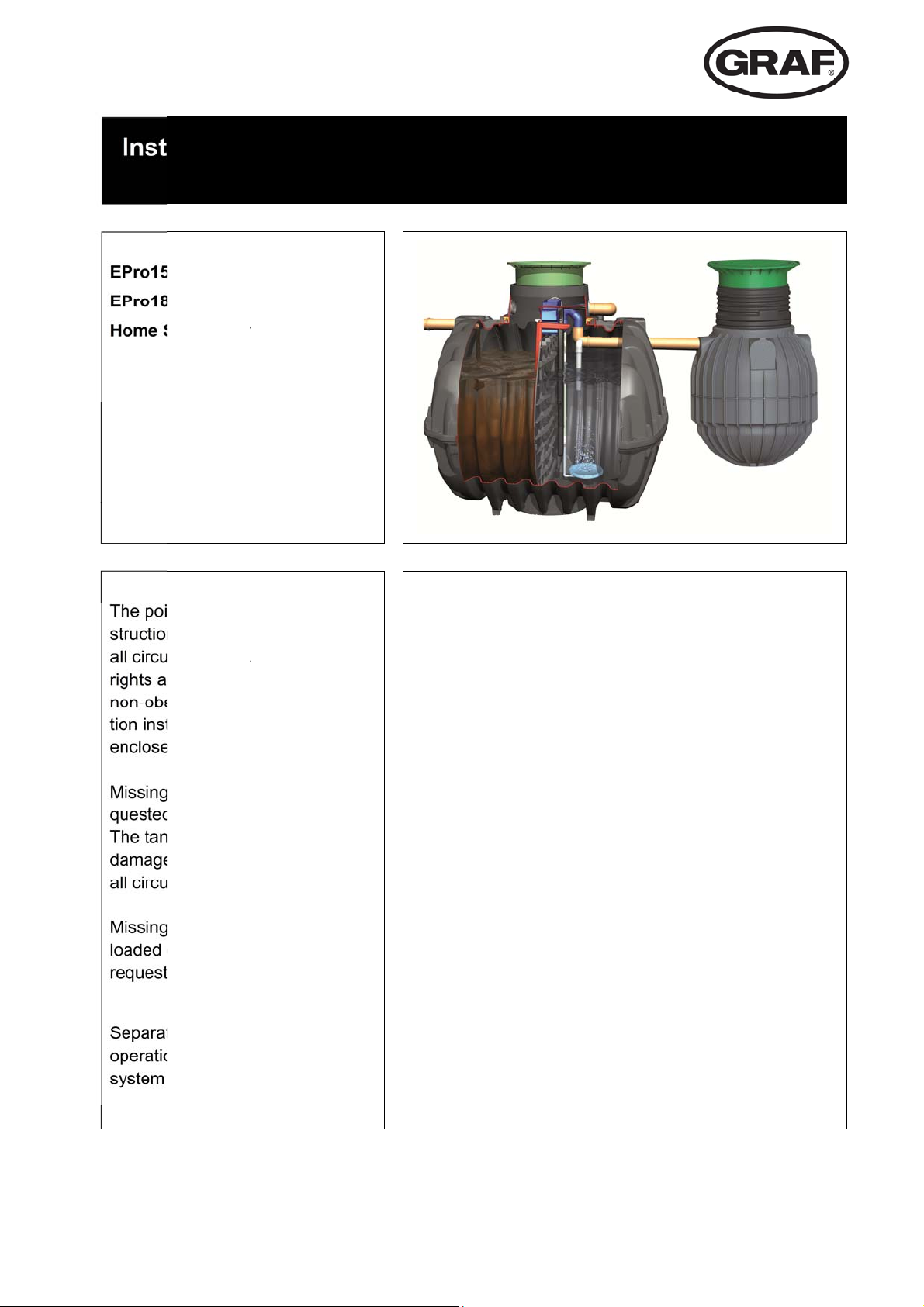

Graf EPro Series, EPro15 Three, EPro15 Two, EPro15 One, EPro15 Three +O Installation Instruction

Page 1

a

n

c

y

e

A

n

S

n

n

m

c

s

a

R

o

n

c

u

A

y

o

s

e

r

r

n

o

a

-

f

b

C

12345

6

7

E

m

s

m

A

b

A

b

s

a

c

h

s

t

3

425

llatio

Domestic

Commer

ewage S

nts describ

s must be

mstances.

e invalid i

ervance.

ructions a

d in the co

instruction

from us i

k must be

prior to in

mstances.

instru

ial

stems

d in these

observed

ll warrant

the event

eparate in

d manuals

trol cabin

s must be

mediately.

hecked fo

tallation u

tion fo

innder

f

tallaare

t.

e-

any

der

r Graf

syste

ontents

.

.

.

.

.

.

.

Genera

Dimen

Syste

ssem

ssem

Commi

Notes

Pro w

l

ions

design

ly of tank

ly of switc

sioning

stewat

omponent

cabinet

er trea

ment

2

3

4

6

1

2

instruction

n www.gr

ed from G

e instructi

n and mai

supplied in

s can be d

f.info or c

AF AU.

ns for start

tenance o

control ca

wn-

n be

up,

the

inet.

Page 2

G

e

TTh w

i T

csb

t

o

T

t

T

u

e

o

w

t

T

c

e

s

a

t

s

p

t

c

e

a

y

e

e

a

b

o

t

e

r

d

a

v

f

A

a

r

r

o

s

a

p

T

e

h

s

e

l

o

h

e

n

a

(

n

o

h

o

o

s

s

d

e

-

-

d

-

-

1.

