Page 1

info@graf.info

www.graf.info

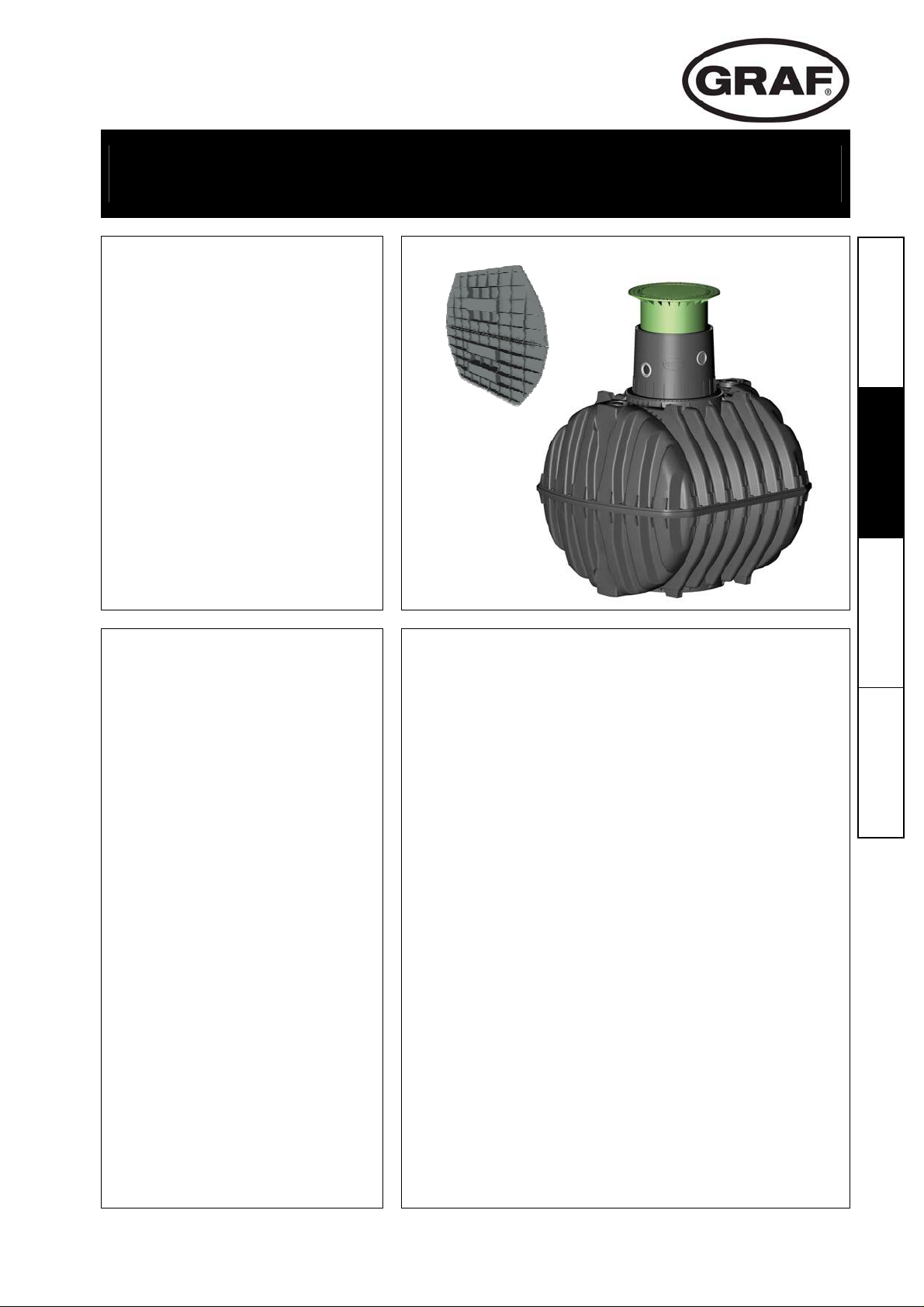

Installation and maintenance instructions for GRAF septic

tanks, Carat series

3750 L

4800 L

6500 L

Order No. 370016

Order No. 370017

Order No. 370018

Deutsch 1

The points described in these

instructions must be observed

under all circumstances. All

warranty rights are invalidated

in the event of non-observance.

Separate installation

instructions are enclosed in the

transportation packaging for all

additional articles purchased

from GRAF.

The tank must be checked for

any damage prior to insertion

into the trench under all

circumstances.

Missing instructions can be

downloaded on www.graf.info or

can be requested from GRAF.

