Graco Ultra 1500 Mark V 236-401, Ultra 1500 Mark V 236-400, Ultra 1500 Mark V, 236-401, 236-400 Instructions-parts List Manual

Page 1

INSTRUCTIONS–P

This manual contains important

warnings and information.

READ AND RETAIN FOR REFERENCE

220 VAC, 50 HZ, 12 AMP

ARTS LIST

308–263

Rev

D

Supersedes C

and PCN D

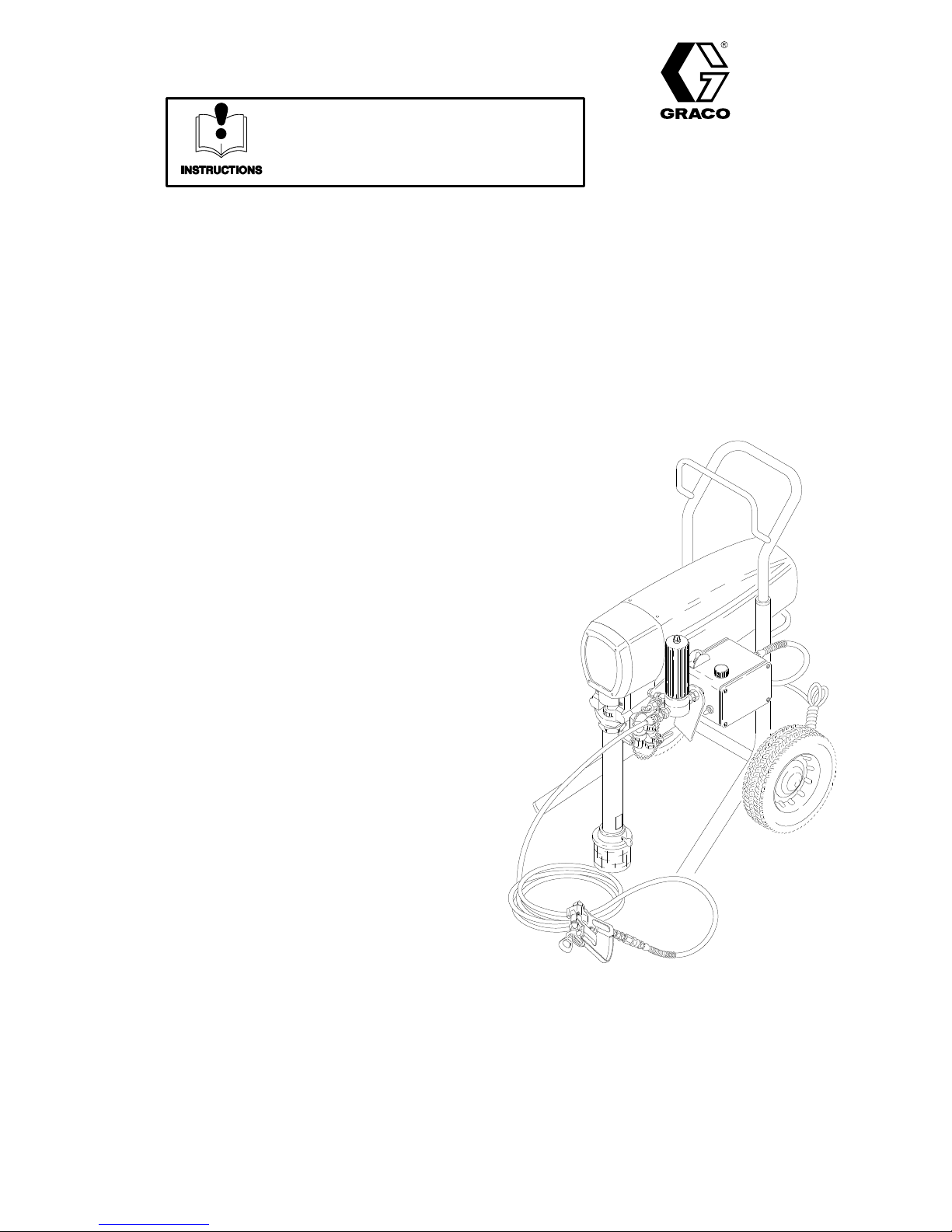

Ultra 1500 Mark V T

210 bar (3000 psi) Maximum Working Pressure

Model

This

a 1 m hose, a Contractor gun, RAC IV

guard and a Size 621 DripLess SwitchT

Model

This

a 1 m hose, a Silver Plus gun, a Heavy Duty RAC

IV

Patents

236–401, Series A

model includes a basic sprayer

, a 15 m hose,

DripLess

ip

236–400, Series A

model includes a basic sprayer

tip guard and a Size 629 DripLess SwitchT

Pending

, a 15 m hose,

tip

ip

exture Sprayer

GRACO INC. P.O. BOX 1441

COPYRIGHT

MINNEAPOLIS, MN

1993, GRACO INC.

55440–1441

Page 2

Table

PTFE

PTFE

PTFE

PTFE

PTFE

PTFE

Setup 4.

Operation 5

Flushing 7

Troubleshooting 9

Motor

Displacement

Motor

Pressure

Bearing

Connecting Rod Replacement

Drive

Parts

Parts

Technical

Dimensions 24

Warranty 24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brush Replacement

Replacement

Control Replacement

Housing and

Housing Replacement

– Sprayer

– Displacement Pump

Data

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

of Contents

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

Pump Repair

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

11.

12.

16.

17.

18.

19.

20.

22.

24.

Technical

Power

Requirements (full output)

W

orking Pressure Range

Cycles/Liter 27.5

Power

Outlet

Fluid Outlet Size

Wetted

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cord

Paint Filter

Parts:

.

. . . . . . . . . . . . .

.

. . . . . . . . . . . .

.

. . . . . . . . . .

Displacement Pump

polyethylene,

Filter

NOTE:

marks of the DuPont Company

Aluminum, Carbon steel, Stainless Steel,

.

. . . .

and Delrin are a registered trade

.

Stainless

.

. .

Data

220 V

.

. . .

1

phase, 10 amp minimum

0 – 210 bar (0–3000 psi)

. . .

No. 12 A

250 micron (60 mesh)

steel screen, reusable

1/4 npsm from fluid filter

Carbon steel, Polyurethane,

.

AC, 50Hz,

WG, 3 wire, 3 m

Delrin, Leather

-

Dimensions

W

eight (basic sprayer)

Height 813 mm.

Length 616 mm.

Width 572 mm.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . .

55.5 kg

Safety

The

English language DANGER label shown below is

also on your sprayer

read English, order one of the following labels in an

appropriate language. Apply the label to the sprayer

The drawing shows the best placement of the new la

bels for good visibility

Order the labels directly from your Graco distributor

Spray painting, flushing or cleaning equipment with flammable

in confined areas can result in fire or explosion.

liquids

Use

outdoors or in extremely well ventilated

hoses, containers and objects being sprayed.

ment,

Avoid all ignition sources such as static electricity from plastic

cloths, open flames such as pilot lights, hot objects such as

drop

cigarettes,

turning

Failure

arcs

light switches on and off.

to follow this warning can result in death or serious injury

. If you have painters who do not

.

FIRE

AND

EXPLOSION HAZARD

areas. Ground equip

from connecting or disconnecting power cords or

Labels

.

-

.

Language

French 185–955

Spanish 185–962

German 186–042

Greek 186–046

Korean 186–050

Liquids

or

leaks – especially hose leaks.

-

Keep

body. Drain all pressure before removing parts.A void accidental

triggering

Never

In case of accidental skin injection, seek immediate

“Surgical

.

Failure

injury.

Apply

a label in

Part No.

can be injected into the body by high pressure airless spray

body clear of the nozzle. Never stop leaks with any part of

of gun by always setting

spray without a tip guard.

Treatment inch.

to follow this warning can result in

another language

at this location

SKIN INJECTION

HAZARD

the

safety latch when not spraying.

amputation or serious

READ AND UNDERSTAND ALL LABELS AND INSTRUCTION MANUALS BEFORE USE

Page 3

High

Observe All W

WARNINGS

Pressure Spray Can Cause Serious Injury

arnings. Read and understand all instruction manuals before operating equipment.

. For Professional Use Only.

FLUID

General

This

the

your

including the need for amputation. Also, fluid injected or

splashed into the eyes or on the skin can cause serious damage.

NEVER

NEVER put hand or fingers over the spray tip. NEVER try to

“blow back inch paint; this is NOT an air spray system.

ALWAYS have the tip guard in place on the spray gun when

spraying.

ALWAYS

cleaning or removing the spray tip or servicing any system

equipment.

NEVER

Be

each

Medical

If any fluid appears to penetrate your skin, get EMERGENCY

MEDICAL CARE AT ONCE. DO NOT TREAT AS A SIMPLE

CUT.

Note

is

important to treat the injury surgically as soon as possible.

not delay treatment to research toxicity. T

with some exotic coatings injected directly into the blood

stream. Consultation with a plastic surgeon or reconstructive

hand

Spray

Be sure all gun safety devices are operating properly before

each

cause

Safety

equipment generates very high fluid pressure. Spray from

gun, leaks or ruptured components can inject fluid through

skin and into your body and cause extremely serious injury

point the spray gun at anyone or at any part of the body

follow the Pressure Relief Procedure

try to stop or deflect leaks with your hand or body

sure equipment safety devices are operating properly before

use.

Alert––Airless Spray W

T

ell the doctor exactly what fluid was injected.

to Physician: Injection in the skin is a traumatic injury. It

surgeon may be advisable

ounds

oxicity is a concern

.

Gun Safety Devices

use. Do not remove or modify any part of the gun; this can

a malfunction and result in serious injury

INJECTION HAZARD

, below

, before

.

Do

.

Safety Latch

Whenever you stop spraying, even for a moment, always set

the

,

gun trigger safety in

the

gun inoperative. Failure to set the safety latch can result

accidental

triggering of the gun.

the closed or “safe inch position, making

Diffuser

.

The gun diffuser breaks up spray and reduces the risk of fluid

injection

regularly

remove

gun

the gun. If the fluid emitted

stream,

when the tip is not installed. Check dif

. Follow the

the spray tip. Aim the gun into a metal pail, holding the

firmly to the pail. Using the lowest possible pressure, trigger

replace the dif

Pressure Relief Procedure

is not

fuser immediately

diffused into an irregular

.

