Page 1

INSTRUCTIONS/FIELD REPAIR e

307-643

ORACO

Rev E

SUPERSEDES D ’

This manual contains IMPORTANT

WARNINGS and INSTRUCTIONS

READ AND RETAIN FOR REFERENCE

120 VAC, 15 Amp

ULTRA’“333 AIRLESS PAINT SPRAYER

3ooo psi (207 bad MAXIMUM WORKING PRESSURE

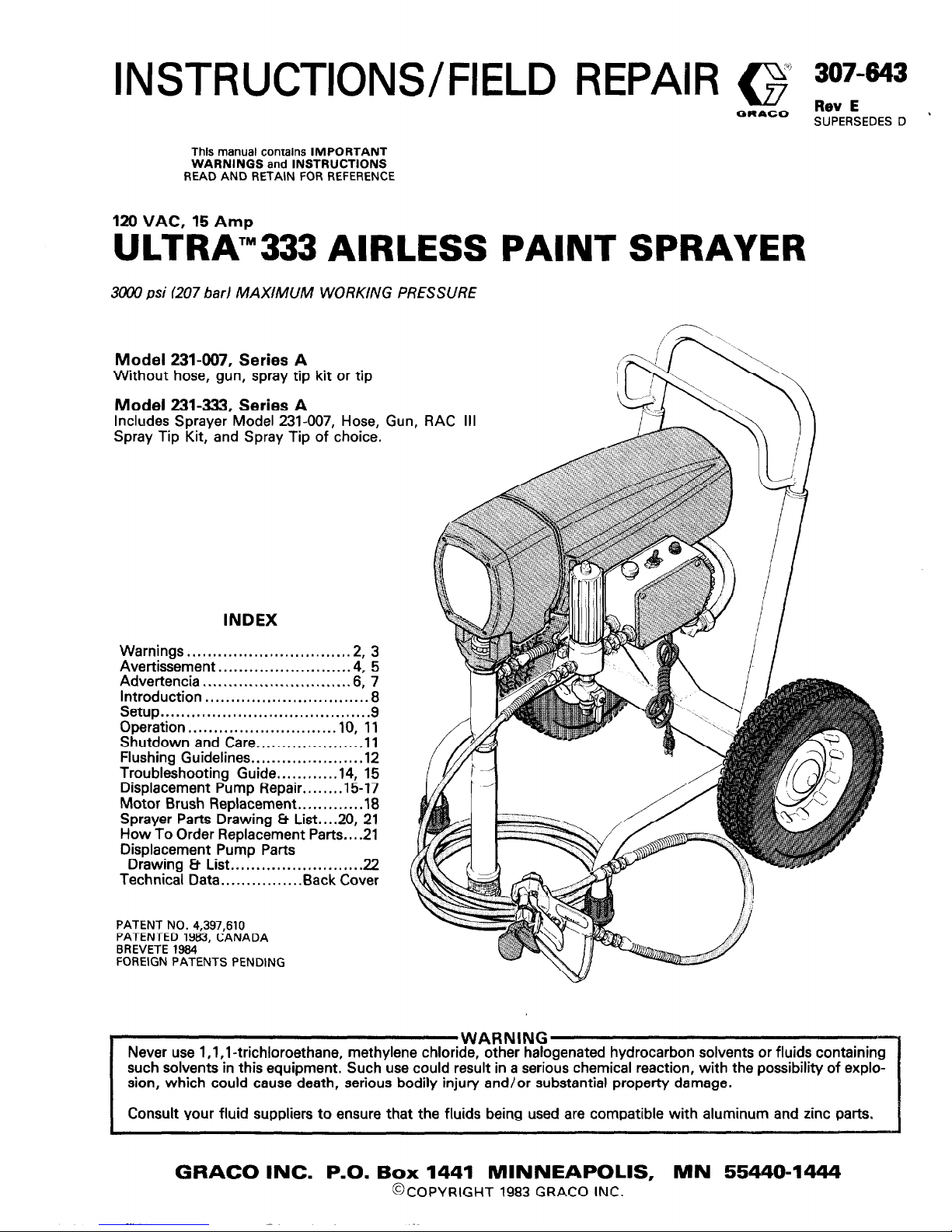

Model 231-007, Series A

Without hose, gun, spray tip kit

Model 231433, Series A

Includes Soraver Model 231-007.

or tip

Hose.

GI

Spray Tip Kit, and Spray Tip of ‘choice.

INDEX

Warnings ................................ 2, 3

Avertissement

......................... .4, 5

Advertencia

............................

.6, 7

Introduction..

.............................

.8

Setup ........................................ .9

Operation

............................. 10,

11

Shutdown and Care.. .................. .11

Flushing Guidelines..

...................

.12

Troubleshooting Guide..

.........

.14, 15

Displacement Pump Repair ...... ..15-17

Motor Brush Replacement ............ .18

Sprayer Parts Drawing 8 List....20, 21

How To Order Replacement Parts ...

.21

Displacement Pump Parts

Drawing 8 List ........................ ..22

Technical Data .............. ..Bac k Cover

PATENT NO. 4,397,610

PATENTED 1963, CANADA

BREVETE 1964

FOREIGN PATENTS PENDING

Never use l,l, 1 -trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids containing

such solvents in this equipment. Such use could result in a serious chemical reaction, with the possibility of explo-

property damage.

Consult your fluid suppliers to ensure that the fluids being used are compatible with aluminum and zinc parts.

GRACO INC. P.O. Box 1441 MINNEAPOLIS, MN 55440-1444

@COPYRIGHT 1983 GRACO INC.

Page 2

WARNING

HIGH PRESSURE SPRAY CAN CAUSE SERIOUS INJURY.

FOR PROFESSIONAL USE ONLY. OBSERVE ALL WARNINGS.

Read and understand all instruction manuals before opera:ing equipment.

This equipment generates very high fluid pressure. Spray from

the gun, leaks or ruptured components can inject fluid

through your skin and into your body and cause extremely

serious bodily injury, including the need for amputation. Also,

fluid injected or splashed into the eyes can cause serious

damage.

NEVER point the spray gun at anyone or at any part of the

body. NEVER put hand or fingers over the spray tip. NEVER

try to “blow back” paint; this is NOT an air spray system.

Spray Gun Safety Devices

Be sure all gun safety devices are operating properly before

each use. Do not remove or modify any part of the gun; this

can cause a malfunction and result in serious bodily injury.

Safety Latch

Whenever you stop spraying, even for a moment, always set

the gun safety latch in the closed or “safe” position, making

the gun inoperative. Failure to set the safety latch can result in

accidental triggering of the gun.

Diffuser

ALWAYS have the tip guard in place on the spray gun when

spraying.

The gun diffuser breaks up spray and reduces the risk of injec-

tion when the tip is not installed. Check diffuser operation

ALWAYS follow the

Pressure Relief Procedure,

below,

before cleaning or removing the spray tip or servicing any

system equipment.

NEVER try to stop or deflect leaks with your hand or body,

Be sure equipment safety devices are operating properly

before each use.

lI)rledifiaJ Treatment

any urd appears to penetrate your skin, get

EMERGENCY MEDICAL CARE AT ONCE.

DO NOT TREeT/IS A SIMPLS C&Jzeatment

Tell the doctor exactly w at lurd was rnjecte .

instructions, have your doctor call the

NATIONAL POISON CENTER NETWORK

(4121681-6669

regularly. Follow the

Pressure Relief Procedure,

below,

then remove the spray tip. Aim the gun into a metal pail,

holding the gun firmly to the pail. Using the lowest possible

pressure, trigger the gun. If the fluid emitted is not diffused into an irregular stream, replace the diffuser immediately.

Tip Guard

ALWAYS have the tip guard in place on the spray gun while

spraying. The tip guard alerts you to the injection hazard and

helps prevent accidentally placing your fingers or any part of

your body close to the spray tip.

Spray Tip Safety

Use extreme caution when cleaning or changing spray tips. If

the spray tip clogs while spraying, engage the gun safety latch

immediately. ALWAYS follow the

Pressure Relief Pro-

cedure

and then remove the spray tip to clean it.

NEVER wipe off build-up around the spray tip until pressure is

fully relieved and the gun safety latch is engaged.

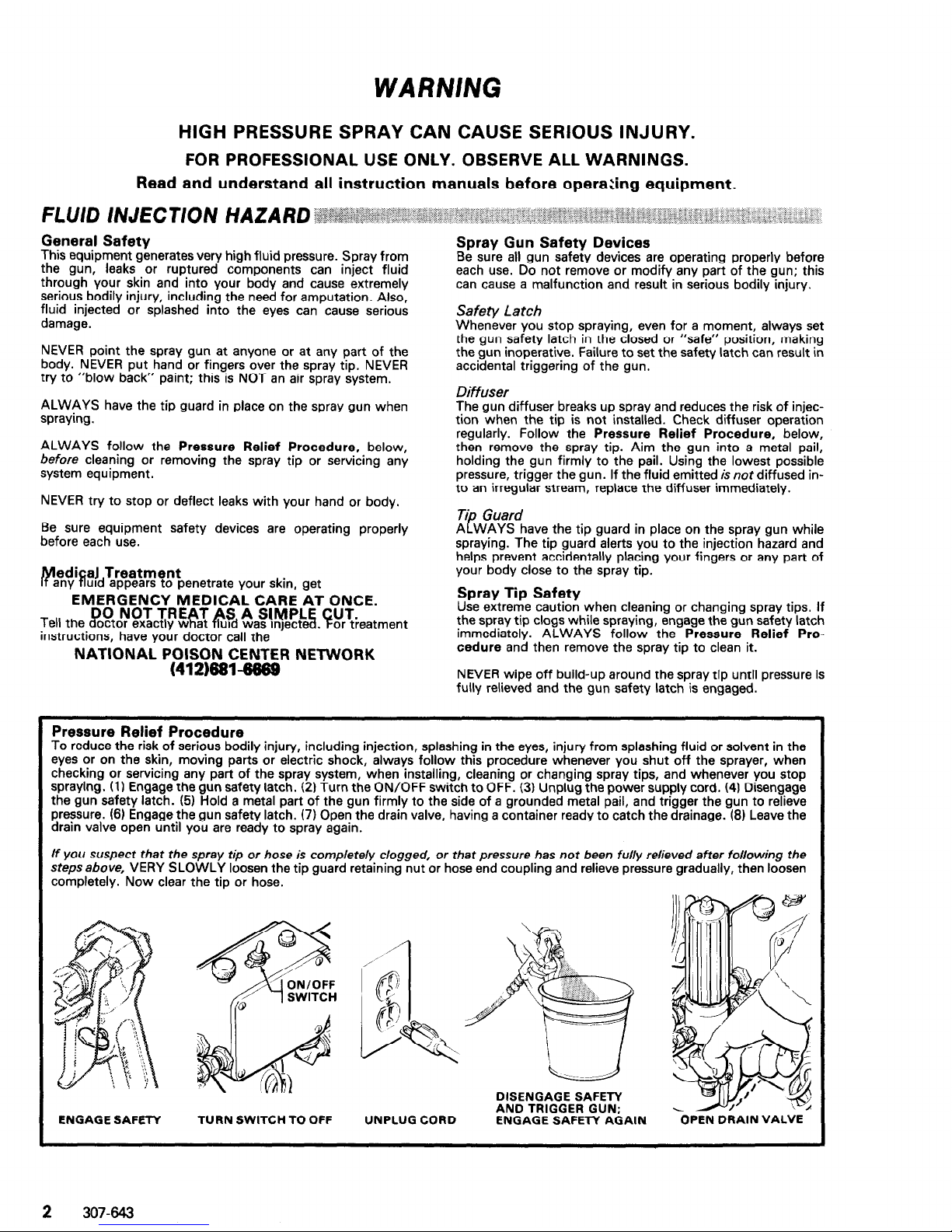

Pressure Relief Procedure

To reduce the risk of serious bodily injury, including injection, splashing in the eyes, injury from splashing fluid or solvent in the

eyes or on the skin, moving parts or electric shock, always follow this procedure whenever you shut off the sprayer, when

checking or servicing any part of the spray system, when installing, cleaning or changing spray tips, and whenever you stop

spraying. (11 Engage the gun safety latch. (2) Turn the ON/OFF switch to OFF. (3) Unplug the power supply cord. (41 Disengage

the gun safety latch. (5) Hold a metal part of the gun firmly to the side of a grounded metal pail, and trigger the gun to relieve

pressure. (61 Engage the gun safety latch. (7) Open the drain valve, having a container ready to catch the drainage. (8) Leave the

drain valve open until you are ready to spray again.

