Page 1

Operation,Repair,andParts

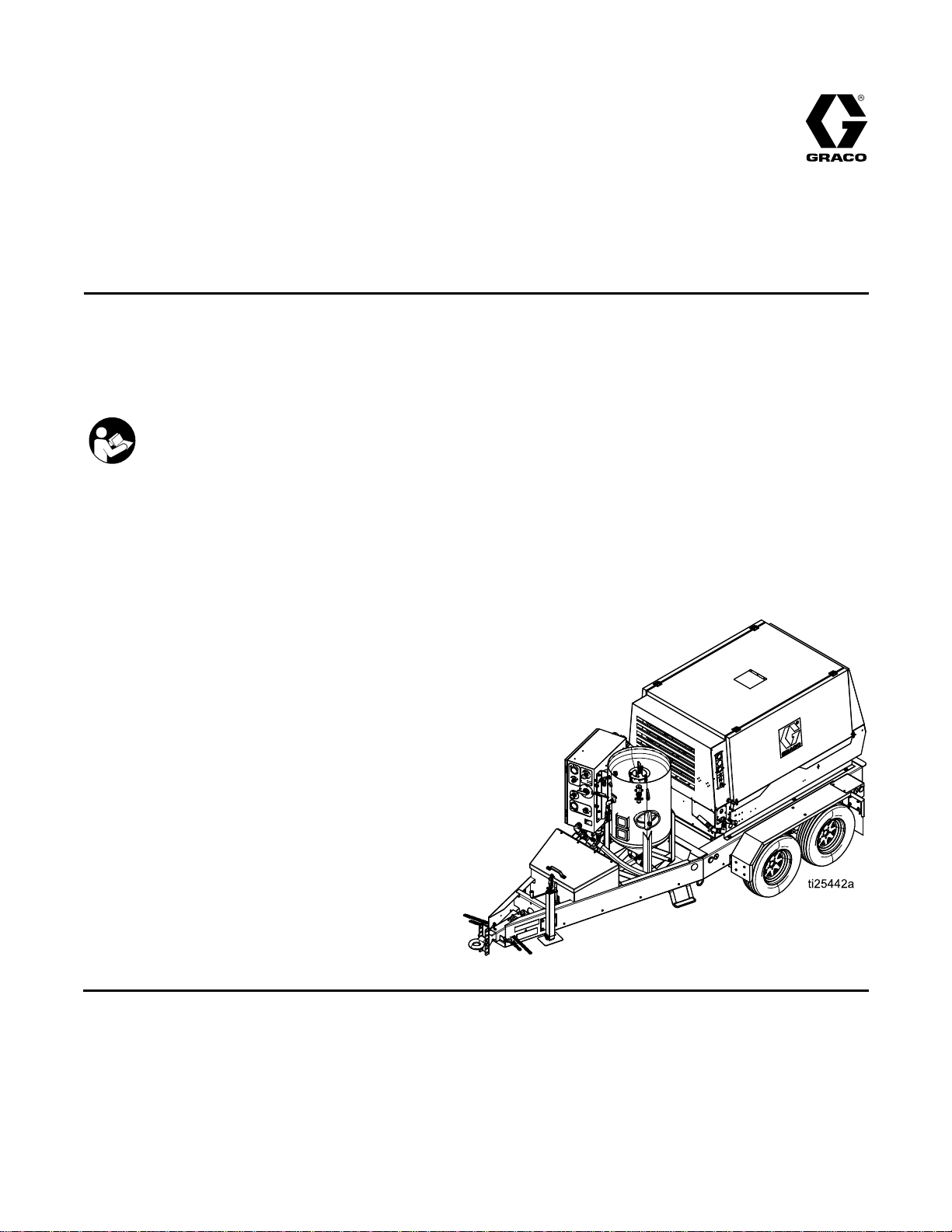

EcoQuip

EcoQuip EcoQuip

Blast

Blast Blast

Vapor

Vapor Vapor

or

hazardous

or or

hazardous hazardous

125 psi (8.6 bar, 0.86 MPa) Maximum

Working Pressure

See page 2 for Model information.

System

System System

abrasive

abrasive abrasive

locations.

locations. locations.

Important

Important Important

Readallwarningsandinstructionsinthismanual.Savethese

instructions.

Vapor

Vapor Vapor

Abrasive

Abrasive Abrasive

334666B

EN

blast

system.

blast blast

system. system.

Safety

Safety Safety

Instructions

Instructions Instructions

For

professional

For For

professional professional

use

only.

Not

use use

only. only.

approved

Not Not

approved approved

for

use

for for

use use

explosive

in ininexplosive explosive

atmospheres

atmospheres atmospheres

PROVENQUALITY.LEADINGTECHNOLOGY.