Tip Guard

ALWAYS have the tip guard in place on the spray gun while

spraying. The tip guard alerts you to the fluid injection hazard

and

helps reduce, but does not prevent, the

placing

your

tip.

fingers or any part of your body close to the spray

risk of accidentally

Trigger Guard

Always

have the trigger guard in place on the gun when spray

ing to reduce the risk of accidentally triggering the gun if it is

dropped

Spray T

Use extreme caution when cleaning or changing spray tips. If

the

immediately. ALWAYS follow the Pressure Relief Procedure

and

NEVER

fully

or bumped.

ip Safety

spray tip clogs while spraying, engage the gun trigger

then remove the spray tip to clean it.

wipe of

relieved and the gun trigger safety is engaged.

f build–up around the spray tip until pressure

in

fuser operation

, below

, then

safety

is

-

Pressure

To

reduce the risk of serious injury, including fluid injection,

splashing

from

dure whenever you shut off the sprayer, when checking or

servicing any part of the spray system, when installing,

cleaning or changing spray tips, and whenever you stop

spraying.

1. Lock

2. T

3.

Relief Procedure

fluid or solvent in the eyes or on the skin, or injury

moving parts or electric shock, always follow this proce

the gun trigger safety

urn of

f the ON/OFF switch.

Unplug the power supply cord.

.

1

4. Unlock

-

5.

6. Open

If you suspect that the spray tip or hose is completely

clogged,

low these additional precautions,

the

to

relieve the pressure gradually. Now loosen the part com

pletely.

2

3

the gun

firmly

to the

gun

to relieve the pressure.

Lock the gun trigger safety

the pressure drain valve, having a container ready

to

catch the drainage. Leave the valve open until you are

ready

to spray again.

or that the pressure has not been fully relieved,

retaining nut on the tip guard or loosen a hose coupling

Clear the tip or hose obstruction.

trigger safety

side of a grounded metal pail, and trigger the

. Hold a metal part of the gun

.

VER Y SLOWLY loosen

4

5

fol

-

-

Page 4

EQUIPMENT MISUSE HAZARD

System

This sprayer can develop

Working

sories used are rated to withstand this pressure. DO NOT exceed

cessory

General

Any misuse of the spray equipment or accessories, such as

overpressurizing, modifying parts, using incompatible chemicals and fluids, or using worn or damaged parts, can cause

them

or

erty

NEVER alter or modify any part of this equipment; doing so

could

Pressure

Pressure

the maximum working pressure

used in the system.

. Be sure that all spray

210 bar (3000 psi ) Maximum

equipment and acces

of any component or ac

Safety

to rupture and result in fluid injection, splashing in the eyes

on the skin, or other serious injury, or fire, explosion or prop

damage.

cause it to malfunction.

HOSE SAFETY

High

pressure fluid in the hoses can

hose develops a leak, split or rupture due to any kind of wear,

damage

cause

damage.

All

spring guards help protect the hose from kinks or bends at or

close

TIGHTEN

pressure

sure

NEVER

tire

movement of the hose couplings. If

ist, replace the hose immediately

pressure hose or mend it with tape or any other device. A repaired

or misuse, the high pressure spray emitted from it

a fluid injection injury or other serious

fluid hoses must have spring guards on both ends!

to the coupling which can result in hose rupture.

all fluid connections securely before each use. High

fluid can dislodge a loose coupling or allow high pres

spray to be emitted from the coupling.

use a damaged hose. Before each use, check the en

hose for cuts,

hose cannot contain the high pressure fluid.

leaks, abrasion, bulging cover

be very dangerous. If the

can

injury or property

The

, or damage or

any of these conditions ex

. DO NOT try to recouple high

FIRE OR EXPLOSION HAZARD

Static

electricity

hose. If every part of the spray equipment is not properly

grounded, sparking may occur , and the system may become

hazardous. Sparking may also occur when plugging in or unplugging

can

ignite fumes from solvents and the fluid being sprayed, dust

particles and other flammable substances, whether you are

spraying

and

serious injury and property damage.

If you experience any static sparking or even a slight shock

while

using this equipment, STOP SPRA

Check the entire system for proper grounding. Do not use the

system again until the problem has been identified and

corrected.

Grounding

To

reduce the risk of static sparking, ground the sprayer and

other spray equipment used or located in the spray area.

CHECK

tions

all

1.

2.

your local electrical code for

for your area and type of equipment. BE SURE to ground

of this spray equipment:

Sprayer:

move the grounding prong of the plug, and do not use an

adapter.

Fluid hoses:

150

m (500 feet) combined

continuity.

is created by fluid flowing through the pump and

a power supply cord or using a

indoors or outdoors, and can cause a fire or explosion

plug into a properly grounded outlet. Do not re-

Extension cords must have three wires.

use only grounded hoses with a maximum of

See

Hose Grounding Continuity.

hose length to ensure grounding

gasoline engine. Sparks

YING IMMEDIA

detailed grounding instruc

TELY.

all

CHECK all spray equipment regularly and repair or replace

worn

or damaged parts immediately

-

-

wear protective eyewear

Always

tor

as recommended by the fluid and solvent manufacturer

.

, gloves, clothing and respira

Fluid and Solvent Compatibility

All

chemicals used in the sprayer must be chemically compatible

with

the wetted parts shown in

2.

Consult your chemical supplier to ensure compatibility

not use 1,1,1-trichloroethane, methylene chloride, other ha

Do

logenated hydrocarbon solvents or fluids containing such sol-

vents in this equipment, which contains aluminum and/or zinc

parts.

Such

the

possibility of explosion, which could cause death, serious in

jury

and/or substantial property damage.

Handle

equipment.

of

the pump and gas engine. Do not use fluids or solvents which

are

not compatible with

NOT

or

below –40 C (–40 F).

use could result in a serious chemical reaction, with

and route hoses carefully

Keep hoses clear of moving parts and hot

expose Graco hose to temperatures above

the

TECHNICAL DATA on page

. Do not pull on hoses to move

the inner tube and cover of the hose. DO

82 C (180

Hose Grounding Continuity

Proper

hose grounding continuity is essential to maintaining a

grounded

fluid

tag on it which specifies the maximum electrical resistance,

-

contact

sistance

-

for your hose to check the resistance. If the resistance exceeds

the recommended limits, replace it immediately . An ungrounded

ardous.

3.

4.

5.

6.

7.

Flushing

Reduce the risk of fluid injection injury , static sparking, or

splashing

of

this manual. Follow the

3, and remove the spray tip before flushing. Hold a metal part

of

-

the gun firmly to the side of

lowest

spray system. Check the electrical resistance of your

hoses at least once a week. If your hose does not have a

the hose supplier or manufacturer for the maximum re

limits. Use a resistance meter in the appropriate range

or poorly grounded hose can make

Also read

Spray

gun:

erly

grounded fluid hose and sprayer

Object being sprayed:

Fluid supply container:

FIRE OR EXPLOSION HAZARD.

obtain grounding through connection

according to local code.

according to local code.

All solvent pails used when flushing,

code. Use only metal pails, which are conductive. Do not

place

the pail on a non–conductive surface, such as

or

cardboard, which interrupts the grounding continuity

To

maintain grounding continuity when

pressure

side

, always hold a metal part of the gun firmly to the

of a grounded metal pail, then trigger the gun.

your system haz

.

according to local

flushing or relieving

Safety

by following the flushing procedure given on page 7

possible fluid pressure during flushing.

Pressure Relief Procedure

a grounded metal pail and use the

MOVING PARTS HAZARD

Moving

parts

parts.

the

sprayer

before checking

it

from starting accidentally

can pinch or amputate your fingers or other body

KEEP CLEAR of moving parts when starting or

. Follow the

Pressure Relief Procedure

or servicing any part of the sprayer

.

.

.

surfaces

F

to a prop

paper

.

on page

operating

on page

, to prevent

-

-

-

-

-

-

3

4 308-263

Page 5

Setup

WARNING

Proper

electrical–grounding is essential to reduce

the risk of a fire or an explosion. A fire or an explo

sion can cause a serious injury and property dam

age. For the detailed grounding–instructions, refer

to the warning section,

HAZARD,

on page 4.

FIRE OR EXPLOSION

WARNING

If you supply the hoses and the spray gun for the

sprayer

hoses are electrically conductive. Be sure the spray

gun has a tip guard. Be sure that each part is rated

for at least 210 bar (3000 psi) working pressure

These precautions reduce the risk of a serious

injury

ing, over–pressurizing or rupturing the hose or the

gun.

, follow these precautions. Be sure the

, including skin injection, due to static spark

-

-

.

-

3.

Be sure the electrical service is 220 V

an electrical outlet that is properly grounded. Have

a licensed electrician attach an appropriate plug to

the power supply cord. Do not remove the ground

ing prong of the power supply cord. Do not use an

ungrounded adapter

three wires which have a minimum 2.5

gauge) size. Long extension cords reduce the per

formance of the sprayer

4. T

urn of

f the power switch (A). Plug the power

supply cord into a grounded electrical outlet which

is located at least 6 m (20 feet) away from the

spray area.

5.

If you are spraying texture material, remove the

screen from the fluid filter

procedure on page 8.

6.

Flush the pump before using it. Refer to page 8.

. Extension cords must have

.