Table of contents

1. GENERAL NOTES 11

1.1 Safety 11

2. INSTALLATION CONDITIONS 12

3. TECHNICAL DATA 13

4. TANK STRUCTURE 14

5. INSTALLATION AND ASSEMBLY 14

5.1 Construction site 15

5.2 Trench 15

5.3 Insertion and filling 16

5.4 Routing connections 16

6. ASSEMBLING THE TANK DOME AND TELESCOPIC

DOME SHAFT 17

6.1 Assembling the tank dome 17

6.2 Assembling the telescopic dome shaft 17

6.3 Telescopic dome shaft on which persons may walk 17

6.4 Telescopic dome shaft over which passenger cars

may drive 17

6.5 Truck telescopic dome shaft 18

6.6 Assembling the adapter 18

English 10

Français 19 Español 28

7. INSPECTION AND SERVICING 18

10 / 36

Page 2

info@graf.info

www.graf.info

1. General notes

1.1 Safety

The relevant accident prevention regulations according to BGV C22 must be observed during all work.

Particularly when walking on the tanks, a 2nd person is required to secure the tank.

The relevant regulations and standards must additionally be taken into consideration during installation,

assembly, servicing, repair, etc. Relevant notes can be found in the corresponding sections of these

instructions.

When entering the tank it is indispensable to empty all chambers. Under no

circumstances one must not enter the container if there is still an unemptied

chamber.

During all work on the system or parts of the system, the entire system must

always be rendered inoperable and secured to prevent unauthorised

reactivation.

Except in the event of work carried out in the tank, the cover of the tank must

always be kept sealed, as this otherwise constitutes a maximum risk of

accident. The rain protection installed on delivery is merely transportation

packaging. It cannot be walked on and is not child-proof; it must be replaced

with a suitable cover immediately following delivery (telescopic dome shaft

with corresponding cover)! Only original GRAF covers or covers approved in

writing by GRAF must be used.

GRAF offers an extensive range of accessories, all of which are designed to

match each other and which can be extended to form complete systems. The use of other accessories

may lead to impediments to the system's functional capability, therefore invalidating liability for resulting

damage.

