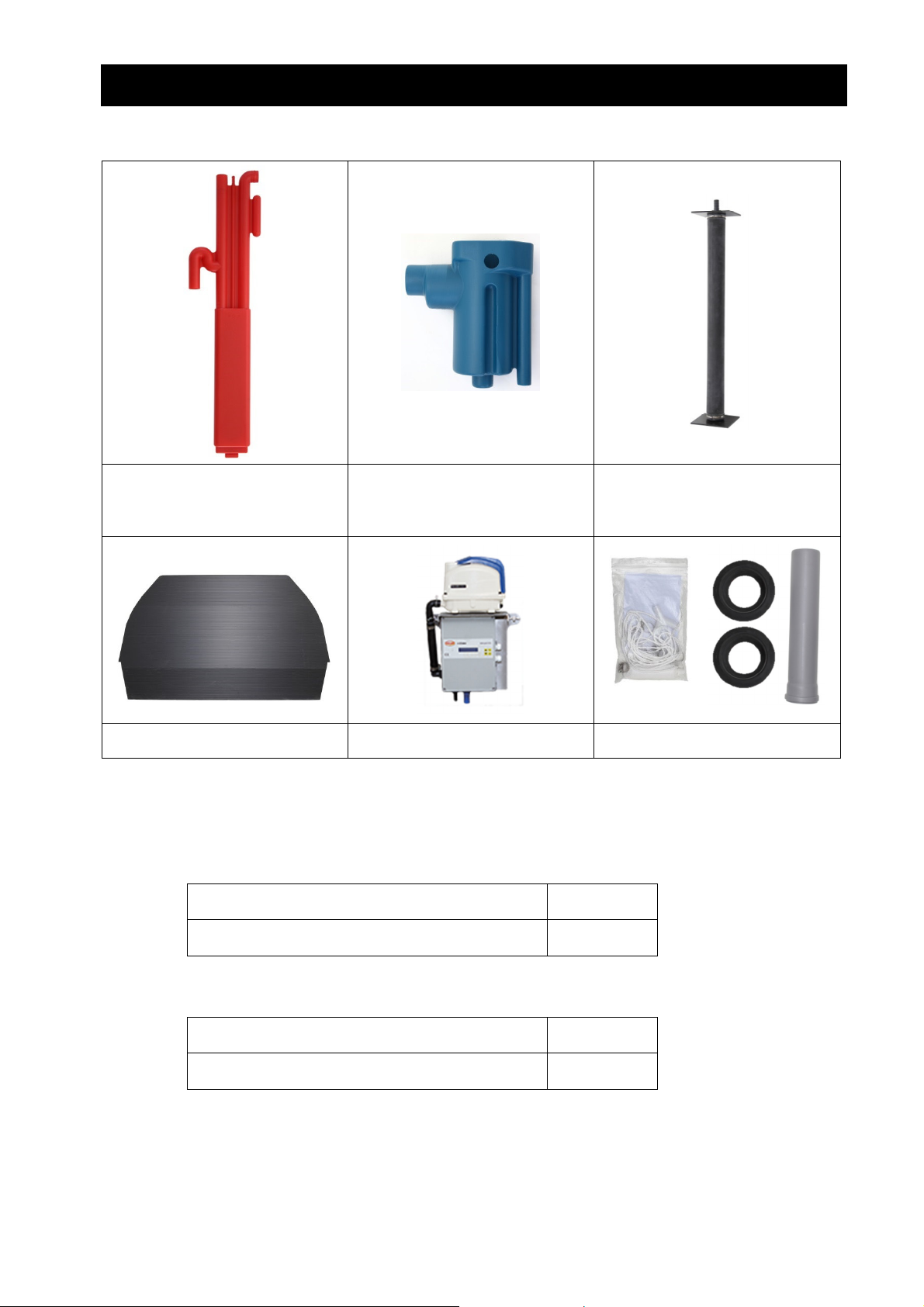

1. Scope of delivery

Jack Sampler 1 pipe aerator for 3 and 5

1. Scope of delivery

inhabitants

2 pipe aerators for 7 and 9

inhabitants

Scum board Control (one2clean plus control

without illustration)

The following is not included in the scope of delivery:

• Hoses to supply air from the control cabinet to the septic tanks. One 13 mm air hose and one 19

mm air hose are required.