neral

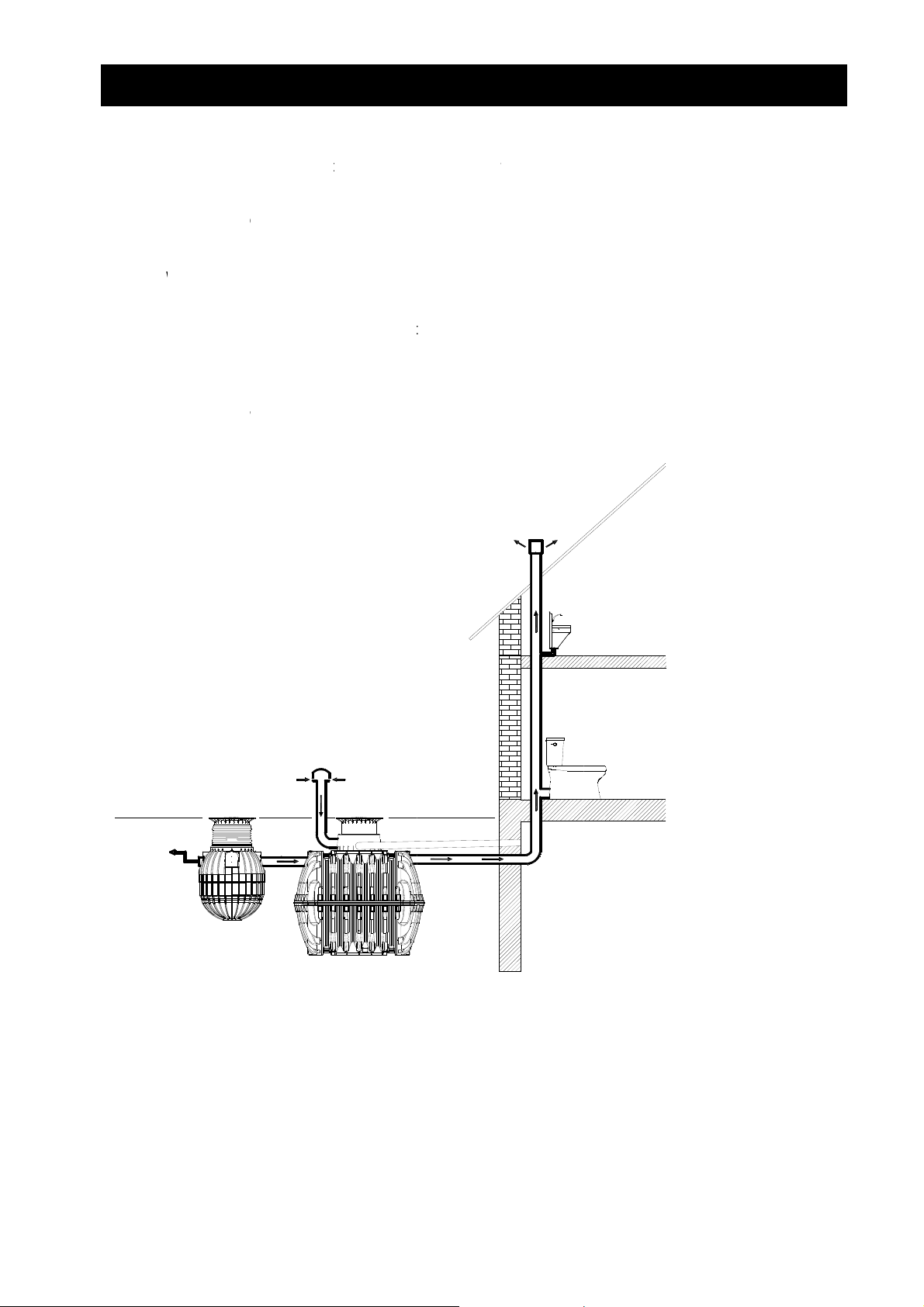

he installa

ion of the

ank must f

1. Gene

llow the di

al

ections in t

e enclosed

installation

instructions

.

hese instr

how to conn

During the

astewater

ings, etc.).

he treatme

ape togeth

uch as to a

ble (more th

ed if neces

ctions also

ct up the in

peration of

reatment s

nt system n

r with gas

llow natural

n 3 m reco

ary.

ontain furth

and outl

le

wastewate

stem shoul

eds ventilat

s without c

entilation (

mended).

er informati

t lines.

r treatment

be situated

ion so that

using any

lue effect).

