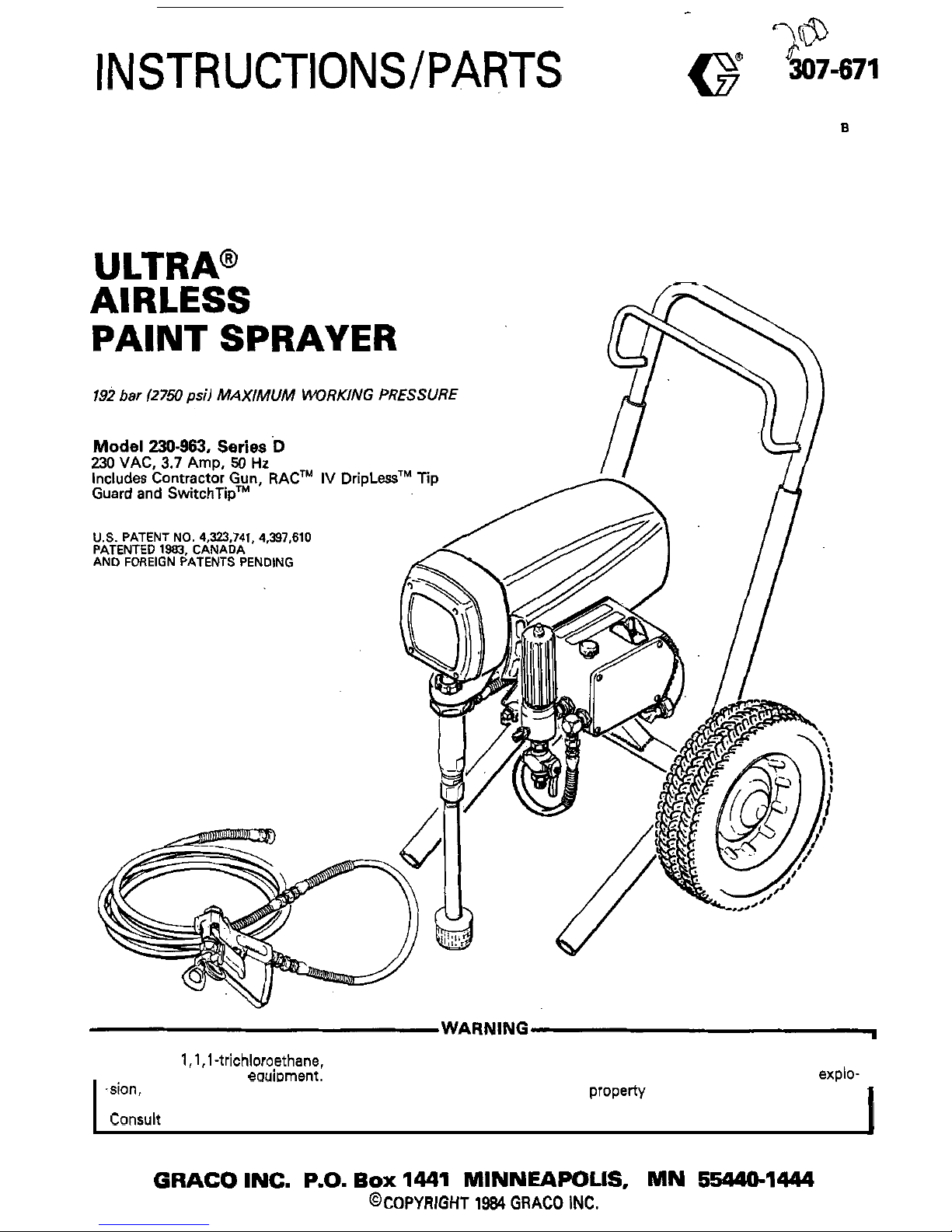

Page 1

INSTRUCTIONS/PARTS LIST

e

507-671

ORACO

Rev

D

SUPERSEDES

A

and

PCN

B

This

manual contains

IMPORTANT

WARNINGS

and

INSTRUCTIONS

READ

AND

RETAIN

FOR

REFERENCE

ULTRA@

400

I

Hazard

of

Using Fluids Containing Halogenated Hydrocarbons

such solvents in this

eauimnent. Such use could result in a serious chemical reaction, with the possibility

of

explo-

Never use l,l,l-tnchloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids containing

I

.sion, which could cause death, serious bodily injury and/or substantial property damage.

Consult your fluid suppliers to ensure that the fluids being used are compatible with aluminum and zinc

parts.

Page 2

INDEX

WARNINGS

..................................................

2

.

3

SETUP

.............................................................

5

INTRODUCTION

................................................

4

OPERATION;

.................................................

6. 7

SHUTDOWN 8 CARE

.........................................

7

TROUBLESHOOTING GUIDE

FLUSHING GUIDELINES

8

.....................................

Motor Won't Operate

...................................

9-11

Low output

..................................................

12

No

Output

...............................................

12. 13

Excessive Pressure Fluctuations

.........................

13

Motor

Is

Hot and Runs Intermittently

..................

13

Electrical Short

......................................

:

.......

14

Spin Test

.....................................................

15

Bridge Test

16

General Repair Notes

...................................... 17

Power Supply Cord Replacement

18

List of Tools

17

Filter Replacement

.........................................

18

ON/OFF Switch Replacement

...........................

19

...................................................

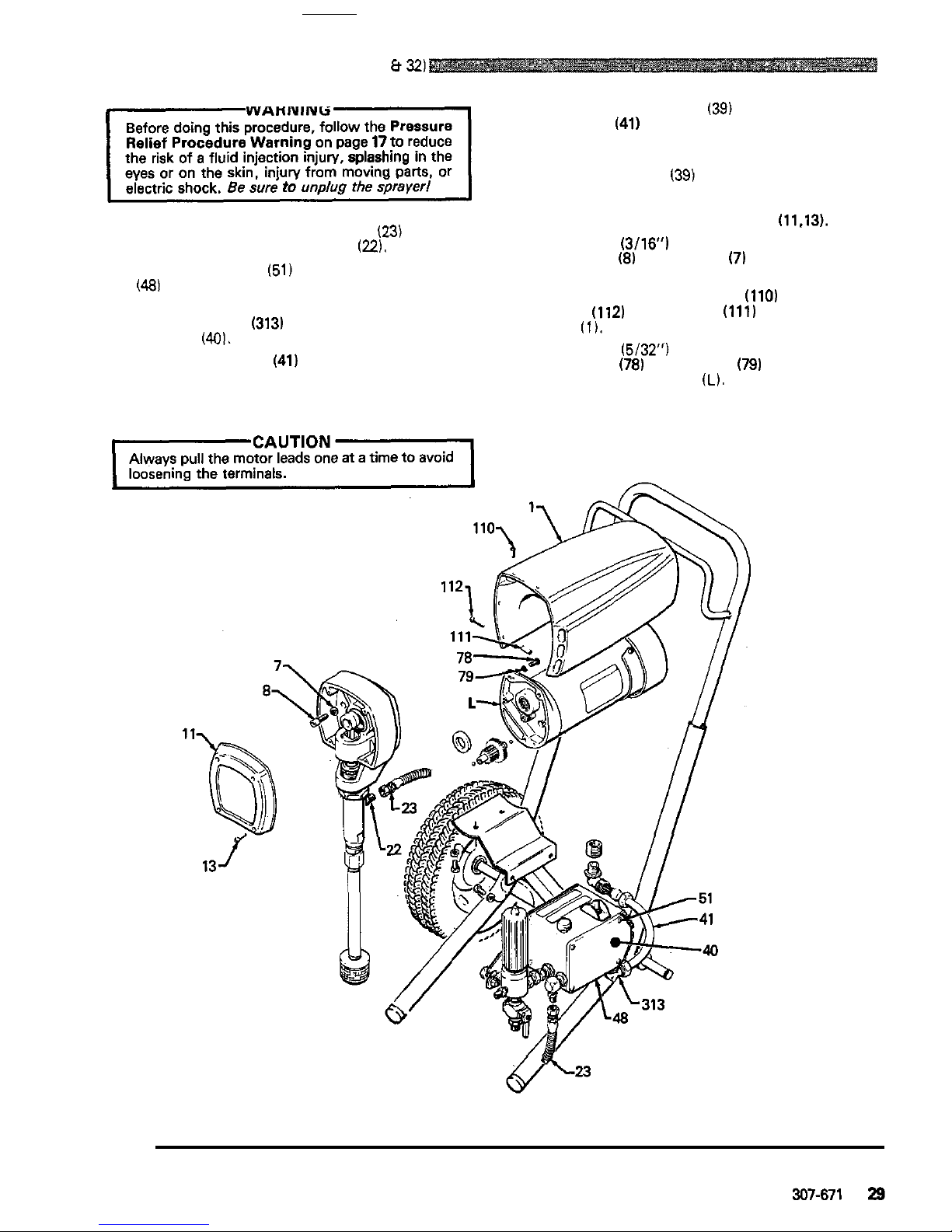

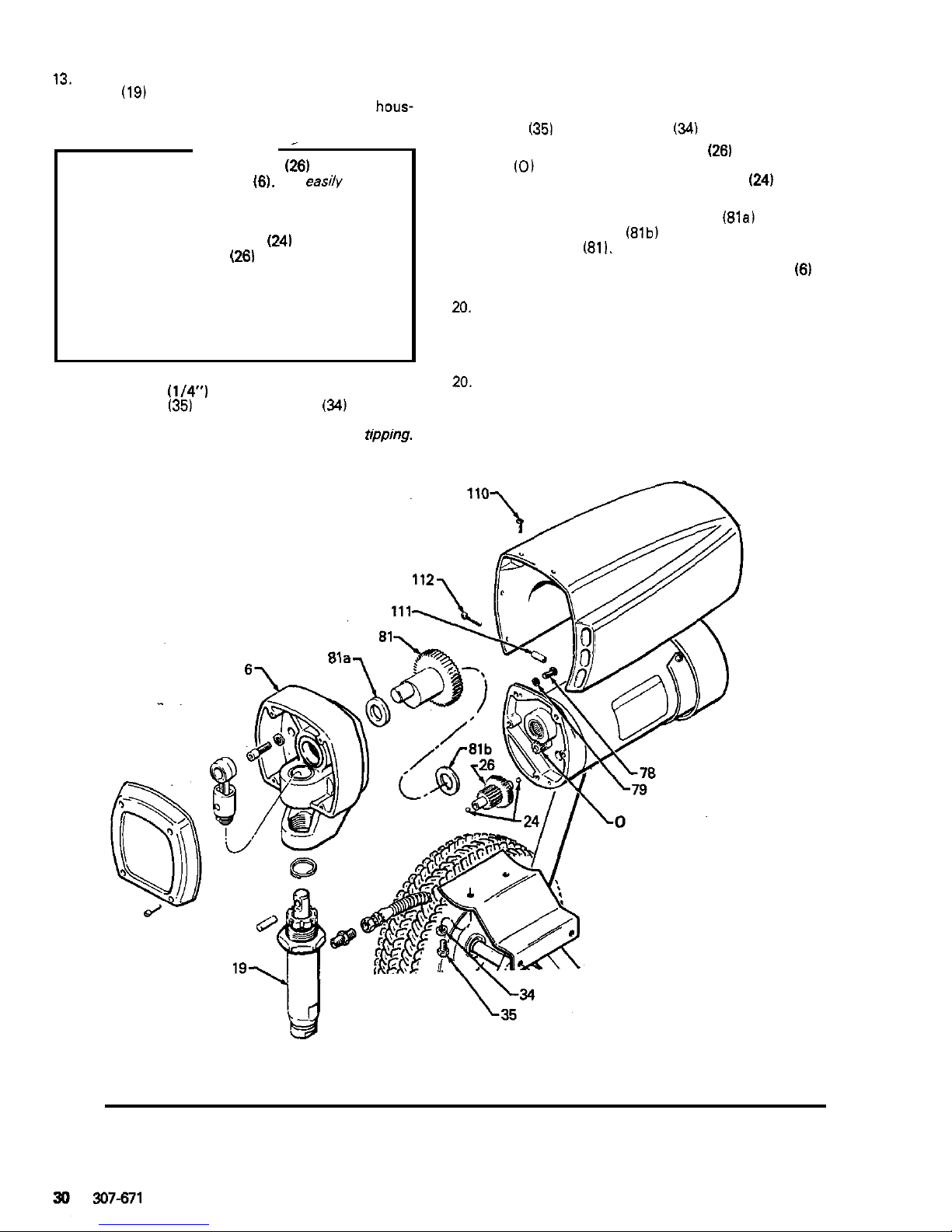

REPAIR SECTION

..................................................

.......................

Microswitch Replacement

................................

19

Bridge Rectifier Replacement

............................

20

Choke Replacement

........................................

21

Varistor Replacement

......................................

21

Pressure Control Replacement

23

Circuit Board Replacement

22

Stall Pressure Calibration

.................................

24

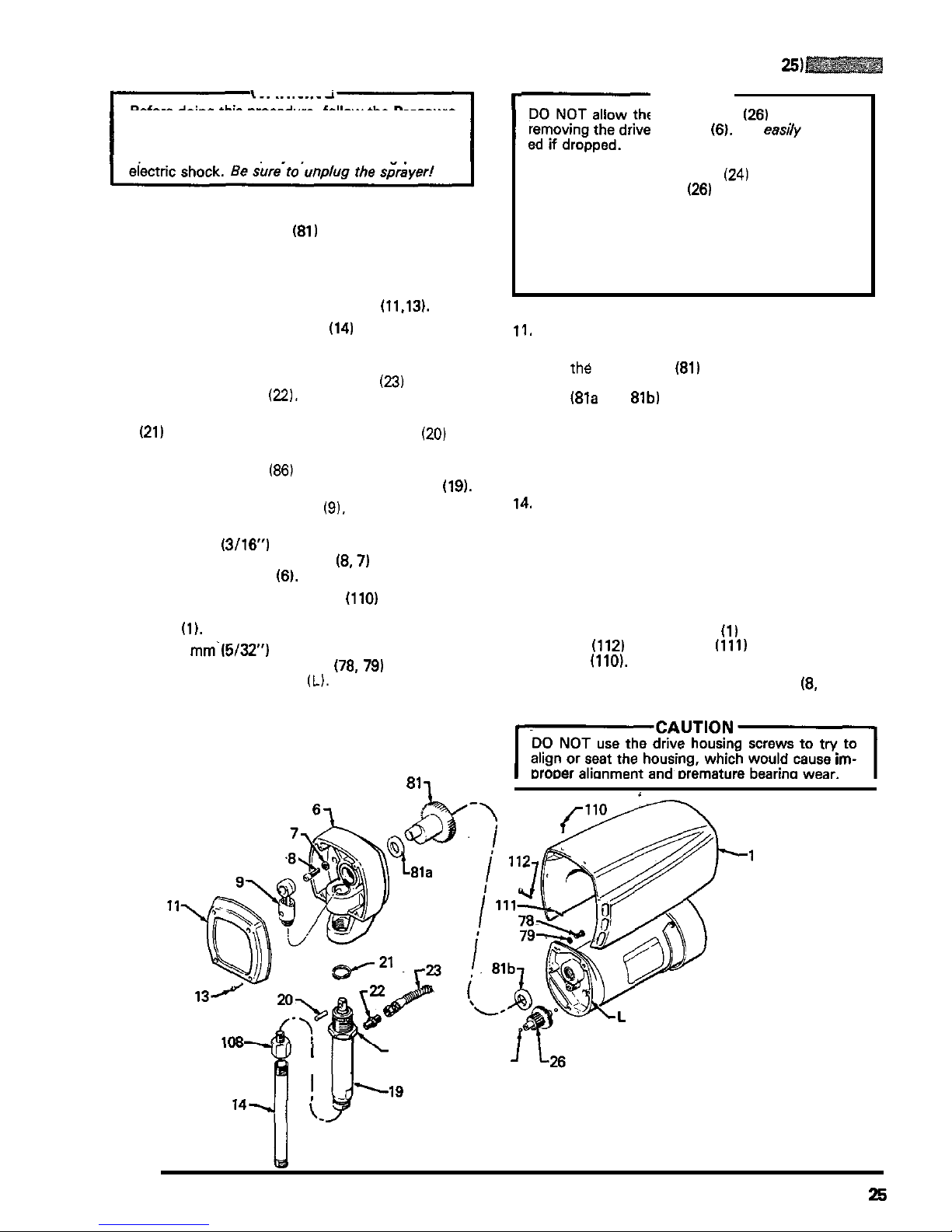

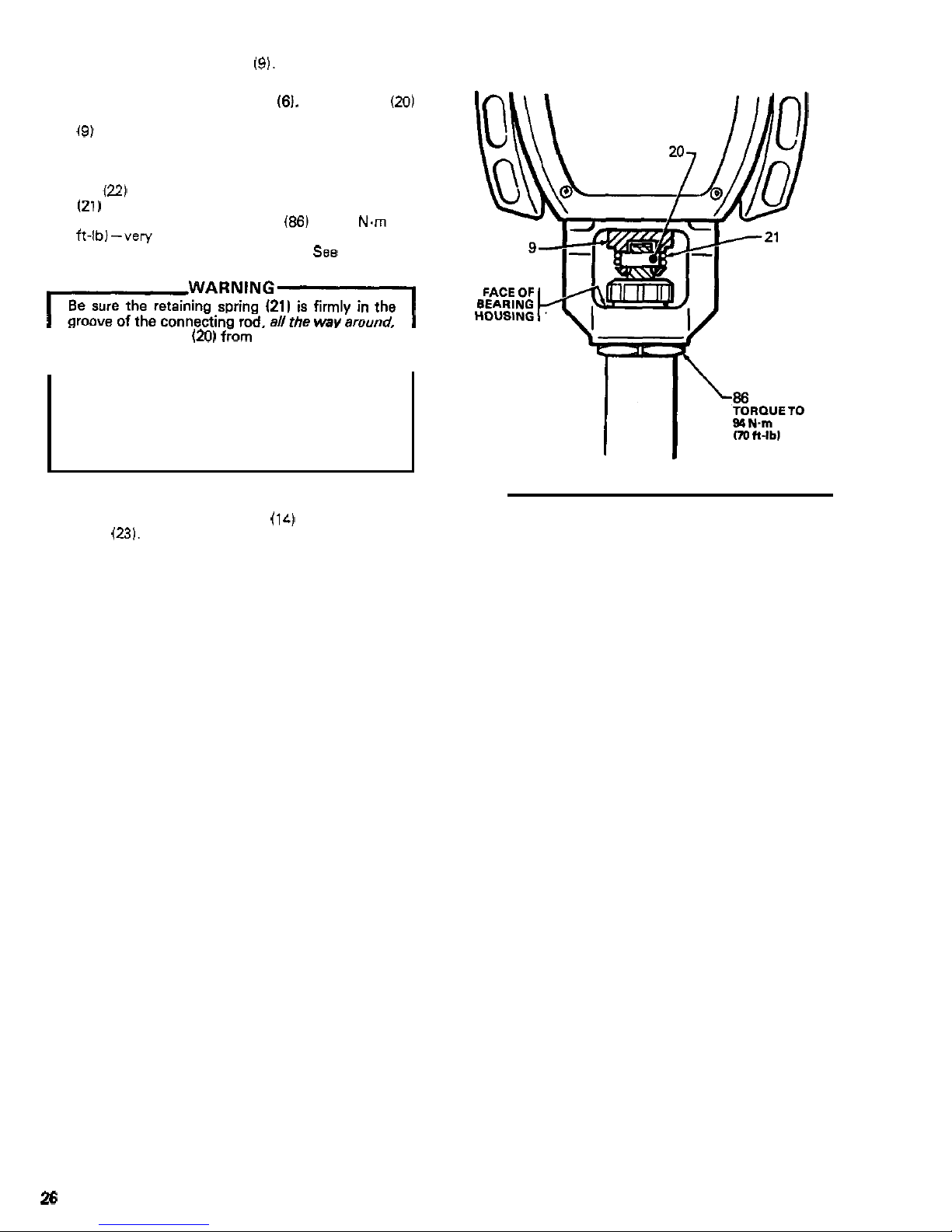

Connecting Rod. Drive Housing or Crankshaft

Replacement

............................................