. Refer to the Flushing

, 50 Hz. Use

mm2 (12

-

-

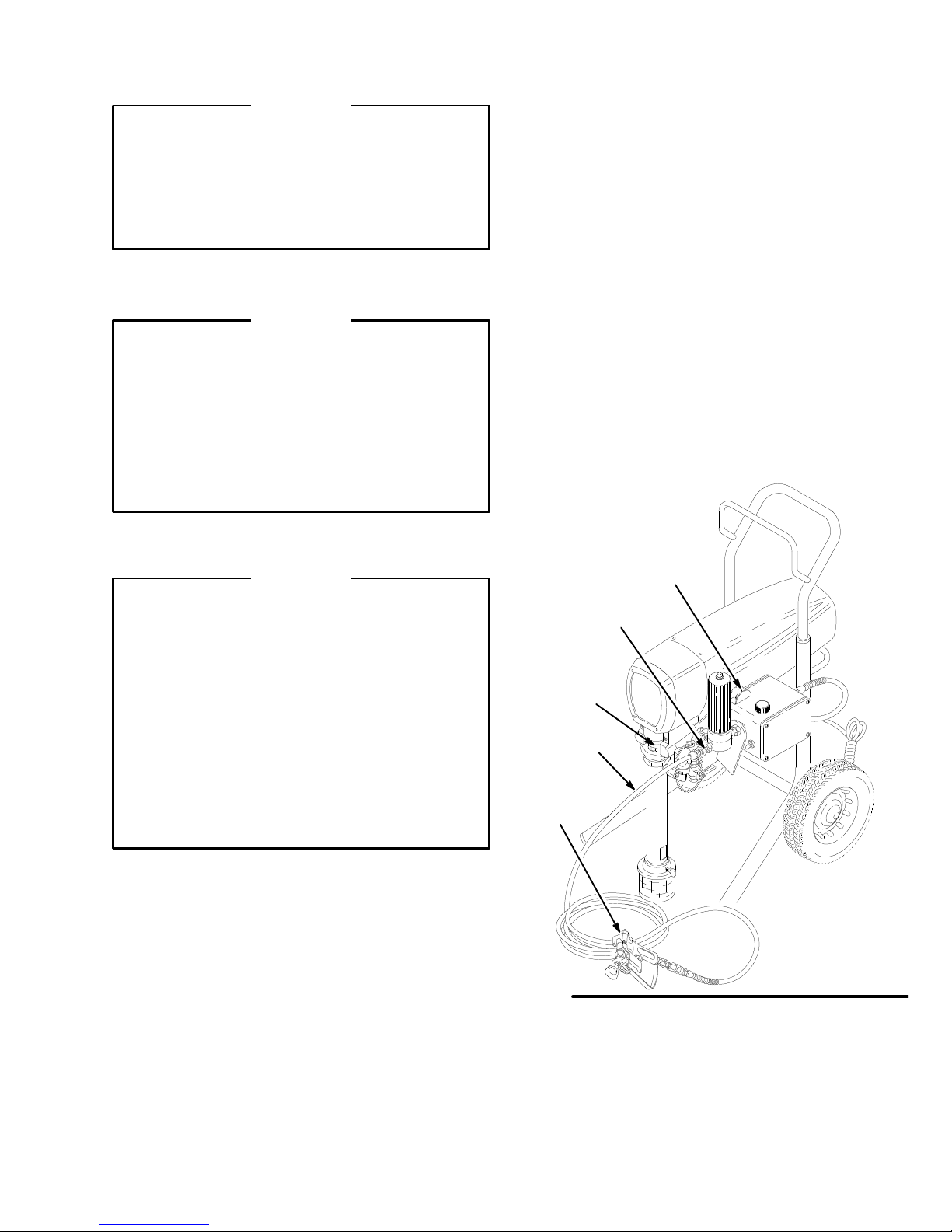

CAUTION

A damaged pressure control can cause poor

sprayer performance and may damage other parts

of the sprayer

damaging the pressure control.

1.

Use a nylon spray hose (99) that is at least

15 m (50 feet) long.

2.

Never use a wire braid hose. It is too rigid to

absorb the pulsations of the fluid in the hose.

3.

Never install a shutoff device between the fluid

filter and the main hose. See Ref. B in Fig. 1.

1.

Connect the gun (101) and the 15 m (50 feet) hose

(99). Do not install the spray tip yet.

2.

Fill the wet–cup (216) with Graco Throat Seal Liq

uid, supplied, until it is 1/3 full.

. Follow these precautions to avoid

A

B

216

99

101

-

Fig. 1

308-263 5

Page 6

Operation

WARNING

T

o reduce the risk of a serious injury

the

Pressure Relief Procedure W

3 before checking, adjusting, cleaning, and shut

ting of

f the sprayer

.

Startup

Always use this procedure to help ensure that the

sprayer is ready to operate and that you start the

sprayer safely

1.

Flush the sprayer before you use it for the first

time. Refer to page 8.

2.

Close the pressure drain valve (55).

3.

Do not install the spray tip until the pump is primed

with fluid!

4.

Put the pump (39) into the supply pail

5. T

urn the pressure–adjusting knob (A) counter

clockwise to the lowest setting.

6.

Unlock the gun trigger safety

.

, always follow

arning

.

on page

.

Check all fluid connections for leaking. If you find

8.

any leaks, relieve the pressure before tightening

the connections.

-

9.

Lock the gun trigger safety

and the tip guard (96, 103). Follow the instructions

supplied with the tip guard.

10.

Adjust the pressure.

a. Slowly

b.

c. T

-

, turn the pressure–adjusting knob (B)

clockwise just until spray from the gun is com

pletely atomized. T

fogging, and to lengthen the life of the spray

tip and sprayer

needed for good atomization.

If more fluid coverage is needed, use a larger

spray tip rather than increasing the pressure.

est the spray pattern. Follow this procedure

to adjust the direction of the spray pattern.

Lock the gun trigger safety

ing nut on the tip guard. T

hozontal position for a horizontal pattern. T

the tip guard to a vertical position for a vertical

pattern. T

, use the lowest fluid pressure

ighten the retaining nut.