If YOU suspect that the spray tip or hose is completely clogged, or that pressure has nor been fully relieved after following the

steps above, VERY SLOWLY loosen the tip guard retaining nut or hose end coupling and relieve pressure gradually, then loosen

completely. Now clear the tip or hose.

UNPLUG CORD

DISENGAGE SAFETY

AND TRIGGER GUN;

ENGAGE SAFETY AGAIN

ENGAGE SAFETY TURN SWITCH TO OFF

OPEN DRAIN VALVE

2

307-643

Page 3

General Safety

Any misuse of the spray equipment or accessories, such as

overpressurizing, modifying parts, using incompatible

chemicals and materials, or using worn or damaged parts, can

cause them to rupture and result in injection or other serious

bodily injury, fire, explosion or property damage.

NEVER alter or modify any part of this equipment; doing so

could cause it to malfunction.

CHECK all spray equipment regularly and repair or replace

worn or damaged parts immediately.

System Press&e

This sprayer can develop 3ocyI psi 1207 bar) MAXIMUM

WORKING PRESSURE. Be sure that all spray equipment and

accessories are rated to withstand the maximum working

pressure of this sprayer. DO NOT exceed the maximum working pressure of any component or accessory used in the

system.

Fluid Compatibility

BE SURE that all fluids and solvents used are chemically compatible with the wetted parts shown in the Technical Data on

the back cover. Always read the fluid and solvent manufacturer’s literature before using them in this sprayer.

High pressure fluid in the hoses can be very dangerous. If the

hose develops a pinhole leak, split or rupture due to any kind

of wear, damage or misuse, the high pressure spray emitted

from it can cause an injection injury or other serious bodily in-

jury or property damage.

ALL FLUID HOSES MUST HAVE SPRING GUARDS!

The

spring guards help protect the hose from kinks or bends at or

close to the coupling which can result in hose rupture.

TIGHTEN all fluid connections securely before each use. High

pressure fluid can dislodge a loose coupling or allow high

pressure spray to be emitted from the coupling.

NEVER use a damaged hose. Before each use, check entire

hose for cuts, leaks, abrasion, bulging cover, or damage or

movement of the hose couplings. rf any of these condgions

exist, replace the hose immediatelv. DO NOT trv to recouole

high pressure hose or mend it with tape or any other device: A

repaired hose cannot contain the high pressure fluid.

HANDLE AND ROUTE HOSES CAREFULLY. Do not pull on

hoses to move equipment. Do not use fluids or solvents which

are not compatible with the inner tube and cover of the hose.

DO NOT expose Grace hose to temperatures above 180°F

KW’C) or below -4W’F (-40°C).

Hose Grounding Continuity

Proper hose grounding continuity is essential to maintaining a

grounded spray system. Check the electrical resistance of your

air and fluid hoses at least once a week. If your hose does not

have a tag on it which specifies the maximum electrical

resistance, contact the hose supplier or manufacturer for the

maximum resistance limits. Use a resistance meter in the appropriate range for your hose to check the resistance. If the

resistance exceeds the recommended limits, replace it im-

mediately. An ungrounded or poorly grounded hose can make

your system hazardous. Also read

FIRE OR EXPLOSION

HAZARD.

Static electricity is created by the high velocity flow of fluid

through the pump and hose. If every part of the spray equipment is not properly grounded, sparking may occur, and the

system may become hazardous. Sparking may also occur

when plugging in or unplugging a power supply cord. Sparks

can ignite fumes from solvents and the fluid being sprayed,

dust particles and other flammable substances, whether you

are spraying indoors or outdoors, and can cause a fire or explosion and serious bodily injury and property damage.

Always plug the sprayer into an outlet at least 20 feet (6 ml

away from the sprayer and the spray area. Do not plug in or

unplug any power supply cords in the spray area when there is

any chance of igniting fumes still in the air.

If you experience any static sparking or even a slight shock

while using this equipment,

STOP SPRAYING IMMEDI-

ATELY.

Check the entire system for positive grounding. Do

not use the system again until the problem has been identified

and corrected.

Grounding

To reduce the risk of static sparking, ground the sprayer and

all other spray equipment used or jo&ed in the spray area.

CHECK vour local electrical code for detailed aroundino instruction; for your area and type of equipment-BE SURE to

ground all of this spray equipment:

1.

2.

3.

4.

5.

6.

Sprayer: plug the power supply cord, or extension cord,

each equipped with an undamaged three-prong plug, into

a properly grounded outlet. Do not use an adapter. All extension cords must have three wires and be rated for 15

amps.

Fluid hoses: use only grounded hoses with a maximum of

500 feet (150 ml combined hose length to ensure grounding continuity. Refer to

Hose Grounding Continuity.

Spray gun: obtain grounding through connection to a

properly grounded fluid hose and sprayer.

Object being sprayed: according to local code.

All solvent pails used when flushing, according to local

code. Use only metalpails, which are conductive. Do not

place the pail on a non-conductive surface, such as paper

or cardboard, which interrupts the grounding continuity.

To maintain grounding continuity when flushing or relievingpressure, always hold a metal part of the gun firmly to

the side of a grounded metal pail, then trigger the gun.

Flushing Safety

Reduce the risk of injection injury, static sparking, or splashing

by following the specific flushing procedure given on page 12

of this manual. Follow the

Pressure Relief Procedure

on

page 2, and remove the spray tip before flushing. Hold a metal

part of the gun firmly to the side of a metal pail and use the

lowest possible fluid pressure during flushing.

MOVING PARTS HAZARD i :‘:.,..:. :

.

Moving parts can pinch or amputate your fingers or other

bodv Darts. KEEP CLEAR of movina oarts when startina or

operating the sprayer. Unplug the sp;ayer and relieve pressure

before checking or servicing the sprayer to prevent it from

starting accidentally.

IMPORTANT

United States Government safety standards have been adopted under the Occupational Safety and Health Act. These standards-par-

ticularly the General Standards, Part 1910, and the Construction Standards, Part 1926-should be consulted.

Page 4

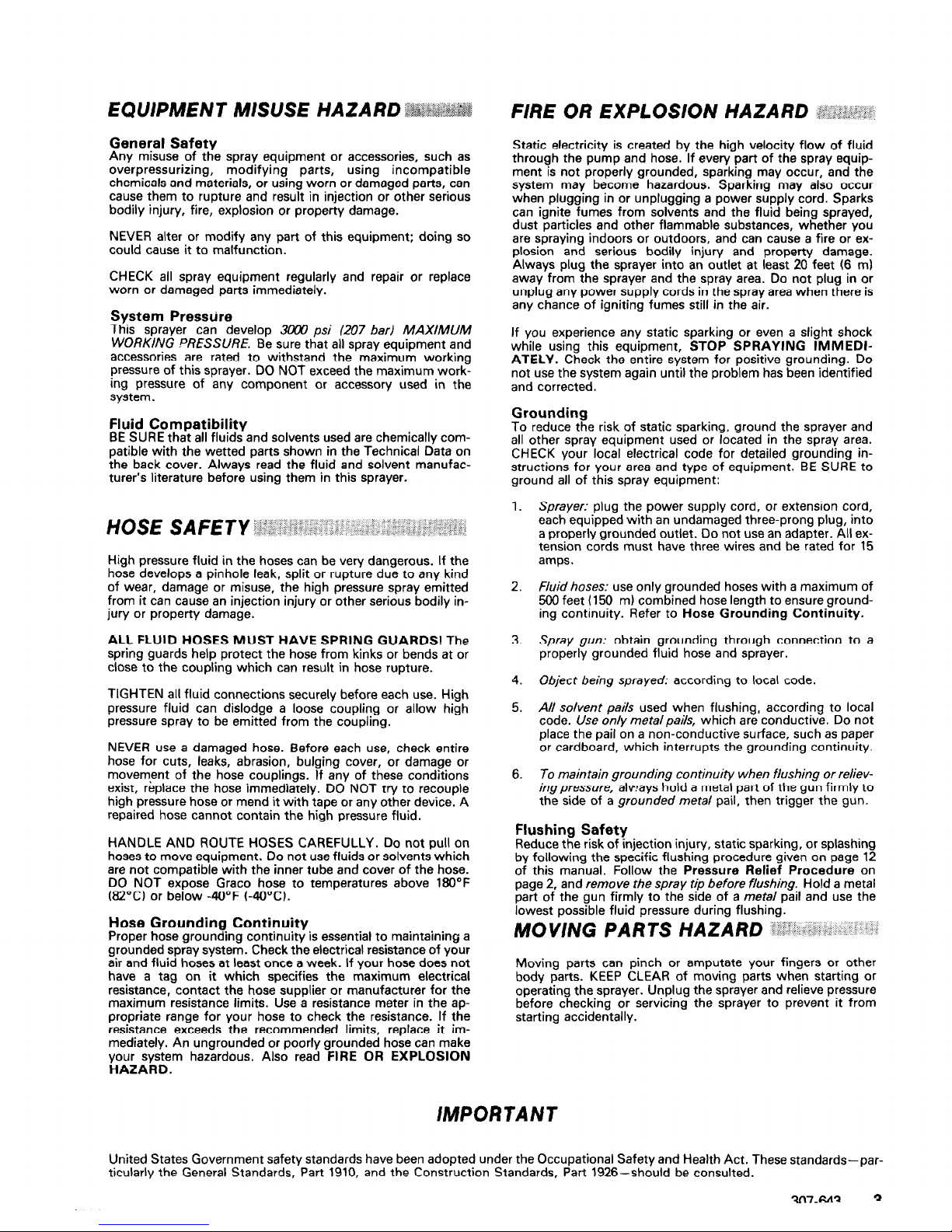

AVERTISSEMENT

La pulv&isation

il haute

pression peut causer des blessures t&s graves.

FUserv6 exclusivement A I’usage professionnel. Observer toutes les consignes de s6curit6.

Bien lire et bien comprendre tous les manuels d’instructions avant d’utiliser le materiel.