Page 2

Contents

Contents Contents

Models...............................................................2

RelatedManuals................................................2

Warnings...........................................................3

Notes.................................................................5

SystemComponentIdentication.........................6

EQ200TandEQ400T...................................6

DataTrakControls........................................7

PressureReliefProcedure..................................8

Operation...........................................................9

ChecklistBeforeStarting..............................9

LiftingtheTrailerSystems............................9

ConnectingtheBlastHoseandAir

Hose..............................................10

SettingUptheEquipment.............................11

BlastingTips................................................15

UsingtheWashFeature...............................17

RellingthePotwithAbrasive.......................18

ShuttingDown.............................................19

WinterizingtheEquipment............................21

Troubleshooting..................................................22

TroubleshootingExamples...........................26

Repair................................................................28

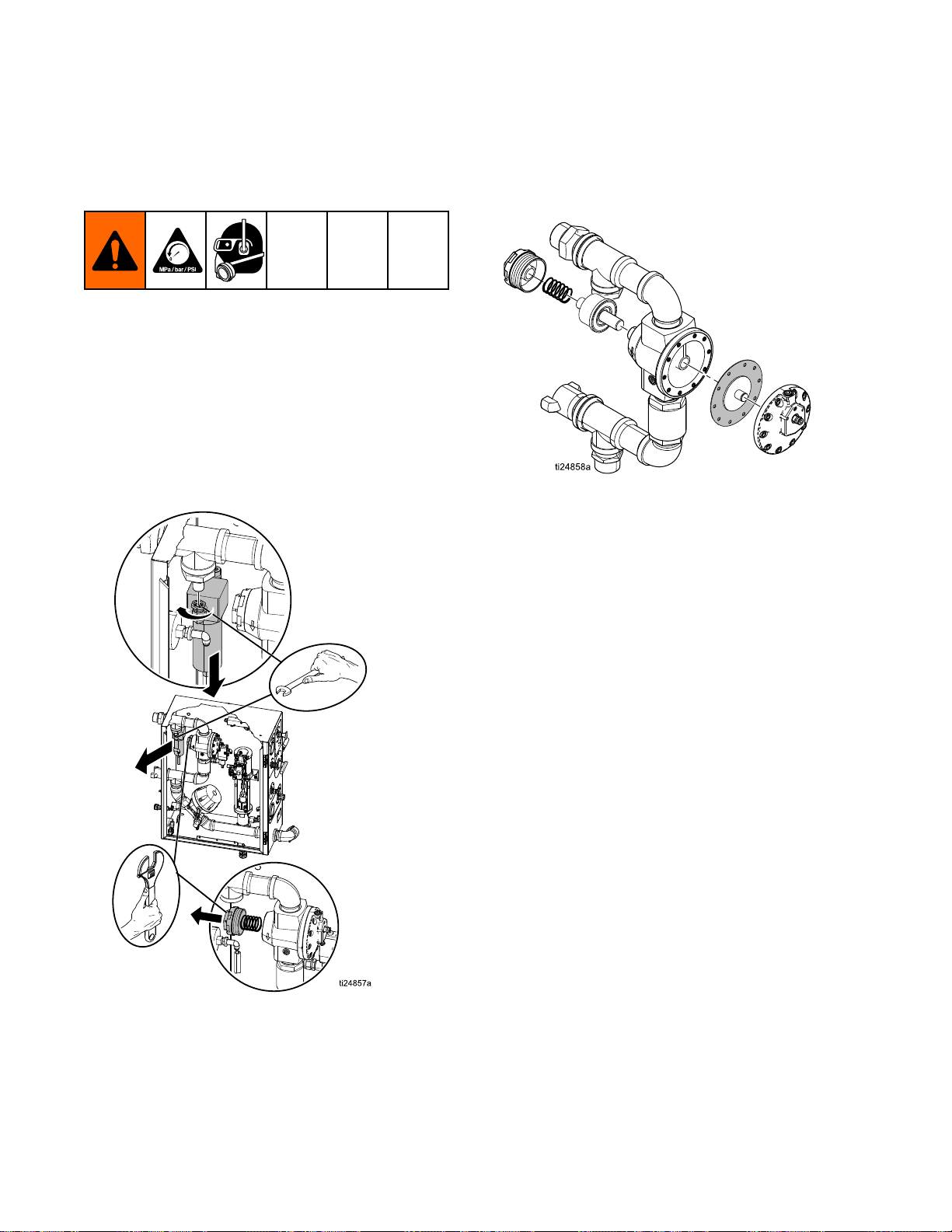

RepairingtheMainAirRegulator..................28

FlushingtheDiaphragmValve......................29

RepairingtheDiaphragmValve.....................30

CleaningtheAuto-VentValve.......................31

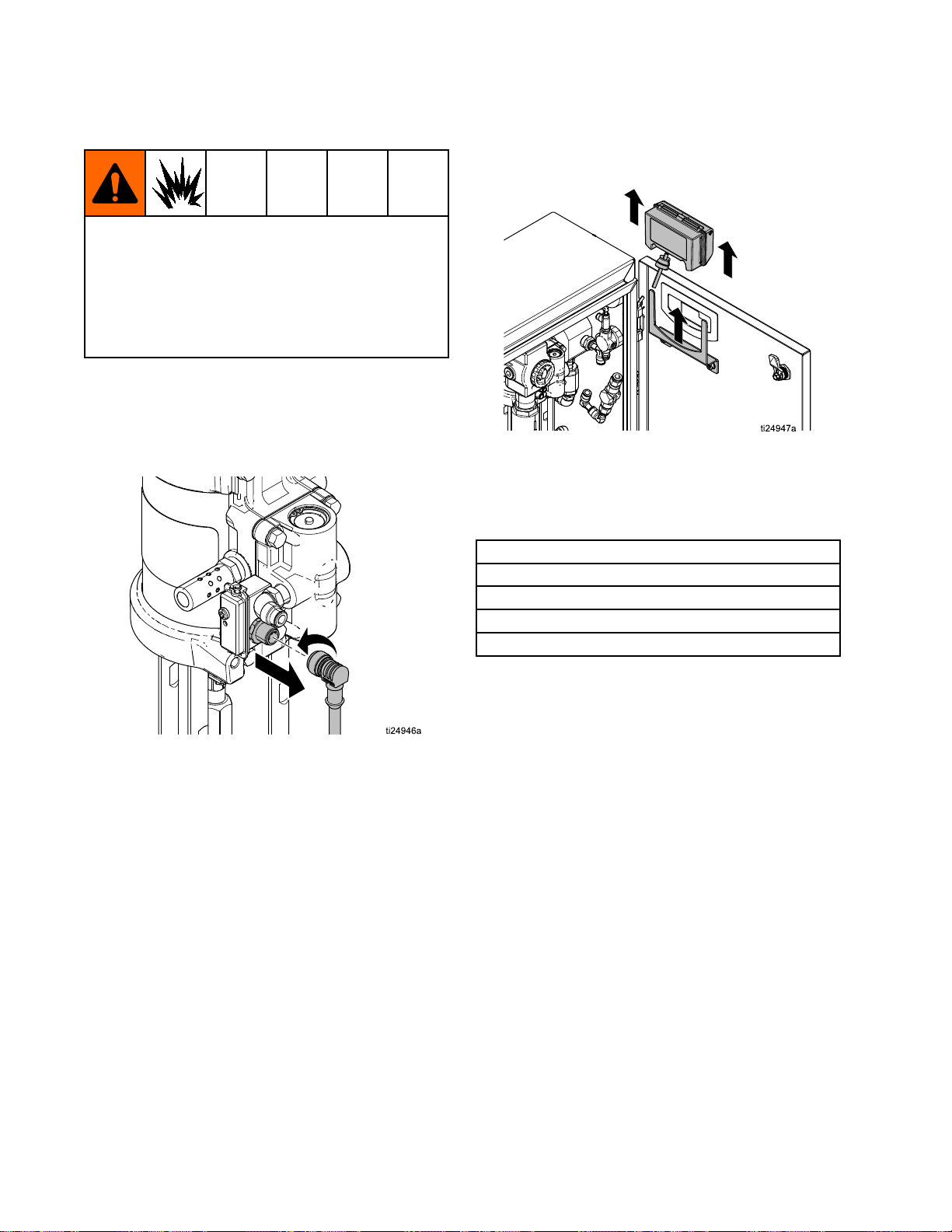

ReplacingtheDataTrakBattery....................32

ReplacingtheDataTrakFuse.......................33

Parts..................................................................34

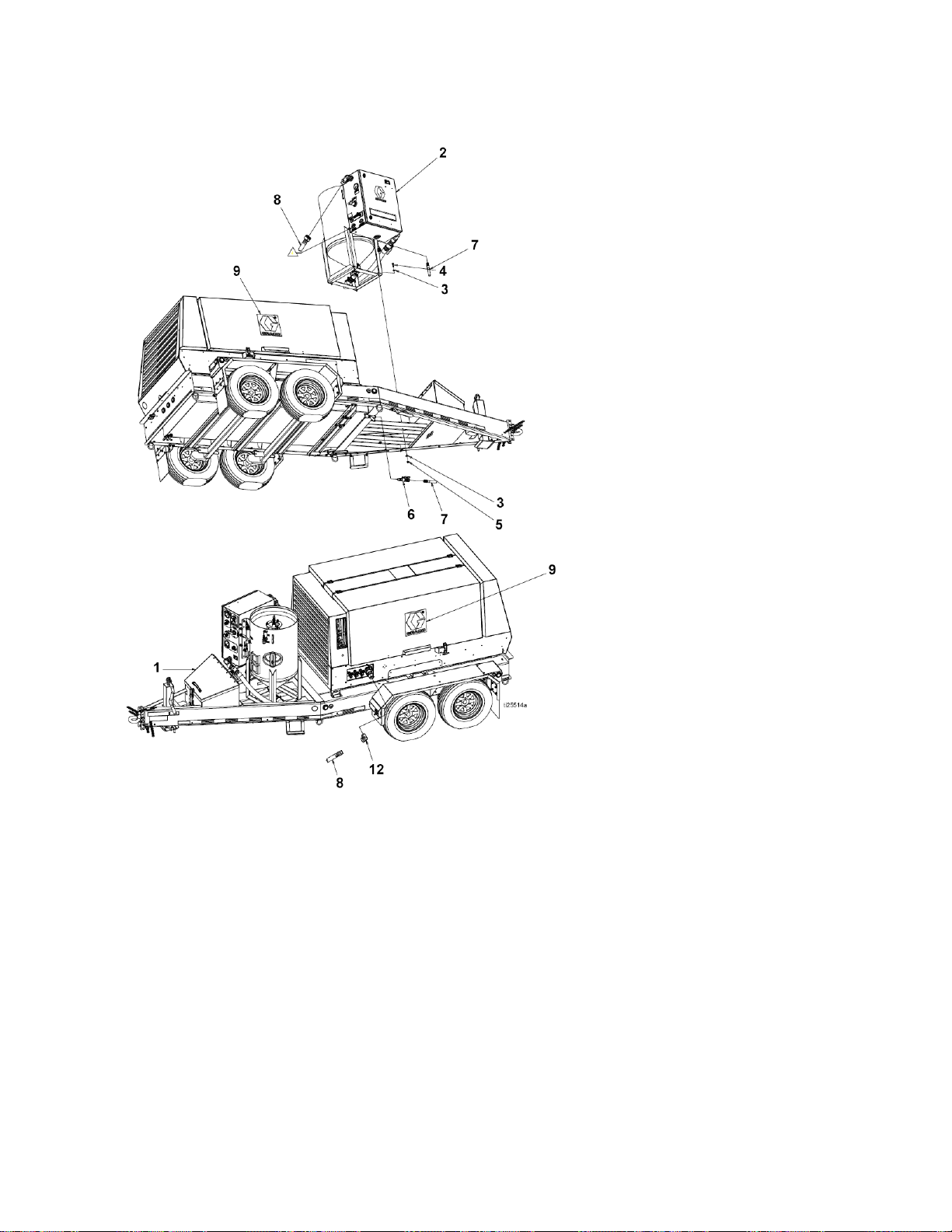

EQ200TandEQ400T...................................34

Enclosure....................................................36

Trailers........................................................38

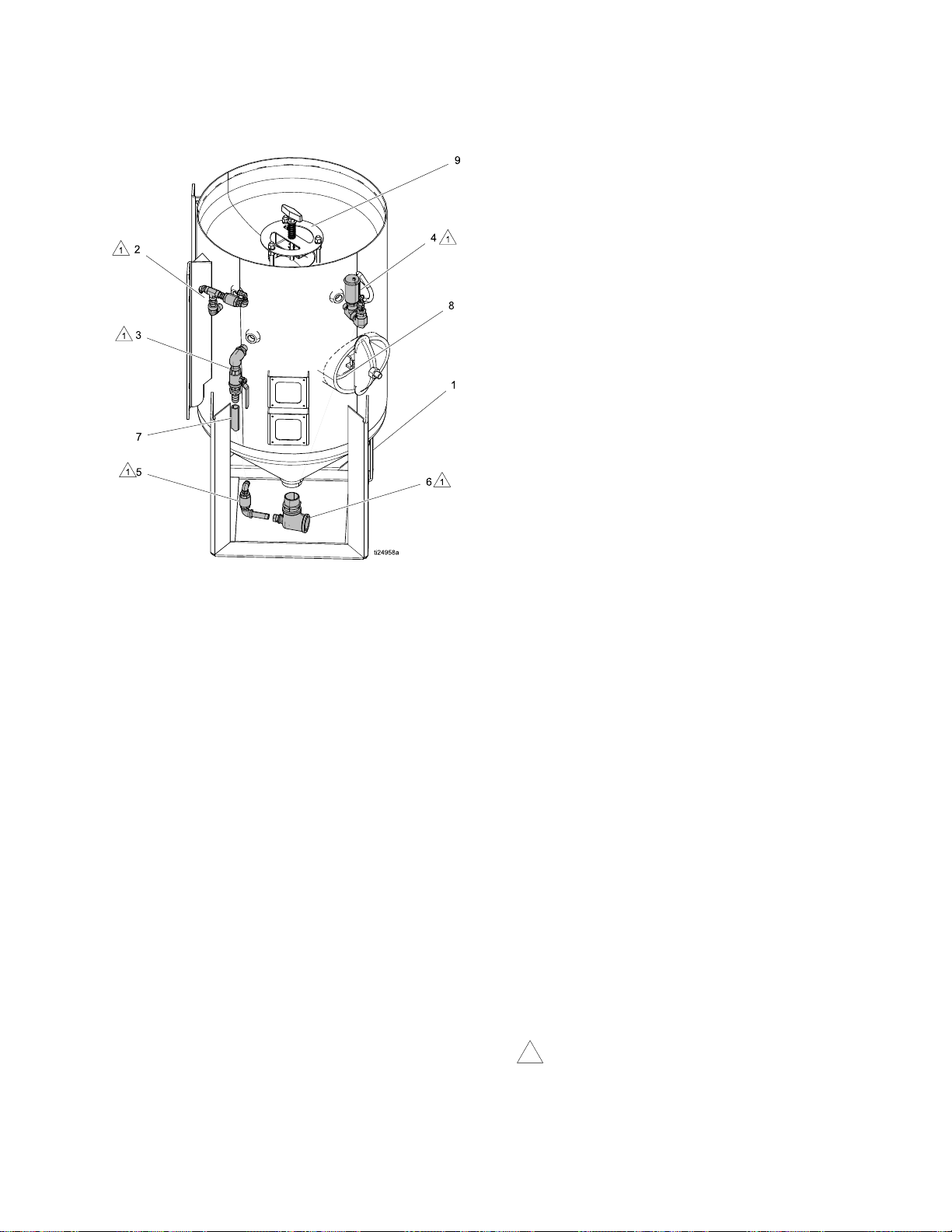

PressurePot................................................41

HoseSchematic.................................................42

VaporAbrasiveBlastSystemsand

Accessories..........................................43

EcoQuipSkidSystems.................................43

EcoQuipTrailerSystems..............................43

Mobile/SkidUnits.........................................44

TrailerUnits.................................................44

Hoses.........................................................45

Nozzles.......................................................45

CommonSpareParts...................................46

OtherAccessories........................................46

Dimensions........................................................47

TechnicalSpecications......................................48

Notes.................................................................49

GracoExtendedWarrantyforEcoQuip™

Components.........................................50

Models

Models Models

Part

Part Part

EQ200TEcoQuip200VaporBlastSystem

EQ400TEcoQuip400VaporBlastSystem

Related

Related Related

2

Manuals

Manuals Manuals

Manual

Manual Manual

Number

Number Number

313840DataTrak

333397Pump

334142

334143

334667

Product

Product Product

EQ100M

EQ300M,EQ600M

EQ300C,EQ600C

Description

Description Description

334666B

Page 3

Warnings

Warnings Warnings

Thefollowingwarningsareforthesetup,use,grounding,maintenance,andrepairofthisequipment.The

exclamationpointsymbolalertsyoutoageneralwarningandthehazardsymbolsrefertoprocedure-specic

risks.Whenthesesymbolsappearinthebodyofthismanualoronwarninglabels,referbacktothese

Warnings.Product-specichazardsymbolsandwarningsnotcoveredinthissectionmayappearthroughout

thebodyofthismanualwhereapplicable.

WARNING

WARNING WARNING

DUST

DUST DUST

Useofthisequipmentcanresultinthereleaseofpotentiallyharmfuldustortoxicsubstances

fromtheabrasivebeingused,thecoatingsbeingremoved,andthebaseobjectbeingblasted.

•Foruseonlybysophisticatedusersfamiliarwithapplicablegovernmentalsafetyandindustrial

•Useequipmentonlyinawell-ventilatedarea.

•Wearaproperlyt-testedandgovernmentapprovedrespiratorsuitableforthedustconditions.

•Followlocalordinancesand/orregulationsfordisposaloftoxicsubstancesanddebris.

EQUIPMENT

EQUIPMENT EQUIPMENT

AND

DEBRIS

AND AND

DEBRIS DEBRIS

hygieneregulators.

MISUSE

MISUSE MISUSE

HAZARD

HAZARD HAZARD

HAZARD

HAZARD HAZARD

Warnings

Misusecancausedeathorseriousinjury.

•Donotoperatetheunitwhenfatiguedorundertheinuenceofdrugsoralcohol.

•Donotexceedthemaximumworkingpressureortemperatureratingofthelowestrated

systemcomponent.SeeTechnical Technical

•Donotusethisequipmentwithouthoserestraintsandcouplerpinsinstalledonallairand

blasthosecouplings.

•Donotblastunstableobjects.Thehighamountofuidowfromthenozzlecanpotentially

moveheavyobjects.

•Donotexceedloadratingoflifteyes.

•Donotoperateequipmentonorstandonanunstablesupport.Keepeffectivefootingand

balanceatalltimes.

•Useuidsandsolventsthatarecompatiblewithequipmentwettedparts.SeeTechnicalData

inallequipmentmanuals.Readuidandsolventmanufacturer’swarnings.Forcomplete

informationaboutyourmaterial,requestMSDSfromdistributororretailer.

•Donotleavetheworkareawhileequipmentisenergizedorunderpressure.

•TurnoffallequipmentandfollowthePressure Pressure

•Checkequipmentdaily.Repairorreplacewornordamagedpartsimmediatelywithgenuine

manufacturer’sreplacementpartsonly.

•Donotalterormodifyequipment.Alterationsormodicationsmayvoidagencyapprovals

andcreatesafetyhazards.

•Makesureallequipmentisratedandapprovedfortheenvironmentinwhichyouareusingit.