. Install the spray tip

o reduce the overspray and

. Loosen the retain

urn the tip guard to a

urn

-

-

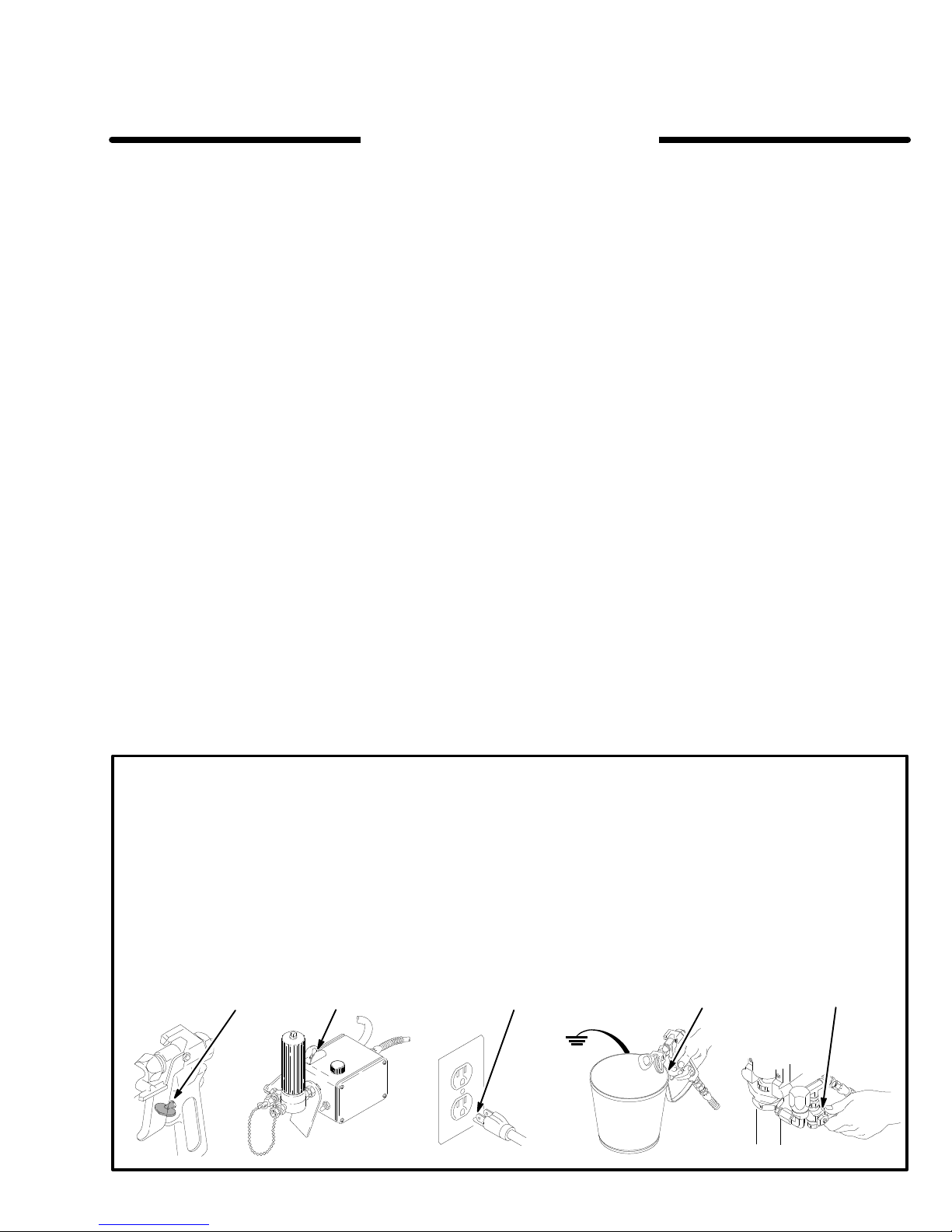

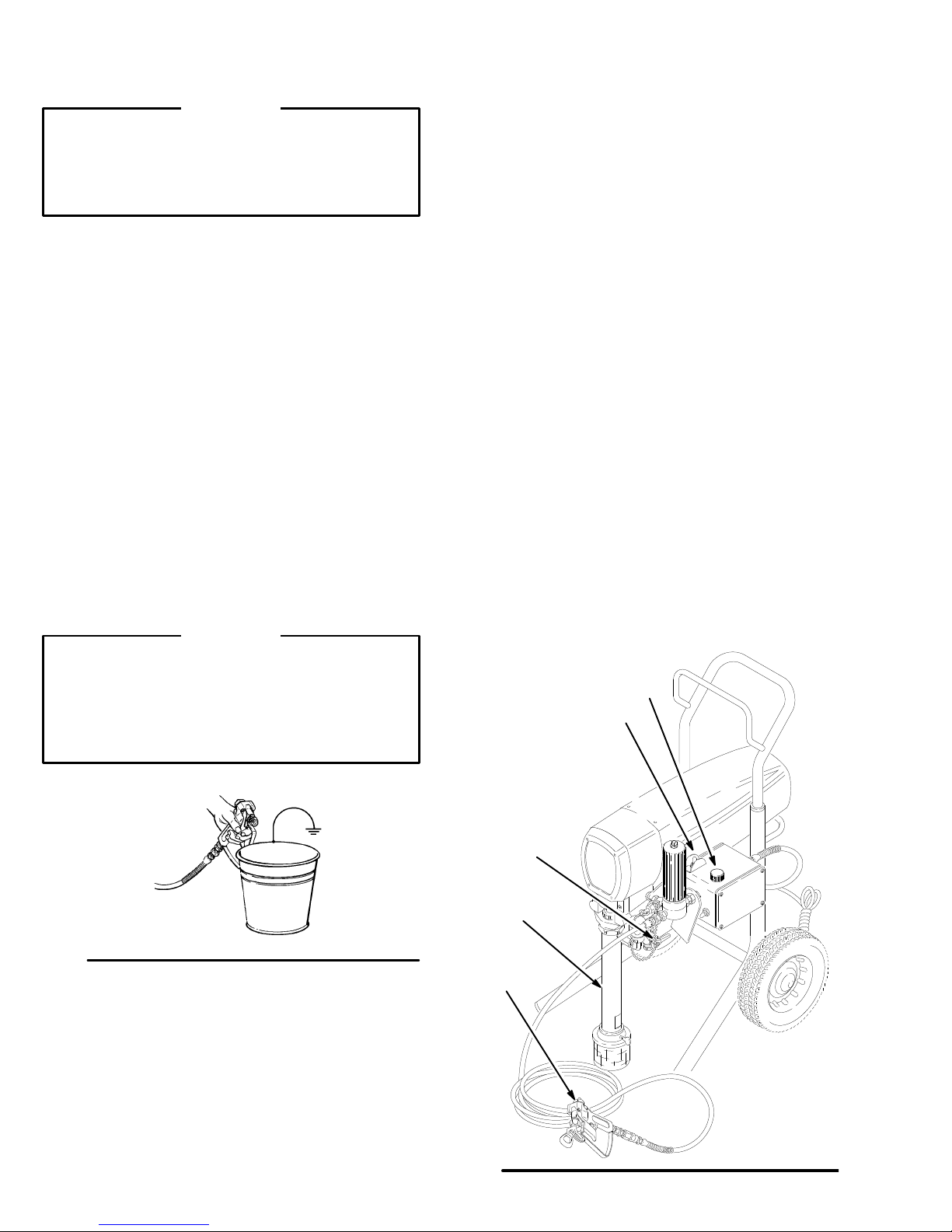

WARNING

T

ake precautions to reduce the risk of static spark

ing and splashing when you prime or flush the

sprayer

metal part of the gun firmly to the side of grounded

metal pail. See Fig. 2.

Fig. 2

7.

. Be sure the spray tip is removed. Hold a

Prime the pump. Squeeze the gun trigger and hold

it open. T

the pressure–adjusting knob (B) clockwise only

until the sprayer starts. Keep the gun triggered

until the air is forced out of the system and the

fluid flows freely from the gun. Release the gun

trigger and lock the gun trigger safety

urn of

f the power switch (A). Slowly turn

.

-

B

A

55

39

96,

103

NOTE: To avoid damaging the pump packings, do not

operate the sprayer without fluid in it for more than 30

seconds.

Fig. 3

Page 7

Operation

Cleaning a Clogged Tip

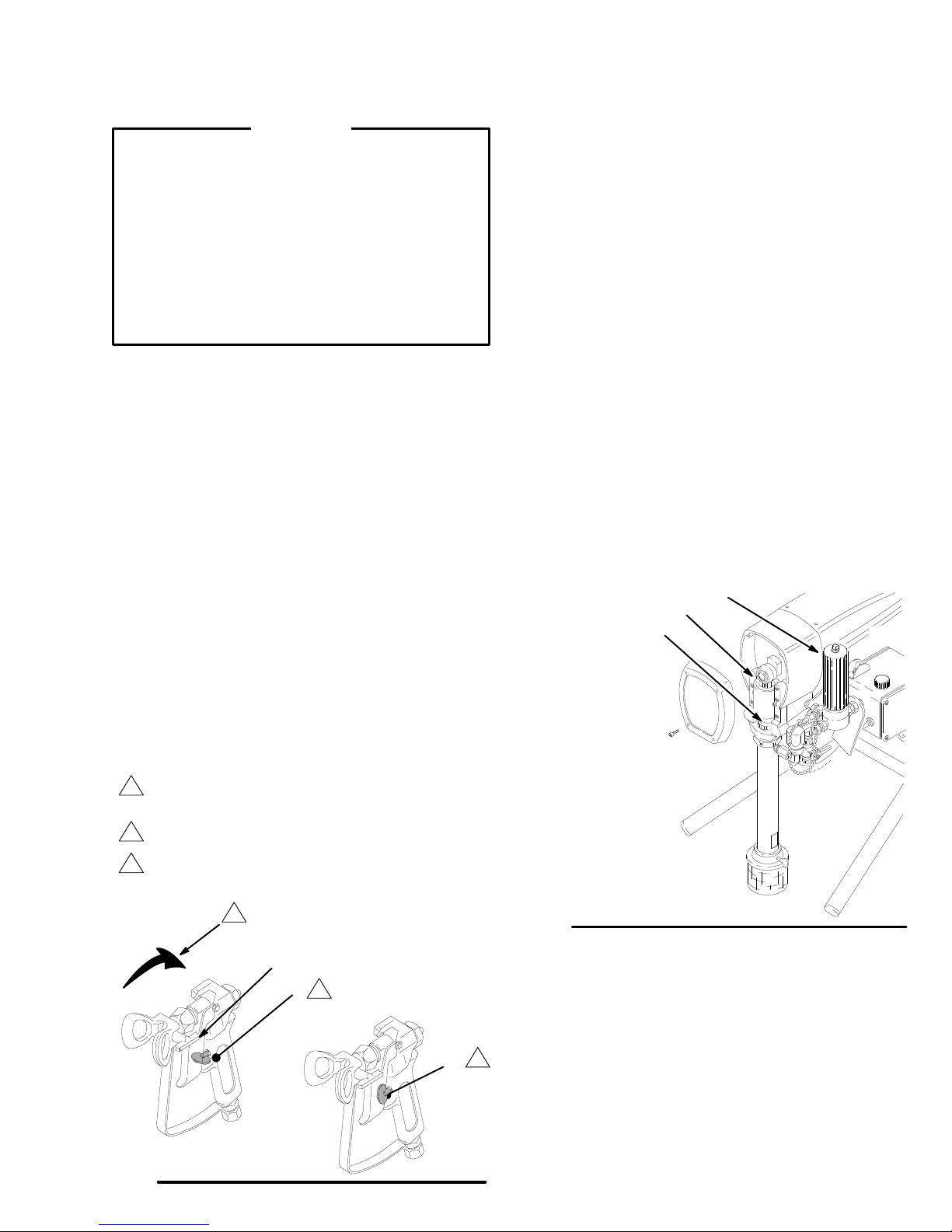

WARNING

Follow

these precautions to reduce the risk of a

serious injury when cleaning a clogged tip.

Do not hold a hand, a body

spray tip. Always point the gun toward the ground

or into a waste container when triggering the gun to

see if the spray tip is unclogged.

DO NOT try to “blow back inch fluid; this is NOT an

air spray sprayer

1.

Release the gun trigger

Lock the gun trigger safety (B).

2.

3.

Rotate the HD RAC IV handle 180. See Ref. A in

.

Fig. 4.

4.

Unlock the gun trigger safety (C).

5. T

rigger the gun into a waste container

Lock the gun trigger safety again. See Ref. A in

6.

Fig. 4.

, or a rag in front of the

.

.

Shutdown and Care

1. Keep

2.

3.

the wet–cup (216) 1/3 full with Graco Throat

Seal Liquid. The liquid helps prevent fluid from

building up on the piston rod. Fluid build–up

causes the packings to wear prematurely

relieve the pressure before checking, filling or

tightening the wet–cup. See Fig. 5. Remove the

plug from the wet-cup. T

ighten the wet cup, which

is also the packing nut, just enough to stop leak

age. If you over–tighten the wet–cup, the packings

may bind and wear out more quickly

. Use a screw

driver and a light hammer to adjust the wet-cup.

Clean the fluid filter (48) often and whenever the

sprayer is stored. See manual 307–273 for the

cleaning procedure.

After each 100 hours of operation, fill the cavity of

the connecting rod (D) with motor oil. First Relieve

the pressure and then remove the front cover

Fig. 5.

. Always

-

-

. See

7.

Rotate the tip handle to the original position.

8.

Unlock the gun trigger safety

If the tip is still clogged, lock the gun trigger safety

9.

shut of

f and unplug the sprayer

.

, and open the

pressure drain valve to Relieve the pressure.

Remove the spray tip and soak it in solvent. Do

not scrape or chip debris from the spray tip.

10.

Resume spraying.

The

1

2

3

tip handle (A) is shown in the spraying

position. Rotate the tip handle 180 in the

direction of the arrow for clearing a clog.

T

rigger safety shown in the locked position.

T

rigger safety shown in the unlocked position.

1

A

B

2

48

D

216

,

Fig. 5

4.

When you shut of

f the sprayer for a short time,

leave the pump in the fluid–supply container

02067A

, re-

lieve the pressure, and clean the spray tip.

Fig. 4

3

C

5.

Before you store the sprayer

, flush it thoroughly

.

Always use mineral spirits for the final flushing.

Relieve the pressure.

6. T

0137

o protect the hose, coil it and hang it on the cart

handle

when storing the sprayer

.