11 / 36

Page 3

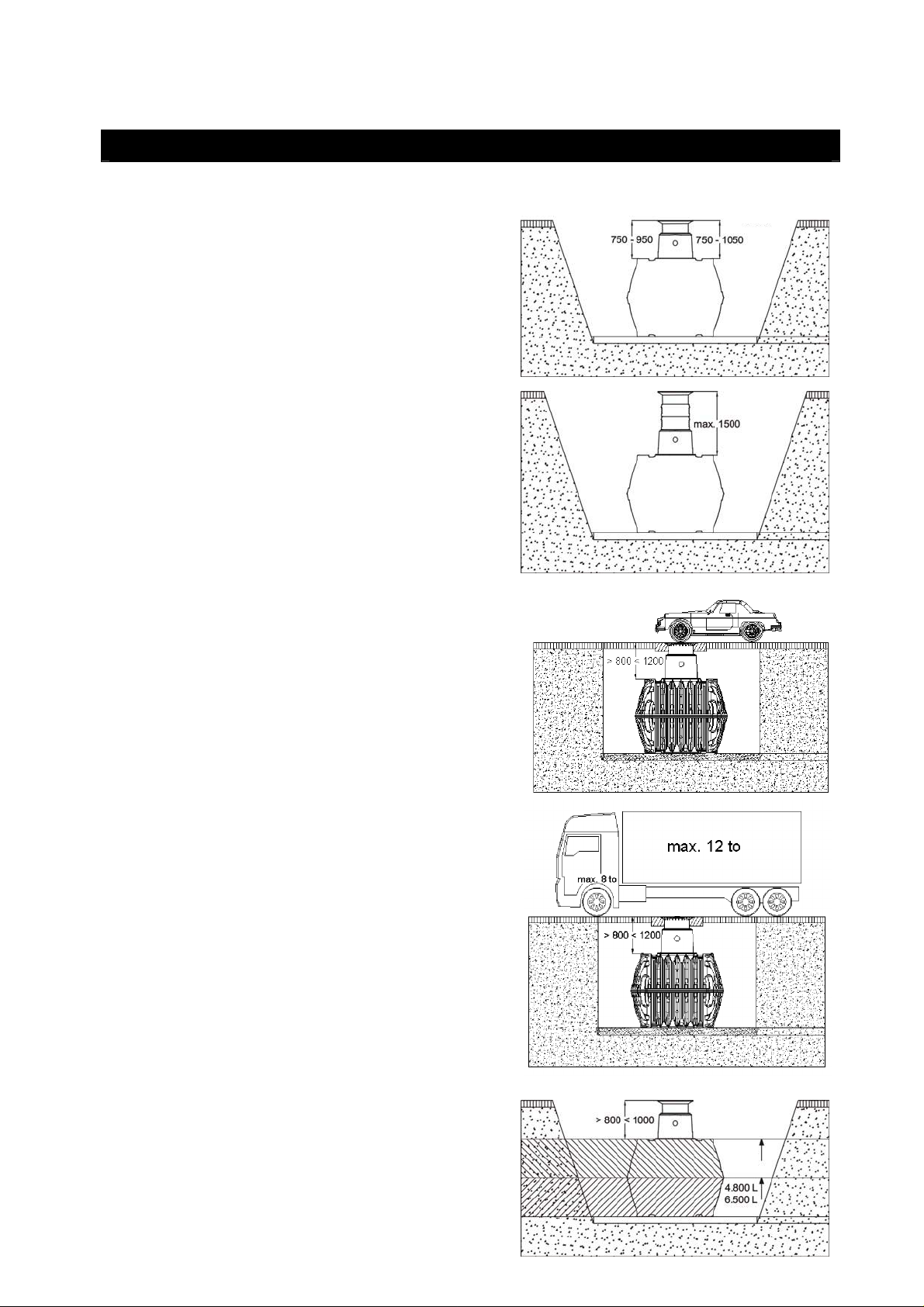

2. Installation conditions

Coverage heights with telescopic dome shaft in

green areas.

The mini dome shaft produces a depth of cover

of between 420 – 620 mm.

Maximum coverage heights with intermediate

section and telescopic dome shaft.

(in green areas only, without groundwater and

stratum water)

info@graf.info

www.graf.info

Mini telescopic

dome shaft

Maxi telescopic dome shaft

+

Telescopic with cast iron lid

Covering heights with cast telescopic dome shaft

(with class B cast cover) in areas with car traffic

(load up to 3.5 t).

Coverage heights with truck telescopic dome

shaft (with cover class D – to be provided at

construction site) in areas used by trucks with a

max. weight of 12 t.

Coverage heights on installation in groundwater

– the hatched areas specify the permissible

immersion depth for the adjacent tank size.

(not under areas used by passenger cars or

trucks)

12 / 36

3.750 L

Page 4

info@graf.info

www.graf.info

3. Technical data

440

200

140

290

Hges

440

Hges

Hges

L

B

with mini tank dome

140

245

355

245

610

Hges

245

520

H

L

B

with tank dome, high version

Tank 3750 litres 4800 litres 6500 litres

Art. No. 370002 370003 370004

Weight

150 kg 185 kg 220 kg

L 2280 mm 2280 mm 2390 mm

W 1755 mm 1985 mm 2190 mm

H 1590 mm 1820 mm 2100 mm

Htot* 2200 mm 2430 mm 2710 mm

Htot*

with mini tank dome

*Htot = total height

1870 mm 2100 mm 2380 mm

13 / 36

Page 5

4. Tank structure

Cover

Telescopic dome shaft (can be inclined by 5°)

Profile seal

Tank dome (can be rotated by 360°)

Tank - tank dome seal

Carat underground tank

Baffle

5. Installation and assembly

Subsoil

Telescopic dome shaft

Compacted foundation

Surrounding (round-grained gravel, max.

grain size 8/16)

1

4

7

info@graf.info

www.graf.info

Covering layer

Carat underground tank

Concrete layer for surfaces used by

passenger cars / trucks

2

1

2

3

4

5

6

ß according to DIN 4124

ß nach DIN 4124

5

7

ß

> 100 mm

< 300 mm

< 300 mm

< 300 mm

< 300 mm

< 300 mm

< 300 mm

< 300 mm

< 300 mm

> 150 mm

14 / 36

6

3

Page 6

info@graf.info

www.graf.info

5. Installation and assembly

5.1 Construction site

Under all circumstances, the following points must be clarified prior to installation:

The structural suitability of the ground according to DIN 18196

Maximum groundwater levels which occur and drainage capability of the subsoil

Types of load which occur, e.g. traffic loads

An expert ground report should be requested from the local planning authority to determine the physical

characteristics of the subsoil.

5.2 Trench

To ensure that sufficient space is available for working, the base area of the trench must exceed the

dimensions of the tank by 500 mm on each side; the distance from solid constructions must be at least

1000 mm.

The embankment must be designed according to DIN 4124. The construction site must be horizontal and

plane and must guarantee sufficient load-bearing capacity.