dditional v

n on the in

ystem som

away from

ir blown int

roblems. T

he vent outl

ntilation lin

tallation co

odour can

iving areas

the tank by

e ventilatio

et height sh

s or ventilat

ditions for t

arise. The l

patio, wind

the compre

lines must

uld be as h

ion opening

e tanks an

cation of th

ws on build

sor, can es

be arrange

igh as possi

must be fit

Ventilati

n with see

age or an o

structed dr

in

2 / 25

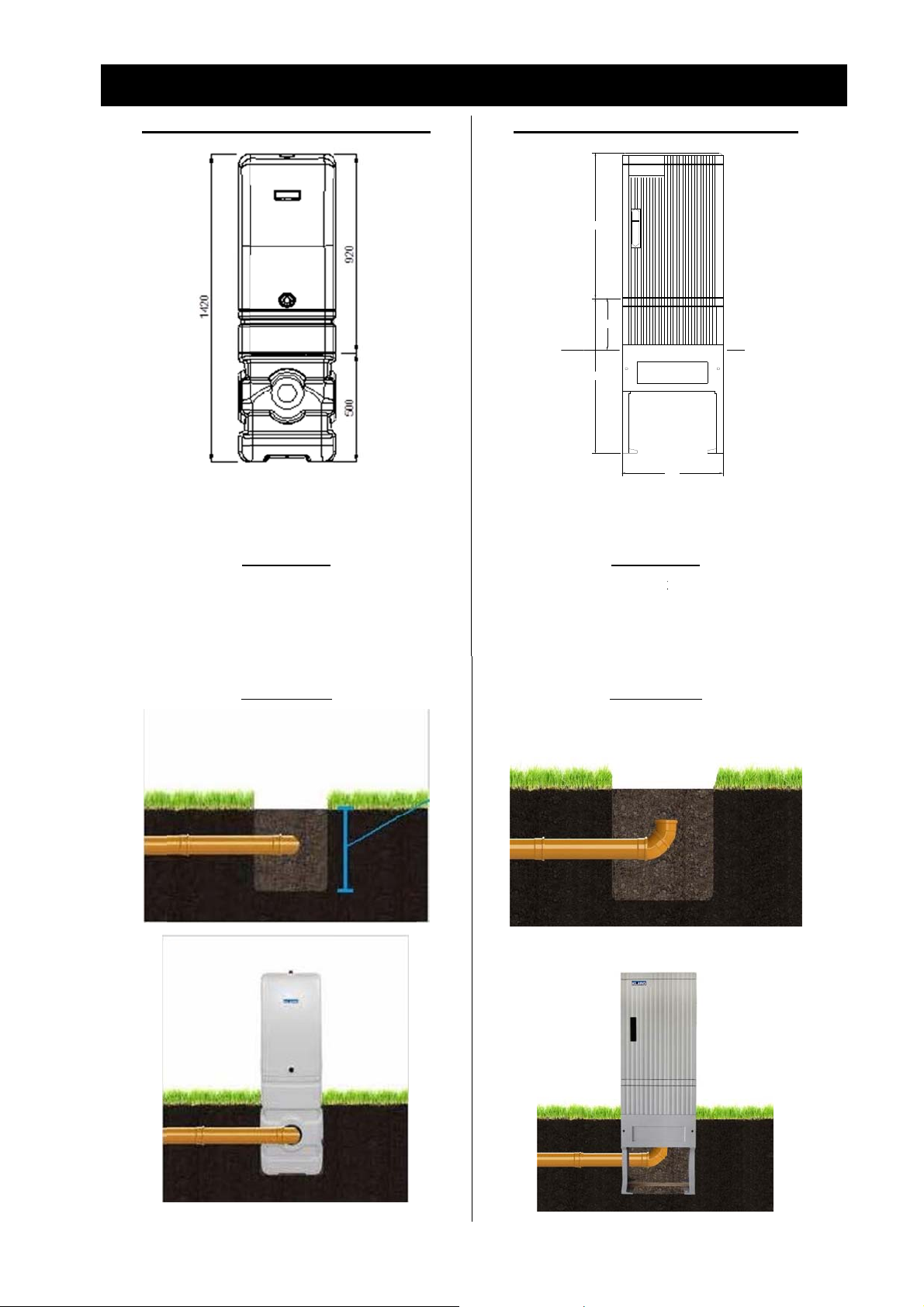

Page 3

m

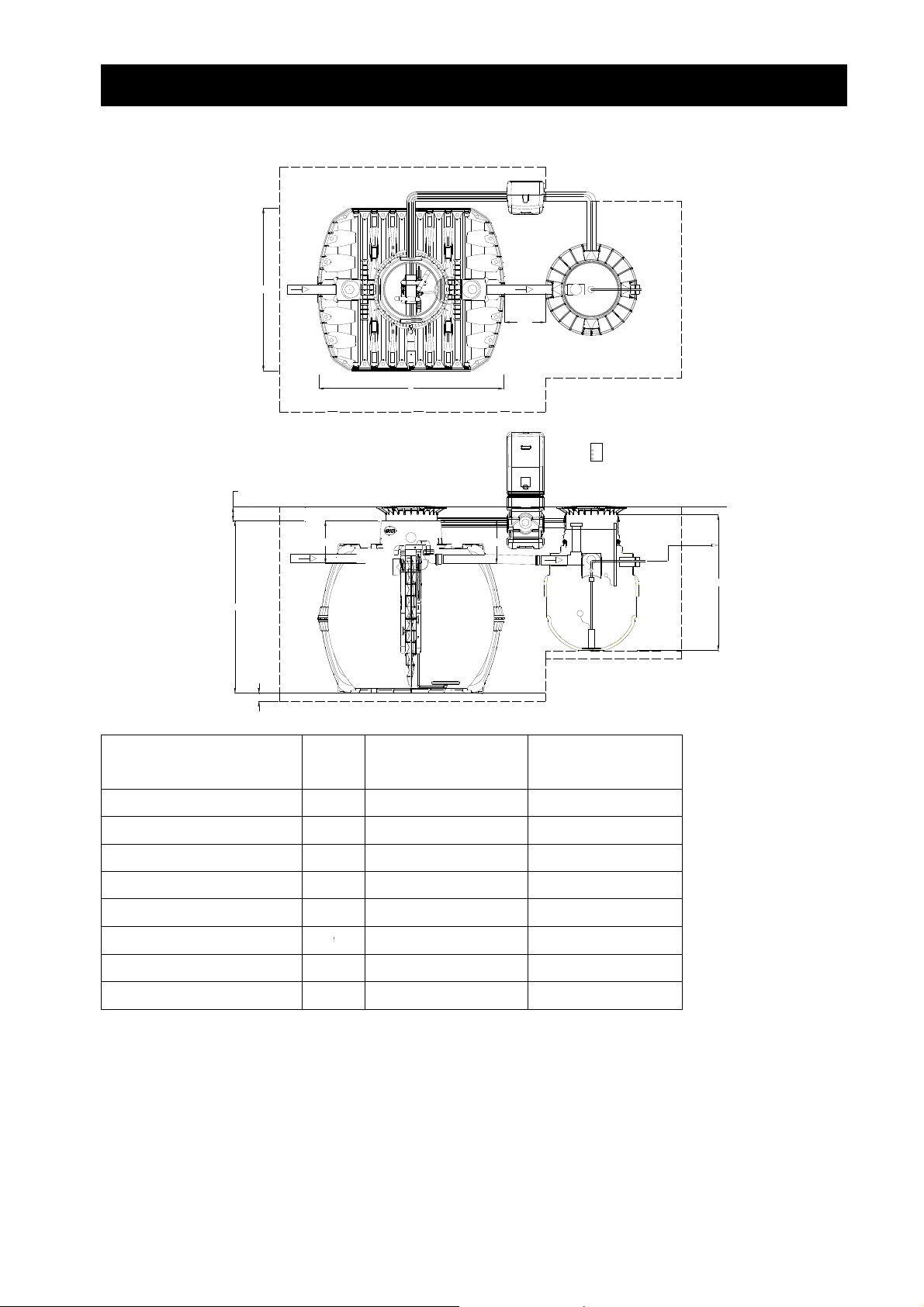

2.