Consignes g&i&ales de s6curit6

Cet appareil produit un fluide B t&s haute.pression. Le fluide

pulv&isk par le pistolet ou le fluide sous pression provenant de

fuites ou de ruptures peut p&&rer sous la peau ou B I’intbrieur

du corps et entrainer des blessures tr&s graves, voir mQme une

amputation. Mdme

sans

btre sous pression, le fluide Bclaboussant ou entrant dans les yeux peut aussi entrainer des

blessures graves.

NE JAMAIS pointer le pistolet vers quelqu’un ou vers une partie quelconque du corps. NE JAMAIS mettre la main ou les

doigts sur I’ajutage du pulvkisateur. NE JAMAIS essayer de

“refouler” la peinture. Cet appareil N’est PAS un compresseur

pneumatique.

TOUJOURS garder la protection de I’ajutage en place sur le

pistolet pendant la pulvt%isation.

TOUJOURS observer la

March B Suivre pour DBtendre la

Pression

don&e plus loin,

avant

de nettoyer ou d’enlever

l’ajutage du pulvkisateur, ou d’effectuer un travail quelconque sur une partie de I’appareil.

NE JAMAIS essayer d’arrbter ou de dkvier les fuites avec la

main ou le corps.

Avant chaque utilisation, bien s’assurer que les dispositifs de

skuritk fonctionnent correctement

Soins m6dicaux

En cas de p&&ration de fluide sous la peau:

DEMANDER IMMEDIATEMENT DES SOINS

MEDICAUX D’URGENCE.

NE PAS SOIGNER CETTE BLESSURE COMME

UNE SIMPLE COUPURE.

Dire exactement au mbdecin quel type de liquide a BtB inject6.

Pour avoir des instructions concernant le traitement appropri8, dire au mbdecin d’appeler le

CENTRE ANTI-POISON SUIVANT:

NATIONAL POISON CENTER NETWORK

(4121681-6669

Disoositifs de skurit6 du oistolet

vaht chaque utilisation, bien s’ksure que tous les dispositifs

enlever ni modifier une partie quelconque du pistolet; ceci risquerait d’entrainer un mauvais fonctionnement et des

blessures graves.

Verrou de s&&t+

A chaque fois que I’on s’arrbte de pulkiser, mGme s’il s’agit

d’un court instant, toujours mettre le verrou de srkurit~ du

pistolet sur la position “fermbe” ou “st5curiW (“safe”) pour

empkher le pistolet de fonctionner. Si le verrou de skuritk

n’est pas mis, le pistolet peut se declencher accidentellement.

Diffuser

Le diffuseur du pistolet sert & diviser le jet et B reduire les risques d’injection accidentelle quand I’ajutage n’est pas en

place. Wrifier le fonctionnement du diffuseur rt%gulibrement.

Pour cette vkification, d&endre la pression en observant la

Marche B Suivre pour DBtendre la Pression

donnbe plus

loin puis enlever I’ajutage du pulwkisateur. Pointer le pistolet

dans un seau en m&al, en le maintenant fermement contre le

seau. Puis, en utilisant la pression la plus faible possible, appuyer sur la gachette du pistolet. Si le fluide projetk n’est pas

diffuse sous forme de jet irkgulier, remplacer immbdiatement

le diffuseur.

Protection de l’ajutage

TOUJOURS maintenir la protection de I’ajutage en place sur le

pistolet du pulvbrisateur pendant la pulvtkisation. La protection de I’ajutage attire I’attention sur les risques d’injection et

contribue B Bviter que les doigts ou une partie quelconque du

corps ne passe accidentellement B proximitb immediate de

I’ajutage du pulv&isateur.

Consignes de skurit6 concernant I’ajutage du

pulv&lsateur

Faire extrgmement attention B I’occasion du nettoyage ou du

remplacement des ajutages du pulvkisateur. Si I’ajutage se

bouche pendant la pulv&isation, mettre immbdiatement le

verrou de skuritk du pistolet. TOUJOURS bien observer la

Marche B Suivre pour DBtendre la Pression

puis enlever

I’ajutage du pulv&isateur pour le nettoyer.

NE JAMAIS essuyer ce qui s’est accumuk autour de I’ajutage

du pulvckisateur avant que la pression ne soit compktement

tombbe et que le verrou de skuritd du pistolet ne soit engag&

? securite du pistolet fonctionnent correctement. Ne pas

Marche B Suivre pour D6tendre la Pression

Pour reduire les risques de blessures graves, y compris les blessures par injection de fluide ou celles causkes par d’Bcla boussant

dans les yeux ou au de peau, des pikes en mouvement ou par Electrocution, toujours bien observer cette marche a suivre B chaque fois que I’on arrdte le pulwkisateur, 3 I’occasion de la wkification ou de la rkparation d’une pike de I’appareil de pulvkisation, B I’occasion de I’installation, du nettoyage ou du remplacement des ajutages et d’une manibre g&-kale B chaque arrbt. 1)

Engager le verrou de s&urite du pistolet. 21 Mettre I’interrupteur Marche-Arrbt sur ARRET (“OFF”). 31 DBbrancher le cordon

d’alimentation. 4) DBsengager le verrou de skuritb du pistolet. 5) En maintenant une partie m&allique du pistolet fermement appuybe contre le c&B d’un seau en m&al, appuyer sur la gachette du pistolet pour libker la pression. 6) Engager le verrou de

skuritb du pistolet. 7) Ouvrir le robinet de purge en prenant soin d’avoir un recipient pr& & r&cup&er le liquide. 8) Laisser le

robinet de purge ouvert jusqu’8 ce que le pulwkisateur soit de nouveau pr& ?I Btre utilisB.

Sil’on soupconne que I’ajutage do pulv&isateur au le tuvau est compktement bouchb, ou que la pression n’a pas 4th compktement lib&&e apr& avoir proct!dh aux opharions ci-dessus, desserrer TRES LENTEMENT I’Bcrou de retenue de la protection de

I’aiutaae ou le raccord du bout du tuvau et liberer orogressivement la pression, puis terminer le desserrage. On peut maiAtenant

dlboucher I’ajutage ou le tuyau.

’

1

2

4,5.6

Page 5

RISQUES EN CAS DE MAUVAISE UTILISATION DU MATERIEL

Consignes g6n6rales de s&wit6

Pression

Toute utilisation anormale de I’appareil de pulverisation ou des

Ce pulverisateur peut produire une PRESS/ON MAXIMUM DE

accessoires comme, par exemple, la mise sous une pression

TRAVAIL 207 bar (300 lb/po.2). S’assurer que tous les

excessive, les modifications de pieces, I’utilisation de produits

elements du pulverisateur et ses accessoires sont concus pour

chimiques et de mat&es incompatibles et I’utilisation de

resister a la pression maximum de travail de ce pulverisateur.

pieces u&es ou abimees peut causer des degats a I’appareil ou

NE PAS depasser la pression maximum de travail d’aucun des

des ruptures de pieces et entrainer une injection de liquide ou

elements ou accessoires utilises avec cet appareil.

d’autres blessures serieuses, un incendie, une explosion ou

d’autres d&g&.

Compatibilit6 chimique des corps

BIEN S’ASSURER que tous les corps des solvants utilises

VERIFIER regulierement tout I’appareil de pulverisation et ses

Bquipements et &parer ou remplacer immediatement les

pieces u&es ou abimees.

NE JAMAIS alterer ou modifier une piece de cet appareil; ceci

sont chimiquement compatibles avec les parties mouillees in-

risquerait d’entrainer son mauvais fonctionnement.

diquees dans les “Don&es techniques”, au dos de la couverture. Toujours lire soigneusement I& documents et brochures

du fabricant des fluides et solvants utilises avant de s’en servir

dans ce pulverisateur.

MESURES DE SECURITE CONCERNANT LES TUYAUX FLEXIBLES

Le fluide a haute pression circulant dans les tuyaux peut dtre

t&s dangereux. En cas de fuite sur le tuyau, m&me minuscule,

de fissure, dechirure ou rupture a la suite de I’usure, de degdts

ou d’une mauvaise utilisation, les projections de fluide haute

pression qui en proviennent peuvent entrainer des blessures

graves par pen&ration sous la peau ou par contact, ainsi que

des degdts materiels.

TOUS LES TUYAUX FLEXIBLES DOIVENT AVOIR DES

RESSORTS SPIRALE DE PROTECTION!

Les spirales de

protection contribuent a Bviter la formation de pliures, de

boucles ou de noeuds sur les tuyaux qui pourraient entrainer la

rupture du tuyau a I’endroit du raccord ou a son voisinage.

SERRER FERMEMENT tous les raccords avant chaque utilisa-

tion. Le fluide sous pression peut faire sauter un raccord

desserre ou produire un jet a haute pression s’echappant par le

raccord.

NE JAMAIS utiliser un tuyau endommage. Avant chaque

utilisation, verifier entierement chaque tuyau pour deceler les

coupures, fuites, abrasions, boursouflures de I’enveloppe ou

toute autre deterioration ou jeu des raccords. Si I’on constate

I’une de ces deteriorations, il faut remplacer le tuyau immediatement. NE PAS essayer de refaire le raccord d’un tuyau

haute pression ni de r&parer le tuyau avec du ruban adhesif ou

RISQUES D’INCENDIE OU D’EXPLOSION

De l’electricite statique est produite par le passage du fluide a

grande vitesse dans la pompe et dans les tuyaux. Si toutes les

pieces de I’appareil de pulverisation ne sont pas convenablement reliees a la masse ou a la terre, des Btincelles peuvent se

produire et I’appareil risque d’etre dangereux. Des Btincelles

peuvent Bgalement se produire a I’occasion du branchement

ou du debranchement du cordon d’alimentation. Les Btincelles

sont suffisantes pour allumer les vapeurs de solvants et le

fluide pulverise, les fines particules de poussiere ainsi que

d’autres substances inflammables, quand on pulverise a I’interieur ou a I’exterieur, et elles peuvent causer un incendie ou

une explosion, ainsi que des blessures graves et des degats

materiels. Toujours brancher le pulverisateur dans une prise se

trouvant a au moins 6 m (20 piedst de I’appareil et de I’endroit

ou se fait la pulverisation. Ne pas brancher ou debrancher un

cordon d’alimentation quel qu’il soit dans la zone air se fait la

pulverisation quand il y a le moindre risque que des vapeurs

encore presentes dans I’air prennent feu.

Mise a la terre ou d la masse

Pour reduire les risques de production d’etincelles d’electricite

statique, le pulverisateur et tous les Bquipements utilises ou se

trouvant dans la zone de pulverisation doivent etre relies 8 la

terre ou a la masse. Pour connaitre le detail des instructions de

mise a la terre dans la region et le type particulier d’equipement, CONSULTER le code ou les reglementations Blectriques

locales. S’ASSURER que tous les Bquipements de pulverisa-

tion suivants sont bien relies a la terre:

1. PuWrisateur: Brancher le cordon d’alimentation ou la

rallonge qui doivent dtre equip& d’une prise B 3 fiches en bon

&at, dans une prise de courant convenablement mise a la

terre. Ne pas utiliser d’adaptateur. Toutes les rallonges doivent

avoir 3 fils et etre prevues pour 15 amperes.

par tout autre moyen. Un tuyau repark ne peut pas resister au

fluide sous pression.