The depth of the trench must be dimensioned so that the max. earth coverage (see point 2 – installation

conditions) above the tank is not exceeded. To use the system throughout the entire year, it is necessary

to install the tank and those parts of the system which conduct water in the frost-free area. The frost-free

depth is usually approx. 600 mm – 800 mm; precise information in this regard can be obtained from the

responsible authority.

A layer of compacted, round-grain gravel (grain size 8/16, thickness approx. 150 - 200 mm) is applied as

the foundation.

5.2.1 Slope, embankment, etc.

On installation of the tank in the immediate vicinity (< 5 m)

of a slope, earthen mound or slope, a statically calculated

supporting wall must be erected to absorb the soil

pressure. The wall must exceed the dimensions of the

tank by at least 500 mm in all directions, and must be

located at least 1000 mm away from the tank.

5.2.2 Groundwater and cohesive (water-impermeable)

soils (e.g. clay soil)

If it is anticipated that the tanks will be immersed deeper

into the groundwater than is shown in the adjacent figure,

sufficient dissipation must be ensured. (See table for

3.750 L

max. immersion depth).

Dissipation of the drainage water (e.g. via an annular

drainage system) is recommended in the case of

cohesive, water-impermeable soils.

Tank size

3750 L 4800 L 6500 L

Immersion depth

1590 mm 910 mm 1050 mm

5.2.3 Installation adjacent to surfaces used by

vehicles

If the underground tanks are installed adjacent to

surfaces which are used by heavy vehicles weighing over

12 t, the minimum distance away from these surfaces is

at least the depth of the trench.

15 / 36

Page 7

info@graf.info

www.graf.info

5. Installation and assembly

5.2.4 Connection of several tanks

Two or more tanks are connected via the assembly

surfaces by means of GRAF special seals and basic pipes

(to be provided at construction site).

The apertures must be drilled to the corresponding size

using only the GRAF special crown bit. It must be ensured

that the distance between the tanks is at least 600 mm.

The pipes must project at least 200 mm into the tanks.

5.3 Insertion and filling

The tanks must be inserted, impact-free, into the prepared

trench using suitable equipment. The tank is filled with 1/3

water before filling in the tank surrounding.

Afterwards the surrounding (roundgrain gravel, max. grain

size 8/16) is then filled in layers of max. 30 cm steps and

is compacted.

The individual layers must be well-compacted (manuel

tamper). Damage to the tank must be avoided during

compaction. Mechanical compaction machines must not

be used under any circumstances. The surrounding must

be at least 500 mm wide.

5.4 Routing connections

All feed and overflow pipes must be routed with a decline

of at least 1% in the direction of flow (possible,

subsequent settling must be taken into consideration in

this case).

All suction, pressure and control lines must be routed in

an empty pipe, which must be routed as straight as

possible, without bending, to the tank with a decline.

Necessary bends must be formed using 30° moulded

sections.

2. 3/3

>1%

>1%

>1%

1. 1/3

Important: The empty pipe must be connected to an

aperture above the max. water level.

16 / 36

Page 8

info@graf.info

www.graf.info

6. Assembling the tank dome and telescopic dome shaft

6.1 Assembling the tank dome

Prior to assembly, the enclosed seal is inserted into the tank

domes’s groove „B“. The tank dome is then aligned with the

piping connections and is locked to the tank neck. It is essential

to make sure that the upper seal "A" is correctly installed.

„A“ „B“

6.2 Assembling the telescopic dome shaft

The telescopic dome shaft enables infinite adaptation of the

tank to given site surfaces with earth coverage of between

750 mm and 950 mm (Mini telescopic dome shaft) or 750 mm

and 1050 mm (Maxi telescopic dome shaft).

„A“

„B“

For assembly purposes, the enclosed profile seal (material

EPDM) is inserted into the tank dome's sealing groove and is

coated generously with soft soap (do not use mineral oilbased lubricants, as these attack the seal). The telescope is

then greased, inserted and aligned with the surface of the

site.

6.3 Telescopic dome shaft on which persons may walk

Important: To prevent loads from being transferred onto the tank,

round-grain gravel (max. grain size 8/16) is filled in in layers

around the telescope and is evenly compacted. Damage to the

tank dome and telescope must be avoided during this step. The

cover is then positioned and is sealed to prevent entry by children.

Tighten the threaded connection on the cover so tightly that it

cannot be opened by a child!

