Page 1

INSTRUCTIONS-PARTS

LIST

308–551

This

manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

120 V

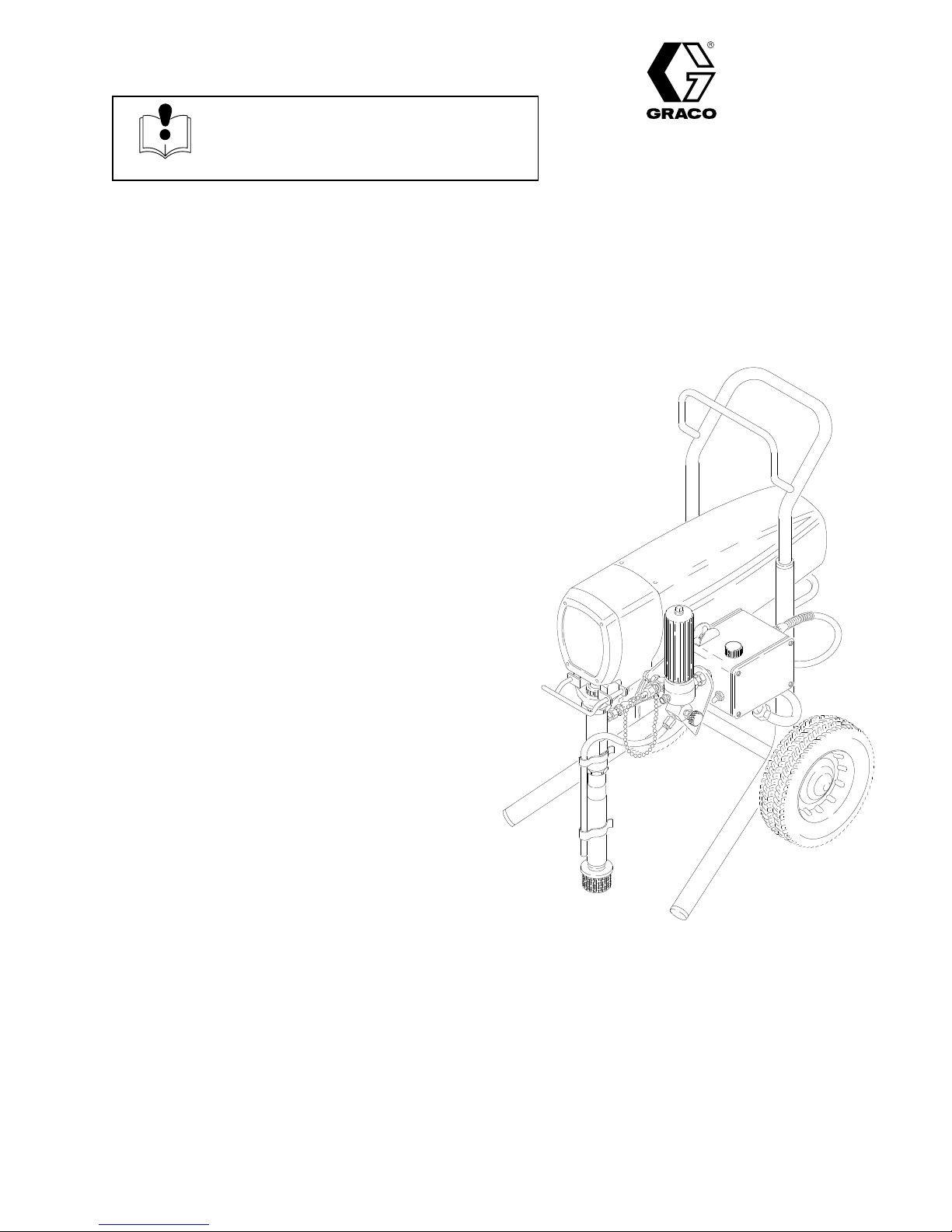

ULTRA

AC, 18A

Plus

+ 1500

Airless Paint Sprayer

3000 psi (21.0 MPa, 210 bar) Maximum Working Pressure

Part No. 223–773, Series A

Basic

Sprayer on upright cart, CSA certified

Patents

Pending

First

choice when

quality counts.

Rev. G

Supersedes D

and PCN E

GRACO INC. P.O. BOX 1441

MINNEAPOLIS, MN

http://www.graco.com

COPYRIGHT

Graco

Inc. is registered to I.S. EN ISO 9001

1994, GRACO INC.

55440–1441

Page 2

Table

of Contents

Warnings 2.

Setup 6

Operation

Flushing 9

Troubleshooting 10

Motor

Displacement

Pressure

Power

Motor 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brush

Supply Cord

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump

Control

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

12.

13.

18.

18.

Symbols

Warning Symbol

WARNING

his

symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

Bearing

Drive

Sprayer

Sprayer

Displacement

Accessories 25

Technical

Dimensions 27

Graco Warranty 28.

Phone

Housing & Connecting Rod

Housing

Parts Drawing

Parts List

Data

Number

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump Parts Drawing and List

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . .

20.

21.

22.

23.

24.

27.

28.

Caution Symbol

CAUTION

This

symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

INSTRUCTIONS

WARNING

WARNING

EQUIPMENT MISUSE HAZARD

Equipment

This equipment is for professional use only

Read all instruction manuals, tags, and labels before operating the equipment.

Use the equipment only for its intended purpose. If you are not sure, call Graco T

tance at 1–800–543–0339.

Do not alter or modify this equipment.

Check equipment daily

Do not exceed the maximum working pressure of the lowest rated system component. Refer to

the Technical Data

Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the

nical Data

ings.

Do not use hoses to pull equipment.

misuse can cause the equipment to rupture or malfunction and result in serious injury

.

echnical Assis

. Repair or replace worn or damaged parts immediately

on page 27 for the maximum working pressure of this equipment.

section of all equipment manuals. Read the fluid and solvent manufacturer’s warn

.

.

-

Tech-

-

Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not ex

pose Graco hoses to temperatures above 82C (180F) or below –40C (–40

Do not lift pressurized equipment.

Comply with all applicable local, state, and national fire, electrical, and safety regulations.

-

F).

Page 3

WARNING

WARNING

INJECTION HAZARD

Spray

from the gun, leaks or ruptured components can inject fluid into your body and cause ex

tremely serious injury

can also cause serious injury

Fluid injected into the skin is a serious injury

injury

. Get immediate medical attention.

Do not point the gun at anyone or at any part of the body

Do not put your hand or fingers over the spray tip.

Do not stop or deflect leaks with your hand, body

Do not “blow back” fluid; this is not an air spray system.

Always have the tip guard and the trigger guard on the gun when spraying.

Check the gun dif

Be sure the gun trigger safety operates before spraying.

Lock the gun trigger safety when you stop spraying.

, including the need for amputation. Fluid splashed in the eyes or on the skin

.

. The injury may look like just a cut, but it is a serious

.

, glove or rag.

fuser operation weekly

. Refer to the gun manual.

-

Follow the

checking or servicing the equipment.

T

ighten all fluid connections before operating the equipment.

Check the hoses, tubes, and couplings daily

not repair high pressure couplings; you must replace the entire hose.

Fluid hoses must have spring guards on both ends, to help protect them from rupture caused by

kinks or bends near the couplings.

Pressure Relief Procedure

on page 10 if the spray tip clogs and before cleaning,

. Replace worn or damaged parts immediately

TOXIC FLUID HAZARD

Hazardous

skin, inhaled, or swallowed.

Know the specific hazards of the fluid you are using.

Store hazardous fluid in an approved container

state and national guidelines.

Always wear protective eyewear

and solvent manufacturer

fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the

. Dispose of hazardous fluid according to all local,

, gloves, clothing and respirator as recommended by the fluid

.

. Do

Page 4

WARNING

WARNING

FIRE AND EXPLOSION HAZARD

Improper

result in a fire or explosion and serious injury

grounding, poor ventilation, open flames or sparks can cause a hazardous condition and

.

If there is any static sparking or you feel an electric shock while using this equipment,

spraying immediately. Do not use the equipment until you identify and correct the problem.

Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being sprayed.

Keep the spray area free of debris, including solvent, rags, and gasoline.

Electrically disconnect all equipment in the spray area.

Extinguish all open flames or pilot lights in the spray area.

Do not smoke in the spray area.

Do not turn on or of

Do not operate a gasoline engine in the spray area.

f any light switch in the spray area while operating or if fumes are present.

MOVING PARTS HAZARD

Moving

parts can pinch or amputate your fingers.

stop

Keep clear of all moving parts when starting or operating the pump.

Before servicing the equipment, follow the

NOTE: This

your sprayer

equipment from starting unexpectedly

is an example of the DANGER label on

. This label is available in other

.

languages, free of charge. See page 25 to order

FIRE

AND

EXPLOSION HAZARD

Spray

painting,

in confined areas can result in fire or explosion.

uids

Use outdoors or in extremely well ventilated areas. Ground equip

hoses, containers and objects being sprayed.

ment,

Avoid

all ignition sources such as

cloths,

open flames

arcs from

rettes,

light switches on and off.

ing

Failure

to follow this warning can result in death or serious injury

flushing or cleaning equipment with flammable liq

static electricity from plastic drop

such as pilot lights, hot objects such as ciga

connecting or disconnecting power cords or turn

READ AND UNDERSTAND ALL LABELS AND INSTRUCTION MANUALS BEFORE USE

Pressure Relief Procedure

on page 10 to prevent the

.