25. 26

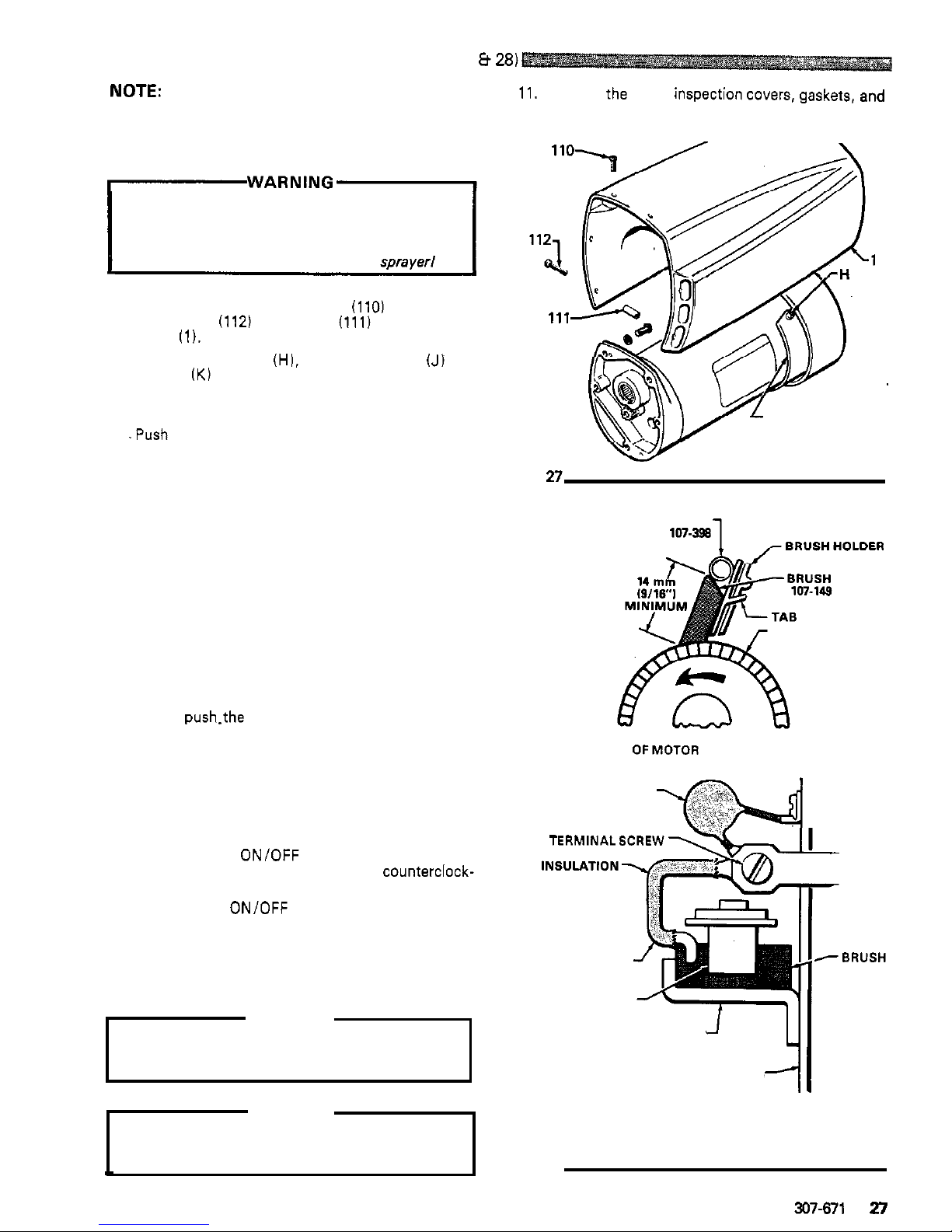

Motor Brush Replacement

................................

27

Motor Capacitor Replacement

...........................

28

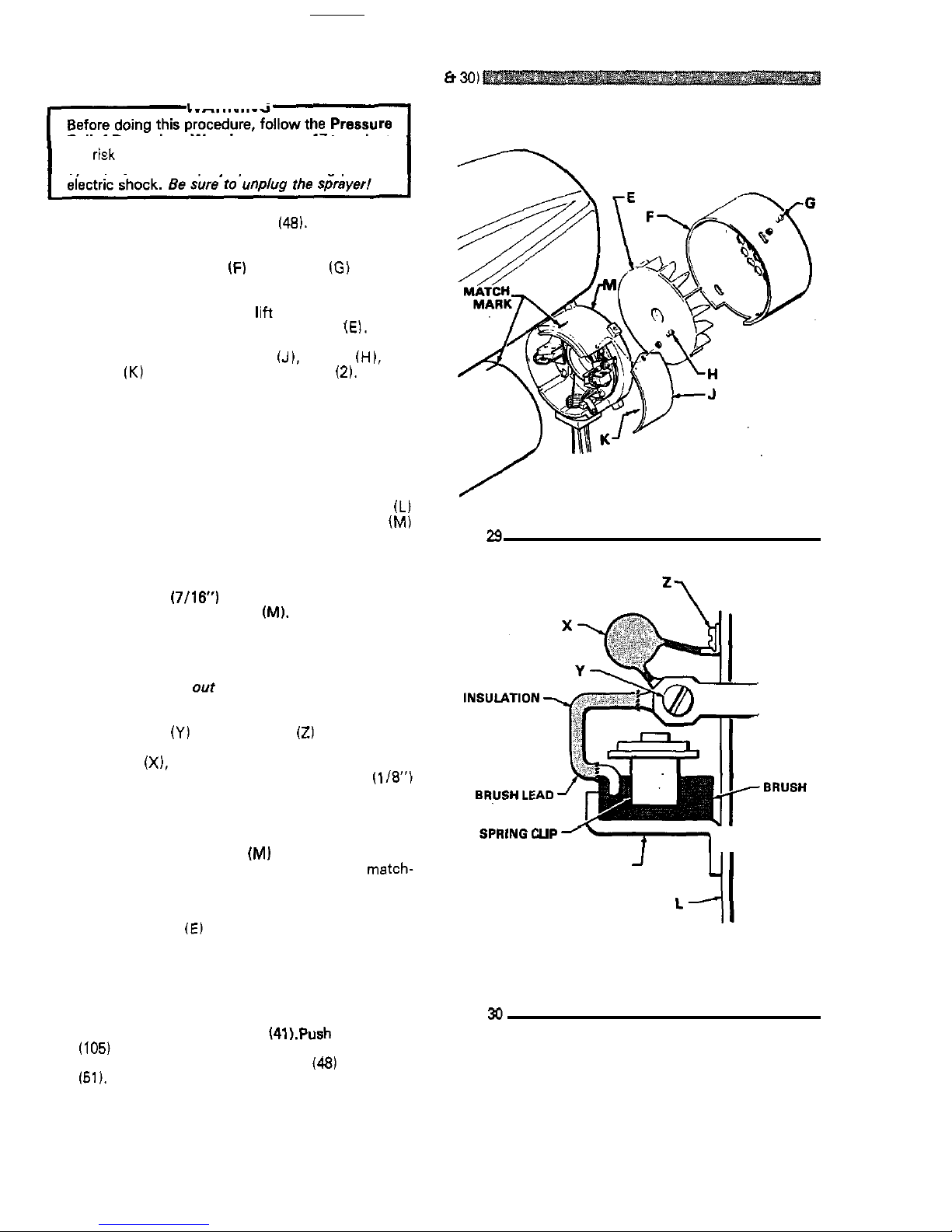

Motor Replacement

...................................

29.

30

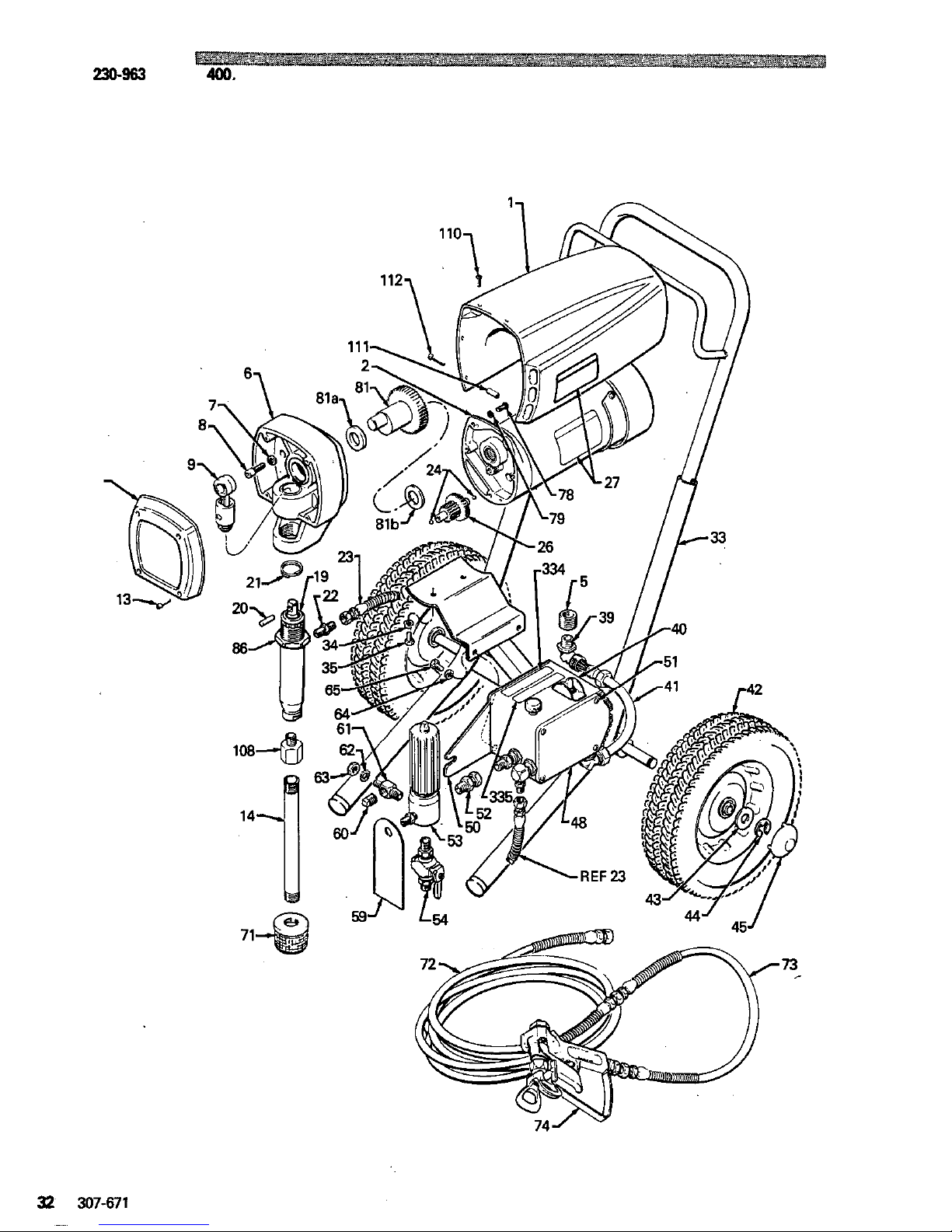

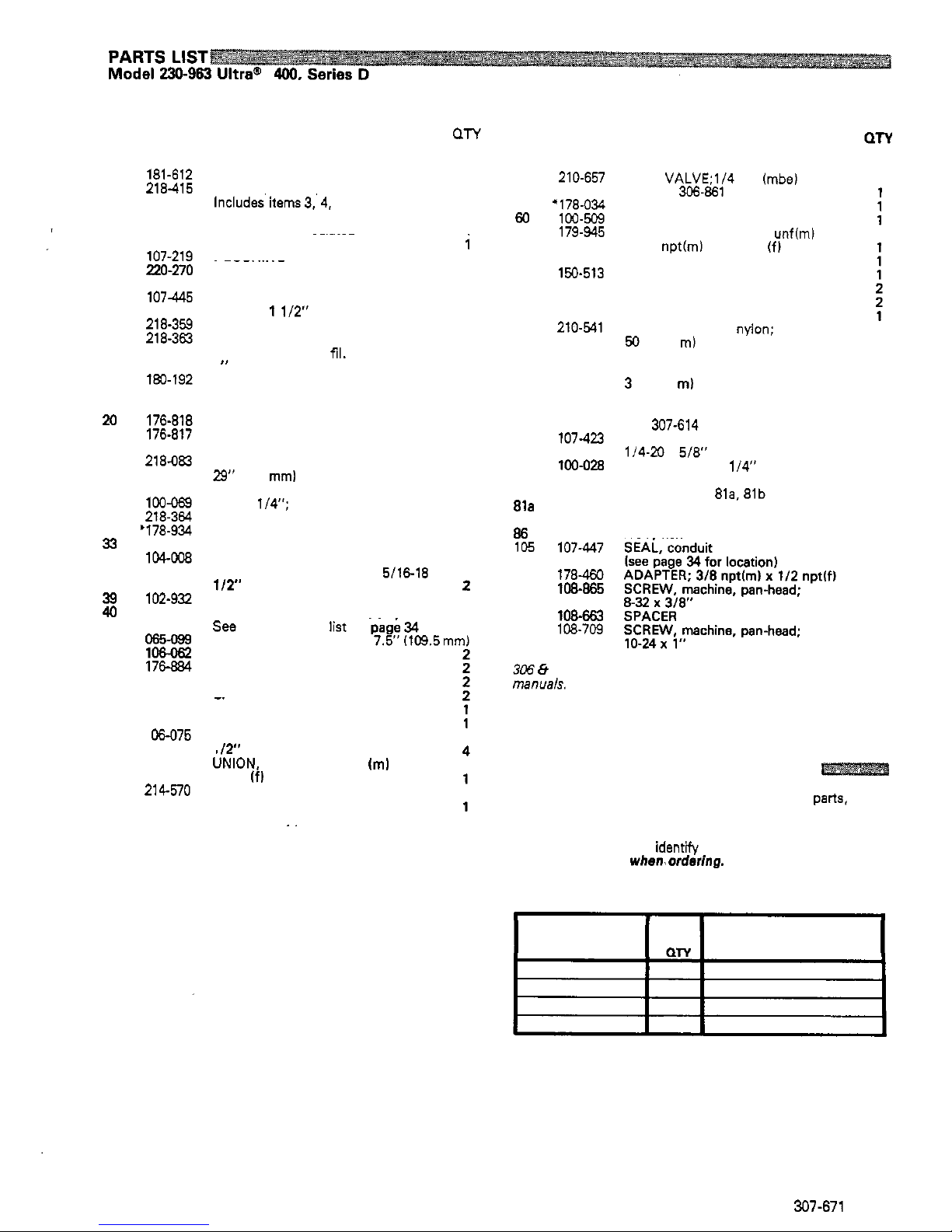

Sprayer

..................................................

32.

33

Pressure Control

.......................................

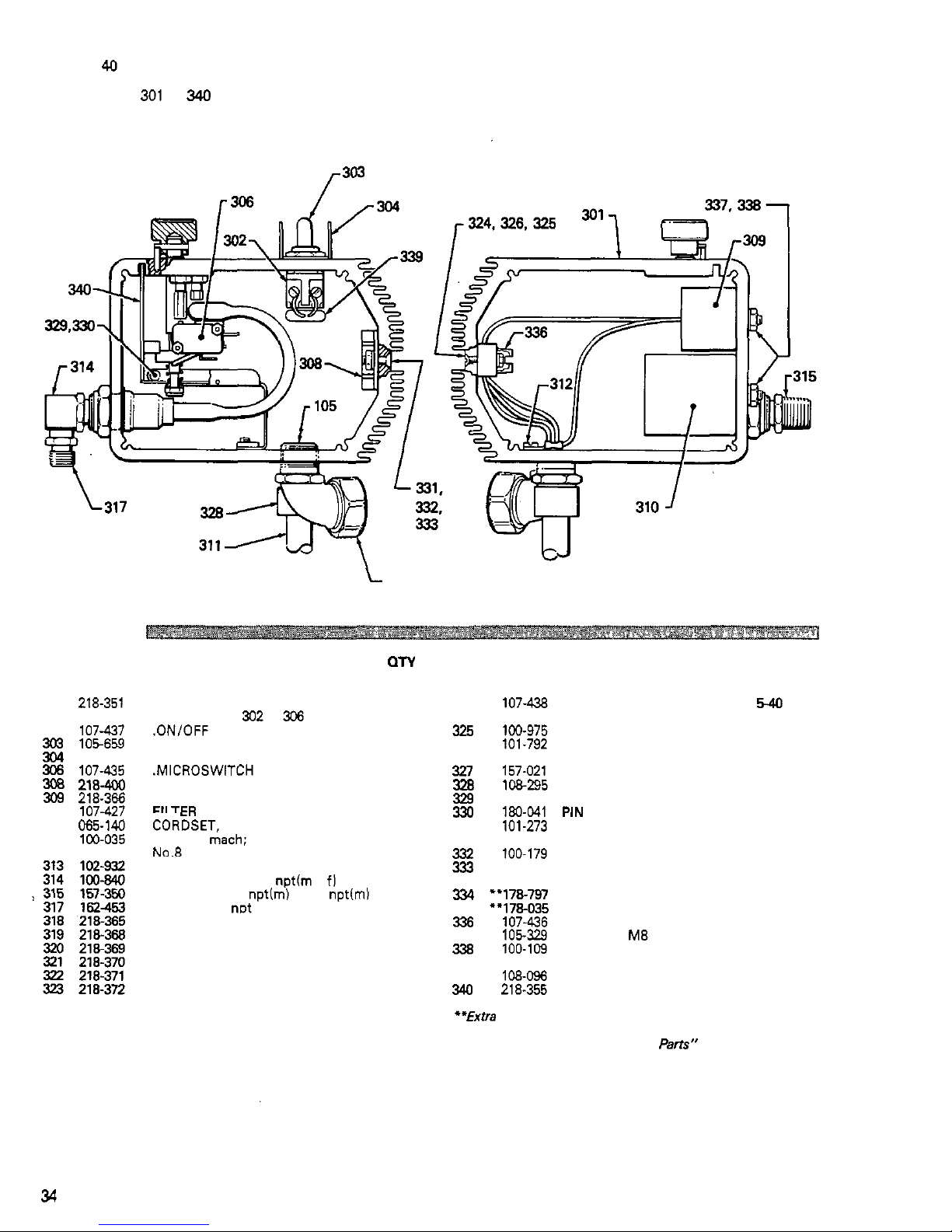

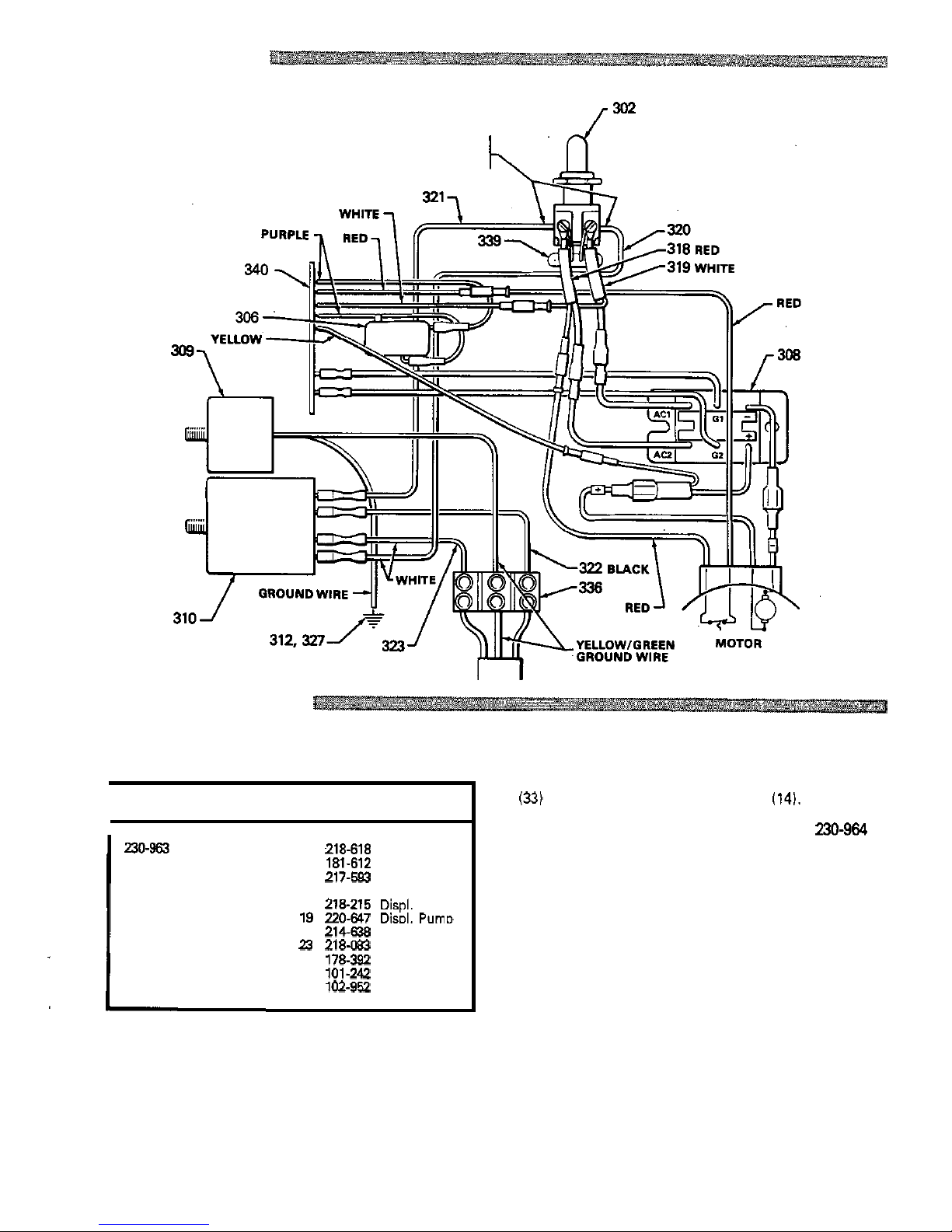

34.