•Useequipmentonlyforitsintendedpurpose.Callyourdistributorforinformation.

•Routehosesandcablesawayfromtrafcareas,sharpedges,movingparts,andhotsurfaces.

•Donotkinkoroverbendhosesorusehosestopullequipment.

•Keepchildrenandanimalsawayfromworkarea.

•Complywithallapplicablesafetyregulations.

Technical

Data

Data Data

Pressure

inallequipmentmanuals.

Relief

Relief Relief

Procedure

Procedure Procedure

whenequipmentisnotinuse.

334666B 3

Page 4

Warnings

WARNING

WARNING WARNING

BURN

BURN BURN

Equipmentsurfacesanduidthatisheatedcanbecomeveryhotduringoperation.Toavoid

severeburns:

•Donottouchhotuidorequipment.

FIRE

FIRE FIRE

Flammablefumes,suchassolvent,inworkareacanigniteorexplode.Tohelppreventre

andexplosion:

•Useequipmentonlyinwellventilatedarea.

•Abrasivematerialexitingblastnozzlecangeneratesparks.Whenammableliquidsareused

•Keepworkareafreeofdebris,includingsolvent,ragsandgasoline.

•Keepaworkingreextinguisherintheworkarea.

PERSONAL

PERSONAL PERSONAL

HAZARD

HAZARD HAZARD

AND

EXPLOSION

AND AND

EXPLOSION EXPLOSION

neartheblastnozzleorforushingorcleaning,keeptheblastnozzleatleast20feet(6

meters)awayfromexplosivevapors.

PROTECTIVE

PROTECTIVE PROTECTIVE

HAZARD

HAZARD HAZARD

EQUIPMENT

EQUIPMENT EQUIPMENT

Wearappropriateprotectiveequipmentwhenintheworkareatohelppreventseriousinjury,

includingeyeinjury,hearingloss,inhalationoftoxicfumes,andburns.Protectiveequipment

includesbutisnotlimitedto:

•Protectiveeyewear

•Protectiveshoes

•Gloves

•Hearingprotection

•Properlyt-testedandgovernmentapprovedrespiratorsuitableforthedustconditions

RECOIL

RECOIL RECOIL

Blastnozzlemayrecoilwhentriggered.Ifyouarenotstandingsecurely,youcouldfalland

beseriouslyinjured.

HAZARD

HAZARD HAZARD

4

334666B

Page 5

Notes

Notes

Notes Notes

334666B 5

Page 6

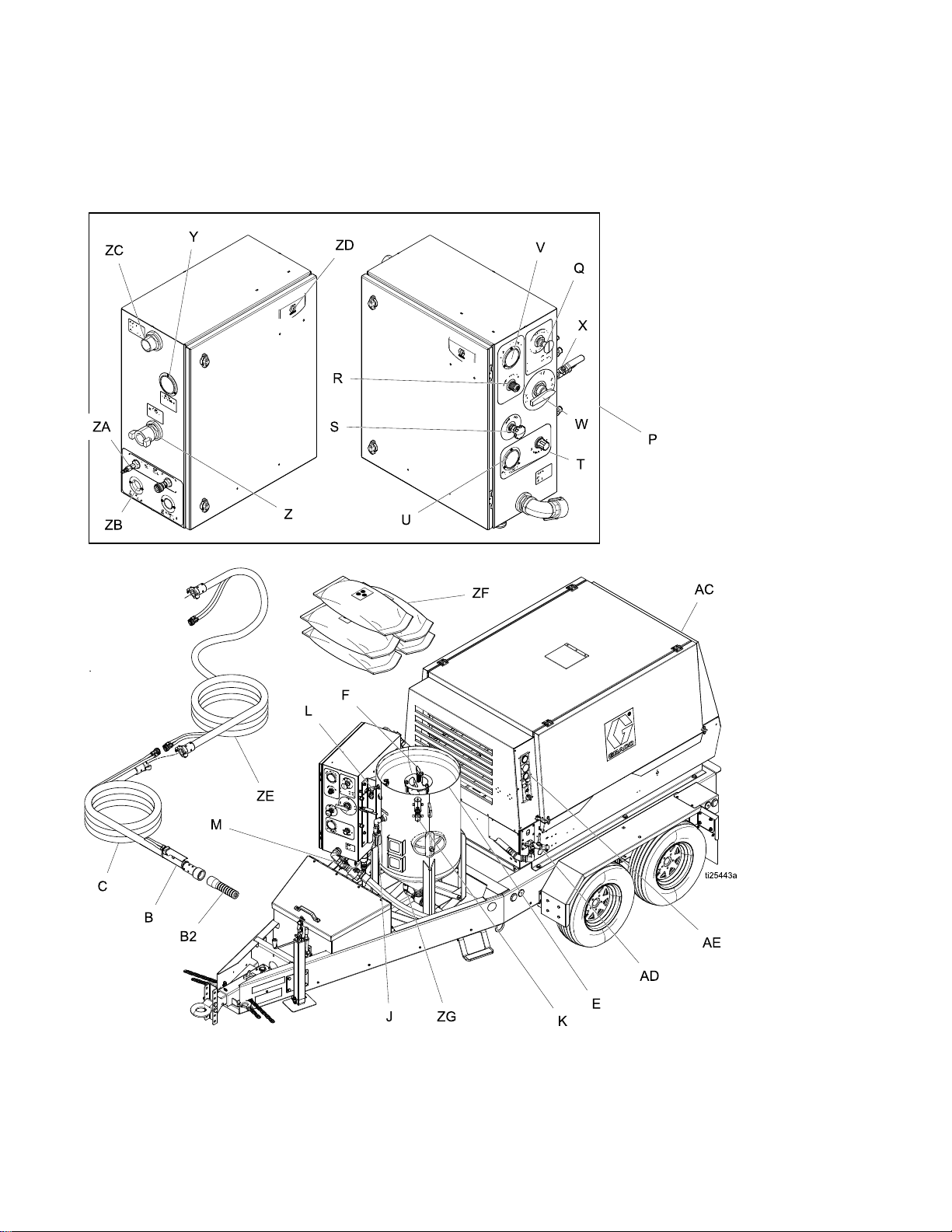

SystemComponentIdentication

System

System System

EQ200T

EQ200T EQ200T

Component

Component Component

and

EQ400T

and and

EQ400T EQ400T

Identication

Identication Identication

6 334666B

Page 7

SystemComponentIdentication

8800000

83000

9

Key:

Key: Key:

B

B2BlastNozzle

C

EPot

FBungPin

JPotDumpValve

KAutoVentValve

L

MAbrasiveBallValve

P

QEmergencyStop

RBlastAirRegulator

S

TPotPressureRegulator

U

DataTrak

DataTrak DataTrak

BlastControlSwitch

BlastHose

BlastCheckValve

ControlBox

AbrasiveMeter

PotPressureGauge

Key:

Key: Key:

V

W

XRinseBallValve

Y

Z

ZA

ZB

ZCSupplyAirPressureGauge

ZD

ZEAccessoryExtensionhose

ZFAbrasiveMaterial

ZGFillPortCheckValve

ACAirCompressor

AD

AE

Controls

Controls Controls

BlastAirPressureGauge

SelectorValve

AirSupplyConnection

BlastConnection

PneumaticControlConnection

ElectricControlConnection

DataTrak(seeDataTrakControls,page7)

AirConnections

AirCompressorControls

Key:

Key: Key:

RK

CRCycle/Rate

BTBatchTotalizer

GTGrandTotalizer

334666B

ResetKey—Resultsinfaults.Pressand

holdforthreesecondstoclearthebatch

totalizer.

7

Page 8

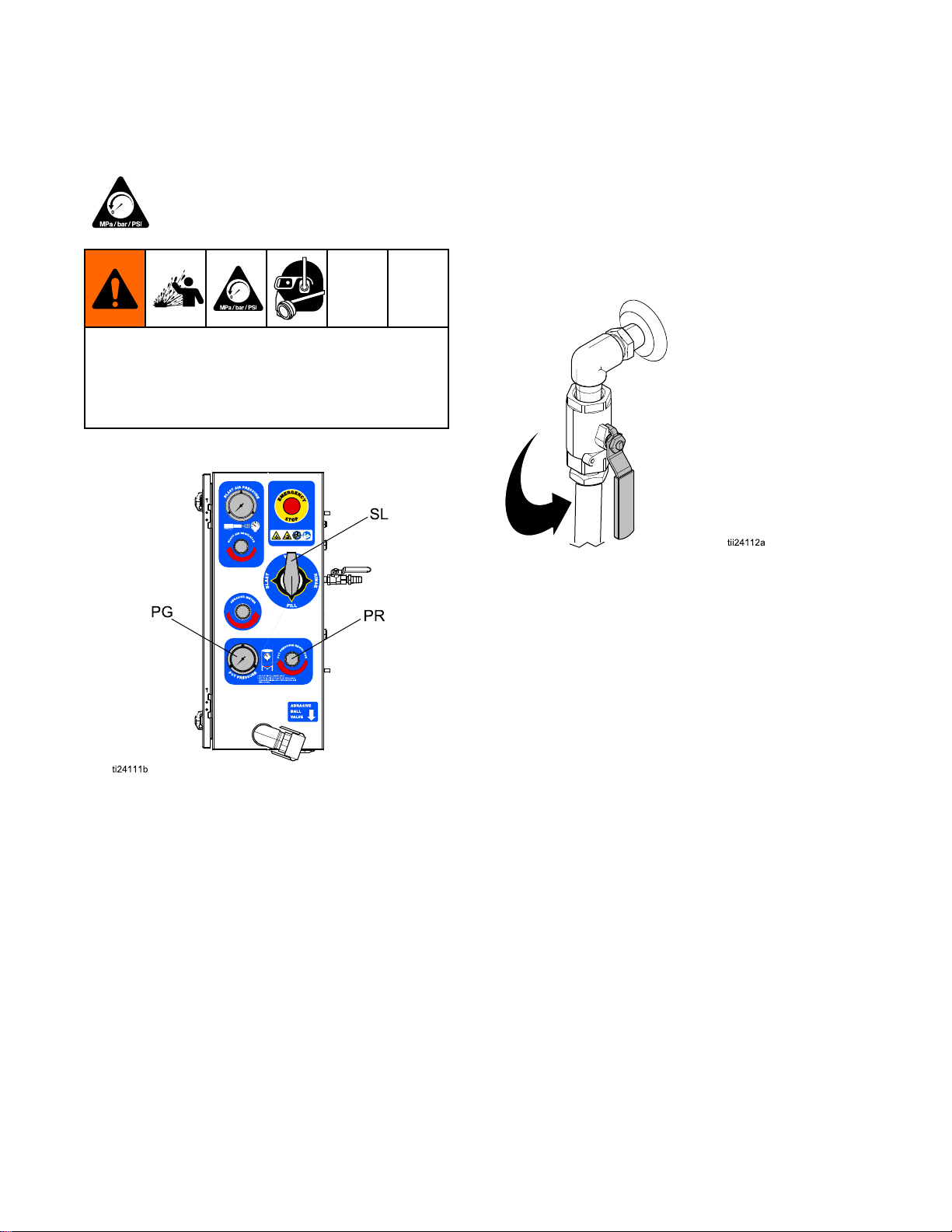

PressureReliefProcedure

Pressure

Pressure Pressure

FollowthePressureReliefProcedure

wheneveryouseethissymbol.

Thisequipmentstayspressurizeduntilpressure

ismanuallyrelieved.Tohelppreventserious

injuryfrompressurizeduid,suchassplashing

uid,followthePressureReliefProcedurewhen

instructed.

1.Turnthepotpressureregulator(PR)off.

Relief

Relief Relief

Procedure

Procedure Procedure

2.Closetheabrasiveballvalve.

3.Turnthecompressoroffandclosetheinlet

ballvalve.Closethecompressorsupplyair

valve.Engagetheblastcontrolswitchtorelieve

pressureinthesystem.Thendisconnecttheair

inlethosefromthesystem.

4.Turntheselectorvalve(SL)toFILL.

5.Openthedumpvalve.

6.Verifythatthepotpressuregauge(PG)displays

zeropressure.

