Gradian UAM Service manual

®

Universal Anaesthesia Machine®

Maintenance Manual

HOW TO GET HELP 1

GENERAL DESCRIPTION OF THE UNIVERSAL ANAESTHESIA MACHINE® 1-2

SPECIFICATIONS 2-5

COMPONENTS OF THE UAM® 6-10

UNPACKING AND PREPARING FOR USE 11-15

RECOMMENDED UAM MAINTENANCE SCHEDULE 15

FULL FUNCTION TEST 16-17

MAINTENANCE PROCEDURES 17

Cleaning or Replacing the Oxygen Concentrator Filter 17-18

Replacing the Oxygen Sensor 18

Removing and Replacing the Draw-Over Vaporizer 18-19

Cleaning the Halothane Vaporizer 19

Replacing the Fenton Balloon 20

Replacing the Control Screen Circuit Board 21

Replacing the Concentrator Loss of Power Alarm Battery 22

Removing the Concentrator 23-24

Installing the Concentrator 25

Replacing the Control Screen Battery 26

Removing, Inspecting and Cleaning the Pressure Relief Valve 27-30

PROBLEM SOLVING 31

MAIN PARTS 32-33

ILLUSTRATED PARTS 33-37

APPENDIX I: BREATHING CIRCUIT DIAGRAM 38

APPENDIX II: OXYGEN CONCENTRATOR FLOW DIAGRAM 39

APPENDIX III: ELECTRICAL DIAGRAM 40

APPENDIX IV: UAM SERVICE RECORD 41

APPENDIX V: UAM INSPECTION LABEL 42

APPENDIX VI: PRESSURE CONVERSIONS & COLOUR IDENTIFICATION FOR MEDICAL GASES 42-43

Copyright © 2013 by Gradian Health Systems, LLC. All rights reserved.

Gradian Health Systems, UAM and the Gradian logo are registered trademarks (®)

of Gradian Health Systems, LLC, registered in the United States.

Printed in the United States of America. Rev 1.0, P/N: 1974-005, December 2013 CE 0120.

The UAM is manufactured by OES Medical Ltd., Witney, Oxon, UK.

HOW TO GET HELP

HELP

AIL

A

EMAIL: service@gradianhealth.org

WEB: www.gradianhealth.org

PHONE: +1.212.537.0340

ADDRESS: Gradian Health Systems, 160 Fifth Avenue, 7th Floor, New York, NY 10010, USA

NOTE: For the latest UAM specifications and technical materials please visit us online at:

http://ww.gradianhealth.org/universal-anaesthesia-machine/

DESCRIPTION OF THE UNIVERSAL ANAESTHESIA MACHINE

The UAM® combines elements from both continuous flow and draw-over designs to provide a workstation that delivers

controlled anaesthesia in all hospital settings.

The breathing system is a low pressure (limited to 5 cm H2O) continuous flow system that defaults to a demand-flow (drawover) system when the supply fails. There are three one-way valves and a balloon operated inflating valve which provide this

uniquely versatile method of anaesthesia delivery.

Oxygen can be provided from a variety of sources, and if none of those sources is available the machine will automatically

draw in room air without the need for the user to change settings. The vaporizer provides calibrated delivery of anaesthetic

agent and the manual bellows ensures that safe assisted respiration can continue without requiring a high pressure gas

source.

The system has been designed to accept standard anaesthesia accessories such as the breathing circuit, oxygen sensor,

and standard connectors for the oxygen and nitrous oxide supplies. The UAM is also designed for simple field service. Most

components can be removed with standard tools and local technicians can install replacement parts without removing the

workstation from the hospital.

The UAM carries the CE Mark, having passed EU regulatory inspections. It is manufactured in an ISO-certified factory in

England. It is used in a wide variety of hospitals, from internationally recognized academic centres to resource-constrained

district hospitals.

The Universal Anaesthesia Machine ensures that an adequate supply of oxygen and anaesthesia is always available to meet

patient demand, no matter what the environment.

®

The UAM provides several ways to deliver oxygen, including connections for cylinder and pipeline. Most importantly, the

machine produces its own oxygen using an integrated concentrator that converts room air into 95% oxygen. Air is drawn

into the UAM and is purified by 2 dierent filters. Ambient air is made up of 78% nitrogen, 21% oxygen and 1% other gases.

The electrically powered oxygen concentrator in the UAM removes nitrogen from room air, creating a mixture that is 95%

oxygen and 5% other gases.

The compressed air passes into a canister filled with a powdered material called Zeolite. Nitrogen sticks to the Zeolite,

while oxygen and other gases flow through it to a reservoir tank. The UAM produces up to 10 liters per minute of up to 95%

oxygen. The oxygen then travels through the flow meter into the back bar and reservoir bag.

GAS FLOW IN THE PATIENT SYSTEM

The flow meter controls the amount of oxygen entering the back bar and available for the patient. The spinning bobbin

shows the flow rate in liters per minute.

The back bar provides the following functions:

1. The reservoir bag stores up to 2 liters of oxygen.

2. The pressure relief valve limits pressure in the back bar to 5 centimetres of water, protecting the patient from harm.

3. The air inlet valve allows room air to be drawn in whenever the supply of oxygen is less than the demand, as expressed

by the patient’s minute volume.