They can be ordered under the following item numbers:

Hose package, 10 metres 107686

Hose package, 20 metres 107688

The hose packages each contain one 13 mm air hose and one 19 mm air hose. Alternatively, the

hoses can be ordered as rolled goods:

PVC hose, 20 metres, black, 13 x 3 mm 934017

PVC hose, 20 meters, blue, 19 x 3 mm 934020

• Core drill with a diameter of 124 mm. This can be purchased from Otto Graf GmbH using item

number 202003.

• The Carat S septic tank and covers are to be ordered separately.

Accessories

13 / 33

Page 3

2. Notes

2. Notes

2.1 Safety

Observe the national accident prevention regulations during all work. Particularly for inspecting the tanks,

a second person is required for safety reasons.

Furthermore, observe the valid national regulations and standards during installation, assembly, maintenance and repair work, etc.

During all work on the system or parts thereof, always shut down the entire system and secure it against

unauthorised re-start.

Always keep the tank cover closed, except when working in the tank. Otherwise, there is a high risk of an

accident occurring. Only genuine GRAF covers or covers that GRAF has approved in writing must be

used.

GRAF offers an extensive range of accessories, which are all coordinated to one another and can be

expanded to form complete systems. The use of accessories that have not been approved by GRAF results in the exclusion of the warranty/guarantee.