35

TECHNICAL DATA Back Cover

How To Order Replacement Parts

33

NOTE:

See manual

307.793.

supplied. for the

displacement pump repair instructions and

parts list

.

...............................

..........................

PARTS LISTS 8 DRAWINGS

......................

...............................

307-671

1

Page 3

HIGH

PRESSURE SPRAY CAN CAUSE EXTREMELY SERIOUS INJURY.

FOR

PROFESSIONAL

USE

ONLY.

OBSERVE

ALL

WARNINGS.

Read

and

understand

all

instruction

manuals,

tags,

and

warnings

before

operating

equipment.

FLUID INJECTION

HAZARD

General Safety

This equipment generates very high fluid pressure. Spray from

the gun, leaks or ruptured components can inject fluid

through your skin and into your body and cause extremely

serious bodily injury, including the need for amputation. Also,

fluid injected or splashed into the eyes or onto the skin can

cause serious damage.

NEVER point the spray gun at anyone or any part of the body.

NEVER put hand or fingers over the spray tip. NEVER try to

“blow back” paint; this is NOT an air spray system.

spraying.

ALWAYS have the

tip

guard in place on the spray gun when

ALWAYS follow the Pressure Relief Procedure. below.

before cleaning or removing the spray tip or servicing any

system equipment.

~.

~~ ~

NEVER try to.stop or deflect leaks

with

your hand or body.

before each use.

Be sure equipment safety devices are operating properly

Medical Alert

-

Airless

Spray

Wounds

If any fluid appears to penetrate your skin, get

EMERGENCY

MEDICAL CARE AT ONCE.

DO

NOT TREAT AS A

SIMPLE CUT.

Tell the doctor exactly what fluid was injected.

jury.

It

Is

important

to

treat the

injury surgically as

soon

Note

to

Physician: injection

in

the skin is a traumatic

in-

as possible.

Do

not delay treatment to research toxiciry.

Toxicity

is

a

concern

with

some exotic coatings injected

directly into the blood stream. Consultation with a plastic

surgeon or reconstructive hand surgeon may be advisable.

Spray Gun Safety

Devices

Be sure

all

gun safety devices are operating properly before

each use. Do not remove or

modify

any part of the gun; this

can cause

a

malfunction and result

in

serious bodily injury.

Whenever you stop spraying, even for a moment, always set

Safety

Latch

the gun safety latch in the closed or “safe” position, making

the gun inoperative. Failure to set the safety latch can result

in

accidental triggering of the gun.

The gun diffuser breaks up spray and reduces the risk of fluid

Diffuser

injection when the tip is not installed. Check diffuser operation

regularly. Follow the Pressure Relief Procedure, below,

then remove the spray tip. Aim the gun into

a

metal

pail,

holding the gun firmly to the pail. Using the lowest possible

to an irregular stream, replace

the diffuser immediately.

pressure, trigger the gun. If the fluid emitted is not diffused

in-

Tip

Guard

ALWAYS have the tip guard in place on the spray gun while

spraying. The tip guard alerts you to the fluid injection hazard

and helps reduce, but does not prevent, the risk of accidental

ly placing your fingers or any part of your body close to the

spray tip.

Spray

Tip

Safety

the spray tip clogs while spraying, engage the gun safety latch

Use extreme caution when cleaning or changing spray tips.

If

immediately. ALWAYS follow the Pressure Relief Pro

-

cedure and then remove the spray tip to clean

it.

fully relieved

and the gun safety

latch is engaged.

NEVER wipe

off

build-up around the spray tip

until

pressure is

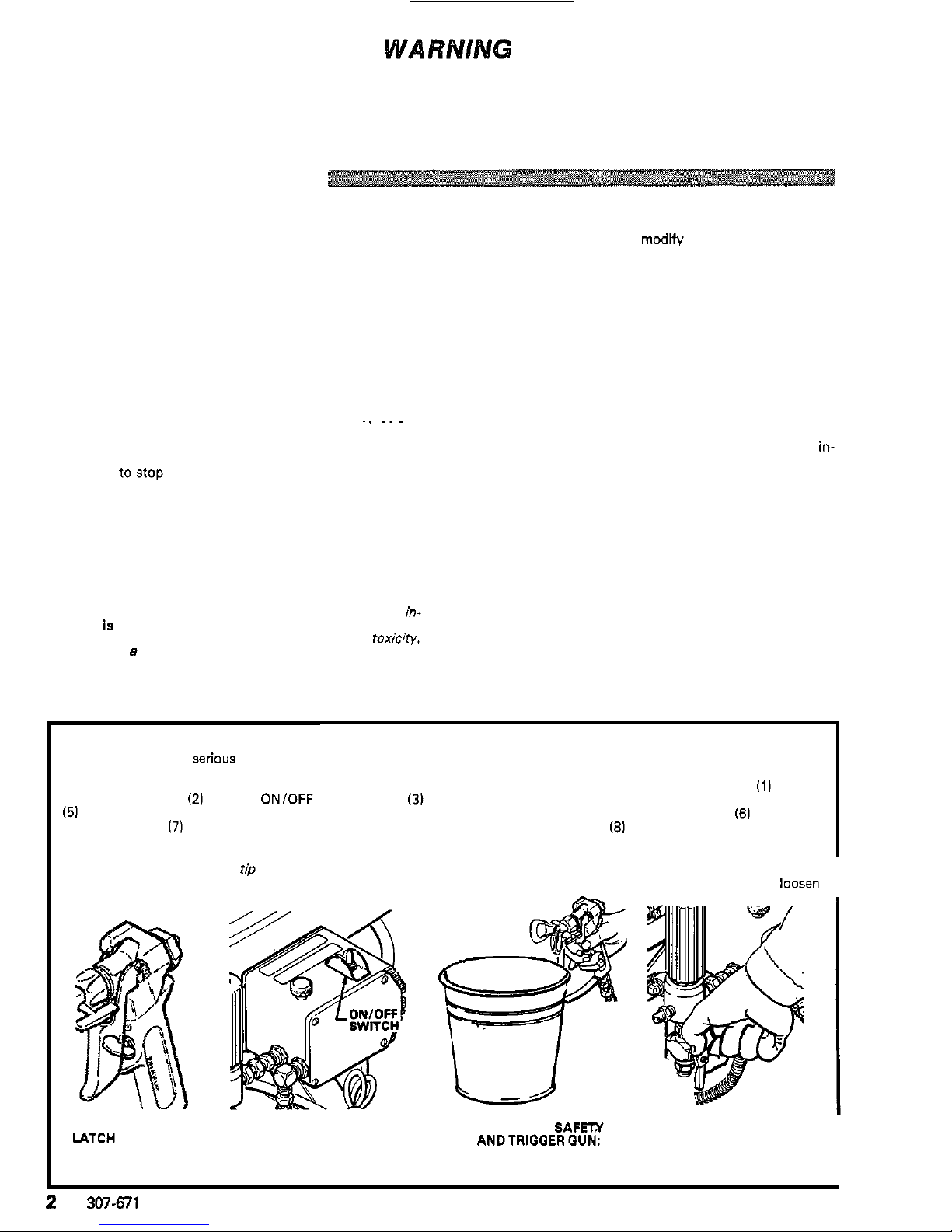

Pressure

Relief

Procedure

To reduce the risk of serious bodily injury, including fluid injection, injury from splashing fluid or solvent

in

the eyes or on the

skin, moving parts or electric shock, always follow this procedure whenever you shut

off

the sprayer, when checking or servic

-

ing any part of the spray system, when installing, cleaning or changing spray tips, and whenever you stop spraying.

(1

1

Engage

the gun safety latch.

(21

Turn the ON/OFF switch to OFF.

(31

Unplug the power supply cord.

(4)

Disengage the gun safety latch.

gun safety latch.

17)

Open the drain valve, having a container ready to catch the drainage.

181

Leave the drain valve open until

(51

Hold a metal pan

of

the gun firmly to the side of a grounded metal pail, and trigger the gun to relieve pressure.

(61

Engage the

you are ready to spray again.

steps above, VERY SLOWLY loosen the tip guard retaining nut or hose end coupling and relieve pressure gradually, then

loosen

If

you

suspect that the spray

tip

or hose

is

completely clogged, or that pressure has not been

fully

relieved after following the

completely. Now clear the

tip

or hose.

I

~~

ENGAGE SAFETY

TURN

SWITCH

TO OFF

IATCH

UNPLUG

CORD

DISENGAGE SAFETX

ANDTRIGGERQUN:

ENGAGE SAFETY AGAIN

OPEN DRAIN VALVE

I

2

307-671

Page 4

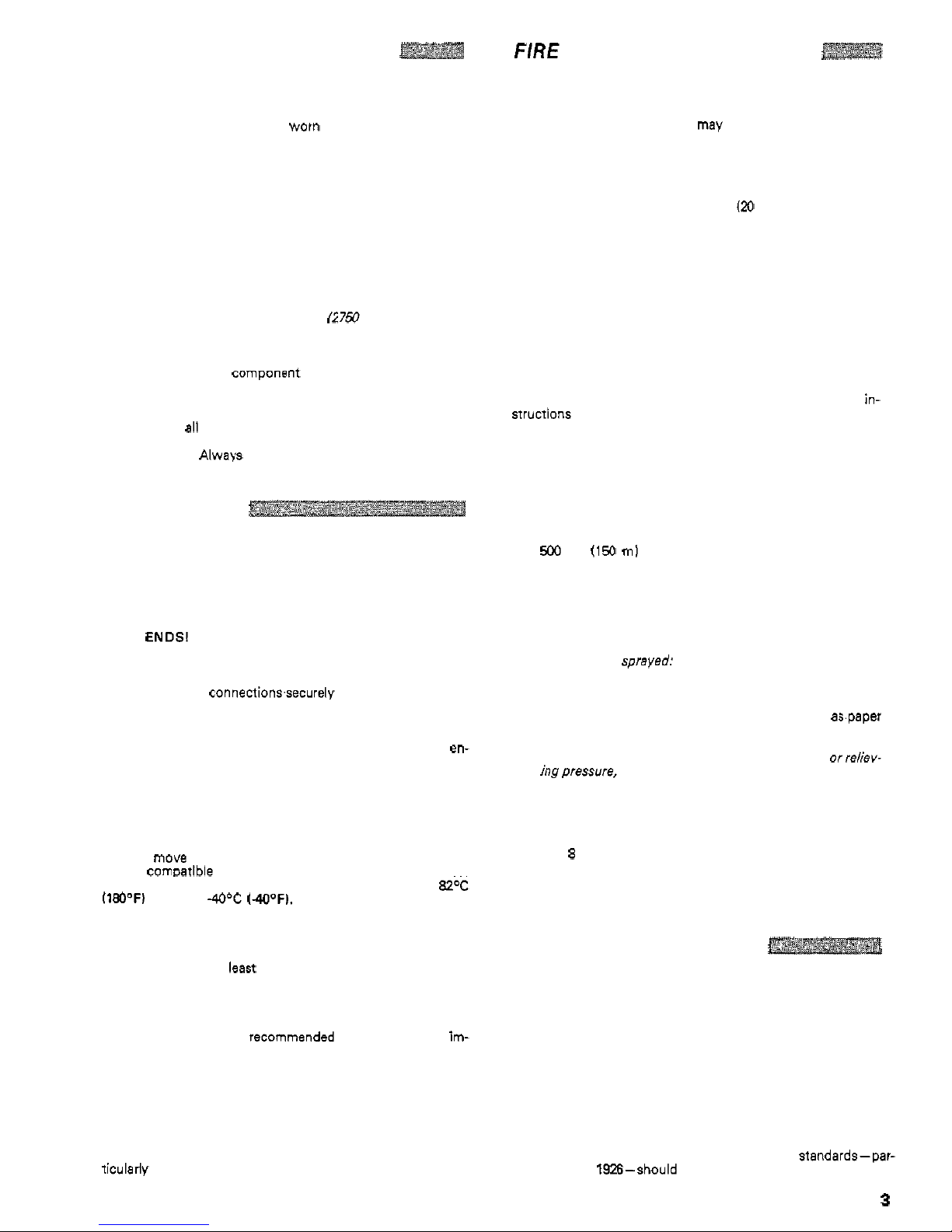

EQUIPMENT MISUSE HAZARD

General Safety

Any misuse of the spray equipment or accessories, such as

overpressurizing, modifying parts, using incompatible

chemicals and fluids, or using

worn or damaged parts, can

cause them to rupture and result

in

fluid injection or other

serious bodily injury, fire, explosion or property damage.

could cause

it

to malfunction.

NEVER alter or modify any part of this equipment; doing

so

CHECK

all

spray equipment regularly and repair or replace

worn or damaged parts immediately.

Read and follow the fluid and solvent manufacturer's literature

regarding the use of protective clothing and equipment.

,

System Pressure

This sprayer can develop

192

bar

(2750

psi) MAXIMUM

WORKING

PRESSURE.

Be sure that all spray equipment and

accessories are rated to withstand the maximum working

pressure

of

this sprayer. DO NOT exceed the maximum work

ing pressure of any component or accessory used in the

system.

Fluid Compatibility

BE SURE that

a11 fluids and solvents used are chemically com

-

patible with the wetted parts shown

in

the Technical Data on

the back cover.

Always read the fluid and solvent manufac

-

turer's literature before using them in this sprayer.

HOSE SAFETY

High pressure fluid

in

the hoses can be very dangerous.' If the

hose develops

a

leak, split or rupture due to any kind of wear,

damage or misuse, the high pressure spray emitted from

it

can

cause a fluid injection injury or other serious bodily injury or

property damage.

ALL FLUID HOSES MUST HAVE SPRING GUARDS ON

kinks or bends at or close to the coupling which can result in

BOTH

ENDS1 The spring guards help protect the hose from

hose rupture.

TIGHTEN all fluid

connections.securely before each use. High

pressure fluid can dislodge

a

loose coupling or allow high

pressure spray to be emitted from the coupling.

tire hose for cuts, leaks, abrasion, bulging cover, or damage or

NEVER use a damaged hose. Before each use, check the

en-

movement of the hose couplings.

If

any of these conditions

exist, replace the hose immediately.

DO

NOT try to recouple

high pressure hose or mend

it

with tape or any other device.

A

repaired hose cannot contain the high pressure fluid.

HANDLE AND ROUTE HOSES CAREFULLY. Do

not

pull on

hoses to

move equipment.

Do

not use fluids or solvents which

are not

comoatible with the inner tube and cover of the hose.

DO NOT expose Graco hose to temperatures above

820C

1180°F) or below -4OOC (-4OOF).

Hose

Grounding

Continuity

Proper hose grounding continuity is essential to maintaining a

grounded spray system. Check the electrical resistance of your

air and

fluid

hoses at least once a week. If your hose does not

have a tag on

it

which specifies the maximum electrical

resistance, contact the hose supplier ormanufacturer for the

maximum resistance limits. Use a resistance meter in the ap

propriate range for your hose to check the resistance. If the

resistance exceeds the

recommended limits, replace

it

im-

your system hazardous. Also read FIRE

OR

EXPLOSION

mediately. An ungrounded or poorly grounded hose can make

HAZARD.

FIRE

OR

EXPLOSION HAZARD

Static electricity is created by the flow of fluid through the

pump and hose.

If

every pan of the spray equipment is not

properly grounded, sparking may occur, and the system may

become hazardous. Sparking

may also occur when plugging

in or unplugging a power supply cord. Sparks can ignite fumes

from solvents and the fluid being sprayed, dust particles and

other flammable substances. whether you are spraying in

doors or outdoors, and can cause a fire or explosion and

serious bodily injury and property damage. Always plug the

sprayer into an outlet at least

6

m

I20

feet) away from the

sprayer and the spray area. Do not plug in or unplug any

power supply cords in the spray area when there is any chance

of igniting fumes still in the air.

If you experience any static sparking or even a slight shock

while using this equipment, STOP SPRAYING IMMEDI

-

ATELY. Check the entire system for proper grounding. Do not

use the system again until the problem has been identified and

corrected.

Grounding

To reduce the risk of static sparking, ground the sprayer and

all other spray equipment used or located

in

the spray area.

structions for your area and type of equipment, BE SURE to

CHECK your local electrical code for detailed grounding

in-

ground all of this spray equipment:

1.

2.

3.

4.

5.

6.

7.

Sprayer: plug the power supply cord, or extension cord,

each equipped with an undamaged three

-

prong plug, into

a properly grounded outlet. Do not use an adapter. All ex

-

tension cords must have three wires and be rated for

15

amps.

Fluid

hoses: use only grounded hoses with a maximum of

500

feet

1150

m) combined hose length to ensure ground

-

ing continuity. Refer to Hose Grounding Continuity.

Spray

gun:

obtain grounding through connection to a

properly grounded fluid hose and sprayer.

Fluid

supply container: according to local code.

Object being

Sprayed: according to local code.

All solvent pails used when flushing, according to local

code. Use only metalpails, which are conductive. Do not

place the pail on a non

-

conductive surface, such aspaper

or cardboard, which interrupts the grounding continuity.

To

maintain grounding continuity when flushing orreliev-

ingpressure, always hold a metal part of the gun firmly to

the side of a grounded metal pail, then trigger the gun.

Flushing Safety

Reduce the risk of fluid injection injury, static sparking, or

splashing by following the specific flushing procedure given

on page

0

of this manual. Follow the Pressure Relief Pro

-

cedure on page

2,

and remove the spray

tip

before flushing.

and use the

lowest possible fluid pressure

during flushing.

Hold a metal

part of the gun

firmly to the

side of

a metal pail

MOVING PARTS HAZARD

Moving parts can pinch or amputate your fingers or other

body parts. KEEP CLEAR of moving parts when starting or

operating the sprayer. Unplug the sprayer, and follow the

Pressure Relief Procedure on page

2

to prevent

it

from star

-

ting accidentally.

IMPORTANT

ticularly the General Standards, Part

1910,

and the Construction Standards, Pan 1926-should be consulted.