1

The low-resistance draw-over vaporizer adds volatile agent to the carrier gas passing through it. Volatile agent is added by

using the selector wheel to achieve the desired percentage. The resulting anaesthetic supply gas is comprised of oxygen,

volatile agent and a variable amount of room air. The anaesthetic supply gas flows from the back bar at low pressure to the

breathing block and the bellows.

An oxygen monitor measures the oxygen concentration of the supply gas passing to the patient. The reading is displayed on

the control screen.

As the supply gas flows from the oxygen sensor it passes the first one-way valve, then the bellows chamber, followed by the

second one-way valve.

During spontaneous breathing both non-return valves open for inspiration and close during expiration. The bellows will not

fill with exhaled gas.

The bellows is used for intermittent positive pressure ventilation, also known as IPPV or controlled ventilation. When the

bellows is raised, supply gas flows through the first non-return valve into the bellows. The second non-return valve remains

closed.

As the bellows are pushed down, the supply gas flows out through the second non-return valve into the inspiratory limb. The

first non-return valve is closed.

Another pressure relief valve ensures that excessive manual force on the bellows cannot cause harm to the patient.

The UAM uses a conventional Y-piece patient connection. Exhaled gas returns to the UAM via the expiratory limb of the

Y-piece and then passes by the Fenton balloon and a third one-way valve to the scavenger port. The balloon acts as an

inflating valve which enables controlled ventilation of the lungs, the third valve prevents back-flow during spontaneous

breathing.

SPECIFICATIONS

PHYSICAL AND ELECTRICAL

gWorkstation: 146cm x 53cm x 69cm, 130kg, aluminium frame, vertical dove mount side rails on both sides, nylon internal

tubing

gTop Shelf: 46cm x 31cm, 88cm above floor, 35kg weight limit

gDrawer: 10cm x 29cm x 32cm, 35kg weight limit, stainless steel, removable for cleaning.

gTop shelf: Epoxy powder coated pressed aluminium; side slots for nylon strap to secure equipment; optional monitor

brackets are available to bolt items to the top of the top shelf, 54 cm (W) x 37 cm (D), Load maximum: 35 kg with even

load distribution.

gWork surface: Stainless steel, removable for cleaning, 46 cm (W) x 31 cm (D) x 88 cm (H) above ground

gMains power supply: 220V, 50-60Hz

gPower: 500 Watts/220v = 2.27 amps

gControl screen power: CE-marked, fused and medical grade. Mains powered with battery backup for one day of use.

gAutomatic over/under voltage mains power isolator protects oxygen concentrator, and sockets for monitor and

accessories

g3.5” TFT touch screen for oxygen display and alarm setting

gMembrane switch for oxygen and alarm settings

gCasters: 150 mm diameter single wheel antistatic casters, front lockable casters

OXYGEN SUPPLY AND MONITORING

gOxygen concentrator flow rate: 0.1 to 10.0 liters per minute

gMaximum oxygen concentration: 95%

NOTE: The oxygen concentration may vary according to ambient humidity and maintenance of the air filter

gAlternative sources: cylinder yoke, pipeline, or other external flow regulated portable oxygen source

gAutomatic room air intake when patient minute volume exceeds supply gas flow

gAccuracy of glass rotameters: +/- 2.5% when using 100% O

gIntegrated inspiratory oxygen monitoring uses MOX-3 oxygen sensor

gCalibration for room air (21%) and 100% oxygen

gPressure sensitive apnea or high flow alarm

gAdjustable minimum and maximum oxygen alarm settings

2

2

gUp to ten hour battery backup, trickle recharge from mains power

gMembrane keypad and touch screen

OPTIONAL USE OF NITROUS OXIDE

gSources: pipeline or cylinder

gHypoxic cut-o: A solenoid automatically shuts o nitrous oxide delivery if supply gas O2 level falls below a minimum of 25%

gFlow of N2O stops if electrical power fails

gSight and touch dierentiated flow control knob per ISO standards

gAccuracy of glass rotameter for N2O: +/- 2.5%

VENTILATION

gBellows for adult and paediatric use made from durable, long-lasting silicone rubber

g1600cc capacity

gInspiratory pressure relief of 55 cmH2O for pressure created during mechanical ventilation

gAluminium bellows block

gSilicone balloon inflating valve at the expiratory port

g15mm female/22mm male ISO standard taper connection for breathing circuit 30mm male ISO standard taper

connection for AGSS scavenging equipment

VAPORIZERS

gStainless steel and plated brass construction

gDraw over flow type

gPour filler type.