d

5

L

B

t

I

A

2

o

1

2

1

t

i

c

E

6

8

3

1

5

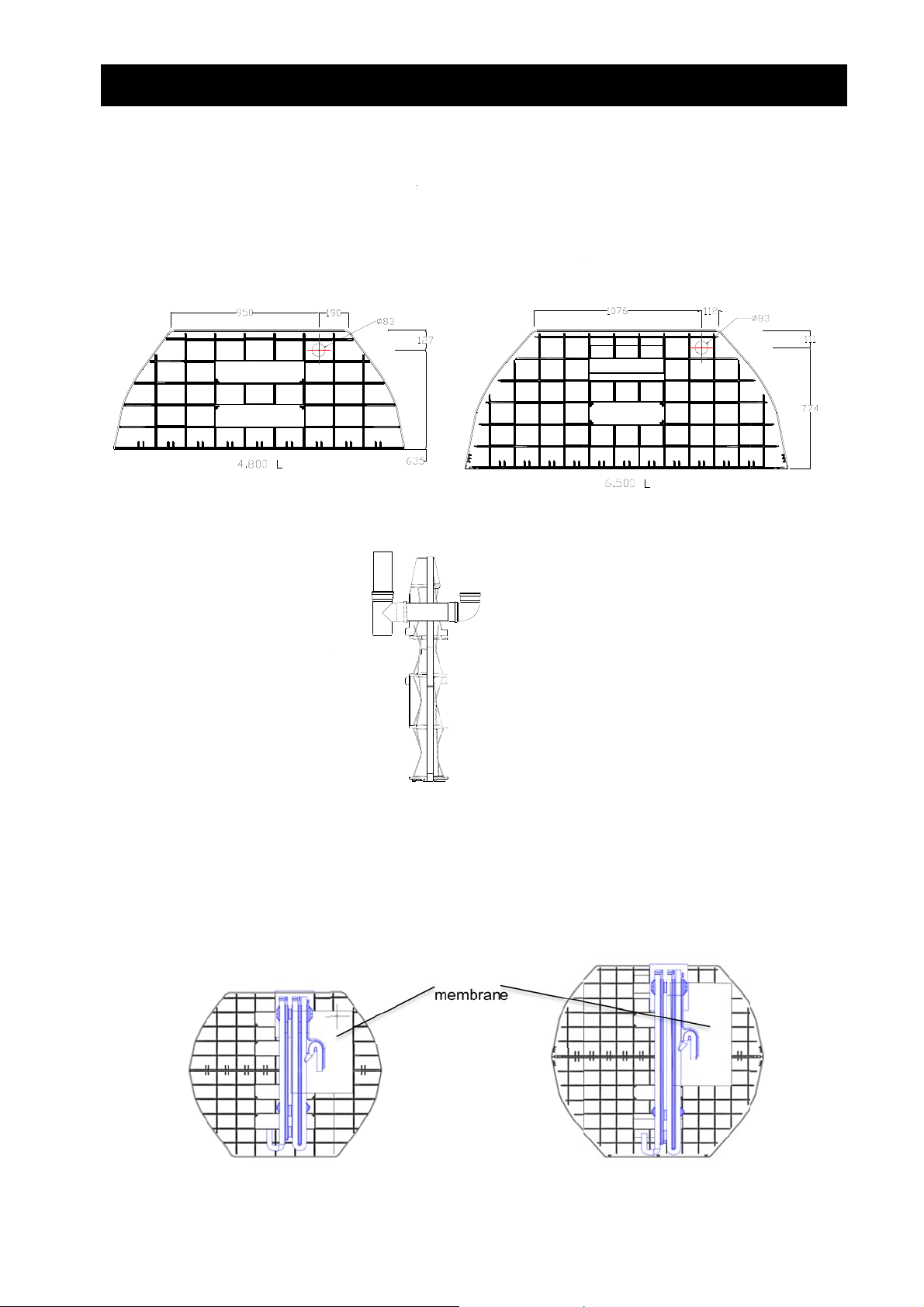

Di

ensions

21

-340

. Dimens

B

L

ons

500

Tank

PE

Max. hy

Length

Width

Height

Inlet

Htot

draulic loa

I

100

Epr

H

ot

15 Domesti

4800 L

10

500 L/d

280 mm

985 mm

O

to irrigation /

infiltration

system

1655

Co

pro18

mercial

500 L

10

1

00 L/d

2

90 mm

2

90 mm

Outlet

95 mm

3 / 25

Page 4

s

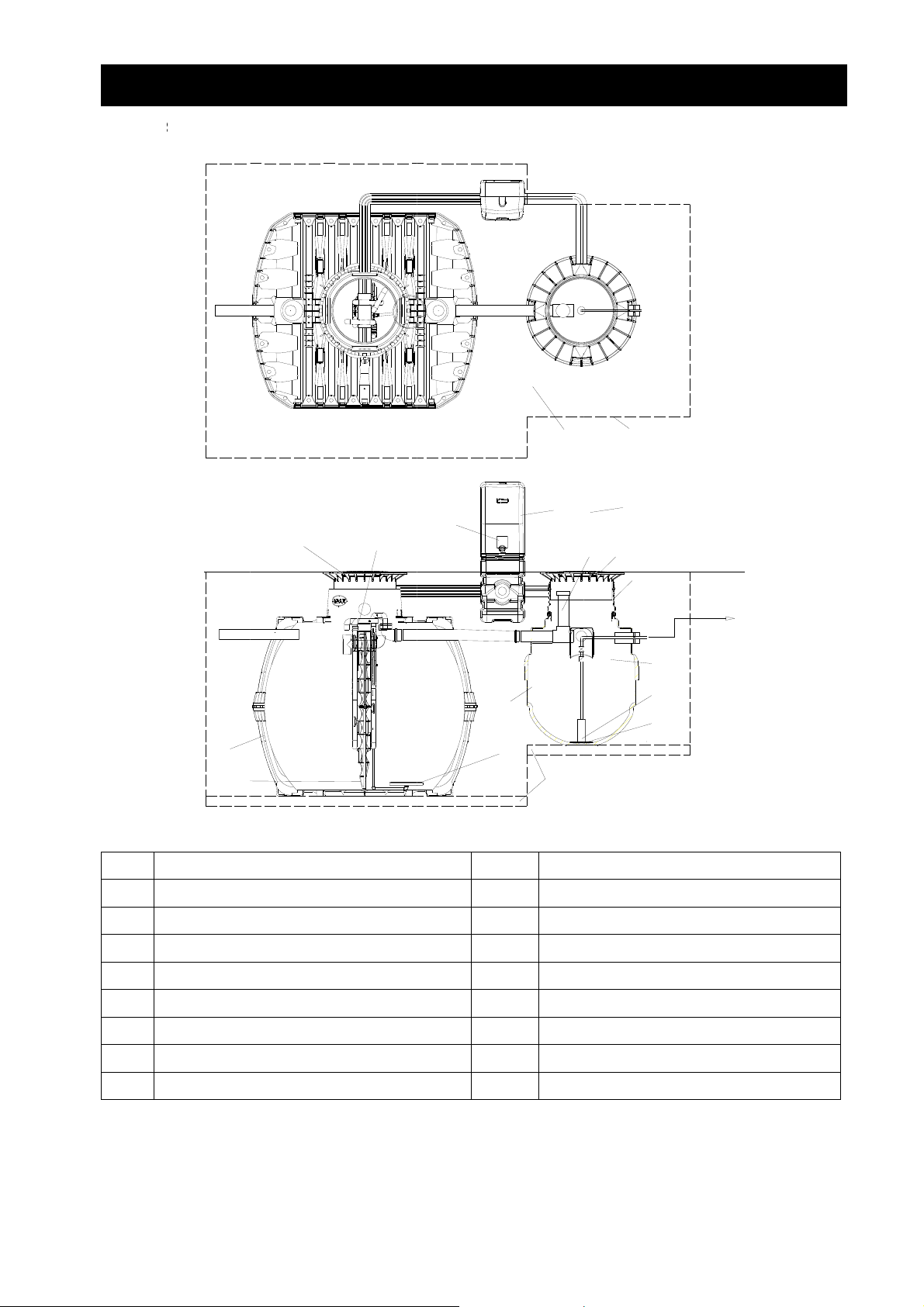

3.

C

T

TD RE BF AG O

P

C

s

i

M

a

b

b

H

t

e

p

n

A

i

n

m

A

o

v

F

a

o

t

a

Sy

tem des

gn

3. FSystem d

esign

A

A

arat Tank

Q

O

C

N

E

J

G

P

Irriga

R

M

I

C

D

ion Pump

K

J

L

B

C

H

I

ank Dome

ele Lid Mini

iser Extens

affle

ir Lift / Aer

utdoor Ca

ump Well 9

hlorine Ta

ini

ion

tion

inet Poly

00 l

let Feeder

K

L

M

N

O

P

Q

R

4 / 25

Highl

Pum

Inter

ir D

Cabi

100

ppr

Exca

vel Alarm

Platform

al Alarm Pl

ffusor

et Ventilati

m Compac

ved Backfill

ation

loat

te

n Fan

ed Base M

terial

Page 5

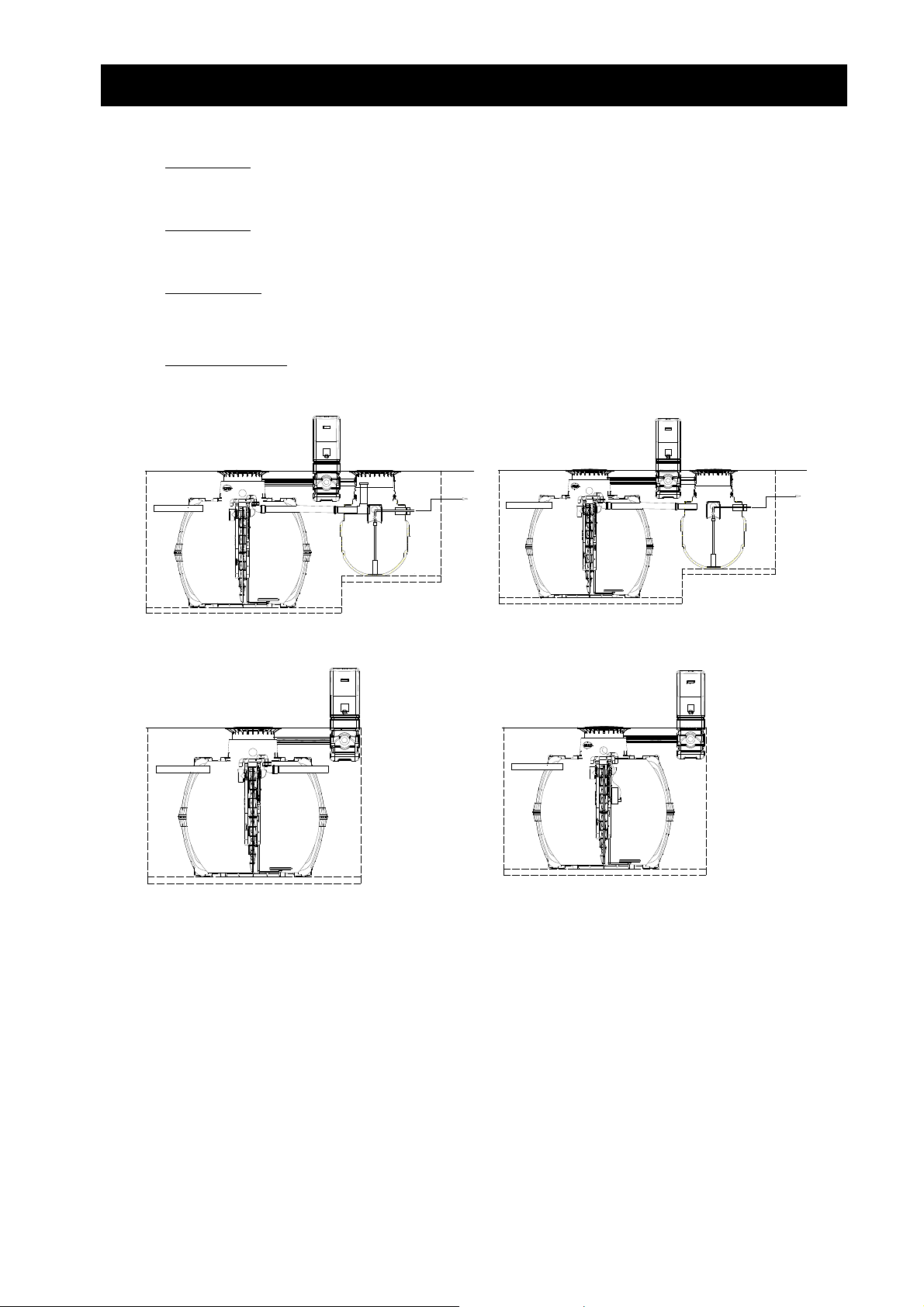

3. System design

EPro15 systems are available in 4 different versions:

EPro15 One

with chlorination and effluent pump in additional Sapphire 900 L tank

EPro15 Two

with effluent pump in additional Sapphire 900 L tank

EPro15 Three

w/o additional tank. Outflow free slope.

