Grady-White Journey 258, Chase 273, Advance 257, Fisherman 222, Tournament 225 User Manual

...

TABLE OF CONTENTS

T ABLE OF C ONTENTS

WELCOME ABOARD!

T

ABLE OF CONTENTS

CHAPTER 1: CONSUMER INFORMATION

Owner’s Packet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

Dealer’s Responsibilities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

Consumer Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

Hazard Warning Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

CHAPTER 2: SAFETY

Required Safety Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

Additional Recommended Equipment . . . . . . . . . . . . . . . . . . . . . . . 2–1

Registration Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

Emergency Stop Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

Emergency Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

Boating Safety Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–3

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–4

Loading Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–4

Carbon Monoxide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–5

Suggested Boating Classes And Reading Material . . . . . . . . . . . . . . 2–6

CHAPTER 3: GENERAL INFORMATION

Fueling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

Fuel Select Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–3

Pollution Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–3

Discharge of Oil or Hazardous Substances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

Disposal of Plastics or Garbage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

Trailering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

Predeparture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

Casting Off & Approaching The Dock . . . . . . . . . . . . . . . . . . . . . . . 3–5

Anchoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

Shallow Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

Windlass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–7

General Information On Boat Handling . . . . . . . . . . . . . . . . . . . . . . 3–7

Twin Engine Boats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–7

Commonly Used Nautical Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–8

CHAPTER 4: PERFORMANCE

Performance Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

Engine Efficiency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

Weather Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

Load Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

Marine Growth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

Propeller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Propulsion System – Outboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–3

T ABLE OF CONTENTS

Engine Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–3

Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–4

Throttle/Shift Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–5

CHAPTER 5: INSTRUMENTATION AND SWITCHES

Yamaha Instrumentation Panel . . . . . . . . . . . . . . . . . . 5–1

Digital Speedometer and Fuel Management . . . . . . . . . . . . . . . . . . . 5–1

Digital Tachometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–2

Switch Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–3

CHAPTER 6: MAINTENANCE AND SERVICE

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

Exterior Fiberglass Finish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

Finish/Waxing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–2

Repairing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–3

Bottom Paint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–3

Canvas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–3

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–3

Snaps And Zippers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–4

Vinyl. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–4

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–4

Upholstery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–5

Duratrim/Polyethylene/Plexiglass/Vinyl . . . . . . . . . . . . . . . . . . . . . 6–5

Scuppers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–5

Caulking/Gasket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–5

Hardware/Hardtop Frame/Stainless Steel Rails . . . . . . . . . . . . . . . . . 6–5

Hardware Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–6

Maintenance Procedure For Anodized Aluminum Components . . . . . 6–6

Fuel System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–6

Fuel Tank Compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–7

Shower Sump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–7

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–7

Light Bulb Replacement Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–9

Accessory Wiring Color – Fuse/Breaker Sizes . . . . . . . . . . . . . . . . 6–10

CHAPTER 7: WINTERIZATION AND STORAGE

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–1

Boat Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–1

Cleaning And Lubricating The Boat . . . . . . . . . . . . . . . . . . . . . . . . . 7–2

Draining & Water System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–2

Head System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–2

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–3

Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–3

Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–3

Storage Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–3

Getting Boat Out After Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–4

Prior To Launching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–4

After Launching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–4

T ABLE OF C ONTENTS

CHAPTER 8: 306 BIMINI

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–1

Optional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–1

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–1

Canvas Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–1

Operation Of Standard Features . . . . . . . . . . . . . . . . . . 8–2

Switch Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–2

Auxiliary Fuse Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–3

Main Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–4

Accessory Outlet - 12 Volt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–4

Compass. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–4

Aft Rigging Compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–4

Bilge Pump With Float Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–4

Bilge Pump Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–4

Shower Sump Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–5

Cockpit Shower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–5

Console Fresh Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–5

Leanbar Fresh Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–5

Windshield Washer Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–5

Transducer Flats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–5

Seacocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–6

Livewell - Raw Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–6

Washdown Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–7

Battery Select Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–7

Trim Tabs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–8

Head Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–9

Marine Head (W/ Hand Pump) Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–9

Electric Marine Head Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–9

Emptying Marine Head Holding Tank By Overboar d D ischarge . . . . . . . . . . . . . . . . . . . . 8–9

Emptying Marine Head Holding Tank Through Deck Pump-out . . . . . . . . . . . . . . . . . . . . 8–9

Operation Of Optional Features . . . . . . . . . . . . . . . . . 8–10

Bow Thruster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–10

Dockside Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–10

Connecting The Dockside Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–10

Disconnecting The Dockside Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–10

Battery Charger (Dockside Power Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–11

T-top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–11

Outriggers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–11

Power Assist Hydraulic Steering . . . . . . . . . . . . . . . . . . . . . . . . . . 8–12

Stereo. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–12

Sirius Satellite Radio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–12

In for mat ion al D raw ings . . . . . . . . . . . . . . . . . . . . . . 8–13

Access Plate And Rigging Tube Location. . . . . . . . . . . . . . . . . . . . 8–13

Labels And Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–14

Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–15

Livewell/Washdown System Layout . . . . . . . . . . . . . . . . . . . . . . . 8–16

Livewell/Washdown System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–17

Freshwater System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–18

Marine Head Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–19

Thru Hull Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–20

Accessory Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–21

T ABLE OF CONTENTS

Upper & Lower Console Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . 8–22

Battery Wiring With Select Switches . . . . . . . . . . . . . . . . . . . . . . . 8–23

Hard Top Layout and Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–24

Stereo Layout and Wiring with Factory T-top . . . . . . . . . . . . . . . . 8–25

Stereo Layout and Wiring without Factory T-top . . . . . . . . . . . . . . 8–26

Typical Outboard Switch Panel Wiring . . . . . . . . . . . . . . . . . . . . . 8–27

Dockside Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–28

CHAPTER 9: LIMITED WARRANTY

Registration Of Purchase: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–1

Five Year Hull Transferable Warranty . . . . . . . . . . . . . . . . . . . . . . . 9–1

One Year Material And Workmanship Warranty . . . . . . . . . . . . . . . . 9–1

Warranty Claim Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–2

TRANSFERABLE WARRANTY FORM

WELCOME

Chapter 1: Consumer Information

OWNER’S PACKET

Your Grady-White has many features and accessories that have existing printed material

provided by the various equipment manufacturers. This information is compiled in a package that

we will reference throughout this manual as an “Owner’s Packet.” This Owner’s Packet includes a

Grady-White Owner’s Manual and Engine Manual(s) to advise on operation, service,

specifications, maintenance, warranty, and other useful facts. While reading your Grady-White

manual, you will find other technical literature referenced as resources for detailed information.

The Owner’s Packet will also consist of operation guides, informative labels, and product

warranties you will need to be acquainted with. Your Owner ’s Packet can also be used to retain

instructions and data compiled on additional equipment and accessories installed after delivery.

Sportfish, Cruisers, Yachts Owner’s Manual, a book published by the National Marine

Manufacturer’s Association (NMMA), has been included with your Owner’s Packet as a

supplement. This publication will be referenced in your Grady-White Owner’s Manual to present

additional instructions and information on basic boating.

WARRANTY INFORMATION

The Grady-White warranty is located on the next to last page of this manual. Upon the

purchase of your new Grady-White Boat, the dealer will fill out a warranty card. This card

will be kept on file at the dealership and at the Grady-White factory. A copy will be provided for

your records and should be kept with other valuable documents for future reference. For questions

regarding your warranty please contact your dealership.

DEALER’S RESPONSIBILITIES

Throughout the fabricating and assembly processes, your Grady-White has undergone a series

of strict inspections. Subsequent to the final factory overview, your dealer must perform

additional pre-delivery checks and approve your Grady-White for delivery.

DEALER RESPONSIBILITIES INCLUDE PROVIDING THE FOLLOWING:

• An orientation of the general operation of your Grady-White.

• A warranty card to be completed and signed by the dealer and the customer. This warranty card

is to be sent to Grady-White Boats to validate the warranty.

• An explanation of safety issues regarding the use of containment systems and components.

• A complete Owner’s Packet containing literature and information regarding your Grady-White

and its separate warranted products’ operation, installation, and maintenance instructions.

• A review of all warranties pointing out the importance of mailing warranty and registration to

various manufacturers within the required time limits.

• Guidance on acquiring local and out of area service during and out of warranty periods.

1–1

W ELCOME

CONSUMER RESPONSIBILITIES

THE FOLLOWING ARE RESPONSIBILITIES OF THE GRADY-WHITE OWNER:

• Read and understand the express limited warranty.

• Study in detail all literature and instructions enclosed, and use all equipment in accordance.

• Examine the boat and confirm all systems are working suitably at the time of accepting

delivery.

• Render proper maintenance and periodic servicing of the boat in accordance with suggestions

in the Owner’s Manual.

• Return the boat to the selling dealer for an engine inspection. Refer to the engine’s owner ’s

manual for the proper maintenance schedule.

Grady-White Boats has a permanent record of your boat which is retained under its “Hull

Identification Number” (HIN). Data regarding equipment and accessories, as well as dealer/

shipping information is documented. When contacting your dealer concerning warranties or

service, please have all relevant information such as serial numbers (HIN) and model number

available. This information is on your copy of the warranty card.