SKIN INJECTION

HAZARD

Liquids

-

-

-

-

.

can be injected into the body by high

or

leaks – especially hose leaks.

Keep

body clear of the nozzle. Never stop leaks with any part of the

body.

Drain all pressure before removing parts.A

of gun by always setting safety latch when not spraying.

gering

Never spray without a tip guard.

In case of accidental skin injection, seek immediate

“Surgical

Failure to follow this warning can result in amputation or serious

injury.

T

reatment”.

pressure airless spray

void accidental trig

-

4 308-551

Page 5

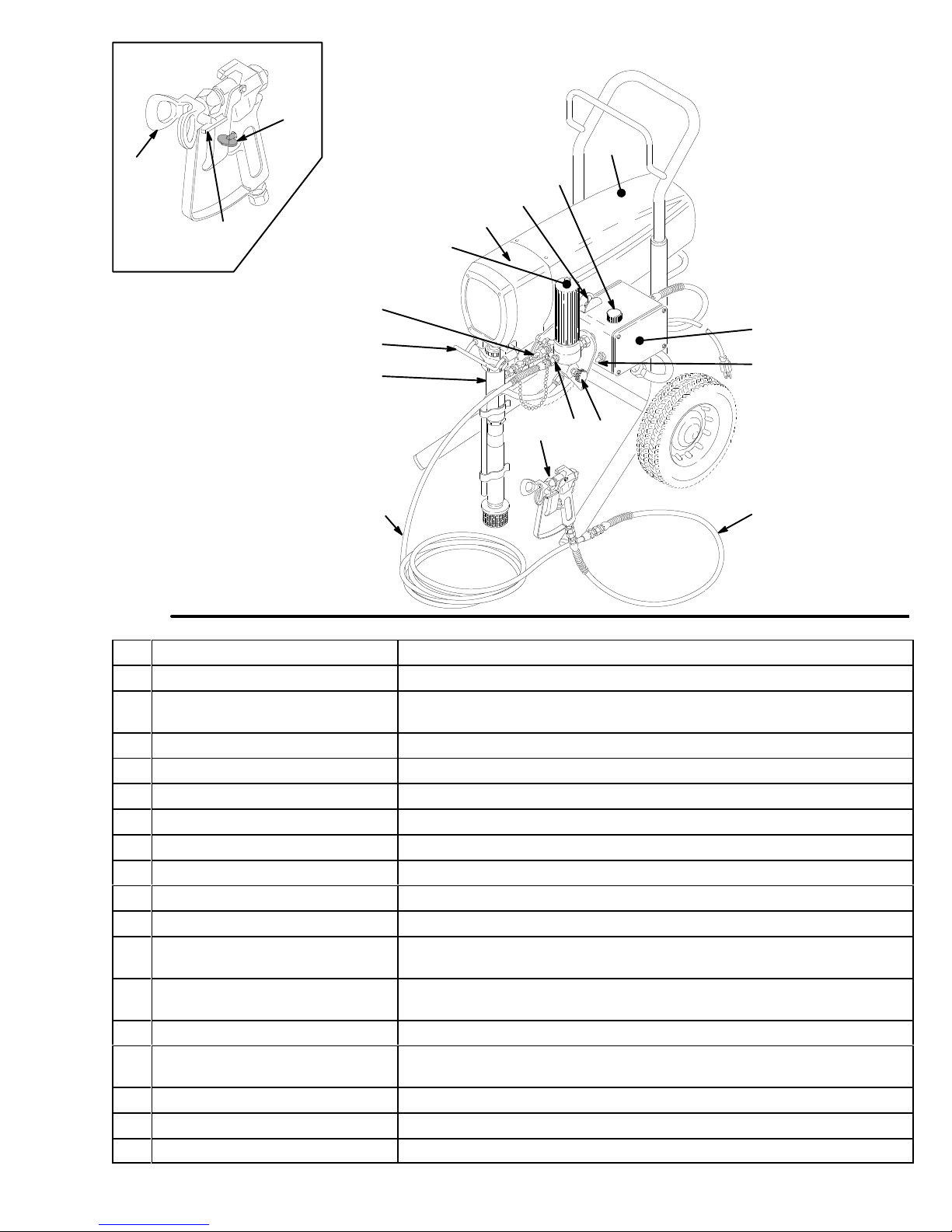

Major Components

S

A

K

Fig. 1

M

B

C

D

E

F

R

G

H

U

LTP

J

N

01888

A Motor

B

C

(Under shield shown) DC motor

Pressure Adjusting Knob

ON/OFF Switch, Circuit Breaker

, 120 V

ac, 18A, 1 phase

Controls fluid outlet pressure

Power switch that controls 120 V

breaker

D

Drive Assembly

E

Fluid Filter

F

Secondary Fluid Outlet

G

Pail Hanger

H

Displacement Pump

J

50 ft (15 m) Main Hose

K

RAC IV T

L

Contractor Gun

M

RAC IV Switch T

ip Guard

ip

T

ransfers power from DC motor to the displacement pump

Filter of fluid between source and spray gun

Second hose and spray gun is connected here

Container of fluid to be sprayed may be hung here

Pressures fluid to be sprayed through spray gun

1/4 in. ID, grounded, nylon hose with spring guards on both ends

Reverse-A-Clean (RAC) ti

High pressure spray gun with gun safety latch

RAC switch tip atomizes fluid and removes clogs from spray tip without

removing tip from spray gun

N

3 ft (0.9 m) Hose

3/16 in. ID, grounded, nylon hose used between 50 ft hose and spray

gun to allow more flexibility when spraying

P

Pressure Drain V

R

Pressure Control

alve

Relieves fluid pressure when open

Controls motor speed to maintain fluid pressure. W

adjusting knob.

S

Spray Gun Safety Latch

T

Primary Fluid Outlet Hose and spray gun is connected here

U

15/20 Amp Switch

Inhibits accidental triggering of spray gun

Allows sprayer to operate on 15A service with reduced performance

p g

uard reduce

ac power to sprayer; with circuit

s t

he ris

k o

f f

lui

d i

njectio

orks with pressure

n i

njury

Page 6

Setup

WARNING

If you supply your own hoses and spray gun, be

sure the hoses are electrically conductive, that the

gun has a tip guard, and that each part is rated for

at least

Pressure

ry caused by static sparking, fluid injection or overpressurization and rupture of the hose or gun.

3000 psi (21.0 MPa, 210 bar) Working

. This is to reduce the risk of serious inju

4.

Check the electrical service.

cal service is 120 V

grounded outlet. Do not remove the grounding

prong of the power supply cord. Do not use an

adapter

minimum 12 gauge size. Long extension cords

-

reduce sprayer performance. If 20A service is not

available, flip the 15/20 Amp switch (U) to 15 set

ting to avoid nuisance tripping of circuit breakers.

5. With the the ON/OFF switch OFF, plug the cord

into a grounded electrical outlet

20 ft. (6 m) away from the spray area.

. Extension cords must have 3 wires of a

AC, 60 Hz, 20A. Use a properly

Be sure the electri

located at least

-

-

CAUTION

T

o avoid damaging the pressure control, which

may result in poor equipment performance and

component damage, follow these precautions:

1.

Always use a nylon spray hose at least 50 ft.

(15 m) long.

2.

Never use a wire braid hose as it is too rigid to

act as a pulsation dampener

3.

Never install any shutof

filter and the hose. See Fig. 2.

1. Assemble the gun (L), 3 ft. whip hose (N) and

50 ft. hose (J).

guard yet.

2. Two gun hookup.

1/4 npsm(m) secondary hose outlet and attach a

minimum 50 ft. long hose. For more flexible gun

movement, install a 3/16 in. ID, 3 ft. whip hose be

tween the main hose and the gun.

3. Fill the packing nut/wet–cup (216)

Graco Throat Seal Liquid (TSL), supplied.

Don’t install the spray tip and tip

Remove the cap (12) from the

.

f device between the

1/3 full with

6. Flush the pump

which was left in to protect pump parts after fac

tory testing. See page 9.

Do

not install any

fluid shutof

46

12

216

-

to remove the lightweight oil

f device here

42

L

-

C

B

U

50

WARNING

FIRE AND EXPLOSION HAZARD

Proper electrical grounding is essential

to reduce the risk of fire or explosion

which can result in serious injury and

property damage. Also read

EXPLOSION HAZARD

6 308-551

on page 4.

FIRE OR

Fig. 2

KJ N

01888

Page 7

Operation

WARNING

INJECTION

T

o reduce the risk of serious injury

whenever you are instructed to relieve

pressure, follow the

Procedure

on page 10.