8 334666B

Page 9

Operation

Operation

Operation Operation

Checklist

Checklist Checklist

•Checkthecompressedairsupplyaccordingtoits

operatormanual.Makesuretheairbeingsupplied

iscleanandrelativelyfreeofmoistureandoil

topreventwatercontaminationoftheaircontrol

components.

•Makesureairdeliveryvalvesareclosedbeforethe

airsupplycompressorisstarted.

•Makesureallrequiredhoserestraintsandcoupler

pinsareinworkingconditionandproperlyinstalled.

•Makesuretheequipmentissituatedonlevel

ground.Failuretokeeptheunitonlevelground

willmakeitdifcultorimpossibletopurgeallofthe

airfromthepressurevessel.

•Makesuretheequipmentisproperlysupportedon

asurfacethatcanholditstotalweight.Theweight

ofallpersonnel,thematerialbeingblasted,and

anyabrasivebeingstoredmustalsobeconsidered

(seeTechnicalSpecications,page48).

•Makesurethewatertankwillremainfullysupplied

withcleanwatertoavoidanypossibilityofthe

pumprunningdryduringblasting.

Before

Before Before

Starting

Starting Starting

•Makesuretousethecorrecttypeofblastcontrol.

Blastingwith150feet(45m)ormoreofblasthose

requirestheuseofanelectricblastcontrol.An

electricblastcontrolcanalsobeusedonhose

lengthsbelow150feet(45m).

•Makesuretheblasthoseislaidoutasstraightas

possiblebetweentheequipmentandtheworksite

(acoiledblasthosewilluncoilunderpressure).

NOTICE

NOTICE NOTICE

Sharpbendsintheblasthosecouldcausethe

abrasivetowearthroughthehoseandcause

prematurefailureofthehose.

•Makesuretherubbergasketineachhosecoupler

isinworkingcondition.

Lifting

Lifting Lifting

•Lifttheunitwithaliftapparatusratedfor10,000

lb(4535kg)minimum.

•Donotliftthesystembytheliftringontopofthe

compressor.

the

Trailer

the the

Trailer Trailer

Systems

Systems Systems

•Makesurethatthepotiscleanandfreeofany

internaldebris.

•Donotliftthesystembythetie-downringsonthe

trailer.

334666B 9

Page 10

Operation

OFF

START

RUN

ti24706a

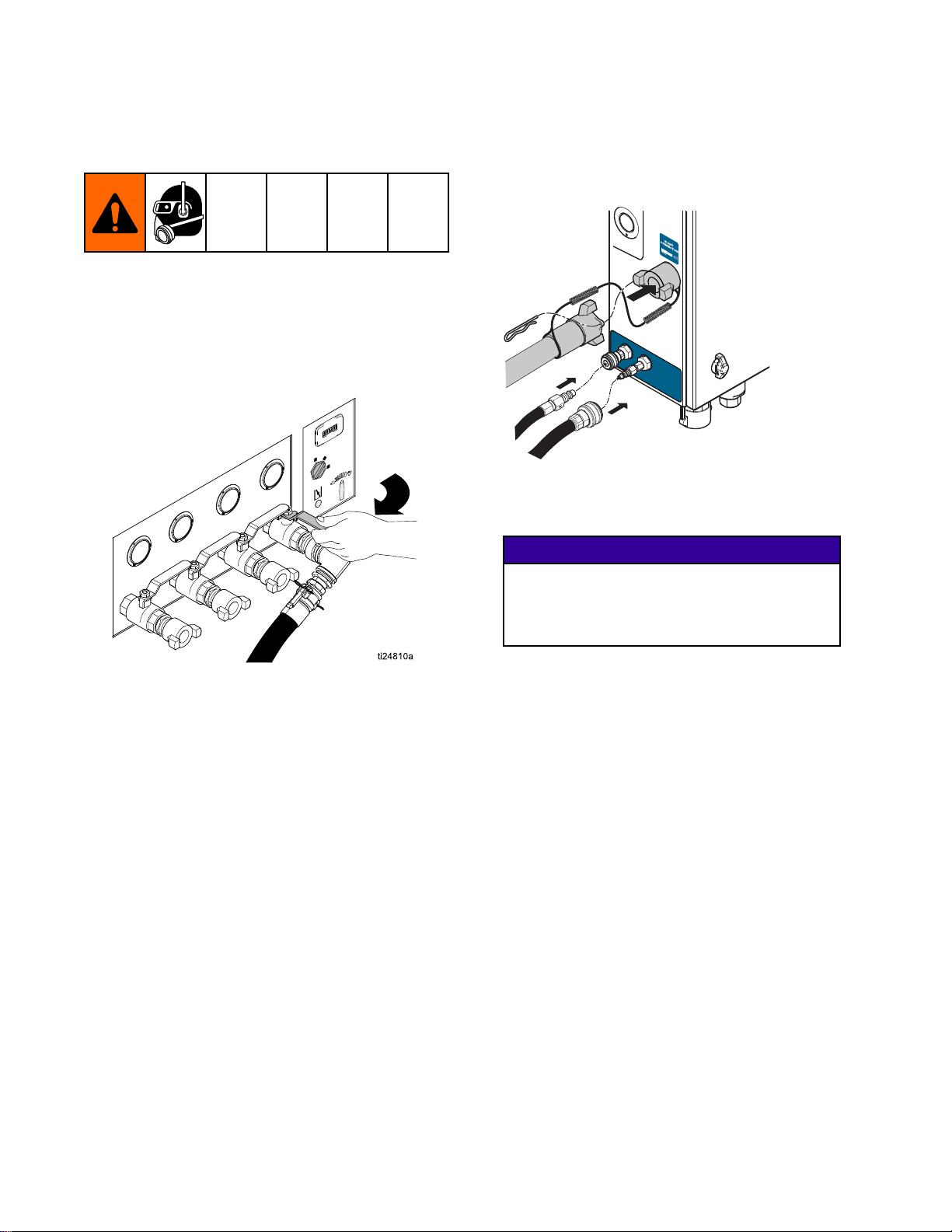

Connecting

Connecting Connecting

Hose

Hose Hose

1.Makesuretheinlethoseconnectionsaretight,

andthathoserestraintsareproperlyinstalled

andsecure.

2.Opentheairsupplyvalve(125psi,8.6Bar,0.86

MPamaximum).Ifnecessary,usearegulatorin

thesupplyairlinetomeetthesespecications.

the

Blast

the the

Blast Blast

Hose

Hose Hose

and

and and

Air

Air Air

NOTE:

NOTE: NOTE:

andstartupinformation.

3.Connecttheblasthose,hoserestraints,control

hoses,andcouplerpins.

NOTE:

NOTE: NOTE:

checkalloftheelectricalconnectionsfromthe

paneltotheblastcontrol.

Seeaircompressormanualforoperation

Ifyouareusinganelectricblastcontrol,

NOTICE

NOTICE NOTICE

Makesurenoelectricalconnectionswill

beexposedtowater.Exposuretowater

couldcauseashortcircuitanddamagethe

equipment.

10 334666B

Page 11

Operation

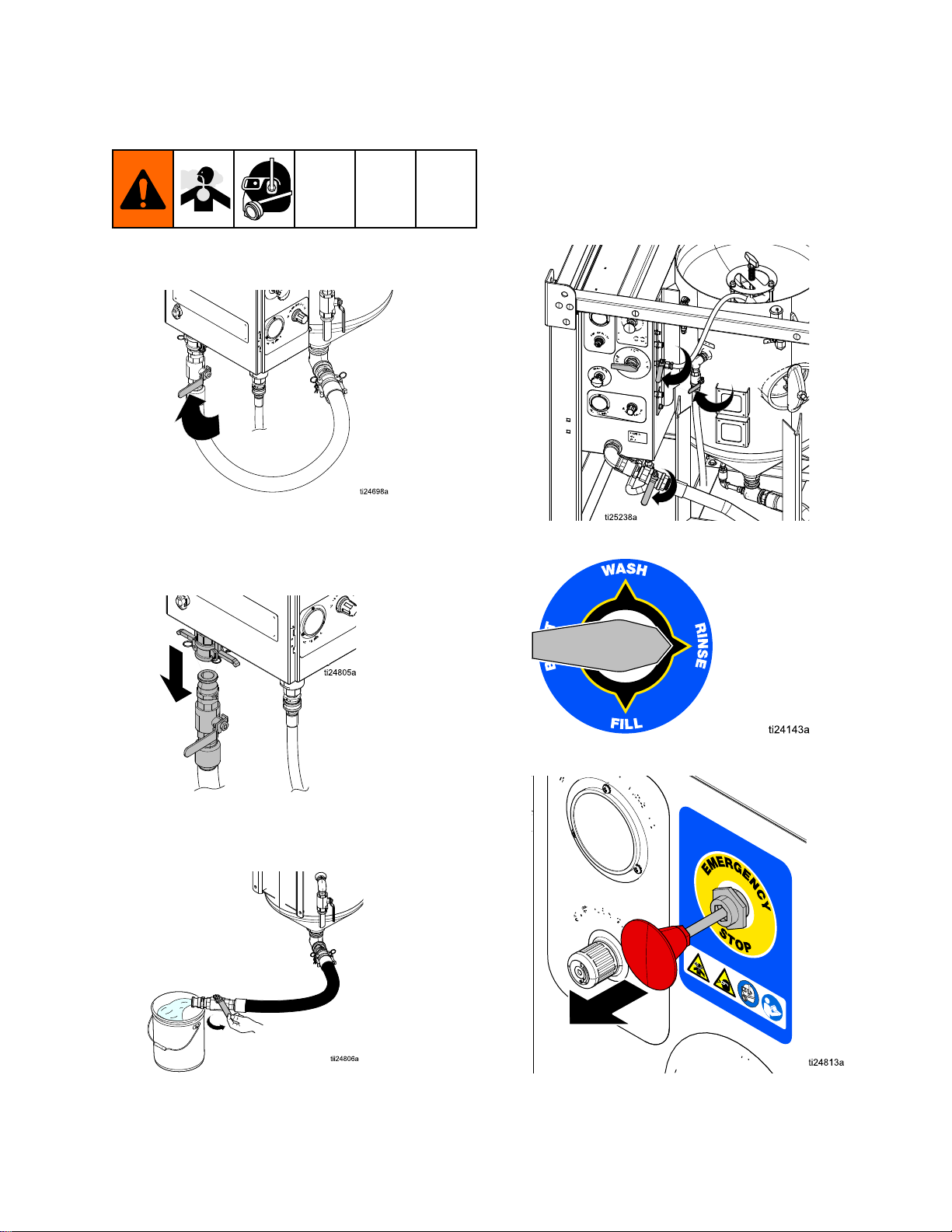

Setting

Setting Setting

1.Disconnecttheabrasivehoseatthecamand

Up

the

Up Up

groovewiththeabrasiveballvalveclosed.

NOTE:

NOTE: NOTE:

(especiallyunderpressure),releasingthecam

andgroovewiththeballvalveopenwillcausean

unintentionalreleaseofabrasive.

Ifthepotcontainswaterandabrasive

Equipment

the the

Equipment Equipment

4.Disconnectthepumpinlethoseandushthe

watertanktoremoveanyremainingdebris.

Reconnectthepumpinlethose.

5.Fillthewatertankonlywithfreshwater,then

opentheinletballvalve.

6.Closetherinse,dump,andabrasiveballvalves.

7.TurntheselectorvalvetoRINSE.

2.Flushwaterthroughthepotandoutthe

disconnectedabrasiveballvalvebeforellingthe

potwithwaterandabrasive.

3.Reconnecttheabrasivehose.

334666B

8.DisengagetheEmergencyStop.

NOTE:

NOTE: NOTE:

EmergencyStopisdisengaged.