Page 8

Flushing

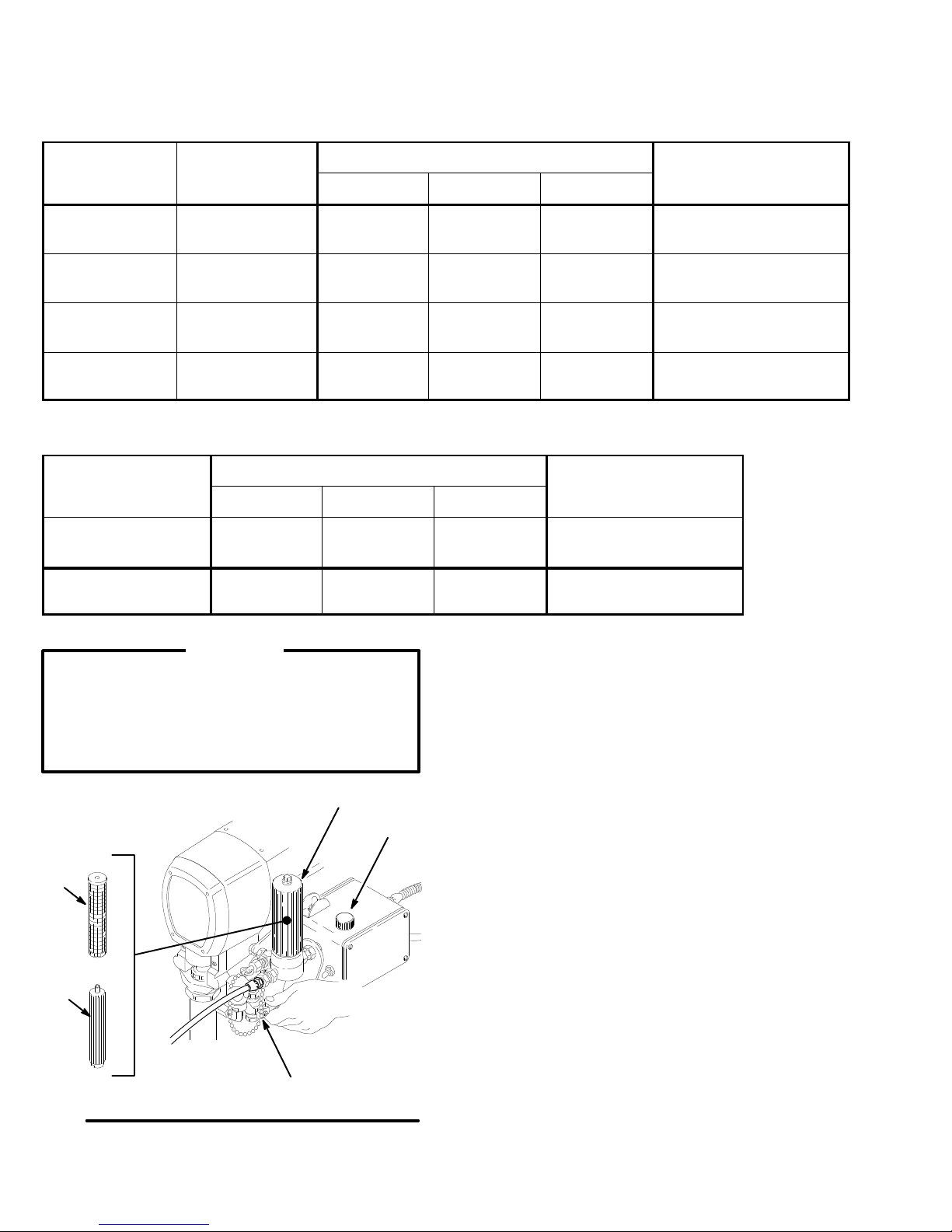

1

Use this category when flushing a new sprayer and

when flushing the sprayer after it has been stored.

The system has

this fluid in it:

1

Oil-base solvent

or paint.

Oil-base solvent

or paint.

Water or waterbase paint.

Water or waterbase paint.

Use the following information to prepare the sprayer for storage.

The system has this

fluid in it:

Oil-base solvent or

paint.

W

ater or water-base

paint.

The next fluid to

be sprayed is:

Oil-base fluid in a

new color

W

ater-base paint.

W

ater-base fluid

in a new color

Oil-base paint.

Flush the sprayer in the order given.

First flush

Mineral spirits

W

arm, soapy

water

Flushing the sprayer in the order given.

First flush

Mineral spirits

Mineral spiritsWarm, soapy

W

arm, soapy

.

water

W

arm, soapy

water

Second flush

none none

Clean water

Second flush

none none

water

Clean water

Clean water

Third flush

Mineral spirits

Before you use the

Third Flush

Clean water

none

Mineral spirits

Before you store the

sprayer:

Relieve the pressure.

Relieve the pressure.

sprayer:

Prime the sprayer with

oil-base paint.

Prime the sprayer with

water-base paint.

Prime the sprayer with

water-base paint.

Prime the sprayer with

oil-base paint.

CAUTION

Never allow water to freeze in the pressure

control. A frozen pressure control prevents the

sprayer from being started and causes serious

damage to the pressure control. Pump out the

water with mineral spirits.

C

D

E

55

1.

Relieve the pressure.

2.

Remove the bowl (C) and the screen (D) from the

filter

. Leave the filter support (E) in place. Install

the bowl (C), only

3.

Close the pressure drain valve (55). See Fig. 8.

4.

Pour two liters of a compatible solvent into a

grounded metal pail. Put the pump in the pail.

A

5.

Remove the spray tip from the gun.

6. T

urn the pressure–adjusting knob (A) counter

clockwise to the lowest pressure setting.

. See Fig. 8.

-

Fig. 6

Page 9

Flushing

WARNING

T

ake precautions to reduce the risk of static spark

ing and splashing when you prime or flush the

sprayer

metal part of the gun firmly to the side of grounded

metal pail. See Fig. 7.

Fig 7

7.

. Be sure the spray tip is removed. Hold a

Hold a metal part of the gun firmly against a

grounded metal pail. See the W

T

rigger the gun. T

Slowly

, increase the pressure just until the sprayer

starts. Keep the gun triggered until all air is forced

out of the system and the solvent flows freely from

the gun. Release the trigger

safety.

urn on the power switch (B).

ARNING, above.

. Lock the gun trigger

Leave the pressure drain valve (55) open until you

9.

-

are ready to use the sprayer again. See Fig. 8.

10.

Clean the filter screen (D). Remove the bowl (C)

from the filter

and tighten it by hand. See Fig. 8.

11.

If you flushed with mineral spirits and now plan to

use a water–base paint, flush the sprayer with

soapy water and then with clean water

pressure.

D

E

. Install the screen. Install the bowl

. Relieve the

C

B

A

NOTE:

sure drain valve. Close the pressure drain valve when

fluid comes from it. Proceed as in Step 7.

8.

If the pump is hard to prime, open the pres

Remove the pump from the pail. Unlock the gun

trigger safety

the hose. T

do not operate the pump without fluid in it for more

than 30 seconds! Shut of

. T

rigger the gun to force solvent from

o avoid damaging the pump packings,

f the sprayer

.

-

Fig. 8

55

Page 10

Troubleshooting

WARNING

T

o reduce the risk of a serious injury

Pressure Relief Procedure W

before checking, adjusting or repairing the sprayer

, follow the

arning

on page 3

.

Read the entire T

TYPE OF PROBLEM WHA

The building’

opens.

The sprayer’s circuit breaker

opens.

roubleshooting section before disassembling the sprayer

If check is OK, go to next check

s circuit breaker

Check all electrical wiring to see if there is

damaged insulation.

Check to see if there are other electrical

appliances on the same circuit.

Check the position of the 10–12 (Lo–High)

amp switch.

Check to see if the motor rotor is dislocated.

Unplug the power supply cord. T

the motor’s fan blades with a screwdriver

Check to see if the motor has an electrical

short. Use an ohmmeter to check for electri

cal shorts between the electical leads of the

motor and the motor frame.

Check the electrical supply using a volt

meter

VAC.

T T

O CHECK

ry to turn

. The meter should indicate 210–250

.

WHA

T T

O DO

When check is not OK refer to this column

Replace any damaged wiring.

Shut of

f other electrical appliances on the

same circuit.

Put the switch in the 10–12 amp (LO) posi

tion.

Repair the gear train or the pump, if either of

them is damaged. Thaw the sprayer if it is

.

frozen–see the NOTE on page 11. Replace

the pressure control, if it is damaged.

Inspect the leads of the motor brushes to see

-

if they are damaged. Replace the motor

brushes or the motor as necessary.

Connect the sprayer to an electrical outlet

which has the correct voltage.

-

The sprayer will not operate.

The spray from the gun has a

poor pattern.

Check the pressure control knob. If the knob

is turned fully counterclockwise, which is the

minimum pressure setting, the motor will not

operate.

Check to see if the spray tip is clogged.

Refer to page 7.

Check the extension cord for visible dam

age. Check the extension cord outlet with a

volt meter or a test lamp.

Check the power supply cord for visible

damage such as broken insulation or broken

wires.

Check the electrical supply using a volt me

. The meter should indicate 210–250 V

ter

Check the motor for damage. Remove the

drive housing assembly

T

ry to rotate the blades of the fan manually

Check to see if the spray tip is worn.

. Refer to page 17.

-

AC.

Slowly increase the pressure to see if motor

will start.

Relieve the pressure. Refer to page 7 for

instruction on how to clean the spray tip.

Replace the extension cord.

Replace the power supply cord.

-

Reset the

circuit’s fuse. T

Replace the motor (1) if the blades of the fan

won’t rotate.

.

Relieve the pressure. Replace the spray tip.

Refer to the instruction manual supplied with

the spray tip.

building’

s circuit breaker

ry another electrical outlet.

, or replace

10 308-263

Page 11

Troubleshooting

TYPE OF PROBLEM WHA

If check is OK, go to next check

The motor operates and the

pump strokes, but the fluid

output is low or there is no fluid

output.

Check to see if the spray tip is worn.

Check the motor brushes for these

problems: Loose electrical leads or

terminals, a brush which is worn to less than

10 mm long, a broken or misaligned spring,

brushes which are binding in their holders.

Refer to page 12.

Check the armature of the motor for

electrical shorts by using an armature tester

(growler).

Check to see if the pump continues to stroke

when the gun trigger is released.

Check to see if the intake valve ball and the

piston ball are seating properly

Check for leaks around the throat packing

nut which may indicate that the packings are

worn or damaged.

T T

O CHECK

WHA

T T

O DO

When check is not OK refer to this column

Follow

Pressure Relief Procedure

Warning

your separate gun or tip manual.

Replace any damaged parts as needed.

Refer to page 12.

Replace the motor

Repair the pump. Refer to page 14.

Remove the intake valve and clean it.

.

Check the balls and seats for nicks; replace

if necessary

paint before using it to remove particles that

could clog the pump.

Replace the packings. Refer to page 14.

Also check the piston valve seat for

hardened paint or nicks and replace any

damaged parts. T

nut/wetcup.

, then replace the spray tip. See

. Refer to page 17.

. Refer to page 14. Strain the

ighten the packing

The motor operates but the

pump does not stroke.

The motor is hot and operates

intermittently.