EPro15 Three +O

according to EPro15 Three, but with additional effluent pump inside the treatment plant

Figure 1: Epro15 One

Figure 1: Epro15 Three

Figure 2: Epro15 Two

Figure 2: Epro15 Three +O

5 / 25

Page 6

4.

p

m

s

c

e

c

f

a

o

s

P

o

e

c

f

E

4

m

r

8

V

e

g

n

a

8

x

t

m

b

o

l

s

d

h

a

n

t

k

b

r

e

r

h

w

2cha

E

e

e

f

w

a

m

r

8

t

e

g

n

w

e

6

d

w

r

w

f

0

n

s

s

-

As

sembly o

tank co

. Assem

ponents

ly of tan

compon

nts

Carat S

the top

4.1 E

tank has to

art of the b

ergency

Drill hole wit

Put in DN70

be installed

ffle for eme

verflow

h diameter

seal and P

according t

gency overf

3 mm in the

C-fittings a

instruction

low.

top part of

shown in d

manual. Be

affle as sho

awing:

ore installin

n in drawi

the baffle

g:

rill a hole i

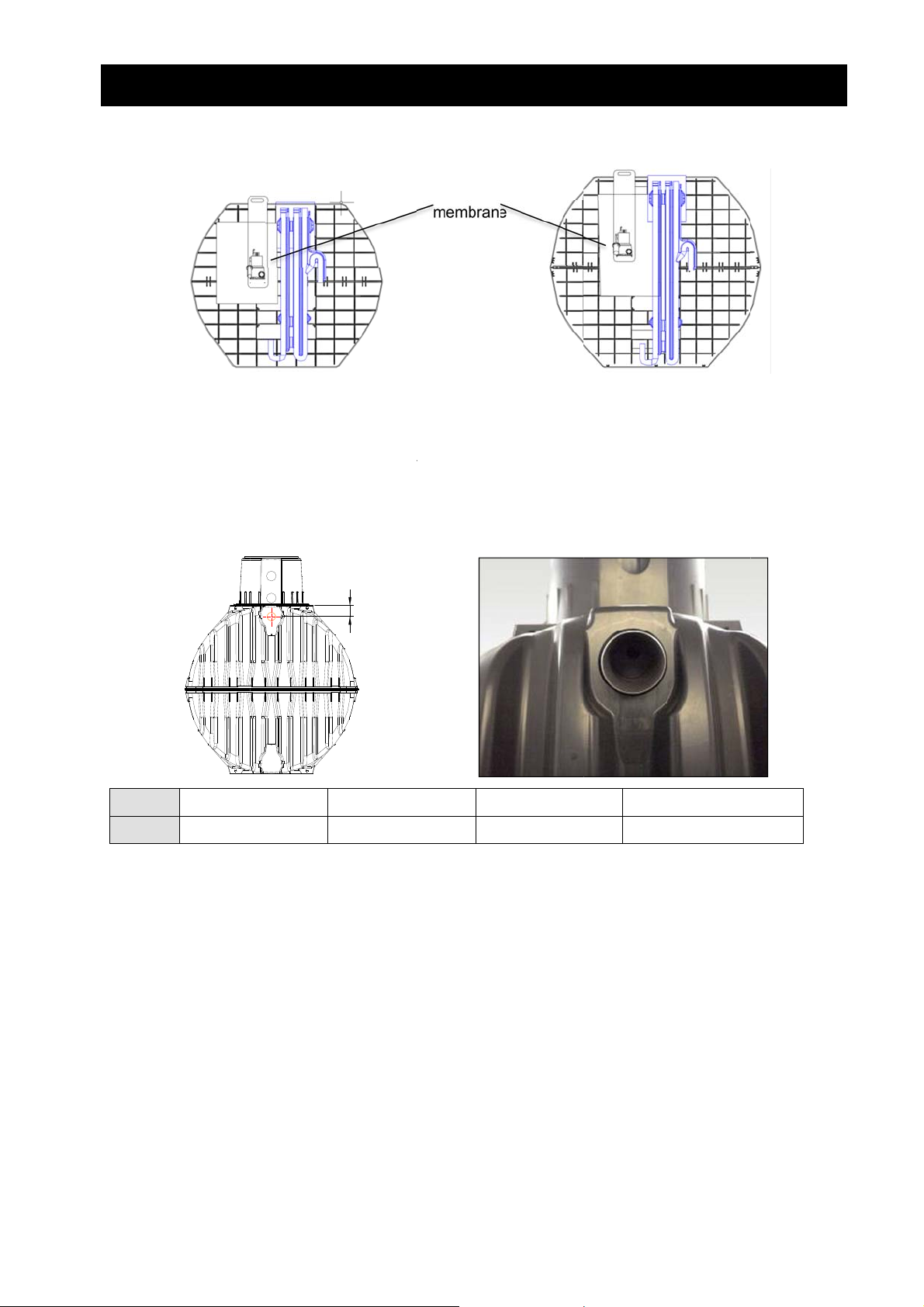

4.2 A

The bla

(3.5x13

on the b

tion kit,

The exa

sembling

k PE memb

mm). The c

affle from b

nsure that t

t position o

1s

cha

E-membra

rane suppli

rrespondin

ing drawn i

he outlet sid

the membr

ber

ne

d is screwe

washers s

by the cle

e is on the s

ne is show

on to the b

ould be us

r water lifte

ide where t

in the dra

black P

membran

nd

mber

affle (2

. During the

nd

ch

d. The me

e PE memb

ing.

mber side)

brane prev

subsequent

ane is fitted

ith 6 self-d

nts sludge

mounting o

.

illing screw

hich settle

the installa

EPro1

5 / Carat 4.

with P

sheet 600

00 L

800

6 / 25

EPro1

Commercia

wi

h PE sheet

l / Carat 6.5

600 x 1000

0 L

Page 7

o

o

g

r

E

o

/

n

l

0

0

4

a

x

/

n

d

. Assem

b

t

e

L

k

e

e

e

Cwit

+

6

w

e

w

.

D

e

ly of tan

black PE

membran

compon

nts

4.3 H

Holes f

seals. A

The hei

Tank

Height

EPro15 Th

with P

les for In-

r DN 100 i

core drill (Ø

ht of the ho

27

14

ee +O / Car

sheet 600

Outflow

let and drai

124 mm) is

e on the en

0 L

mm

t 4.800 L

800

pipes are

required for

faces of th

H

3750

150 m

to be drilled

drilling.

tank can b

L

m

EPro18

in all tanks

found in th

4800 L

230 mm

ommercial

h PE sheet

and fitted

table belo

O / Carat 6

600 x 1000

ith GRAF

.