Thewaterpumpwillnotworkunlessthe

11

Page 12

Operation

1

2

10 gal

(30 L)

200-500 lb

(90-227 kg)

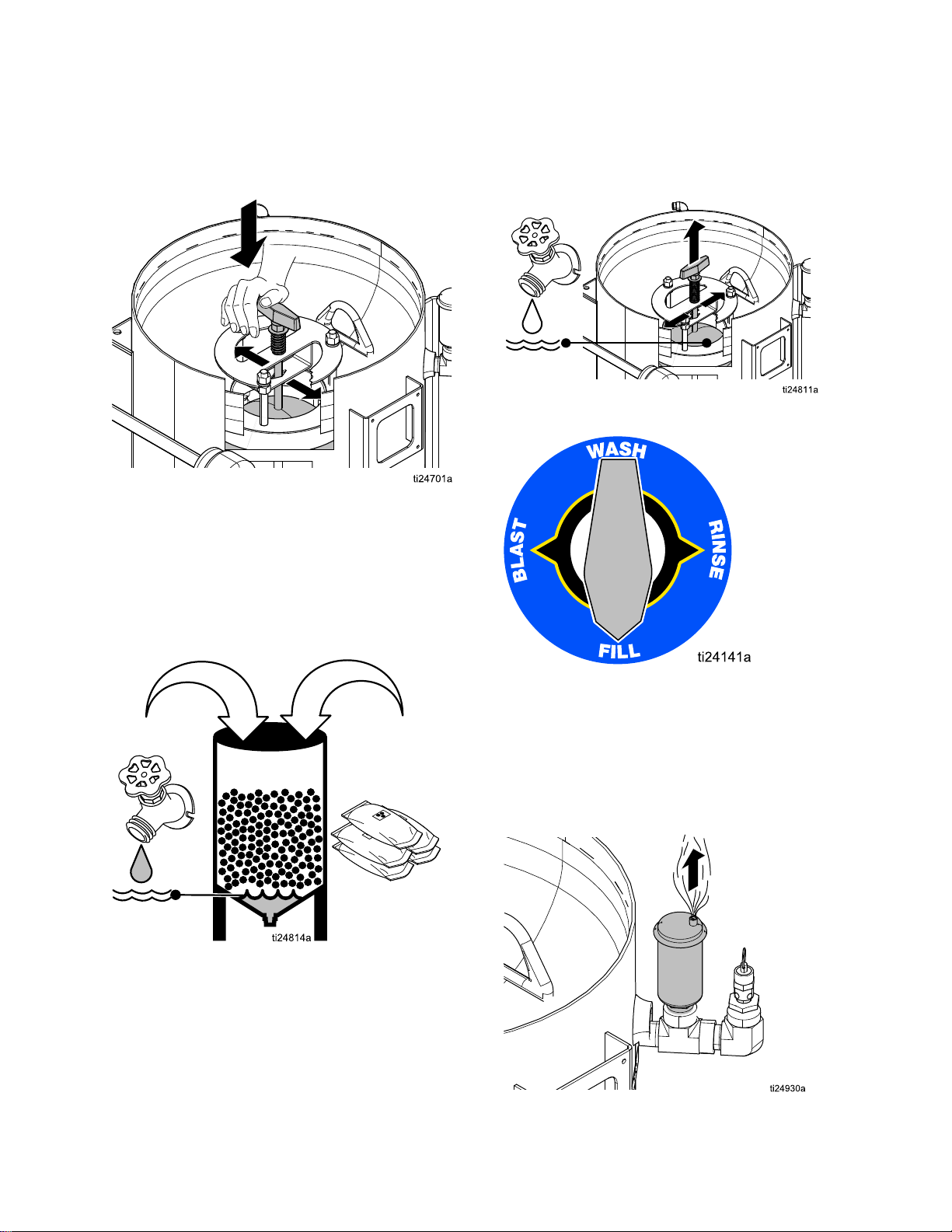

9.Alignthebunghandlewiththepinslot,andthen

rmlypushandturnthehandle90°afterthepin

isbelowthebracketslot.Properengagementof

thepinwillholdthebungdownuntilitisreleased.

10.Add10gallons(30liters)offreshwaterto

thepot.Wearappropriatepersonalprotective

equipment,includinganappropriatelyt-tested

governmentapprovedrespiratorsuitableforthe

dustconditions.Addabrasivematerial(minimum

fourbags,maximumten50lb(23kg)bagsof

high-massabrasive,oreight50lb(23kg)bags

oflowmassabrasive).

12.Whenthewaterlevelreachesthebungseal,

rotatethehandletoreleasethebungpin(this

willcausethebungtopopupagainsttheseal

andclosethebung).

13.TurntheselectorvalvetoFILL.

11.Useagardenhoseortherinsehosetowashthe

abrasiveintothepotandclearanyabrasivefrom

thebungandbungseal.

NOTE:

NOTE: NOTE:

not,openthepotpressureregulatorenoughto

causethepumptorunat60cpm.

NOTE:

NOTE: NOTE:

oftheairtrappedinthetopofthepottovent.

Whenairstopsventing,thepotpressuregauge

willstarttoregisterpressure.

Thewaterpumpshouldbegincycling.If

Theautovent/purgevalvewillallowall

12

334666B

Page 13

Operation

ti24824a

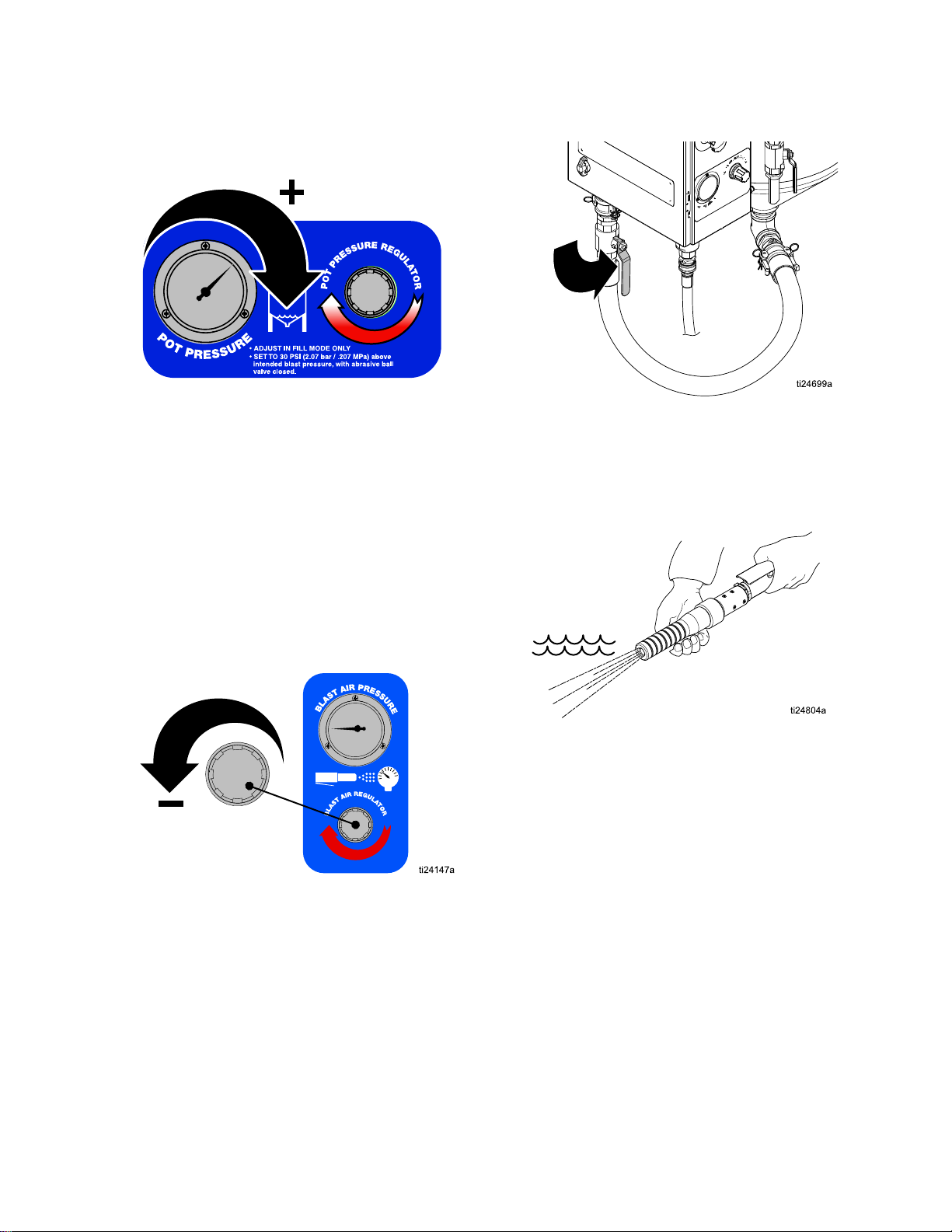

14.Waitforpotpressuretoincrease.NOTE: NOTE:

cantakeuptoseveralminutesforthepotto

pressurize.

NOTE:

NOTE: NOTE:

Thebungcannotbepusheddownunless

allofthepressureinthepotisreleasedby

openingthedumpvalve.

15.Setthepotpressure30psi(2.0Bar,0.2MPa)

higherthantheintendedblastpressure.Quickly

openandclosethedumpvalveafterthepump

stalls.Relievepotpressureto40psi(2.7Bar,

0.27MPa)beforeclosingthedumpvalve.

Repeatuntilpotpressureisconsistent.

NOTE:

It

19.Opentheabrasiveballvalve.

NOTE:

NOTE: NOTE:

Makesurethepotpressurereturnstothe

initialsetting(itwillnotreturntotheinitialsetting

ifthemeteringvalveisclosed).

20.Engagetheblastcontrolswitchandbegin

blasting.

16.TurntheselectorvalvetoWASH.

17.Settheblastairpressure30psi(2.0Bar,0.2

MPa)lowerthanthepotpressurewhileblasting.

NOTE:

NOTE: NOTE:

Inordertoadjusttheblastpressure,the

blastcontrolmustbeengaged.Fortheinitial

setting,leavetheabrasiveballvalveclosed.

NOTE:

NOTE: NOTE:

Engageandreleasetheblastcontrol

handleeachtimetheblastregulatorisadjusted.

18.TurntheselectorvalvetoBLAST.

NOTE:

NOTE: NOTE:

Youmayhavetowait1–2minutesforthe

abrasivematerialtoreachthenozzle.

NOTE:

NOTE: NOTE:

Potpressureandblastpressureshould

equalizeduringblasting.Onlysetpotpressure

withtheabrasiveballvalveclosed.Neveradjust

potpressurewhileblasting.

334666B 13

Page 14

Operation

8800000

83000

9

21.Slowlyadjusttheabrasivemetervalvewhilethe

abrasiveisblastingfromthenozzle.Typical

adjustmentrangesfrom1/8to1/4turnopen.

NOTE:

NOTE: NOTE:

settingthepumpcyclerate.Optimalabrasive

mediaconsumptiontypicallyoccurswiththe

cycleratesetat7–10cyclesperminute.

TheDataTrakcanbeusedtoassistin

NOTE:

NOTE: NOTE:

whatyouwillbeblasting.

NOTE:

NOTE: NOTE:

thenincreasetheblastforceasnecessaryto

cleanwithoutdoinganydamagetothesubstrate.

Whenproperlyset,thepumpshouldcycle7-10

timesperminute.Highproductionrateusers

mayneedtoincreasecyclerateabove10cycles

perminute.

Useapieceoftestmaterialsimilarto

Alwaysstartasgentlyaspossibleand

NOTE:

NOTE: NOTE:

youstopblastingformorethan2-3minutes.

Thiswillhelptoextendtheservicelifeofthe

diaphragmvalve.

Closetheabrasiveballvalvewhenever

14

334666B

Page 15

Operation

Blasting

Blasting Blasting

Whenrstlearningtheeffectsoftheblaster,geta

betterunderstandingoftheresultsbystartingata

shallowangle(closerto0°thanto90°)andkeep

thenozzleapproximately16in.(40cm)fromthe

application.Observetheresults,thenreducethe

distance,steepentheangle,andadjusttheblast

regulator.

Astheblastpressureisincreased,slowlyadjust

themeteringvalveandwatchtheDataTrakto

achieve7-10pumpcyclesperminute.See

DataTrakControls,page7.

NOTE:

NOTE: NOTE:

(i.e.80-grit),themoreaggressivetheresults.