Check the connecting–rod pin (20) in the

displacement pump. Refer to page 13.

Check for frozen or hardened paint in the

pump (39).

Be sure the crank in drive housing can

rotate.

Remove the

housing.

on the sprayer

sprayer.

Determine if the sprayer was operated at a

high pressure while using a small–orifice

spray tip. These conditions cause the motor

to function at a low RPM and produce

excessive heat.

Locate the sprayer where the ambient

temperature is no higher than 32C. Do not

place the sprayer in the direct sunlight.

Determine if the sprayer was turned on and

pressurrized, but not operating, for long

periods of time.

Plug in the sprayer and briefly turn

front cover from the drive

. T

urn of

f and unplug the

Replace pin, if missing. Be sure retainer

spring (35) is fully in groove all around

connecting rod. Refer to page 13.

Thaw.

See the NOTE below. Plug in sprayer

and turn on. Slowly increase pressure

setting to see if motor starts.

Check the drive housing assembly for

damage. Replace damaged parts. Refer to

page 20.

Decrease the pressure setting or use a

larger tip.

Move the sprayer to a shaded, cooler area,

if possible.

T

urn of

f the sprayer whenever you stop

spraying for a while and whenever you

relieve the pressure.

NOTE:

Thaw the sprayer if water or water–base paint has frozen in it. Place the sprayer in a warm area. Do not try

to start the sprayer until it has thawed completely

packings. Refer to page 14.

. If fluid has hardened or dried in the sprayer, replace the pump

308-263 11

Page 12

Motor

Brush Replacement

NOTE:

Replace the brushes when they have worn to

about 10 mm in length. Always check both of the

brushes. A Brush Repair Kit, part number 222–157,

and a new spring clip, part number 110–816, may be

purchased separately

.

NOTE: The replacement brushes may last only half as

long as the original brushes. To maximize the life of the

brushes,

allowing

operate the sprayer for at least one hour without

the pump to stroke. See Steps 10 to 12.

WARNING

Follow the

on page 3 to reduce the risk of a serious injury

1.

Relieve the pressure.

2.

Remove the shield (14). Remove the covers (A)

from both brush inspection ports. See Fig. 9.

Pressure Relief Procedure W

14

arning

.

10. T

est the brushes.

a.

Remove the connecting rod pin (20) only

Fig. 13, page 13.

b.

With the sprayer turned of

f, turn the pressure

control knob to the minimum pressure setting.

Plug in the sprayer

c. T

urn on the sprayer

.

. Slowly increase the pres

sure until the motor is at full speed.

d.

Inspect the contact area of the brush and com

mutator

. The arcs should not circle around the

commutator surface.

CAUTION

Do not touch the brushes, leads, springs, or brush

holders while the sprayer is plugged in, to reduce

the risk of an electric shock and a serious injury

11.

Install the brush inspection plates, gaskets, and

covers.

Operate the sprayer for at least one hour

12.

install the pump connecting rod pin. See page 13.

. Then,

. See

-

-

.

A

Fig. 9

3.

Push in the clip (D) to unhook it, and then pull out

the clip. See Fig. 10.

4.

Loosen the screw (F). Pull away the brush’

trical lead (E), leaving the motor’s electrical lead

(G) in place. Remove the brush (C) and the spring

(B). See Fig. 1

5.

Inspect the motor’s commutator for excessive pit

1.

ting, burning or gouging. A black color on the com

mutator is normal. If the brushes seem to wear too

quickly

, have the commutator resurfaced by a

qualified motor repair shop.

6.

Install the new brush (C) so its electrical lead is in

the long slot (K) of the brush holder (H). Slide the

terminal of the brush’

s electrical lead (E) under the

washer of the screw (F). Make sure the motor

electrical lead (G) is still connected the at the

screw. T

7.

Place the spring (B) on the brush (C) as shown in

ighten the screw (F). See Fig. 12.

Fig. 12.

s elec

’s

B

C

D

Fig. 10

01227

B

D

C

-

-

E

F

Fig. 11

The

spring must coil in

this direction.

The minimum brush

length is 10 mm.

G

H

01227

J

C

B

D

8.

Push in the clip (D) and hook it. See Fig. 12.

9.

Repeat this procedure for the other side.

12 308-263

Fig. 12

01227

Page 13

Displacement

Removing the pump

1.

Flush the pump, if possible. Relieve the pressure.

Stop the pump with the piston rod in its lowest po

sition, if possible.

2.

Remove the hose (47).

3.

Remove the intake screen (99).

4.

Push the retaining spring (35) up and push out the

pin (20).

5.

Loosen the locknut (38). Unscrew the pump from

the bearing housing (27) by one half turn.

6.

Remove the check valve assembly (A) from the

pump.

7.

Remove the pump.

Installing the pump

1.

Screw the pump into the bearing housing (27) until

the pin holes in the connecting rod assembly (29)

and the displacement rod (224) are aligned. Install

the pin (20).

2.

Continue to screw the pump into the bearing hous

ing until the top threads of the pump cylinder are

even with the face of the bearing housing and the

pump outlet faces straight back. Unscrew the

pump one half turn so the pump outlet is at the

side. Push the retaining spring (35) into the groove

all the way around the connecting rod. T

locknut (38) to 95 N.m (70 ft-lb).

See Fig. 13.

See Fig. 13 and 14.

ighten the

Pump Repair

Install the intake screen (99). See Fig. 13..

3.

4.

-

-

Install the check valve assembly (A).

5. T

ighten the wet-cup just enough to stop leakage,

but no tighter

until it is 1/3 full.

Fig. 13

. Fill the wet–cup with Graco TSL

27

35

224

20

38

39

99

47

A

02069A

WARNING

Push the retaining spring (35) completely and firmly

into the groove around the connecting rod to pre

vent it from working loose due to vibration.

If the pin works loose, the pin or other parts could

break off as the pump operates. The broken parts

could damage the sprayer or they could be pro

pelled toward the operator and cause a serious

injury.

CAUTION

If the locknut (38) loosens during operation, the

threads of the bearing housing (27) will be dam

aged. Ttighten the locknut firmly

Torque

1

-

-

-

.

2

Fig. 14

to the nut to 95 N.m. (70 ft–lb).

This

is the face

bearing

housing.

of the

29

27

2

20

35

38

1

02083

308-263 13

Page 14

Displacement

WARNING

Follow

the

Pressure Relief Procedure W

on page 3 to reduce the risk of a serious injury

arning

Pump Repair

lips of the v-packings in the throat

The

must face down.

The throat packings and glands.

The throat packings and glands.

.

NOTE:

223–41

Use the Packing Repair Kit, part number

1. The parts included in the kit are marked with

an asterisk (*). Use all the new parts in the kit. Clean

all parts. Inspect all parts, including the inside of the

sleeve (218) and the outside of the displacement rod

(224). Replace worn or damaged parts.

Disassembling the Pump

1. Unscrew

Clean the parts. If no further repair is needed,

reassemble the intake valve, using a new o-ring

(202*). See Fig. 15.

2.

Remove the packing nut (216) and plug (205). T

down the piston rod (224) using a plastic mallet.

Pull the piston rod out the bottom of the cylinder

(219). Remove the throat packings and the glands.

See Fig. 16.

3.

Clamp the piston rod (224) in a vise. Loosen the

piston nut (21

and remove all the parts. See Fig. 17.

and disassemble the intake valve (223)

1). Unscrew the piston valve (222)

WARNING

If the pump sleeve (218) cannot be removed easily

use the sleeve–removal tool, part number

235–376, as instructed in Step 4. T

risk of a serious injury

, do not use any other

method to remove the pump sleeve.

o reduce the

ap

,

Fig. 16

The

and glands.

*205

216

*209

*213

*208

piston packings

207*

219

224

224

211

NOTE:

If you have an old–style sleeve–removal tool,

part number 220–991, you can purchase just the

sleeve–removal extension, part number 188–734. The

extension makes the old tool equivalent to the tool

235–376.

4. T

o remove the pump sleeve (218), screw the large

nut (C) of the sleeve–removal tool into the top of

the cylinder (219). Screw the rod (B) downward to

push out the sleeve. Remove the tool. See Fig. 18.

219

220

204*

202*

223

226

Fig. 15

14 308-263

Fig.

Fig.

17

18

222

02086

B

C

219

218

Page 15

Displacement

Pump Repair

1

T

orque the intake valve to 146 N.m (1

2

The

lips of the V

3

The lips of the V

The lips of the U-cup seal must face down.

4

-packings in the throat must face up.

-packings in the piston must face down.

*209

2

*207

*208

10 ft–lb).

205

216

213*

219

224

NOTE:

Soak the leather packings in oil before reas

-

sembling the pump.

1.

Stack the following parts onto the piston valve

(222): the backup washer (214), the seal

(203*)–with the lips of the seal facing downward,

and the female gland (215*). Alternately install the

three plastic packings (212*) and the two leather

packings (206*) with the lips of the packings facing

up. Install the male gland (210*). See Fig. 19.

2.

Screw the retaining nut (211) on to the piston valve

(222). T

orque the nut to 0.35 N.m (4 in-lb). See

Fig. 20.

3.

Place the ball (225) on the piston valve (222). See

Fig. 20.

4.

2

Apply one drop of the adhesive, supplied, to the

threads of the piston valve. Hand tighten the pis

ton–valve assembly in to the piston rod just until

the nut (21

5. Note the alignment

(21

1). Use two wrenches to maintain the alignment

1) contacts the piston rod. See Fig. 20.

of the piston (222) to the nut

through Steps 6 and 7.

6.

Place the flats at the top of the piston rod (224) in

a vise.

*210

*206

3

*215

*214

220

*202

226

Fig.

19

Reassembling the Pump

NOTE:

an incorrect installation.

Follow all of the notes in the drawings to avoid

225*

217*

218

211

212*

203*

222

202*

223

3

4

1

02073

7.

Using two wrenches,

(21

1) against the piston rod. Torque the nut to 26

N.m (56 in–lb). See Fig. 21.

the nut (21

Torque

1

to 0.35 N.m (4 in–lb).

1)

Fig. 20

Apply one drop of the adhe

1

sive to the threads of the

piston valve (222).

T

orque the nut (21

2

rod to 27 N.m (56 in–lb).

Do not allow the nut (21

3

to move when screwing it

on to rod.