6500 L

250 mm

500 L

N 100 edg

7 / 25

Page 8

s

5.

n

p

e

n

o

A

e

t

r

e

n

t

i

t

w

a

o

d

e

t

-

n

d

n

s

F

e

T

a

t

x

a

a

d

o

-

In

tallation

set-up ki

5. Ins

tallation

et-up kit

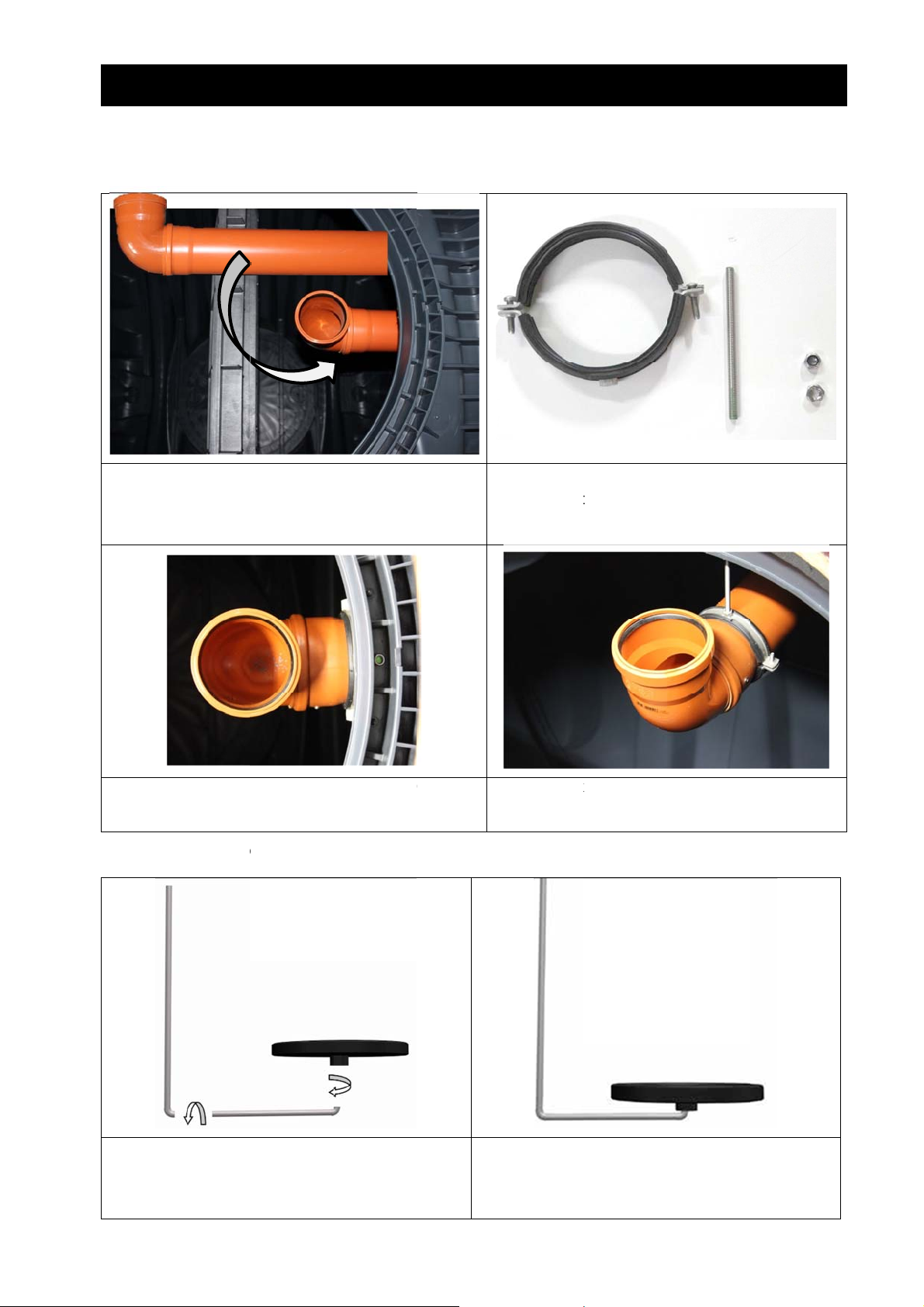

5.1 I

Drain pi

instead

outside.

stallation o

e (pipe DN

orange)) is

f the outflo

110 (pipe

installed fr

pipe

nd bow ca

m the insi

be grey

e to the

or fixing dr

d stud and

in pipe, DN

wo nuts are

100 pipe cl

required.

mp, thread

For fast

through

5.2 I

Screw t

ll conn

Tighten

ning the th

the tank.

stallation a

gether stai

ctions are t

he plastic d

eaded rod,

ration uni

less steel pi

o be sealed

ffuser hand

rill with a 9

es.

using Teflo

tight

mm drill

tape.

he pipe is fi

Do

not allow w

ed by threa

ter to enter

ded bolt an

the ventilati

pipe clamp

n system!

.

8 / 25

Page 9

By Epro

e

n

r

r

w

d

o

a

o

o

h

o

s

t

s

18 Comme

cial, the tw

5. Ins

disc aerat

tallation

rs are

et-up kit

connect

5.3 I

d to the do

stallation o

npipe with

f the aerati

Y-piece.

n unit to t

e set-up ki

The stai

the clea

By snap

nless steel

water lifter.

ping - a clea

ownpipe is

rly audible c

inserted int

lick sounds.

the clamp

9 / 25

provided between the excess sludge lifter and

Page 10

n

k

n

e

i

k

t

s

e

d

p

t

a

e

n

5. Ins

-

b

r

t

s

a

w

t

e

A

e

s

a

u

r

tallation

et-up kit

5.4 I

Set-up

5.5 I

serting/Ins

it has to be

stallation o

allation set

et on the m

f drain (U B

up kit

iddle of the

end)

affle. Disc

erator must

be installed

on side of o

tflow.

The U-b

5.6 F

Set-up

nd is place

xing set-u

it is fixed wi

on the cle

kit and sle

h a screw o

r water lifte

ve connec

the baffle.

. The outflo

ions

of the U-b

ll loos

drilling

nd must le

pipe conne

crews.

d into the d

ctions must

ain pipe.

be fixed with

10 / 25

Page 11

A

e

a

e

n

e

i

m

o

c

e

s

f

5. Ins

p

m

o

u

s

l

s

o

h

e

s

w

m

C

u

c

e

d

r

h

tallation

et-up kit

5.7 A

ir hose con

ection

olored ma

-kit

king at the

EPro set-

ir hos

hose cl

The blu

s have to b

mps accord

hose Ø19

drawn thr

ng to color-

m must be

The gr

The di

for the

ugh the em

oded grom

connected t

en air hose

charge of s

irst critical fl

ty pipe. Co

ets on the

the stainle

is used for t

spended so

ushing surg

ored hoses

et-up kit.

s steel do

e patented

lids is enor

.

have to be

npipe. Ther

air barrier.

ous reduce

onnected a

is no color

nd fixed wit

marking.