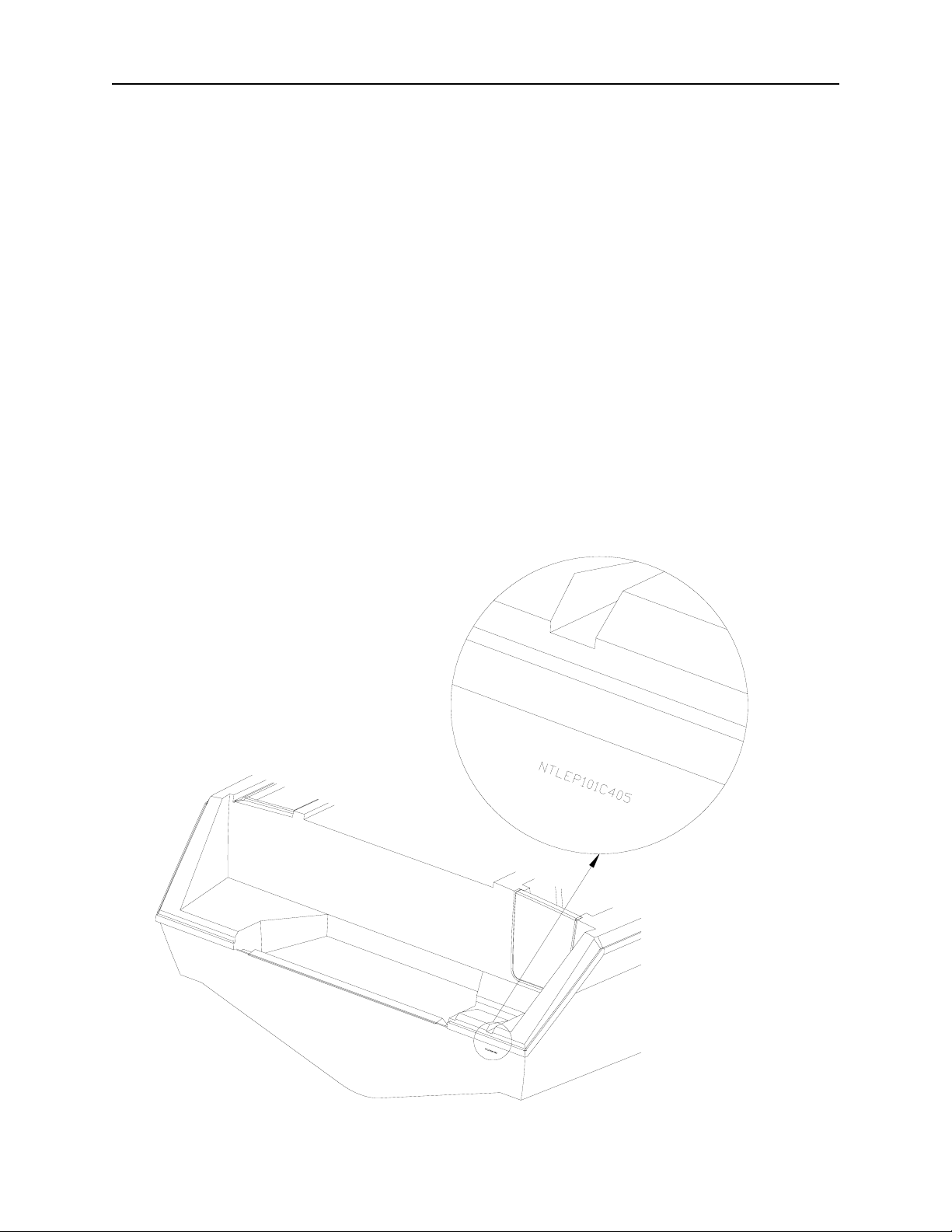

The “Hull Identification Number,” located on the starboard side of the transom, is a

significant source of identification and must be noted in all correspondence and orders. Failure to

include the HIN only creates delay.

1–2

WELCOME

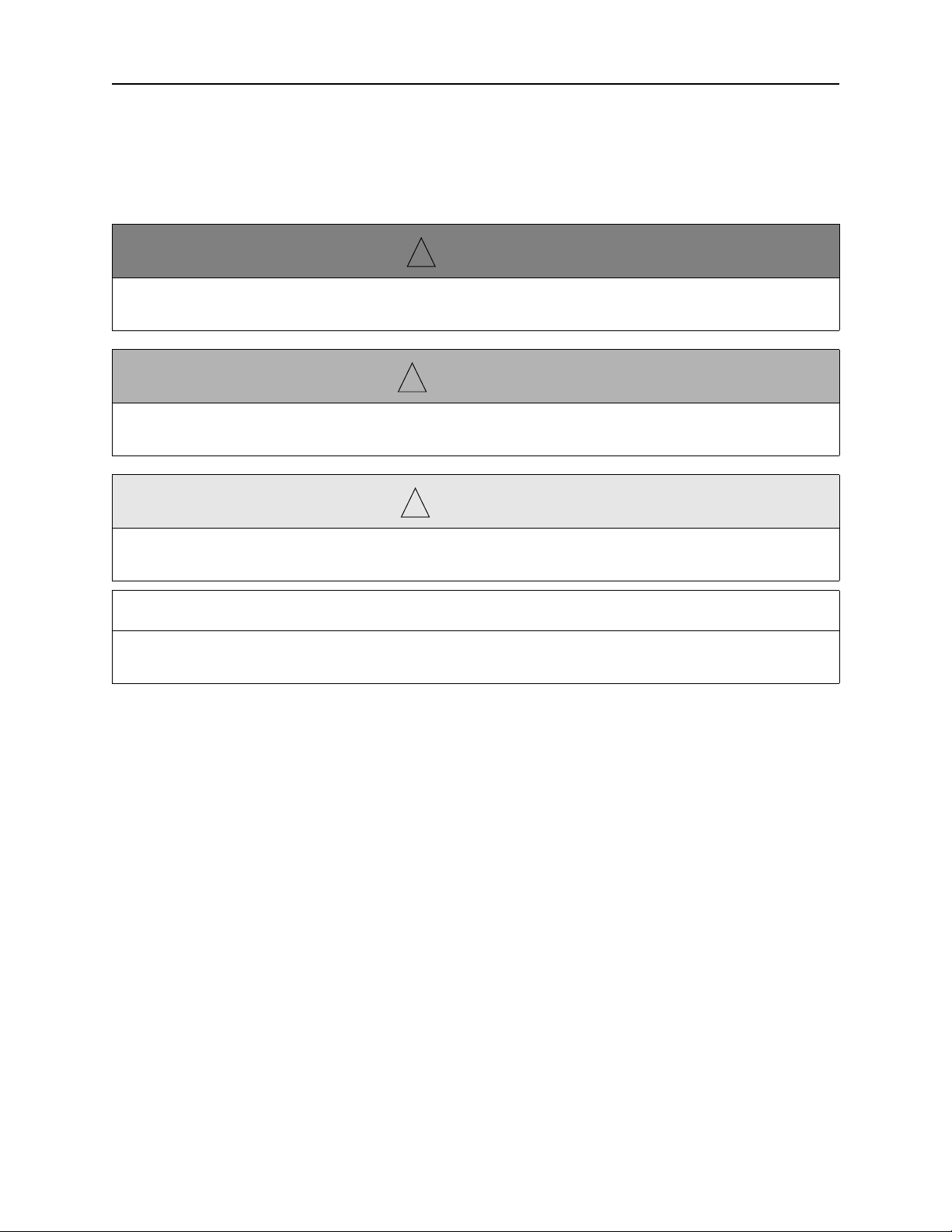

HAZARD WARNING LABELS

The hazard warning labels shown below are applied throughout this manual to alert the

customer of potentially dangerous situations that can lead to death, personal injury, and/or product

damage. We urge you to observe these warnings and comply with all safety recommendations.

D A N G E R

!

This symbol alerts you to imminently hazardous situations which will cause severe personal injury

or death if the warning is ignored.

W A R N I N G

!

This symbol alerts you to potentially hazardous situations or unsafe practices that could resul t in

severe personal injury or death if the warning is ignored.

C A U T I O N

!

This symbol alerts you to potentially hazardous situations that may result in minor personal

injury or cause product or property damage if the warning is ignored.

N O T I C E

This symbol calls attention to installation, operation, or maintenance information which is

important for proper operation, but is not hazard related.

1–3

W ELCOME

1–4

SAFETY

Chapter 2: Safety

REQUIRED SAFETY EQUIPMENT

The US Coast Guard (USCG) requires that every boat have specific equipment on board.

Check with local regulations on mandatory equipment apart from the list of Coast Guard

requirements. See Sportfish, Cruisers, Yachts Owner’s Manual, page 17, for details on the

following required safety equipment.

•Fire Extinguisher

Boats should be equipped with a marine approved fire extinguisher.

• Personal Flotation

All passengers must have an USCG approved personal flotation device (PFD).

Children and non-swimmers are advised to wear a PFD at all times.

• Sound Signaling Device (Horn, Bell Or Whistle)

Your Grady-White is equipped with a horn that meets USCG requirements.

• Visual Distress Signals

USCG approved visual distress signals are required on U. S. waters. See page 33 of the

pamphlet Sportfish, Cruisers, Yachts Owner’s Manual enclosed with this manual for more

information.

• Lighting

Grady-White boats are equipped with navigational lights that meet requirements for

recreational vessels for inland and international waters.

ADDITIONAL RECOMMENDED EQUIPMENT

In addition to the required safety equipment, there are additional items that will provide an

extra margin of safety and convenience for you and your passengers while boating. For an

extended list of basic gear, tools and spare parts, reference page 18 of the pamphlet Sportfish,

Cruisers, Yachts Owner’s Manual enclosed with this manual.

Keep tools and spare parts in good condition. Replace parts removed from spare parts kit.

Most importantly, use US Coast Guard approved or marine certified parts where applicable.

Conditions found requiring corrective action should be worked on by a qualified repairman.

REGISTRATION NUMBERS

Federal and State laws require a powerboat to be registered in the State where it is primarily

used. Registration numbers and validation stickers must be displayed according to regulations.

The registration certificate must be on board when boating. The boat serial number or Hull

Identification Number (HIN, page 1–2) is required on the registration form. The HIN is located

on the upper right hand corner of the transom, and is the most important identifying factor. The

HIN should be included in all documents and correspondence to provide you timely service.

2–1

S AFETY

EMERGENCY STOP SWITCH

All Grady-Whites are equipped with an emergency stop switch. This is a safety feature that if

used properly will shut the engine(s) down if the operator leaves or falls from the helm position.

The ignition shutdown system includes a shut-off switch, switch clip, lanyard and lanyard clip.