United States Government safety standards

have been adopted under the Occupational Safety and Health Act. These

standards-par-

307-671

3

Page 5

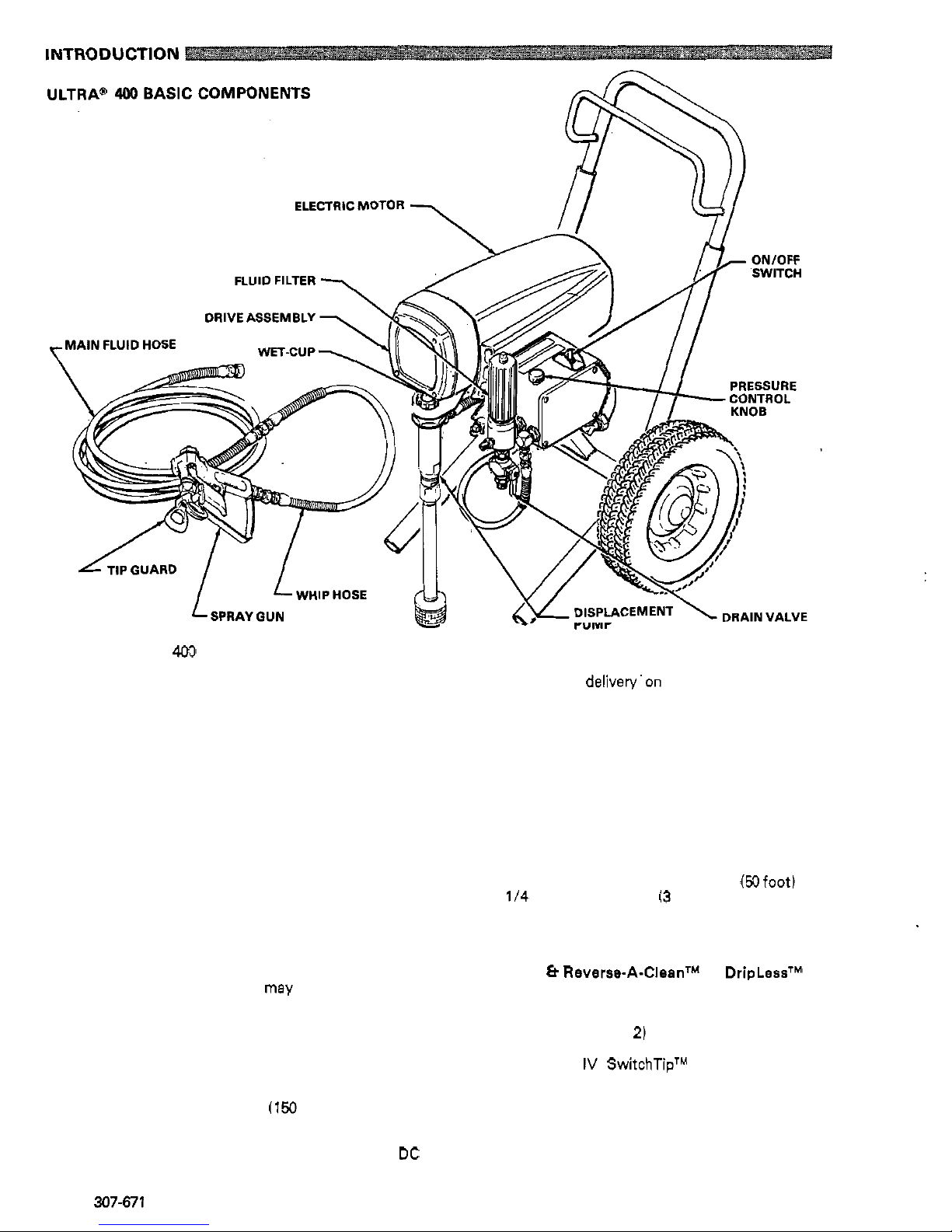

Your new Ultra

"

400

Sprayer functions and operates

differently than other airless paint sprayers. This section

will

help

you

become familiar with the sprayer before

operating

it.

Pressure Control

The pressure control includes an

ONlOFF

switch for the

sprayer, the pressure adjusting control knob, and

a

pressure sensing device.

Its

function is to control the

motor speed

so

that the sprayer maintains constant

fluid pressure

at

the pump outlet.

The DC motor has sealed bearings and replaceable

Motor

motor brushes.

Its

function

is

to drive the displacement

volume

at

the selected pressure.

pump

at

the rate needed to supply sufficient .paint

Working together, the pressure control and motor

cause

the pump to cycle whenever there is fluid or

pressure demand. When the pump is cycling, the motor

sounds like an automobile starter cranking. When the

pump is not cycling, the motor

may hum intermittently

shut itself off. However, there will

still

be power to the

until the fluid pressure stabilizes, then the motor will

sprayer and

it

will stay pressurized and ready to use

unless you manually shut

it

off

and relieve pressure.

Because the motor

is

DC,

it

is less sensitive to low

voltage or voltage fluctuations than an AC motor, and

an extension cord of up to

45

m

(150

feet) can be used.

The sealed drive assembly transfers power from the

DC

Drive Assembly

motor to the displacement pump.

4

307-671

Displacement Pump

The positive displacement, volume

-

balanced pump pro

vides equal fluid delivery'on both the up and down

pump strokes. The pump has a wet-cup which, when

filled with Graco Throat Seal Liquid, helps prevent

damage to the throat packings and piston rod.

Fluid Filter

The fluid filter provides the final paint straining to help

avoid clogs in the hose and spray tip. The filter includes

a

reusable element and a drain valve for relieving fluid

pressure when shutting

off

the sprayer.

Two grounded, nylon spray hoses with spring guards

Hoses

are included with the sprayer. The

15.2

m (50foot) hose

hose allows flexible gun movement. The nylon hose

has

a

114

in. ID. The

0.9

m

(3

foot),

3/16

in. ID whip

material acts

as a

pulsation dampener to absorb

pressure fluctuations.

Spray Gun

&

Reverse-A-CleanTM IV DripLessTM Tip

The spray gun includes

a

trigger safety latch which

Guard

prevents accidental triggering when

it

is engaged (see

the WARNING on page

2)

and a trigger guard which

prevents accidental triggering if the gun is dropped. The

Reverse

-A-

Clean

IV

SwitchTipTM uses high pressure

fluid to remove clogs from the spray tip without remov

-

ing

it

from the gun.

It

includes a safety tip guard which

helps reduce the risk of fluid injection injury.

Page 6

SETUP

1.

Connect

Hose

and Gun (Refer

to

Fig

1.)

NOTE:

When tightening fittings at the pressure control, hold one wrench firmly on the hex of

the pressure control fitting

to

keep

it

from

rotating. Use another wrench

to

tighten the

mating fitting.

a. Remove the plastic cap plug from the filter

outlet nipple and tightly screw the

15.2

m

(50

ft)

fluid hose onto the nipple.

b. Tightly connect the whip hose between the

c. Don't use thread sealant on swivel couplings.

The sealant can prevent the swivel from

rotating freely.

fluid hose and the gun inlet connection.

d. Don't install the spray tip

yet1

IcAUTioNl

To avoid damaging the pressure control, which

may result in poor equipment performance and

component damage, follow these precautlons:

1.

2.

3.

4.

Always use nylon spray hose

at

least

15.2

m

(50

ft)

long.

to act

as a pulsation dampener.

Never use a wire braid hose as it

is

too rigid

Never install any shutoff device between

the filter and the main hose. See

Flg

1.

Always use the main filter outlet for one-

gun operation. Never plug this outlet.

~~

2.

Fill Packing Nutiwet-Cup

(See

Fig

2.)

Throat Seal Liquid (TSL), supplied.

Fill

the packing nut/wet-cup

1/3

full with Graco

3.

Check Electrical Service

a.

Be

sure the electrical service is properly rated

for your sprayer and that the outlet you use

Is

properly grounded.

b. Attach an appropriate plug to the power supply

cord, according

to

your local electrical codes.

c. Use an extension cord which has

3

wires of

a

minimum

12

gauge size, and a maximum of

45

m

(150

ft)

long. Longer lengths may affect

sprayer performance.

4.

Plug

in

the Sprayer

a.

Be sure the ONlOFF switch

is

OFF. 'Refer

to

Fig

3.

Then plug the cord into a grounded elec

-

trical outlet

at

least 6 m

(20

ft)

away from the

spray area.

WARNING

Proper electrical grounding is essential

to

reduce

the risk of fire or explosion which can result in

serious

bodily.injury and property damage. Refer

to the warning section

FIRE

OR

EXPLOSION

HAZARD

on page 3 for more detailed grounding

instructlons.

5.

Flush the pump to remove the lightweight oil

which was left in to protect pump parts after fac-

tory

testing.

a. Before using water-base paint, flush with

mineral spirits followed by soapy water, and

then

a

clean water flush.

b. Before using oil

-

base painr, flush with mineral

c.

See

"

Flushing Guidalines" on page 8 for

6.

Prepare the paint according

to

the manufacturer's

recommendations.

a.

Remove any skin that may have formed.

b.

Stir the paint

to

dissolve hard pigments.

c. Strain the paint through

5

fine nylon mesh

bag

ticks that could clog the filter or spray tip. This

(available

at

most paint dealers)

to

remove par-

is probably the

mosr

importanr step toward

trouble-free spray painting,

307-671

6

spirits only.

flushing procedure.

~ ~~

Page 7

OPERATION

WARNING

Pressure Relief Procedure

To reduce the risk of serious bodily injury, in

cluding fluid injection, injury from splashing fluid

or solvent in the eyes or on the skin, moving parts

whenever you shut

off

the sprayer, when check-

or electric shock, always follow this procedure

when installing, cleaning or changing spray tips,

ing or servicing any part of the spray system,

and whenever you stop spraying.

1.

Engage the gun safety latch.

2.

Turn the ON/OFF switch to OFF.

3.

Unplug the power supply cord.

4.

Disengage the gun safety latch.

5.

Hold a metal part of the gun firmly to the

side of a grounded metal pail, and trigger

the gun to relieve pressure.

6.

Engage the gun safety latch.

7.

Open the filter drain valve, having a con-

8.

Leave the drain valve open until you are

tainer ready to catch the drainage.

ready to operate the sprayer again.

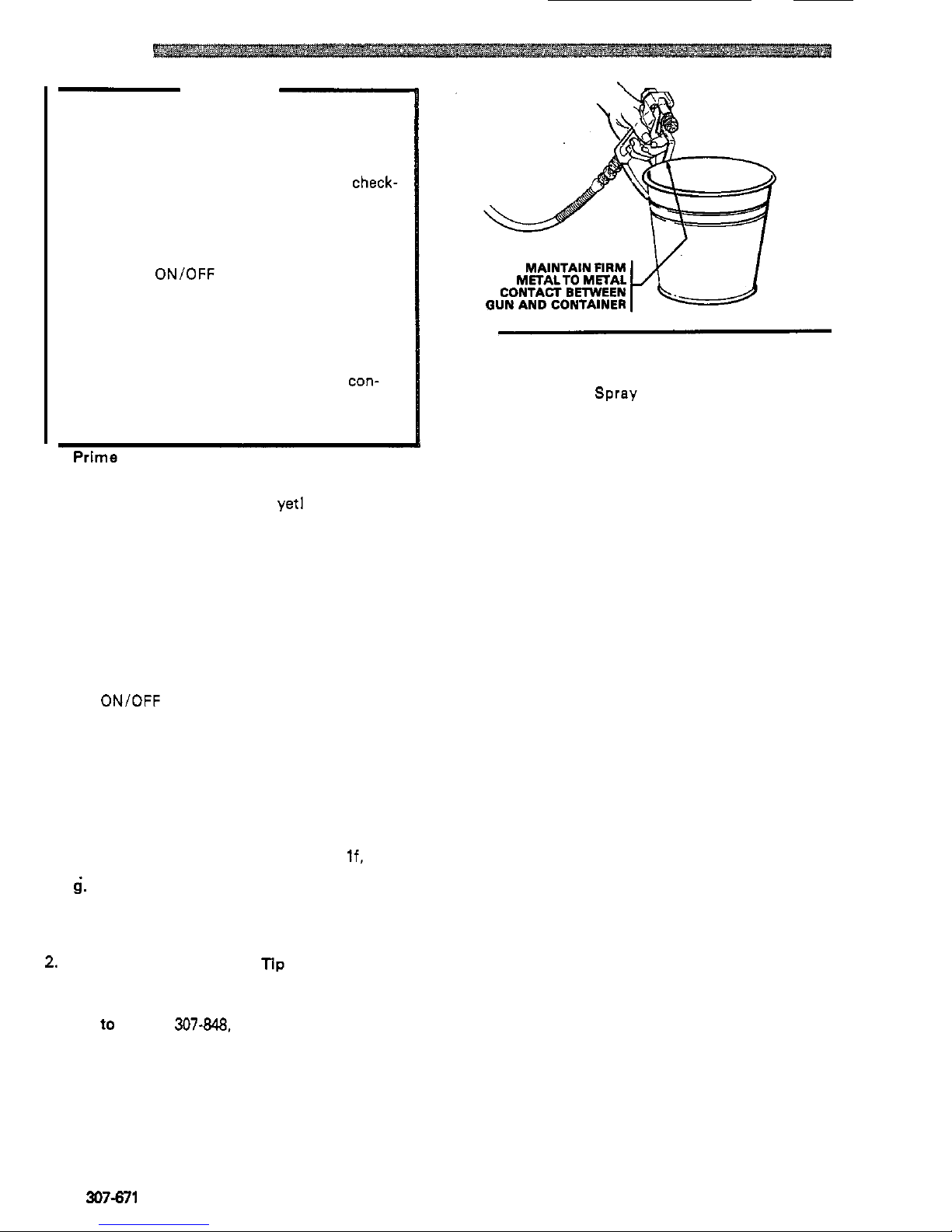

a.

Close the filter drain valve.

Prime the Sprayer

with

Paint.

b. Don't install the spray tip

yet1

c. Put the suction tube into the paint container.

d. Turn the pressure adjusting knob all the way

counterclockwise to the lowest pressure set

-

ting.

e.

Disengage the gun safety latch.

f. Hold

a

metal part of the gun firmly against and

aimed into

a

metal waste container.. See Fig

4.

ON/OFF switch to ON, and slowly increase the

Squeeze the trigger and hold

it

open, turn the

the gun triggered until

all

air is forced out of the

pressure setting until the sprayer starts. Keep

system and the paint flows freely from the gun.

Release the trigger and engage the safety.

NOTE: If the pump

is

hard to prime, place a container under the drain valve and open the

drain valve. When fluid comes from the

valve, close

it.

Then disengage the gun

safety and proceed

as

in Step If, above.

4.

Check

all

fluid connections for leaks. If any are

found, follow the Pressure Relief Procedure

Warning, above, before tightening connec

-

tions.

2.

Install the Spray Tip and

Tip

Guard

a.

Be

sure the gun safety latch

is

engaged.

b. Install the spray tip. If using the RAC

IV,

refer

to manual

307-848,

supplied with the gun, for

installation instructions.

Fig

4

3.

Adjusting the Spray Pattern

a.

Increase the pressure adjusting knob setting

just until spray from the gun

is

completely

fogging, and to decrease tip wear and extend

atomized.

To

avoid excessive overspray and

the life of the sprayer, always use the lowest

possible pressure needed to get the desired

results.

b. If more coverage is needed, use

a

larger tip

rather than increasing the pressure.

c. Test the spray pattern.

To

adjust the direction

of the spray pattern, engage the gun safety and

loosen the retaining nut. Position the tip guard

for

a

vertical pattern. Then tighten the retaining

horizontally for

a

horizontal pattern or vertically

nut.

6

307-671

Page 8

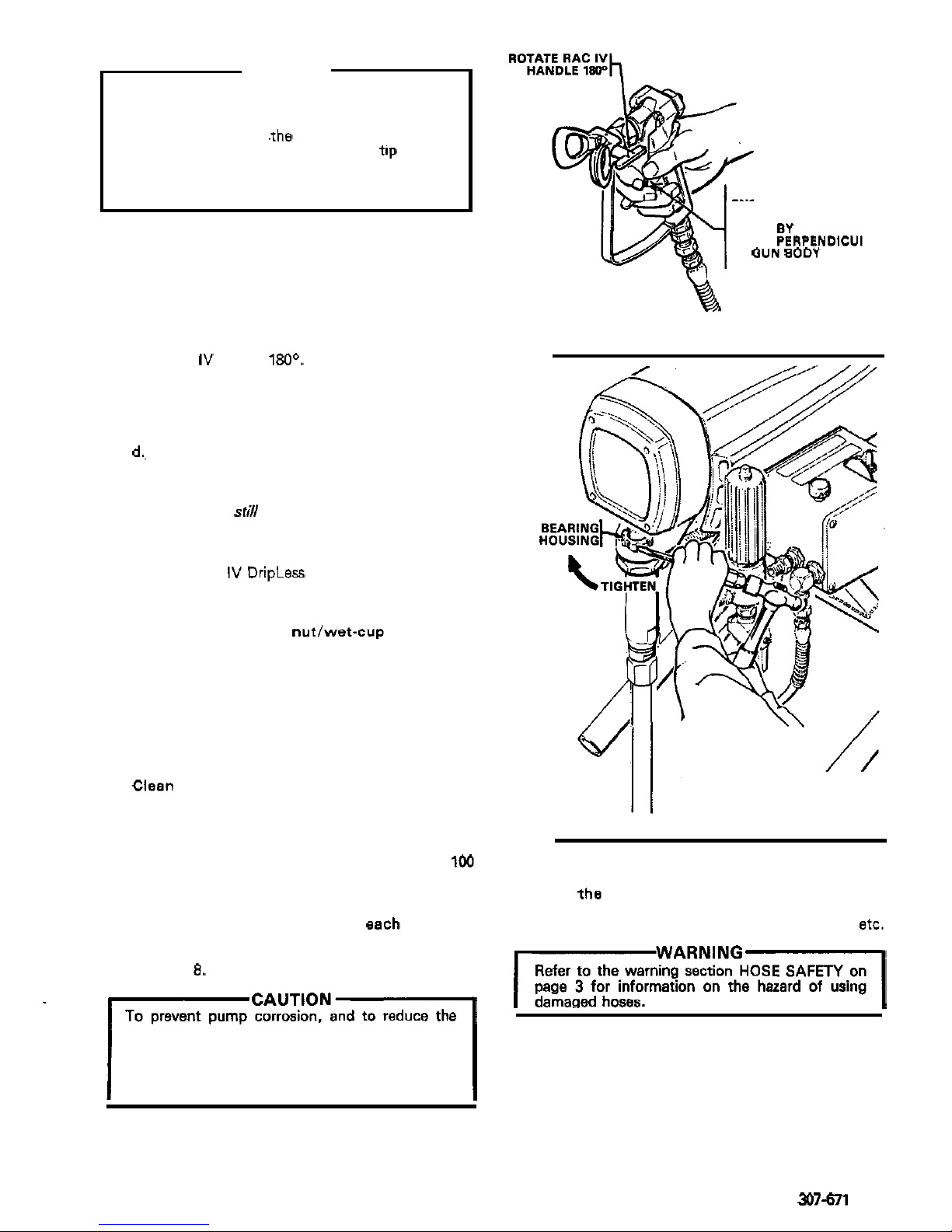

4.

Cleaning a Clogged Tip

WARNING

To avoid

a

fluid injection injury,

DO

NOT hold

your hand, body, or

a

rag in front of the spray tip

when cleaning or checking

a

clogged tip. Always

point the gun toward

.the ground or into a waste

container when checking to see if the

tup

I

S

clear.

DO

NOT try to "blow back" paint; this is NOT an

air spray sprayer.

a. Clean the front of the tip frequently during the

day's operation.

First,

follow the Pressure

Relief Procedure Warning on page

6.

Then

use a solvent-soaked brush to keep fluid from

building up and clogging the tip.

b. If the spray tip does clog, release the gun trig-

ger, engage the gun safety, and rotate the

RAC

IV

handle

180°.

See Fig

5.

c. Disengage the gun safety and trigger the gun

into

a

waste container. Engage the gun safety

again.

d., Return the handle to the original position,

disengage the gun safety, and resume spraying.

e.

if

the tip is stili dogged,

engage the gun safety,

shutoff and unplug the sprayer, and open the

drain valve to relieve pressure. Clean the spray

tip as shown in manual

307-848,

supplied with

the RAC

IV

DripLess tip guard.

SHUTDOWN

AND

CARE

1.