gSeparate units for isoflurane and halothane per ISO standards

gAgent delivery range: 0.5% to 4%

g120ml capacity

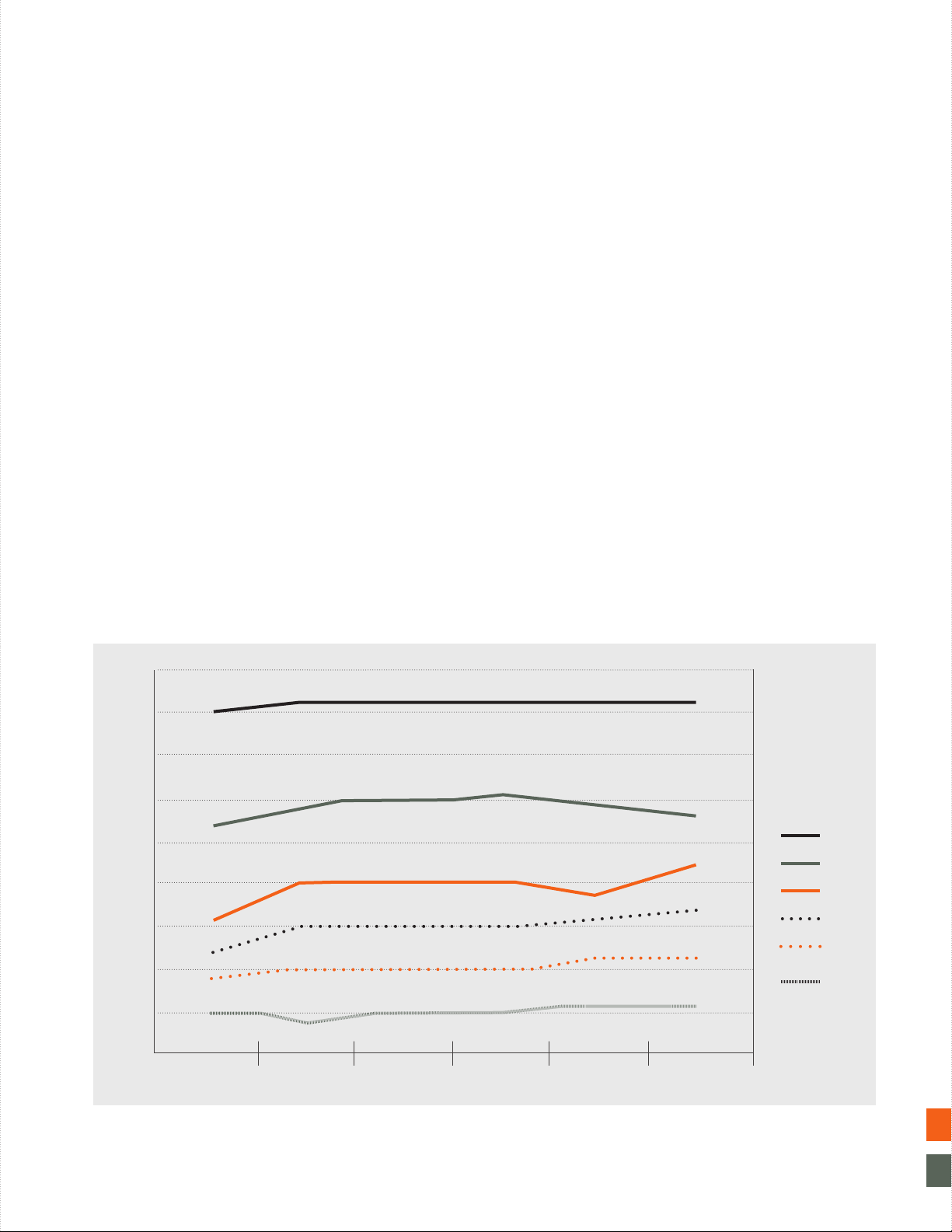

gPerformance:

4.5

3.5

2.5

1.5

.5

4

3

4%

3%

1

2%

1.5%

1%

1

.5%

0

3LPM 4LPM 5LPM 6LPM 7LPM 8LPM

TYPICAL HALOTHANE VAPORIZER PERFORMANCE WITH FLOW

3

6

5

4

3

2

1

0

4.5

3.5

4%

3%

2%

1%

15C 22C 25C 30C 35C

TYPICAL HALOTHANE VAPORIZER PERFORMANCE WITH TEMPERATURE

4

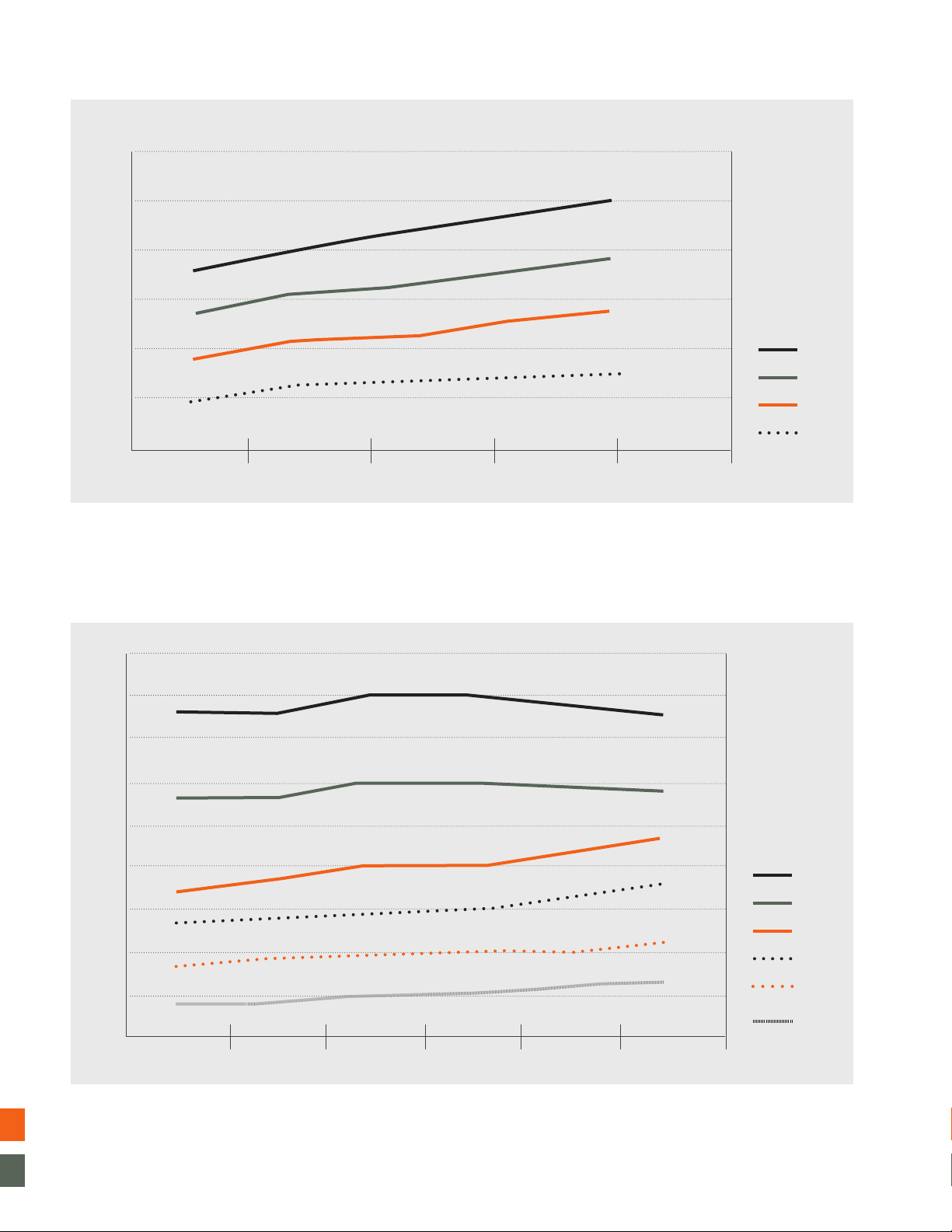

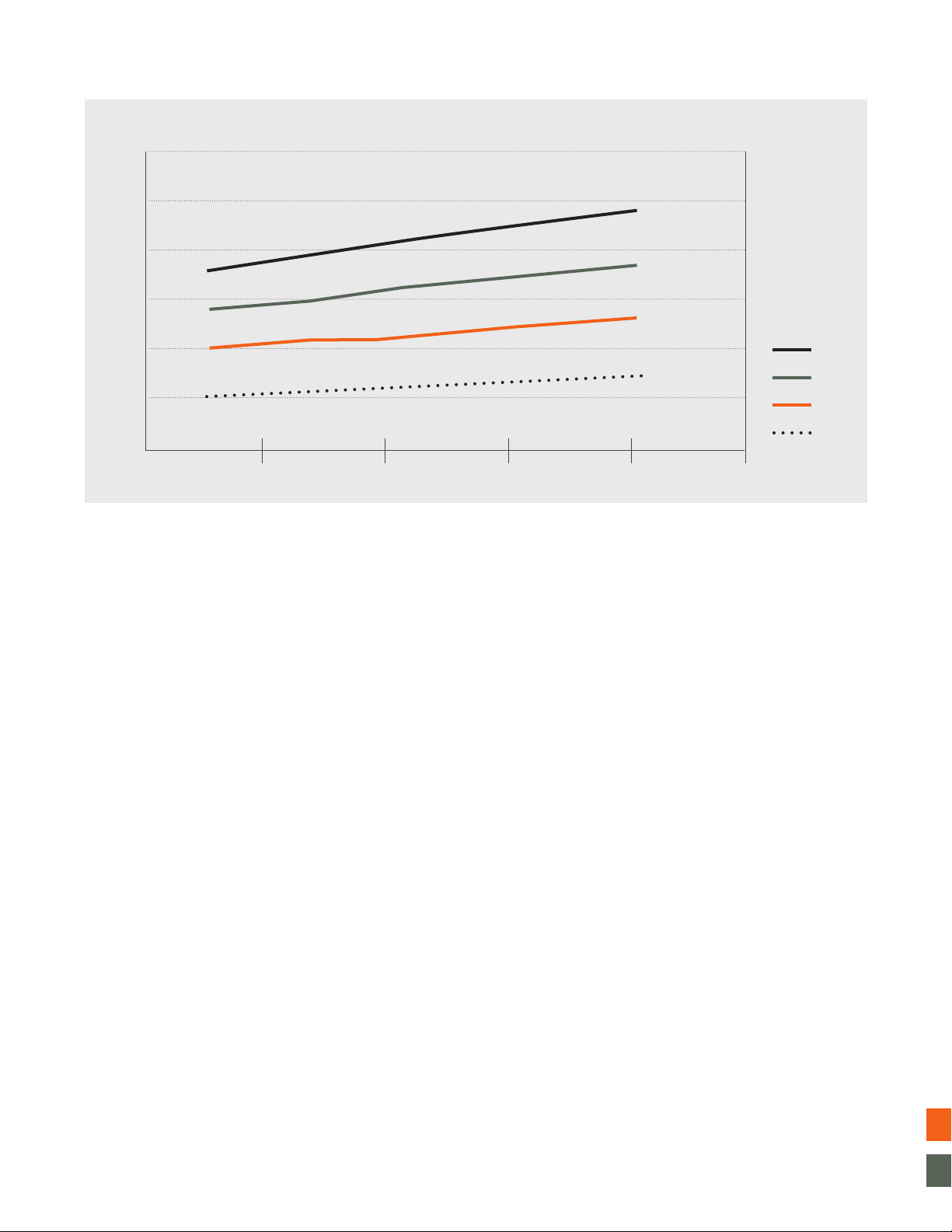

3

2.5

1

1.5

1

.5

4%

3%

2%

1.5%

1%

.5%

0

3LPM 4LPM 5LPM 6LPM 7LPM 8LPM

TYPICAL ISOFLURANE VAPORIZER PERFORMANCE WITH FLOW

4

6

5

4

3

2

1

0

15C 22C 25C 30C 35C

TYPICAL ISOFLURANE VAPORIZER PERFORMANCE WITH TEMPERATURE

REAR PANEL CONNECTORS

gMains isolator switch, 2 UK style power sockets

gOxygen and nitrous pipeline NIST connectors and cylinder yokes

gMulti-diameter external oxygen hose connector

4%

3%

2%

1%

5

COMPONENTS OF THE UAM

1. Patient Vital Signs Monitor

2. Oxygen monitor and

control screen

3. Oxygen and Nitrous Oxide

Flow Meters

4. Back bar with air inlet,

pressure relief valve and

2 liter reservoir bag

5. Low resistance vaporizer