The lanyard clip is attached to the operator. If a situation arises where the boat should stop, a pull

on the cord to release the clip from the shut-off switch will shut down the engine(s). To reset the

emergency stop switch, simply reinstall the switch clip. The decision to use the emergency stop

switch rests with the owner/operator. See page 72 in Sportfish, Cruisers, Yachts Owner’s Manual.

EMERGENCY INFORMATION

While boating, unpleasant situations may develop. You should prepare yourself on how to

cope with them whether they happen aboard your vessel or someone else’s. Anticipate and game

plan for specific situations such as fire, man overboard, collision, etc. to give you the confidence

and ability necessary to handle an emergency. The key is to remain calm. For emergency

procedures, see Section 4 in Sportfish, Cruisers, Yachts Owner’s Manual.

• Rendering Assistance

The owner or operator of a vessel is required by law to render all practical or necessary

assistance to any person or vessel affected by collision, accident or casualty. However, you

are not required to endanger your vessel or passengers to render assistance.

• Accident Reporting

Report all boating accidents to your local authorities. Federal regulations require boat

operators involved in an accident to submit a written report within 48 hours. In the event of

death or disappearance, notification is required immediately by phone or radio in addition

to the written report. These reports can be submitted to the State Boating Law Administrator.

Forms can be obtained through the USCG, local harbor patrol offices, sheriff, and police

stations.

• Lightning Precautions

This awareness is included to ensure the safety of the owner and passengers. Always be

mindful of the weather! When a lightning storm advances, certain safety precautions should

be taken. Dock the boat and seek shelter on land. If this is not possible, seek refuge inside the

boat until the storm has passed. Stay out of the water! Lightning will seek a ground when it

strikes and may pass through metal components if it hits your boat. For this reason, avoid

contact with metal parts of the boat under these conditions.

2–2

SAFETY

BOATING SAFETY TIPS

Safety is an important aspect of boating. Your safety as well as the safety of your passengers

and vessel is your responsibility. The following precautions and the ones mentioned in section 1

of Sportfish, Cruisers, Yachts Owner’s Manual will add to you and your passengers’ boating

safety and pleasure.

• Before operating your Grady-White READ AND STUDY ALL OPERATION AND

MAINTENANCE MANUALS. It is important that you fully understand how to use your

boat. Contact your Grady-White dealer for questions. Proper use and service will insure quality

performance and longevity of your boat.

• A written float plan left with a RESPONSIBLE person can serve as valuable information

should you not return as scheduled. Upon returning, your primary responsibility is to notify the

person of your return.

• NEVER operate or allow anyone to operate your boat while under the influence of drugs or

alcohol.

• Individuals under the age of 16 should not be allowed to operate your boat.

Inexperienced drivers should have constant and direct supervision.

• Instruct at least one passenger on the fundamentals of basic boating and safe operation in the

event of an emergency.

• While boating, passengers should be settled in a safe position. Use hand holds and rails for

steadiness. Do not allow bow, transom or gunwale riding. The captain is ultimately responsible

for their passenger’s safety.

• Keep your boat speed under control. Respect for other boaters and those on shore are common

courtesies. The boat’s operator is responsible for injury or damage caused by the boat or the

wake. Your wake could swamp a smaller craft and endanger its passengers. Stay alert for

posted “No Wake Zones”.

• Become familiar with the handling personality and limitations of your boat.

• Never allow swimmers/skiers to enter or exit the boat with engine(s) running. A shift lever

in neutral could become engaged accidentally. Also, exhaust fumes from the outboard

engine(s) contain carbon monoxide gas. These fumes may concentrate in this area. See more

information on “Dangers of Carbon Monoxide” on page 2-5.

• Obtain information and a chart for new areas when possible.

• Clean water and air are responsibilities for all persons. Use litter containers on board and

dispose of refuse properly. See “Pollution Regulations” on page 3–3.

• Know and obey the “Rules of the Road”. See Sportfish, Cruisers, Yachts Owner’s Manual,

beginning on page 19, for a better understanding of right of ways, signals and waterway

markers.

2–3

S AFETY

CERTIFICATION

At the helm station you will find a NMMA (National Marine Manufacturers Association)

Yacht Certification tag. This means your yacht complies with the Coast Guard safety standards.

(NOTE: Any boat with an overall length of 26 feet or greater is defined as a “yacht” by NMMA.)

This label means your Grady-White is certified by the NMMA. With

this tag, you are assured your fuel system, electrical system, lighting,

ventilation, and steering are not only in compliance with the US Coast

Guard regulations, but also meet the more stringent standards of the

NMMA. The NMMA is a national trade organization serving all

elements of the recreational boating industry including manufacturers

of boating equipment. With this tag, you can have confidence in the

safety of your boat.

This label means that Grady-White has designed and built your boat to the ABYC standard

H-8, buoyancy in the event of swamping. Basic flotation is defined as having enough foam in the

boat to create buoyancy and prevent sinking under swamped conditions.

LOADING CAPACITY

Though overloading is a primary cause of many boating accidents, improper loading is

equally hazardous. Boaters should know the amount of weight on board and evenly distribute the

weight within the boat.

2–4

SAFETY

CARBON MONOXIDE

W A R N I N G

!

(CO) is produced by all combustion engine(s) and generator sets.

Avoid brain damage or death from carbon monoxide.

Keep cockpit and cabin areas well ventilated.

Avoid blockage of exhaust outlets.

Signs of exposure include headache, nausea, dizziness and drowsiness.

Carbon Monoxide, commonly written (CO), is a colorless, odorless gas emitted from any

boat’ s exhaus t. The gas is s imila r in weight to the air we breathe. Therefore, it cannot be expected

to rise or fall, but will accumulate in confined spaces.

Carbon monoxide is poisonous, and potentially fatal if breathed over an extended period of

time. Symptoms of CO poisoning include dizziness, nausea, headache, sleepiness, vomiting,

throbbing in the temples, muscular twitching, and an inability to think clearly. If you or anyone

else experience these symptoms, immediately get away from fumes and into an area where

plenty of FRESH air can be consumed. If any symptoms from above persist, seek medical

attention.

Carbon monoxide can accumulate in cabins and under canvas. If your boat is equipped

with a canvas that encloses the aft cockpit and propulsion equipment, do not operate the boat with

this canvas closed.

Outboard engine exhaust fumes contain carbon monoxide. These fumes may concentrate at

the motorwell area. Do not board your vessel with the engine(s) running. Also, do not occupy the

motorwell area with the engine(s) running.

Operators need to be aware of the influence of other boats on their vessel as well as the effects

they have on neighboring crafts. Of primary concern is the operation of an auxiliary generator

with boats moored along side each other. This situation creates an atmos phere which is filled with

CO, and extremely dangerous.

W A R N I N G

!

BE AWARE of the significance your exhaust may have on other vessels. Likewise, BE AWARE

that the operation of other vessel's equipment may influence the carbon monoxide concentration

on your vessel.

W A R N I N G

!

Exhaust fumes from engine(s) contain (CO). Boats with canvas deployed are more likely to collect

exhaust fumes. Avoid brain damage or death from (CO). Keep cockpit and cabin areas well

ventilated. Signs of exposure include headache, nausea, dizziness and drowsiness.

2–5

S AFETY

SUGGESTED BOATING CLASSES AND READING MATERIAL

Like a car, boats must be operated according to safety rules and traffic regulations. Although

we include some basic boating tips in this manual, a thorough review of the safety rules and

regulations for boating is beyond the scope of this text.

We support the work of the United States Coast Guard Auxiliary and the United States Power

Squadrons. We urge you to attend any instructional classes sponsored by these organizations.

Reference page 8 of Sportfish, Cruisers, Yachts Owner’s Manual for training options, and page 23

for information on charts and maps. For further knowledge on boating, we advise that you review

the following publications:

• Piloting, Seamanship And Small Boat Handling

(Chapman)*

Motor Boating and Sailing

Post Office Box 2319 -- F.D.R. Station

New York, New York 10022

*Available on CD ROM

• Pleasure Boating And Seamanship

US Coast Guard Auxiliary

306 Wilson Road Oaklands

Newark, Delaware 19711

• Boatman’s Handbook

by Tom Bottomly

Motor Boating and Sailing

Post Office Box 2319 -- F.D.R. Station

New York, New York 10022

FOR MORE INFORMATION ON BOATING SAFETY COURSES IN YOUR AREA CALL:

• Boating Education Hotline......................................................1-800-336-BOAT (2628)

• Us Coast Guard Boating Hotline.............................................1-800-368-5647

• Contact Your Local Coast Guard.

2–6

G ENERAL I NFORMATION

Chapter 3: General Information

FUELING

W A R N I N G

!

Safety during fueling requires CAUTION and COMMON SENSE.

Please study the following precautions carefully. Consult your dealer if you have any

questions. Prior to your initial fill-up, check your engine manual to confirm the type of fuel and

octane rating specified by the manufacturer. Tanks should be filled when the boat is not in use to

reduce the accumulation of moisture and condensation. Add stabilizer to fuel that won’t be used

in 60-90 days.

Fuel containing up to a 10% ethanol blend (E10) is acceptable for use in your boat. Do not use

alcohol blended fuel that has greater than 10% ethanol such as E20 or E85. These concentrations

may be harmful to fuel system components and outboard engines.

Other considerations related to Ethanol fuel blends:

•Avoid mixing E10 with fuels that contain MTBE, an additive to gasoline in some fuel

blends that oxygenates the fuel to reduce emissions.

• Use a 10 micron fuel filter to capture particulate contaminants that may be loosened from

the fuel system due to the solvent nature of alcohol blended fuels.

• Carry spare fuel filters with a 10 micron rating on your boat for emergency replacement if

required.

• Before Fueling

•Shut down all engines.

•Turn battery select switch(es) to “OFF” to insure that all fans, lights, etc. are off.

•Close all ports, hatches, windows and engine compartments to prevent fumes from

accumulating in closed areas.

•Extinguish cigarettes and all other lighted materials.