Check the packing nutlwet-cup daily. First

follow the Pressure Relief Procedure Warning

on page

6.

Be sure the wet-cup is

113

full of TSL

at

all

times to help prevent fluid buildup on the piston

rod and premature wear of packings. The packing

nut should be tight enough to stop leakage, but no

tighter. Overtightening may cause binding and

ex

-

cessive packing wear.

Use

a

screwdriver and light

hammer to adjust the nut. See Fig

6.

2.

Clean the fluid filter often and whenever the

sprayer is stored. First follow the Pressure Relief

Procedure Warning on page

6.

Refer to manual

307-273,

supplied, for the cleaning procedure.

3.

Lubricate the bearing housing after every

100

hours of operation. Fill the cavity

of

the bearing

housing with SAE

10

nondetergent oil.

4.

Flush the sprayer at the end

of

each work day

and fill

it

with mineral spirits to help prevent pump

corrosion and freezing.

See

"

Flushing Guidelines

"

on page

0.

chance of fluid freezing in the pump or pressure

type of paint in the sprayer when it is not in use.

control in cold weather, never leave water or any

result in loss of pressure or stalling.

Freezing can seriously damage the sprayer and

TRIGGER SAFETY

ENGAGETHE

LATCH

BY

TURNING

LATCH

PERPENDICUI

TO

QUN

BODY

AR

Fig

5

Fig

6

6.

Coil the hose and hang

it

on the hose rack when

storing

it,

even for overnight, to help protect the

hose from kinking, abrasion, coupling damage,

etc.

rWARNiNG1

Refer to the warning section

HOSE

SAFETY on

page

3

for information on the hazard of using

damaged hoses.

5.

For vary short shutoff periods, leave the suction

tube in the paint, follow the Pressure Relief Procedure Warning on page

6,

and clean the spray

tip.

307-671

7

Page 9

FLUSHING

GUIDELINES

When to Flush

1.

New Sprayer. Your new UltraQ

400

Sprayer was

factory tested in lightweight motor'oil which was

5.

Storage.

left

in to protect pump parts. spirits and leave the pump, hose and gun filled with

Water

-

base paint: flush with water, then mineral

Before using water-base paint, flush with mineral

spirits, followed by soapy water, and then

a

clean

mineral spirits. Shutoff and unplug the sprayer,

open the drain valve to relieve pressure and leave

water flush.

Before using oil

-

base pain!, flush with mineral

open.

spirits only. and unplug the sprayer, open the drain valve to

Oil-base paint: flush with mineral spirits. Shutoff

2.

Changing Colors. Flush with*a compatible solvent

relieve pressure and leave open.

such as mineral spirits or water.

6.

Startup after storage.

3.

Changing from water-base

to

oil-base paint.

Before using water

-

base paint, flush out mineral

Flush with soapy water, then

minera1,spirits.

spirits with soapy water and then a clean water

flush.

4.

Changing from oil-base to water-base paint.

Flush with mineral spirits, followed by soapy water, spirits with the fluid to be sprayed and the sprayer is

When using oil

-

base paint, flush out the mineral

then

a

clean water flush. ready to use.

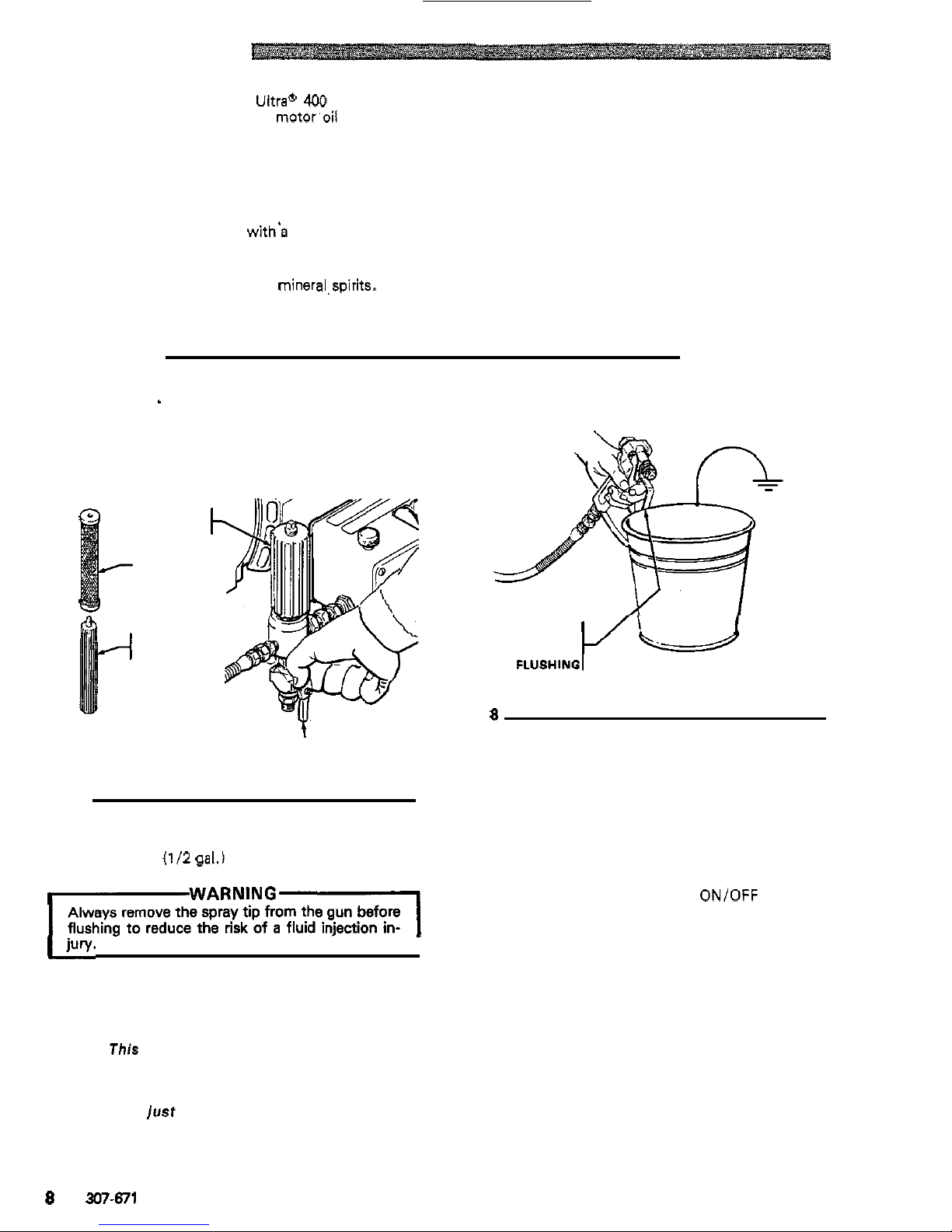

How to Flush

1.

Follow the Pressure Relief Procedure Warning

on page

6.

'

2.

Remove the filter bowl and screen; see manual

307-273

supplied. Clean the screen separately and

install the bowl without the screen.

FILTER

BOWL

SCREEN

MAINTAIN FIRM

METAL TO METAL

CONTACT WHEN

FILTER

SUPPORT

Fig

8

4

DRAIN VALVE

SHOWN OPEN

Fig

7

3.

Close the filter drain valve.

4.

Pour 2 liters

(112

gal.) of compatible solvent into a

bare metal pail. Put the suction tube in the pail.

Always remove the spray tip from the gun before

flushing to reduce the risk of a fluid injection in-

IWARNING1

5.

Disengage the gun safety latch.

6.

Point the spray gun into a grounded metal waste

container and with a metal part of the gun firmly

touching the metal container, squeeze the gun trig-

ger.

This procedure helps avoid static sparking

which can cause fire or explosion and splashing.

With the gun triggered, turn the ONIOFF switch to

clockwise

just

until

the sprayer starts. Keep the

ON

and slowly

turn

the pressure adjusting knob

gun triggered until clean solvent comes from the

nozzle. Release the trigger and engage the gun

safety latch.

7.

Check

all

fluid connections for leaks. If any leak,

follow the Pressure Relief Procedure Warning

on page

6.

Now tighten the connections, start the

sprayer, and recheck the connections for leaks.

8.

Remove the suction tube from the pail. Disengage

the gun safety and trigger the gun to force solvent

from the hose.

Do

not let the pump

run

dry for

more than

30

seconds to avoid damaging the

pressure control. Then turn ON/OFF switch

to

OFF and engage the gun safety latch.

9.

Unplug the power supply cord. Open the drain

valve and leave open until you

are

ready to use the

the clean screen. Reinstall the bowl, hand tight

sprayer again. Unscrew the filter bowl and reinstall

only.

10.

If

you have flushed with mineral spirits and are going to use a water-base paint, flush with soapy

water followed by

a

clean water flush. Then repeat

Step

1.

8

307-671

Page 10

TROUBLESHOOTING GUIDE

WARNING

To reduce the risk of serious .bodilv

injury.

in-

Pressure

Relief

Procedure

6.

Engage the gun safety latch.

cluding fluid injection, splashing fluid in ihe eyes

7.

Ooen the drain valve. havina a container readv

~~

or on the skin, or injury from moving parts or elec

-

to

catch the drainage.

tric shock, always follow this procedure whenever

you shut

off

the sprayer, when checkingor servic-

8.

Leave the drain valve open until you are ready

ing

any part of the spray system, when Installing,

to spray again.

you stop spraying.

cleaning or changing spray tips, and whenever

pletely clogged, or thatpressure has not been fully

If

you suspect that the spray

tip

or hose

is

com-

1.

Engage the gun safety latch.

relieved after following the steps above, VERY

2.

Turn

the

ON/OFF switch to

OFF.

SLOWLY loosen the

tip

guard retaining nut or

hose end

couolina and relieve oressure araduallv.

I

3.

Unplug

the

power supply cord. then loosen comphely. Nowciearthe tip or hosb:

4.

Disengage the gun safety latch.

5.

Hold a metal part of the gun firmly to the side of

a grounded metal pail,

and3rigger the gun to

relieve pressure.

I~~~~

TYPE

OF

PROBLEM

MOTOR

WONT

OPERATE

Basic Fluid Pressure Problems

Basic Mechanical Problems

Basic Electrical Problems

WHAT TO CHECK

If

check is

OK,

go

to next check

1.

Check the pressure control knob sening.

The motor

will

not run if

it

is at the

minimum sening (fully

counterclockwise).

2.

Check for a clogged spray tip. Refer

to

your separate gun or tip instruction

manual.

-

-

-

-

i

1

it,

due

to

exposure

to low temperatures, by placing

it

in

a

'Thaw the sprayer if water or water-based paint has frozen in

warm area.

Do

not try to start the sprayer until

it

has thawed

completely. If the bourdon tube was not damaged by the

freezing, the pump should operate. If paint hardened (dried1 in

the sprayer. the pump packings and/or bare pressure control

mum be replaced.

See

page

23

or manual

307-793.

1.

Check for frozen or hardened paint

in

the pump (19) andlor pressure control

bourdon tube. Using a screwdriver,

carefully try to rotate fan

at

back of

motor.

See

page

15.

2.

Check displacement pump connecting

rod pin

(m).

It

must be completely

pushed into connecting rod

(91 and

spring retainer

(21)

should be firmly in

groove of connecting rod. See page

26.

3.

Check for motor damage. Remove drive

to

rotate fan bv hand.

housing assembly

(6).

See page

25.

Try

1.

Check electrical supply with volt meter.

Meter should read 190-250

Volts.

2.

Check extension cord for visible

damage. Use a volt meter or

test

lamp

m

extension cord outlet

to

check.

3. Check sprayer power supply cord

(311)

for visible damage such

as

broken in

-

sulation or wires.

4.

Check motor brush leads, terminals and

brush length. Brush length should be

14

mm minimum. See

DaQe

28.

WHAT.TO

DO

If

check is

NOT

OK

refer to this column

1. Slowly increase the pressure setting to

see

if

the motor starts.

2.

Relieve pressure, refer

to

your separate

gun or tip instruction manual for tip

cleaning.

1.

Thaw'.

Plug

in

sprayer

and

turn

on.

Slowly increase pressure setting

to

see

if

motor starts. If

it

doesn't, replace the

displacement pump packings

(see

manual

307-793)

andlor replace the bare

23.

pressure control box (3011'. See page

2.

Push pin into place and secure with the

spring retainer.

3.

Replace motor I1 1 if

fan won't turn.

1.

Reset building circuit breaker; replace

building fuse. Try another electrical

outlet.

2.

Replace extension cord.

3. Replace power supply cord.

See page 18.

4.

lighten terminal screws; replace

brushes. See page

27.

'When replacing the bare pressure control box (item

301).

trical hardware and reinstall these parts in the bare box.

remove the ONlOFF switch, bridge, circuit board and elec

-

Troubleshooting continued on next page.

307-671

9

Page 11

TYPE

OF

PROBLEM

MOTOR

WON7

OPERATE

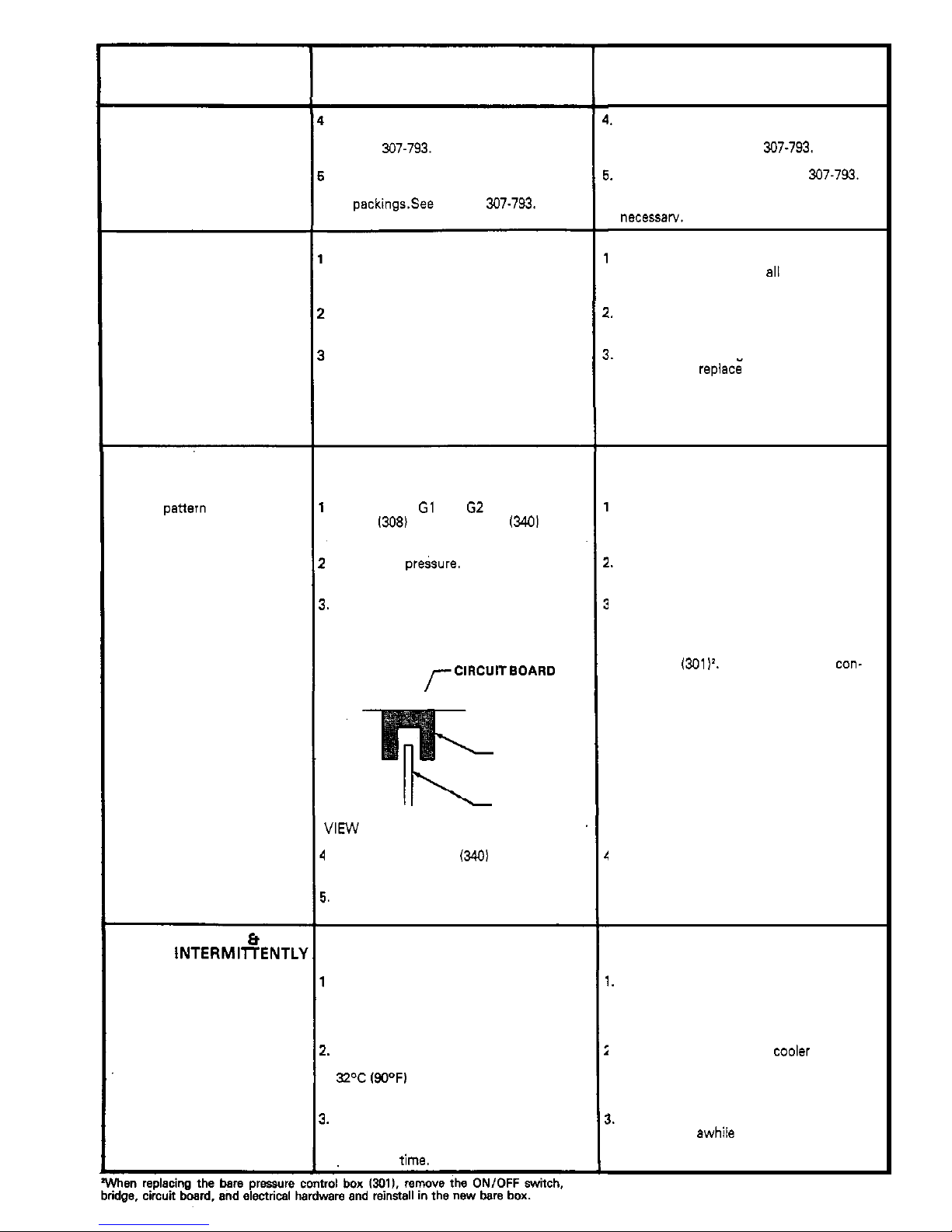

Diagnosing circuit board

in

-

dicator lamps. The normal

condition is red lamp on,

clear lamp

on

when board

is

telling

pump

to

run.

cedure

Warning. Remove

Follow

Pressure Relief

Pro-

gun from hose. Remove

pressure control cover and

check for faulty condition of

circuit board lamps.

Condition A both lamps on;

