Page 1

INSTRUCTIONS-PARTS

LIST

@

307-827

120

VAC,

I

a

AMP

This

manual contains

IMPORTANT

INSTRUCTIONS

and

WARNINGS.

GRACO

Rev

A

READ

AND RETAIN

FOR

REFERENCE.

ULTRA@

1500

AIRLESS

PAINT

SPRAYER

3000

psi

(210

bar)

MAXIMUM

WORKING

Model

220-627,

Series

A

hose or gun

Basic sprayer on Upright cart without

Model

231-053

Complete sprayer on Upright cart with hose,

gun, RAC

IV'",

DripLess'" Tip Guard

and SwitchTip'"

PATENTS PENDING

$x;*$>*,

TABLE

CONTENTS

..

<>$&3;$4$;.

($97

*;:,.,.,.

<*....

;.*

Warnings

......................

2

Avertissement

..................

4

Advertencia

....................

6

Setup

.........................

8

Operatlon

......................

9

Troubleshooting Guide

12

Flushing Guidelines

11

c.,.

?#

.

............

.........

Repair..

......................

13

Parts

Lists

and Drawinas

........

22

Accessories

25

Technical Data..

...............

26

Warranty.

Back Cover

Dimensions

26

-

..................

...................

.............

WARNING

Hazard

of

Uslng

Fluids

Containing Halogenated Hydrocarbons

such solvents

in

this equipment. Such use could result in a serious chemical reaction, with the possibilityof explosion,

Never use

1.1,

1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids containing

which could cause death, serious bodily injury and/or substantial property damage.

Consult your fluid suppliers to ensure that the fluids being used are compatible with aluminum and zinc parts.

Refer to the Technical Data on page

26

for more information.

J

GRACO INC.

PO.

BOX

1441 MINNEAPOLIS, MN 55440-1441

QCOPYRIGHT

1989,

GRACO INC.

Page 2

I

i

!

..

.I

.,

I

General Safety

the gun. leaks or ruptured

components can inject fluid through

This equipment generates

very high

fluid

pressure. Spray from

yourskinandintoyourbodyandcauseextremelyseriousbodily

injury. including the need for amputation. Also, fluid injected or

spiashedintotheeyesorontheskincancauseseriousdamage.

N NER point the spray gun at anyone or at any part of the body.

NNER put hand or fingers over the spray tip. NNER

try

to

"blow back" paint: this is NOT an air spray system.

ALWAYS have the

tip

guard

in

place

on

the spray

gun

when

spraying.

ALWAYSfollow the Pressure Rellef Procedure. below, before

cleaning or removing the spray tip or servicing any system

equipment.

NNER

try

to stop or deflect leaks

with

your hand or body.

each use.

Be sure equipment safety devices are operating properly before

Medical Alert--Airless Spray Wounds

MEDICAL

CARE

AT

ONCE.

DO

NOT

TREAT

AS A SIMPLE

If

any fluid appears to penetrate your skin, get

EMERGENCY

CUT.

Tell the doctor exactly what fluid was injected.

Note

to

Physician:

Injection

in

the skin

is

a traumatic

injuv.

It

is

impoftant to treat the

injuv

surgically

as

soon

as possible.

Do

not

delay treatment to research toxfcity. Toxicity

is

a

concern with some exotic coatings injected directly into the

blood stream. Consultation with

a

piastic surgeon or re-

constructive hand surgeon may be advisable.

Spray

Gun Safety Devices

Be sure all gun safety devices are operating properly before

cause

a

malfunction

and

resuit

in

serious bodily injury.

each use.

Do

nd

remove or modify any part of the gun; this can

Safety

Latch

Whenever you stopspraying, even for a moment, always setthe

gun safety latch in the closed or "safe" position, making thegun

inoperative.Faiiuretosetthesafetyiatchcanresultinaccidental

triggering of the gun.

Diffuser

The

gun diffuser breaks up spray and reduces the risk of fluid

regularly, Follow the Pressure Relief Procedure, below, then

injection when the

tip

is not installed. Check diffuser operation

remove the spray

tip.

Aim the gun into a metal pail, holding the

gunfirmlytothepail.Usingthelowestpossibiepressure,trigger

the gun.

If

the fluid emitted

is

not diffused into an irregular

stream, replace the diffuser immediately,

Tip

Guard

ALWAYS have the tip guard in place on the spray gun while

spraying. The tip guard alerts you

to

the fluid injection hazard

and heips reduce, but does

not

prevent, the risk of accidentally

tip.

placing your fingers or any part

of

your body close to the spray

Trigger Guard

Always have the trigger guard in place on the gun when spray-

dropped or bumped.

ing to reduce the risk of accidentally triggering the gun

if

it

is

Spray Tip Safety

Use extreme caution when cleaning or changing spray tips.

If

the spray tip clogs while spraying, engage the gun safety latch

and then remove the spray tip

to

clean it.

immediately. ALWAYS follow the Pressure Relief Procedure

NEVER wipe

off

build-up around the spray

tip

until pressure is

fully relieved and the gun safety latch is engaged.

Pressure Relief Procedure

TO reduce the risk

of

serious bodily injury, including fluid in-

jection, splashing

fluid

or solvent in the eyes or on the skin,

this procedure whenever

you

shut

off

the sprayer, when

or injury from moving

parts

or

electric shock, always follow

stalling, cleaning or changing spray tips. and whenever

you

checking or servicing any part of the spray system, when in-

stop

spraying.

1.

Engage the gun safety latch.

2.

Turn the ONiOFF switch

to

OFF.

3.

Unplug the power supply cord.

4.

Disengage the gun safety latch. Hold a metal part of the

gun firmly to the side of a grounded metal pail. and trigger the gun to relieve pressure.

5.

Engage the gun safety latch.

6.

Openthepressuredrainvalve, havingacontainerready

tocatch thedrainage. Leavethevalve open

until

you are

ready to spray again.

If you suspect that the spray tip or hose

Is

completely

clogged,

orthatpressureh.asn0tbeenfullyrelievedafterfol-

lowing the steps above, wrap a rag around the tip guard re-

the pan to relieve pressure gradually, then loosen com-

taining

nut

or hose end.coupling and VERY SLOWLY loosen

pleteiy. Now clear the tip or hose.

Page 3

:

I

I

~

1

,

I

MOVING

PARTS HAZARD

~~~~

<xy

,,....,

x.:.>:

.....

<.X.,L

....

CL.:.?,:.

Moving parts can pinch or amputate your fingers or other

body

the sprayer. Follow the Pressure Relief Procedure

on

page

4

parts. KEEP CLEAR of moving parts when starting or operating

before checking or servicing any part of the sprayer, to prevent

it from starting accidentally.

EQUIPMENT MISUSE

HAZARD

~~~~.~~

General Safety

Any misuse of the spray equipment or accessories, such as

overpressurizing, modifying parts, using incompatible chemi-

calsandfiuids,orusingwornordamagedparts,cancausethem

to rupture and resuit

in

fluid injection, splashing

in

the

eyes

or

on the skin,

or

other serious bodily injury, or fire, explosion or

property damage.

NEVER alter or modify any part of this equipment; doing

so

could cause it to malfunction.

worn or damaged parts immediately.

CHECK all spray equipment regularly and repair or replace

Always

wearprotectiveeyewear,gloves,ciothingandrespirator

as recommended by the fluid and wlvent manufacturer.

System Pressure

This sprayer can develop

3000

psi

(270

bar)

MAXIMUM

WORK-

ING

PRESSURE.

Besure that all spray equipment and accesso-

ries used are rated to withstand this pressure.

DO

NOTexceed

the maximum working pressureof

any

component oraccessory

used in the system.

Fluid and Solvent Compatibility

patible with the welted parts shown in the TECHNICAL DATA

BE SURE that ail fluids and solvents used are chemically com-

on page

26.

Always read the

fluid

and Solvent manufacturer's

lit-

erature before using them in this sprayer.

High pressure

fluid

in

the hoses can

be

very dangerous.

if

the

hose develops a leak, split or rupture due to any kind of wear.

damage or misuse, the high pressure spray emitted from it can

cause a fluid injection injury or other serious bodily injury or

property damage.

ALL FLUID

HOSES

MUST HAVE SPRING GUARDS

ON

BOTH

ENDS

The spring-guards help protect the hose from

kinks or bends

at

or close to the coupling which can result

in

hose rupture.

TIGHTEN all fluid connections securely before each use. High

pressure fluid

can

dislodge a loose coupling or allow high pres-

sure spray to be emitted from the coupling.

NEVER use a damaged hose. Before each use. checktheentire

hose for cuts, leaks, abrasion, bulging cover, or damage or

movement of the hose couplings.

If

any of these conditions ex-

ist.

replace the hose immediately. DO NOT try lo recouple high

pressure hose or mend it with tape or any other device.

A

re-

paired hose cannot contain the high pressure fluid.

HANDLE AND ROUTE HOSES CAREFULLY

Do

not pull

on

hoses

to

move equipment. Keep hoses clear of moving parts

or solvents which are not compatible with the inner tobe and

and hot surfaces of :he pump and gas engine.

Do

not use fluids

cover

of

the hose.

DO

NOT expose Graco hOSe lo temperatures

above

180° F (82' C)

or

below

-40'

F

(-40'

C).