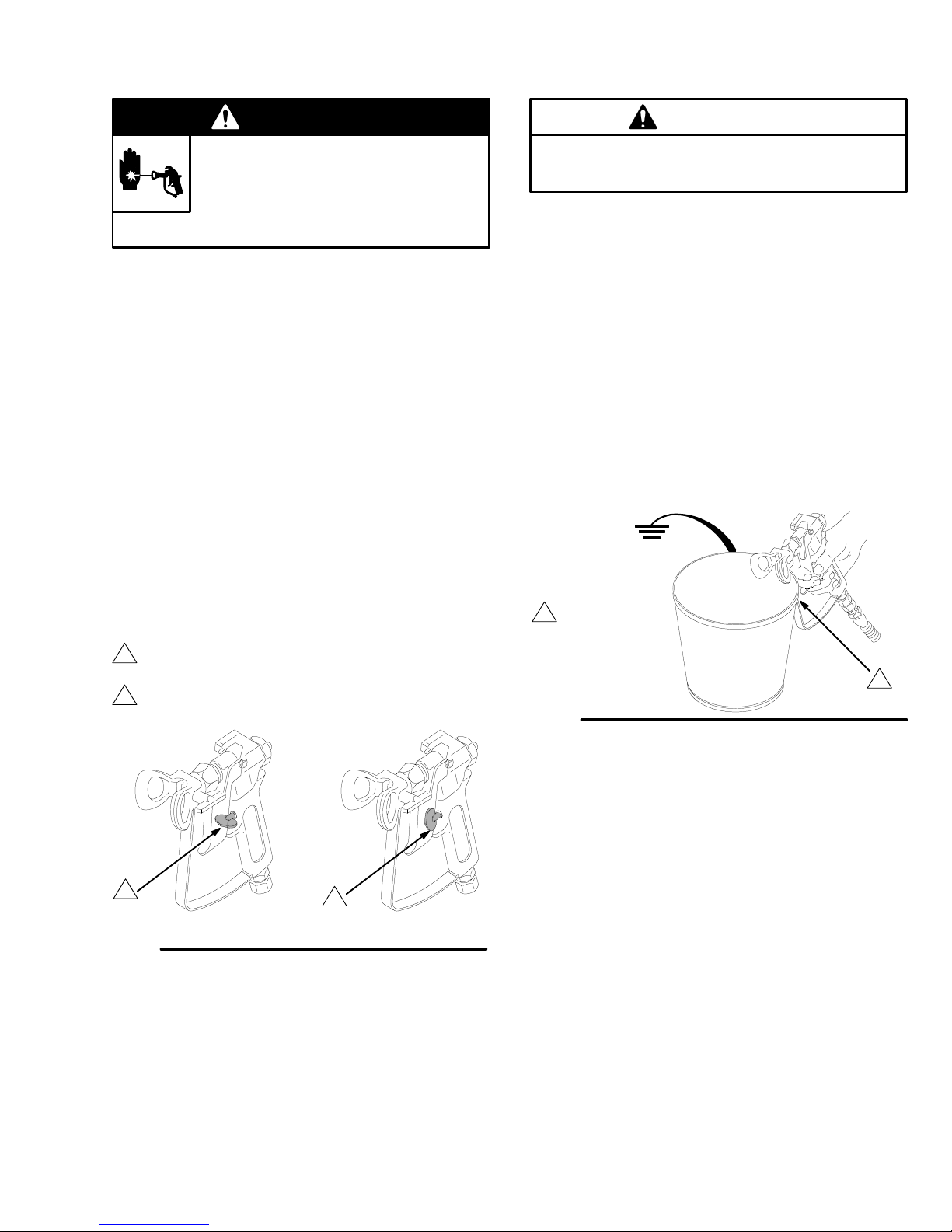

Startup (Fig. 2)

Always

is ready to operate and that you start it safely

1.

2.

3. Don’t install the spray tip and tip guard until

4. Put the suction tube (42) into the paint con-

5.

6. Disengage the gun safety latch.

use this procedure to help ensure the sprayer

For a first time startup

page 9.

Close the pressure drain valve (50).

the pump is primed!

tainer.

Lower the pressure setting

sure adjusting knob (B) fully counterclockwise.

Gun

1

2

safety latch

shown engaged

Gun safety latch

shown disengaged

HAZARD

Pressure Relief

, flush the sprayer

by turning the pres

,

.

. See

See Fig 3.

CAUTION

Do

not run the sprayer dry for more than 30 sec

onds to avoid damaging the pump packings.

7. T

o prime the pump

a.

Open the drain valve.

b. T

urn the ON/OFF (C) switch to ON.

c.

Slowly increase the pressure setting until the

:

sprayer starts.

d.

When fluid is flowing from the valve, turn down

the pressure and close the valve.

e.

Hold a metal part of the gun firmly against a

grounded metal waste container

. See Fig. 4.

-

Maintain

metal to metal

1

contact when

flushing

firm

Fig. 4

-

1

0143

1

Fig. 3

f. Trigger

the gun and slowly increase the pres

sure setting until the sprayer starts. Keep the

gun triggered until all air is forced out of the

system and the paint flows freely from the gun.

g.

Release the trigger and engage the gun safety

latch. See Fig 3.

2

0137

8. Check all fluid connections for leaks

. If any

leaks are found, relieve pressure before tightening

the connections.

308-551 7

Page 8

Operation

9. Install the spray tip and tip guard.

gun safety latch. Install the spray tip. If you are

using the RAC IV tip guard, refer to manual

307–848 for installation instructions.

10.

Adjust the pressure.

a. T

urn the pressure adjusting knob clockwise

just until spray from the gun is completely at

omized. T

ging, and to decrease tip wear and extend the

life of the sprayer

sible pressure needed to get the desired re

sults.

b.

If more coverage is needed, use a larger tip

rather than increasing the pressure.

c. T

est the spray pattern. T

of the spray pattern: engage the gun safety

latch, loosen the retaining nut, position the tip

guard horizontally for a horizontal pattern or

vertically for a vertical pattern and tighten the

retaining nut.

o avoid excessive overspray and fog

, always use the lowest pos

o adjust the direction

Engage the

Cleaning a Clogged Tip

WARNING

INJECTION HAZARD

To

reduce the risk of serious injury

whenever you are instructed to relieve

Procedure

pressure, follow the

on page 10.

Pressure Relief

3. Return

gage the gun safety latch, and resume spraying.

4.

If the tip is still clogged, engage the gun safety

latch, shut of

the pressure drain valve to relieve pressure. Clean

the spray tip as shown in manual 307–848, sup

-

-

plied with the RAC IV

the switch tip to the original position, disen

f and unplug the sprayer

.

, and open

-

-

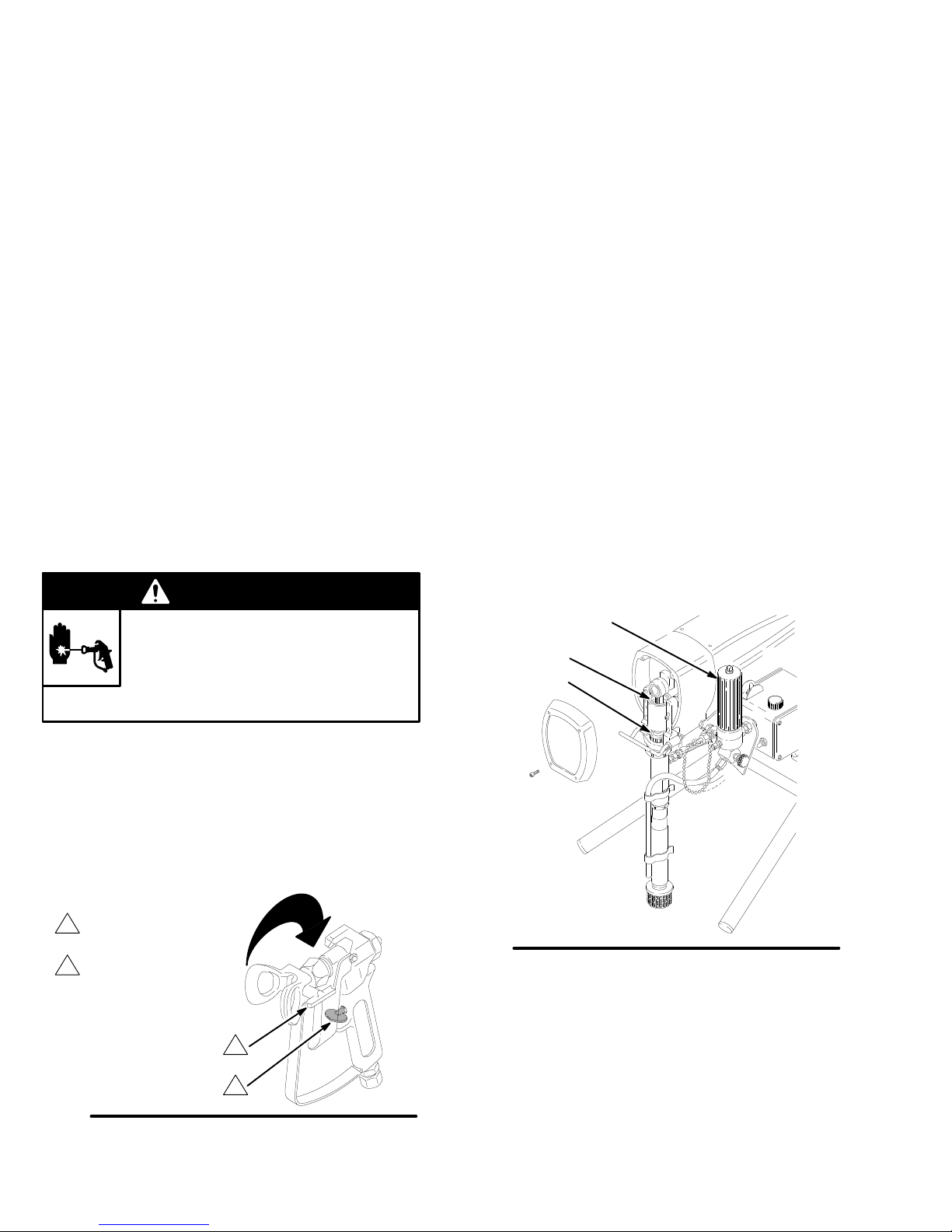

Shutdown and Care

-

-

,

1. Check the packing nut/wet-cup (216) daily.

lieve the pressure. Keep the packing nut/wet-cup

1/3 full with TSL at all times to help prevent fluid

buildup on the piston rod and premature wear of

packings. Tighten the packing nut just enough to

stop leakage. Overtightening may cause binding

and excessive packing wear

and light hammer to adjust the nut. See Fig. 6.