6. Oxygen concentrator

on/o switch

7. Oxygen cylinder and

pipeline pressure gauges

8. Nitrous Oxide cylinder

and pipeline gauges

SEE INSET PAGE 7

9. Bellows

10. Pressure relief valve

and gauge

11. Fenton Balloon

expiratory valve

12. Y-piece connectors

13. Water trap

14. Oxygen concentrator

status screen

15. Integrated oxygen

concentrator

16. Castors (front lockable)

6

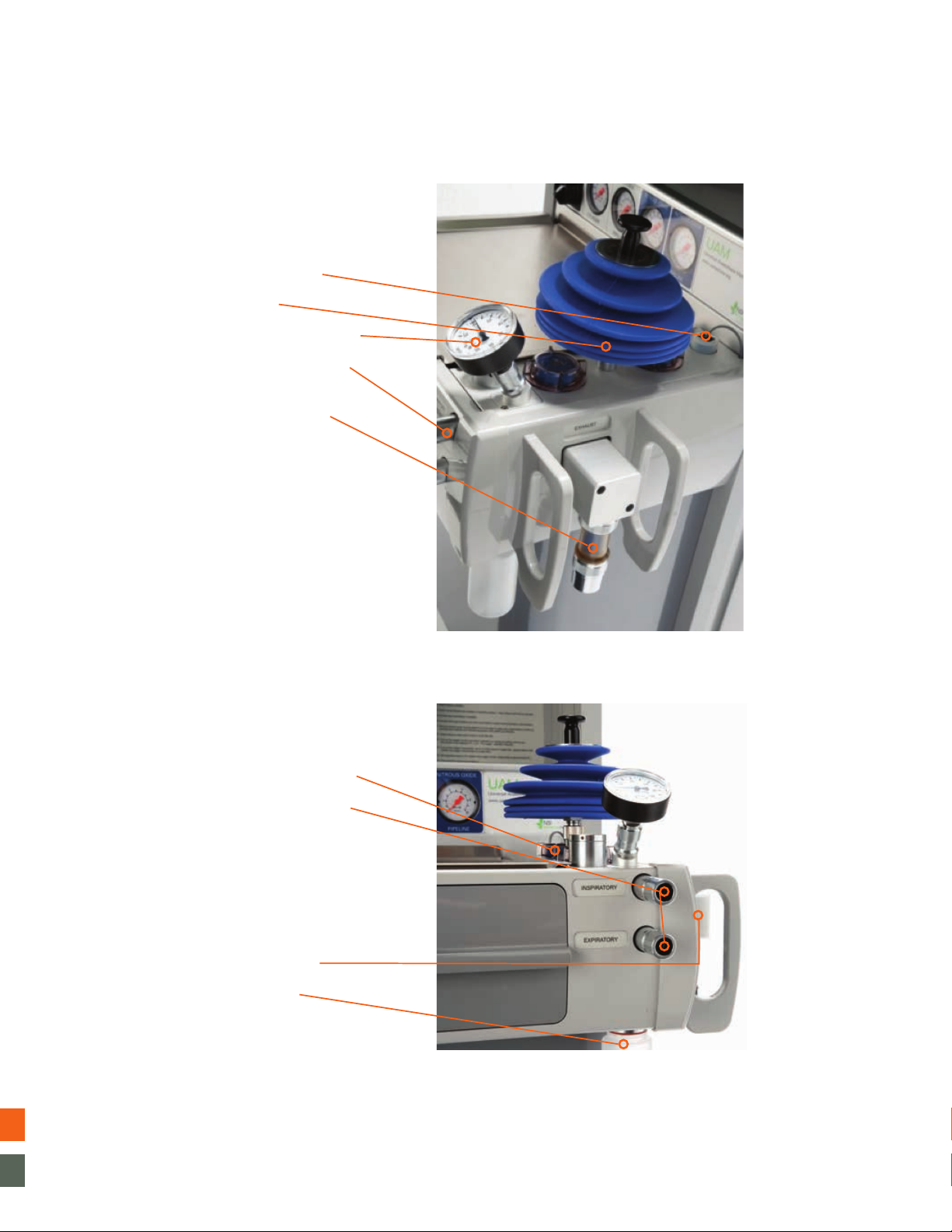

2. Oxygen monitor

and control screen

3. Oxygen and Nitrous

Oxide Flow Meters

4. Back bar

a. Air inlet valve

b. Pressure relief valve

c. Reservoir bag

5. Low resistance vaporizer

6. Oxygen concentrator

on/o switch

7. Oxygen cylinder and pipeline

pressure gauges

8. Nitrous Oxide cylinder

and pipeline gauges

INSET

7

Oxygen sensor

Bellows

Pressure relief gauge

Y-piece connectors

Fenton Balloon

inflating valve

Pressure relief valve

Y-piece connectors

Fenton Balloon

inflating valve

Water trap

8

THE CONTROL SCREEN

Calibration settings (to

calibrate oxygen sensor

and apnea alarm)