•Have a fire extinguisher near.

• During Fueling

•Observe all safety regulations for the safe handling of fuel.

•Keep the fuel supply nozzle in contact with the fuel tank opening to prevent any static

sparks.

• After Fueling

•Secure the fuel cap, and check fuel lines and connections for leakage. Wash and clean up

any spilled fuel. Dispose of clean up rags or sponges on shore. Do not store these clean up

rags in the boat.

•After fueling ventilate all ports, windows, hatches and other closed areas. Conduct a “sniff

test” to make certain all fumes are vacant before using the battery select switch(es).

3–1

G ENERAL INFORMATION

•If your boat is equipped with two fuel tanks use the fuel select valve (see “Fuel Select

Valve” on page 3–3) to select the main or aux tank. Select the tank to be used first taking

into consideration the distribution of your load as fuel is consumed. Performance will be

influenced by weight distribution.

See warnings and check list in Section 6, page 37 of the Sportfish, Cruisers, and Yachts

Owner’s Manual. Reference “Fuel Tank Compartment” on page 6–7 for more information on

cleaning the fuel storage area.

FUEL SYSTEM

After fueling, inspect the fuel hoses, connections, and tanks for signs of leaks or deterioration.

Annually conduct a more detailed inspection of fuel system components, especially those hidden

from routine inspection. Replace deteriorated hoses, clamps, connections or fittings immediately.

If you are experiencing fuel flow problems, there is a simple method to determine if the

problem is in your fuel system or your engine. Connect a six-gallon portable tank to your engine.

If the problem persists, the likely cause is with the engine itself. If the problem goes away, the

source must be in the boat’s fuel system. One component that should be inspected if a restriction

occurs is the anti-siphon valve. If fuel does not flow properly through this part it must be cleaned

and/or replaced. Do not remove the anti-siphon valve and replace with a regular barb.

3–2

G ENERAL I NFORMATION

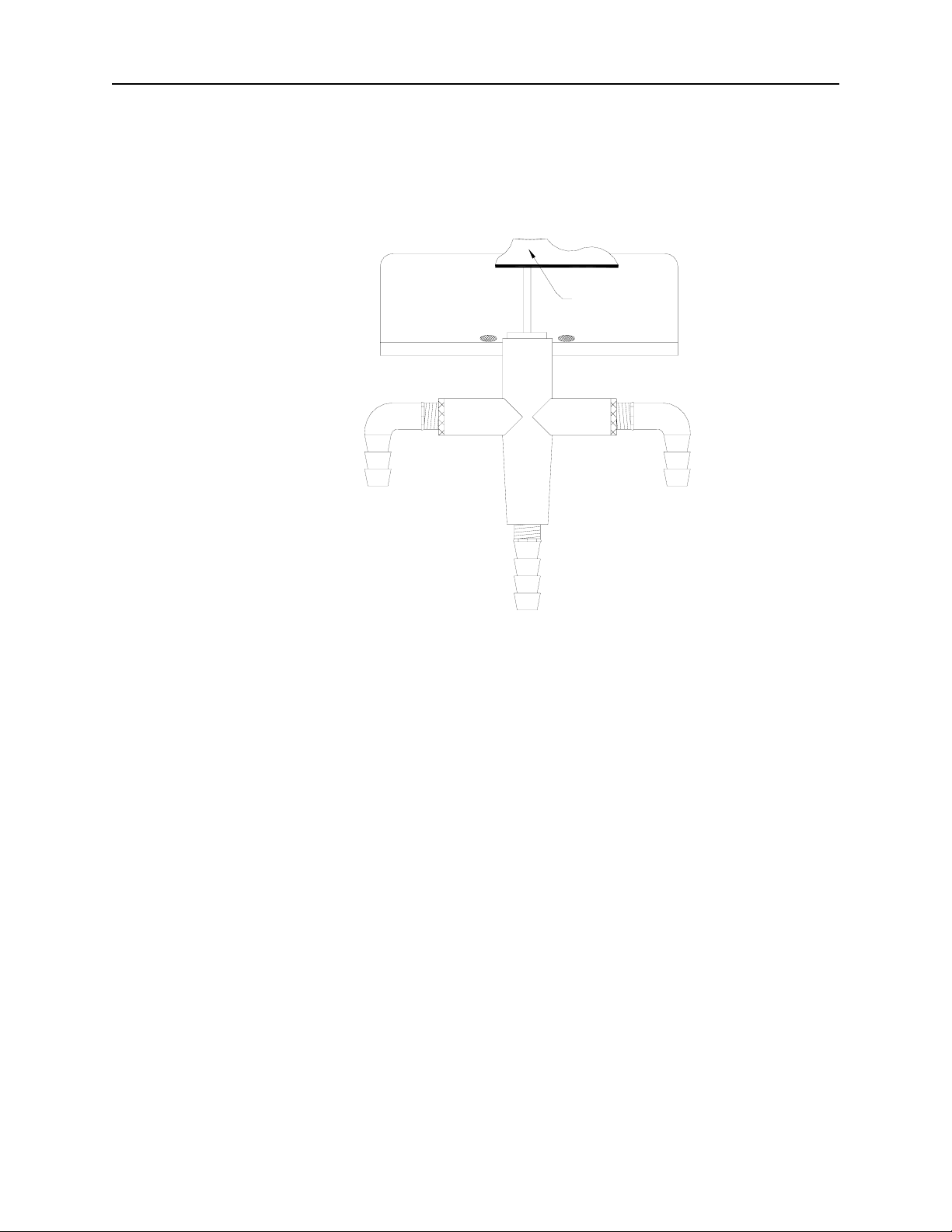

FUEL SELECT VALVE

If your boat is equipped with dual fuel tanks, you will have a manual fuel select valve

installed. This valve allows you to choose from which tank fuel will be consumed. Remember, as

the fuel is consumed and the fuel load redistributes the performance will be influenced. Select the

tank that allows the best performance for your boat.

Aluminum

Angle

Brass Elbow

1/4" Male X 3/8"

Barb

3-way Shut

Off Valve

To Aux

Tank

To

Engine

To Main

Tank

POLLUTION REGULATIONS

The U.S. Coast Guard defines restrictions on the discharge of oil or hazardous substances and

plastics or garbage in the “Federal Requirements for Boating and Boating Safety”. You should

have received this pamphlet when you registered your boat. Detailed below is a summary of those

regulations. You should read the pamphlet and become familiar with any local restrictions where

you operate your vessel. Passengers or crew members aboard your boat should also be notified of

these regulations.

3–3

G ENERAL INFORMATION

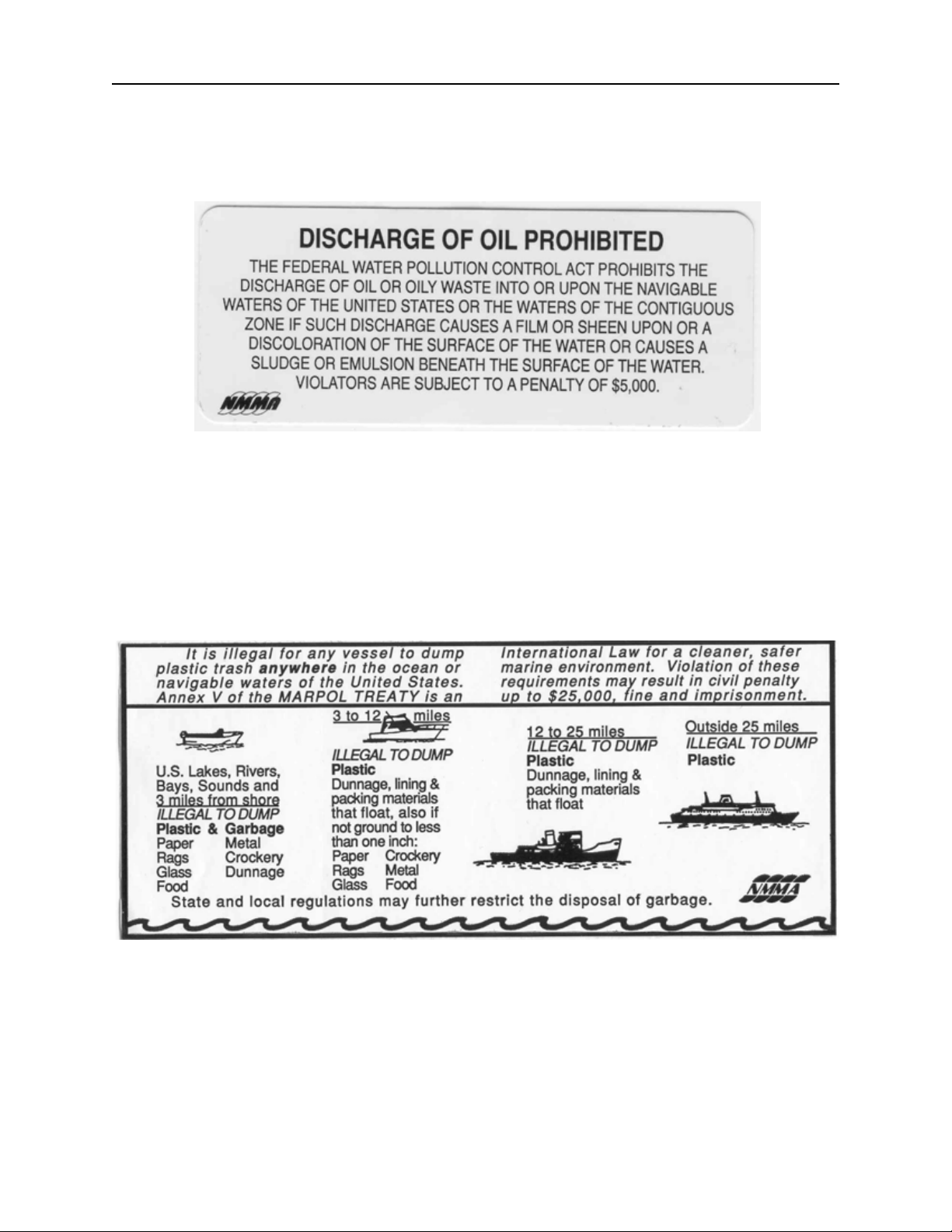

Discharge of Oil or Hazardous Substances

The Federal Water Pollution Control Act prohibits the discharge of oil or hazardous

substances, which may be harmful, into or upon U.S. navigable waters. Vessels 26 feet in

length or over must display a placard at least 5” x 8”. The placard should state the following:

Disposal of Plastics or Garbage

The MARPOL ANNEX V is the Act to prevent pollution from ships and other vessels.