Fig.

21

1) against

carefully

-

1)

tighten the nut

225

211

222

224

211

222

308-263 15

1

02074

2

3

1

02075

Page 16

Displacement

Pump Repair

8. Place

9.

10.

11.

12.

13.

14.

15.

a new seal (217*) into the cylinder (219).

Lubricate the inside of the cylinder with oil. See

Fig. 20.

Install the male gland (208*) in the top of the cylin

der (219). Alternately install the three plastic pack

ings (213*) and the two leather packings (207*) so

that the lips of the packings face up. Install the fe

male gland (209). See Fig. 20.

Install the packing nut (216) loosely

plug (205) in the packing nut. See Fig. 20.

Lubricate the piston rod and the packings with oil.

Slide the assembly into the top of the sleeve (218).

See Fig. 22.

Slide the sleeve and the piston rod assembly into

the bottom of the cylinder (219). See Fig. 23.

Screw the cylinder locknut (38) downward to the

bottom of the external threads on the cylinder

T

ighten the locknut gently

Place the intake valve (223) in a vise. Install a new

o-ring (202*). Screw the cylinder (219) on to the

intake valve. T

(1

10 ft-lb). See Fig. 20.

Refer to page 13 to install the pump.

orque the intake valve to 146 N.m

.

. Install the

Lubricate.

1

224

-

-

-

Fig. 22

1

Lubricate

.

Fig. 23

1

218

217*

219

218

02087

1

02076

16 308-263

Page 17

Motor

Replacement

WARNING

Follow

the

Pressure Relief Procedure W

on page 3 to reduce the risk of a serious injury

NOTE:

1.

2.

3.

4.

5.

6. T

See Fig. 24 except where noted.

Remove the shield (14), the front cover (31), and

the pressure control cover (36). Disconnect the

hose (47).

Disconnect the motor’s electrical leads. See Fig.

25, page 18.

Unscrew the connector (44) on the pressure con

trol. Pull out the motor’s electrical leads.

Unscrew the connector (54) from the motor

Remove the conduit (22).

Remove the screws (51) from the drive housing.

Remove the screws (21,30) from the motor (1).

ap the rear of the pump (39) with a plastic mallet

to loosen the drive housing (18) from the motor

(1). Pull of

f the drive housing.

arning

.

.

NOTE:

Do not drop the gear cluster (9), which may

stay engaged in the front of the motor or in the drive

housing. Do not lose the balls (10) or drop them be

tween the gears. The balls usually stay in the recesses

for the shaft, but the balls could be dislodged. If the

balls are not in place, the bearings will wear prema

turely.

7.

Remove the screws (37). Lift of

8.

Mount the new motor on the cart. Install the

f the motor

.

screws (37).

9.

Slide the connector (54) over the electrical leads of

the new motor

connector into the motor

locknut until it contacts the motor

10.

-

Grease the gear cluster (9) and the pinion gear (G)

liberally

. Screw two or three threads of the

. T

ighten the connector

.

. Pack all the bearings in the front of the

’s

motor with grease. Be sure the balls (10) are in

place.

Place the bronze–colored washer (18b) and then

11.

the silver–colored washer (18a) on the shaft which

protrudes from the large gear in the drive housing

(18).

12.

Align the gears and push the drive housing (18)

straight onto the front of the motor (F) and its

locating pins.

13.

Continue to reassemble the sprayer

.

Torque

1

2

3

4

the screw to 34 N.m (300 in-lb).

The bronze–colored washer

Apply 175 cc of bearing grease.

The silver–colored washer

.

.

1

33

49

31

Fig. 24

51

27

18

14

21

63

1

G

4

18a

3

9

2

18b

54

37

44,22

36

30

63

40

10

47

41

02080

308-263 17

Page 18

Pressure

Control Replacement

WARNING

Follow

the

Pressure Relief Procedure W

on page 3 to reduce the risk of a serious injury

NOTE:

1.

2.

3.

4.

5.

See Fig. 26 except where noted.

Disconnect the hose from the outlet of the fluid

filter (48).

Loosen the nut (28). Loosen the swivel fitting (8).

Remove the fluid filter (48).

Remove the cover (36) from the pressure control.

Disconnect the four motor leads. See Fig. 25.

Unscrew the connector (44) from the pressure

control (43). Loosen the nuts on the connector

Pull out the conduit (22) and the motor’s electrical

leads from the pressure control.

Remove the screws (37) which hold the pressure

control (43) to the cart. Remove the pressure con

trol. Install the connector (44) on the new pressure

control.

arning

8.

Install the cover (36) on the pressure control.

.

9.

Connect the swivel fitting (8) to the fluid filter (48).

TIghten the nut (28) so that the filter is held

securely to the mounting plate (16).

1

The

seal (93) is located inside this fitting.

.

-

Black/

White(–)

6.

Remove the screws (84) and the mounting plate

(16) from the old pressure control. Install these

parts on the new pressure control.

7.

Install the new pressure control. Mount the pres

sure control with the screws (37). Place the seal

(93) around the motor’

the seal into the top of the connector (44). See Fig.

25.

s electrical leads and push

24

1

-

Fig. 25

93

44

41

40

84

16

44,22

43

36

Red

47

Black(–)

01897

28

Fig.

26

18 308-263

13

48

37

8

02077A

Page 19

Bearing

Housing and Connecting Rod

Replacement

WARNING

Follow

the

Pressure Relief Procedure W

on page 3 to reduce the risk of a serious injury

arning

9.

Install the screws (33). T

to 34 N.m (300 in–lb).

.

10.

Reinstall all the parts. Refer to page15 to install

the pump.

orque the screws evenly

NOTE:

get the crank (H) in its lowest position. T

crank manually

of the motor’s fan.

1.

2.

3. T

4.

5.

6.

Stop the sprayer at the bottom of its stroke to

o lower the

, use a screwdriver to rotate the blades

Remove the pump. Refer to page 1

Remove the front cover (31). Remove the screws

(33).

ap the lower rear of the bearing housing (27) with

a plastic mallet to loosen it from the drive housing

(18). Pull the bearing housing and the connecting

rod (29) straight of

Inspect the crank (H) and all other parts for exces

sive wear

Lubricate the inside of the bronze bearing (K)

evenly with motor oil. Pack the roller bearing (J)

liberally with bearing grease.

Assemble the connecting rod (29) and the bearing

housing (27).

. Replace worn or damaged parts.

f of the drive housing.

1.

Torque

33

-

31

to 3 N.m (300 in-lb)

Lubricate

J

29

27

49

35

20

38

18

H

K

7.

Clean the mating surfaces of the bearing housing

and the drive housing.

8.

Align the connecting rod with the crank (H). Align

the locating pins in the drive housing with the holes

in the bearing housing (27). Push the bearing

housing on to the drive housing or tap the bearing

housing into place using a plastic mallet.

Fig. 27

39

47

308-263 19

Page 20

Drive

Housing Replacement

WARNING

Follow

the

Pressure Relief Procedure W

on page 3 to reduce the risk of a serious injury

arning

6.

Remove the screws (30, 21) from the motor (1).

7. T

.

ap the drive housing (18) with a plastic mallet to

loosen it from the motor

straight of

f of the motor

. Pull the drive housing

.

NOTE:

NOTE:

get the crank (H) in its lowest position. T

crank manually

See Fig. 28 for this procedure

.

Stop the sprayer at the bottom of its stroke to

o lower the

, use a screwdriver to rotate the blades

of the motor’s fan.

1.

Remove the front cover (31). Remove the shield

(14).

2.

Disconnect the spray hose.

3.

Remove the screws (33) from the bearing

housing.

ap the rear of the pump (39) with a plastic mallet

4. T

to loosen it from the drive housing (18). Pull the

bearing housing (27) straight of

f of the drive

housing (18).

5.

Remove the screws (51) from the drive housing.

NOTE:

Do not drop the gear (9), which may stay en

gaged in the front of the motor or in the drive housing.

Do not lose the balls (10) or drop them between the

gears. The balls usually stay in the recesses for the

shaft, but the balls could be dislodged. If the balls are

not in place, the bearings will wear prematurely

8.

Use approximately 175 cc of the bearing grease,

.

supplied with the drive housing replacement kit, to

grease the gear cluster (9). Check to be sure the

balls (10) are in place.

9.

Place the bronze–colored washer (18b) and the

the silver–colored washer (18a) on the shaft which

protrudes from the large gear in the drive housing

(18).

10.

Align the gears. Push the new drive housing

straight onto the motor and its locating pins.

11.

Continue to reassemble the sprayer

. T

orque the

screws (33) to 34 N.m (300 in–lb).

-

1

2

3

4

Fig. 28

the screws to 34 N.m (300 in-lb).

Torque

The bronze–colored washer

Apply 175 cc of bearing grease.

The silver–colored washer

.

.

51

27

49

33

1

31

63

18

14

21

63

1

4

3

2

18b

18a

9

30

63

10

H

39

47

02082

Page 21

Parts–Displacement

PTFEPTFEPTFE

Pump

Model 235–731, Series A

Displacement

Includes items 202 to 226

Ref

No.

202 107–098*

203 110–284*

204 102–972*

205 183–171

206 183–174* V–P

207 183–175* V–P

208 185–474*

209 185–475*

210 185–476*

211

212 183–182* V–P

213 183–183* V–P

214 186–653* W

215 185–473*

216

217 183–172*

218

219

220

222

223

224

225 101–947*

226 185–522 ST

Pump

Part No.

183–179

183–186

183–361

188–361

185–312

235–203

222–691

235–730

Description Qty

SEAL, sleeve

SEAL, u–cup, polyurethane

BALL; sst

PLUG

ACKING, leather

ACKING, leather

GLAND, male

GLAND, female

GLAND, male

NUT

, hex, retaining

ACKING, plastic

ACKING, plastic

ASHER, backup

GLAND, female

NUT

, packing

O–RING,

SLEEVE, cylinder

CYLINDER 1

GUIDE, ball

VAL

VE, piston

VAL

VE, intake

ROD, piston

BALL

AND OFF

1

205

216

1

1

1

1

2

2

1

1

1

1

3

3

1

1

1

1

1

1

1

1

1

1

209*

213*

207*

213*

207*

213*

208*

219

224

*225

211

*210

*212

*206

*212

*206

*212

*Included in the

223–411.

time.