2. Clean the fluid filter (48) often

sprayer is stored. First relieve pressure. See man

ual 307–273 for the cleaning procedure.

3. Fill the connecting rod cavity (A)

every 100 hours of operation. Relieve pressure

first. See Fig. 6.

48

A

216

. Use a screwdriver

and whenever the

with motor oil

Re

-

-

1.

If the spray tip clogs, release the gun trigger, en

gage the gun safety latch, relieve pressure, and

rotate the RAC IV switch tip 180. See Fig. 5.

2.

Disengage the gun safety latch and trigger the gun

into a waste container

latch again.

Switch tip

1

in spraying position

Gun safety latch

2

shown engaged

Fig. 5

shown

. Engage the gun safety

1

2

-

0137

Fig. 6

4. For very short shutoff periods,

tube in the paint, relieve pressure, and clean the

spray tip.

5. Coil the hose and hang it on the hose rack

when storing it, even for overnight, to help protect

the hose from kinking, abrasion, coupling damage,

etc.

leave the suction

01892

Page 9

When to Flush

1. New

Sprayer. The sprayer was factory tested in

lightweight oil which was left in to protect pump

parts.

Before using water–base paint

spirits, then warm, soapy water

water.

, flush with mineral

, and then clean

Flushing

5.

Storage.

sprayer

pressure and leave it open.

W

ater–base paint:

spirits. Leave the system filled with mineral spirits.

Oil–base paint:

Flush as indicated below

, open the pressure drain valve to relieve

flush with water

flush with mineral spirits.

, shut of

, then mineral

f the

Before usin

2. Changing

vent.

3. Changing water–base to oil–base paint.

with warm, soapy water

4. Changing from oil–base to water–base paint.

Flush with mineral spirits, then warm, soapy water

and then clean water

g o

il–bas

e p

aint,

f

lus

h with m

Colors. Flush with a compatible sol

, then mineral spirits.

.

inera

l s

Flush

pirits.

How to Flush

A

B

CAUTION

Never

allow water to freeze in the pressure control.

-

,

Doing so prevents the sprayer from being started

and causes serious damage to the pressure control.

Push the water out with mineral spirits.

6. Startup

paint, flush out the mineral spirits with soapy water

and then clean water

flush out the mineral spirits with the paint to be

sprayed.

7.

Open the drain valve. T

increase the pressure until until the sprayer starts.

When fluid comes from the valve, close it. Hold a

metal part of the gun firmly against a metal waste

container. T

of the system and the solvent flows freely from the

gun. Release the trigger and engage the gun

safety latch.

after storage.

rigger the gun until all air is forced out

Before using water–base

. When using oil–base paint,

urn on the sprayer and

C

Fig.

7

1.

Relieve pressure.

2.

Remove the filter bowl (A), support (C) and screen

(B); see manual 307–273. Install the bowl and

support. Clean the screen separately and install

after flushing.. See Fig 7.

3.

Close the pressure drain valve.

4.

Pour one–half gallon of compatible solvent into a

grounded metal pail. Put the suction tube in the

pail.

Remove the spray tip from the gun, if it is installed.

5.

6. T

urn the pressure adjusting knob all the way coun

terclockwise to lower the pressure setting.

50

WARNING

FIRE AND EXPLOSION HAZARD

T

o reduce static sparking and splashing,

always remove the spray tip from the

gun, and hold a metal part of the gun

firmly to the side of a grounded metal pail when

flushing.

8.

Remove the suction tube from the pail. Disengage

the gun safety latch and trigger the gun to force

solvent from the hose. Do not run the pump dry for

more than 30 seconds to avoid damaging the

pump packings! Relieve pressure.

9.

Leave the pressure drain valve open until you are

ready to use the sprayer again. If the screen was

removed, unscrew the filter bowl and reinstall the

clean screen. Reinstall the bowl, hand tight only

If you flushed with mineral spirits and are going to

10.

-

use a water–base paint, flush with soapy water

and then clean water. Relieve pressure.

308-551 9

.

Page 10

Troubleshooting

Pressure Relief Procedure

T

o reduce the risk of serious bodily injury

, including

fluid injection, injury from splashing fluid or solvent in

the eyes or on the skin, moving parts or electric

shock, always follow this procedure whenever you

shut of

f the sprayer

, when checking or servicing any

part of the spray system, when installing, cleaning or

changing spray tips, and whenever you stop spray

ing.

1.

Engage the gun safety latch.

2. Turn the ON/OFF switch to OFF

3.

Unplug the power supply cord.

.

Check everything in the troubleshooting table

before disassembling the sprayer

TYPE OF PROBLEM WHA

Building circuit breaker opens

.

T T

If check is OK, go to next check

Check all electrical wiring for damaged

insulation.

Check for other electrical appliances on

circuit.

O CHECK

4.

Disengage the gun safety latch. Hold a metal

part of the gun firmly to a grounded metal pail.

T

rigger the gun to relieve pressure.

5.

Engage the gun safety latch.

6. Open the pressure drain valve. Leave the pres

sure drain valve open until you are ready to

spray again.

-

If you suspect that the spray tip or hose is completely

clogged, or that pressure has not been fully relieved

after following the steps above

loosen the tip guard retaining nut or hose end cou

pling to relieve pressure gradually

pletely

. Now clear the tip or hose obstruction.

WHA

T T

When check is not OK refer to this column

Replace any damaged wiring.

Shutdown other electrical appliances on

circuit.

O DO

, VER

Y SLOWL

, then loosen com

Y

-

-

Sprayer circuit breaker opens

Sprayer will not run

Check position of 15–20 (Lo-High) amp

switch.

Check for locked motor rotor

and try to turn fan blades with a screwdriver

Check for shorted motor

check for shorts between motor leads or

between motor leads and motor frame.

Check electrical supply with voltmeter

should read 105–125 V

Check pressure control knob setting. Motor

will not run if it is at minimum setting (fully

counterclockwise).

Check for a clogged spray tip. Refer to

separate gun or tip instruction manual.

Check extension cord for visible damage.

Use a volt meter or test lamp at extension

cord outlet to check.

Check sprayer power supply cord for visible

damage such as broken insulation or wires.

Check electrical supply with volt meter

should read 105–125 V

Check for motor damage. Remove drive

housing assembly

fan by hand.

. See page 21. T

. Unplug cord

. Use ohmmeter to

. Meter

AC.

. Meter

AC.

ry to rotate

Put switch in 15 amp (LO) position.

Repair gear train or pump, if damaged.

.

the sprayer

the pressure control, if damaged.

Inspect for damage to motor brush leads.

Replace motor

Connect to outlet of correct voltage.

Slowly increase pressure setting to see if

motor starts.

Relieve pressure. Refer to separate gun or

tip instruction manual for tip cleaning.

Replace extension cord.

Replace power supply cord.

Reset building circuit breaker; replace

building fuse. T

Replace motor (1) if fan won’t turn.

, if frozen; See NOTE 1. Replace

, if necessary.

ry another outlet.

Thaw

Poor spray pattern

Check for worn spray tip.

Relieve pressure and then replace the tip.

See the separate gun or tip manual.

Page 11

Troubleshooting

TYPE OF PROBLEM WHA

If check is OK, go to next check

Motor runs and pump strokes,

but output is low or there is no

output.

Check extension cord size and length.

Check paint supply

Check for clogged intake strainer

Check for loose suction tube or loose fittings.Tighten; use thread sealant or sealing tape

Check for worn spray tip.

Check motor brushes; check for loose leads

and terminals, minimum 1/2” brush length,

broken or misaligned springs, or brushes

binding in holders. See page 12.

Check motor armature for shorts by using an

armature tester (growler).

Check to see if pump continues to stroke

when gun trigger is released. With pump on

and primed, trigger gun momentarily

release and engage safety latch. Relieve

pressure, turn of

T T

O CHECK

.

.

f and unplug sprayer

, then

.