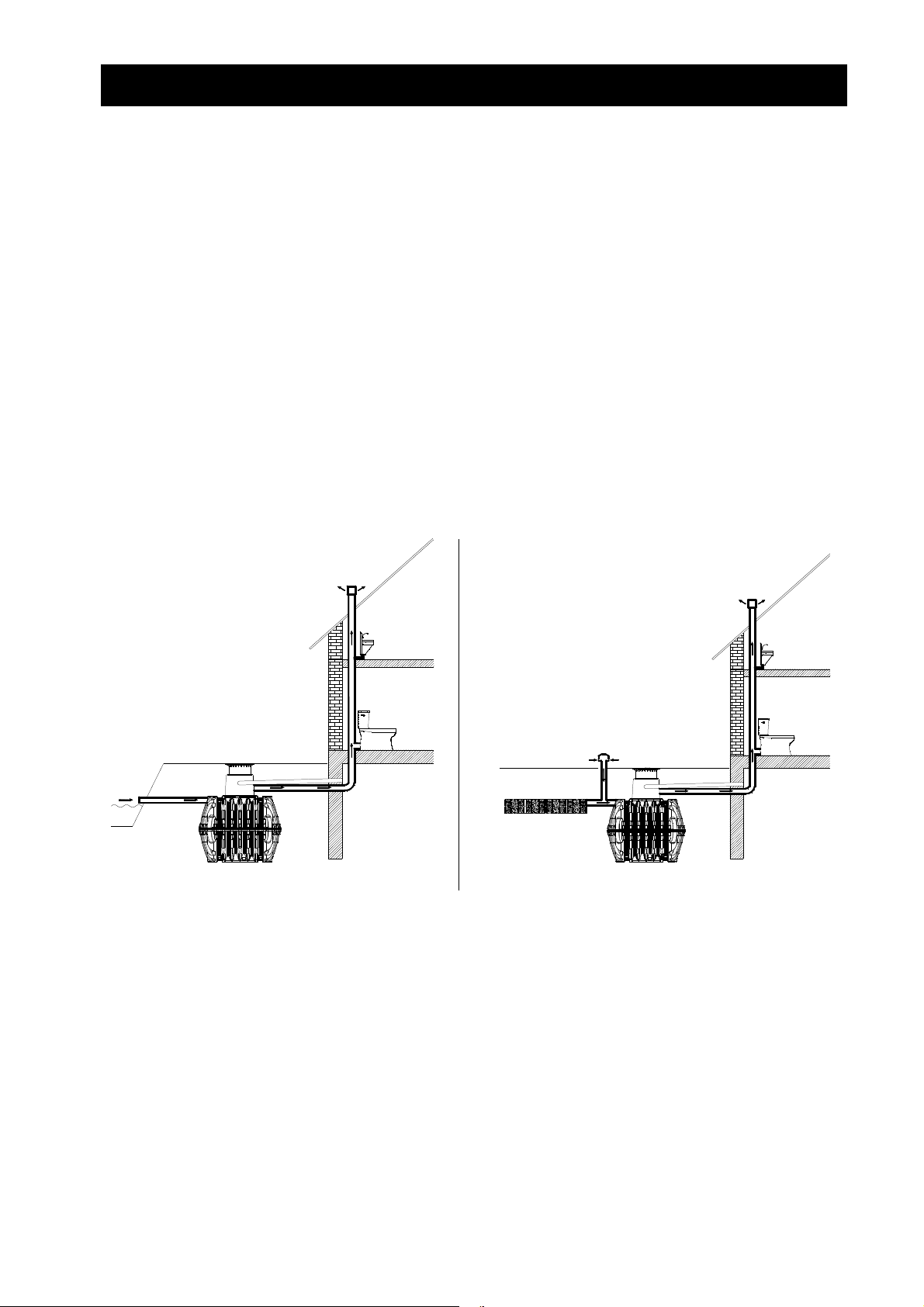

2.2 Ventilation and bleeding

All tanks must be ventilated and bled. Additional ventilation lines or ventilation openings must be ordered

if necessary. Ventilation lines should be ordered to guarantee natural ventilation (chimney effect).

Bleeding with a free outflow Bleeding with percolation or an obstructed outflow

14 / 33

Page 4

3. Construction and functional principle

3. Construction and functional principle

The small wastewater treatment system is fully biological and works according to the retention process

with long-term aeration. The system is made up of an aerobic stage. A scum board is used to split this

stage into a coarse substance chamber and an activation chamber. The chambers are connected to one

another in the bottom section. During this process, therefore, all domestic sewage is immediately exposed

to aerobic wastewater treatment. The entire system is aerated due to compressed air being blown in and

the sludge activated as a result of this biologically cleans the wastewater.

15 / 33

Page 5

4. Assembling the set-up kit

4. Assembling the set-up kit

1. 2.

Unfold the scum board. Place the clamps on either side of the folding edges.

Insert the scum board into the upper shell. A

groove offsets in an off-centre position.

3. 4.

>4cm

The fixing clamp has to be pushed with the

rounded stick in to the baffles side. The fixing

clamp has to be fixed.

Once the baffle has been positioned perforate the

inner rib directly above the wall using an 8mm. drill

head.

Perforate the baffle 4 cm. from its edge using the

same 8 mm. drill head.

5. 6.

Pass a cable tie through both holes and tighten it.

Cut the excess cable tie.

Repeat this procedure on the opposite side

Continue assembling the Carat RS tank according

to the installation instructions (seal, centring pins,

lubricant).

16 / 33

Page 6

4. Assembling the set-up kit

H

7. 8.

Place the upper shell with the scum wall on top of

the lower shell. Assemble the clamps for connecting the upper and lower shells.

Assemble the clamps for connecting the upper and

lower shells.

9. 10.

H

2700 L 3750 L 4800 L 6500 L

145 mm 145 mm 190 mm 205 mm

Drill the inflow and outflow with a DN 100 core

drill (with a diameter of 124 mm).

11.

De-burr the hole. Insert the DN 100 lip seal. In the

case of the outflow, the direction of the feedthrough must be from the inside out. Affix the “Outflow” sticker.

12.

Slide the outflow pipe through the outflow hole

from the inside.