Tips

Tips Tips

Theheavierandsmallertheabrasiveparticle

Blasting

Blasting Blasting

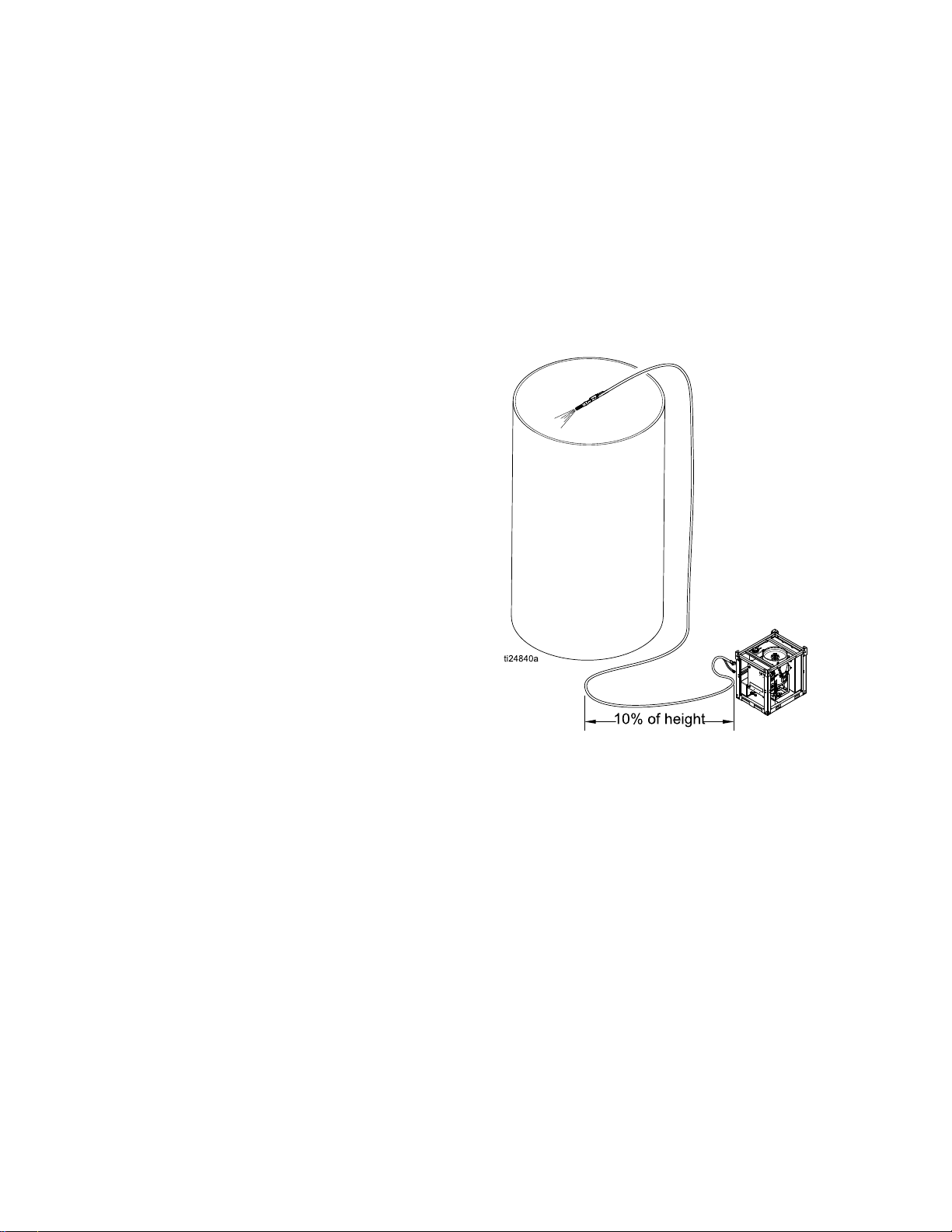

Whenblastingonasurfacehigherthanthe

equipment,makesurethatthereisalengthofblast

hoseonthegroundequalto10-20%oftheheight.

Thehoseonthegroundpreventsunspentabrasive

inthehosefromback-llingtheinternalplumbingof

thepanel.

Forexample:Whenblasting50feet(15m)straight

up,useatleast10feet(3m)ofblasthoseonthe

groundbeforetheblasthosegoesuptotheblasting

height.

on

Higher

on on

Higher Higher

Surfaces

Surfaces Surfaces

334666B 15

Page 16

Operation

Metering

Metering Metering

Thereisnoxedformulaforwhatworksbestineachapplication.Theinformationbelowworksbestforthe

majorityofthetime.Fromthisinitialsetting,adjustmentscanbemadeupordowntogetthefastestremoval

rateswithoutdamagetothesurface.

Normalsettingsare:110psi(7.5Bar,0.75MPa)initialpotsetting,lessthan1/2turnopenmeteringvalve,

blastingpressureat80psi(5.5Bar,0.55MPa).Forapplicationsrequiringhigherperformance,use

high-performanceabrasive(theheaviestmass@80grit)suchasGarnet,andthehighestpressuresthe

compressorcansupport.Theinitialpotpressureshouldalwaysbe30psi(2.0Bar,0.2MPa)abovethe

intendedblastpressure.

Graduallymakeadjustmentstomeetthespecicrequirementsforeachapplication.Higherblastpressures

willrequireturningtheabrasivemeteringvalveslightlymoreopen(andviceversa).Maketheadjustments

(seeDataTrakControls,page7)toachieve7-10cyclesperminutetobethemostefcient(cutatthefastest

ratewhileusingtheleastamountofabrasive).Blastingpressurescanrangebetween30-120psimax

(2.0Bar,0.2MPa–8.2Bar,0.82MPa).

Unlikeconventionalsandblasting,higherpressuresdonotnecessarilymeanbettercleaning.Nozzledistance

andtheangletothesurfacehasaneffectonperformance,asdoestheblastpressure.Choiceofabrasive

alsohasagreateffect.High-performanceabrasiveproducesthebestperformanceandcansaveenough

timetomakeupthedifferenceincost.

NOTE:

NOTE: NOTE:

General

General General

Wood

Wood Wood

Steel

Steel Steel

Fiberglass

Fiberglass Fiberglass

Valve

Valve Valve

Blastingwith150+feetofblasthoserequirestheuseofanelectricblastcontrol.

Settings

Settings Settings

Grit

Grit Grit

40/70

80(usingalow

massabrasive

likeglass)

80-100(using

ahigh-mass

abrasivelike

Garnet)

40-70lowmass

Blast

Size

Size Size

60-80psi(4.1Bar,

0.41MPa-5.5Bar,

0.55MPa)

40-50psi(2.7Bar,

0.27MPa-3.4Bar,

0.34MPa)

100-120psi(6.8Bar,

0.68MPa-8.2Bar,

0.82MPa)

45-65psi(3.1Bar,

0.31MPa-4.4Bar,

0.44MPa)

Pressure

Blast Blast

Pressure Pressure

Abrasive

Abrasive Abrasive

1/4to1/2turns

1/8to1/4turns

1/4–1/2turns

1/8to1/4turns

Dose

Dose Dose

35°-65°

15°-30°

65°-85˚

35°-45˚

Blast

Angle

Blast Blast

Angle Angle

Whentheblast

pressureis

increased,the

abrasivedoseturns

willalsoneedtobe

increased.

Donotwash,asit

mayraisethewood

grain.Brushoff

excessabrasiveafter

thewooddries.

Whentheblast

pressureis

increased,the

abrasivedoseturns

willalsoneedtobe

increased.

Whentheblast

pressureis

increased,the

abrasivedoseturns

willalsoneedtobe

increased.

Notes

Notes Notes

16 334666B

Page 17

Operation

Using

Using Using

Thewashfeaturecausesair-drivenwater(without

abrasive)toblastandrinseareasthathavealready

beenblastedwithabrasive.Itisalsoaconvenient

featureforushingabrasivefromtheblasthose.

Therewillalwaysbesomeresidualabrasivein

theblasthose.Neverusethewashfeatureon

anysurfaceotherthanwhereyouhaveblasted,or

intendtoblast.Itwillaffect/dullthesurface.

Donotusethewashfeatureonwoodthathas

beenblasted.Itcoulddamagethewoodandcause

thegraintorise.Waitforthewoodtodryandthen

useabroom,brush,orvacuumtoremoveany

residualabrasive.

1.Closetheabrasiveballvalve.

the

Wash

the the

Wash Wash

Feature

Feature Feature

NOTICE

NOTICE NOTICE

NOTICE

NOTICE NOTICE

2.TurntheselectorvalvetoWASH.

3.Blast1–2minutesuntiltheabrasiveiscleared

fromthehose.

4.Theequipmentisnowreadytowashany

previouslyblastedsurfaces.

334666B

17

Page 18

Operation

Relling

Relling Relling

1.Closetheabrasiveballvalve.

2.TurntheselectorvalvetoRINSE.

3.Openthedumpvalveslowlytorelievethewater

pressureinthepot.

the

Pot

with

the the

Pot Pot

Abrasive

with with

Abrasive Abrasive

4.Afterallofthepressureinthepothasbeen

relieved,engagethebungpinbycompressing

thespringandturningthehandle90°toholdthe

bungintheopenposition.

5.Addtheabrasive(minimumfourbags,maximum

ten50lb(23kg)bagsofhigh-massabrasive

oreight50lb(23kg)bagsoflow-mass

abrasive)andcontinuetheproceduresfrom

SettingUptheEquipment,page11.

NOTE:

NOTE: NOTE:

willbedrainedfromthepot.Alldisposalsmust

complywithnational,state,andlocalregulations.

Bepreparedtocapturethewaterthat

NOTE:

NOTE: NOTE:

thepottoallowadditionalabrasivetobeadded.

Morewatermayneedtobedrainedfrom

18 334666B

Page 19

Operation

Shutting

Shutting Shutting

1.Whenyouhavenishedblasting,performwash

untilalloftheabrasiveisushedfromtheblast

hose.SeeUsingtheWashFeature,page17.

2.TurntheselectorvalvetoRINSE,andwiththe

abrasiveballvalveclosed,continuetoblastuntil

waterisclearedfromthehose.Thisistodrythe

insideofthehoseforstorage.

Down

Down Down

5.Holdabucketunderthecam-lockcoupler,then

turntheselectorvalvetoWASH.Thiswillclean

debrisfromthecam-lockcouplerandgasket.

NOTE:

NOTE: NOTE:

procedure.

NOTE:

NOTE: NOTE:

thatwillbewashedoutofthepanelplumbingand

outofthegroovetting.

6.TurntheselectorvalvetoFILL.Thiswillhelp

pushtheabrasiveoutthroughtheabrasivehose.

7.Placeabucketundertheabrasivehose.Slowly

openandclosetheabrasiveballvalvetoush

abrasivematerialfromthepot.Repeatseveral

times.Oncenoabrasivematerialowsfromthe

hose,closetheabrasiveballvalve.

Makesurethegasketisinplaceafterthe

Besuretocatchtheunspentabrasive

3.Opentheabrasiveballvalve,thenopenthedump

valveuntilthepotpressuregaugereads0psi.

Closetheabrasiveballvalveanddumpvalve.

NOTE:

NOTE: NOTE:

Iftheuntilwillbeshutdownformorethan24

hours,proceedtothenextstep.

4.Disconnecttheabrasiveballvalvecam-lockby

removingthecouplerpinsandpullingtherings

outanduptopullthetwocamsawayfromthe

groove.

Short-termshutdownisnowcomplete.

NOTE:

NOTE: NOTE:

neededforeachbagofabrasivestillinthepot.

Coverthebucketsduringstoragesodebrisdoes

notcontaminatetheabrasive.

Estimatethata5gallonpailwillbe

334666B 19

Page 20

Operation

8.Engagethebungpintoholdthebungopenand

allowairtoenter.

9.Opentheabrasiveballvalveandushthepotof

anyremainingabrasivematerial.

10.Closethepotbungandconnectthe

abrasivehose.Relievepressure

tocompletesystemshutdown(see

PressureReliefProcedure,page8).

NOTE:

NOTE: NOTE:

beexposedtotemperaturesbelowfreezing.See

WinterizingtheEquipment,page21.