Fenton Balloon

Inflating Valve

One Way Valve and

scavenging 30mm

taper connection

Percent Oxygen (shows the

oxygen percentage of the

anaesthetic gas measured

before inspiration)

Battery charge status

High oxygen percentage

alarm (user adjusted)

Mode (opens screen for

system settings)

Low oxygen percentage

alarm (user adjusted)

Message Area

Apnoea alarm on/o

Mains power indicator

(machine is on mains power supply)

9

Pin-indexed connectors for E-size

oxygen and nitrous oxide cylinders

Oxygen inlet

Pipeline connections for

oxygen and nitrous oxide

Mains isolator (Power On/O)

Fuses for oxygen monitor,

oxygen concentrator

British style fused 3-pin plugs

10

UNPACKING THE UAM AND PREPARING FOR USE

Use only 1 liter/min flow to conserve the oxygen in the external cylinder. This will provide 30-35% oxygen to the

1. Remove front panel from the crate and remove the internal wooden crossbeam. If applicable remove the vital signs

monitor box and set it aside.

2. Remove accessories from underneath and along the sides of the UAM and set aside.

3. Unlock the front wheels and carefully roll the machine out of the packing case, supporting the weight as you lower the

machine to the floor. Remove all packing material.

4. Unpack work tray from its cardboard packaging. Remove film from work tray and place on top of the drawer.

5. Connect pipeline hoses and cylinders.

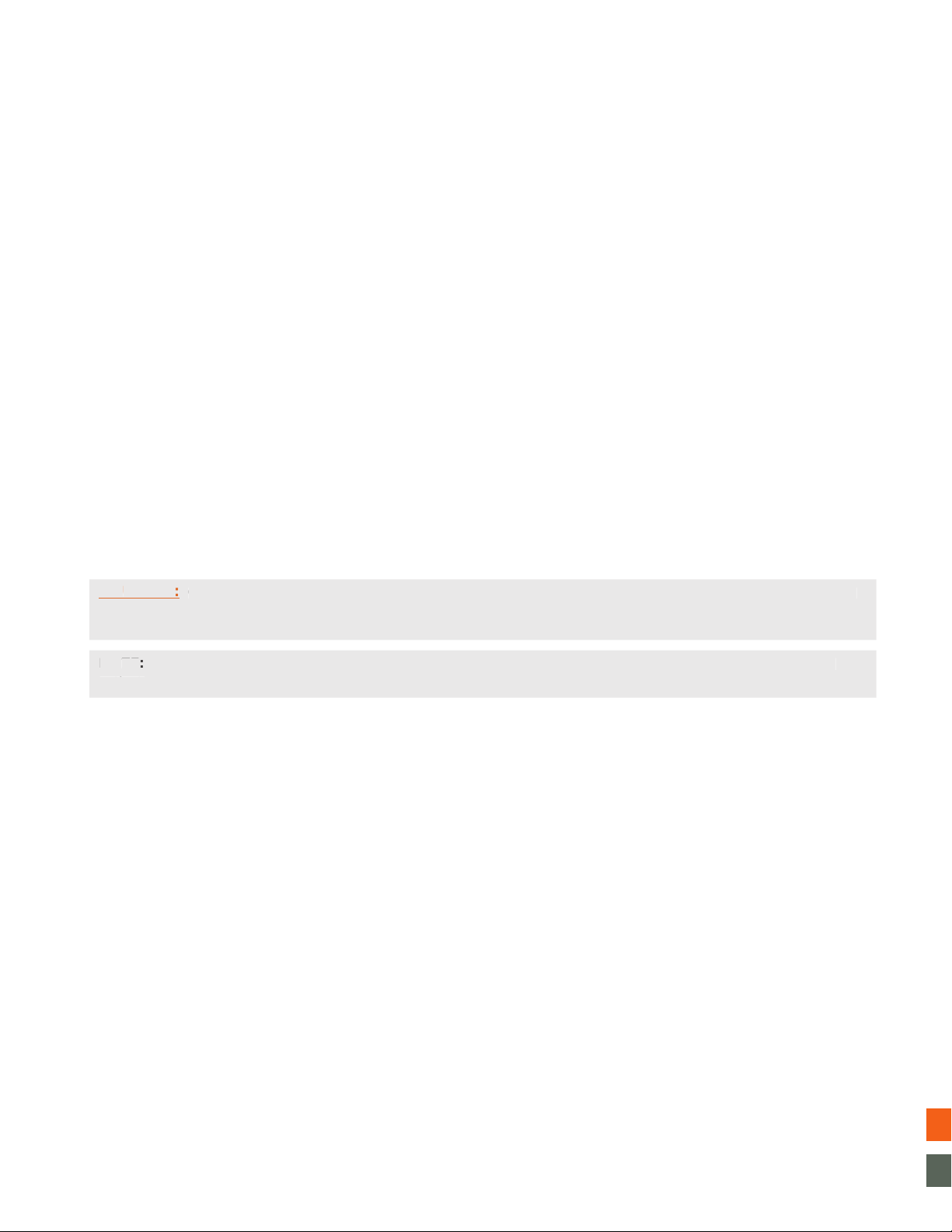

6. Screw in oxygen sensor and connect telephone-style cable. Some oxygen sensors come with an extra piece: this may be

discarded. (See photo on next page.)