WHA

T T

O DO

When check is not OK refer to this column

Replace cord with a larger size, grounding

type extension cord.

Refill and reprime pump.

Remove and clean strainer and reinstall.

on threads, if necessary

Follow

Pressure Relief Procedure

Warning

separate gun or tip manual.

Replace parts as needed. See page 12.

Replace motor

Service pump. See page 13.

, then replace tip. See your

. See page 19.

.

Motor runs but pump does not

stroke.

Motor is hot and runs

intermittently.

Check to see if intake valve ball and piston

ball are seating properly

Check for leaking around throat packing nut

which may indicated worn or damaged

packings.

Check displacement pump connecting rod

pin (20). See page 17.

Check for frozen or hardened paint in the

pump (39).

Be sure crank in drive housing rotates; plug

in sprayer and turn on briefly to check. T

f and unplug sprayer

of

Determine if sprayer was operated at high

pressure with small tips, which causes low

motor RPM and excessive heat build up.

Be sure ambient temperature where sprayer

is located is no more than 90F and sprayer

is not located in direct sun.

Determine in sprayer was turned on,

pressurized, but not operating for long

periods of time.

.

urn

.

Remove intake valve and clean. Check balls

and seats for nicks; replace if necessary.

See page 14. Strain paint before using to

remove particles that could clog the pump.

Replace packings. See page 13. Also check

piston valve seat for hardened paint or nicks

and replace if necessary

packing nut/wetcup.

Replace pin, if missing. Be sure retainer

spring (35) is fully in groove all around

connecting rod. See Fig. 38, page 17.

Thaw

. See NOTE 1. Plug in sprayer and turn

on. Slowly increase pressure setting to see if

motor starts.

Check drive housing assembly for damage

and replace if necessary

Decrease pressure setting or increase tip

size.

Move sprayer to shaded, cooler area, if

possible.

T

urn of

f sprayer whenever you stop spraying

for a while and relieve fluid pressure.

. T

ighten the

. See page 21.

NOTE 1:

Thaw the sprayer if water or water-based paint has frozen in it, by placing it in a warm area. Do not try to

start the sprayer until it has thawed completely

See page 15.

. If paint hardened (dried) in the sprayer

, replace the pump packings.

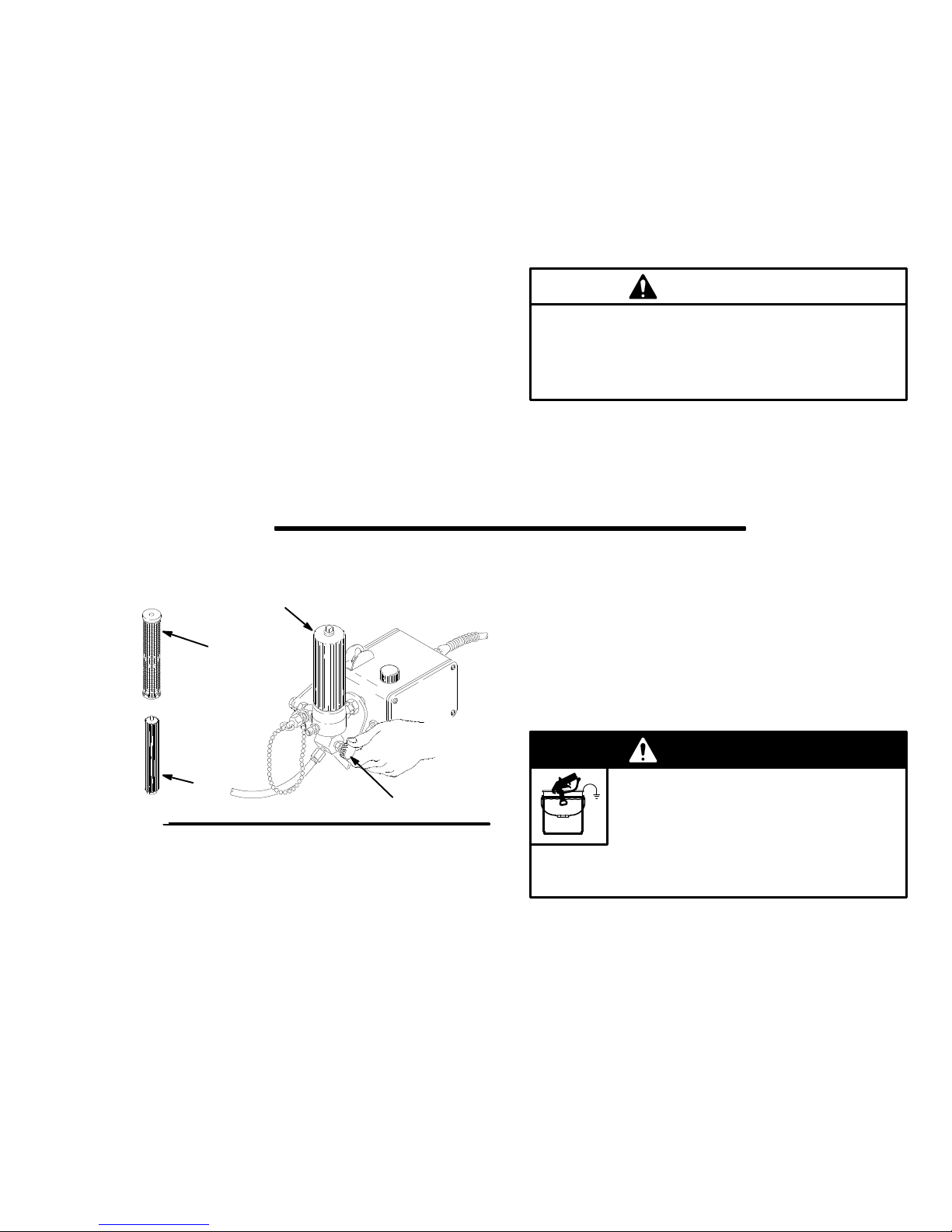

Page 12

Motor

Brush

NOTE: Replace

about 0.4 in (10 mm). Always check both brushes and

replace them together

220–853, and the spring clip, p/n 1

able. Order separately

NOTE:

long as the original ones. To maximize brush life, break

in new brushes by operating the sprayer for at least

one hour with no load (remove the pump connecting

rod pin).

Replacement brushes may last only half as

the brushes when they have worn to

. A Brush Repair Kit, p/n

10–816, are avail

.

-

WARNING

INJECTION HAZARD

T

o reduce the risk of serious injury

whenever you are instructed to relieve

pressure, follow the

Procedure

1.

Remove the motor cover (14) and both inspection

covers (A). See Fig 8.

2.

Push in the spring clip (D) to unhook it, and then

pull it out. See Fig 9.

on page 10.

Pressure Relief

,

9.

Reinstall the remaining parts.

14

Fig. 8

B

Part

1

No.

110–816

A

01891

C

D

1

3.

Loosen

(G) away

the brush (C) and spring (B). See Fig 10.

4.

Inspect the commutator for excessive pitting, burn

ing or gouging. A black color on the commutator is

normal. Have the commutator resurfaced by a

qualified motor repair shop if the brushes seem to

wear too fast.

5.

Install the new brush (C) so its lead is in the long

slot (K) of the holder (H). Slide the terminal (E)

under the terminal screw (F) washer

the motor lead terminal (G) is still connected at the

screw. T

Place the spring (B) on the brush (C) as shown in

6.

Fig 1

7.

Push in and hook the spring clip (D). See Fig 1

8.

Repeat for the other side.

the terminal screw (F). Pull the brush lead

, leaving the motor lead in place. Remove

. Make sure

ighten the screw

1.

. See Fig 1

1.

1.

Fig. 9

B

-

C

E

F

Fig.

10

Note:

1

2

Spring must coil

in this direction

Minimum brush length:

0.4 in. (10 mm)

G

D

H

J

K

C

B

D

CAUTION

Do not run the sprayer dry for more than 30 sec

onds while checking the brushes to avoid damag

ing the displacement pump.

2

-

-

Fig. 11

1

01227

Page 13

Displacement

Pump

Removing the Pump

WARNING

INJECTION

T

o reduce the risk of serious injury

whenever you are instructed to relieve

pressure, follow the

Procedure

1.

Flush the pump, if possible, and relieve pressure

again. Stop the pump with the piston rod in its

lowest position, if possible.

2.

Remove the hose (47), clips and drain tube (101).

Remove the suction tube (42); hold the wrench

on the pump intake valve (223) to keep the pump

from loosening. See Fig. 12.

3.

Push the retaining spring (35) up. See Fig. 13.

4.

Push out the pin (20). See Fig. 14.

on page 10.

HAZARD

Pressure Relief

WARNING

INJECTION HAZARD

Always use the special sleeve removal

tool to remove the sleeve. Other removal

,

ture, resulting in serious bodily injury

cannot be removed easily using the tool, return the

sleeve and cylinder to your Graco distributor for

removal.

Fig. 12

methods could cause the pump to rup

. If the sleeve

101

47

42

-

02553

5.

Loosen the locknut (38) and unscrew the pump

from the bearing housing (27). See Fig. 15.