Federal regulations prohibit the discharge of plastic garbage anywhere in the marine

environment. Plastic includes, but is not limited to: synthetic fishing nets, ropes, lines, straws,

six pack holders, styrofoam cups and lids, bottles, buckets and plastic bags. These regulations

also restrict the disposal of other types of garbage within specified boundaries from shore.

Any vessel 26 feet and over must display the placard below or a similar version which details

the regulations. The placard must be at least 4” x 9” and should be available from your dealer.

TRAILERING

The adjustment and balance of your boat on the trailer determines how easily your boat may

be transported. The tongue weight on the hitch ball should be 5-10% of the total weight of your

boat, motor and trailer. Tail-heavy loads cause swaying while trailering. The rollers and/or

bunkers of your trailer should be adjusted so that the weight is distributed evenly across the stern

and forward throughout the keel sections. Your dealer can help adjust your trailer properly.

3–4

G ENERAL I NFORMATION

Practice maneuvering the trailer; the trailer always backs in the opposite direction of the

vehicle. To maneuver the trailer, turn the steering wheel in the direction you want the trailer to go.

Familiarize yourself with this manual and all aspects of your boat prior to initial launch. At the

launch site, go through a pre-launch checklist. The list should be suited to your specific needs.

Trailering and relative information can be found on page 94 in Sportfish, Cruisers, Yachts

Owner’s Manual.

PREDEPARTURE

See the checklist on page 35 in Sportfish, Cruisers, Yachts Owner ’s Manual before starting

out.

CASTING OFF & APPROACHING THE DOCK

Unlike an automobile, the stern of your boat reacts first when turning. A turn to the right will

swing the stern to the left and vice-versa. Remember that turning your boat away from an object,

such as a dock, will tend to swing the stern toward that object. Reference procedures for casting

off and approaching the dock on page 42 of Sportfish, Cruisers, Yachts Owner’s Manual.

ANCHORING

Some factors that determine the size and type of anchor most suitable for your boat include

the size of your boat and the type of lake, sea or river bottom in your boating area. Sportfish,

Cruisers, Yachts Owner’s Manual has a list of tips concerning anchoring starting on page 46.

N O T I C E

It is illegal to tie your boat to navigational aids such as buoys and markers.

W A R N I N G

!

Never anchor off the stern of the boat especially in strong winds or currents. The weight of the

stern and flat surface to the seas can easily cause water to enter over the transom and swamp the

boat.

3–5

G ENERAL INFORMATION

TOWING

In the event of a mishap or power loss you may need to tow a boat or be towed. You should

not tow a boat larger than your own. Always use safety and good judgement when towing. Never

tow a boat if you are not equipped with the proper lines. Passengers should never grasp a towline.

It should be secured to the boat. See page 30 in Sportfish, Cruisers, Yachts Owner’s Manual.

Before towing a boat, make a bridle and tie it securely to the pad eyes on the transom with

enough slack to clear the engines. Pad the line wherever it comes into contact with the boat to

prevent chafing. Attach a tow line to the bridle so that it can slide from side to side to prevent too

much pressure on a single pad eye. The tow line should then be attached to the bow eye or to a

bridle on the towed boat. The tow line should be a minimum of twice the length of the towing

boat, the longer the better. Do not try to run in too close when passing the towline to the other

boat. Send either a light line or attach the towline to a life preserver to be pulled in. Be aware of

the other boat’s propeller.

The towed boat should always have someone at the wheel since the boat may swing off

course. Start the tow off slowly; a steady pull at a moderate speed should be used. It is important

to keep the slack out of the propeller area. Watch the action of the towing boat. If excessive slack

develops in the towline and contact is obvious, turn in either direction to avoid hitting the stern.

W A R N I N G

!

As a precaution, passengers on both boats should stay clear of the towline; lines under stress could

snap and fly in either direction causing injury.

SHALLOW WATER

Most boats that become grounded can be floated off with engine(s) tilted to reduce the draft at

the transom. With motors tilted, try rocking the boat from side to side to break the suction of mud

from the keel. Move passengers or heavy objects from the point where the boat is grounded. Do

not lower or start the engine(s) until the boat is clear of the ground. Refer to page 53 in Sportfish,

Cruisers, and Yachts Owner’s Manual.

C A U T I O N

!

Do not lower or start engines if the propeller is in mud or sand. Wait until the boat is refloated to

avoid damage to the cooling system of your engine.

Be mindful of water level fluctuations when boating in water with tidal changes. If you are

grounded on an incoming tide, you can wait until the tide is high enough to refloat your boat.

However, on an outgoing tide, quick action should be taken to refloat your boat. If this is not

possible, set an anchor to keep the boat from becoming driven further aground. Set the anchor to

counter the action of the wind or current. The anchor, in some cases, can also be used to pull the

boat free.

Many inland areas have rocks and stumps which could crack or puncture a fiberglass hull. Be

familiar with the boating area, and use caution in shallow water.

3–6

G ENERAL I NFORMATION

WINDLASS

Anchoring can be less laborious if your boat has a windlass accessory . If your boat is equipped

with a windlass, reference your windlass Operation Manual for instructions.

GENERAL INFORMATION ON BOAT HANDLING

The best method of learning how to handle and obtain the best performance from your boat is

to practice and experiment. After several hours of operation, you should experiment with the

throttle settings to discover the setting that will be the most comfortable and economical range for

your particular load conditions.

We suggest that you make a speed and RPM chart to obtain the most economical operation.

Operate the boat at various speeds and check the fuel consumption. Compute the amount of

operating time remaining when the fuel gauge has only one bar remaining on the display. Make a

log of this type of information and have it available when using your boat. Other statistics you

may want to determine could include the following:

• Minimum speed for effective steering.

• Turning radius at different speeds.

• Response to steering at low speeds.

• Accelerating and deceleration rates.

• Time and distance to bring the boat to a stop at different speeds.

• Control of the boat using both engines in close quarters.

Also read the section in Sportfish, Cruisers, Yachts Owner’s Manual beginning on page 49 for

information on safe operating speed.

TWIN ENGINE BOATS

T win engine boats are easier to maneuver than si ngle engine crafts. However, they still require

practice to ensure comfortable operation. The boat will run ahead or backward in a straight line

when both engines are working together at the same speed. The engines also can be used to steer

to port as well as starboard. Moving ahead on one engine will cause the bow to swing away from

the running engine side and to move forward at the same time. Backing up with one engine will

cause the bow to swing toward the running engine side and the boat to move backward. Running

one engine ahead and one engine astern will cause the boat to turn end-for-end in little more than

its own length. Running both engines in the same direction at different speeds will cause the boat

to move in the direction dictated by the faster engine but its influence will be modified by the

slower engine.

3–7

G ENERAL INFORMATION

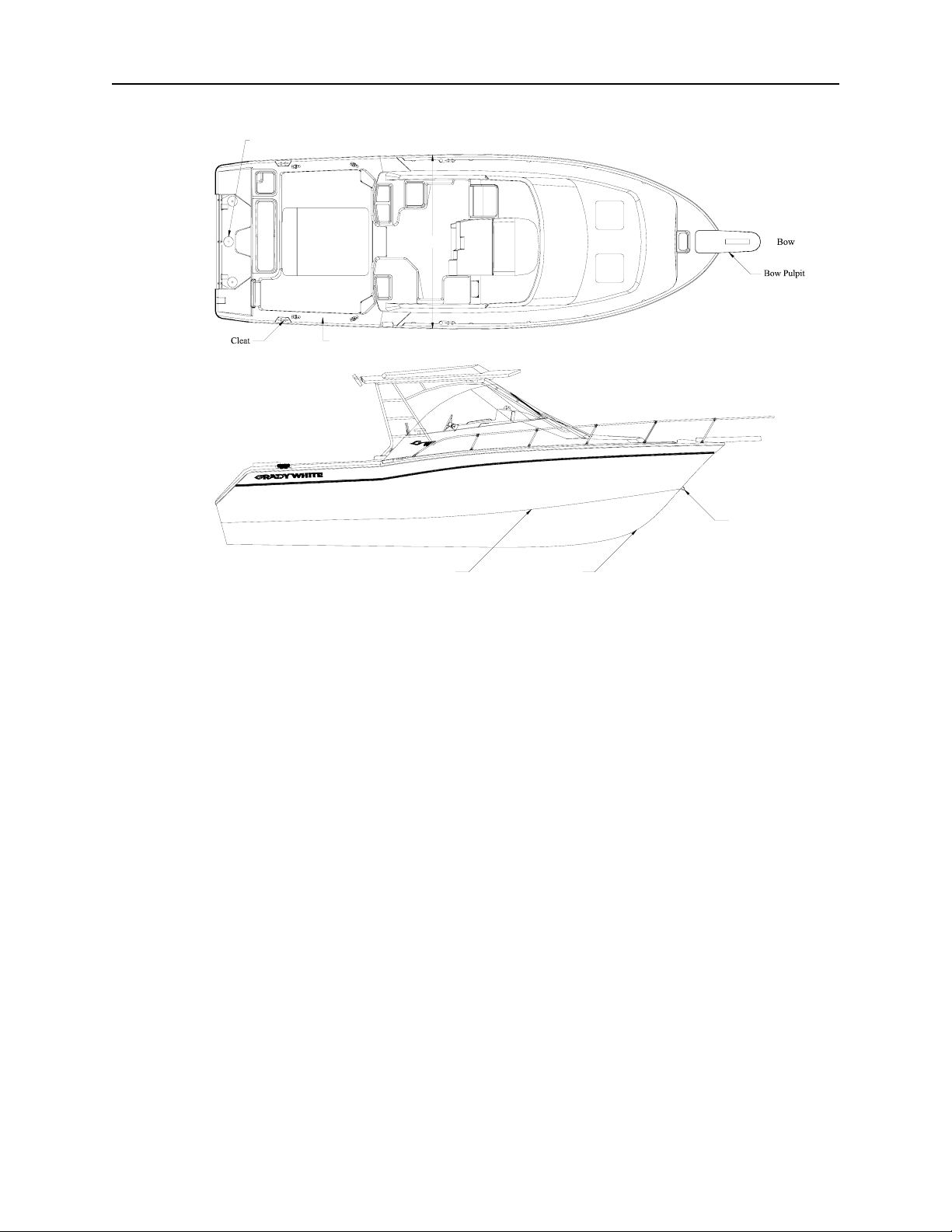

COMMONLY USED NAUTICAL TERMS

Access Plate

Port Side

Stern

Abeam - a line perpendicular to a

boat’s keel

Access Plate - a removable,

watertight cover that provides quick

entry to enclosed areas for

maintenance or visual inspection.