MANIPULER LES TUYAUX AVEC PRECAUTION ET

CHOISIR SOIGNEUSEMENT LEUR CHEMIN. Ne pas deplacer

le fluide en tirant sur le tuyau. Ne pas utiliser de fluides ou de

solvants qui ne sont pas compatibles avec I’enveloppe interieure ou exterieure du tuyau. NE PAS exposer le tuyau a

des temperatures superieures a 82°C (180°F) ou inferieures a

-40°C (-40°F).

Continuit6 de la mise B la terre des tuyaux

Une bonne continuite de la mise a la terre des tuyaux est

essentielle pour maintenir la mise a la terre de I’ensemble de

vaporisation. Verifiez la resistance Blectrique de vos tuyaux a

fluides et a air, au moins une fois par semaine. Si votre tuyau

ne comporte pas d’etiquette qui precise la resistance Blectrique maximum, prenez contact avec le fournisseur de tuyaux

ou la fabricant pour avoir les limites de resistance maximum.

Utilisez un metre de resistance de la gamme appropriee pour

votre tuyau et verifiez la resistance. Si celle-ci depasse les

limites recommandees, remplacez le tuyau immediatement.

Un tuyau sans mise a la terre ou avec une mise a la terre incorrecte peut entrainer des risques pour votre systeme. Lisez

aussi

LES RISQUES D’INCENDIE OU D’EXPLOSION

ci-

dessus.

2. Tuyaux flexibles: Afin d’assurer la continuite de la mise a la

terre, n’utiliser que des tuyaux comportant une mise a la terre

et ayant une longueur maximum combinee de 150 m

(1500 pieds). Se reporter Bgalement au paragraphe

“Con-

tinuitb du circuit de mise B la terre des tuyaux”.

3. Pistolet: Realiser la mise B la terre en le raccordant a un

tuyau flexible et a un pulverisateur deja convenablement relies

B la terre.

4. Objets, mathriel ou surfaces recevant la pulvkrisation:

observer le code ou les reglementations locales.

5. Tous /es seaux de solvants utilisb pour le rincage: observer

le code ou les reglementations locales. N’utilser que des seaux

mhfalliques conducteurs de I’electricite. Ne pas mettre le seau

sur une surface non conductrice comme sur du papier ou du

carton car cela interromprait la continuite le la mise a la terre.

6. Pour conserver la continuit& de la mise d la terre quand on

rince le mat&iel ou quand on lib&e la pression, toujours

maintenir une partie metallique du pistolet fermement appuyee

contre le c&e dun seau en m&al puis appuyer sur la detente

du pistolet.

Mesures de S6curit6 concernant le Rincage

Pour reduire les risques de blessures par pen&ration de la

peau et les risques dirs aux Btincelles d’electricite statique ou

aux Bclaboussures, observer la marche a suivre pour le rincage

don&e a la page 12 de ce manuel. Observer la

“Marche Zi

Suivre pour DBtendre la Pression”

donnee a la page 4 en

enlever l’ajutage du pulvhisateur avant le rincage. Maintenir

une partie metallique du pistolet fermement appuyee contre le

cot& d’un seau en m&a/ et utiliser la pression la plus faible

possible pendant le rincage.

307-643 5

Page 6

EL ROCIADO A ALTA PRESION PUEDE CAUSAR GRAVES LESIONES.

SOLO PARA US0 PROFESIONAL. RESPETE LOS AVISOS DE ADVERTENCIA.

Lea y entienda todo el manual de instrucciones antes de manejar el equipo.

PELlGRO DE INYEGGlON DE FLUID0

Seguridad general

Este equip0 genera un fluid0 a una presidn muy alta. El

rociado de la pistola, 10s escapes de fluid0 o roturas de 10s

componentes pueden inyectar fluid0 en la piel y el cuerpo y

causar lesiones extremadamente graves, incluyendo a veces la

necesidad de amputation. Tambien, el fluid0 inyectado o

salpicado en 10s ojos puede causar graves dafios.

NUNCA apuntar la pistola hacia alguien o alguna parte del

cuerpo. NUNCA colocar la mano o 10s dedos encima de la bo-

quilla. NUNCA tratar de “hater retornar la pintura”; este NO

es un sistema de rociado de aire.

SIEMPRE tener colocado el protector de la boquilla en la

pistola mientras se esta pulverizando.

SIEMPRE seguir el

procedimiento de descarga de presih,

dado m&s abjo, antes de limpiar o sacar la boquilla o de dar

servicio a cualiquier equip0 del sistema.

NUNCA tratar de parar o desviar 10s escapes con la mano o el

cuerpo.

Aparatos de seguridad de la pistola pulverizadora

Asegurar que todos 10s aparatos protectores de la pistola

estan funcionando bien antes de cada uso. No sacar ni

modificar ninguna pieza de la pistola pues podria causal el

malfuncionamiento de la misma con las consiguientes lesiones

personales.

Pestiffo de segoridad

Cada vez que se deje de pulverizar, aunque sea por un breve

momento, siempre colocar el pestillo de seguridad en la

position “cerrada”, lo que deja la pistola inoperante. El no

hacerlo puede llevar al disparo imprevisto de la pistola.

Difusor

El difusor de la pistola dispersa el chorro pulverizado y reduce

el riesgo de inyeccion cuando no esta instalada la boquilla.

Revisar con regularidad el funcionamiento del difusor. Seguir

el

procedimiento de descarga de presih,

dado m&s abajo,

y despues sacar la boquilla. Apuntar la pistola a un balde

metalico, sosteniendola bien firme contra BI. Utilizando la

presibn mas bajo posible, disparar la pistola. Si el fluid0

emitido no sa/e disperse en un chorro irregular, reemplazar de

inmediato el difusor.

Protector de la boquilfa

SIEMPRE tener el protector de la boquilla colocado en la

pistola mientras se esta pulverizando. Este protector llama la

atencibn contra el peligro de inyeccibn y ayuda a prevenir la

colocacion accidental de 10s dedos o cualquier otra parte del

cuerpo cerca de la boquilla.

Seguridad de la boquilla pulverizadora

Tener mucho cuidado al limpiar o cambiar las boquillas. Si

llegara a obstruirse mientras esta pulverizando, enganchar el

pestillo de la pistola de inmediato. SIEMPRE seguir el

pro-

cedimiento de descarga de presih

y despues sacar la bo-

quilla para limpiarla.

NUNCA limpiar la acumulacion de pintura alrededor de la bo-

quilla antes de que se haya descargado por complete la

Asegurar que todos 10s aparatos de seguridad del equip0

estan funcionando bien antes de cada uso.

Tratamiento medico

Si pareciera que un poco de fluid0 penetrb la piel, conseguir

TRATAMIENTO MEDICO DE URCENCIA DE

INMEDIATO.

NO TRATAR LA HERIDA COMO UN SIMPLE CORTE

Decir al medico exactamente cua fluid0 fue. Para instrucciones de tratamiento, pedir al medico que llame a la

CADENA DEL CENTRO NACIONAL DE

ENVENENAMIENTO

(4121681-6669

presion y el pestillo este enganchado.

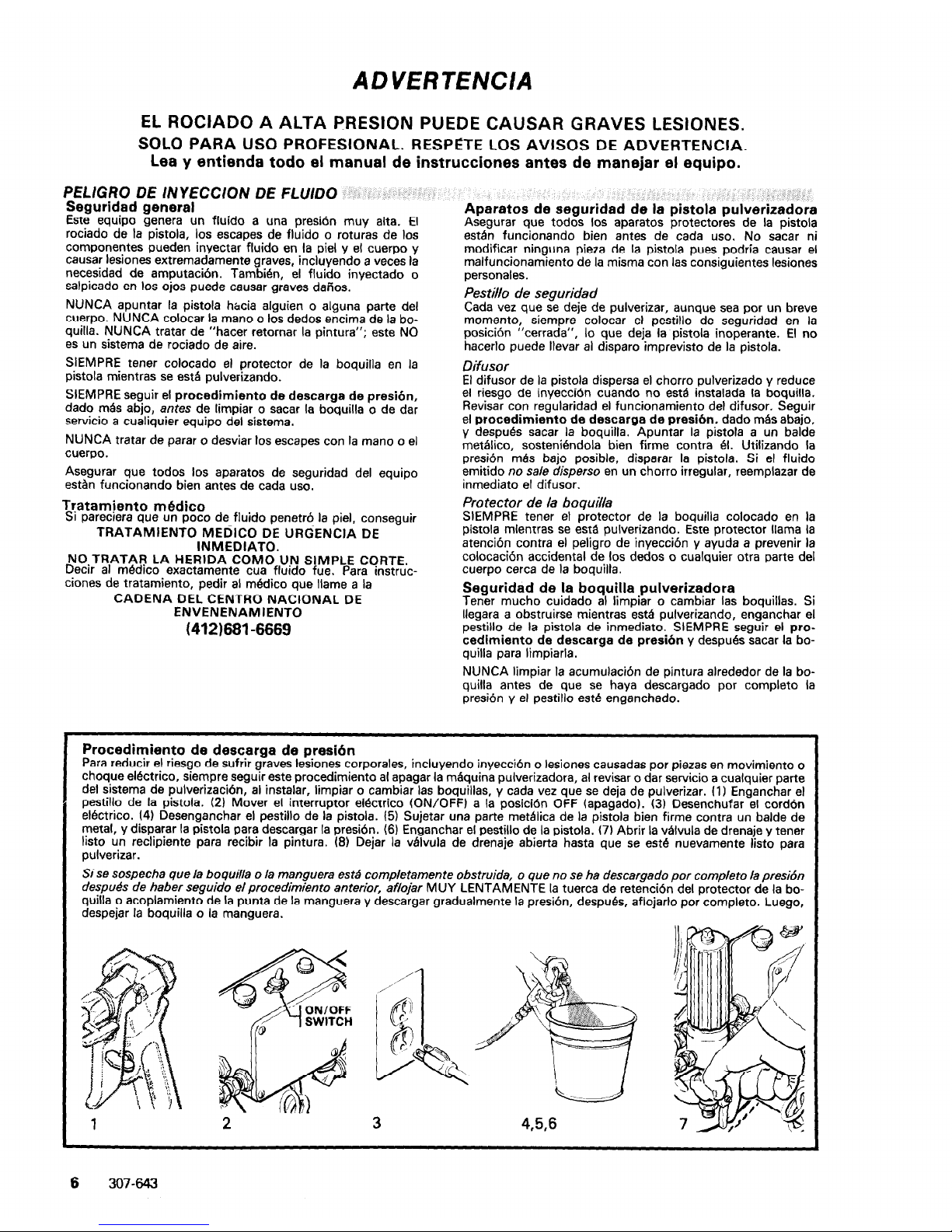

Procedimiento de descarga de presih

Para reducir el riesgo de sufrir graves lesiones corporales, incluyendo inyeccion o lesiones causadas por piezas en movimiento o

choque electrico, siempre seguir este procedimiento al apagar la mtiquina pulverizadora, al revisar o dar servicio a cualquier parte

del sistema de pulverizacibn, al instalar, limpiar o cambiar las boquillas, y cada vez que se deja de pulverizar. (1) Enganchar et

pestillo de la pistola. (2) Mover el interruptor electrico (ON/OFF) a la posicidn OFF (apagado). (3) Desenchufar el cordon

electrico. (4) Desenganchar el pestillo de la pistola. (5) Sujetar una parte metalica de la pistola bien firme contra un balde de

metal, y disparar la pistola para descargar la presion. (6) Enganchar el pestillo de la pistola. (7) Abrir la v&lvula de drenaje y tener

listo un reclipiente para recibir la pintura. (8) Dejar la valvula de drenaje abierta hasta que se este nuevamente listo para

pulverizar.