Tools Needed for Pump Repair

Repair

Kit, P/N 220–877

Sleeve Removal T

Heavy duty vise

1-1/16’

’ open end wrench for Pump 220–872

2-1/4’

’ adjustable, open-end wrench

Plastic mallet

Small screwdriver

Throat Seal Liquid

Thread Sealant

NOTE:

Soak leather packings in oil before installing.

ool, P/N 220–991

Cleaning and Inspecting Parts

Clean

and inspect the parts. Pay particular attention to

the ball seat in the intake valve, which should have no

nicks or wear

outside of the piston rod, which should not be worn or

scratched. Replace worn or damaged parts.

, and to the inside of the sleeve and the

Fig. 13

Fig. 14

02554

02555

Remove and clean the sleeve when you are repacking

the pump. A special sleeve removal tool is available.

See the chart, above, for the tool number for your

pump.

Fig. 15

02556

Page 14

Displacement

Disassembly

NOTE:

220–877, are marked with an asterisk (*) in the text

and drawings. Use all the new parts in the kit.

1.

2.

3.

4. T

5.

6.

Parts included in the Packing Repair Kit, P/N

Loosen the packing nut (216) and remove the plug

(205). Unscrew the cylinder from the intake valve.

See Fig. 16.

Disassemble the intake valve. Use a pick to

remove the old gasket (202). Clean and inspect

the parts. See Fig. 17.

Reassemble the intake valve using a new gasket

(202*), ball (204*) and pin (221*). See Fig. 17.

ap the piston rod (224) out of the cylinder

Fig. 18.

Screw the sleeve removal tool’

the top of the cylinder

the sleeve out. See Fig. 19. Remove the tool.

Clean and inspect the parts.

Clamp the piston rod (224) in a vise. Loosen the

retaining nut (21

(222). See Fig. 20.

. Screw down the rod to push

1). Unscrew the piston valve

s large nut (A) into

. See

Pump

Fig. 18

Fig. 19

224

02561

A

02562

222

211

7.

Disassemble the piston and discard the packings

and glands. See Fig. 21.

8.

Remove and discard the throat packings and

glands from pump cylinder

Fig. 16

*204

*202

. See Fig. 22.

205

216

221*

02558

Fig. 20

Fig. 21

224

02563

02564

Fig. 17

14 308-551

02559

Fig. 22

02565

Page 15

Pump Reassembly

Displacement

Pump

1. Clean

the piston valve threads. One at a time,

stack the backup washer (203*), seal (215*) (with

lips facing down), and female gland (214*) on the

piston. Alternately stack the polyethylene (212*)

and leather (206*) packings (lips facing up) on the

piston. Then install the male gland (210*). See Fig.

23.

2.

Place the flats of the piston valve in a vise. T

the packing retaining nut against the piston valve

to 4 in-lb (0.35 N.m). See Fig. 24.

Note th

nut

3.

e a

. Maintai

lignment o

n this a

f the p

lignmen

isto

t t

hroug

n to the p

h S

tep

acking retainer

s 4 and 5.

Apply one drop of Locktite to the threads. Place

the ball (225*) on the piston valve. See Fig. 25.

4.

While maintaining the alignment, thread the piston

valve assembly into the piston rod just until the

piston valve nut contacts the rod. See Fig. 26.

5.

Place the flats of the rod in a vise. Carefully tighten

the piston valve nut (21

1) against the piston rod to

19 ft-lb (27 N.m). Use two wrenches to maintain

the alignment. See Fig. 27.

ighten

Fig.

25

Fig. 26

*225

02568

02569

6.

Place the male gland (208*) in the cylinder

nately stack the polyethylene (213*) and leather

packings (207*) (lips facing down). Then place the

female gland (209*) in the top of the cylinder

the packings. See Fig. 28.

*210

*212

206*

*214

Fig. 23

Torque

to 4 in-lb

(0.35 N.m)

Fig. 24

. Alter

. Seat

215*

203*

02566

02567

Torque

-

Fig. 27

to 19 ft-lb

(27 N.m)

02570

209*

*207

213*

208*

Fig.

28

02571

Page 16

Displacement

Pump

7. Loosely

install the packing nut (216) and plug

(205). See Fig. 29.

8.

Place a o-ring (217*) in the cylinder

. Slide the

sleeve in to the cylinder to seat the o-ring. See Fig.

30. Remove the sleeve.

9.

Grease the piston packings and the top edge of

the sleeve. See Fig. 31.

10.

Carefully slide the piston assembly into the top of

the sleeve. See Fig. 32.

11.

Slide the sleeve/piston rod assembly into the

bottom of the cylinder

12.

Grease the intake valve o-ring with non-silicon

. See Fig. 33.

grease. Screw the pump cylinder into the intake

valve. T

13. T

orque to 70 ft-lb (95 N.m). See Fig. 34.

ighten the packing nut (216) hand tight. Screw

the cylinder locknut (A) down to the bottom of the

external cylinder threads. See Fig. 35.

02575

Fig. 32

Fig. 29

Fig. 30

217*

205

216

02576

Fig. 33

02572

02577

Fig. 34

02573

216

A

Fig. 31

16 308-551

02574

Fig. 35

02578

Page 17

Installing the Pump

Displacement

Pump

1. Screw

2.

3.

the displacement pump into the bearing

housing (27) until the pin holes align. See Fig. 36.

Install the pin (221*). See Fig. 37.

Continue to screw the pump into the bearing hous

ing until the top threads of the pump cylinder are

flush with the face of the bearing housing and the

outlet nipple is straight back. Push the retaining

spring (35) into the groove all the way around the

connecting rod to prevent it from working loose

due to vibration. See Fig. 38.

WARNING

MOVING P

If the pin works loose, it or other parts

could break of

pumping action. These parts could be

projected through the air and result in serious bodi

ly injury or property damage, including damage to

the pump, connecting rod or bearing housing.

ARTS HAZARD

f due to the force of the

-

Fig. 37

35

-

Fig. 38

221*

02580

02581

4. T

ighten the locknut (38) to 70 ft-lb (97 N.m). See

Fig. 39.

CAUTION

If the locknut (38) loosens during operation, the

threads of the bearing housing (29) will be dam

aged. Be sure to tighten the locknut firmly

ighten the packing nut/ wet-cup just enough to

5. T

stop leakage, but no tighter

ing nut 1/3 full with Graco TSL. See Fig. 40.

. Fill the wet-cup/pack

.

-

Torque

to

70 ft-lb

(97 N.m)

-

Fig. 39

02582

Fig. 36

02579

Fig.

40

02583

308-551 17

Page 18

Pressure

4

6

Control

WARNING

INJECTION

T

o reduce the risk of serious injury

whenever you are instructed to relieve

pressure, follow the

Procedure

NOTE:

1.

Disconnect the hose (47).

2.

Disconnect the drain tube (101) from the drain

valve.

3.

Loosen the outside filter bracket nut (28).

Unscrew the swivel fitting (8) and remove the filter

4.

Remove the pressure control cover (36). Discon

nect the four motor leads. See Fig. 42.

5.

Unscrew the connector (54). Pull the wires out of

the pressure control.

6.

Remove the pressure control mounting screws

(37). Remove the pressure control. Install the con

nector (54) on the new pressure control.

7.

Install the new pressure control. Place the seal

(103) around the motor leads and push the seal

into the connector (54). See Fig. 42.

on page 10.

Refer to Fig. 41 except where noted.

HAZARD

Pressure Relief

41

40

84

,

28

13

28

8

.

-

-

Fig. 41

101

16

47

3

5

22

37

01894

Power

WARNING

INJECTION

T

o reduce the risk of serious injury

whenever you are instructed to relieve

pressure, follow the

Procedure

NOTE:

1.

Relieve pressure.

2.

Remove the back pressure control plate (16).

3.

Remove the pressure control cover

the power supply cord leads. See Fig. 42.

4.

Loosen the strain relief bushing (B). Remove the

power supply cord (23).

5.

Install the new cord.

on page 10.

Refer to Fig. 41 except where noted.

HAZARD

Pressure Relief

. Disconnect

Supply Cord

BACK

,

White

23

Black/

white (+)

Fig. 42

Black

B

Green

Black

FRONT

(–)

103

54

VIEW OF PRESSURE CONTROL

01898

VIEW OF PRESSURE CONTROL

Red

01897

Page 19

WARNING

Procedure

INJECTION

T

o reduce the risk of serious injury

whenever you are instructed to relieve

pressure, follow the

on page 10.

HAZARD

Pressure Relief

CAUTION

T

o avoid damage to the drive housing:

Do not drop the gear cluster (9), which may

stay engaged in the motor bell or in the drive

housing.

Do not lose the thrust balls (10) or drop them

between gears. The balls usually stay in the

shaft recesses, but could be dislodged. If the

balls are not in place, the bearings will wear

prematurely.

1.

Remove the motor shield (14). Remove the front

cover (31). Disconnect the hose (47).

2.

Remove the pressure control cover (36). Discon

nect the four motor leads.

3.

Unscrew the connector (54) from the pressure

control. Pull the wires through the connector

4.

Unscrew the connector (54) from the motor and

remove the conduit (22).

5.

Remove the screws (51) from the recess of the

drive housing.

6.

Remove the screws (21 and 30) from the the mo

tor end bell (F).