pump won't operate and

motor is not running

Condition B

Both lamps

off

~~~~~~

WHAT TO CHECK

If

check

Is

OK,

go

to

next check

I.

Check leads from bridge 1308) to motor

to be sure they are securely fastened

and properly mated.

1.

Check G1 and G2 connections between

circuit board

(3401

and bridge

1308)

for

damage or loose terminals.

3.

Check for loose motor brush lead con

-

nections and terminals. See page 27.

4.

Check brush length which should be 14

mm minimum.

See

page 27.

at the same rate on both sides of the

NOTE also

that

the brushes do not wear

motor.

5.

Check for broken or misaligned motor

brush springs. Rolled portion of spring

must rest squarely on top of brush. See

page

27.

6.

Check motor brus'hes for binding

in

brush holders. See page

27.

7.

Check motor armature commutator for

burn spots, gouges and axtreme

rouohness. Remove motor cover and

brush inspection plates to check.

See

page

27.

6.

Check motor armature for shorts using

armature tester (growler) or perform spin

test.

See

page 15.

9.

Check bridge

1308)

by substituting with

a good bridge or performing bridge test.

See

page 16.

CAUTION: D

O

not perform this check

until

armature is determined to be good.

A bad armature will immediately burn

out

a

good bridge.

1. Check electrical supply. Connect

voltmeter to electrical outlet. Meter

should read

190.250 Volts.

2.

Check power supply to circuit board

with sprayer turned ON. Measure

voltage at

TPl and TP2. Meter should

read 190

-

250

Volts.

See page

7.2.

3.

Check a11 terminals and wires fog

damage or loose fit.

4.

Check motor thermal cutout switch.

Unplug sprayer. Allow motor to cool.

at

TP9 to TPlO. Use ohmmeter to check

Disconnect motor thermal switch leads

continuity. Switch should

be closed

when motor is cool.

WHAT TO DO

If

check is

NOT

OK

refer to this column

1.

Replace any loose terminals and crimp

to leads. Be sure male terminal blades

are straight and firmly connected to

mating part.

2.

Clean circuit board male terminals.

Replace loose or damaged terminals.

Securely reconnect leads.

3.

Tighten terminal screws. Replace

brushes if leads are damaged.

See page 27.

4.

Replace brushes. See page 27.

5. Replace spring

if

broken. Realign spring

with brush. See page

27.

6.

Clean brush holders. Remove carbon

with small cleaning brush. Align brush

free vertical brush movement.

lead with slot in brush holder to assure

7. Remove motor and have motor shop

resurface commutator if possible. See

page 27.

8.

Replace motor. See page

29.

9.

Replace bridge. See page

20.

1. Reset circuit breaker or replace outlet

fuse.

If

circuit breaker or fuse continues

to

open, see "Electrical Short", page 14.

2. Unplug sprayer. Check continuity of

TPl to TPZ, and TP2 to TP3.

Replace

both poles of ONlOFF switch

(302) from

switch

if

faulty.

Check continuity of

RFI

filter (3101 from

TP4 to TP6 and TP3 to TP5. Replace

filter if faulty.

tinuity

from TP5 to TP7 and TP6 to

TP8.

Check

power supply cord (3111 for

con

-

Replace cord if faulty.

3. Replace damaged terminals and recon

-

nect securely.

4.

Replace electric motor

if

switch does not

close when motor is cool. See page

29.

10

307-671

Page 12

YPE

OF

PROBLEM

Condition

B

(continued)

Condition

C

Red

lamp on, clear lamp

off

Unplug

sprayer1

WHAT TO CHECK

f

check is

OK,

go

to

next

check

i.

Check microswitch

1306).

With no fluid

pressure in the pressure control discon

-

nect wires TP18 and TP19. Check con

tinuity across switch terminals with an

ohmmeter. Switch contact should be

closed. Depress actuator

bunon. An

audible

"click" indicates the contacts

have opened. Ohmmeter should read in

-

finity.

i.

Check circuit board

(3401

by substituting

with a good board. See page

22.

.

Check circuit board

(3401

by removing

from box

wirhout

disconnecting wires;

sea

page

22

for removal procedure.

WARNING:

Removing the circuit board

while still wired over

-

rides the optical

.

to over-pressurize, if the microswitch

detector which could cause the sprayer

does not function properly. Tum the

sprayer on

ONLY

long enough to check

lamp condition, then shut

off

immediate

-

ly.

WARNING:

To reduce the risk of elec

-

tric shock, handle board by edges only1

Do

not allow any metal objects to come

in

contacl with the boardl

should be

on

now - removing the circuit

Plug in and turn on sprayer. Clear lamp

board over

-

rides the optical detector.

Turn

off

and unplug sprayer.

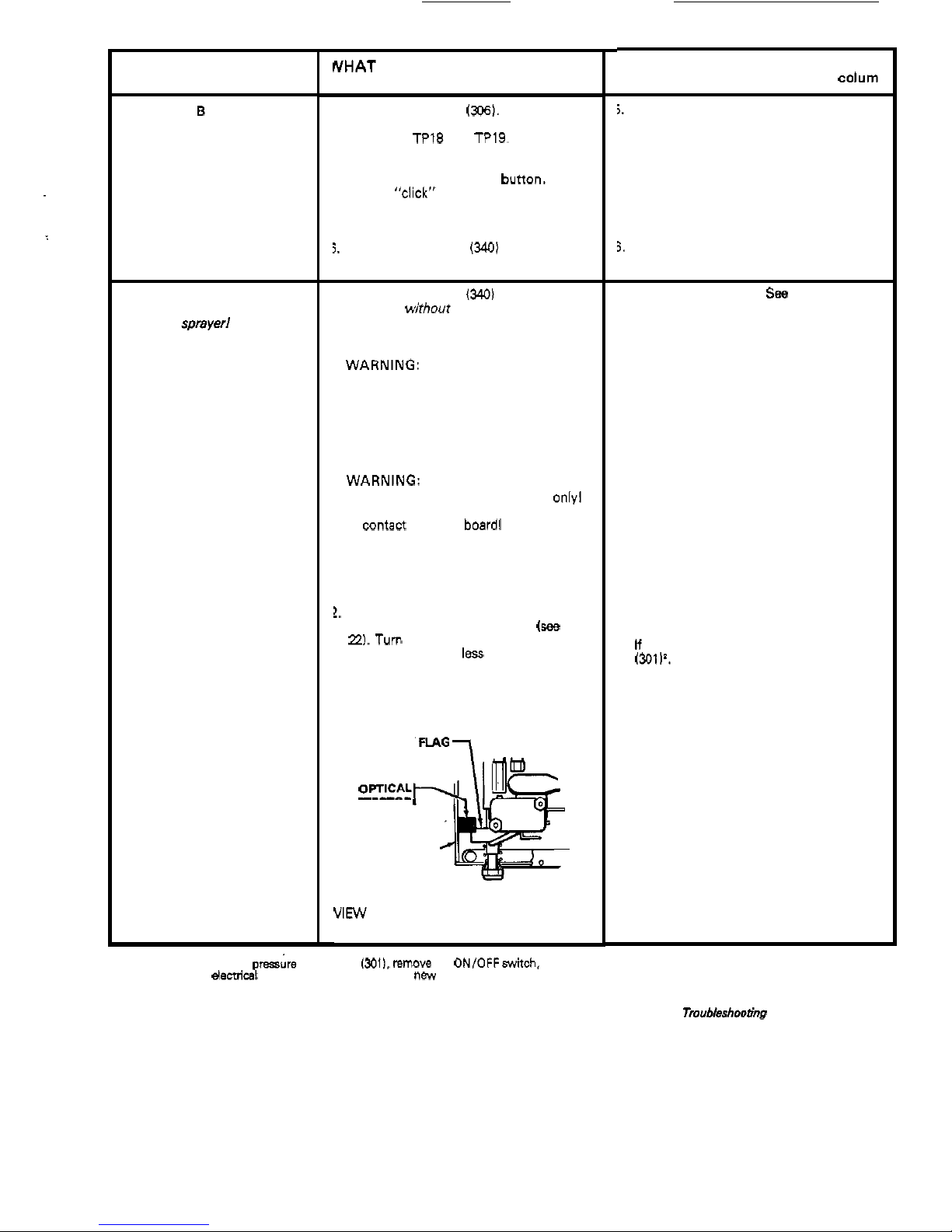

!.

Check bourdon tube flag and detector

position. Reinstall circuit board

(see

page

22.

Turn pressure setting to maximum;

flag should extend

less

than half way into

optical detector slot from the bonom.

DETECTOR

C

I

R

C

U

I

T

-

BOARD

VIEW

OF

OPTICAL DETECTOR AND

FLAG

'When replacing

the

bare pressire control box 13011.

remow

the

ON/OFFswitch,

bridge,

circuit

board

and

elecbical

hardware and

reinstall

in

the

new bare box.

WHAT TO

DO

If

check

is

NOT

OK

refer

to

this colurn

5.

Replace microswitch. See page 19.

3,

Replace circuit board. See page

22.

I.

Replace circuit board.

Sea

page

22.

2.

Calibrate pressure control to

sea

if

that

corrects problem.

See

page

24.

If

not, replace bare pressure control box

13011'.

See

page

23.

Tmubleshooting continued on next

page.

307-671

11

Page 13

~~

TYPE

OF

PROBLEM

LOW OUTPUT

NO OUTPUT

Motor runs and pump stroke:

307-671

WHAT

TO

CHECK

If

check is

OK.

go to next check

1. Check for worn spray tip.

2. Check

to

see

that

pump does not con

-

tinue

to

stroke when gun trigger is

released. Plug in and turn on sprayer.

Prime with paint. Trigger gun momen

tarily, then release and engage safety

latch. Relieve pressure, turn

off

and

unplug sprayer.

3. Check electrical supply with volt meter.

Meter should read

190-250

Volts.

4. Check extension cord size and length;

must be at least 12 gauge wire and no

longer than 15.2 m

(150

ft).

5.

Check G1 and G2 leads from bridge

or loose wires or connectors. Refer

to

WX)

to

circuit board

1340)

for damage

page

22.

6.

Check stall pressure. Refer

to

Calibration

Procedure on page 24.

7.

Check bridge

(308)

+

and - leads and

terminals

to

motor. Inspect

wiring

in

sulation and terminals for signs of

overheating. See page

20.

8.

Check for loose motor brush leads and

terminals. See page

27.

9.

Check for worn motor brushes which

should be 14 mm

(9/16) minimum. See

pBge

27.

10.Check for broken and misaligned motor

brush springs. Rolled portion of spring

must rest squarely on top of brush.

11.Check motor brushes for binding

in

brush holders. See page 27.

12.Check circuit board

1340)

by substituting

with a good circuit board. See page

22.

13.Check motor armature for shorn by us

-

ing an armature tester (growler) or per

-

form spin

test.

See

page 15.

14.Check bridge

(308)

by substituting with

a good bridge or by performing the

bridge test. See page 16 or

20.

CAUTION:

Do

not perform this check

A bad armature

will

immediately burn

until armature is determined

to

be good.

out

a

good bridge.

1.

Check paint supply.

2. Check for clogged intake strainer.

3. Check for loose suction tube or fittings.

WHAT

TO

DO

If

check

is

NOT

OK

refer to this column

1. Follow Pressure Relief Procedure

Warning then replace

tip.

See your

separate gun or tip manual.

2.

Service pump. See manual 307-793.

3. Reset building circuit breaker; replace

building fuse. Repair electrical outlet or

try

another outlet.

4. Replace with a correct, grounded exten

-

sion cord.

5.

Clean circuit board male terminals.

minals. Securely reconnect lead

ter-

Replace loose or defective lead ter

-

minals to board.

6.

Calibrate pressure control. See page 24.

7. Be sure male terminal

blades are

centered and firmly connected to female

terminals. Replace any loose terminal or

damaged wiring. Securely reconnect

wires to bridge.

8.

Tighten terminal screws. Replace

brushes if leads are damaged. See page

27.

9.

Replace brushes. See page

27.

10.Replace spring if broken. Realign spring

with brush. See page

27.

11 .Clean brush holders, remove carbon

dust with small cleaning brush. Align

brush lead with

slot

in brush holder

to

assure free vertical brush movement.

12.Replace circuit board. See page

22.

13.Replace motor.

See

page

29.

14.Repiace bridge. See page

20.

1. Refill and reprime pump.

2.

Remove and clean, then reinstall.

3. Tighten; use thread sealant or sealing

tape on threads if

necessary.

Page 14

TYPE OF PROBLEM

NO OUTPUT

(Continued)

Motor runs but pump does

not stroke

EXCESSIVE PRESSURE

FLUCTUATIONS

Spray panern variations.

MOTOR IS HOT

e

RUNS INTERMllTENTLY

WHAT TO CHECK

If

check is

OK,

go

to next check

,

Check to see

if

intake valve ball and

piston ball are seating properly.

See

manual 307-793.

.

Check for leaking around throat packing

nut which may indicate worn or damag

-

ed packings.See manual 307-793.

.

Check displacement pump connecting

rod

pin.

See

page 26.

,

Check connecting rod assembly for

damage. See page 25.

.

Be sure crank

in

drive housing rotates;

plug

in

sprayer and turn on momentarily

to check. Turn

off

and unplug sprayer.

See

page 25.

.

Be sure both G1 and G2 leads from

firmly

connected. See

page

22.

bridge

1308)

to circuit

board

13401

are

'.

Check stall pressure. Refer to Calibration

procedure on page 24.

i.

Check bourdon tube flag and detector

position. Turn pressure sening to max

-

imum; flag should not drag or bind

in

optical detector slot of circuit board.

r

CIRCU'TBoARD

OPTICAL

DETECTOR

"

OPTICAL

DETECTOR

FLAG

VIEW

OF OPTICAL DETECTOR AND FLAG

I.

Check circuit board

(3401

by substituting

with a good board. See page

22.

i.

Check

LOW

OUTPUT section on page

12.

.

Check to

see

if

sprayer has been

operating at high pressure with small

tips, which causes low motor RPM and

results

in

excessive heat build up.

I.

Check to

see

if ambient temperature

where sprayer is located is more than

32%

(90°F)

or

if

sprayer

is

located

in

direct sun.

!.

Check to

see

if

sprayer has been left in a

stalled condition [sprayer turned on,

pressurized, but not operating) for long

periods of

time.

WHAT TO

DO

If

check

is

NOT

OK

refer to this column

,.

Remove intake valve and clean. Check

balls and seats for nicks; replace if

necessary. See manual

307-793.

#.

Replace packings. See manual 307-793.

Also check piston valve seat for harden

-

ed

paint or nicks and replace

if

necessarv.

.

Replace pin if missing. Be sure retainer

spring is fully in groove

a11 around

connecting rod. See page 26.

!.

Replace connecting rod assembly. See

page 25.

i.

Check drive housino assemblv for

damage and

replac; if necessary.

See

page

25.

.

Reconnect securely. See page

22.

I.

Calibrate pressure control. See page 24.

I.

Carefully bend flag into alignment with

detector slot to see if that corrects pro

-

blem.

assembly

(3011'. Calibrate pressure con-

If not, replace bare pressure control

trol after reassembly.

I.

Replace circuit board. See page

22.

I.

Decrease pressure sening or increase

tip

size.

!.

Move sprayer

possible.

to shaded, coolel ' area if

1.

Turn

off

sprayer whenever you stop

spraying for

awhile and relieve fluid

pressure.

307-671

13

Page 15

TYPE

OF

PROBLEM

ELECTRICAL SHORT

Buildino circuit breaker ooens

as

sooi

as sprayer switch

is

turned on.

CAUTION

Any short in any part of

thf

motor power circuit, which

i$

connected to the output sidc

of the bridge, will cause

thf

bridge to burn out immediate

ly. Correctly diagnose anc

ing and

replacing

bridge

repair all shorts before

check,

as soon as sprayer is plugged

Building circuit breaker opens

turned on.

into outlet and sprayer is

NO1

WHAT TO CHECK

If

check

Is

NOT

OK

refer to this

col

-

If

check

is

OK,

go

to

next check

WHAT TO DO

umn

Check all electrical wiring for damaged

or damage. Be sure to check wires

bet-

insulation, and all terminals for loose

fit

ween pressure control and motor which

are encased in conduit

141

I.

See page

29.

1.

Repair or replace any damaged wiring or

terminals. Securelv reconnect all wires.

,

Check for missing inspection plate

2.

Correct faulty conditions.

gasket

(see page

27).

bent terminal forks

which could cause a short.

or other metal to metal contact points

Check motor armature for shorts by us

-

3.

Replace motor. See page

29.

ing an armature tester (growler) or per

-

form spin test. See page

15.

Inspect

windings for bums.

,

Check bridge

(3081

by substituting with

4.

Replace bridge. See page

20.

a good bridge

or

by performing bridge

test.

See page

16.

CAUTION:

Do

not perform this check

until armature is determined to be

good.

A bad armature will immediately burn

out a good bridge.

Check 'Basic Electrical Problems' on

page

9.

Check ON/OFF switch

1302)

See page

19.

Be

sure

the

sprayer

is

unplugged!

switch with ohm meter. The ohm meter

Disconnect wires from switch and check

should read

infinity

with the ONlOFF

switch OFF, and zero with the switch

ON.

CAUTION:

A short

in

the motor circuit

will burn the bridge out immediately,

which in turn usually causes the ONlOFF

switch

to

fail in the closed mode.

2.

Replace ON/OFF switch. See page

19.

14

307-671

Page 16

~

~_____~

SPIN

TEST

WARNING

Before doing this procedure, follow the Pressure

the risk of

a

fluid injection injury, splashing fluids

Relief

Procedure Warning on page

17

to reduce

in the eyes or on the skin, injury from moving

Darts. or electric shock.

1

~~~ ~~

For checking armature, motor winding and brush elec

-

trical continuity.

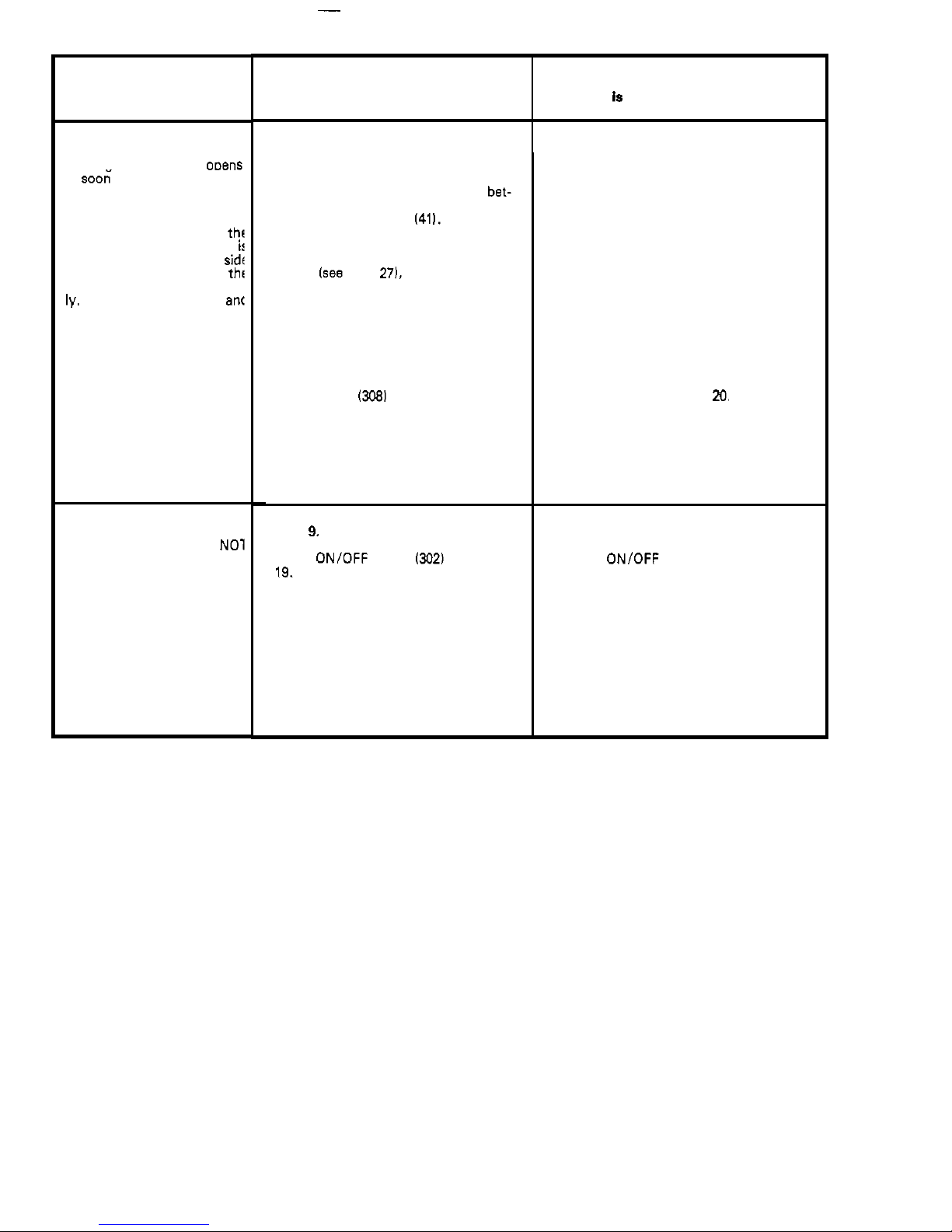

Setup

Remove the drive housing from the sprayer as des

-

cribed in Steps

1-9,

page

25.

Remove the pressure control cover and screws, !he

motor cover, the fan cover (F), and the inspectton

covers

IJ).

See Fig

9.

Disconnect the

two

leads from the motor to the bridge

(308).

See

Fig

10.

Armature

Short

Circuit Test

shorts,

the motor will coast

two

or three revolutions

Quickly turn the motor fan by hand.

If

there are

no

before coming to a complete stop.

If the motor does not spin freely and resists rotation, the

armature

is

shorted and the motor must be replaced.

See page

29.

Armature, Brushes, and Motor Wiring Open

Circuit Test (Continuity)

Connect the

two

black motor leads together with a test

lead.

Turn the motor fan by hand

at

about

two

revolutions

per second.

following:

a)

broken brush springs;

b)

broken brush

If there

is

uneven or no turning resistance, check the

leads;

c) loose brush terminal screws; d) worn brushes;

e)

broken motor leads;

f)

loose

motor lead termlnals.

Repair parts as needed. See page

27.

If there

is

still uneven or no turning resistance, replace

the motor. See page

29.