Si se sospecha que la boquilla o la manguera est& completamente obstruida, o que no se ha descargado por complete la presibn

despub de haber seguido elprocedimiento anterior, aflojar MUY LENTAMENTE la tuerca de retention del protector de la boquilla o acoplamiento de la punta de la manguera y descargar gradualmente la presion, despues, aflojarlo por complete. Luego,

despejar la boquilla o la manguera.

Page 7

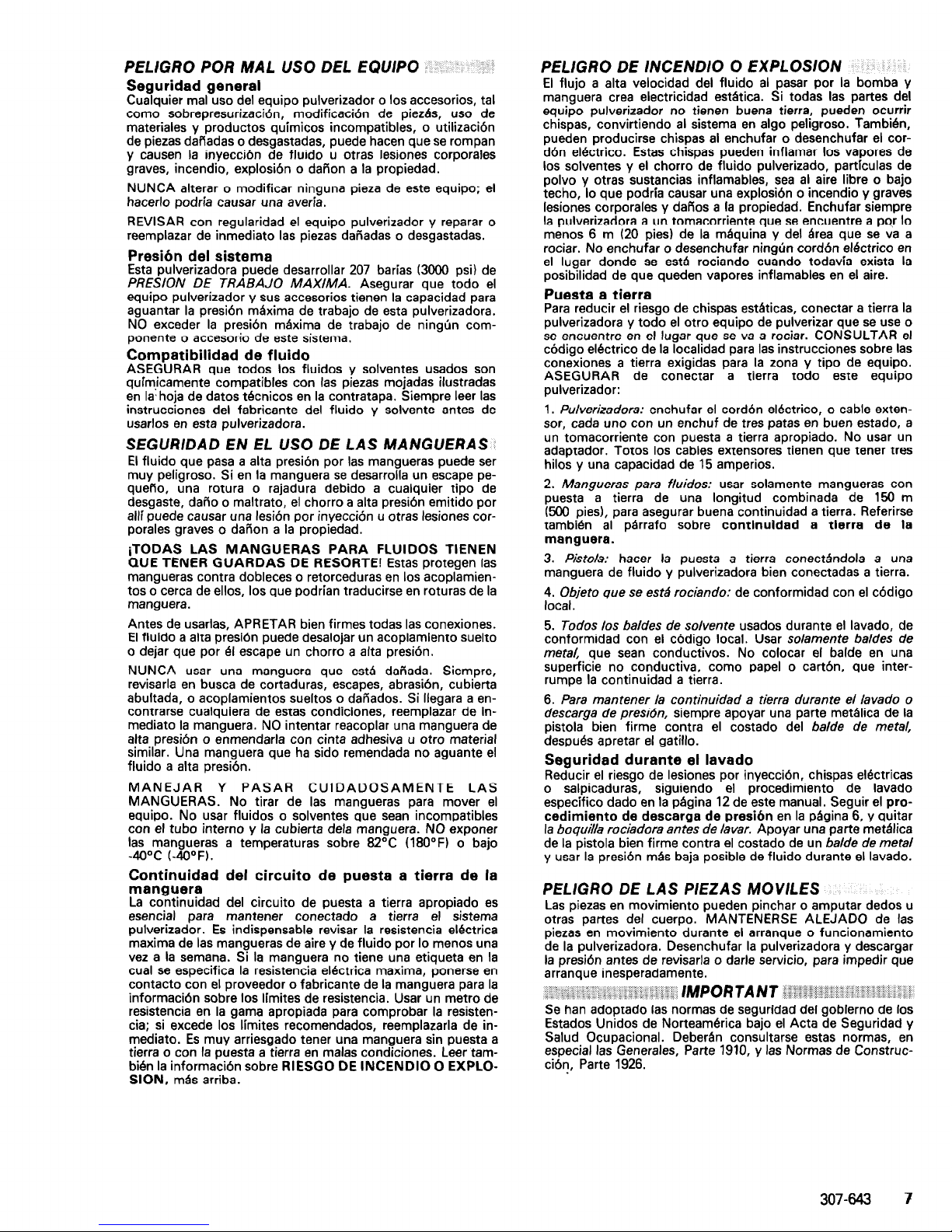

PELIGRO POR MAL US0 DEL EQUIP0

Seguridad general

Cualquier mal uso del equip0 pulverizador o 10s accesorios, tal

coma sobrepresurizacicn, modificacibn de piezk, uso de

materiales y productos quimicos incompatibles, o utilizaci6n

de piezas dafiadas o desgastadas, puede hacen que se rompan

y causen la inyeccibn de fluid0 u otras lesiones corporales

graves, incendio, explosibn o dahon a la propiedad.

NUNCA alterar o modificar ninguna pieza de este equipo; el

hacerlo podria causar una averia.

REVISAR con regularidad el equip0 pulverizador y reparar o

reemplazar de inmediato las piezas dafiadas o desgastadas.

Presih del sistema

Esta pulverizadora puede desarrollar 207 barias (3000 psi) de

PRESlON DE TRABAJO MAXIMA. Asegurar que todo el

equip0 pulverizador y sus accesorios tienen la capacidad para

aguantar la presi6n maxima de trabajo de esta pulverizadora.

NO exceder la presi6n maxima de trabajo de ninglin com-

ponente o accesorio de este sistema.

Compatibilidad de fluid0

ASEGURAR que todos 10s fluidos y solventes usados son

quim,icamente compatibles con las piezas mojadas ilustradas

en Ia, hoja de datos tecnicos en la contratapa. Siempre leer las

instrucciones del fabricante del fluid0 y solvente antes de

usarlos en esta pulverizadora.

SEGURlDAD EN EL US0 DE LAS MANGUERAS

El fluid0 que pasa a alta presi6n por las mangueras puede ser

muy peligroso. Si en la manguera se desarrolla un escape pequefio, una rotura o rajadura debido a cualquier tipo de

desgaste, dafio o maltrato, el chorro a alta presibn emitido por

alli puede causar una lesi6n por inyecci6n u otras lesiones cor-

porales graves o dafion a la propiedad.

iTODAS LAS MANGUERAS PARA FLUIDOS TIENEN

WE TENER GUARDAS DE RESORTE!

Estas protegen las

mangueras contra dobleces o retorceduras en 10s acoplamientos o cerca de ellos, 10s que podrian traducirse en roturas de la

manguera.

Antes de usarlas, APRETAR bien firmes todas las conexiones.

El fluid0 a alta presi6n puede desalojar un acoplamiento suelto

o dejar que por BI escape un chorro a alta presion.

NUNCA usar una manguera que esta dafiada. Siempre,

revisarla en busca de cortaduras, escapes, abrasirkr, cubierta

abultada, o acoplamientos sueltos o dafiados. Si llegara a en-

contrarse cualquiera de estas condiciones. reemplazar de in-

mediato la manguera. NO intentar reacoplar una manguera de

alta presi6n o enmendarla con cinta adhesiva u otro material

similar. Una manguera que ha sido remendada no aguante el

fluid0 a alta presi6n.

MANEJAR Y PASAR CUIDADOSAMENTE LAS

MANGUERAS. No tirar de las mangueras para mover el

equipo. No usar fluidos o solventes que Sean incompatibles

con el tubo interno y la cubierta dela manguera. NO exponer

las mangueras a temperaturas sobre 82°C (180°F) o bajo

-40°C (-40°F).

Continuidad del circuit0 de puesta a tierra de la

manguera

La continuidad del circuit0 de puesta a tierra apropiado es

esencial para mantener conectado a tierra el sistema

pulverizador. Es indispensable revisar la resistencia electrica

maxima de las mangueras de aire y de fluid0 por lo menos una

vez a la semana. Si la manguera no tiene una etiqueta en la

cual se especifica la resistencia electrica maxima, ponerse en

contact0 con el proveedor o fabricante de la manguera para la

informaci6n sobre 10s limites de resistencia. Usar un metro de

resistencia en la gama apropiada para comprobar la resistencia; si excede 10s limites recomendados, reemplazarla de inmediato. Es muy arriesgado tener una manguera sin puesta a

tierra o con la puesta a tierra en malas condiciones. Leer tambien la informaci6n sobre

RIESGO DE INCENDIO 0 EXPLO-

SION, mas arriba.

PELIGRO DE INCENDlO 0 EXPLOSION

El flujo a alta velocidad del fluid0 al pasar por la bomba y

manguera crea electricidad estatica. Si todas las partes del

equip0 pulverizador no tienen buena tierra, pueden ocurrir

chispas, convirtiendo al sistema en algo peligroso. Tambien,

pueden producirse chispas al enchufar o desenchufar el cord6n ektrico. Estas chispas pueden inflamar 10s

vapores

de

10s solventes y el chorro de fluid0 pulverizado, particulas de

polvo y otras sustancias inflamables, sea al aire libre o bajo

techo, lo que podria causal una explosi6n o incendio y graves

lesiones corporales y daAos a la propiedad. Enchufar siempre

la pulverizadora a un tomacorriente que se encuentre a por lo

menos 6 m (20 pies) de la maquina y del area que se va a

rociar. No enchufar o desenchufar ningljn cord&n electrico en

el lugar donde se esta rociando cuando todavia exista

la

posibilidad de que queden vapores inflamables en el aire.

Puesta a tierra

Para reducir el riesgo de chispas estaticas, conectar a tierra la

pulverizadora y todo el otro equip0 de pulverizar que se use o

se encuentre en el lugar que se va a rociar. CONSULTAR el

c6digo elktrico de la localidad para las instrucciones sobre las

conexiones a tierra exigidas para la zona y tipo de equipo.

ASEGURAR de conectar a tierra todo este equip0

pulverizador:

1. Pulverizadora: enchufar el cord6n electrico, o cable exten-

sor, cada uno con un enchuf de tres patas en buen estado, a

un tomacorriente con puesta a tierra apropiado. No usar un

adaptador. Totos 10s cables extensores tienen que tener tres

hilos y una capacidad de 15 amperios.

2. Mangueras para fluidos: usar solamente mangueras con

puesta a tierra de una longitud combinada de 150 m

(500 pies), para asegurar buena continuidad a tierra. Referirse

tambien al parrafo sobre

continuidad a tierra de la

manguera.

3. Pistola: hater la puesta a tierra conectandola a una

manguera de fluid0 y pulverizadora bien conectadas a tierra.

4. Objet0 que se esr8 rociando: de conformidad con el c6digo

local.

5. Todos /OS baldes de solvente usados durante el lavado, de

conformidad con el cddigo local. Usar solamente baldes de

metal, que Sean conductivos. No colocar el balde en una

superficie no conductiva, coma papel o cart6n, que inter-

rumpe la continuidad a tierra.

6. Para mantener la continuidad a tierra durante et lavado o

descarga de presidn, siempre apoyar una parte metalica de la

pistola bien firme contra el costado del balde de metal,

despues apretar el gatillo.

Seguridad durante el lavado

Reducir el riesgo de lesiones por inyecci6n, chispas electricas

o salpicaduras,

siguiendo el procedimiento de lavado

especifico dado en la pagina 12 de este manual. Seguir el

pro-

cedimiento de descarga de presih

en la pagina 6, y quitar

la boquilla rociadora antes de lavar. Apoyar una parte metalica

de la pistola bien firme contra el costado de un balde de metal

y usar la presi6n m&s baja posible de fluid0 durante el lavado.