Thesystemmustbewinterizedifitwill

20 334666B

Page 21

Operation

Winterizing

Winterizing Winterizing

Vapor-AbrasiveBlastersmustbewinterized

wheneverthereisapossibilityoffreezing

temperaturesduringstorage.Itisimperativethat

youanticipatethepossibilityofafreezeandalways

protecttheunitduringfallandwinterseasons,evenif

beingstoredonlyovernight.

1.Makesureallofthewaterhasbeendrained

fromthepot.Reconnecttheabrasivehoseafter

drainingthepot.

2.Makesurethepotbungisintheclosedposition.

Thiswillpreventdebrisfromenteringthepot

duringstorage.

3.Drainthewatertankbydisconnectingthepump

inlethoseandopeningtheinletballvalve.

the

Equipment

the the

Equipment Equipment

5.TurntheselectorvalvetoRINSEandopenthe

rinseball-valve.Whileholdingtherinsehose

overthepot,runthepumpuntilwindshieldwash

comesoutoftherinsehose.

6.Movetheselectorvalveintotheotherthree

positions(WASH,BLAST,andFILL).Conrm

thattheinternalwatertubingllswithwindshield

washbeforeturningtheselectorvalvetothenext

position.

NOTE:

NOTE: NOTE:

windshieldwashforfullprotection.

7.EngagetheE-Stop.

8.Reconnectthepumpinlethosetotheinletball

valve.

9.Add1–2gallons(4–8liters)ofwindshieldwash

tothewatertank.Makesurethattherinse

ball-valveandthedrainball-valveareleftopen.

All3/8in.tubingshouldbelledwith

NOTE:

NOTE: NOTE:

state,andlocalregulations.Inaddition,ifthe

watercontainsarustinhibitor,youmaywantto

retainandpreservethewaterduetotheexpense

oftheinhibitor.

4.Drainthepumpinlethose,theninserttheend

intoawindshieldwashcontainer.Choosea

windshieldwashwitharatingthatwillprotectthe

equipmentforthelowesttemperaturesinyour

area.

Alldisposalsmustcomplywithnational,

NOTICE

NOTICE NOTICE

Wheniceformsbehindtheseals,thesealscan

becomedamaged.Duringstorage,positionall

ball-valvesintheopenposition.

334666B

21

Page 22

Troubleshooting

Troubleshooting

Troubleshooting Troubleshooting

Thepotwillnotproperly

pressurize.

Problem

Problem Problem

Theairsupplyisinadequate.Makesuretheairinletpressuregauge

TheEmergencyStopisengaged.DisengagetheEmergencyStop.

Inadequatewatersupplytothe

pump.

Thepotpressureregulatorisset

toolow.

Thepotbungcannotsealproperly.

TheAuto-Ventvalvewillnotseal.

Thepotpressurereliefvalveis

dischargingwater.

Cause

Cause Cause

reads100-125psi.Ifthegaugedoes

notread100–125psi,checktheair

compressorforpropersetup.

Makesurethewatertankisfullandthe

inletballvalveisopen.

Increasethesettingonpotpressure

regulator.

Cleanallabrasivefromthebungand

seal.Makesurethebungspringislifting

andthebungisrmlyagainsttheseal.If

cleaningdoesnotsolveissue,replace

bungseal.

SeeCleaningtheAuto-VentValve,page

31.

Decreasethepotpressureto145psi

(10.3bar,1.03MPa)orless.Ifthevalve

weepsorrelievesat145psi,replace

valve(Kit17D785).

Solution

Solution Solution

Theblastpressurewillnot

reachthedesiredsetpoint.

22

Thepotorpumpisleaking

pressure.

Thepotpressureregulatoris

malfunctioning.

Theairsupplyisinadequate.Makesuretheairinletpressuregauge

Themainairregulatoris

malfunctioning.

Theblastairregulatoris

malfunctioning.

Makesuretheabrasiveballvalveandthe

dumpvalveareclosed.Ifpotpressure

gaugestillcreepsdownward.See

CheckingforLeaks,page26.

Replacethepotpressureregulator

assembly(17C132).

reads100-125psi.Ifthegaugedoes

notread100–125psi,checktheair

compressorforpropersetup.

SeeRepairingtheMainAirRegulator,

page28(EQ600–Kit17C131,EQ300

–Kit17C129).

Replacetheblastairregulator(Kit

17C625).

334666B

Page 23

Troubleshooting

Problem

Problem Problem

Noabrasiveowsfromthe

nozzleduringblastmode.

Cause

Cause Cause

Thepotdoesnothaveasufcient

amountofabrasive.

Thesystemisnotproperlysetup.

Thereisanobstructioninthe

mediacircuit.

Thediaphragmvalveisnot

working.

Thereisblockageinsidethepotor

insidetheabrasivehosebetween

thepotandthepanel.

Solution

Solution Solution

SeeRellingthePotwithAbrasive,page

18.

SeeSettingUptheEquipment,page11.

Makesurethepotpressureisproperly

set.Thepotpressuremustbeset30

psiabovetheblastpressure.Makesure

theselectorvalveissettoBLAST.The

abrasiveballvalvemustbeopen.The

abrasivemeteringvalvemustbeatleast

1/8turnopen.

SeeFlushingtheDiaphragmValve,page

29.

SeeRepairingtheDiaphragmValve,

page30.

Makesuretheballvalveisclosed,then

disconnectthecam-lockcoupler.Open

theabrasiveballvalveslightlyandmake

sureabrasiveisowingformtheabrasive

hose.Ifnot,followtheshutdown

procedure(seeShuttingDown,page19).

Thoroughlyushthepotandthemedia

hoseafterdrainingmediaandwater.

Noblastairowwhenthe

blastcontrolisengaged.

Thewaterpumpcycles

whiletheblastcontrol

engaged.

Noblastairowwhenthe

blastcontrolisengaged.

Thewaterpumpdoes does

cyclewhiletheblastcontrol

engaged.

does

Theblastregulatorisnotadjusted

tothecorrectpressure.

Thetubingfromthemain

airregulatorisnotproperly

connected.

Theblastairregulatoris

malfunctioning.

Themainairregulatoris

malfunctioning.

Theairsupplyisinadequate.Makesuretheairinletpressuregauge

not

not not

TheEmergencyStopisengaged.DisengagetheEmergencyStop.

Theelectricblastcontrolcircuitis

malfunctioning.

Adjusttheblastregulatortothedesired

pressurewhiletheblastcontrolis

engaged.

Conrmthatthetubingfromtheblast

regulatortothemainairregulatoris

intact.SeeHoseSchematic,page42.

Replacetheblastairregulator(Kit

17C625).

SeeRepairingtheMainAirRegulator,

page28(EQ600–Kit17C131,EQ300

–Kit17C129).

reads100-125psi.Ifthegaugedoes

notread100–125psi,checktheair

compressorforpropersetup.

Inspectthehosecablefordamagedor

shortedwiring.Checkthebatteryand

controlpanelconnections.Makesurethe

DCpowersourceis12V.Checkthe3A

fuseinsidethecontrolpanel,andreplace

itifnecessary.Checkthecurrentowin

thecircuit.Ifcurrentexists,replacethe

relay(EQ5179).

334666B 23

Page 24

Troubleshooting

Problem

Problem Problem

Theblastcontrolisnot

engagedbutblastingstill

occurs.

Theblastspraypatternis

irregular.

Cause

Cause Cause

Thepneumaticblastcontrolcircuit

ismalfunctioning.

Themainairregulatorisstuck

open.

Theblastcontroltubingisnot

connectedproperly.

Electricblastcontrolcircuitis

malfunctioning.

Pneumaticblastcontrolcircuitis

malfunctioning.

Incorrectabrasiveisbeingused.

Thepotdoesnothaveasufcient

amountofabrasive.

Solution

Solution Solution

SeePneumaticBlastControlCircuit,

page27.

SeeRepairingtheMainAirRegulator,

page28(EQ600–Kit17C131,EQ300

–Kit17C129).

Ensureairtubingisroutedandconnected

properly.SeeHoseSchematic,page42.

Inspecthosecablefordamagedor

shortedwiring.Checkbatteryandcontrol

panelconnections.EnsureDCpower

sourceis12V.Check3Afuseinside

controlpanelandreplaceitifnecessary.

Checkcurrentowincircuit,ifcurrent

exists,replacerelay(EQ5179).

SeePneumaticBlastControlCircuit,

page27.

Usethecorrectabrasive.See

MeteringValveSettings,page16.

Rellthepotwithabrasive.See

RellingthePotwithAbrasive,page18.

Thepotpressuresettingis

incorrect.

TheAuto-Ventvalvedoesnotvent

airwhenthepotislled.

Thediaphragmvalveis

malfunctioning.

Thereisblockageinsidethepotor

insidetheabrasivehosebetween

thepotandthepanel.

Performthepressurereliefprocedure

(seePressureReliefProcedure,page8)

andresetpotpressure(see

SettingUptheEquipment,page11).

MakesuretheAuto-Ventvalve

isworking.PerformtheAutoVentcleaningprocedure(see

CleaningtheAuto-VentValve,page31).

Performthediaphragm

ushprocedure(see

FlushingtheDiaphragmValve,page29).

Ifushingdoesnotsolveproblem,see

RepairingtheDiaphragmValve,page30.

Makesuretheballvalveisclosed,then

disconnectthecam-lockcoupler.Open

theabrasiveballvalveslightlyandmake

sureabrasiveisowingformtheabrasive

hose.Ifnot,followtheshutdown

procedure(seeShuttingDown,page19).

Thoroughlyushthepotandthemedia

hoseafterdrainingmediaandwater.

24

334666B

Page 25

Troubleshooting

Problem

Problem Problem

Astronghoserecoiloccurs

frequentlywhentheblast

controlswitchisengaged.

Cause

Cause Cause

Theunitisnotonalevelsurface.Placetheunitonalevelsurface.Ifthis

isimpossible,theAuto-Ventmustbeon

thehighersideoftheunit.

Theinitialpotpressureisnotset

correctly.

TheAuto-Ventismalfunctioning.Performauto-ventclean-

Thediaphragmneedstobe

ushed.

Conrmthattheauto-ventvalveis

workingandsetinitialpotpressure30

psi(2.0bar,0.20MPa)abovetheblast

pressure.

ingprocedure(see

CleaningtheAuto-VentValve,page31).

Performthediaphragm

ushprocedure(see

FlushingtheDiaphragmValve,page29).

Ifushingdoesnotsolvetheproblem,see

RepairingtheDiaphragmValve,page30.

Solution

Solution Solution

334666B 25

Page 26

Troubleshooting

ti24825a

Troubleshooting

Troubleshooting Troubleshooting

Checking

Checking Checking

1.Openthedumpvalve.Checkpotpressure

gauge,thenclosethedumpvalve.

Lookatthepressuregaugetoconrmthatall

pressurehasbeenrelievedfromthepot.

for

Leaks

for for

Leaks Leaks

Examples

Examples Examples

3.Makesurethebungisengagedwithitsseal.

TurntheselectorvalvetoWASH,thenopenthe

abrasiveballvalvetopressurizethepot.Setthe

potpressureto145psi(9.9Bar,0.99MPa).

4.Checkthewaterpumptoconrmthatnowater

isleakingfromtheTSLllport.

NOTE:

NOTE: NOTE:

pressurizes.Ifthepumpdoesnotstall,replace

theseals.Refertothepumpmanualforrepair

information.

5.Checkforanywaterleakingfromeithercheck

valve.Ifacheckvalveisleaking,itmustbe

repairedorreplaced.Ifthevalvesaredamaged,

thepotwillnotbeabletomaintainpressure.

Also,checkthepotpressurereliefvalve.Ifthe

valveisweepingatpotpressuresof145psior

less,itneedstobereplaced.

Thepumpshouldstallafterthepot

2.Disconnectthetubingattheblastcheckvalve(L)

andatthellportcheckvalve(ZG).

6.Closetheabrasiveballvalve,thendisconnect

thequickcouplerandconrmthattheballvalve

isnotleaking.Replacetheabrasiveballvalve

ifitisleaking.

26 334666B

Page 27

Troubleshooting

Pneumatic

Pneumatic Pneumatic

1.AttheAir-Relay,disconnectthepush-to-connect

tubingandcheckthetriggercircuit(fromtheblast

controlhandle).