Hose Grounding Continuity

Proper hose grounding continuity is essential

to

maintaining a

grounded spray system. Check the electrical resistance of your

fluid hoses at least once a week.

if

your hose does not have atag

on

it

which specifies the maximum electrical resistance. contact

the hose supplier or manufacturer for the maximum resistance

limits. Use a resistance meter in the appropriate range for your

hose to check the resistance.

If

the resistance exceeds the rec-

ommended limits, replace

it

immediately. An ungrounded or

poorly grounded hose

can

make your system hazardous. Also

read

FIRE

OR

EXPLOSION HAZARD.

Static electricity is created by the flow of fluid through the pump

and hose.

If

every part

of

the spray equipment is not properly

grounded, sparking may occur, and the system may become

hazardous. Sparking may also occur when plugging in or unplugging a power supply cord or using a gasoline engine.

Sparks can ignite fumes from SOiVentS and the fluid being

sprayed, dust particles and other flammable substances,

a

fire

or

explosion and serious bodily injury and property

whether you are spraying indoors or outdoors, and can cause

damage.

Ifyouexperienceanystaticsparkingorevenaslightshockwhiie

using this equipment, STOP SPRAYING IMMEDIATELY.

Check the entire system for proper grounding.

Do

not use the

system again until the problem has been identified and

corrected.

Grounding

To reduce the risk of static sparking, ground the sprayer and all

other spray equipment used or located in the spray area.

CHECK your local electrical code for detailed grounding

in-

structions for your area and type of equipment.

BE

SURE

to

ground ail of this spray equipment:

1.

Sprayer: plug into a properly grounded outlet. Do not re-

move the grounding prong of the plug, and do not use an

adapter. Extension cords must have three wires.

2.

Fluid hoses: use only grounded hoses

with

a maximum

of

500

fl(150

m) combined hose length

to

ensure grounding

continuity. See Hose Grounding Continuity.

3.

Spraygun: obtaingrounding through connection to aproperly grounded fluid hose and sprayer.

4.

Object being sprayed: according

to

local code.

5.

Fluid

supply container: according to iocai code.

6.

All

Solvent pails used when flushing, according to local

code. Use

only

metal pails, which are conductive.

Do

not

place the pail

on

a non-conductive surface, such as paper

or cardboard, which interrupts the grounding continuity.

7.

To

maintain grounding continuity when flushing or reliev-

ing

pressure. always hold a metal part of the gun firmly

to

the side of a grounded metal pail, then trigger the gun.

Flushing Safety

Reduce the risk of fluid injection injury, static sparking, or

splashing by following thefiushing proceduregivenon page

11

ofthismanual. Follow the Pressure Relief Procedure onpage

2,

and remove the spray

tip

before flushing. Hold a metal part of

the gun firmly to the side

of

a grounded metal pail and use :he

lowest possible fluid pressure during flushing.

Page 4

i

i

j

~

I

i

I

I

i

I

i

I

i

Consignes generales de securite

Cet appareil produit un fluide a tres haute pression. Le fluide

pulverise par le pistolet ou le fiuide sous pression provenant de

fuites

ou

de ruptures peut penetrer sous la peau

ou

a

i'interieur

du corps et entrainer des blessures tres graves, voir meme une

amputation. Meme sans &re sous pression. ie fluide eclabousSant ou entrant dans ies yeux peut aussi entrainer des biessures

graves.

NE JAMAIS pointer ie pistolet vers quelqu'un

ou

vers une partie

quelconque du corps. NE JAMAIS mettre la main ou Ies doigts

sur I'ajutage du pulverisateur. NE JAMAIS essayerde "refouler"

pneumatique.

la peinture. Cet appareil N'est PAS un compresseur

TOUJOURSgarderiaprotectiondei'ajutageenplacesurlepis-

toiet pendant la puiverisation.

TOUJOURS observer ia March

A

Sulvre pour Detendre

la

Pression donnee pius loin, avant de netloyer

ou

d'eniever

sur une partie del'appareil.

I'ajutage du pulverisateur,

ou

d'effectuer un travail queiconque

NEJAMAlSessayerd'arreterouded~vierlesfuitesaveclamaIn

ou le corps.

Avant chaque utiiisation, bien s'assurer que Ies dispositifs de

securite fonctionnent correctement.

Soins medlcaux

En casde penetration de fluidesous ia peau: DEMANDER IM-

MEDIATEMENT DES

SOINS

MEDICAUX D'URGENCE. NE

PAS SOIGNER CETTE BLESSURE COMME UNE SIMPLE

COUPURE.

Avis

au

medecin:

La

penetration des fluides sous la peau est un

traumatisme.

II

est Important de tralter chirurgicalement

cette blessure Immediatement. Ne pas retarder ie traite-

ment pour effectuer des recherches sur la toxicite. Certains

revktements exotiques sont dangereusement toxiques

quand ils sont injectes directement dans le sang.

II

est

Souhaitable de consulter un chirurgien esthelique ou un

ChiNrgien specialise dans la reconstruction des mains.

Dispositifs de securite

du

pistolet

desecuri1edupistoletfonctionnentcorrectement.Nepaseniever

Avant chaque utilisation, bien's'assure que tous les dispositifs

ni modifier une Dartie auelconoue

du

Distolet: ceci risouerait

Verrou

de

s6curit6

A

chaque fois que i'on s'arrete de'puiveriser, meme s'il s'aait

d'un

court instant, toujours mettre

18

verrou de securite du pis-

tolet sur

la

position 'ferde"

ou

"securite" ("safe") pour

empecher ie pistoiet de fonctionner. Si le verrou de securite

Voir la Fig.

1.

ci-dessus.

n'est pas mis. le pistoiet peut se declencher accidentellement.

Diffuser

d'injection accidentelle quand I'ajutage n'est pas en place.

Lediffuseurdupistoletsenadiviserlejetetgreduirelesrisques

Verifieriefonctionnementdudiffuseurreguii6rement.

Pourcene

verification, detendre ia pression en observant ia Marche

a

Suivre pour Detendre la Pression donnee plus loin puis en-

en metal, en ie maintenant fermement

contre ie seau. Puis. en

lever i'ajutage du pulverisateur. Pointer

le pistolet dans

un seau

utilisant la pression ia pius faibie possible, appuyer sur ia

gachette du pistoiet. Si le fluide projete n'est

pas

diffuse

sous

forme de jet ineguiier, remplacer immediatement ie diffuseur.

Protection

de

I'ajutage

TOUJOURS maintenir

ia

Drotection de I'aiutaae en dace sur le

pistoiet du puiverisateur pendant lapulveiisa<on.

Li

Protection

de i'ajutage attire I'attention sur Ies risques d'injection et contribue a reduire, mais n'evite pas le risque, que Ies doigts ou une

partie quelconque du corps ne passent accidenteilement

a

pro-

ximite immediate de I'ajutage du pulverisateur.

pulverisateur

Conslgnes de securlte concernant I'ajutage

du

Faire extremement attention I'occasion

du

nenoyage ou du

remplacement des ajutages du pulverisateur. Si I'ajutage se

rou de securite du pistolet. TOUJOURS bien observer la

bouche pendant la pulverisalion. menre immediatement lever-

I'ajutage du puiverisateur pour le nenoyer.

Marche

a

Suivre pour Detendre

la

Pression puis enlever

du

pulverisateur avant que ia pression ne soit completement

NE JAMAIS essuyer ce qui s'est accumule autour de i'ajutage

tombee el qJe le verrou de securite du pistolet ne soit engage.

Marche a Suivre pour Detendre la Pression

Pour reduireies risquesde biessuresgraves, y oompris

Ies

blessures

par injection de fluide

ou

celles causees par des Bclaboussures dans

ies

yeux

ou

sur

ia

peau.

des

pieces

en

mouvement

ou

parblectrocu-

lion. toujours bien observer cene marche

a

Suivre a chaque

fois

que

I'm

arr6te

le

puiverisateur. a I'occasion de

la

verification. du regiage

ou

du nettoyage du

systeme

ou IorS du changement des ajutages.

1.

Engager

ie

verrou

de

s6curitb

du

pistolet.

2.

Bascuier I'interrupteur de commande de pression

sur

ARRET

(OFF).

3.

Debrancher le cordon d'aiimentation.

4.

DBsengager

le

verrou de sbcuritb du pistolet. Tout en maintenant

une

partie

metailique du pistolet fermement appuyee contre le

cbte d'un

seau

en metal, actionner

ie

pistoiet pour liberer

la

pres-

sion.

5.

Engager

le

verrou

de

securiie du pistolet.

6.

Ouvrir

la

sou

ape de securitb

et

ia

laisser

ouverte jusqu'a ce que

I'on

Soit

pret

gse

setvir

de nouveau du pulverisateur. Debrancher

ie

fii

de

ia

bougie.

d'entrainerunmauvaisfonctionnementetdes biessuresgraves.

.

,

~

.~

~ ~

I

I

i

-

4

i'aiutaae

et

liberer oroafessivement

la

Dression.

I

3137477

Page 5

..

...

:I

I

RlSQUES EN CAS DE MAUVAlSE UTlLlSATlON DU MATERIEL

'~:~~~:~~~:~l'"."':~"~.~~~~:~~~~~~?~~~~~~~~~~~~~

Consignes generales de sCcurite

Pression

Toute utilisation anormale de I'appareil de pulverisation ou des

Ce pulverisateur peut produire une PRESSION MAXIMUM DE

accessoires comme, par exempie, la mise sous une pression

TRAVAIL210 bar

(3000

iblpo2).