Aft - toward the rear or stern of the

boat

Beam - the greatest width of the

boat

Bilge - the lower interior area of the

hull

Bow - the forward section of the

boat

Bow Eye - a U-shaped hull fitting

used to attach the trailer winch to the

boat

Bulkhead - vertical partition in the

boat

Chine - point where the topside and

bottom of the boat join

Cleat - deck fitting with arms or

horns on which lines are fastened

Beam

Gunwale

Starboard Side

Deck - upper structure which covers

the hull

Draft - depth of water required to

float a boat

Fathom - a depth measurement

equal to six feet

Freeboard - distance measured

between waterline and deck

Gunwale (Gunnel) - point where

the deck and hull join

Hatch - an opening in the deck to

provide access below

Headroom - vertical distance

between the floor and over head

structure or canopy ceiling

Hull - major component that

provides a watertight platform

buoyant enough to float a craft and

its load

Keel - the major longitudinal

member of a hull -the lowest

external portion of the boat

Knot - a measurement of speed

equal to nautical miles per hour

Bow Eye

KeelChine

Lee - the side that is sheltered from

the wind

List - a tilt or lean to one side

Port - a term designating the left

side of the boat when facing forward

Scupper - holes permitting water to

drain overboard from deck and

cockpit

Sheer - curve or sweep of the deck

as viewed from the side

Starboard - a term designating the

right side of the boat when facing

forward

Stern - rear of the boat

Stringer - longitudinal members

fastened inside the hull to add

rigidity and strength

Wake - the movement of water

created by a moving boat

Windward - side facing the

direction of the wind (against the

wind)

3–8

PERFORMANCE

Chapter 4: Performance

PERFORMANCE FACTORS

Maximum performance is dependent on many factors and cannot be guaranteed. These factors

will vary with changing conditions. Some of these factors are listed below. Reference the troubleshooting guide on page 65 in Sportfish, Cruisers, Yachts Owner’s Manual for additional

suggestions on adjusting performance.

Engine Efficiency

Engines operate most efficiently when they are properly tuned, and the props are in good

condition. Efficiency will decrease if normal care and maintenance is not performed.

Neglecting the engines will cause power to drop and speed to decrease. In addition, expensive

repairs may become necessary. Be sure to follow all instructions in the engine operation

manual(s).

Weather Conditions

Weather conditions sway engine performance. Barometric pressure and humidity affect

horsepower. A change of weather could amount to a 10% loss in horsepower on some hot

days.

Load Distribution

A decrease in performance will be noted when gear, equipment, passengers, and fuel are

added. This extra load will affect the performance of your boat according to the distribution of

the weight. Another type of extra load that could affect performance is the accumulation of

water in the bilge. Keep the bilge dry to eliminate this type problem.

Marine Growth

Maximum performance is obtained only when your hull bottom is clean. Marine growth on

the bottom of the boat will increase resistance and decrease speed. These conditions will also

increase fuel consumption. Reference “Cleaning” on page 6–1 for more information on

cleaning your hull bottom.

Trim

The outboard engines are equipped with power tilt and trim mechanisms. The purpose of

power tilt is to raise the engine(s) for launching, loading or trailering. Power trim may be

used to adjust the boat’s planing performance and running attitude. See power trim, page 52

and 72, in Sportfish, Cruisers, Yachts Owner’s Manual.

Trim refers both to the weight distributions inside the boat and to the angle of thrust of the

engine. The angle of thrust of the engine forces the bow up or down. The trim tabs on your

boat also control the trim of the boat, similar to the po wer trim. Refe r to the Trim Tabs section

in Chapter 8 for additional information.

4–1

P ERFORMANCE

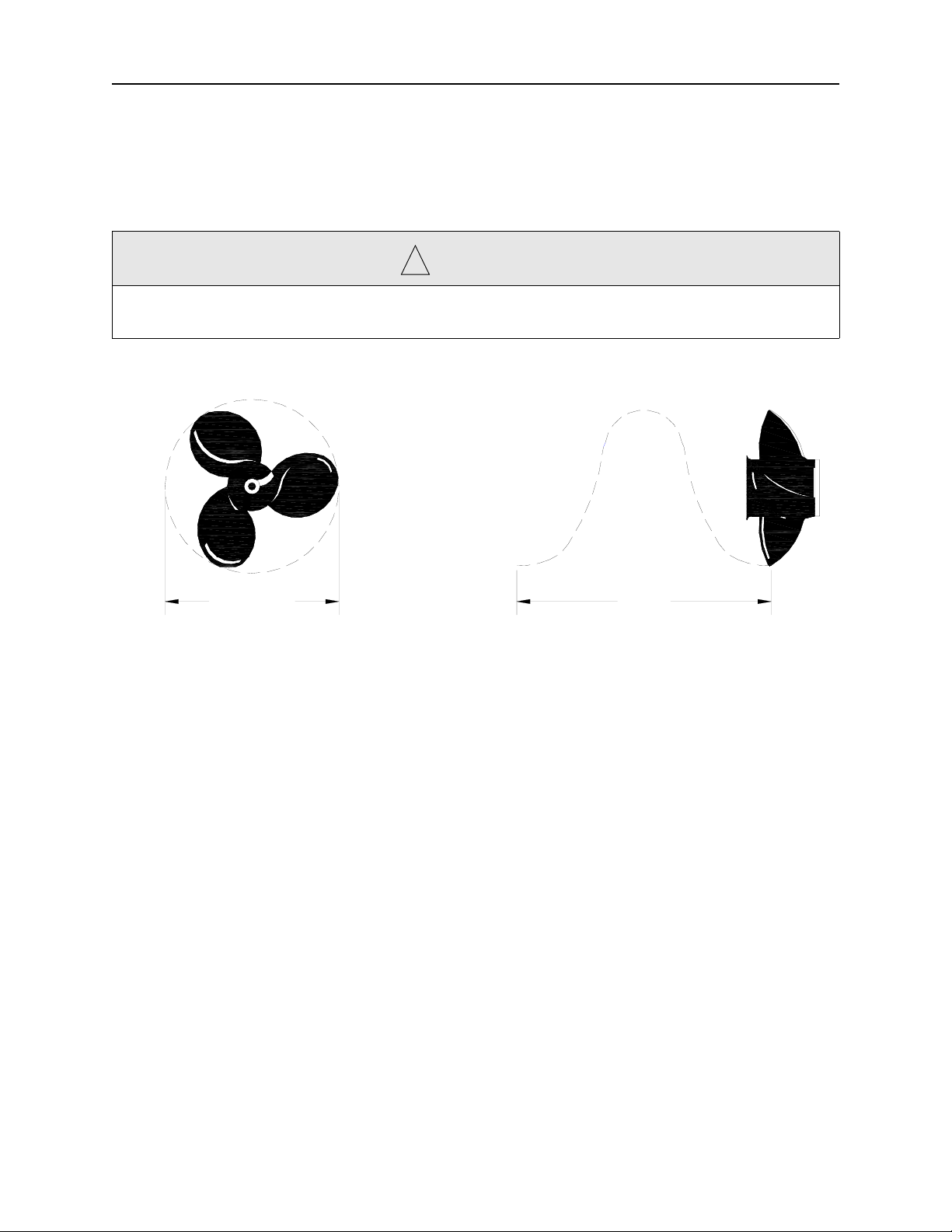

Propeller

The condition of your prop has a major influence on the performance of your boat. Your

engine(s) should be equipped with the best size prop for normal conditions. Unusual uses or

weight conditions may require special props. A damaged prop can affect your boat's top

speed, cause vibrations, create a sudden drop in RPMs or even increase fuel consumption.

C A U T I O N

!

Stay within the engine manufacturer's maximum and minimum RPM ranges when replacing

props. This information is located in your engine manual.

PitchDiameter

Diameter = 14 Pitch = 14

Diameter and pitch are the two basic dimensions of a propeller. Diameter is the distance

across the circle made by the blade tips as the propeller rotates. Pitch is the theoretical (not

accounting for slippage) forward distance the propeller would move in one revolution. An

example of a propeller dimension would be 14 X 17 for a propeller having a diameter of 14”

and a pitch of 17”.

4–2

PERFORMANCE

PROPULSION SYSTEM – OUTBOARD

The engine manufacturer supplies all vital information concerning your engine(s) in the

Operation and Maintenance Manual(s). Details of important engine functions such as the

lubrication system, cooling system, and alarm/monitoring system are outlined in these manuals.

Your familiarization with this engine reference material will result in the proper usage and service

essential for safe and enduring engine performance. These manuals are included with the Owner’s

Packet.

D A N G E R

!

Do not inhale exhaust fumes! Exhaust contains carbon monoxide — a dangerous gas which is

potentially lethal.