Fig

9

307-671

15

Page 17

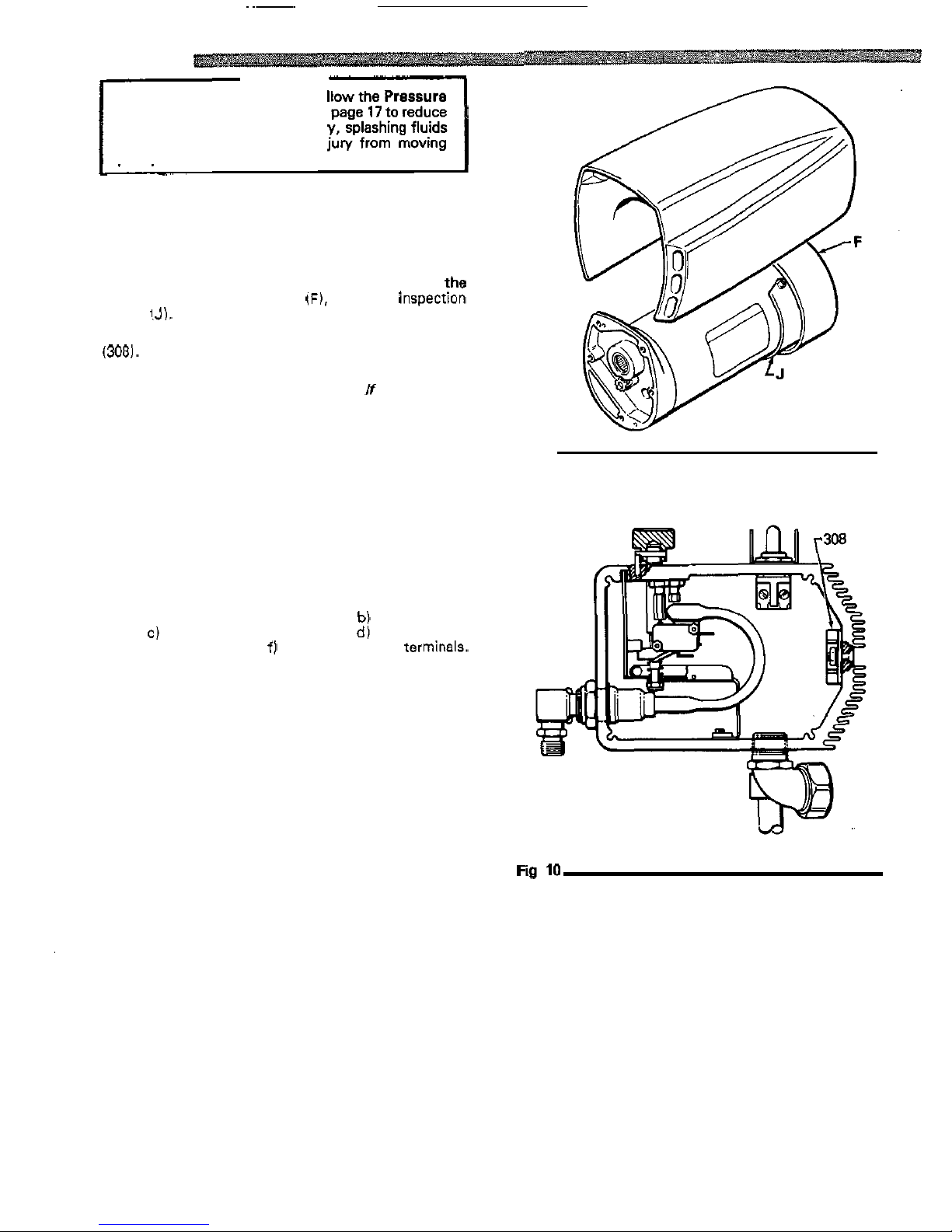

BRIDGE

TEST

Remove the bridge from the pressure control box and

perform this test to determine if the bridge is functional.

continuity tester, such

as

multi-meter set on the X1

See Bridge Rectifier Replacement, page

20.

Use

a

ohms scale

(

n

).

the bridge fails even one test,

it

must be replaced.

Eight individual checks, or tests, must be performed.

If

Fig

11

shows the position of the wires on the bridge.

Us

-

ing the chart

at

the right, connect the meter wires

as indicated by the black dots for each test, then check the

continuity.

In Tests 1,

2

and

3,

there should be

NO

continuity.

indicated, check continuity,

then.switch the meter wire

In Tests

4, 5 and

6,

connect the + and - meter wires

as

get

NO

continuity one way, and

YES

continuity the

connections and check continuity again.

You

should

other way.

In Tests 7 and

8.

connect the meter wires

as

indicated

by

the black dots. Touch the indicated

"G"

wire to one

meter wire, and then the other.

You

should get

NO

con

-

tinuity one way, and

YES

continuity the other way.

BRIDGE

WIRES

Fig

11

16

307-671

Page 18

GENERAL

REPAIR

NOTES

WARNING

Pressure Relief Procedure

To'reduce the risk of serious bodily injury,

in

-

cluding fluid injection, splashing fluid in the eyes

or on the skin, or injury from moving parts or elec

tric shock, always follow this procedure whenever

you shut

off

the sprayer, when checking or servic:

ing any part of the spray system, when installing,

cleaning or changing spray tips, and whenever

you stop spraying.

1 .Engage the gun safety latch.

2 .Turn the

ONIOFF switch to OFF.

3

.Unplug the power supply cord.

4 .Disengage the gun safety latch.

5

.Hold a metal part of the gun firmly to the side of

a grounded metal pail, and trigger the

gun

to

relieve pressure.

6

.Engage the gun safe& latch.

7 .Open the drain valve, having a container ready

8

.Leave the drain valve open until you are ready

If

you suspect that the spray

tip

or hose

is

com

-

pletely clogged, or that pressure has not been fully

relieved after following the steps above, VERY

SLOWLY loosen the tip guard retaining nut or

hose end coupling and relieve pressure gradually,

then loosen completely. Now clear the

tip

or hose.

to catch the drainage.

to spray again.

Tool

List

The following tools are needed when repairing this

sprayer.

Phillips screwdriver

Small flatblade screwdriver

Needle nose pliers

Plastic mallet

Adjustable wrench

2

"

adjustable, open-end wrench

Torque wrench

114"

hex key wrench

3/16

"

hex key wrench

518"

socket wrench

318"

open end wrench

314"

open

end wrench

112''

open

end wrench

718"

open end wrench

High quality motor oil

Bearing grease

318

ignition wrench

For calibration procedure only:

0.015'

spray tip

High pressure, oil

-

filled test gauge, Part No. 102-814

5

gallon pail

Clean water

Mineral spirits

NEW

207

bar

(3oM)

psi) high pressure spray hose,

Part

No.

214-915.

ing

general repair notes and the repair procedure. Be

Before repairing any part of the sprayer, read the

follow-

sure you have the necessary tools and parts available.

1.

When disconnecting wires

in

the pressure control

assembly, use needle nose pliers to separate mating

connectors.

When reconnecting the wires, be sure the flat blade

wrap

-

around blade of the female connector when

of the insulated male connector is centered

in

the

the connection is made.

CAUTION

tion, be sure to properly mate connectors, and

never pull on a wire to disconnect

it.

Pulling on a

wire could loosen the connector from the wire.

2.

Route wires in the pressure control assembly

carefully through the legs of the U

-

shaped bourdon

tube, where appropriate, to avoid interfering with

the bourdon tube which moves as the pressure set

-

ting changes and to avoid pinching the wires be

-

tween the pressure control box and cover.

CAUTION

Improper wire routing can result

in

poor sprayer

performance or damage to the pressure control.

3.

Keep

all

screws, nuts, washers, gaskets, and elec

trical fittings removed during repair procedures.

These parts are not normally provided with replace

-

ment assemblies.

4.

Test your repair before regular operation of the

sprayer to be sure the problem is corrected.

If the sprayer does not operate properly, review the

repair procedure again to verify that everything was

done correctly. If necessary, refer to the

Troubleshooting Guide, pages

9-16,

to help identify

other possible problems and solutions.

FWARNlNGl

To reduce the risk of serious bodily injury, in

-

cluding electric shock, DO NOT touch any moving

while

inspecting.the repair.

parts or electrical parts with your fingers or a tool

complete the inspection.

Shut

off

the sprayer and unplug

it

as soon as you

before operating the sprayer.

Reinstall all covers, gaskets, screws and washers

CAUTION

seconds to avoid damaging the pump packings.

Do not run the sprayer dry for more than

30

5.

Reinstall the motor cover before regular operation

of the sprayer and replace

it

if

it

is damaged. The

cover directs cooling air around the motor to help

prevent overheating.

It

can also help prevent burns,

fire or explosion; see the WARNING, below.

WARNING

and could burn your skin if touched. Flammable

During operation, the motor becomes very hot

materials spilled on the hot, bare motor could

cause a fire or explosion. Always have the motor

cover in place during regular operation to reduce

the risk of burns, fire or explosion.

307-671

17

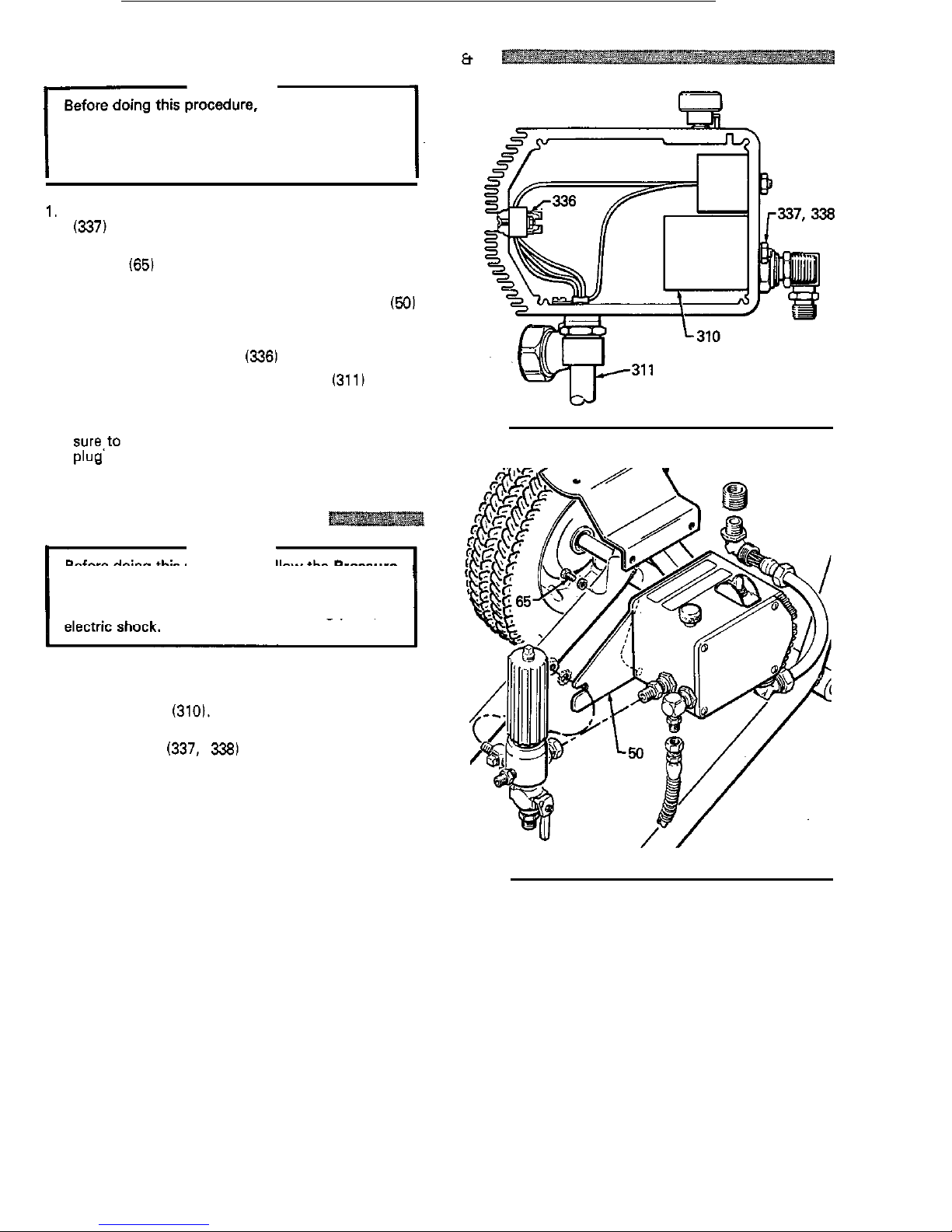

Page 19

POWER SUPPLY CORD REPLACEMENT

(See

Fig 12

Et

131

WARNING

follow the Pressure

Relief Procedure Warning on page 17 to reduce

the risk of

a

fluid injection injury, splashing in the

eyes or on the skin, injury from moving parts, or

electric shock.

1. Use the

19

mm open end wrench to remove the nut

(337)

from the filter stud (310).

2.

Use

the

13 mm socket wrench to remove the

two

screws (651 holding the pressure control to the

frame.

3. Remove the pressure control mounting bracket

(50)

using a Phillips screwdriver.

4.

Disconnect the power supply cord wires from the

control box terminal strip

(336) using a screwdriver.

5. Install the new power supply cord

(3111 in the

reverse order of disassembly.

Install

a

new plug on the other end

of

the cord. Be Fig

12

sure,to follow

all

local codes regarding the type of

olua to use.

.I

FILTER REPLACEMENT

(See Fig 12)

WARNING

Before doing this procedure, follow the Pressure

the risk of

a

fluid injection injury, splashing in the

Relief

Procedure Warning on page 17 to reduce

eyes or on the skin, injury from moving parts, or

1. Remove the pressure control cover and screws.

2.

Use

a

needle nose pliers to remove the four wires

from the filter (3101.

3.

Use the

M8

wrench to remove the lower nut and

lockwashers

(337,

338)

on the outside of the

pressure control box.

4.

Remove the old filter and install a new one in the

reverse order of disassembly.

Fig

13

18

307-671

Page 20

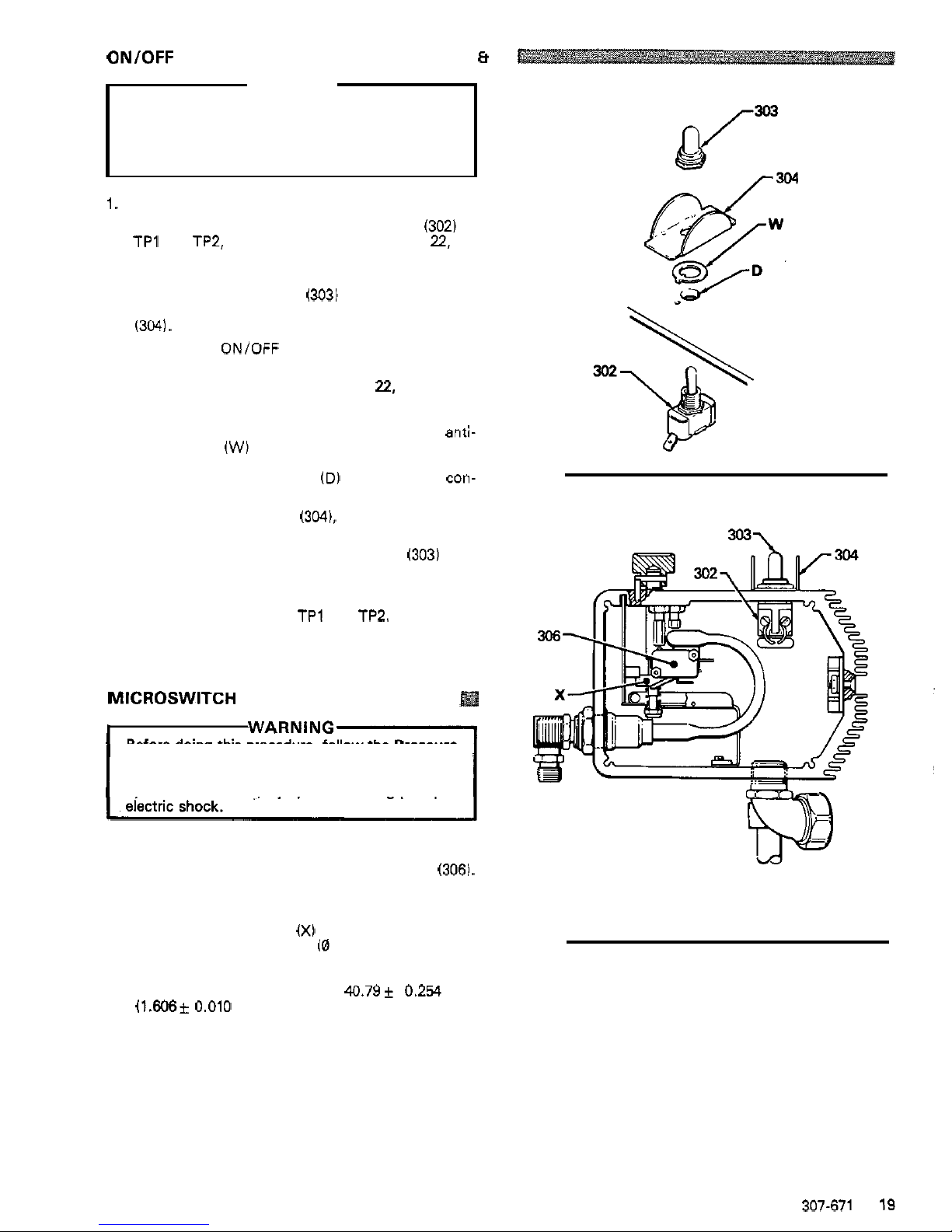

ON/OFF SWITCH REPLACEMENT

(See Figs 14

Et

WARNING

Before doing this procedure, follow the Pressure

Relief Procedure Warning on page 17 to reduce

the risk of

a

fluid injection injury, splashing

in

the

eyes or on the skin, injury from moving parts, or

electric

shock.

1. Remove the pressure control cover and screws.

2. Remove the wires attached to the switch

(302) at

TPl and TP2, using a screwdriver. See page

22,

Fig

21.

3.

Use a 16 mm socket wrench to loosen and remove

the nut and rubber boot

(303)

from the top of the

pressure control box. Remove the switch guard

(304).

4. Remove the ONIOFF switch.

5. Remove the wires attached to the switch TP4 and

TP3 using a screwdriver. See page

22,

Fig 21.

6. Attach the wires to TP4 and TP3 of the new switch.

7. Install the new switch

so

the internal tab of the anti-

rotation ring

(W)

engages with the vertical groove

engages

with

the blind hole

(D)

of the pressure con-

in

the threads of the switch, and the external tab

trol box.

8.

Install the switch guard (304). aligning the internal

tab with the groove

in

the threads.

9. Powder the inside of the rubber boot

(303)

with

talcum, then shake excess out of boot.

10. Install the nut and rubber boot and tighten.

11. Reconnect the wires to

TP1 and TP2.

12. Reinstall the pressure control cover and screws.

MICROSWITCH REPLACEMENT

(See Fig 15)

Before doing this procedure, follow the Pressure

the risk of a fluid injection injury, splashing

in

the

Relief Procedure Warning on page 17 to reduce

eyes or on the skin, injury from moving parts, or

1. Remove the pressure control cover and screws.

2. Disconnect both wires from the microswitch

(3061.

3. Use the socket wrench to remove the nuts from the

microswitch.

4. Check to see if the flag

(X)

is loose. If

it

is, be sure

the

fluid

pressure is 0 bar

(0

psi), then loosen the

two 6 mm hex nuts behind the microswitch. Adjust

the distance from the top of the flat to top inside

of

the pressure control box to 40.79k 0.254 mm

(1.606*

0.010

in.).

Tighten the screwsand recheck

the dimension. Refer to Fig 1.

5. Perform the

STALL

PRESSURE

CALIBRATION

on page 24 before regular operation of the sprayer.

6. Reinstall the cover

and

screws.