S'assurerquetousleselemenls

excessive, les modifications de pieces, I'utilisation de produits

du pulverisateur et ses accessoires

sonl

conws pour resister

A

chimiquesetdematieresincompatibiesetl'utilisationdepieces

la pression maximum de travail de ce pulverisateur. NE PAS

usees ou abimees peut causer des degats

a

I'appareil ou des

depasser la pression maximum de travail d'aucun des elements

ruptures de pieces et entrainer une injection de liquide ou

ou accessoires utilises avec cet appareil.

d'autres biessures serieuses, un incendie. una explosion ou

ComDatibilite chimiaue des COrDS

*,

:..::.:...~~:'".;:~:i'~:~:;.?:,;:,:.:.,.:.:~~~~~~'~~:~~~,,:,:,:,:.:

.:.:.,

::.*<,:.:

.,_

d'autres deg%ls.

BEN

S'ASSURER que tous les corps des solvants utilises sont

risquerait d'entrainer

son

mauvais fonctionnement.

NE JAMAiS alterer ou modifier Une Piece de Cet appareil; CeCi

chimiquementcompatiblesaveclespaniesmouiiieesindiquees

Verifier reaulierement tout I'aDpareil de pulverisation

81

ses Iesdocuments el brochuresdufabricant desfluides etsolvants

danslesTechnicalDaia,apage26.Toujoursliresoigneusement

equipeme?its et reparer ou rempiacer 'immediatement ies Utilises avant de s'en Servir danS ce puiverisateur.

pieces usees

ou

abim&e,s.

MESURES

DE

SECURITE

CONCERNANT

LES

TUYAUX

FLEX~BLES

~~~~~~~~~~,~~~~~~~~~~~~~

Lefluideahautepressioncirculanldansiestuyauxpeut~tretres

MANIPULER LESTUYAUX AVEC PRECAUTiON

ET

CHOlSlR

dangereux. Encasdefuitesur letuyau. defissure, dechirureou

SOIGNEUSEMENT LEUR CHEMIN. Ne pas deplacer le fluide

rupturealasuiledeI'usure,dedegBtsoud'unemauvaiseutilisa-

en1irantsurietuyau.Nepasutiliserdefluidesoudesolvantsqui

lion. les projections de fluide haute pression qui en proviennent

ne

son1

pas compatibles avec I'enveloppe interieure ou

pauvent entrainer des blessuresgraves par penetration sous la

exterieuredutuyau.

NEPASexposerletuyauadestemperatures

Deau ou oar contact, ainsi que des degats materiels. SuDerieures a 820 C

(180°

F)

ou inferieures

a

-40°

C

(-4OO

F).

TOUSLES TUYAUX FLEXIBLES DOIVENTAVOIR

DES

RES-

Continuitb de la mise a ia terre des tuyaux

SORTSSPIRALEDEPROTECT~ONAUXBOUTS~L~~~~~~~~~~

Unebonnecontinuiledelamisealaterredestuyauxestessen-

de

protection

contribuent

a

eviter

la

formation

de

pliures,

de

tieilepourmaintenirlamisealaterredei'ensembledevaporisa-

boucles

ou

de

nmuds

sur

les

tUYaUX

qui

pourraien~

la

tion. Verifiez la resistance electrique de vos tuyaux a fluides et

rupture du tuyau

a

I'endroit du raccord ou

a

son

voisinage.

a

air, au moins une fois parsemaine.Si votre tuyau necompone

oas d'etiauette aui orecise la resistance electriaue maximum.

SERRER

FERMEMENTtous Ies

raccordsavantchaqueutilisa-

prenez contact ave'c le fournisseur de tuyaux ou la fabricanl

lion.

Lefluidesouspressionpeutfairesauterunraccorddesserre

pour avOir les limites de resistance maximum. Utilisez un metre

ou produire un jet

a

haute pression s'echappant par le raccord.

de resistance de la gamme appropriee pour votre tuyau

et

veri-

fiez la resistance. Si ceile-ci depasse les limites recom-

refaire le raccord d'un tuyau haute pression ni de reparer ie mise

a

la terre ou avec une mise a la terre incorrecte peut en-

NE JAMAiS utiliser un tuyau endommage. NE PAS essayer de mandees, remplacez le tuyau immediatement. Un tuyau sans

tuyau avec du ruban adhesif ou par tout autre moyen. Un tuyau trainer des risques pour votre systeme. Lisez aussi LES

repare ne peut

pas

resister au fluide sous pression.

<..*:>;.%

,~-

~ ~

~I

RlSQUES D'INCENDIE OU D'EXpLOSIbN

~~~~~,~~~~~~~~~~~~~~~~~~~~~~~~~~~~,~~~~~,~~~~~~~~~~~"~~,

RISQUES D'INCENDIE

OU

D'EXPLOSION ci-dessus.

Qrande vitesse dans la pompe et dans les tuyaux. Si toutes Ies

De I'electricite statique est produite par le passage du fiuide

a

pieeces de I'appareil de pulverisation ne

sonl

pas convenable-

produire et i'appareil risque d'elre dangereux. Des elincelles

ment reiiees

a

la masse ou a la terre, des etinceiles peuvent se

du debranchement du cordon d'alimentation. Les etincelles

peuventegalemenlseproduireai'occasiondubranchemenlou

sont suffisantes pour allumer les vapeurs de solvants et le fluide

pulv6ris6. les fines panicules de poussieere ainsi que d'autres

substances inflammables, quand

on

pulverise a I'interieur ou

a

I'exterieur, el elles peuvenl causer un incendie ou une explo-

sion, ainsi que des biessures graves et des degats materiels.

Toujours brancher le pulverisateur dans une prise se trouvant

a

au moins

6

m

(20 pieds) de I'appareil et de i'endroit od se fail la

pulverisation. Ne pas brancher ou debrancher un cordon

d'alimenations auel aui'il soit dans la zone

olj

se fail la oulveri-

salion quand

il

y a Iemoindre risque que des vapeursencore

presentes dans I'air prennent feu.

S'iiseproduitdesetincellesd'elecl~icitestatique,ousivousres-

sentez la moindre decharge. ARRETE2 IMMEDIATEMENT

LA

PULVERISATION. Verifiez que le systeme enlier est bien mis

a

laterre. Ne vous Servez pas du systeeme avant que le probleme

soil identifie el corrige.

Mise a la terre

ou

a

la masse

Pour reduire le5 risques de production d'etincelies d'eiectricite

statique. le pulverisateur

et

tous Ies dquipements utilises ou se

lrouvant dans la zone de pulverisation doivent &re relies a la

terre ou

a

la

masse. Pour connaitre le detail des instructions de

mise a iaterredans la region

et

ie type particuiier d'equipement,

cales. S'ASSURER clue tous les BauiDements de Dulverisation

CONSULTER le code ou les reglementations eiectriques

lo-

suivants sont bien reiies a ia terre:

1.

Pulverisateur: Brancher le cordon d'alimentation ou la ral-

etat, dans une prise de courant convenablement mise

a

la

iongequidoiventetreequipesd'uneprisea3fichesenbon

doivent avoir 3 fils.

terre. Ne pas utiiiser d'adaptateur. Toutes les rallonges

..

2.

Juyauxflexibles: Afin d'assurer la continuite de la mise a la

terre, n'utiiiser que des tuyaux componant une mise

a

la

telre et ayant une longueur maximum combinee de

150

m

(1500

pieds). Se reporler egalement au paragraphe Conti-

nuke du circuit de mise

a

la

terre des

tuyaux.

3.

Pistolet: Realiser la mise la terre en le raccordant a un

luyau flexible et

a

un pulverisateur deja convenablemenl

reiies

a

la terre.

4.

Recipient d'alimentation: observer ie code ou les regle-

mentations locales.

5.

Objets, materiel

ou

surfaces reqevant la pulverisation:

ob

server le code ou les reglementations locales.

6.

Jous les seaux de solvants utilises pour le rinCage: ob-

setverlecodeoulesreglementationsiocales.N'utiliserque

des saux m~lalliques conducleurs de I'eiectricite. Ne pas

du papier ou du carton car cela inlerromprait

la

continuite

mettre ie seau sur une surface

non

conductrice comme sur

de la mise

a

la

terre.

7.

Pour consewer

la

continuite de la mise a la terre quand on

rince le materiel

ou

quand on libere la pression, toujours

maintenir une partie metaliique du pistolel fermement appuyee contre le cbte d'un seau en metal puis appuyer sur

la detente

du

pistoiet.

Mesures de securite concernant le Rincage

Pour reduire les risques de blessures par penetration de

la

peau

et 18s risques dijs aux etincelles d'electricite statique ou aux

eclaboussures, Observer la marche

a

suivre pour le rincage

SuivrepourDetendrelaPression"donneeaiapage4enenlever

donnee a la page

11

de ce manuel. Observer la "Marche

a

l'ajutage

dupulverisateuravantlerincage.

Maintenirunepartie

metallique du pistolel fermement appuyee conlre

18

cbte d'un

seau en metal et utiliser la pression la plus faible possible pendant le rincage.

307-827

5

Page 6

..

:.,

..

..

..