W A R N I N G

!

Do not attempt to service any engine or drive component without being totally familiar with the

safe and proper service procedures. Certain moving parts are exposed and can be dangerous.

C A U T I O N

!

Do not paint the outboard motors with anti-fouling paints designed for boat hulls. Many of these

paints can cause severe damage to the engines.

ENGINE WARRANTY

A warranty registration card is included with all engine manuals. It should be completed and

returned to the engine manufacturer as soon as possible.

4–3

P ERFORMANCE

STEERING

Most outboard engines are equipped with an adjustable rudder trim tab. This trim tab should

be adjusted to balance the steering at the speed which you travel most frequently. Variations in

speed, boat load or engine trim will cause the steering to pull in one direction. If the boat pulls to

the left, adjust the trim tab to the left and vice-versa.

• Hydraulic Steering

Hydraulic steering systems (not to be confused with power steering) require regular

preventative maintenance for continued safe and reliable operation. The oil level in the helm

pump must be maintained within acceptable operating levels. A low oil level will allow air to

get into the steering system and result in unresponsive steering. The oil level should always be

within 1/2 inch from the base of the fill hole, located on the front top portion of the helm

pump. Check the entire steering system regularly for oil leaks. Unobserved leaks over a period

of time will result in unresponsive steering and possibly loss of steering. Refer to the steering

manual for specific recommendations and additional maintenance requirements.

Any slow or sudden change in the “feel” of your steering system indicates an immediate need

for a thorough inspection. All repairs and replacements to steering systems should be made

only by a qualified marine technician.

• Tilt Steering

This feature enables the operator to tilt the wheel up or down. Refer to the steering system's

manual for information on oil levels with hydraulic tilt steering.

4–4

PERFORMANCE

THROTTLE/SHIFT CONTROL

The throttle/shift controls located at the helm station control the flow of fuel to the engine.

They also act as gear shift levers to control the forward and aft thrust of the propellers.

The middle position of the throttle control is the neutral position. Move the control forward to

engage the shifting mechanism which creates a forward thrust of the propeller. Advance the

forward movement to increase the fuel flow to the engine and boost the forward lunge.

Move the control lever aft of the neutral position to reverse the shift mechanism and create a

reverse thrust of the propeller. Increase the aft movement to increase the reverse thrust.

Remember that propellers are designed for maximum forward thrust; so, reverse thrust will not be

as efficient.

All controls have a neutral safety mechanism. This mechanism will not allow the engine to

start when the control is in gear. You may use the neutral lock out feature on the control handle to

increase the flow of fuel to the engine while remaining in the neutral position.

Neu tral Lo c k-o ut B u tton

for Mechanical Shifter is

located on starboard handle.

Reverse the shift mechanism to stop a boat that is moving forward. This change in direction

will provide a “braking action” and slow the boat.

C A U T I O N

!

The braking action causes a wake which may wash over the transom and flood the boat if the

vessel is moving too fast. Allow engine RPMs to decrease before shifting into reverse.

If your boat has mechanical controls, there will be control cables that operate the shift and

throttle functions on the engine. If your throttle or shift cables need replacing, use the same style

and length as the original equipment.

4–5

P ERFORMANCE

4–6

I NSTRUMENTATION AND S WITCHES

Chapter 5: Instrumentation and Switches

YAMAHA INSTRUMENTATION PANEL

Grady-White installs full Yamaha Command Link instrumentation on pre-rig boats. The

instruments are powered by the ignition key(s) and will operate when the ignition switch(es) is in

the “on” position.

DIGITAL SPEEDOMETER AND FUEL MANAGEMENT

• Fuel Level

This feature indicates the gas tank(s) fuel level. Remember two things when reading this

gauge:

• The accuracy of your gauge varies with the attitude of your boat in the water (trim or list).

• The fuel pickup tube inside the gas tank is not capable of withdrawing all of the fuel from

the tank.

For these reasons, never operate your boat at extremely low fuel levels.

• Fuel Economy

This feature indicates the engine’s fuel economy in miles per gallon.

• Fuel Consumption

This feature indicates the fuel consumption in gallons since the feature was last reset. For twin

engine applications, this may be monitored individually or as a total.

•Fuel Flow

This feature indicates the fuel flow through the engine(s) in gallons per hour.

• Low Fuel Warning Indicator

This feature indicates the amount of fuel in gallons per hour flowing through the engines.

Each engine may be monitored separately or a total amount displayed.

5–1

I NSTRUMENTATION AND SWITCHES

• Speedometer

This feature indicates boat speed in miles per hour, knots per hour, or nautical miles per hour.

On boats with V8 engines, this gauge must be interfaced with a GPS.

• Trip Distance Meter

This feature indicates the distance traveled in miles or nautical miles since the meter was last

set.

DIGITAL TACHOMETER

• Revolutions Per Minute (RPM)

This feature indicates the RPM using 100 RPM intervals. Consult your engine Owner's

Manual for the recommended operating RPM range.

• Trim Position

This feature indicates the angle of thrust of the engine. See “Trim” on page 4–1 for

adjustment recommendations.

• Battery Voltage Indicator

This feature indicates the battery charge when the engine is off and indicates the alternator

output when the engine is running. A reading of 12 or 13 volts is normal indicating a fullycharged battery. Readings below 11 indicate a weak battery which may not start the engine. A

reading of 13 to 15 volts when the engine is running is normal. Readings over 15 volts may

indicate regulator problems. Low or fluctuating readings may indicate loose connections or

trouble in the regulator and alternator circuit.

• Cooling Water Temperature with Warning

This feature indicates the temperature of the cooling water circulating through the engine and

warns you when the temperature exceeds the recommended operating range indicated by your

engine owner's manual. Should you receive this warning, immediately shut off your engine to

prevent damage. Overheating is often caused by obstruction of your engine's intake on the

lower unit. Check this water intake first if you experience trouble.

• Hour Meter

This feature records the cumulative number of hours the engine has been in use.

• Tripped Hour Meter

This feature indicates the number of hours the engine has been in use since it was last set.

• Oil Pressure with Warning

This feature indicates the engine oil pressure with a warning for low oil pressure. Refer to

your engine owner's manual for information regarding engine oil and oil pressure.

5–2

I NSTRUMENTATION AND S WITCHES

SWITCH PANEL

At the helm station you will find an accessory switch panel. Not all boats are equipped with

the same accessories. Consult your dealer for specific information or questions on the accessories

included on your boat. More detailed descriptions of switch functions are located in Chapter 8 of

this manual.

M

COCKPIT

LIGHT

NAV/

ANCHOR

WASHDOWN

LIVEWELL

WATER

PRESSURE

MACERATOR

HORN

WIPER

FWD

BILGE

AFT

BILGE

ELEC

BOX

ACC

This represents a generic switch panel layout. Actual panels will

differ depending on the boat model and optional accessories installed

during manufacturing.

5–3

I NSTRUMENTATION AND SWITCHES

5–4

M AINTENANCE AND S ERVICE

Chapter 6: Maintenance and Service

GENERAL

The amount of maintenance required to keep your boat operating properly and to maintain the

appearance is dependent on how the boat is used, amount of usage, salt or fresh water, geographic

location, etc.

Your hull and deck are constructed by the “hand lay-up method” using the highest quality

fiberglass mat and woven roving. This method of construction ensures a proper fiberglass-to-resin

ratio and uniform thickness resulting in a much stronger boat than those constructed of “chopped

glass”. This process ensures your Grady-White is the strongest, most durable fiberglass boat

possible.

Keep the bilge area clean and dry. Leaks found early and corrected will less likely cause

damage. Do not allow grease, grime, and dirt to build up.

While proper maintenance of your boat is a source of pride, it is also key to maintaining your

boat's value. A few simple steps will keep your fiberglass Grady-White looking showroom bright

for years.

EXTERIOR FIBERGLASS FINISH

The exterior finish of your Grady-White is a thin layer of resin with a finished color pigment

called gel-coat. It is used for cosmetic purposes and makes routine maintenance relatively simple.

Although gel-coat has a hard smooth surface, it does contain microscopic pores that will allow

surface discoloration if not kept clean.

Maintenance

Normal exterior finish maintenance of your Grady-White is similar to the care you would give

your automobile. Do not use caustic, highly alkaline cleaners or those containing ammonia.

These cleaning agents may darken gel-coat. The resulting stain is a chemical reaction and can

be removed with a rubbing compound followed by waxing. Also, using common household

bleach (chlorine) may damage the gel-coat finish just like bleach can damage clothing with

colors. Bleach impacts solid colors by causing blushing or fading and for this reason should

not be used on gel-coat.

Cleaning

The best way to prevent discoloration and soil build-up is to hose the boat with fresh water

after each outing or on a regular basis. This build-up is the result of use and environmental

pollutants. Clean the boat regularly with a mild household detergent and plenty of fresh water.

Avoid strong detergents, citrus based cleaners, or bleaches. These products are potentially

harmful to the appearance and durability of your boat’s gel-coat. Always read the label before

using any cleaning product to make sure it says safe for use on fiberglass finishes. Use a

sponge on smooth surfaces and the deck. A brush can be used on the nonskid areas. Rinse

away all grime and residue.

6–1

M AINTENANCE AND SERVICE

Finish/Waxing

Gel-coat will age or dull naturally due to constant exposure to the natural environment and

pollutants. Discolorations are shallow in depth. Factors that will affect the rate of

discoloration are: the sun, pollution, old wax accumulation, and the salt content of water.

Polishing compound (fine abrasive) or rubbing compound (coarse abrasive) is recommended

for use on fiberglass finishes to remove scratches and stains or restore severely weathered

surfaces. These products can be applied by hand or mechanical means. The process below will

help restore fiberglass finishes:

•Clean the affected area with a good detergent.

•Remove stubborn stains or discoloration by gently wet sanding the affected areas with 600

grit “wet or dry” sandpaper. ALWAYS SAND IN ONE DIRECTION. Use plenty of

water and sand curves in the same direction. Dry the area to make sure all the discoloration

has been removed. Repeat this process if necessary.