PELIGRO DE LAS PIEZAS MOVILES

Las piezas en movimiento pueden pinchar o amputar dedos u

otras panes del cuerpo. MANTENERSE ALEJADO de las

piezas en movimiento durante el arranque o funcionamiento

de la pulverizadora. Desenchufar la pulverizadora y descargar

la presi6n antes de revisarla o darle servicio, para impedir que

arranque inesperadamente.

,’ ,.:>,

.I1 .:,. >,

: I:,;;,” /MpORTANJ’;;:;;$j. ;;- ; <: ’ :

,1 . ‘i,

Se han adoptado las normas de seguridad del gobierno de 10s

Estados Unidos de Norteamerica bajo el Acta de Seguridad y

Salud Ocupacional. Deberan consultarse estas normas, en

especial las Generales, Parte 1910, y las Normas de Construc-

ci6n, Parte 1926.

307-643 7

Page 8

INTRODUCTION .I

,..!

,:, ,:;,_ ,.,:;.. :..“c:‘;;.

““c;‘:!;“; p:”

:i~“$&;r:;ye

ULTRATM 333 BASIC COMPONENTS

Model 231-333 shown

PRESSURE CONTROL KNOB

ELECTRIC MOTOR

FLUID FILTER

DRIVE ASSEMBLY

CIRCUIT BREAKER

FLUID OUTLET

RESET BUlTON

ON/OFF SWITCH

DISPLACEMENT PUMP

DRAIN VALVE

MAIN FLUID HOSE

TIP GUARD -/

Your new UltraTM 333 Sprayer functions and operates

differently than other airless paint sprayers. This section

will help you become familiar with the sprayer before

operating it.

Pressure Control

The pressure control includes an ON/OFF switch for the

sprayer, the pressure adjusting control knob, a pressure

sensing device, and a current overload circuit breaker

with a manual reset button. Its function is to control the

motor speed so that the sprayer maintains constant

fluid pressure at the pump outlet.

Motor

The DC motor has sealed bearings and replaceable

motor brushes. Its function is to drive the displacement

pump at the rate needed to supply sufficient paint

volume at the selected pressure.

Working together, the pressure control and motor

cause the pump to cycle whenever there is fluid or

pressure demand. When the pump is cycling, the motor

sounds like an automobile starter cranking. When the

pump is not cycling, the motor hums, hums intermittently, or appears to have shut itself off. However, there

will still be power to the sprayer and it will stay

pressurized and ready to use unless you manually shut it

off and relieve pressure.

Because the motor is DC, it is less sensitive to low

voltage or voltage fluctuations than an AC motor, and

an extension cord of up to 150 feet (45 m) can be used.

Drive Assembly

The sealed drive assembly transfers power from the DC

motor to the displacement pump.

8

307643

Displacement Pump

The positive displacement, volume-balanced pump pro-

vides equal fluid delivery on both the up and down

pump strokes. The pump has a wet-cup which, when

filled with Grace Throat Seal Liquid, helps prevent

damage to the throat packings and piston rod.

Fluid Filter

The fluid filter provides the final paint straining to help

avoid clogs in the hose and spray tip. The filter includes

a reusable element and a drain valve for relieving fluid

pressure when shutting off the sprayer.

Hoses

The grounded, nylon spray hoses have spring guards on

both ends. The 50 foot (15.2 m) hose has a l/4 in. ID.

The 3 foot (0.9 m), 3/16 in. ID whip hose allows flexible gun movement. The nylon hose material acts as a

pulsation dampener to absorb pressure fluctuations.

Spray Gun & Reverse-A-Clean Ill Spray Tip

Both the “Contractor” and “Flex” spray guns include a

trigger safety which prevents accidental triggering

when it is engaged (see the WARNING on page 3):The

Reverse-A-Clean III

spray

tip uses high pressure fluid to

remove clogs from the spray tip without removing it

from the gun. It includes a safety tip guard which helps

reduce the risk of injection injury.

Page 9

SETUP

1.

Connect Hose and Gun (Refer

to Fig 1.1

a.

Remove

the plastic cap plug from the filter

outlet nipple and screw the 50 ft (15.2 m) fluid

hose onto the nipple.

b. Connect the whip hose between the fluid hose

and the gun inlet connection.

c. Don’t use thread sealant, and don’t install the

spray tip yet!

2. Two Gun Hookup.

(Refer to Fig 1.1 Remove the

plug from the tee which holds the fluid filter to the

sprayer and install an accessory l/4 npt ball valve.

Connect an accessory hose and gun to the ball

valve.

CAUTION

To avoid damaging the pressure control, which

may result in poor equipment performance and

component damage, follow these precautions:

1. Always use nylon spray hose of at least

50 ft (15.2 m) long.

2. Never use a wire braid hose as it is too rigid

to act as a pulsation dampener.

3. Never install any shutoff device between

the filter and the main hose. See Fig 2.

4. Always use the main filter outlet for onegun operation. Never plug this outlet.

3. Fill Packing Nut/Wet-Cup (See

Fig 2.1

Fill the packing nut/wet-cup l/3 full with Grace

Throat Seal Liquid (TSL), supplied.

4. Check Electrical Service

a. Be sure the electrical service is 120 V,

60 HzAC, 15 Amp (minimum) and that the

outlet you use is properly grounded.

”

b. Use an extension cord which has 3 wires of a

Fig

i-MAlN FLUID HOSE

minimum 12 gauge size, and a maximum of

150 ft (45 m) long. Longer lengths may affect

sprayer performance.

5. Plug in the Sprayer

a.

Be sure the ON/OFF switch is OFF. Refer to

Fig 3.

b. Plug the power supply cord into a grounded

electrical outlet that is at least 20 ft (6 m) away

from the spray area to reduce the chance of a

spark igniting the spray vapors.

c. Do not remove the third prong of the power

supply cord plug, which is the grounding

prong, and do not use an adapter.

Fig 3

6. Flush the pump

to remove the No. 10 motor oil

which was left in to protect pump parts after fac-

tory testing.

a.

Before using water-base paint,

flush with

mineral spirits followed by soapy water, and

b. Stir the paint to dissolve pigments.

then a clean water flush.

7. Prepare the paint

according to the manufacturer’s

recommendations.

a.

Remove any skin that may have formed.

b.

Before using oil-base paint,

flush with mineral

spirits only.

c. See ‘*Flushing Guidelines”

on page 12 for

flushing procedure.

c. Strain the paint through a fine nylon mesh bag

(available at most paint dealers) to remove par-

ticles that could clog the filter or spray tip.

This

is probably the most important step toward

trouble-free spray painting.

307-643

9

Page 10

WARNING’

Pressure Relief Procedure

To reduce the risk of serious bodily injury, including injection or injury from moving parts or

electric shock, always follow this procedure

whenever you shut off the sprayer, when checking or servicing any part of the spray system,

when installing, cleaning or changing spray tips,

and whenever you stop spraying.

1.

Engage the gun safety latch.

2.

Turn the ON/OFF switch to OFF.

3.

Unplug the power supply cord.

4.

Disengage the gun safety latch.

5.

Hold a metal part of the gun firmly to the

side of a metal pail, and trigger the gun to

relieve pressure.

6.

Engage the gun safety latch.

7. Open the drain valve, having a container

ready to catch the drainage.

8. Leave the drain valve open until you are

ready to operate the sprayer again.

If you suspect that the spray tip or hose is completely CLOGGED, OR THAT PRESSURE HAS

NOT BEEN FULLY RELIEVED after following the

steps above,

VERY SLOWLY loosen the tip guard

retaining nut or hose end coupling and relieve

pressure gradually. Then loosen the nut completely. Now clear the tip or hose obstruction.

1. Prime the Sprayer with Paint.

a.

Close the filter drain valve (and the secondary

hose ball valve).

b.

Don’t install the spray tip yet!

c.

Put the suction tube into the paint container.

d. Turn the pressure adjusting knob all the way

counterclockwise to lower the pressure setting.

e.

Disengage the gun safety latch.

f.

Hold a metal part of the gun firmly against and

aimed into a metal waste container. See Fig 4.

Squeeze the trigger and hold it open, turn the

ON/OFF switch to ON, and slowly increase the

pressure setting until the sprayer starts. Keep

the gun triggered until all air is forced out of the

system and the paint flows freely from the gun.

Release the trigger and engage the safety.

NOTE:

If the pump is hard to prime, place a container under the drain valve and open it.

When fluid comes from the valve, close it.

Then disengage the gun safety and pro-

ceed as in Step If, above.

g. Check all fluid connections for leaks If any

leaks are found, follow the

Pressure Relief

Procedure Warning,

above, before tightening

the connections.

2.

Install the Spray Tip and Tip Guard

(Refer to Fig 5.1

a.

Be sure the gun safety latch is engaged.

b. Unscrew the retaining nut from the gun.

c. Install the Reverse-A-Clean III spray housing

with tip installed (See manual 307-321,

supplied).

10

307-643

MAINTAIN FIRM

METAL TO METAL

CONTACT BETWEEN

GUN AND CONTAINER

L/-/4

Fig 4

BE SURE GUN SAFETY LATCH

IS ENGAGED!

TIGHTEN SNUGGED

RETAINER NUT 1/8TO

lI8TURN WITH WRENCH

Fig 5

d. Tighten the retaining nut by hand until

snug.

e. Use a wrench to tighten the retaining nut about

l/8 to l/6 turn.

seat gasket and result in leakage.

3. Adjusting the Spray Pattern

a.

Increase the pressure adjusting knob setting

just until spray from the gun is completely

atomized. To avoid excessive overspray and

fogging, and to decrease tip wear and extend

the life of the sprayer, always use the lowest

possible pressure needed to get the desired

results.

b. If more coverage is needed, use a larger tip

rather than increasing the pressure.

c. Test the spray pattern. To adjust the direction

of the spray pattern, engage the gun safety and

loosen the retaining nut. Position the tip so the

groove is horizontal for a horizontal pattern or

vertical for a vertical pattern. Then tighten the

retaining nut.

Page 11

4. Cleaning a Clogged Tip

WARNING

To reduce the risk of serious bodily injury from injection, use extreme caution when cleaning or

changing spray tips. If the spray tip clogs while

spraying, engage the gun safety latch immediate-

ly, then follow the procedure in Steps 4a-4e,

below.

NEVER wipe off build up around the spray tip until

pressure is fully relieved and the gun safety latch is

engaged.

a. Clean the front of the tip frequently during the

day’s operation.

First,

follow the

Pressure

Relief Procedure Warning

in on page 10.

Then use a solvent-soaked brush to keep fluid

from building up and clogging the tip.

b. If the spray tip does clog, release the gun trig-

ger, engage the gun safety, and rotate the

spray tip handle 1W. See Fig 6.

c. Disengage the gun safety and trigger the gun

into a waste container. Engage the gun safety

again.

d. Return the handle to the original position,

disengage the gun safety, and resume spraying.

e. If the tip is still clogged,

engage the gun safety,

shutoff and unplug the sprayer, and open the

drain valve to relieve pressure. Clean the spray

tip as instructed in “Service” in instruction

manual 307-321, supplied.