15)

Fig

14

Fig

15

307-671

19

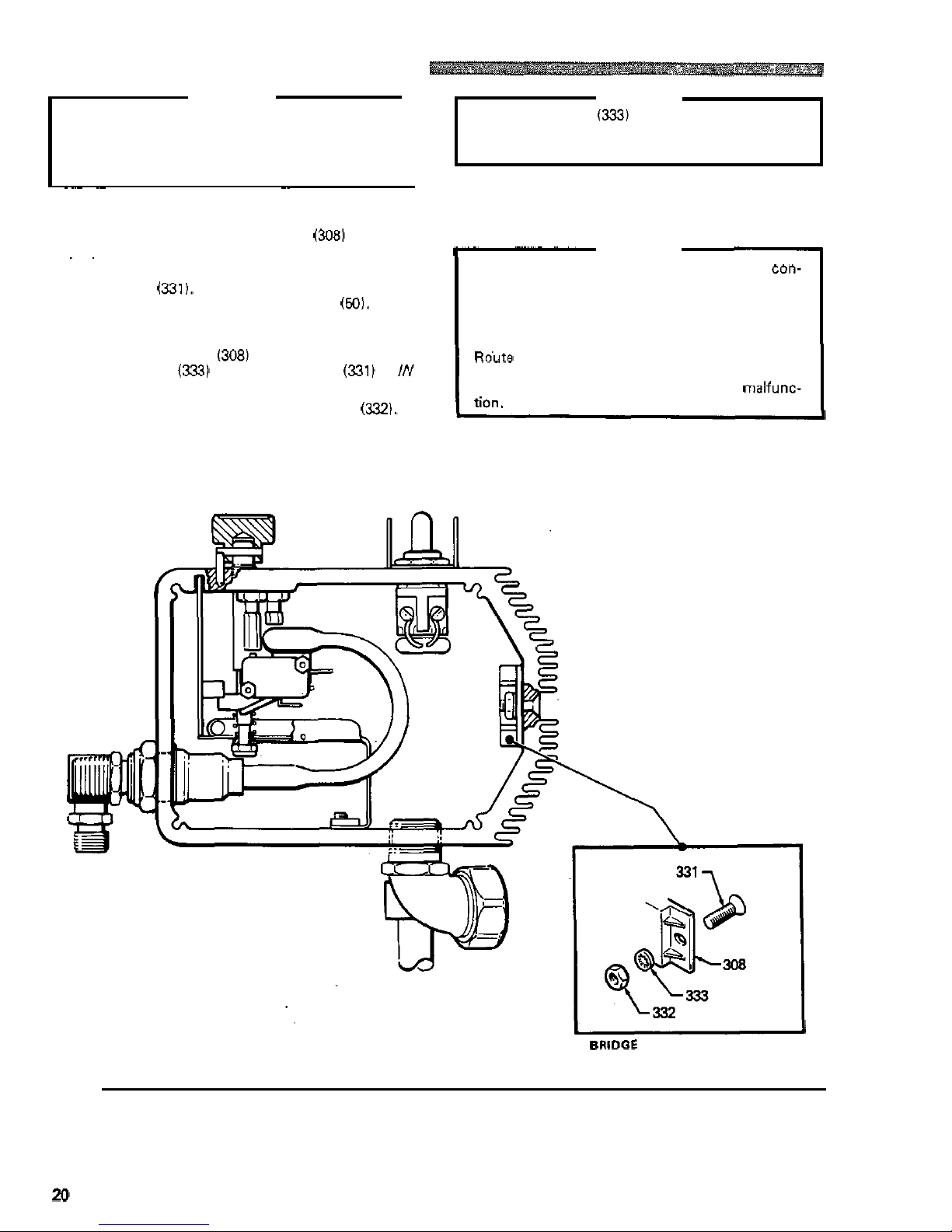

Page 21

BRIDGE RECTIFIER REPLACEMENT

(See

Fig 161

WARNING

Before doing this procedure, follow the Pressure

the risk of a fluid injection injury, splashing

in

the

Relief Procedure Warning on page 17 to reduce

eyes or on the skin, injury from moving parts or

electric shock.

1

~ ~~~ ~~ ~~

1.

Remove the pressure control cover and screws.

2.

Disconnect all wires from the bridge

(3081

at the ap

-

propriate terminals.

.

CAUTION

The lockwashers

(333)

must be in front

of

the

bridge to avoid overheating which

will

result

in

bridge failure. Refer to the Detail

in

Fig 16.

6. Make sure the bridge is flush with the side of the box

7. Connect all wires. Carefully route the wires.

I-

CAUTION

and tighten the screws securely.

3. Outside the pressure control box on the right side are

Be sure the flat blade of the insulated male

con-

two

screws

(331).

Loosen,

but don't remove the

nector is centered in the wrap

-

around blade of the

screw near the back mounting plate

(50).

Then

female connector when the connections are

loosen and remove the front screw. Slide the bridge

made. Improper connections may cause the

out.

~~

sprayer to malfunction.

4.

Slide the new bridge

(308)

into the box being sure

the lockwasher

(333)

on the rear screw (331) is

/N

Ro'ute all wires carefully to avoid interference with

FRONT

of the bridge. Refer to the Detail in Fig 16.

the movement of the bourdon tube, circuit board,

or control box cover which could cause a

malfunc-

5.

Install the front screw, lockwasher and

nut

(332).

8.

Reinstall the pressure control cover and screws.

BRIDCE

INSTALLATION

DETAIL

Fig

16

20

307-671

Page 22

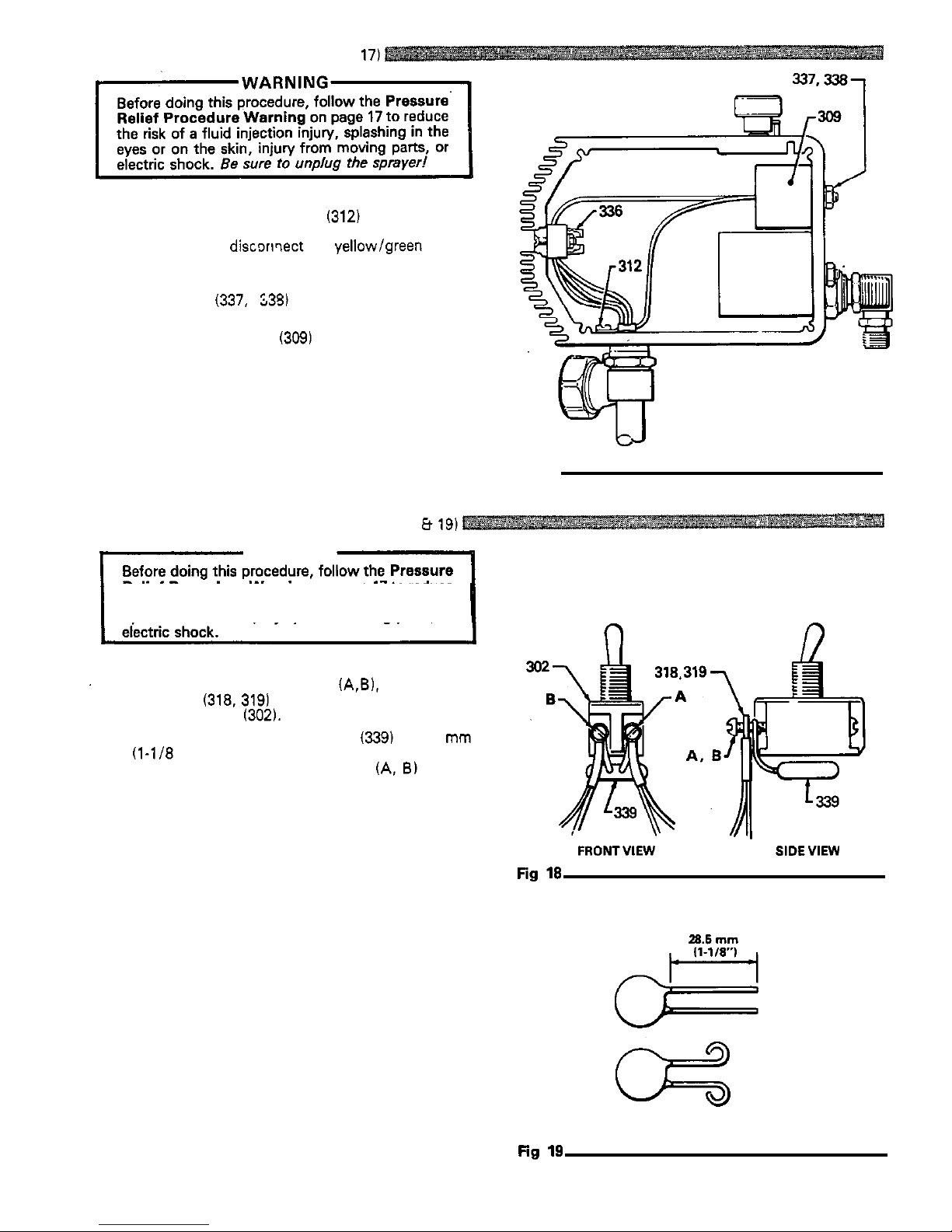

CHOKE REPLACEMENT

(See

Fig 17)

1. Remove the pressure control cover and screws.

2. Remove the grounding screw

(312) and remove the

lead. Loosen the appropriate screw on the terminal

lead.

strip (336) and

discornect the yellow/green choke

3.

Use

the M8 wrench

to

remove the upper nut and

lockwasher

(337,

US)

on the outside of the

pressure control box.

4.

Remove the old choke (309) and install a new one in

the reverse order of disassembly.

Fig

17

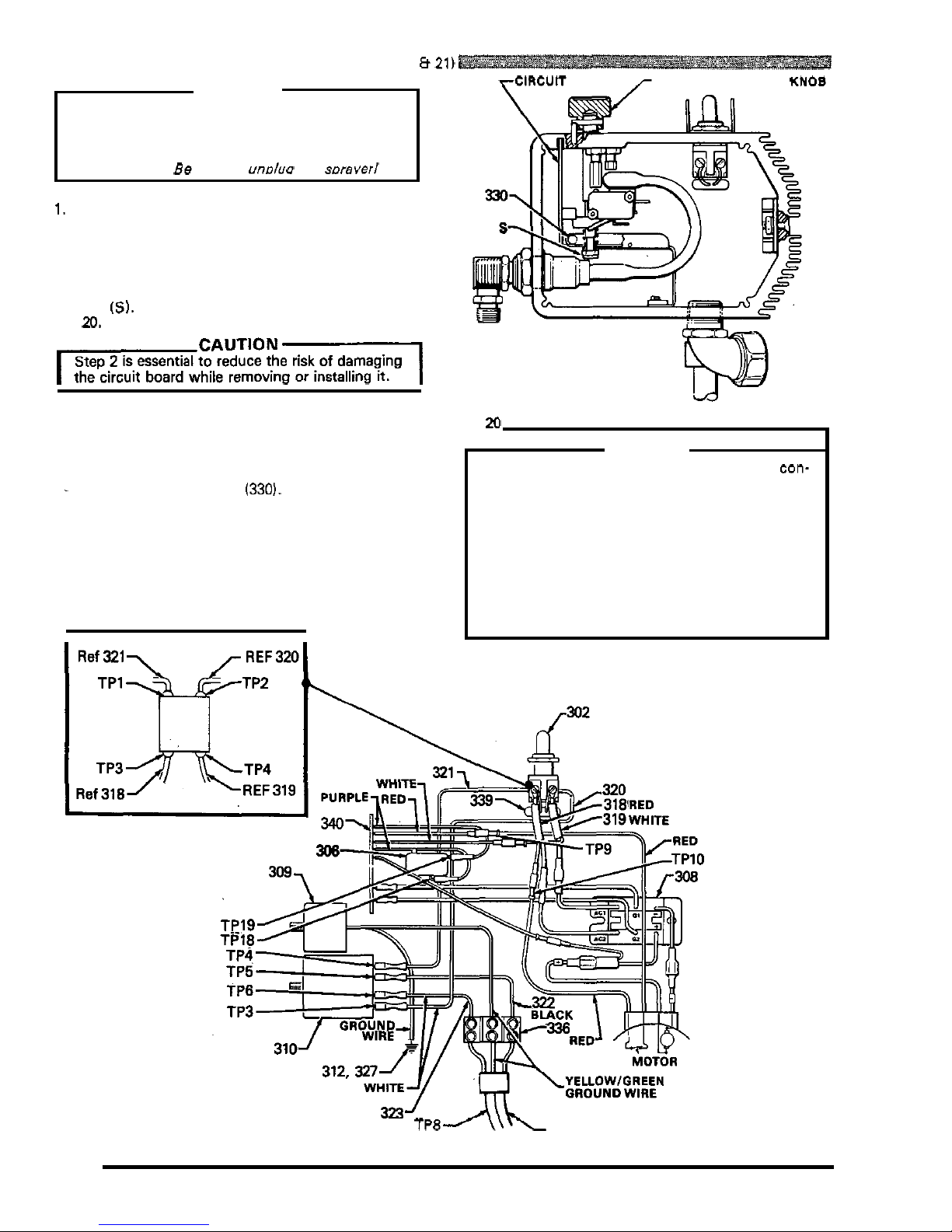

VARISTOR

REPLACEMENT

(See

Figs 18 8 19)

WARNING

Relief Procedure

Warning on page 17 to reduce

the risk of a fluid injection injury, splashing in the

eyes

or on the skin, injury from moving parts, or

n

1.

'

2.

3.

4.

5.

Remove the control box screws and cover.

Remove the

two

screws

(A$).

the wiring

harnesses

(318, 319) and the old varistor from the

ONlOFF switch

(302).

Trim the leads on the new varistor

(339)

to 28.5 mm

(1-118 in.). Turn each lead outward to form a loop

that

is

large enough for the screws

(A,

8) to pass

through.

loop

of

the varistor leads on each screw and thread

Place

a

wiring harness on each screw, then place

a

the screws into the switch.

Wrap the varistor under the switch.

n

FRONTVIEW

SIDEVIEW

307-671

21

Page 23

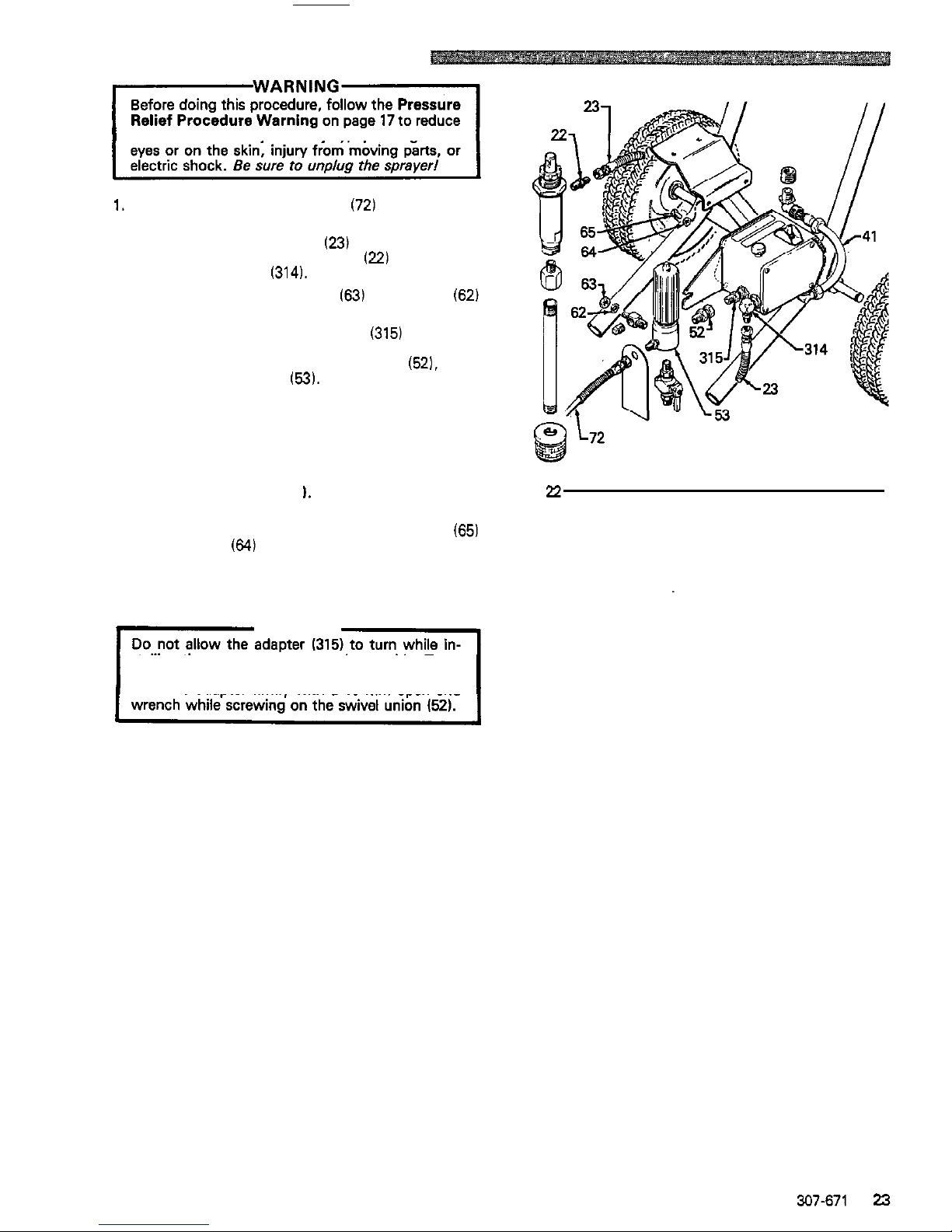

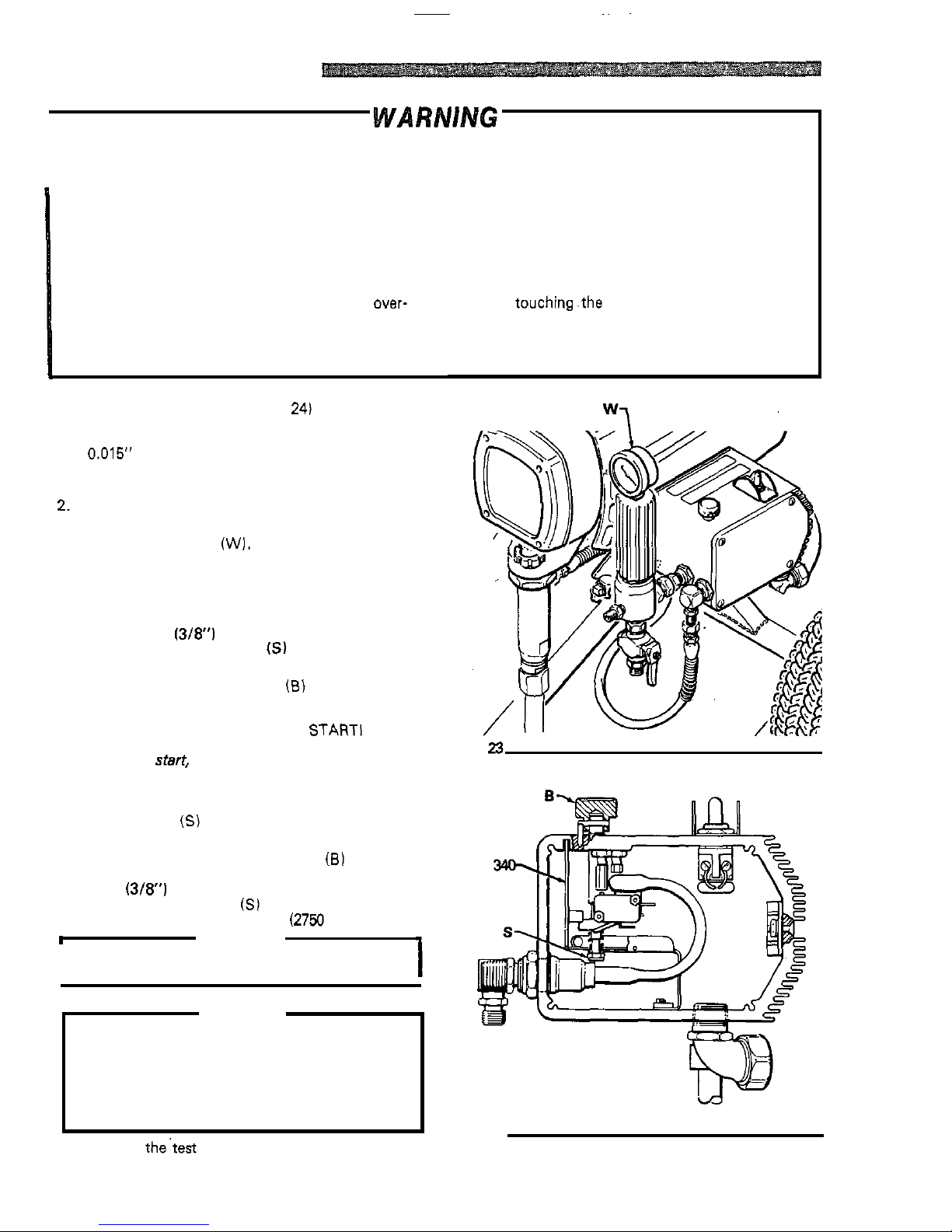

CIRCUIT BOARD REPLACEMENT