Seguridad

general

Este equipo genera un fluido a una presion muy alta. El rociado

de la pistola,

10s

escapes de fluido 0 roturas de

10s

componentes pueden inyectar fluido en la piel y el cuerpo y causar

lesiones ertremadamenle graves, incluyendo a veces la

necesidad de amputaclon. Tambien, el fluido inyectado

o

sai-

picado en

10s

ojos

puede causar graves dafios.

NUNCA apuntar la pistola hacia aiguien

0

alguna parte del

quilia. NUNCA tratar de "hacer retornar la pintura"; este NO es

cuerpo. NUNCA colocar la mano

o

10s

dedos encima de la bo-

un sistema de rociado de aire.

SIEMPRE tener colocado el protector de la boquilla en la pis-

tolamientras se est& puiverizando.

SIEMPRE seguir ei procedimiento de descarga

de

presion,

dado masabjo, antes de limpiar

0

sacar

la

boquilia 0 de Uar ser-

vicioa cualiquier equipo del sistema.

NUNCA tratar de parar.0 desviar

10s

escapes

con

ia mano o el

cuerpo.

Asegurar que

todos

ios aparatos de seguridad del equipo esian

funcionando bien antes de cada uso.

Tratamiento

medico

Si pareciera que

un

poco de fluido penelro la piel. conseguir

TRATAMIENTO medlco DE URGENCIADE INMEDIATO. NO

TRATAR

LA

HERIDA COMO UN SIMPLE CORTE. Decir ai

medico exactamente cua fluido fue.

Aviso a/ medico: Si se llega a inyectar este fluido en la plel se

causa una lesiontraumatica.

Es

lmporianie iratar qulrurglca-

mente la lesi6n a

la

brevedad poslble. No demorar el

tratamiento para investigar la toxicidad.

La

toxicidad es algo de

Suma importancia en algunas plnturas exoticas cuando se in-

yectan directamente al torrente sanguineo. Sira convenienle

consultar a un especialista en cirugia plastica

o

reconstructiva

de las manos.

Aparatos

de

seguridad

de

la

pistola

pulverizadora

Asegurar que

todos

10s

aparatos protectores de la pistola eshn

funcionando bien antes de cada uso. No sacar

ni

modificar

ningtjna pieza de ia pistola pues podria causarel malfuncionamiento de la misma con las consiguientes lesiones personales.

Pesti//o de seguridad

Cada vez que se deje de pulverizar, aunque sea por un breve

momento, siempre colocar

el

pestillo de Seguridad en la posi-

cion "cerrada"

lo

que deja

la

pistola inoperante. El

no

hacerlo

puede llevar al disparo imprevisto de la pistola.

Difusor

El difusor de ia pistola dispersa el chorro pulverizado

y

reduce

el riesgo de inyeccion cuando

no

esta instalada la boquilla.

Revisar con regularidad el funcionamiento

del

difusor. Seguirel

procedimiento de descarga de presi6n. dado

mas

abajo,

y

despues sacar la boquilla. Apuntar la pistola a un balde metali-

co. sosteniendola bienfirmecontra el. Utiiizando la presion

mas

bajo posible. disparar la pistola. Si el fluido emitido

no

sale dis-

persoenunchorroirregular,ree'mplazardeinmediatoeldifusor.

Protector de la boquilla

SIEMPREtenerelproteclordelaboquillacolocadoenlapistola

contra el peligro de inyeccion y ayuda a reducir, per0

no

evita,

mientras se esta pulverizando. Este protector llama la alencion

cuerpo cerca de la boquilia.

la colocacion accidental de ios dedos

o

cualquier otra parte del

Seguiidad

de

la

boquilla

pulverizadora

Tener mucho cuidado a1 limpiar

o

cambiar las boquillas. Si

Ile-

garaaobstruirse

mientrasestapulverizando.

enganchar el pes-

till0

de la pistola de inmediato. SIEMPRE seguir ei procedlmlento de descarga de presi6n y despues sacar la boquilla para limpiarla.

NUNCA limtiar la acumulacion de ointura alrededor de

la

bo-

quillaantesdequesehayadescargadoporcompletolapresion

y el pestillo este enganchado.

~ ~ ~

"

~

.~

~

..

Procedimiento

de

descarga

de

presi6n

Para reducir ei riesgo de sufrir graves lesiones corporales.

in-

cluyendo inyeccion 0 lesiones'causadas por pieias en

movimiento o choque electrico. siempre seguir este

procedimiento

al

apagar la m6quina pulverizadora, al revisar

al instalar, limpiar

o

cambiar las boquillas, y cada vez que se

o

dar

Servicio

a cualquier parte del sistema de pulverizacibn,

deja de pulverizar.

2.

Mover

ei

interrupt& el6ctrlco

(ON/OFF)

ala posici6n

OFF

1.

Enganchar

el

pestlllo de

la

pistola.

3.

Desenchufar

ei

cordirn electrico.

(apagado).

I

4.

Desenganchar

e1

pestillo de la plstoia. Sujetar una parte

metiiica de

la

pistola bien firme contra un balde de

metal,

y

dlsparar la pistola para descargar

la

presibn.

5.

Enganchar

e1

pestillo de

la

pistola,

6.

Abrlr

la

vAlvula

de

preslirn y tener llsto

un

recliplente

para

recibir

la

pintura.

Dejar

la

valvula de

alivio

de presbn

verizar.

ablerta

hasta

que

se

este nuevamente listo para

pul-

Si se sospechz que la boquilla 0 la manguera esta com-

pietamente obslruida,

o

que

no

se ha descargado por

com-

anterior, aflojar MUY LENTAMENTE latuercade retenciondel

pleto la presibn despues de haberseguido el procedimiento

protectordelabcquiliaoacoplamientodelapuntadeiaman-

guera y descargar gradualmente la presion, despues,

aflojarlo por completo. Luego, despejar la boquilia o la

manguera.

6

307-827

Page 7

.. .

i

i

!

~

i

Cualquier mal us0 del equipo pulverizadoro ios accesorios, tal

esta pulverizadora puede,desarrollar

210

barias

(3000

psi) de

cOmo

sobre presurizacion, modificacion de piezh us0 de

presion DE TRABAJO MAXIMA. Asegurar que todo el equipc

materiaiesvoroductosauimicos

incomDatibles,outilizaci6nde

DUlveriZadOry sus accesorios tienen lacapacidad Daraaquan-

piezas dahadas

o

desgastadas, puedehacen que se rompan y

iar la presion-maxima de trabajo de est& pulverizadora. Nb ex-

causen la inyeccib de fluido

u

otras iesiones corporales

ceder la presion maxima de trabajo de ningirn componenle

o

graves, incendio, explosion o dahon a la propiedad.

accesorio de este sistema.

NUNCA alterar

0

modificar ningka pieza de este equipo; ei

Compatibilidad de fluido

hacerio podria causar una averia. Siempre leer laS instrucciones del fabricante del fiuido

y

sol-

REViSAR con regularidad el equipo pulverizador y reparar

o

pagina

vente antes de uSarlOS en esta pulverizadora, dadas en

ia

reemplazar de inmediato las piezas dahadas 0 desgastadas.

Siempre usar gafas. guanles, vestimetas protectora y un

respiradero,

tal

cOmO recomiendan

10s

fabricantes del tluido y

del solvenle.

SEGURlDAD EN EL

US0

DE

WS

MANGUERAS

~~~,~~~,~~~~~~~,~

+<:

.,~,~,'~.~~~j~~~~~.,~,,,~~~~~.:,~~~~~~:~~~~~~~~~~~~~~~~~~~~~~~.~,~~~~~~~~~~~~~~~~~:,~:::~~

~~~~~~~~~~:~~~~~:~.~'~~~~~'~~~.~~~.::

...~~'~~~~~,:.~~~~

Elfluidoqueescapaaaltapreslonporlasmangueraspuedeser

MANEJARYPASARCU~DADOSAMENTELAS

MANGUERAS,.

rotura

0

rajadura debido a cualquier tip0 de desgaste, dah0

0

o

soiventes que Sean incompatibles con el tub0 interno y ia

muy paligroso. Si en ia manguera se desarrolla

un

escape, una No tirar de las mangueras para mover el equipo. No usarfluidos

una lesion por inyeccion u otras lesiones corporales graves

o

turas sobre

820

c

(1800

F)

0

bajo

-400

c

(-400

F).

mailrato. el chorro a alta presibn emitido por alli puede causar

cubiertadela manguera. NOexponer lasmanguerasatempera-

darios a la propiedad.

Contlnuidad del circuit0 de ouesla

a

lierra

de

la

TENER GUARDAS

DE

RESORTE EN AMBOS EXTREMOSI

iTODAS

US

MANGUERAS PARA FLUIDOS TIENEN

QUE

Estas protegen las mangueras Contra dobleces o retorceduras

traducirse en roturas de la manguera.

en

10s

acopiamientos o cerca de eilos,

10s

que podrian

Antes de usarias, APRETAR bien firmes todas las conexiones.

El

fiuido a alta presion puede desaiojarun acoplamienlo sueito

o

dejar que por el escape un chorro a alta presion.

NUNCA usar una manguera que

esta

dariada. Siempre,

revisaria en busca de corladuras. escapes, abrasion, cubierta

abuitada,

0

acopiamienlos sueltos 0 dahados. Si llegara a en-

contrarse cualquiera de estas condiciones, reemplazar de in-

aila presion

0

enmendarla con cinta adhesiva u otro material

mediato la manguera.

NO

intentar racopiar una manguera de

similar. Una manguera que ha Sido rernendada no aguante el

fiuido a alta presion.