11 / 25

Page 12

o

CB H

b

L

m

A

e

F

5. Ins

o

s

n

D

p

s

e

tallation

et-up kit

5.8 C

mponents

of Sapphir

disinfecti

n (as optio

) and pum

-out tank

A

C I

hlorine Ta

igh Water

rrigation Pu

B

let Feeder

evel Alarm

p

loat

Pres

Lip S

E

ure Pipe 40

al DN50

mm

C

D

E

12 / 25

Page 13

o

PB CC MD A

s

f

o

K

h

m

s

d

a

o

t

a

d

b

m

.

w

n

n

e

o

A

m

r

a

g

e

e

b

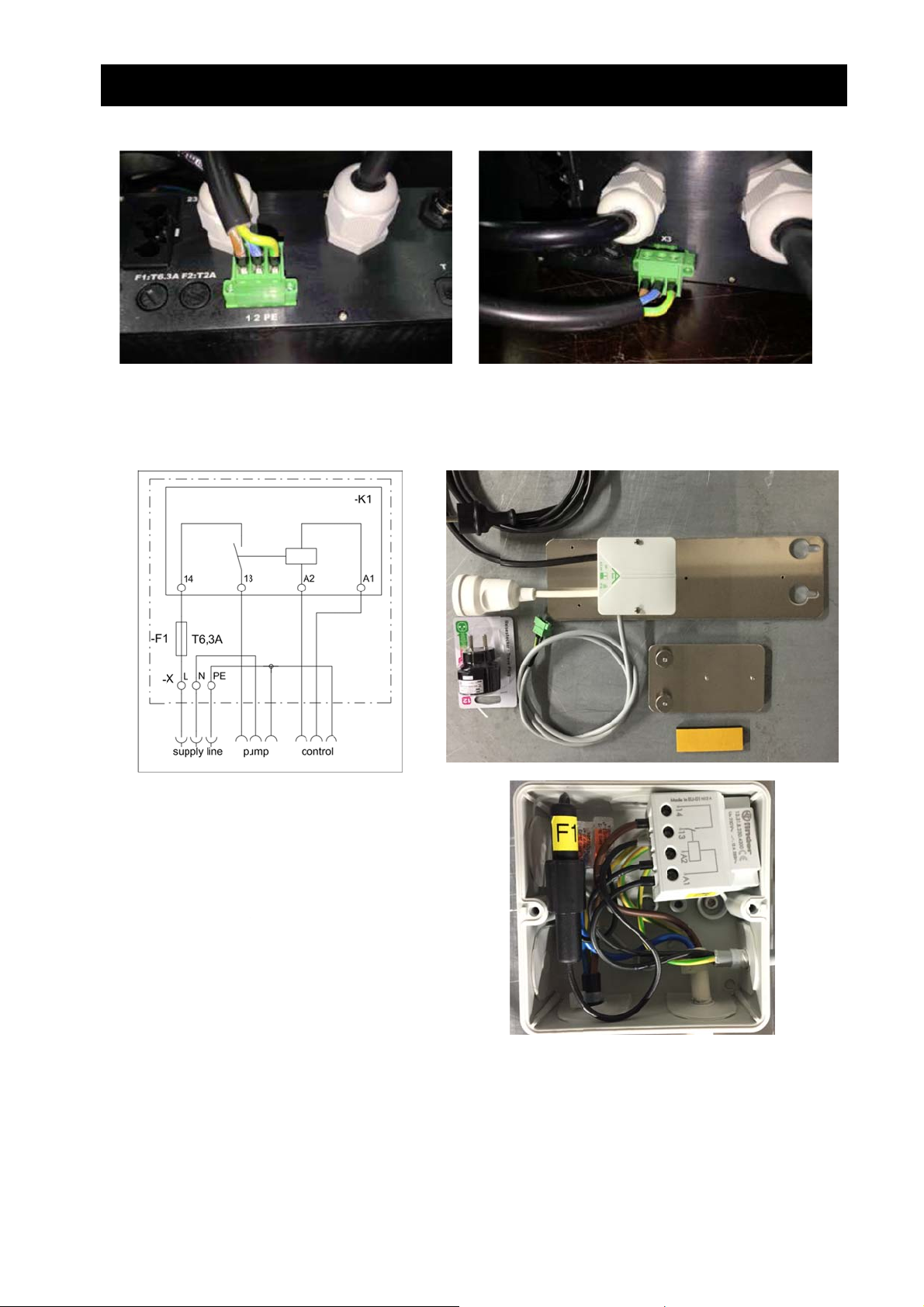

6.

As

sembly o

switch c

6. Asse

binet

bly of s

itch cabi

et

6.1 C

mponents

A

B

C

D

G

F

E

A

6.2 A

iston Air C

ontrol Unit

anifold wit

uxiliar Alar

sembly an

Find proper

o Clo

o Sha

mpressor

L24plus

Step Motor

Unit

d installati

location for

e to the tre

y as possi

Valves

n

he cabinet:

tment tanks

le

E

F

G

. Mind given

13 / 25

Cooli

Pow

Rem

lar

length of ai

g Fan

r Supply

te Alarm Pl

LED (not fi

hoses (5 m

te

ured)

ter) and ca

les

Page 14

t

E

h

C

t

0

0

6. Asse

m

1

w

n

a

b

i

L

WDep

P

c

i

x

x

5

m

o

e

5

a

-

bly of s

itch cabi

et

Graf plastic ex

erior cabin

xcavations:

et for EPro

5

Plastic c

Assem

accord

binet for E

845

300

900

le bottom p

ng to instru

Excavat

ro18 Com

Inst

600

85

art and fix t

tions includ

ions:

ercial

llation depth

640

top part

d

Lengt

Width

Depth

approx. 40

approx. 450

approx. 50

onduit pipe:

mm

mm

mm

ength appro

idth appro

th approx 6

x 585 mm

315 mm

00–640 mm

Conduit

pipe:

14 / 25

Page 15

Gr

a

a

u p

i

Saa

t

l

t

c

r

a

c

n

h

S

n

a

a

e

t

w

r

d

h

U

m

1

r

n

c

y

A

s

d

w

c

m

m

a

n

a

g

t

a

h

g

e

C

b

P

c

n

e

e

g

d

(

d

r

r

n

m

e

e

m

7

o

e

e

o

d

t

l

f plastic ex

erior cabin

E

ectric cable:

6. Asse

et for EPro

bly of s

5

itch cabi

Plastic c

Can

et

binet for E

Electric

o directly i

ro18 Com

able:

to the cabin

ercial

Illustr

tion only: M

Elec

Make sure

upright befo

Use only m

prevent the

ust comply

rical standa

Filling up:

abinet stan

e filling up t

terial that is

abinet from

ith all Aust

ds

s levelled a

e pit

free from ro

damage

alian

d

k to

through op

Make

uprigh

Filling

filling

granul

soil w

in lon

sure cabin

before fillin

up the insi

granulate

run. The g

Filling

te reduces

ich can lea

n bottom

up:

t stands l

up the pit

e of botto

GRAF 10

humidity c

to corriosi

anulate do

velled and

part with

607). The

ming from

on damage

s not need

6.3 A

r hose con

Pull the air

eal the co

nd causing

lso the oth

ection

oses throug

duit pipe to

corrosion.

r end (tank

h the condui

prevent an

se one GR

ide) of con

t pipe (100

gases fro

F sealing c

uit pipe.

to be r

m DWV PV

transfering

p at the ca

placed.

). Make su

from treatm

inet side a

re hoses ar

ent tank int

t the secon

not kinked.

the cabine

one to sea

15 / 25

Page 16

h

h

C

e

C

a

s

n

s

m

)

e

b

(

6. Asse

m

s

u

o

w

s

m

s

h

c

d

u

a

h

n

s

a

n

m

3

3

h

a

bly of s

itch cabi

et

Insert t

cap

Cut off t

.

e hoses fro

e end of th

m the thin

hose to re

ide of the

ove this pl

ealing Pu

of

g. Pu

tig

h the hose

aterial rem

h the seali

tly.

through th

ins stuck in

g cap into t

e thin top l

the end of t

e conduit pi

yer. A plug

he hose.

e to seal it

onnect the

Charging

Aeration (

Dischargi

Sludge ret

hoses at bo

ir lifter (red

tainless ste

g air lifter (

urn air lifter

th ends acc

l)

lack)

white)

rding their

re

bl

bl

w

16 / 25

olour code:

hose, 13m

e hose, 19

ck hose, 1

ite hose, 1

m

m

mm

mm

Page 17

S

PC PD RE E

A C C

C “

C

n

t

t

p

A

a

C

y

C

g

C

h

“

C

t

e

K

t

n

m

k

s

n

e

n

6. Asse

m

d

h

r

m

n

w

E

p

o

n

t

s

n

A

s

m

p

l

5

u

a

r

n

A

bly of s

itch cabi

et

6.4 A

I

H

uxiliary co

troller

A

B

ystem Faul

ower outpu

ower Input

emote Out

ffluent High

uxiliary Al

Pump Run”