18

T

orque to

1

175 in-lb (19 N.m)

Bronze

2

6 oz.

Apply

3

bearing grease

4

Silver

31

32

33

1

27

49

39

Motor

,

-

.

-

18a

4

3

9

2

18b

10

7.

Use a plastic mallet to tap the displacement pump

(39) from the rear to loosen the drive housing (18)

from the motor end bell (F). Pull of

f the drive hous

ing.

8.

Remove the screws (37) holding the motor to the

frame. Lift of

9.

Mount the new motor on the frame.

10.

Slide a connector (54) over the conduit (22) of the

f the motor

.

new motor and screw two or three threads of it into

the motor

11.

Liberally grease the gear cluster (9) and pinion

. T

ighten the locknut (44) up to the motor

gear (G) and pack all bearings in the motor end

bell. Be sure the thrust balls (10) are in place.

(One ball is included with a replacement drive

housing.)

12.

Place the bronze-colored washer (18b) and THEN

the silver-colored washer (18a) on the shaft pro

truding from the big gear in the drive housing (18).

13.

Align the gears and push the drive housing (18)

straight onto the motor bell (F) and locating pins.

14.

Continue to reassemble the sprayer

.

14

64

37

21

63

F

G

10

40

41

-

.

-

54

36,15

30

63

Fig. 43

51

47

63

54

22

308-551 19

Page 20

Bearing

Housing & Connecting Rod

WARNING

INJECTION

T

o reduce the risk of serious injury

whenever you are instructed to relieve

pressure, follow the

Procedure

1

Torque

Lubricate with motor oil

2

Liberally pack roller bearing with bearing grease

3

1

on page 10.

to 175 in-lb (19 N.m)

2

K

27

49

33

3

29

HAZARD

Pressure Relief

18

H

J

NOTE: Stop

get the crank (H) in its lowest position.T

crank manually

a screwdriver

,

1.

Remove the pump. See page 13.

2.

Remove the front cover (31). Remove the bearing

housing screws (33).

3. T

ap the lower rear of the bearing housing (27) with

a plastic mallet to loosen it from the drive housing

(18). Pull the bearing housing and the connecting

rod (29) straight of

4.

Remove the pail bracket assembly (L) and reinstall

it on the new bearing housing.

5.

Inspect the crank (H) for excessive wear and re

place parts as needed.

6.

Evenly lubricate the inside of the bronze bearing

(K) with motor oil. Liberally pack the roller bearing

(J) with bearing grease.

7.

Slide the connecting rod (29) into the bearing

housing (27).

the sprayer at the bottom of its stroke to

o lower the

, rotate the blades of the motor fan with

.

f the drive housing.

-

Fig. 44

32

31

8.

Clean the mating surfaces of the bearing and drive

housings.

L

02654

9.

Align the connecting rod with the crank (H) and

align the locating pins in the drive housing with the

holes in the bearing housing (27). Push the bear

ing housing onto the drive housing or tap it into

place with a plastic mallet.

10.

Install the bearing housing screws (33). T

evenly to 175 in-lb (19 N.m).

11.

Reinstall all parts. See page 17 to install the pump.

-

orque

Page 21

Drive

WARNING

INJECTION

T

o reduce the risk of serious injury

whenever you are instructed to relieve

pressure, follow the

Procedure

NOTE:

get the crank (H) in its lowest position. T

manually

screwdriver.

1.

Remove the front cover (31). Remove the motor

shield (14).

2.

Disconnect the pump outlet hose (47).

3.

Remove the screws (33) from the bearing housing.

4.

Lightly tap the lower rear of the bearing housing

(27) with a plastic mallet to loosen it from the drive

housing (18). Pull the bearing housing and con

necting rod assembly straight of

5.

Remove the screws (51) from the recess of the

drive housing.

on page 10.

Stop the sprayer at the bottom of its stroke to

, carefully rotate the blades of the fan with a

HAZARD

Pressure Relief

o lower it

f the drive housing.

Housing

7. T

,

8.

-

9.

10.

ap the drive housing (18) with a plastic mallet to

loosen it from the motor end bell, then pull it

straight of

f.

CAUTION

T

o avoid damage to the drive housing:

Do not drop the gear cluster (9), which may

stay engaged in the motor bell or in the drive

housing.

Do not lose the thrust balls (10) or drop them

between gears. The balls usually stay in the

shaft recesses, but could be dislodged. If the

balls are not in place, the bearings will wear

prematurely.

Use approximately 6 oz. of the bearing grease

supplied with the drive housing replacement kit to

grease the gear cluster (9). Check to be sure the

thrust balls (10) are in place.

Place the bronze-colored washer (18b) and THEN

the silver-colored washer (18a) on the shaft pro

truding from the big gear in the drive housing (18).

Align the gears and push the new drive housing

straight onto the motor bell and locating pins.

-

6.

Remove the screws (30 and 21) from the motor

end bell (F).

T

orque to

1

175 in-lb (19 N.m)

Bronze

2

Apply

3

4

31

6 oz. bearing grease

Silver

49

1

33

27

2

18b

18

H

11.

Continue to reassemble the sprayer

screws (33) to 175 in-lb (19 N.m).

64

21

63

F

4

3

10

18a

9

10

63

51

. T

orque the

14

64

30

63

32

Fig. 45

47

01896

Page 22

46

28

13

28

85

34

71,

77

107

Sprayer

84

16

95

88

Parts Drawing

92

43

23

87

15

37

98

3

6

14

32

4

12

31

33

49

27

Ref 101

29

18

46

10

50

18b

48

9

69

8

18a

57

10

51

37

1

99

41

40

63

63

21

97

37

64

109

54

22

30

63

40

41

2

82

64

91

81

64

35

100

101

102

20

75

38

39

42

7

19

47

108

53

Ref

37

60

26

58

11

Page 23

Sprayer Parts List

Model

223–773, Series A

Basic Sprayer

Ref.

No. Part No. Description Qty.

1 220–854 MOTOR KIT

, CSA certified, Includes items 1–109

Includes 1 of item 92

2 290–058

3 290–059

4 290–057

6 220–636 CART 1

7 187–147 STRAINER 1

8 155–665

9 220–637 GEAR REDUCER 1

10 100–069

11 104–811 HUBCAP 2

12 220–285 CAP 1

13 100–322 LOCKW

14

15

16 185–539 BRACKET

18 220–879 DRIVE HOUSING KIT

223–153 MOTOR SHIELD KIT 1

110–037 SCREW

LABEL, identification, motor cover

LABEL, identification, motor cover

LABEL, identification, front cover

UNION, adapter; 3/8” npsm swivel

x 3/8 npt(m)

BALL, steel; 1/4” dia.

ASHER, ext., 7/16”

, pnh; 10–24 type C x 1/2”

, mounting

Includes items 18 a and 18b,

and one of item 10

18a 183–209 BEARING, thrust 1

18b 106–227 SPACER 1

19 186–227 HANGER, pail 1

20 183–210

21 100–644 SCREW

22

23 POWER SUPPLY CORD

24 107–264

26 154–636 WASHER 2

27 220–639 BEARING HOUSING KIT 1

28 150–513 NUT

29 220–640 CONNECTING ROD KIT 1

30 100–643 SCREW

31 183–168

32 108–850

33

34

35 183–169

36 185–000 COVER, pressure control 1

37 110–963 CAPSCREW

38 183–170 NUT

39 220–872 DISPLACEMENT PUMP

40 100–214 LOCKW

41 100–188 NUT

42 183–423 TUBE, INTAKE 1

065–312 CONDUIT, electrical, 13 in.

238–342

238–167

110–141 CAPSCREW

186–374 ADAPTER, elbow

PIN, straight, 3/8 x 1–1/8”

, soc head, no. 1/4–20 x 3/4”

For Models 231–351, 231–352

For Model 223–773

TERMINAL, female

, jam; 7/16”

, socket head, no. 1/4–20 x 1”

COVER, housing 1

SCREW

1/4–18 npt(m x f)

SPRING, retaining

5/16–18 x 3/4”

, filh; no. 8–32 x 1–1/4”

, sch; 3/8–16 x 1–1/5”

, special;

, flange head,

, hex, 1 13/16 unc–2b

see page 24

ASHER, spring; 5/16”

, heavy hex; 5/16–18 unc–2a

Ref.

No. Part No. Description Qty.

43 PRESSURE CONTROL KIT 1

includes

items 13, 16, 23, 2 of 28, 34,4 of 84

223–803 NEW

223–804 REBUILT

224–018 NEW

46

1

47 220–849

1

48 214–570

1

1

49 106–115 LOCKWASHER,

50 221–077 PRESSURE DRAIN VALVE 1

51 108–849 CAPSCREW

1

53 108–691

54 108–460 CONNECTOR 2

1

56 102–556 RIVET

57 178–034 TAG, WARNING 1

58 101–242

1

59 206–994 THROA

60 179–81

4

63

1

64 108–865 SCREW

69 110–814 NUT

71 177–762

1

75 183–461

77 290–060 LABEL, IDENTIFICATION 1

81 185–384 BRACKET 2

82 110–240 NUT 2

1

84 106–078 SCREW

2

85 100–040 PLUG 1

1

87 106–170 BUSHING, strain relief 1

88 185–565

1

89 100–035 SCREW

1

2

90 157–021 LOCKWASHER,

162–453

1

105–510

KIT

,

for

Models 231–351 & 231–352

KIT

,

for Models 231–351

& 231–352

KIT

,

for

Sprayer 223–773

NIPPLE, hex; 1/4 npsm x 1/4 npt,

1–3/16” long

HOSE, 3/8 npsm(f) x 14–1/2”

FLUID FIL

see

includes one of items 46 and 85

PLUG, tubing

RING, retaining

WHEEL 2

LOCKW

LABEL, W

ADAPTER; 3/8 npsm x 1/4 npt

LABEL, control

inside

TER

manual 307–273 for parts

spring; 3/8”

, sch; 1/4–20 x 3”

, blind; 1/8” dia.