SHUTDOWN AND CARE .‘.::, ‘:“ ;‘,/ -‘,::jy“ ,:,‘; .l_‘.

1.

Check the packing nut/wet-cup daily.

First

follow the

Pressure Relief Procedure Warning

on

page 10. Be sure the wet-cup is l/3 full of TSL

at all times to help prevent fluid buildup on the

piston rod and premature wear of packings. The

packing nut should be tight enough to stop

leakage, but no tighter. Over-tightening may cause

binding and excessive packing wear. Use a screwdriver and light hammer to adjust the nut. See

Fig 7.

2. Clean the fluid filter often

and whenever the

sprayer is stored. First follow the

Pressure Relief

Procedure Warning

on page 10. Refer to manual

307-273, supplied, for the cleaning procedure.

3. Flush the sprayer at the end of each work day

and fill it with mineral spirits to help prevent pump

corrosion and freezing. See “Flushing Guidelines”

on page 12.

CAUTION

Never leave water or any paint in the sprayer overnight to: (1) prevent pump corrosion; (2) to pre-

vent the material from freezing in the pump and

pressure control which can cause loss of pressure,

stalling or serious sprayer damage. Always use

mineral spirits for the final flush, relieve pressure,

and leave the mineral spirits in the sprayer.

4. For very short shutoff periods,

leave the suction

tube in the paint, follow the

Pressure Relief Pro-

cedure Warning

on page 10, and clean the spray

tip.

5.

Coil the hose

and hang it on the hose rack when

storing it, even for overnight, to help protect the

hose from kinking, abrasion, coupling damage, etc.

ROTATE

HANDLE

180°

t

-3

c

BE SURE GUN

SAFETY LATCH

Fig 6

ACCESSORY BALL

VALVE SHOWN

Fig 7

307-643

11

Page 12

1.

2.

3.

4.

New Sprayer.

Your new UltraTM 333 Sprayer was

factory tested in No. 10 motor oil which was left in

to protect pump parts.

Before using water-base paint,

flush with mineral

spirits, followed by soapy water, and then a clean

water flush.

Before using oil-base paint,

flush with mineral

spirits only.

Changing Colors.

Flush with a compatible solvent

such as mineral spirits or water.

Changing from water-base to oil-base paint.

Flush with soapy water, then mineral spirits.

Changlng from oil-base to water-base paint.

Flush with mineral spirits, followed by soapy water,

then a clean water flush.

Water~base paint:

flush with water, then mineral

spirits and leave the pump, hose and gun filled with

mineral spirits. Shutoff and unplug the sprayer,

open the drain valve to relieve pressure and leave

open.

Oil-base paint:

flush with mineral spirits. Shutoff

and unplug the sprayer, open the drain valve to

relieve pressure and leave open.

6. Startup after storage.

Before using water-base paint,

flush out mineral

spirits with soapy water and then a clean water

flush.

When using oil-base paint,

flush out the mineral

spirits with the material to be sprayed and the

sprayer is ready to use.

How to Flush

1.

2.

3.

4.

5.

Follow the

Pressure Relief Procedure Warning

on page 2 or 10.

Remove the filter bowl and screen; see manual

307-273 supplied. Clean the screen separately and

install the bowl without the screen.

Close the filter drain valve.

FILTER

BOWL

SCREEN

FILTER

SUPPORT

4

DRAIN VALVE

SHOWN OPEN

Pour one-half gallon (2 liters) of compatible solvent

into a bare metal pail. Put the suction tube in the

pail.

Remove the spray tip from the gun.

To reduce the risk of static sparking and

IWARIIINOl

splashing always remove the spray trp from the

gun, and hold a metal part of the gun firmly to the

side of a grounded metal pail when flushing.

6. Disengage the gun safety latch. Point the spray gun

into a metal waste container and with a metal part

of the gun firmly touching the metal container,

squeeze the gun trigger.

This procedure helps

avoid stat/c sparking and splashing.

With the gun

triggered, turn the ON/OFF switch to ON and slowly turn the pressure adjusting knob clockwise /usl

until

the sprayer starts. Keep the gun triggered until

clean solvent comes from the nozzle. Release the

trigger and engage the gun safety latch.

7.

8.

9.

10.

Check all fluid connections for leaks. If any leak,

first follow the Pressure Relief Procedure Warning

on page 2 or 10. Now tighten the connections, start

the sprayer, and recheck the connections for leaks.

Remove the suction tube from the pail. Disengage

the gun safety and trigger the gun to force solvent

from the hose. Do

not let the pump run dry for

more than 30 seconds to avoid damaging the

pump packings!

Then turn ON/OFF switch to OFF

and engage the gun saftey.

Unplug the power supply cord. Open the drain

valve and leave open until you are ready to use the

sprayer again. Unscrew the filter bowl and reinstall

the clean screen. Reinstall the bowl, hand tight

only.

If you have flushed with mineral spirits and are going to use a water-base paint, flush with soapy

water followed by a clean water flush. Then repeat

Step 1.

12 307643

Page 13

TROUBLESHOOTING GUIDE

AND

REPAIR INSTRUCTIONS

307-643 13

Page 14

TR()UBLESHOOTlNG GUIDE,~.,r,.. ,.? :; ;: ;z.<!:.tr”.z “I,.: ,,;:ijv :I,.> ; ‘r:,“ir’i”ii::i,,;,. ;~$$~;i;~\r”$f;;c;;

This guide will help you identify the causes and solu-

dicated, contact your nearest authorized service agency

tions to sprayer problems. If you cannot identify and

for instructions on where and how to return the sprayer

resolve the Droblem. or if “Return for reoair” is in-

for reoair.

Pressure Relief Procedure

,To reduce the risk of serious bodily injury, in-

eluding injection or injury from moving parts or

electric shock, always follow this procedure,

whenever you shut off the sprayer, when check-

ing or servicing any part. of the spray system,

when installing, cleaning or changing spray tips,

and whenever you stop spraying.

of a metal pail, and trigger the gun to relieve

pressure.

6. Engage the gun safety latch.

7. Open the drain valve, having a container

ready to catch the drainage.

8. Leave the drain valve open until you are ready

to spray again.

If you suspect that the spray tip or hose is com-

1. Engage the gun safety latch.

pletely CLOGGED, OR THAT PRESSURE HAS

2. Turn the ON/OFF switch to OFF.

NOT BEEN FULL Y RELIEVED after following the

3. Unplug the power supply cord.

steps above,

VERY SLOWLY loosen the tip guard

4. Disengage the gun safety latch.

retaining nut or hose end coupling and relieve

5. Hold a metal part of the gun firmly to the side

pressure gradually. Then loosen the nut completely. Now clear the tip or hose obstruction.

PROBLEM

I. Electric motor won’t operate

II. Electric motor stops while spraying

III. Electric motor runs, but output low

(See Problem VII also.)

IV. Electric motor runs, but no output

and pump not stroking

1. Drive assemby damaged

V. Paint leaks into wet-cup

1. Packing nut too loose

VI. Excessive surge (pulsing) at spray

gun

CAUSE

1. Power cord unplugged, or

building circuit fuse blown

2. Current overload circuit breaker

has opened

3. Pressure setting too low

4. Damaged extension cord

5. Motor brushes worn

6. Pressure control damaged by

freezing (b) or overpressurizing

(cl

7. Material or water frozen in

sprayer (b)

1. Power cord unplugged, or

building circuit fuse blown

2. Pressure setting too low

3. Tip or filter plugged

4. Pressure control or motor failure

1. Piston ball check not seating

2. Piston packing worn or damaged

3. Intake valve ball check not

seating

4. Displacement pump frozen (b) or

gear train damaged

5. Pressure control frozen (b) or

damaged by over-pressurization

(cl

2. Throat packings worn or

damaged

3. Damaged or worn piston rod

1. Filter partially clogged

2. Spray tip too big or worn

3. Paint too thick

4. Wrong type hose

5. Displacement pump check balls

dirty or sticking

6. Displacement pump check balls

and packings worn or damaged

7. Pressure control or motor

damaged

SOLUTION

1. Check,

reset or

replace.

2. Depress reset button on top of

pressure control (a).

3. Increase.

4. Replace.

5.

Replace. See page 18.

6. Return for repair.

7. Thaw; try to start; return for

repair if needed.

1. Check, reset or replace.

2. Increase.

3. Remove and clean.

4. Return for repair.

1. Repair. See page 15.

2. Replace. See page 15.

3. Repair. See page 15.

4. Thaw; restart; return for repair if

needed.

5. Thaw; restart; return for repair if

needed.

1. Return for repair.

1. Tighten just enough to stop

leakage.

2. Repl?ce (d). See page 15.

3. Replace (d). See page 15.

1. Remove and clean.

2. Change tip.

3. Thin per paint manufacturer’s

recommendations.

4. Use minimum 50 ft (15.2 m)

grounded nylon hose; do not use

wire braid hose.

5. Flush, then remove and clean if

needed.

6. Replace. See page 15.

7. Return for repair.

14

307-643

Page 15

‘ROBLEM

1 CAUSE

[ SOLUTION

AI. Not enough paint pressure (See Pro-

1. Pressure setting too low

1. Increase.

blem III also.)

2. Spray tip too big or worn

2. Change tip; see manual 307321.

3. Motor brushes worn

3. Replace. See page 14.

4. Pressure control or motor

4. Return for repair.

damaged

‘Ill. Poor spray pattern

1. Clogged spray tip

2. Pressure setting too low

3. Outlet filter or hose partially

clogged

4. Spray tip too big or worn

5. Paint supply low or pail empty

6. Paint too thick

1. Clean. See manual 307321.

2. Increase.

3. Clean; see manual 367-273.

4. Change tip; see manual 307-321.

5. Fill; reprime to remove air.

6. Thin per paint manufacturer’s

recommendations.

IX. Spitting from spray gun

X. Static sparking from gun

1. Paint supply low or pail empty

2. Sprayer sucking air or gun

needle not seating

1. Sprayer or work not grounded

1. Fill, reprime to remove air.

2. Tighten fittings; repair gun; see

manual 307-614.

1. Check hose continuity and electrical ground connection.

(a) Engage gun safety latch, Depress manual reset button on top of pressure control. If the sprayer continues to shut

off,

reduce

spraying pressure. If the problem isn’t corrected, return for repair.

(b) Freezing results from failure to replace water-base paint or flushing water with mineral spirits at shutdown.

(cl Overpressurization results from (1) using less than 50 ft (15.2 m) of nylon spray hose; (2) using wire braid hose: (3) adding a

shutoff device between filter and main hose; (4) plugging the main fluid outlet of the filter and using drain valve as a shutoff; and

(51 a clogged or incorrectly assembled filter.

(d) EIIesr;z to keep packing nut l/3 full of Throat Seal Liquid to help prevent premature wear of throat packings and paint drying on

DISPLACEMENT PUMP REPAIR

Tools Needed:

Heavy duty vise

718” open end wrench

2’ open end wrench

Plastic mallet

Small screwdriver

Before doing this

procedure, follow the Pressure

Lh:yNG-i

Relief Procedure Warning on page 14 to reduce

the risk of an injection injury, injury from moving

Removina the Puma

(Refer to Fia 8.1

1.

2.

3.

4.

5.

Flush the pump,‘if possible, &d relieve pressure

again. Stop the pump with the piston rod (223) in

its lowest position.