•Buff using a polishing compound suitable for fiberglass, an electric buffer (1750-1800

RPM), and an 8-inch lamb’s wool pad.

C A U T I O N

!

Keep buffer moving. Do not allow it to rest in one spot. Heat build up will quickly distort the

surface.

C A U T I O N

!

Compounding too often or excessive compounding can wear away the gel-coat.

•When buffing is complete, wash away compound with clear water and dry the area.

•Once the area is clean it may be waxed. This will enhance the gloss while providing a seal

to retard staining or soil accumulation.

•See a local dealer for advice on wax for your boating region. The wax film will seal the

pores as well as enhance the looks of your boat. DO NOT wax surfaces that may be

walked on; they will become slippery. While waxing your boat, inspect the surface for

any damage. Have the damage corrected as soon as possible.

6–2

M AINTENANCE AND S ERVICE

Repairing

Though gel-coat is a very durable material, it is susceptible to scratches, blistering, and weblike cracking (crazing) over time. It is elastic enough to withstand strong blows while flexing

with the hull's movement. Gel-coat problems are cosmetic and will not effect the structural

integrity of your boat.

Some gel-coat damage and imperfections such as nicks and scratches can be repaired by

obtaining a color match patch kit. This kit can be purchased through your Grady-White dealer .

Acetone, the most suitable cleaning agent for gel-coat, can also be acquired through your

dealer. Instructions are included in the patch kit.

W A R N I N G

!

M.E.K.P. (Methyl ethyl ketone peroxide), gel-coat and acetone are flammable and hazardous

chemicals that must be handled properly. Follow instructions carefully. After the gel-coat is

catalyzed, it will soon heat up and put off fumes. When finished with catalyzed chemicals, or if

they start to build up heat, submerse completely in water until cool.

BOTTOM PAINT

If your boat is left in the water for more than a few days at a time, the hull bottom below the

waterline should be painted with anti-fouling paint to protect it from marine growth and barnacles

that hinder performance. Since anti-fouling paint slowly dissolves, yearly inspection and cleaning

of the hull bottom to prevent marine growth is advised. Repaint when necessary. To help prevent

blistering, use an epoxy barrier coat to be applied in conjunction with the anti-fouling paint.

CANVAS

Grady-White’s canvas is made using the highest quality vinyl and latest sewing techniques.

The canvas will not be completely leak proof. The seam holes in your canvas may stretch and tend

to leak. However, you can correct this problem by applying *Apseal® or Uniseal™ to the seams.

Please understand that Grady-White does not warrant the fit and design of the canvas to be

entirely watertight.

Maintenance

To maintain your boat's top and other canvas follow these guidelines:

Fabric should be cleaned regularly to prevent the buildup of soil and soil penetration of the

fabric. Simply brush off any loose dirt, hose down canvas and clean with a mild solution and

warm water . Do not use petroleum-based or ammonia cleaners on canvas or clear vinyl as they

will yellow. For heavily soiled fabric, remove the top from the frame. Soak the fabric in a

solution of 1/2 cup of Clorox™ and 1/4 cup of Ivory or Lux soap per gallon of warm water.

Let soak until mildew and stains can be brushed out with a common kitchen brush. Rinse

thoroughly with cold water until all soap is removed. Allow fabric to air dry completely. DO

NOT STEAM PRESS OR DRY IN AN ELECTRIC OR GAS DRYER. This will damage

the canvas fabric. Water repellent was applied to your canvas during manufacturing. The

repellent may have diminished after extended cleaning. Re-treatment of the fabric is

recommended. Do not use wax-based products. Use a water based repellent like *Apseal® or

Uniseal™. Scotchguard® is effective for short-term use only.

6–3

M AINTENANCE AND SERVICE

Snaps And Zippers

To protect the snaps and zippers on your boat’s canvas and cushions from corrosion and

binding, Grady White includes a snap/zipper assist tool and a tube of lubricant (E-Z Snap™)

in your owner’s packet. The lubricant, manufactured by IOSSO (part number 10909), should

be applied per the manufacturer’s directions during the initial use of your canvas and

cushions. The lubricant should be reapplied every 3 months or sooner depending on your

boating environment and usage. The snap/zipper assist tool included in your owner’s packet

should be used whenever you remove the canvas, cushions, or operate the zippers to prevent

damaging or tearing the material. Contact your dealer if you need to replace your assist tool or

reorder the lubricant.

Vinyl

•Clean clear vinyl thoroughly with denatured alcohol and apply a protective layer of clear

wax. Do not use paste wax, as it will turn the vinyl yellow. This process should be repeated

as necessary to maintain the protective wax coating.

•Store and secure canvas before trailering.

•Dry all canvas before storing to prevent mildew.

•Remove the top, front, and side panels. Roll them for storage. This is necessary to prevent

the front and side vinyl pieces from cracking. NEVER FOLD THESE PIECES!

Storage

Consider the following steps when putting your folding top canvas option in the stored

position:

•Fold the top and zip it into the canvas cover provided.

•Pivot the covered top into the stowed position on the foredeck. The canvas cover is

equipped with a strap on each side and an eyelet in each strap. Place the eyelets over the

male fasteners located on the port and starboard foredeck.

•Twist the male fastener 90 degrees to engage.

C A U T I O N

!

Secure the folded top when in the stowed position to prevent damage or the loss of your canvas.

6–4

M AINTENANCE AND S ERVICE

UPHOLSTERY

Your exterior vinyl upholstery may be cleaned with a mild solution of household detergent

and fresh water. Commercial cleaners for vinyl also work well. Since the seams of your exterior

upholstery are not waterproof, your upholstery should be stored in the cabin or covered when not

in use. Exterior cushions will trap moisture between themselves and the gel coat. If a cushion is

not removed to allow the moisture to dry, blistering of the gel coat may occur. Cockpit bolsters

may be removed if you desire. These bolsters clip onto brackets mounted to the deck structure.

Screws are then installed through the underside of the bolster to hold them in place. Most cabin

cushions are removable and may be dry-cleaned or steam cleaned. Some cabin cushions are of a

Herculon-type fabric and may be cleaned with upholstery cleaner.

C A U T I O N

!

Do not machine wash cabin fabrics.

DURATRIM/POLYETHYLENE/PLEXIGLASS/VINYL

In the cockpit area of your boat, duratrim, plexiglass, and vinyl are used for trim and

polyethylene is used for the toe rails and rod racks. Routine maintenance for duratrim and vinyl

should include regular cleaning with soapy water and the application of a surface protector at least

twice per year. Polyethylene can be cleaned with products such as 409 or any spray and wipe

cleaner. Plexiglass, used to cover your instruments’ radio box and also as interior storage doors,

can be maintained by use of a glass cleaner and a soft cloth.

SCUPPERS

Grady-White boats have self-bailing cockpits meaning water on the cockpit floor drains by

gravity through large aft scuppers and not into the bilge. The aft drains (scuppers) have an

external scupper flap assembly that restricts the flow of water back into the boat. Inspect the flaps

periodically to make sure they are free of debris. The scupper flaps may need periodic

replacement if the rubber becomes damaged or no longer seals properly in the thru-hull.

CAULKING/GASKET

Deck fittings, bow rails, windows, hatches, etc. have been caulked or gasketed with the

highest quality material to ensure a waterproof joint with the boat. However, the working action

of normal use will tend to flex the joint and eventually break down the seal between them.

Periodically inspect the caulking or gaskets for leaks. Recaulk or replace the gaskets necessary, or

have your dealer do the repair.

HARDWARE/HARDTOP FRAME/STAINL ES S STEEL RAILS

The hardware on your Grady-White is made of laboratory grade 316 stainless steel and needs

regular cleaning to maintain its “less staining” properties. The key to maintaining your stainless

steel is to keep it clean with a mild solution of soap and FRESH water. Remove salt or dirt from

your stainless steel on a regular basis.

6–5

M AINTENANCE AND SERVICE

HARDWARE MOUNTING

Ensure all holes are sealed properly when mounting hardware in the boat surface. Sealing will

prevent water leakage. This is crucial in fiberglass areas that have been reinforced with plywood.

A hole sealed improperly allows water inside the fiberglass leading to saturation of the plywood

reinforcement.

MAINTENANCE PROCEDURE FOR ANODIZED ALUMINUM COMPONENTS

(Lean Bars, Rod Holders, T-Top and Hardtop Frames, Outriggers, Etc.)

Due to the nature of anodized aluminum and the harsh exposure conditions of the marine

environment, it is important to follow a required maintenance procedure. Failure to follow a

preventative maintenance procedure will most likely result in aluminum pitting.

These parts must be washed periodically with a very mild soap and water solution. Grady

White recommends washing with a mild soap (such as Ivory Liquid) after each use and every two

to three weeks if stored in an outside marine environment. Strong cleaners and soaps must not be

used. Never use abrasive cleaners or products that contain chlorine bleach. These products can

remove the anodized coating.

Give special attention to the upper tubes of a hardtop or T-top frame. The area just below the

top is shielded by the canvas or fiberglass top and does not receive the natural rinse that rainwater

provides. Failure to thoroughly clean and maintain this area will allow contaminates that attack

the anodized aluminum to remain on the frame.

For maximum protection, coat parts with a non-abrasive metal protector. The best protectors

will displace moisture, remove contaminates, and leave a wax film protecting the anodized

aluminum. Follow the application guidelines for the product you choose. A sample of one metal

protector has been provided with your boat.

METAL PROTECTORS:

Boeshield T-9 Aluma Guard Premier Polish

PMS Products Inc. Rupp Marine, Inc. Aquatech

76 Veterans Dr. Unit 1104761 Anchor Ave. 6726 Netherlands Drive, Suite 200

Holland, MI 49423 Port Salerno, FL 34992 Wilmington, NC 28405

800-962-1732 561-286-5300 800-853-7760

C A U T I O N

!