El

fiujo a alta velocidad del fluido al pasar por ia bomba y man-

guera crea electricidad estktica. Si todas las partes del equipo

convirtiendo ai sistema

en

aigo peiigrmo. Tambien. pueden

puiverizador

no

tienen buena tierra. pueden ocurrir chispas.

eiectrico

0

al usar un motorde gasoiina. est& chispas pueden

prcducirse chispas a enchufar

0

desenchufar ei cordon

inflarnar ios vapores de

10s

soiventes y el chorro de fluido pul-

verizado, parliculas de polvo y otras Sustancias in flamabies,

seaalaireiibreobajotecho,loquepodriacausarunaexplosiirn

oincendioygravesiesionescorporalesydahosalapropiedad.

Enchufar siempre la pulverizadora a un tomacorriente que se

que se va a rociar. No enchufar

0

desenchufar ningirn cordon

encuentre a por

Io

menos

6

m

(20

pies) de la maquina y del area

electric0

en

el iugar donde se esta rociando cuando todavia ex-

istalaposibilidaddequequedenvaporesinfiamabieseneiaire.

Si ocurre una chispa de eiectricidad estatica o incluso un iigero

VERIZAR DE INMEDIATO. Revisartodoel Sistemaen buscade

choque electrico mientras se usa ei equipo. DEJAR

DE

PUL-

una tierra apropiada. No usar de nuevo el sistema hasta haber

identificado y soiucionado ei problema.

Peusta a

tierra

Para reducir ei reisgo de chispas estaticas, conectar a tierra

ia

puiverisadora y todo el otro equipo de pulverisar que se use

o

se encuentre en el lugar que se va a rociar. CONSULTAR el

conexiones a tierra exigidas para ia zona y tip0 de equipo.

codigo electric0 de la localidad para las instrucciones sobre ias

ASEGURAR de conectar a tierra todo este equipo pulverisador:

1.

Pulverizadora: enchufar el cordon eiectrico, o cable exten-

tomacorreinte con puesat

a

tierra aporpiado. No usar un

sor, cada uno

un

enchuf de tres patas en buen estkdo. a un

tres hilos.

adaptador. Totos

10s

cables extensores tienen que tener

manguera

Lacontinuidaddeicircuitodepuestaatierraapropiadoesesen-

cia1 para mantener conectado a tierra el sislema puiverizador.

ES

indispensable revisar la resistencia electrica maxima de las

manguerasdeaireydefluidoporiomenosunavezalasemana.

Si la manguera notiene una etiqueta en

la

cual se especifica la

fabricante de ia manguera para la

informacion sobre

10s

limites

resistencia electrica. ponerse en contact0 con el proveedor

o

de resistencia. Usar un metro de resistencia en ia gama

apropiade para comprobar ia resistencia: si excede

10s

limites

recomendados. reemplazarla de inmediato.

Es

muyarriesgado

tener una manguera sin puesta a tierra

o

con

ia puesta a tierra

en malas condiciones. Leer tambien ia informaci6n sobre

RIESGO DE iNCENDlO 0 EXPLOSION, masarriba.

2.

Mangueras para fluidos: usar solamente mangueras con

puesta a tierra de una iOnQitud combinada de 150 m (500

pies), para asequrar buena continuidad a tierra. Referirse

tambien al parrafo sobre continuidad

a

tierra de

la

manugeura.

3.

Pistola: hace la puesta a tierra conectandola a una manguera de fluido y pulverizadora bien conectadas a tierra.

4.

Suministrar un recipiente: de acuerdo al codigo de

ia

localidad.

5.

Objeto

que

se

estd rociando: de conformidad con el

codigo local.

6.

Todos

10s

baldes de soivente usados durante el lavado,

de

conformidad con el c6digo local. Usar solamente baldes

superficie

no

conductiva, como papei 0 carton, que inter-

demetai,queseanconductivos.nocoiocarelbaldeenuna

umpe

la

continuidad a tierra.

7.

Para mantenar la continuidad a tierra durante el lavado

o

descarga de

presih,

siempre apoyar una parte metalica

metal, despues apretar el gatilio.

de la pistola bien firme contra el costado del balde de

Seourldad durante el lavado

-

Para reducir ei riesgo de que se inyecte o salpique fiuido en la

piel. o que ocurra una descarga de eiectricidad estalica.

siemDreseauiriasINSTRUCCiONESPARAELLAVAD0,dadas

en

la

pagina 11. Seguir ei procedimiento de descarga de

presion en ia pagna

6,

y quita la boquilla rociadora antes de

lavar: Apoyar una parte metalica de la pistola bien firme contra

el costado de un baide de metal

y

usar le presion

mi5

baja

posible de fiuido durante si lavado.

307-827

7

Page 8

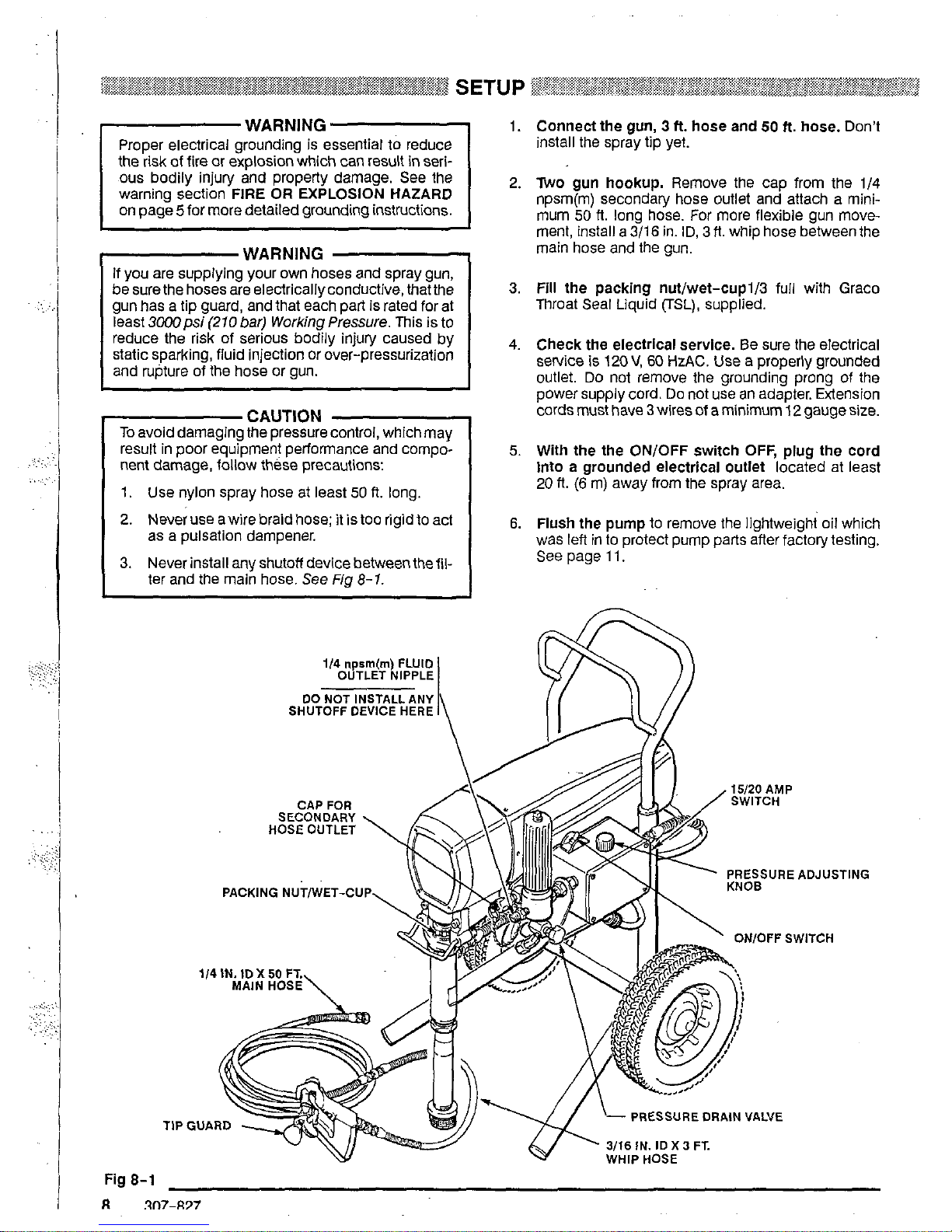

WARNING

Proper electrical grounding is essential to reduce

the risk of fire or explosion which can result

in

seri-

warning section

FIRE

OR

EXPLOSION

HAZARD

ous

bodily injury and property damage.

See

the

on page 5for more detailed grounding instructions.

WARNING

If you are supplying your own hoses and spray gun,

be surethe hoses are electricaliyconductive, that the

gun has a

tip

guard, and that each pari

is

rated for at

least

3wOpsi

(270

bar) Working Pressure.

This is to

reduce the risk of serious bodily injury caused by

static sparking, fluid injection or over-pressurization

and rupture of the hose or gun.

CAUTION

result in poor equipment performance and component damage, foiiow these precautions:

1.

Use

nylon spray hose at least

50

ft.

long.

2. Never

use

awire braid

hose;

it is

too

rigid to act

3.

Never install any shutoff device betweenthefil-

the pressure controi, which may

as a pulsation dampener.

fer and the main hose. See

Fig

8-1.