USING OXYGEN

The UAM accepts an E-size pin-index oxygen cylinder. The cylinder connects via a yoke and Bodok seal and the pressure is

displayed on the pressure gauge on the front of the machine.

Bull-nose cylinders may be attached to the pipeline inlet using an approved 4 Bar medical regulator.

USING A PIPELINE CONNECTOR

The UAM accepts pipeline connections for oxygen. Each machine is supplied with an oxygen hose connecting to the UAM’s

NIST inlet. The other end is typically shipped with a BS 5682 probe, which is the British standard. Probes for other connector

types can be arranged. Pipeline pressure is displayed on the gauge on the front of the machine.

USING THE EMERGENCY OXYGEN INLET

An emergency oxygen supply connection is mounted on the back of the machine. It accommodates diering tube sizes

from ward-style flow-meters.

CAUTION: Oxygen from this source is not controlled by the glass flow meter on the front of the UAM. Rather, it must be

controlled with an external flow meter attached to the cylinder providing the emergency oxygen. The user can confirm that

oxygen is being given by observing the oxygen monitor.

NOTE: Use only 1 liter/min flow to conserve the oxygen in the external cylinder. This will provide 30-35% oxygen to the

patient.

USING NITROUS OXIDE

The UAM supports cylinder and pipeline sources of nitrous oxide. The flow of N2O is controlled by the right hand side flow

meter. The N

The UAM automatically cuts o nitrous oxide if the percent of oxygen in the anaesthetic mix falls to 25% and below. The

oxygen monitor must be powered on and working correctly for nitrous oxide delivery to occur. An exhausted oxygen sensor

or battery will shut o N

The cut o mechanism is electrical, unlike older style mechanical interlocks. The N2O valve is closed in its resting position

and must receive a current from the oxygen monitor to open. Any interruption of that current, including a decrease in

oxygen below 25%, will shut o the flow of nitrous oxide.

O flow knob has a dierent size and shape to distinguish it from the oxygen flow meter control knob.

2

O supply.

2

11

NOTE: Do not open the package of the spare oxygen sensor until it is needed. The oxygen sensor will start to deplete as

Do not open the package of the spare oxygen sensor until it is needed. The oxygen sensor will start to deplete as

soon as it comes into contact with air.

Screw in oxygen sensor and connect telephone-style cable. Some oxygen sensors come with an extra piece: this may be discarded.

6.