T SEAL L

ASHER, spring, 1/4”

, pnh; 8–32 x 3/8”

, retainer

, flat hd; 10–24 x 3/8”

, pnh; 8–32 x 5/16”

pressure control

IQUI

D 8 oz. (

ARNING 1

internal, No. 8

inside pressure control

91 100–020 LOCKWASHER, .194” ID 2

2

92

93 110–619

2

95 178–035

97 185–951 LABEL, DANGER 1

4

98 185–952 LABEL, DANGER 2

4

99 185–955 LABEL, DANGER 1

100 186–490 CLIP

1

101 186–495

1

102 181–102 CLIP

103 107–447 SEAL 2

107 112–152 SWITCH, circuit breaker

7

108 105–659 BOOT

1

1

109 113–605 BOOT

7

7

187–656

105–679

GASKET 2

LABEL, Caution

LABEL, Caution

, spring

TUBE, drain

, spring

, toggle

SWITCH, toggle

, circuit breaker 1

Replacement Danger and W

arning labels, tags and cards

are available at no cost.

0.2

7 l

, 1

10V 1

1

1

1

2

1

1

4

2

2

2

2

iter) 1

6

10

2

1

4

1

1

1

1

1

1

1

1

1

1

Page 24

Displacement

Model

220–872, Series A

Displacement Pump

Includes items 202 to 225

Pump Parts Drawing and List

205

Ref.

No. Part No. Description Qty.

202* 107–098 PACKING, o-ring, PTFE 1

203* 108–690

204* 108–775 BALL; sst 1

205 183–171 PLUG 1

206* 183–174 V-P

207* 183–175 V-P

208* 183–176

209* 183–177

210* 183–178

211

212* 183–182 V-PACKING, plastic 3

213* 183–183 V-PACKING, plastic 3

214* 183–653 WASHER, backup 1

215* 183–185

216

217* 183–172 O-RING, PTFE 1

218

219

220

221* 183–173

222

223

224

225* 101–947

*

183–179

183–186

183–361

183–181

183–180

220–631

220–629

220–630

These parts are also included in Repair Kit 220–877,

which may be purchased separately

SEAL, u–cup, polyurethane

ACKING, leather

ACKING, leather

GLAND, male

GLAND, female

GLAND, male

NUT

, hex, retaining

GLAND, female

NUT

, packing

SLEEVE, cylinder 1

CYLINDER 1

GUIDE, ball 1

PIN, ball stop

VAL

VE, piston

VAL

VE, intake

ROD, piston 1

BALL

.

216

224

209*

1

225*

2

2

1

1

1

*207

1

1

1

213*

208*

*212

211

210*

206*

219

1

1

1

1

215*

203*

214*

222

SLEEVE

REMOV

AL T

OOL 220–991

Use to remove a sleeve that is stuck.

Purchase separately

.

217*

218

220

*204

*202

221*

223

Page 25

Accessories

DANGER

LABELS

The English language DANGER label shown on

page 1 is also on your sprayer

. If you have paint

ers who do not read English, order one of the fol

lowing labels to apply to your sprayer

. The draw

ing below shows the best placement of these la

bels for good visibility

.

Order the labels directly from Graco, free of

charge. T

oll Free:

1–800–367–4023

French 185–956

Spanish 185–961

German 186–041

Greek 186–045

Korean 186–049

English 185–953

Apply

language here

MOT

OR BRUSH KIT

DISPLACEMENT PUMP P

other

220–853

ACKING KIT

220–877

See contents on page 24.

SUCTION

TUBE KIT

208–259

55 gallon (200 liter) size

-

-

-

-

Includes:

Ref

No. Part No. Description Qty

1 156–589 UNION, 90

2 214–961

3 156–591 ELBOW

4 156–593 P

5 100–220 THUMBSCREW

6 176–684

7 156–592 TUBE, riser 1

8 159–100 RETAINER, screen 1

9 161–377 SCREEN, filter 1

10 159–101 NUT

HOSE, cpld 3/4 npt(mbe); 3/4” ID; nylon;

6 ft (1.8 m); spring guard one end

ACKING, o-ring, nitrile

ADAPTER, bung

, screen retainer

;3/4 npt(f) x 3/4 npt(f) sw

, 90; 3/4 npt x 1–1/2 – 24 ns

, 5/16–18 X 1”

1

1

1

1

1

1

2

3

4

6

5

7

SUCTION TUBE KIT

208–920

5 gallon (19 liter) size

Includes:

Ref

No. Part No. Description Qty

1 101–818 CLAMP

2 160–327 UNION, 90

3 170–705 ADAPTER, intake 1

4 170–706 HOSE, 1” ID x 48”; nylon 1

5 170–957 TUBE, suction 1

6 181–072 STRAINER 1

, hose

swIvel; 3/4 npt(m x f)

5

4

6

1

2

3

8

9

10

2

1

1

Page 26

Notes

Page 27

Technical

Power

Requirements (full output)

W

orking Pressure Range

Cycles/Gallon (liter)

Power

Cord

.

. . . . . . . . . . . . . . .

Inlet

Paint Strainer

Outlet Paint Filter

Pump Inlet Size

Fluid

Outlet Size

Wetted Parts:

Displacement Pump

Filter

.

. . . . . . . . . .

.

. . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . .

Data

120 V

. . . . . . . .

1

phase, 18 amp minimum

.

. . . . . . . . . . . . . . . . . . .

(0–21.0

.

. . . . . . . . . . . . . . . . . . . . . . . . .

No. 12 A

.

. . . . . . . . . . . . . . .

Stainless

Stainless

.

. . . . . . .

Polyethylene,

Aluminum, Carbon steel, Stainless steel,

Carbon steel, Polyurethane,

MPa, 0 – 210 bar)

WG, 3 wire, 10’ (3 m)

16 mesh (1

steel screen, reusable

60 mesh (250 micron)

steel screen, reusable

1/4 npsm from fluid filter

PTFE,

AC, 60Hz,.

0–3000 psi

104 (27.5)

190 micron)

3/4 npt(m)

Delrin, Leather

Weight

Height

Length

Width

Dimensions

122 lb (55.5 kg)

32 in. (813 mm)

24.25 in. (616 mm)

22.5 in. (572 mm)

NOTE:

the DuPont Company

Delrin is a registered trademark of

.

Page 28

Graco

Graco

warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date

of sale by an authorized Graco distributor to the original purchaser for use. With the exception of any special, extended, or limited

warranty

determined

dance

This

faulty

stitution

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the

installation,

This

verification

equipment

in

transportation.

THIS

NOT

published

with Graco’

warranty does not cover

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or sub

of non–Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

material or

will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

W

ARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER W

LIMITED T

by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment

by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accor

s written recommendations.

, and Graco shall not be liable

operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor

O WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Standard W

for general wear and tear

ARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

arranty

, or any malfunction, damage or wear caused by

improper design, manufacture,

, and

-

-

Graco’s

remedy (including, but not limited to, incidental or consequential damages for lost

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two

date

Graco

with

by

purchaser

In

hereunder,

breach

FOR GRACO CANADA CUSTOMERS

The

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnais

sent

exécutés,

sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above.

of sale.

makes no warranty

accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

Graco (such as electric motors, switches, hose, etc.), are subject to the warranty

with reasonable assistance in making any claim for breach of these warranties.

no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

TO

or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

of warranty

parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

PLACE AN ORDER

, and disclaims all implied warranties of merchantability and fitness for a particular purpose in

, the negligence of Graco, or otherwise.

Graco

, contact your Graco distributor

Phone Number

, or call this number to identify the distributor closest to you:

1–800–367–4023 T

oll Free.

profits,

lost sales, injury to person or property

, if any

, of their manufacturer

The buyer agrees that no other

(2)

. Graco will provide

, or any

years of the

connection

-

Manual

Models

All

written and visual data contained in this document reflects the latest product information available at the time of publication.

Foreign Offices:

231–351 and 231–352 are obsolete and were removed from this manual.

Graco reserves the right to make changes at any time without notice.

Sales Offices:

Belgium, Canada, England, Korea, France, Germany

GRACO INC. P.O. BOX 1441

PRINTED

IN U.S.A. 308–551 December 1994, Revised December 1997

Change Summary

Minneapolis, Detroit, Los Angeles

MINNEAPOLIS, MN

http://www.graco.com

, Hong Kong, Japan

55440–1441

Loading...

Loading...