6.4 Telescopic dome shaft over which passenger cars may drive

If the tank is installed under areas used by passenger cars, the

collar area of the telescope (colour anthracite) must be

supported with concrete (load class B25 = 250 kg/m²). The

layer of concrete to be installed must be at least 300 mm wide and

approx. 200 mm high all around. The minimum coverage above

the shoulder of the tank is at least 800 mm (max. 1050 mm with

telescope, coverage up to max. 1200 mm possible with

intermediate section).

Attention: It is essential to use the cast telescopic dome shaft

(with class B cast cover).

17 / 36

Page 9

info@graf.info

www.graf.info

6. Assembling the tank dome and telescopic dome shaft

6.5 Truck telescopic dome shaft

On installation under areas used by trucks with a maximum

weight of 12 t, the telescope is supported as described in

point 6.2. The concrete rings (Ø 600 mm) and a cast

frame with star-shaped load distribution for mounting the

cast cover are then installed (observe earth coverage of at

least 800 mm, max. 1200 mm). The cast frame must have a

supporting area of approx. 1 m².

Attention: It is essential to use the truck telescope dome

shaft (class D cover to be provided by customer).

6.6 Assembling the adapter

For lager coverage heights a adapter is needed. To insert the

adapter into the tank dome, soft soap is needed. Into the highest

groove of the adapter the profile seal is inserted an greased

generously. Afterwards push the telescopic dome shaft into the

adapter and adapt it to the planned area surface.

max. earth-cover 1500 mm

(in each case in connection with the Maxi telescopic dome shaft)

Telescopic dome shaft (can be inclined by 5°)

Adapter

Tank dome (can be rotated by 360°)

7. Inspection and servicing

The entire system must be checked for leaks, cleanliness and stability at least every three months.

The entire system should be serviced at intervals of approx. 5 years. In this case, all parts of the system

must be cleaned and their function checked. Servicing should be carried out as follows:

All chambers of the tank have to be emptied completely, one must not enter the tank if there is still an

unemptied chamber.

Drain the tank completely

Clean surfaces and internal parts with water

Remove all dirt from the tank

Check that all internal parts are firmly seated.

Otto Graf GmbH – Carl-Zeiss-Str. 2-6 – D-79331 Teningen – Tel.: 0049/(0)7641/589-0 – Fax: 0049/(0)7641/589-50

GRAF SARL – 45, Route d´Ernolsheim – F-67120 Dachstein Gare – Tel.: 0033/388497310 – Fax: 0033/388493280

GRAF Iberica – C/Marquès Caldes de Montbui, 114 baixos – ES-17003 Girona – Tel.: +34/972 913 767 – Fax: +34/972 913 766

GRAF Ltd – Maidstone, Kent – UK-ME16 8Ry – Phone: +44 (0) 16 22 68 65 50

18 / 36

02-2012

Page 10

3750 L

4800 L

6500 L

info@graf.info

www.graf.info

Notice de montage et d’entretien

du collecteur d’eau de pluie GRAF série Carat

N° de réf. 370016

N° de réf. 370017

N° de réf. 370018

Deutsch 1 English 10

Afin de garantir le bon

fonctionnement et la longévité de

votre installation, les différents

points décrits dans cette notice

doivent scrupuleusement être

respectés. Tout manquement à

ces règles annulera

systématiquement la garantie.

Lisez également toutes les

notices des autres éléments

fournis par la société GRAF. Vous

trouverez les notices de montage

jointes dans l’emballage.

Avant de positionner la cuve

dans la fosse, il est important de

vérifier que celle-ci n’a pas été

endommagée.

Les notices manquantes peuvent

être téléchargées sur

www.graf.info ou être demandées

auprès de la société GRAF.

Sommaire

1. GÉNÉRALITÉS 20

1.1 Sécurité 20

2. CONDITIONS DE MISE EN PLACE 21

3. CARACTÉRISTIQUES TECHNIQUES 22

4. ASSEMBLAGE DU RÉSERVOIR 23

5. MISE EN PLACE ET MONTAGE 23

5.1 Support de construction 24

5.2 Fouille 24

5.3 Mise en place et remplissage 25

5.4 Poser les raccords 25

6. MONTER LE DOME DU RESERVOIR ET LA

CHEMINEE-DOME TELESCOPIQUE 26

6.1 Montage du dôme 26

6.2 Monter la cheminée-dôme télescopique 26

6.3 Cheminée-dôme télescopique résistante aux charges

de pas 26

6.4 Cheminée-dôme télescopique résistante aux charges

de roues 26

6.5 Cheminée-dôme télescopique passage camions 27

6.6 Montage de la rallonge 27

7. INSPECTION ET ENTRETIEN 27

Français 19

Español 28

19 / 36

Loading...

Loading...