Unscrew the suction tube (42) from the pump. Hold

the

wrench on the pump intake valve (222) to keep

the pump from loosening.

Unscrew the hose (47) from the nipple (48) on the

pump outlet and remove the hose.

Use a screwdriver to push the retaining spring (35)

aside and push out the pin (20).

Loosen the locknut (38) and unscrew the pump

from the bearing housing (27).

Fig 8

307-643 15

Page 16

Fig 9

LEATHER PACKINGS

LIPS OF V-PACKINGS

IN THROAT MUST

FACE DOWN

tN PISTON MUST

lbs face down r 1

!

212”

218”

PLASTIC

PACKINGS

217*

PLASTIC

PACKINGS

Fig IO

Disassembling the Pump

(Refer to Figures 9 and IO.)

1. Unscrew the intake valve (222) from the cylinder

(216). Remove the gasket (2061, ball guide (2151,

stop pin (207) and ball (204) from the valve. Clean

and inspect the parts for wear or damage, replacing

parts as needed. Always use a new gasket (included in Repair Kit 218-033).

2. Unscrew and remove the packing nut (221) and

plug (201).

3. Use a plastic mallet to tap the piston rod

down,

then pull the rod out through the bottom of the

cylinder.

4.

Remove the throat packings (209, 218) and glands

(211, 212).

5.

Clamp the flats of the piston rod in a vise. Use a

7/8 in. wrench to loosen the retaining nut (214).

Then use the wrench to unscrew the piston valve

(224) from the rod.

6. Remove the backup washer (219). wiper (2051,

packings (208, 217) and glands (213, 220).

Reassembling the Pump

Assembly Notes:

(1) Use Repair Kit No. 218-033 to repair the displace-

ment pump. Reference number in parentheses with

an asterisk, for exampe, (210*), show the parts included in the kit. Use all the new parts, even if the

old ones still look good as the old parts cause the

new ones to wear prematurely.

(2)

Alternate leather and plastic packings as shown in

Fig 3. Notice that the lips of the throat “V” packings face

down,

against pressure, and the lips of

the piston “V” packings

face up,

against pressure.

The lips of the U-cup wiper (205),

face down.

Incor-

rect installation damages the packings and results

in the pump leaking.

(3)

1.

2.

3.

4.

5.

Coat the piston rod, inside of the cylinder and the

packings with a lightweight oil to help prevent

packing damage when inserting the piston rod.

Check the outside of the piston rod (223) and the inside of the cylinder (216) for scoring or scratches. If

the parts are damaged, new packings will not seal

properly. Replace these parts if needed.

Stack the backup washer (219*), wiper (205*),

female gland E?O*), packings f217*, 208”) and

male gland (213”) onto the piston valve. See

Figures 11 & 12.

Tighten the packing retaining nut (214) onto the

piston valve (224) and torque to 3 to 4 in-lb 10.34 to

0.35 N-m)-about finger tight.

Use a pen to make a light mark on the packings

where they align with one of the flats on the nut.

See Fig 11.

Place ball (203) on piston valve (224). Apply

one

drop

of thread locking compound on threads of

valve. Then hand tighten the valve assembly into

the piston rod just until the nut meets the face of

the rod. See Fig 12.

16

307643

Page 17

6.

Place the flats of the rod in a vise.

CAUTION

Step

7,

tightening the piston valve into the rod, is

critical. Follow the procedure carefully to avoid

damaging the packings by overtightening.

7. Without changing the tightness of the nut against

the packings,

tighten the nut (214) into the piston

rod to

18

to

20

ft-lbs

(24

to 27 N.m). If the pen mark

on the packings loses alignment, back the nut off

and try again.

TORDUUJYJE c, ,.r#-203

1.34-3 Nam) 1

MARK

PACKINGS

AND HEX ALIGNMENT

213"

220"

205"

224

Fig 11

DO NOT LOSE

ALIGNMENT

Fig 12

8.

Stack the male gland (211”), packings (218”,

209")

and female gland (212*), one at a time, into the top

of the cylinder. See Fig 10.

9.

Install the throat packing nut (221) and plug (201)

but leave loose for now.

10. Insert the piston rod

(223)

through the bottom of

+he pump cylinder, pushing it up until the top of the

piston rod extends l-7/8” (32.2 mm) beyond the

top of the cylinder. See Fig 10.

11. Screw down the cylinder locknut (38) until it is

finger tight at the bottom of the external cylinder

threads.

12. Place flats of the intake valve in a vise. Install a new

gasket 006”) and screw the pump cylinder into the

valve. See Fig 9.

13.

Screw the displacement pump about

3/4

of the

way into the bearing housing

(27).

Hold the pin

(20)

up to the pin hole in the connecting rod assembly

(3)

and continue screwing in the pump until the pin

slides easily into th8 hole. Back off the pump until

the top threads of the pump cylinder are flush with

the face of the bearing housing and the outlet nipple (45) is straight back. Push the retaining spring

(35) into the groove all the way around the connecting rod. Tighten the locknut (38) very tight-about

70 ft-lb (94 N-ml-with a 2 in. open-end wrench

and 8 light hammer.

WARNING

Be sure the retaining spring (351 is firmly in the

groove of the connecting rod,

all the way around,

to prevent if from working loose due to vibration.

See Fig 13.

If the pin works loose, it or other parts could break

off due to the force of the pumping action. These

parts could be projected through the air and result

in serious bodily injury or property damage, including damage to the pump, connecting rod or

bearing housing.

If the locknut (38) loosens during operation, the

threads of the bearing housing (27) will be permanently damaged. Be sure to tighten the locknut

firmly.

I

14. Tighten the packing nut (221)

just

enough to stop

leakage, but no tighter. Fill the wet-cup/packing

nut l/3 full with Grace TSL.

15. Replace the motor brushes, included with the repair

kit. See page 18.

FACE OF

BEARING

HOUSING

b?

TORQUE TO

m ft-lb

I

(94 N.ml

Fig 13

307-643 17

Page 18

MOTOR BRUSH REPLACEMENT

Tools Needed:

Phillips screwdriver

Flatblade screwdriver

NOTE:

New motor brushes are included with each

Packing Repair Kit, 218-033. Replace them

when replacing the packings, and/or when

they have been worn to 8 minimum of 9116”

on the longest side.

I.

2.

3.

4.

5.

6.

Remove the motor screws (I 121, washers II 13) and

cover (14). See Fig 14.

Remove the screws (H), inspection covers (J) and

gaskets (K) on each side of the motor. See Fig 14.

Loosen

the brush lead terminal screw and remove

the lead.

Push down on the spring clip slightly then pull the

clip away from and out of the brush holder. Refer to

Fig 15. Keep the spring clip.

Remove and discard the brush.

Inspect the commutator for excessive pitting, burning or gouging.

NOTE:

A black color on the commutator is normal.

Have the commutator resurfaced by a

qualified motor repair shop if the brushes

seem to be wearing too fast.

7. Place a new brush in the holder so the beveled

edges are 8s shown in the first part of Fig 15, and

the brush lead is routed as shown in the second part

of Fig 15.

8. Slowly push the tabbed end of the spring clip into

the brush holder until the clip tab engages in the

holder and the rolled portion of the tension spring

rests squarely on the brush.

9. Route the brush lead to the terminal and tighten the

terminal screws. Be sure the brush lead does not

touch any part of the armature or motor housing.

10. Test the brushes:

a. With the ON/OFF switch OFF, turn the

pressure control knob all the way counterclock-

wise to minimum pressure. Plug in the sprayer.

b. Turn the ON/OFF switch ON and slowly in-

crease the pressure until the motor comes up to

full speed.

c. Inspect the brush and commutator contact area

for excessive arcing. Arcs should not “trail” or

circle around the commutator surface.

11. Reinstall the brush inspection covers, gaskets, and

screws. Reinstall the motor cover, screws and

washers.

/

LFAN COVER

Fig 14

SPFl;-G$LIP

1

rBRUSH HOLDER

‘ATOR

SIDE VIEW OF MOTOR BRUSH INSTALLATION

MOTOR END BELL

TERMINAL SCREW

BRUSH LEAD w

-B #RUSH

SPRING CLIP-

-1

BRUSH HOLDER

1

DETAIL OF MOTOR BRUSH

SHOWN WITH MOTOR LEAD

FACING BACK OF MOTOR

Ic*,noNl

Do not run the sprayer dry for more than 36

seconds while checking the brushes to avold

damaging the displacement pump.

Fig 15

18

307-643

Page 19

PARTS DRAWINGS

AND

PARTS LISTS

Page 20

I I -37

57

58

59

54

125

23-

20

307-543

,15

Page 21

Model 231-007, Series A

Includes replaceable items 14, 20, 35-66, 78-125 listed

below.

Model 231-333, Series A

Includes replaceable items 14-125, 150 listed below.

REF

PART

NO.

NO.

14

218-362

15

214-701

217593

176-818

210541

176-817

179-885

178941

217-577

180-573

162-453

218-083

48

50

53

54

55

56

214-570

210-657 BALL VALVE ’

105-521

101-725

179-775

179-780

DESCRIPTION CITY

COVER, motor; includes labels

1

HOSE, grounded, nylon; 3/16” ID;

3 ft (0.9 m) long; spring guards both

ends

1

GUN, airless

See manual 307-614 for parts

1

PIN, straight, hdls

1

HOSE, grounded, nylon; l/4” ID, 56

(15.2 ml long spring guard both ends 1

SPRING, retaining

WARNING LABEL** i

NUT, hex

1

DISPLACEMENT PUMP

See separate parts list on page 17

SUCTION TUBE

1

NIPPLE, l/4 npt(m) x l/4 npsm

1

HOSE; grounded, nylon; l/4” ID;

29” (736 mm) long; spring guard

both ends 1

FILTER, fluid

See 307-273 for Darts 1

Field-replaceable parts

are

listed below. Replacement ot

any other parts must be done by a qualified repair

agency.

REF PART

NO. NO.

57

154-636

E

178-392

104-811

60

179-811

YE

178-034

216-001

78

179-945

79

155-665

84

206-994

112

107-248

113

157-974

125

181-072

150

DESCRIPTION

WASHER

C&RsApp’ing

WHEEL

WARNING TAG”*

SPRAY TIP KIT

See manual 307-321 for parts

ADAPTER, elbow; 7/16” stud;

l/4 x l/4 npt(f 1

UNION, adapter; 3/8 npsm(f)

swivel x 3/8 npt(m)

THROAT SEAL LIQUID (TSL)

8 oz. (0.23 liters)

SCREW, math, round head, cross

head; No. 10-24x 2.5” long

WASHER, olain; 3/16”

STRAINER’

SPRAY TIP, Customer’s Choice

CITY

s

z

1

1

1

1

1

z

1

1

306 & 307nombers in descriptions refer to separate instruction

manuals.

**Warning labels and tags supplied at no charge.

Order parts by name and series letter of the assembly for

which you are ordering.

HOW TO ORDER REPLACEMENT PARTS

1. To be sure you receive the correct replacement parts,

kit or accessories, always give all of the information

requested in the chart below.

2. Check the parts list to identify the correct part number;

do not use the ref. no. when ordering.

3. Order all parts from your nearest Grace distributor.

6 digit

PART

NUMBER QTY

PART DESCRIPTION

Page 22

Ref No. 39

217-577 Displacement Pump, Series B

Includes items 201 to 224.

REF PART

NO. NO.

201

203