1/4

npsm(m)

FLUID

OUTLET NIPPLE

SHUTOFF DEVICE HERE

00

NOT INSTALL ANY

\

1.

Connect the gun,

3

ft.

hose

and 50 ft.

hose.

Don't

install the spray tip yet.

2.

Two gun hookup.

Remove the cap from the

1/4

npsm(m) secondary hose outlet and attach a mini-

mum 50

ft. long hose.

For

more flexible gun move-

ment, install a

3/16

in.

ID,

3

ft. whip hose between the

main hose and the gun.

3.

Fill

the packing nut/wet-cupi/3

fuii with Graco

Throat Seal Liquid

(TSL),

supplied.

4.

Check the electrical service.

Be

sure the electrical

sewice is

120

V,

60

HzAC.

Use

a properly grounded

outlet.

Do

not remove the grounding prong of the

power supply cord.

Do

not

use

an adapter. Extension

cords must have

3

wires of a minimum

I2

gauge size.

5.

With the the ON/OFF switch OFF, plug the cord

Into

a

grounded electrlcal outlet

located at least

20

ft.

(6

m)

away from the spray area.

6.

Flush the pump

to remove the lightweight oil which

was

left

in to protect pump parts after factorytesting.

See page

11.

Page 9

i

1

To reducethe risk of serious bodily injury, fluid injection. splashing in the eyes or on the skin, or injury

from moving parts, always follow the Pressure Rellet Procedure Warning on page

2

before checking,

adjusting, cleaning and shutting down the sprayer.

Startup

Always

use

this procedure

to

help ensure the sprayer is

ready

to operate and that you start

it

safely.

1.

For a first time startup, flush the sprayer.

See

page

11.

2.

Close the pressure drain valve.

3. Don't install the spray tip

until

the pump

Is

primed!

4. Put the suction tube into the paint container.

5.

Lower the pressure setting by turning the pressure

adjusting knob all the way counterclockwise.

6.

Disengage the gun safety latch.

rCAUTiON7

to

avoid damaging the pump packings.

Do

not run the sprayer dry for more than 30 seconds

~

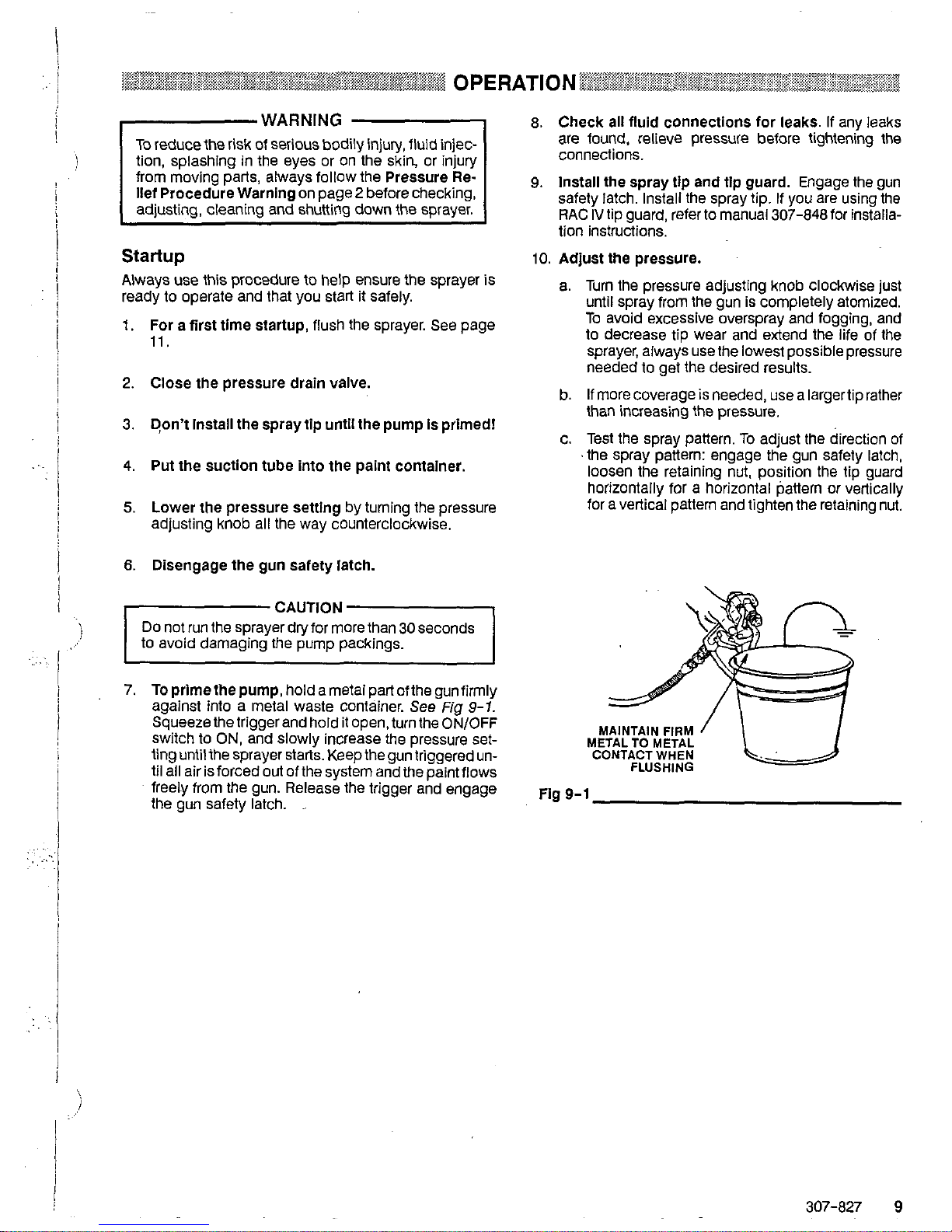

7.

Toprimethepump,holdametaipartofthegunfirmly

against into a metal waste container. See

Fig

9-1.

switch to

ON,

and slowly increase the pressure

set-

Squeeze the trigger and hold

it

open. turn the

ON/OFF

ting until the sprayer starts. Keep the gun triggered until all air is forced

out

of the system and the paint flows

the gun safety latch.

~

freely from the gun. Release the trigger and engage

8. Check all fluid connections for leaks. if any leaks

are found, relieve pressure before tightening the

connections.

9.

Install the spray tip and tlp guard. Engage the gun

safety latch. Install the spray tip. If you are using the

RAC

IV

tip guard, refer

to

manual 307-848 for installa-

tion instructions.

10.

Adjust the pressure.

a.

Turn the pressure adjusting knob clockwise just

until spray from the gun is completely atomized.

To avoid excessive overspray and fogging, and

to

decrease tip wear and extend the life

of

the

sprayer, always

use

the lowest possible pressure

needed

to

get the desired results.

b. If more coverage

is

needed,

use

a largertiprather

than increasing

the

pressure.

c. Test the spray pattern.

To

adjust the direction of

'the spray pattern: engage the gun safety latch,

IOOSen

the

retaining nut, position the tip guard

horizontally for a horizontal pattern or vertically

for a vertical pattern and tighten the retaining nut.

METALTO METAL

CONTACT

WHEN

FLUSHING

MAINTAIN FIRM

/

Fig

9-1

307-827

9

Page 10

Cleaning a Clogged

Tip

WARNING

To reduce the risk of serious bodily injury from from

fluid injection;

DO

NOT hold a hand, body, or rag in front of the

spray tip when cleaning or checking it. Always point

the gun toward the ground or into a waste container

when checking

to

see

if the tip is clear.

DO

NOT try

to

"blow back" paint; this is NOT an air

spray sprayer.

1.

If the spray tip does clog, release the gun trigger, engage the gun safety latch, and rotate the RAC

IV

han-

dle

180".

See

Fig

70-1.

2. Disengage the gun safety latch and trigger the gun

into a waste container. Engage the gun safety latch

again.

3. Return the handle

to

the original position, disengage

the gun safety latch. and resume spraying.

4. If the tip is still clogged, engage the gun safety latch,

sure drain valve to relieve pressure. Clean the spray

shut

off

and unplug the sprayer, and

open

the pres-

tip as shown in manual 307-848, supplied with the

RAC

IV.

SPRAYING

POSITION.

HANDLE SHOWN IN

GUN SAFETY

ENGAGED

LATCH SHOWN

Fig

10-1

Shutdown and Care

1.

Check the packing nut/wet-cup daily. Relieve the

pressure. Keep the packing nut/wet-cup 1/3 full with

TSL at all times

to help prevent fluid buildup

on

the

pistor! rod and premature wear of packings. Tighten

the packing nut

just

enough to stop leakage. Over-

tightening may cause binding and excessive packing

wear.

Use

a screwdriver and light hammer to adjust

the nut.

See

Fig

70-2.

2. Clean the fluid filter often and whenever the sprayer

for the cleaning procedure.

is stored. First relieve pressure.

See

manual 307-273

3. Fill the connecting rod cavity with motor oil every

100

hours of operation. Relieve pressure. Remove

the front cover. See

Fig

10-2.

FILLCONNECTING ROD

CAVITY WITH MOTOR

OIL AFTER

EVERY

100

HOURS

OF

OPERATION

Fig

10-2

4. For very short shutoff perlods, leave the suction

tube in the paint, relieve pressure, and clean the

spray tip.

5.