The jack base must be turned depending on the

tank size. The specified tank size on the base must

be the same as on the jack.

17 / 33

Page 7

4. Assembling the set-up kit

2700 4800 6500

13.

Depending on the tank size, the length of the jack

must be adjusted by moving the jack base. The

rough position is specified on the jack. The exact

height is to be determined inside the tank.

15.

14.

Assemble the jack and sampler. To do this, push

the jack outflow into the sampler hole.

16.

-

Push the jack into the sampler (until it snaps into

place).

17.

Insert the jack into the profile for holding the partition wall from above.

Insert the jack into the tank along with the sampler.

18.

Insert the sampler’s outflow connection into the

sleeve of the outflow pipe (use lubricant!). The

sleeve connection must be secured with a Spax

screw.

18 / 33

Page 8

4. Assembling the set-up kit

6 mm hole

19.

The cord must be secured to the pipe aerator (6

mm hole). The air hose (19 mm) must be connected on the opposite side. Systems for more

than 7 inhabitants have two pipe aerators.

21.

20.

Position the pipe aerator(s) on the bottom of the

tank. It must be slid under the scum board such that

even the first chamber is ventilated. To attach the

cord, a hook is fitted inside the tank dome. The hole

for the hook should be pre-drilled with a 4mm bit.

22.

In systems with two pipe aerators, use a Ypiece to join the hoses of the two pipe aerators.

Assemble the tank dome according to the installation

instructions (seal!).

23. 24.

Secure the sampling tank to the tank dome with

a Spax screw.

Connect the air hose (13 mm) to the in-feed jack.

19 / 33

Page 9

5. Assembling control unit one2clean in the interior

5. Assembling control unit one2clean in the interior

1. 2.

The control must be installed in a dry and dustfree interior. Two 8 mm holes must be drilled

into the wall for assembly.

Secure the control to the wall using the dowels and

screws provided.

3. 4.

Position the compressor on the control. Connect

the compressor to the control unit pipe using the

90 Deg hose piece and hose clamps provided.

Plug the compressor plug into the control socket.

Connect the air hoses to the control’s hose nozzles.

5.

For further information please refer to the Control Unit operating manual.

Note for one2clean plus control: Assembly of one2clean plus control similar to one2clean control.

20 / 33

Page 10

6. Assembling control unit in the external cabinet

6. Assembling control unit in the external cabinet

1. 2.

Please refer to the installation instructions for

the External Cabinet for electrical connection

details.

Before installing the control unit, a strip of foam rubber

must be glued to the back of the control unit.

3. 4.

The Control Unit should be mounted to the

external cabinet with the screws and wing

nuts provided.

Position the compressor on top of the Control Unit and

connect together using the 90 Deg hose piece and

hose clamps provided.

5.

For further information please refer to the

Control Unit operating manual.