G

onnect “S

onnect irri

onnect hig

onnect Ex

F

E

Input from

for irrigatio

ut for Alar

Level / wor

rm Unit mu

stem Fault I

ation pump

-water-leve

(H) shall be

ernal Alarm

D

L24plus

pump

Plate

ing for float

t be installe

put” (A) wit

to “Power O

l / pump wo

set on maxi

Plate to “Re

F

G

H

I

switch

inside the

h alarm out

utput” (B)

king level fl

mum (10 mi

mote Outpu

C

Work

cce

alar

Pum

Statu

Pro Contro

ut plug “X1.

at (E))

)

” (D)

load (option

sory Fault

input)

Run, set to

LEDs

Cabinet

” of KL24pl

B

for addition

(option fo

10 min

s control u

l float)

additional

it

Put the Pow

r Plug (C) i

to the cabi

ets’ power

17 / 25

upply

Page 18

T

a

T

b T

c

a

b

o

T

t

n

c

a

m

6. Asse

m

l

e

w

w

J

w

b

r

J

n

o

s

J

b

w

d

o

bly of s

2

itch cabi

et

he 2 core

void possi

Install Rem

o activate

before mou

front

onnecting

le interferen

te Alarm Pl

he alarm,

ting alarm p

Remote a

able should

ce

te at a plac

ove the Po

late to the

larm plate

be run in a

where ope

er Bridge “

all

ack

separate c

ator can ea

2” on the

nduit to the

ily hear and

ack from on

system po

see it

e pin to bri

er supply t

ge two pins

,

18 / 25

Page 19

e

7.

e

g

6

l

o

h

1

r

X

e

s

r

o

4

e

r

i

4

u

m

w

p

f

f

Cl

ar Water

b

affle height

7. C

Pump M

ear Wate

dule (as

Pump M

ption)

odule (as

option)

7.1 S

480 mm

560 mm

lect the ri

+ XX

min. l

float

Conc

Carat

Carat

ht clip for t

mm

vel when

witch off

ete, 10 EP

4800, 10 EP

6500, 10 EP

e pump

The b

the sw

ackets sho

tch-off point

ld be set

of the pum

ith due con

used.

sideration o

19 / 25

157-162 m

4 pipe cl

ips: 100-10

mm • 108-

16 mm • 12

-132 mm •

Page 20

t

e

7. C

l

r

ear Wate

Pump M

odule (as option)

7.2 M

ounting th

brackets

7.3 S

rain relief

20 / 25

Page 21

o

n

a

n

d

7. C

l

u

r

i

ear Wate

Pump M

odule (as option)

7.4 L

wer pump

socket and

clip mount

ng

7.5 I

The cle

stallation i

r water mo

the tank

ule is hung

p on the pa

rtition baffle.

21 / 25

Page 22

l

t

o

l

s

n

u

e

e

o

n

m

w

n

d

g

n

T

n

7. C

l

r

A

b

r

u

c

p

o

w

U

r

r

o

r

n

o

3

e

u

h

t

d

n

r

h

m

y

A

A

g

ear Wate

Pump M

odule (as

option)

7.6 E

Pumps

connect

7.7 E

ectrical co

hat takes

r and scre

ectrical co

nection fo

aximum 2

ed on with

nection fo

clear wate

mpere can

oth screws

clear wate

pump up

connected

n the left a

pump mo

o 2A

irectly to t

d on the rig

e than 2A (

e control s

t.

aximum 6

stem using

)

a 3-pin plu

Pump i

using a

pulled o

is plugg

and scr

and on

needs t

cabinet.

connecte

EU-AU ad

t with the

d directly i

wed on wit

the right.

plugged i

to the pl

aptor. The

reen 3-pin

to the contr

h both scre

he black E

to the free

g-in coupli

able which

lug connect

l system (X

s on the l

power pl

socket of t

g

is

or

3)

ft

g

e

22 / 25

Page 23

7. Clear Water Pump Module (as option)

7.8 Programming the control unit

For running a submersible clear water pump, we are using the control unit's UV power outlet and UV

setting.

Program settings in the Service Menu need to be changed for T09, T10, T11 and UV:

Time Explanation Valve

EPro15 EPro18 Com.

T 1 [min] charging 1

T 2 [min]

T 3 [min]

T 4 [sek]

Deniphase

off

on

2

T 5 [min] Aeration

T 6 [min] on

2

T 7 [min] off

T 8 [min] Sedimentation

T 9 [min] Discharging

T 10 [min] on

3

12 12

0 0

T 11 [min] off 1 1

T 12 [sec] Sludge return 4

T 13 [min] break of cycle - off

T 14 [min] break of cycle- on

T 15 [min] Holiday - on

T 16 [min] Holiday - off

T 17 [min] total cycle time

T 18 [min] total aeration time

T 19 [min] Total running time

Duty cycle UV module

2

shall be less than 360!

12 12

T-settings can be found in menu "duration period setup" and UV-settings in "UV-light unit setup".

For extending the standard pump time, enlarge T 09 and UV-time. Caution: Check T 17. Total cycle time must be less

than 360 minutes!

Software Jumper

Set Software-Jumper 8 = 0.

The clear water pump can be operated in manual mode, see menu - UV module.

23 / 25

Page 24

C

o

Y C

w

t

A Gbj T

t

n

s

Y

p

C

c

p

e

w

r

t

g

m

A

G

u

j

e

T

t

y

e

r

o

f

a

r

o

a

e

d

a

C

p

r

1

w

n

o

“

t

h

e

i

l

r

x

n

n

c

e

e

Y

t

n

u

c

t

o

n

h

u

e

,

d

e

a

e

s

f

c

c

u

o

a

e

”

u

a

o

p

t

o

T

u

f

a

5

f

g

n

n

e

.

t

.

8.

mmissio

Finish all in

Fill up the tr

ing

tallation wo

eatment tan

8.

k described

with fresh

ommiss

in this instal

water; othe

oning

ation instru

wise no tes

tion

run and sy

tem check

re possible

.

ou can sto

onnect ele

Plug in the

Plug in pow

ill then sta

he system

ESC two ti

rea.

o to “man

by pressing

umping to t

Finally leav

he cabinet

reatment c

Find more

filling up w

tric cable t

ower plug o

r plug com

t automatic

oes on ala

es. Then y

al operation

“1” button

he next. Se

“manual op

is then rea

cle

information

hen water le

Power Sup

the Auxilia

ming from c

lly. At Epro

m and sho

u should e

” in Operati

nd off by

if all air lif

eration” wit

y to operat

in “Start-up

vel is appro

ply – double

y Alarm Co

ontrol unit i

8 Commer

s “Set Dat

ter the corr

n Area and

0” button.

s are worki

ESC.

and will co

, operation

. 20 cm bel

socket (lice

troller into t

to Power s

ial, you hav

and Time”

ct date an

test all valv

ou should

g and aer

nt down in

and maint

w bottom o

sed electri

e GPO.

pply. The

to turn mai

you can q

time in the

s and the c

lways turn

tion on valv

“cyclepause

nance man

outlet pipe

an only!)

ontrol unit

n switch to

it the alarm

control uni

oling fan.

the previo

e 2 shows

” until the st

ual” inside

f an Epro1

osition “I”. I

by pressin

s’ Operatio

urn them o

s off befor

ine bubbles

rt of its firs

the cabinet

Especially r

ad the dos

nd don’ts.

24 / 25

Page 25

tes

o

s

o

9. Note

25 / 25

www.graf.inf

2017-07

Loading...

Loading...