Coil the hose and hang It

on

the hose rack when

from kinking, abrasion, coupling damage, etc.

storing it, even for overnight,

to

help protect the hose

Page 11

I

When to

Flush

1,

New Sprayer. The sprayer was factory tested

in

light-

weight oil which was left in to protect pump parts.

Before using water-base paint, flush with mineral

spirits, then warm, soapywater, and then clean water.

Before usingoi/-basepaint, flushwith mineral spirits.

2.

Changing Colors. Flush with a compatible solvent.

3.

Changing from water-base to oil-base paint.

Flush with warm, soapy water, then mineral spirits.

5.

Storage. Flush as indicated below, shut

off

the

sprayer, open the pressure drain valve to relieve

pressure and leave it open.

Water-base paint; flush with water, then mineral spirits. Leave the system filled with mineral spirits.

Oil-base

paint:

flush with mineral spirits

CAUTION

NEVER

allow water to freeze

in

the pressure control.

Doing sopreventsthe sprayerfrom being startedand

causes serious damage to the pressure

COfltrOi.

Push the water out with mineral spirits.

6. Startup after storage. Before using water-base

4.

Changing

from

oil-base to water-base paint.

paint, flush out mineral spirits with soapy water and

Flush with mineral spirits, then warm, soapy water,

then clean water. When using oil-base paint, flushout

and then clean water. the mineral spirits with the paint to be sprayed.

How

to

Flush

1.

Relieve pressure.

2.

Remove the filter bowl and screen;

see

manual

307-273. Clean the screen separately and install the

bowl without the screen to flush it. See

Fig

11-1.

PRESSURE

DRAIN VALVE

Fig

11

-1

3.

Close the pressure drain valve.

4.

Pour one-haif gallon of compatible solvent into a

grounded metal pail. Put the suction tube

in

the pail.

5.

Remove the spray tip from the gun, if it

is

installed.

6.

Turn the pressure adjusting knob all the way counter-

r-wARN'NG

1

clockwise to lower the pressure setting.

To

reduce the risk

of

static sparking and splashing

when flushing, always remove the spray tip from the

gun, and hold a metal part of the gun firmly to the

side of grounded metal pail.

7. Hold a metal part of the gun firmly against a metal

turn on the sprayer, and slowly increase the pressure

waste container. See

Fig

11-2. Hold the trigger open,

til

all air is forced out of the system and the solvent

just until the sprayer starts. Keep the gun triggered un-

flowsfreeiy from the

gun.

Release the trigger and en-

gage the gun safety latch..

NOTE lfthe pump

Is

hard to prime, place a container un-

fluid comes from the valve, close

it.

Proceed as

der the pressure drain valve and open it. When

in Step 7.

8.

Remove the suction tube from

the

pail. Disengagethe

gun safety latch and trigger the gun to force solvent

from the hose.

Do

not run the pump dry for more than

30

seconds to avoid damaging the pump packings!

Relieve pressure.

9.

Leave the pressure drain valve open until you are

ready

to use the sprayer again.

If

the screen was removed, unscrewthe filter bowl and reinstall the clean

screen. Reinstall the bowl, hand tight only.

IO.

If you flushed with mineral spirits and are going to

use

a water-base paint, flush with soapy water and then

clean water. Relieve pressure.

MAINTAIN

FIRM'

,

CONTACT WHEN

METAL

TO

METAL

FLUSHING

Fig

11

-2

307-827 11

Page 12

.+i

I:.

. ..

..

.

..

..

,.

~.

..

I

WARNING

Pressure Relief Procedure

To reduce the risk of serious bodily injury, including 6. Open the pressure drain valve, having a container

the eyes or on the skin, moving parts or electric shock,

fluid injection, injury from splashing fluid or solvent in ready

to

catch the drainage. Leave the pressure

drain valve open until you are ready to spray again.

spray system, when installing, cleaning or changing

sprayer'

when

checking

Or

any

part

Of

the

clogged,

orthatpressurehasflotbeenfu//yrelievedaf-

spray tips, and whenever you stop spraying.

terfollowiflg

the

steps above, wrap a rag around the tip

1. Engage the gun safety latch.

guard retaining nut or hose end coupling and VERY

2. Turn the ON/OFF switch

to

OFF.

SLOWLY loosen the pari

to relieve pressure gradually,

3.

Unplug the power supply cord.

then

loosen

completely. Now clear the tip or hose

4.

Disengage the gun safety latch. Hold a metal part

obstruction.

the gun

to

relieve pressure.

of the gun firmly

to a grounded metal pail. Trigger

5.

Engage the gun safety latch.

follow

this

procedure

You

shut

Off

the

/f

you

suspect that the spray

tip

or

hose

is

Check everything

in

the guide before disassembling the sprayer.

TYPE

OF

PROBLEM

If

check

is

OK,

go

to

next check

WHAT TO CHECK

When check

is

not

OK

fefer

to

this

column

WHAT TO

DO

Sprayer will not run

Reset

building circuit breaker; replace Check. electrical supply with volt meter.

Meter should read

105-125

VAC. building fuse. Try another

outlet.

Check extension cord for visible damage.

Use

a volt meter or

test

lamp at

ex-

Replace extension cord.

tension cord

outlet

to

check.

Check sprayer power supply cord forvis- Replace power supply cord.

or wires.

ible damage such as broken insulation

Poor spray pattern

Check for worn spray tip.

~

Relieve pressure and then replace the

tip.

See

the separate gun or tip manual.

Low output

Replace cord with a correct size,

Check extension cord size, which must

have at least 12 gauge wire.

grounded extension cord.

I

I

Motor runs and pump strokes Check for clogged intake strainer. Remove and clean strainer and reinstall.

Check for

loose

suction

tube

or

loose

Building circuit breaker opens

tape on threads, if necessary.

fittings.

Tighten; use thread sealant or sealing

Replace any damaged wiring.

Check all electrical wiring for damaged

insulation.

the

circuit.

Check for other electrical appliances on

position.

High) amp switch.

Put the switch inthe

15

(Lo) amp Check the position of the 15-20 (Lo-

Shutdown other electrical appliances

on the circuit.

Page 13

i

NOTE:

Replace the brushes when they have worn to

brushes wear differently on each side of the

mo-

less

than

1/2

in. See

STEP

1, Fig 13-3. The

tor,

so

check them both and replace both at the

same time. Brush Repair Kit

220-853

is

available.

WARNING

page

12

to

reduce the risk of a fluid injection injury,

Follow the Pressure Relief Procedure Warnlng on

splashing in the eyes or

on

the skin, injury from

moving parts, or electric shock.

SPRING

,

I

Flg

13-2

1.

Remove the motor cover (14) and both inspection

covers

(A).

See Fig 13-1.

2.

Pushinthespringcliptounhookit,andthenpullitout.

See

Fig 13-2.

3. Loosen the terminal screw. Pull the brush lead away,

leaving the motor lead in place. Remove the brush

and spring.

See

Fig 13-3.

4. Inspect the commutator for excessive pitting, burning

or gouging.

A

black color on the commutator is nor-

motor. repair shop if the brushes seem

lo

wear too

mal. Have the commutator resurfaced by a qualified

fast.

5.

Install the new brush

so

its lead is

in

the long slot

of

the holder. Slide theterminal underthe terminal screw

washer. Make sure the motor lead

is

still connected

the at the screw. Tighten the screw. See Fig 13-4.

6.

Place the spring on the brush as shown

in

Fig 13-4.

7.

Push

in

and hook the spring clip. See Fig 13-4.

8.

Repeat for the other side.

ICAUTioN7

Do

not run the sprayer dry for morethan

30

seconds

while checking the brushes

to avoid damaging the

displacement pumD.

9.

Reinstall the remaining parts.

2

SPRING CLIP

BRUSH

LEAD

TERMINALSCREW

MOTOR TERMINAL

Fig

13-3

,

BRUSH

HOLDER

SHORT SLOT

'/

Fig

13-4

NOTE: SPRING MUST COIL

IN THIS DIRECTION

I

.

,'

307-827

13

Page 14

..

WARNING

Follow the Pressure Relief Procedure Warning on

page 12 to reduce the risk of a fluid injection injury,

moving parts,

or

electric shock.

splashing

in

the eyes or on the skin, injury from

1. Disconnect the hose (47).

2. Loosen the filter bracket

nut

(28). Remove the fluid

filter.

3.

Remove the pressure control cover (36). Disconnect

the four motor leads.

4. Unscrew the connector (54). Pull the wires out of the

pressure control.

5.

Remove the pressure control mounting screws

(37).

Remove the pressure control.

Remove

the back plate

(1

6).

6.

Install the new pressure control.

1. Remove the back pressure control piate (16).

2. Remove the pressure control cover. Disconnect the

3.

Loosen the strain relief bushing (E). Remove the

4. Install the new cord.

power supply cord leads.

power supply cord (43a).