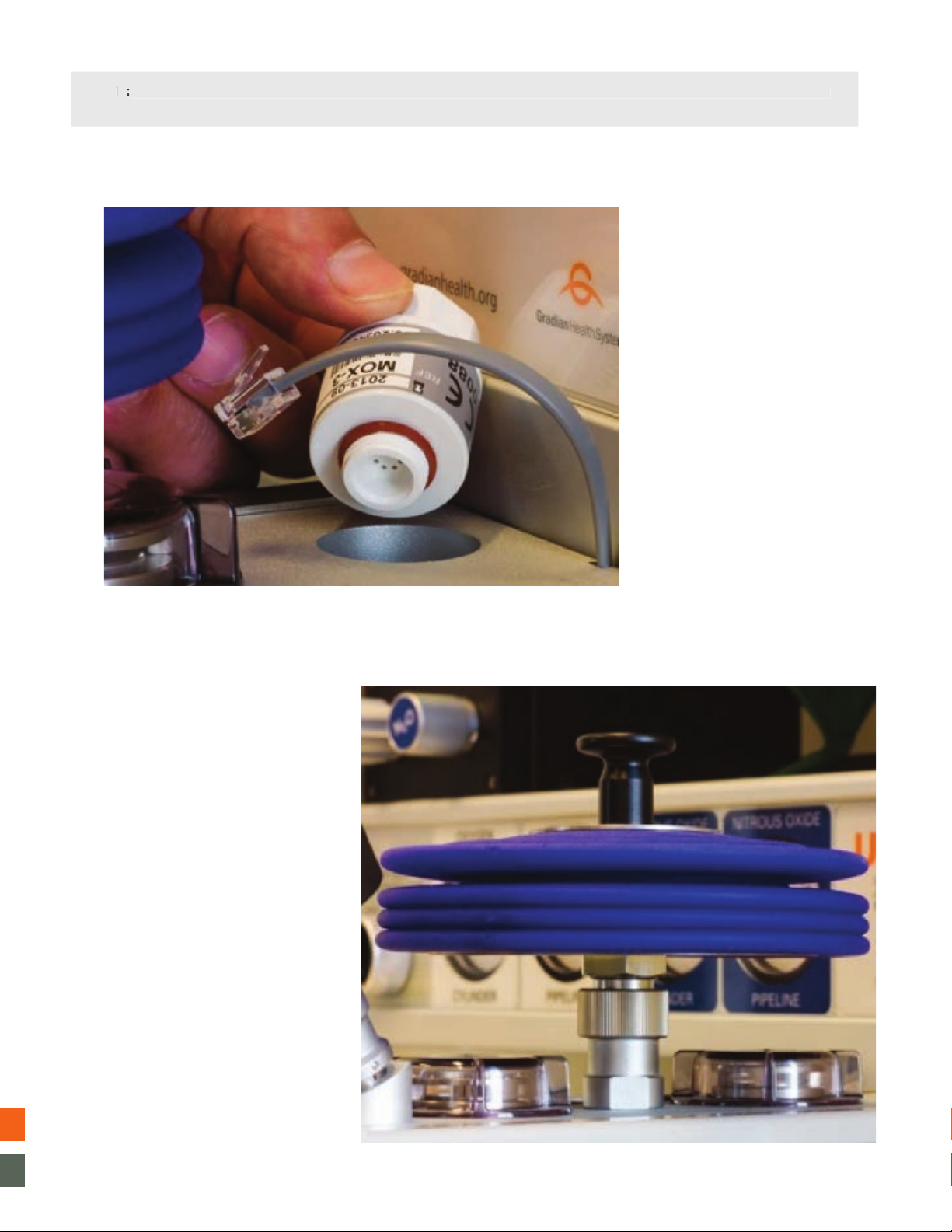

7. Attach bellows assembly to UAM by placing it on top of the connector and firmly pushing down. Then tighten knurled nut fully.

12

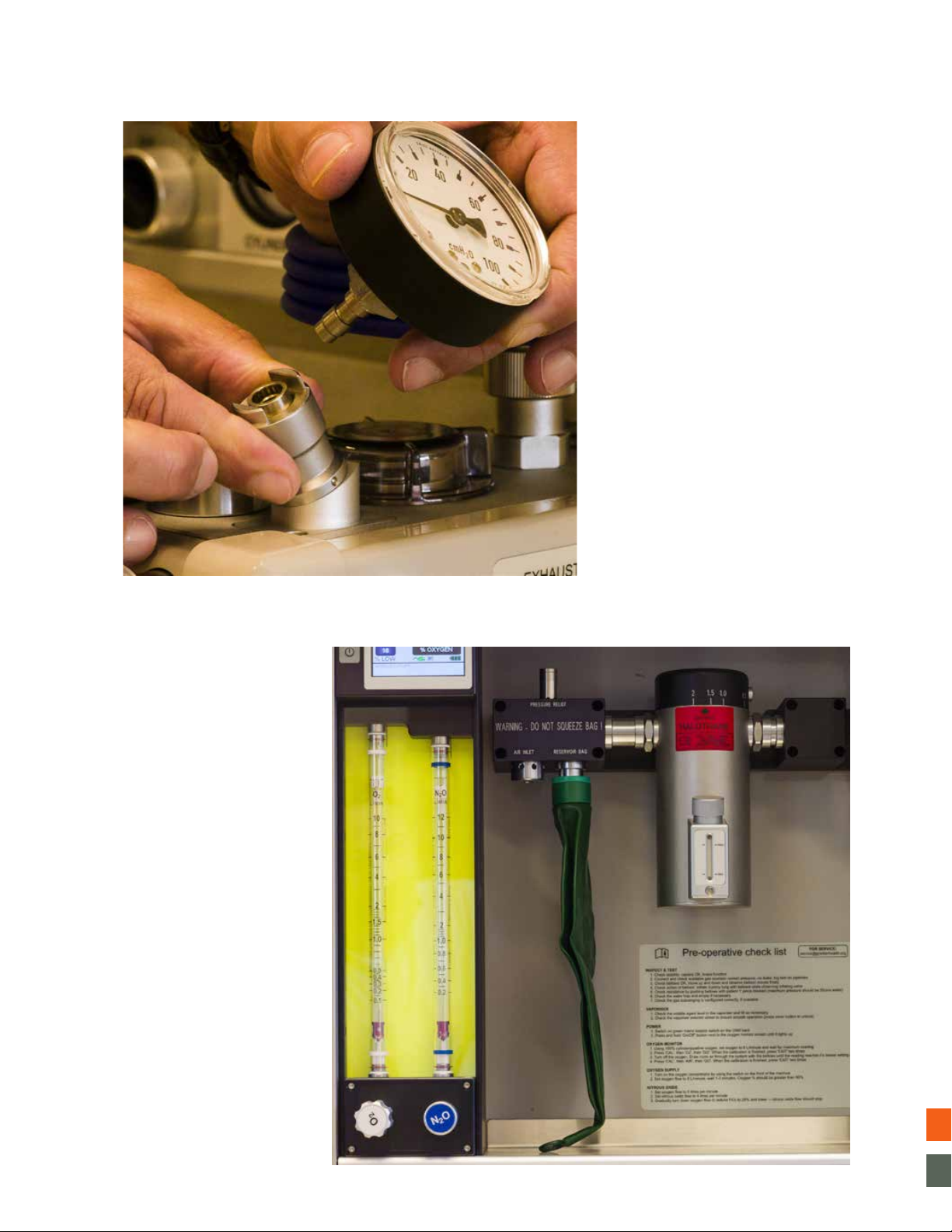

8. Attach airway pressure gauge by pushing down collar and inserting gauge into the port. Press firmly until collar springs up.

9. Attach green reservoir bag to back bar as shown in photo.

13

Loading...

Loading...