Keep a repair kit available to reduce down

Displacement Pump Repair Kit

217*

218

*215

*203

214

222

220

*204

*202

223

226

02064

308-263 21

Page 22

105d or

106d

Parts

106b, 106c

106a,

106e

– Sprayer

105e

3

2

1

98

61

14

105a,

105b,

105c

18

10

18b

9

18a

10

64

1

97

21

63

1

2

64

81

82

64

91

63

29

51

54

37

Ref

61

62

27

33

49

41

40

30

63

40

41

31

4

2

17

83

52

80

Ref 6

1

25

47

32

99

35

20

38

39

92

86

42

75

55

78

79

100,101,102

16

85

43

95

4

88

3

94

3

Ref 37

6

53

44

84

5

60

22

26

87

58

23

11

Ref 47

1

safety label.

A

2

An identification label.

3

An information label.

4

A caution label.

28

13

46

34

12

93

71,

1

77

45

37

57

8

48

50

8

15,

36,

5

2

02065A

02065

Page 23

Parts

– Sprayer

Model

236–401, Series A

This model includes a basic sprayer and a Contractor gun kit.

The

model includes items 1 to 105.

Model

236–400, Series A

This

model includes a basic sprayer and a Silver Plus gun kit

The model includes items 1 to 102 and 106.

Ref

No. Part No. Description Qty

1 235–726 MOTOR KIT 1

2 186–078

3 186–079

4 186–080

5 187–656 GASKET 2

6 220–636 CART 1

7 186–620

8 155–665 ADAPTER 3/8 inch npsm swivel

9 220–637 GEAR REDUCER 1

10 100–069

11 104–811 HUBCAP 2

12 220–285 CAP 1

13 100–322 LOCKW

14

15

16 185–539 BRACKET

17 111–590 BUTTON 2

18 220–879 DRIVE HOUSING KIT

183–204 MOTOR SHIELD KIT 1

110–885 SCREW

LABEL, identification, motor cover

LABEL, identification, motor cover

LABEL, identification, front cover

LABEL, ground symbol

x 3/8 npt(m)

BALL, steel, 1/4 inch diameter

ASHER, 7/16 inch

, No. 10–24 x 3/8 inch

, mounting

Includes 18 a, 18b, and one of 10

18a 183–209 .THRUST BEARING 1

18b 106–227 .SPACER 1

20 183–210

21 100–644 SCREW

22

065–099 CONDUIT, electrical

PIN, 3/8 x 1–1/8 inch

, 1/4–20 x 3/4 inch

specify length when ordering

23 224–263 POWER SUPPLY CORD 1

24 107–264

25 187–959 LABEL 1

26 154–636 WASHER 2

27 220–639 BEARING HOUSING KIT 1

28 150–513 NUT

29 220–640 CONNECTING ROD KIT 1

30 100–643 SCREW

31 183–168

32 108–850

33

34

35 183–169 RETAINING SPRING 1

36 186–918 COVER, pressure control 1

37 110–963 CAPSCREW

38 183–170 NUT

39 235–731 DISPLACEMENT PUMP

110–141 CAPSCREW

187–003

TERMINAL, female

, 7/16 inch

, 1/4–20 x 1 inch

COVER, housing 1

SCREW

ADAPTER, 1/4–18 npt(m x f)

5/16–18 x 3/4 inch

, No. 8–32 x 1–1/4 inch

, 1 13/16 unc–2b

see parts on page 21

40 100–214 LOCKW

41 100–188

42 223–125 CHECK VALVE 1

43 224–385 PRESSURE CONTROL KIT

44 102–932 CONDUIT

45 112–153 CIRCUIT BREAKER 1

46

47 222–516

48

162–453

236–789

NUT 5/16–18 unc–2a

includes

NIPPLE, 1/4 npsm x 1/4 npt,

1–3/16 inch long

HOSE, 3/8 npsm(f) x 14–1/2 inch

FLUID FIL

see

includes one of items 46 and 85

ASHER, spring, 5/16 inch

replaceable items 16, 23, 4 of 84

FITTING, 90

TER

manual 307–273 for parts

, 3/8–16 x 1–1/5 inch

, flange head,

1

296 mm

49 106–115 LOCKWASHER,

50 100–509 PLUG 1

51 108–849 CAPSCREW

52 110–243 RETAINING SPRING 2

53 108–691

54 108–460 CONNECTOR 1

55 235–725 DRAIN VALVE 1

57 178–034 TAG, WARNING 1

58 101–242 RETAINING RING 2

59 206–994 THROA

60 179–81

61

1

62 187–603

1

63

1

64 108–865 SCREW

71 177–762

75 109–544 ELBOW 1

1

77 181–608

78 803–088 TEE 1

2

79 161–889 SWIVEL UNION 1

80 109–032 SCREW

1

81 185–384 BRACKET 2

82 110–240 NUT 2

83 183–350 WASHER, 7/8 inch ID 2

1

84 106–078 SCREW

85 100–040 PLUG 1

4

86 100–083

1

87 106–170 STRAIN RELIEF BUSHING 1

88 185–565

89 100–035 SCREW

1

90 157–021 LOCKWASHER, No. 8 1

91 100–020 LOCKW

92 156–971 NIPPLE 1

1

93 107–447 SEAL 2

2

94 109–547

95 178–035

97 185–951

98 185–952

2

99 236–792

100 107–255 SHROUD 1

101 105–653 BOOT 1

102 112–153 ON/OFF SWITCH 1

2

105

2

105a 220–955 . CONTRACTOR GUN

4

105b 220–422 . RAC IV TIP GUARD 1

4

105c 221–621 . SwitchT

1

105d 223–541 .

ID,

7

105e 214–701 .

1

105f 157–350 . NIPPLE 1

1

106 236–383 SILVER PLUS GUN KIT

7

7

106a 235–460 . SILVER PLUS GUN

106b 222–674 . HEAVY DUTY RAC TIP GUARD 1

1

106c GHD–629 . HEAVY DUTY TIP

106d 214–705 .

1

106e 214–925 SWIVEL 1

1

1

220–633

105–510

236–384

Replacement Danger and W

are available at no cost.

PLUG, tubing

T SEAL LIQUID, 0.27 liter

1

WHEEL 2

HANDLE, cart 1

SLEEVE, cart handle

LOCKW

LABEL, W

LABEL, Identification

COUPLING, 3/8 to 1/4 inch

LABEL, pressure control

LABEL, 10/12 amp

LABEL, Caution

LABEL, Danger

LABEL, Danger

INLET FIL

CONTRACTOR GUN KIT

Includes items 105a to 105f

See manual 307–614 for parts

cpld 1/4 npsm, grounded,

spring guards both ends

0.9 m long, spring guards both ends

Includes items 106a to 106e

See manual 308–236 for parts

cpld 3/8 npsm(f), 15 m,

spring guards both ends

ASHER, 1/4 inch

, 8–32 x 3/8 inch

, pnh, 10–24 x 1/4 inch

, No. 10–24 x 3/8 inch

, No. 8–32 x 5/16 inch

ASHER, 0.194 inch ID

HOSE, nylon, 1/4 inch x 50 ft (15 m)

HOSE, grounded, nylon, 3/16 inch ID,

HOSE, grounded, nylon, 3/8 inch ID,

3/8 inch

, 1/4–20 x 3 inch

arning 1

TER SCREEN 1

ip, Size 621

, size 629

arning labels, tags and cards

4

2

2

1

2

6

10

1

4

4

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

Page 24

Manual

This

manual has been updated to make the following text and

part changes.

Technical

Strainer,

the

fluid

Model 231–207 has been obsoleted.

Data, page 2: Delete the reference to the Inlet Paint

this model does not have one. Delete the reference to

fluid outlet size, this

outlet size should be 1/4 npsm at the filter outlet.

model does not have inlet threads. The

Change Summary

Assembly

Changed

236–400

236–401

Part

Status

Add 99

Ref

No.

100

101

102

Part No.

236–792

107–255

105–653

112–153

Name

Screen

Shroud

Boot

Switch

The

Graco

warrants all equipment manufactured by it and bearing its name to be free from defects in material and workmanship on

the date of sale

warranty

defective, with the exception of defects in parts on the drive train/gear box, which will be repaired or replaced for forty-eight

months from the date of sale and the electric motor (excluding brush replacement, which is routine maintenance) or pressure

control assembly which will be repaired or replaced for twenty-four months from the date of sale. This warranty applies only when

the equipment is installed, operated and maintained in accordance with Graco’

This warranty does not cover

misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non–Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility with Graco

equipment of structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, instal

lation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor

for verification of the claim. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any

defect in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts,

labor and transportation.

DISCLAIMERS AND LIMITATIONS

The terms of this warranty constitute purchaser’s sole and exclusive remedy and are in lieu of any other warranties (express or

implied),

liabilities, including product liabilities, base on negligence or strict liability. Every form of liability for direct, special or consequential

damages or loss is expressly excluded and denied. In no case shall Graco’

Any action for breach of warranty must be brought within two (2) years of the date of sale.

, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the Ultra equipment proven

including warranty of merchantability or warranty of fitness for a particular purpose,

Graco Warranty and Disclaimers

by an authorized Graco distributor to the original purchaser for use. As purchaser’s sole remedy for breach of this

s written recommendations.

, and Graco shall not be liable for

, any malfunction, damage or wear caused by faulty installation,

and of any non–contractual

s liability exceed the amount of the purchase price.

-

EQUIPMENT NOT COVERED BY GRACO WARRANTY

Graco makes no warranty

respect to accessories, equipment, materials, or components sold but not manufactured by Graco. These items sold, but not

manufactured by Graco (such as electric motor

Graco will provide purchaser with reasonable assistance in making any claim for breach of these warranties.

Foreign Offices:

, and disclaims all implied

Sales Offices:

Atlanta, Chicago, Dallas, Detroit, Los Angeles, Mt. Arlington (N.J.)

Canada, England, Korea, Switzerland, France, Germany

GRACO INC. P.O. BOX 1441

PRINTED

warranties of merchantability and fitness for a particular purpose,

, switches, hose, etc.) are subject to the warranty

MINNEAPOLIS, MN

IN U.S.A.

308–263 4–93 Revised 10/94

, if any

, of their manufacturer

, Hong Kong, Japan

55440–1441

24 308-263

with

.

Loading...

Loading...