21 / 33

Page 11

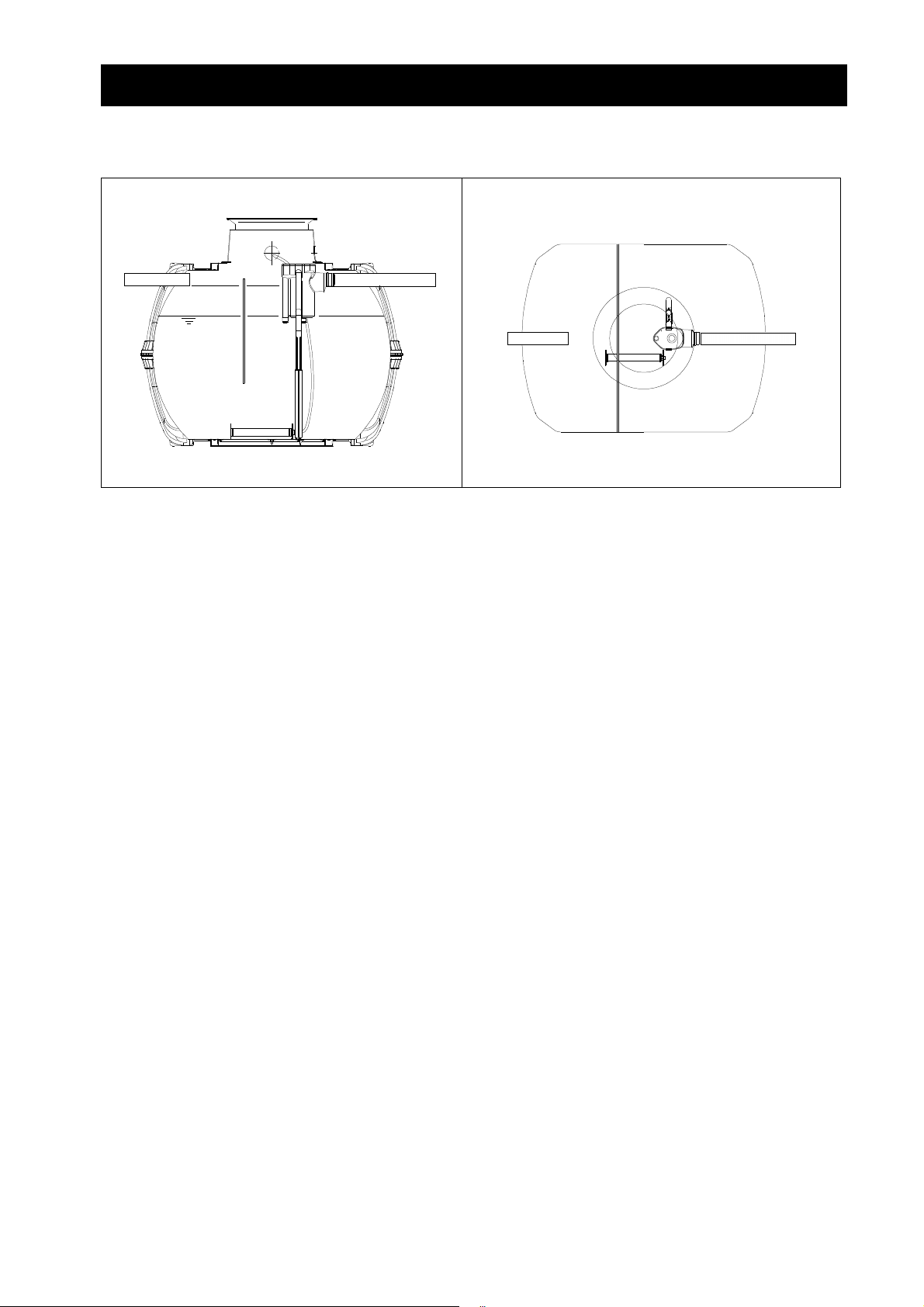

7. Technical data

tot

140-340

Z1

DN100

A

625

7. Technical data

A1

DN 100

Htot

Z2

L

nks 2,700 l 3,750 l 4,800 l 6,500 l

Ta

A2

L

Inhabitants 1-3 inhabitants 4-5 inhabitants 6-7 inhabitants 8-9 inhabitants

Max. daily inflow

0,45 m3/d 0,75 m3/d 1,05 m3/d 1,35 m3/d

Length L 2,080 mm 2,280 mm 2,280 mm 2,390 mm

Width B 1,565 mm 1,755 mm 1,985 mm 2,190 mm

Height H

1,690 / 2,010* mm 1,870 / 2,200* mm 2,100 / 2,430* mm 2,380 / 2,710* mm

Inflow Z1 430 / 750* mm 430 / 750* mm 515 / 835* mm 535 / 855* mm

Inflow Z2 1260 mm 1450 mm 1595 mm 1855 mm

Outflow A1 470 / 800* mm 470 / 800* mm 470 / 800* mm 470 / 800* mm

Outflow A2 1255 mm 1445 mm 1590 mm 1850 mm

* with Maxi tank dome

B

22 / 33

www.graf.info

06-2018

Loading...

Loading...