Fig

14-2

BACKVIEW

OF

PRESSURE CONTROL

Page 15

~~

1

I

I

!

j

i

!

~~~~~~~~~~:

:I

,.a2aBei%:&

REMOVING AND INSTALLING THE DISPLACEMENT PUMP ~~~~~~~~~~

Removal

See

Fig

15-1.

I.

Flush the pump, if possible, and relieve pressure

again. Stop the pump with the piston rod in its lowest

position, if possible.

2.

Remove the suction tube

(42);

hold the wrench on

the pump intake valve

(223)

to

keep the pump from

loosening.

3.

Remove

the

hose

(47).

4.

Push the retaining spring

(35)

up and push out the pin

(20).

5.

Loosen the locknut

(38)

and unscrew the pump from

the bearing housing

(27).

Installation

See

Fig

15-1

and

75-2.

1.

Screw the displacement pump into the bearing hous-

bly

(29)

and the displacement rod

(224)

align. Install

ing

(27)

until the pin hole in the connecting rod assem-

the pin

(20).

2.

Continue to screw the pump into the bearing housing

with the face of the bearing housing and the

outlet

nip-

until

Ihe

top threads

of

the pump cylinder are flush

ple

(75)

is straight back. Push the retaining spring

(35)

Tighten the locknut

(38)

to

70

ff-lb

(97

N.m).

into

the

groove all theway around the connecting rod.

WARNING

groove of the connecting rod, all the way around, to

Be

sure the retaining spring

(35)

is firmly

in the

prevent it from working

loose

due

to

vibration.

off

due

to the force of the pumping action. These

If the pin works loose, it or other parts could break

parts could be projected through the air and result in

serious bodily injury or property damage, including

damage

to

the pump, connecting rod or bearing

housing.

r-cAUT'oN"l

If

the locknut

(38)

loosens during operation, the

threads of the bearing housing

(29)

will

be

dam-

aged. Be sure

to

tighten the locknut firmly.

w..\

223

b42

Fig

15-1

I1

Fig

15-2

!

3.

Tighten the packing

nut/

wet-cup

just

enough to stop

leakage, but no tighter. Fill the wet-cup/packing nul

1/3

full

with Graco TSL.

307-827

15

Page 16

i

'

I

i

I

:

j

I

~~~~~~~~~~~~,~~~~~~~,

WARNING

Follow the Pressure Rellef Procedure Warnlng

6.

Remove the sleeve. Use

on page

12to

reduce the risk of afluid injection inju-

the sleeve removal tool,

part

no.

220-991,

if neces-

ry,

splashing

in

the eyes or

on

the skin, injury from sary.

moving parts

or

electric shock.

To use the tool: screw the

NOTE:

Packing Repair Kit

222-877

is available. Parts

in-

thetop of the cylinder

(19).

large nut

(E)

of

the tool into

cluded in the kit are marked with an asterisk

(*)

in the text. Use all the new parts

in

the kit. Clean

Screw down the rod

(D)

to

push the sleeve out. Reall parts. Inspect the non-kit parts for wear or move the tool. See Fig

damage, and replace them as needed.

16-3.

7.

Clamp the piston rod

(224)

in

a vise. Loosen the jam

nut

(21 1).

Unscrew the pis-

ton valve

(222).

Flg

16-3

8.

Remove all parts from the piston valve

(222).

223

Flg

16-1

Reassembling the

Pump

NOTE:

Alternate leather and plastic packings. The lips

of the throat

"v"

packings must face down.The

lips of the piston

"V"

packings must face

up.

The

lips of the U-cup seal

(203)

face down. Incorrect

installation damages the packings and results in

pump leaking.

NOTE:

Soak leatherpackings in oil before reassembling

the pump.

1.

Check the outside of the piston rod

(224)

and the in-

new packings will

not

seal properly. Replace these

side of the sleeve

(21

8)

for wear. if the parts are worn,

parts if needed.

LIPS

OF

V-PACKINGS

MUST

FACE

DOWN

2.

Stack these parts onto the piston valve

(222):

the

backup washer

(214),

seal

(203*),

female gland

(215*),

alternate the three plastic packings

(212*)

gland

(210*).

Flg

16-2

and the

two

leather packings

(206*),

and the male

Disassembling

the

Pump

3.

Tighten the packingretainingnut

(21

1)

ontothepiston

1.

Remove the intake valve

(223),

O-ring

(202),

ball

guide

(220),

stop

pin

(221)

and ball

(204).

Clean the

valve

(222)

to 4 in-lb

(0.35

Nm). See Fig

17-2.

parts.

See

Fig

16-1.

4.

Place the ball

(225)

on

the piston valve

(222).

2.

Always install anewo-ring

(202*).

Ifnofurther sewice

5.

Apply

One

drop

Of

supplied, to the Piston

is needed, reassemble the intake valve. valve threads. Hand tighten the valve assembly into

the piston rod just until the nut

(21

1)

contacts the rod.

3.

Remove the packing nut

(21 6)

and plug

(205).

See

Fig Note the alignment of the piston

(222)

to

the nut

16-2. (21 l),

and maintain it through Steps

5,

6

and

7.

Use

two

wrenches to maintain the alignment,

4.

Tap the piston rod

(224)

down with a plastic mallet,

and then pull the rod

out

the bottom of the cylinder. 6.

'lace

the

flats

at

the top

Of

the

rod

in

a

5.

Remove the throat packings

(207,

213)

and glands

7.

Use a wrench to

CAREFULLY

tighten the ]am nut

(21

1)

onto the piston rod to

19

lt-lb

(25

N.m). See Fig

lfi

1n7-~37

(208, 209).

See

Fig

16-2.

17-3.

Page 17

..

.

i

8.

Place a new seal (217*) into the cylinder. See Fig

17-1,

9.

Install these parts in the top of the cylinder (219): the

male gland

(208*), alternate the three plastic pack-

then install the female gland

(9).

See

Fig 17-1.

ings (21

3')

and the

two

leather packings

(207*),

and

10.

Loosely install the packing nut (216) and plug

(205).

See

Fig 17-1.

11. Coat the piston rod and packings with oil. Carefully

slide the assembly

Into the

top

of

the sleeve.

12. Slide the sieeve/piston rod assembly

Into the bot-

tom

of the cylinder.

See

Fig 17-4.

13. Screw down the cylinder locknut (47) until it

is

finger

tight at the bottom of the external cylinder threads.

14. Placethe intakevalve

(223)

in avise. Install a new

o-

ring (202*). Screw the pump cylinder into the intake

valve.

Torque to 110 R-lb (146

Nm).

See Fig 17-1,

15.

See

page 15 to reinstall the pump.

.:

4

In

TOROUE TO

21 1

-Ib

(0.35

Nm)

~

Fig

17-2

ADHESIVE TO PISTON

APPLY ONE DROP

OF

VALVE THREADS

II

21

1

TOROUE ROD ONTO JAM

NUT-PISTON ASSEMBLY

TO

19

R-lb

(27

N.m)

DO NOT ALLOW NUT ON

WHEN SCREWING INTO

ROD

PISTON VALVE TO MOVE

Fig

17-3

224

ROD

-

,CYLINDER

SLEEVE

ASSEMBLY

PISTON

Fig

17-4

Page 18

..

WARNING

page 12 to reduce the risk

of

a fluid injection injury,

splashing

in

the

eyes

or

in the skin,

injury

from mov-

ing parts or electric shock.

1. Remove the motor shield (14). Remove the front

cover (32). Disconnect the hose (47).

2. Remove the pressure control cover (36). Disconnect

the four motor leads.

3. Unscrew the connector (54) from the pressure con-

trol.

Pull

the wires through the connector.

4.

Unscrew the connector (54) from the motor and re-

move it from the conduit

'(22).

5.

Remove the screws

(51)

from the recess of the drive

housing.

6. Remove the screws

(21

and 30) from the the motor

bell

(F).

7.

Use a plastic mallet

to

tap the displacement pump

(39) from the rear

to loosen

the

drive housing

(1

8)

from

the motor bell

(F).

Pull

off

the

drive housing.

NOTE:

To

avoid damage

to

the

drive housing:

engaged

in

the motor bell or inthe drive housing.

Do

not

drop the gear cluster

(9),

which may stay

Do

not

lose

the thrust balls

(1

0) or drop them be-

~eengears.Theballsusuallystayintheshaftre-

not in place, the bearings will wear prematurely.

cesses, but could be dislodged. If the balls are

8.

Remove the screws

(8)

holding the motor

to

the

frame. Lin

off

the motor.

9.

Mount the new motor

on

the frame.

10. Slide a connector (54) over the conduit (22) ofthe new

motor and screw

two

or three threads

of

it into the mo-

tor. Tighten the locknut (44) up to the motor.

11. Liberally grease the gear cluster (51) and pinion gear

(G)

and pack all bearings

in

the motor bell.

Be

sure

the

thrust balls (9) are

in

place.

(One

ball is included

with a replacement motor.)

12. Place the bronze-colored washer

(18b)

and THEN

the silver-colored washer (18a)

on

the shaft protrud-

ing from

the

big gear in the drive housing (18).

13. Align the gears and push the drive housing (18)

straight onto the motor bell

(F)

and locating pins.

14. Continue

to

reassemble the sprayer.

Page 19

:.

,

..

!

i

1'

I

.,

i

MOTOR

LEAD

BLACK(-)

BLACWWHITE

(+)

MOTOR

LEAD

\

MOTOR

RED

LEADS

/

I

307-827

19

Page 20

rWAIINING

1

~~~?~~~~~~~~~

~~~~?~~~~~~~~~~~~~

BEARING HOUSING & CONNECTING

ROD

REPLACEMENT

~~~,~~,~~

NOTE:

Stop the sprayer at the bottom of its stroke to get

Follow the Pressure Relief Procedure Warning on the crank

(H)

in

its lowest position.To lower the

page 12 to reduce the risk

of

a fluid injection

injury,

crankmanually. rotatethe blades

of