Blast

Blast Blast

Control

Control Control

Circuit

Circuit Circuit

2.Withtheblastcontrolactivated,conrmthat

thereisairowingfromthedisconnectedtube.

NOTE:

NOTE: NOTE:

pressurebuttheairvolumeisreduceddueto

thesizeofthettingsandtubing.Ifyoudonot

getsupplyairpressure,checktheblastcontrol

handleforproperoperation,andchecktheblast

controlhosestomakesuretheyarenotkinked

orinternallyblocked.

3.Checkthein-linelterattheindustrialinterchange

nippleconnectiononthesideofthepanel(where

youattachtheblastcontrolhose).

4.Ifthepreviousstepsdonotxtheissue,replace

theairrelay(KitEQ5179).

Theairowshouldbeatsupplyair

334666B

27

Page 28

Repair

Repair

Repair Repair

Repairing

Repairing Repairing

NOTE:

NOTE: NOTE:

(EQ600)orKit17C129(EQ300).

1.PerformPressureReliefProcedure,page8.

2.Makesurealloftheairpressureisrelievedin

3.Useacrescentwrenchthatcanopento2in.(5

RepairpartsareavailableinKit17C131

theunit.Removethewaterseparatorlterfor

accesstothepistoncoverandreturnspring.

cm)tounscrewthepistoncover.

NOTE:

NOTE: NOTE:

the

Main

the the

Main Main

Thereisaspringinsidethiscover.

Air

Air Air

Regulator

Regulator Regulator

4.Unscrewthediaphragmcoverforaccesstothe

diaphragmandtotheendofthepistonshaft.

5.Removethediaphragmandinspectforany

cracksortears.Replacethediaphragmif

necessary.

6.Carefullyremovethespringandpistonassembly,

thencleanoutanydebrisinthebodyofthe

regulator.

7.Pushthepistonshaftandremovethepistonfrom

theoppositeendoftheregulatorhousing.

8.Inspectthepistonforanyforeignmatterthatmay

havebeenthecauseforthepistontostayopen.

9.Inspectforanydamagetothepistonshaftwhere

itinteractswiththediaphragmcup.

NOTE:

NOTE: NOTE:

maincheckvalveisnotsealing.Contactyour

distributorifthishappens.

Excessivewearhereindicatesthe

28 334666B

Page 29

Repair

Flushing

Flushing Flushing

Thisprocedurecanbeperformedwiththecomponent

stillmountedinthepanel.

Iflarge-gritabrasiveorotherforeignmatterbecome

lodgedinthediaphragmvalve,itwillbecome

necessarytoushthevalve.Thisisasimple

procedure;however,itdoescausethereleaseofa

largevolumeofairtoescapethroughthereleased

quickcoupling.Youneedtobepreparedforthe

releaseofairbypullingthequickcouplergrommet

outofitsgroovesothatitdoesnotgetlost.

1.OperatetheunitinWASH(see

UsingtheWashFeature,page17)until

allabrasiveclearsfromtheblasthose.

the

Diaphragm

the the

Diaphragm Diaphragm

Valve

Valve Valve

3.Disconnectthequickcouplingattheabrasive

ballvalve(notatthebottomofthepot).

4.TurntheselectorvalvetoWASH.Thiswillpump

wateroutofthequickcouplerandallowyou

toreachupinsideandclearallabrasiveand

removethegrommet.

5.Makesurenothingisinthepathoftheopen

quickcoupler,thenengagetheblastcontrol

brieyandseveraltimes.

NOTE:

NOTE: NOTE:

cam-lockcoupling.Ifthisdoesnotoccur,the

diaphragmvalveismalfunctioning.Replace

entirediaphragmcanister(EQ5140–EQ600,

EQ5142–EQ300).

Highowairshouldescapethroughthe

2.Closetheabrasiveballvalve,thenturnthe

selectorvalvetoRINSE.

6.Holdthemaleendofthequickcouplerupto

thewatercomingfromthecam-lockendofthe

coupler.Cleanoffanydirtorabrasive.

7.TurntheselectorvalvetoRINSEtostoptheow

ofwater.

8.Re-insertthegrommetintoitsinternalgroove

insidethecam-lock.

9.Reconnectthequickcoupler.Ifproperlycleaned

andconnected,thereshouldbenoleaksatthe

couplerduringoperation.

334666B 29

Page 30

Repair

1

2

3

4

Repairing

Repairing Repairing

NOTE:

NOTE: NOTE:

–EQ600)canbereplacedwithoutremovingthe

assemblyfromthepanel.Youwillneedan8mm

AllenwrenchfortheEQ600Sanda6mmforthe

EQ300S.

1.PerformthePressureReliefProcedure,page8.

Thediaphragm(17C127–EQ300,17C128

the

Diaphragm

the the

Diaphragm Diaphragm

Valve

Valve Valve

3.Replacethediaphragm(naturalrubber

compound)andhand-tightenitasfaraspossible

toestablishthealignmentwiththecanister.

NOTE:

NOTE: NOTE:

diaphragmandtheactuator.Keeptheshims

andreusethem(theydonotcomewith

thereplacementdiaphragm).Donotcause

anypre-loadortorqueonthediaphragmby

over-tighteningitinamisalignedposition.

4.Insertall4Allen-headcapboltsbutdonottighten

them.

5.Applymorethan80psi(5.5Bar,MPa)air

pressuretotheregulatorinlettocausethepiston

toretract.

6.Withthepistonretracted,hand-tightenthe4

Allen-headcapbolts.

7.Releasetheairpressure.

8.Tightenthecap-boltsinanalternatingpattern

(seeimagebelow)to80+/-8in-lb(9+/-0.9N•m).

Thiswillcauseaslightbulgeinthediaphragm

betweenthecanisterandthestainlesssteel

casting.

Therearetwoshimsbetweenthe

2.Loosenall4Allen-headcap-boltsevenlyand

thenremovethemcompletelywhilesupporting

thecanisterofthediaphragmvalve.

9.Testandconrmthattheunitisworkingproperly.

NOTE:

NOTE: NOTE:

chargetheequipment–thereisnoneedtouse

abrasiveforthistest.

Thiscanbedoneusingonlywaterto

30 334666B

Page 31

Repair

Cleaning

Cleaning Cleaning

Afterthepop-uphasbeenclosedwhilellingthepot,

theauto-ventvalveshouldreleaseair(youshouldbe

abletoheartheairventing).

Thepotpressuregaugewillnotshowpressureuntil

theauto-ventvalvehasbledalloftheairandsealed.

Iftheauto-ventvalvedoesnotreleaseair,orifwater

leaksfromthestemduringthellprocess,thestem

valvemaybecloggedorfaulty.

Performthefollowingproceduretocleanaclogged

auto-ventvalve.

1.Trytopushandquicklyreleasethevalvewith

yournger.Ifthatdoesnotcausethevalveto

seal,openthedumpvalvetoreleaseallofthe

pressureinthepot.

2.TurntheselectorvalvetoRINSE.

the

Auto

the the

Auto Auto

Vent

- --Vent Vent

Valve

Valve Valve

3.Usetherinsehosetoforcewaterbackwardsinto

thevalvestem.

NOTE:

NOTE: NOTE:

theissue,replacethewholevalveassembly

(EQ1860).

Thevalvestemitselfisinternallyattachedtothe

oatanditisnoteld-serviceable.Donottryto

removethevalvestem.Damagetotheequipment

willoccur.

Ifthepreviousstepsfailtoresolve

NOTICE

NOTICE NOTICE

334666B 31

Page 32

Repair

Replacing

Replacing Replacing

FIRE

AND

FIRE FIRE

AND AND

Toreducetheriskofreandexplosion,thebattery

mustbereplacedinanon-hazardouslocation.

Useonlyanapprovedreplacementbattery(see

table).Useofanunapprovedbatterywillvoid

Graco’swarranty.

Replace

Replace Replace

1.Unscrewcablefromthebackofthereedswitch

assembly.

2.Removethecablefromthetwocableclips.

the

DataTrak

the the

DataTrak DataTrak

EXPLOSION

EXPLOSION EXPLOSION

Battery

Battery Battery

HAZARD

HAZARD HAZARD

Battery

Battery Battery

3.RemovetheDataTrakmodulefromthebracket.

Takethemoduleandattachedcabletoa

non-hazardouslocation.

4.Removethetwoscrewsonthebackofthe

moduletoaccessthebattery.

5.Disconnecttheusedbatteryandreplaceitwith

anapprovedbattery.

Energizeralkaline#522

Vartaalkaline#4922

Ultralifelithium#U9VL

Duracellalkaline#MN1604

Approved

Approved Approved

Batteries

Batteries Batteries

32 334666B

Page 33

Repair

Replacing

Replacing Replacing

FIRE

AND

FIRE FIRE

AND AND

Toreducetheriskofreandexplosion,thefuse

mustbereplacedinanon-hazardouslocation.

Useonlyanapprovedreplacementfuse(see

table).UseofanunapprovedfusewillvoidGraco’s

warranty.

Replace

Replace Replace

1.Removethescrew,metalstrap,andplastic

holder.

2.Pullthefuseawayfromtheboard

3.Replacewithanapprovedfuse.

the

DataTrak

the the

DataTrak DataTrak

EXPLOSION

EXPLOSION EXPLOSION

Fuse

Fuse Fuse

HAZARD

HAZARD HAZARD

Fuse

Fuse Fuse

DataTrak

DataTrak DataTrak

Number

Number Number

289822

Allotherpart

numbers

Approved

Approved Approved

Part

Part Part

*Series

*Series *Series

Fuses

Fuses Fuses

Letter

Letter Letter

AorB

Candlater

A

Bandlater24V216

Fuse

Required

Fuse Fuse

Required Required

24C580

24V216

24C580

334666B 33

Page 34

Parts

EQ200T

Parts

Parts Parts

EQ200T

EQ200T EQ200T

and

EQ400T

and and

EQ400T EQ400T

EQ200T EQ200T

and

EQ400T

and and

EQ400T EQ400T

Parts

Parts Parts

List

List List

Ref.

Ref. Ref.

34 334666B

Part

Part Part

1

2

Description

Description Description

PRESSUREPOT,6.5

cf,assy

ENCLOSURE,blast

Qty.

Qty. Qty.

1

1

Ref.

Ref. Ref.

Part

Part Part

Description

Description Description

EQ200TModels

EQ400TModels

Qty.

Qty. Qty.

Page 35

Parts

Ref.

Ref. Ref.

Part

Part Part

4LABEL,branding1

5

17D786KIT,replacement,hose

17D787KIT,replacement,

7

EQ5149EQ200TModels

EQ5135EQ400TModels

9

EQ5183CABLE,cord,electric,

10

EQ1943EQ200TModels

Description

Description Description

restraint

couplerpin

VALVE,abrasive,

media

blastcontrol

HOSE,abrasivemedia

Qty.

Qty. Qty.

1

1

1

1

Ref.

Ref. Ref.

Part

Part Part

EQ5208EQ400TModels

12ADAPTER,cam

EQ1934EQ200TModels

EQ1046EQ400TModels

14206994

16

EQ1881HOSE,tubing,natural,

17111743

18

EQ1273HOSE,tubing,natural,

19

EQ1151

22

EQ1519BOLT,hexhead,ss,

Description

Description Description

groove,typeF,ss

FLUID,TSL,8oz.

bottle

1/4in.

WASHER,at

3/8in.

NUT,nylok,ss,3/8–164

1/2-13x1–1

Qty.

Qty. Qty.

1

1

2

4

4

4

334666B 35

Page 36

Parts

12

Enclosure

Enclosure Enclosure

Torquettingto35–40ft-lb(47–54N•m).

36 334666B

Page 37

Parts

Enclosure

Enclosure Enclosure

Ref.

Ref. Ref.

1

224V672PUMP,water,sst,3:11

3KIT,blastplumbing1

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

▲20

21127918

22127929

25

26125420

27

30

31127932

34

38

43127917

44111799

45

46

Parts

Parts Parts

Part

Part Part

EQ5109KIT,manifold

EQ5112

EQ5113

EQ1790PLUG,angedinlet,twist-lock

EQ1791CONNECTOR,angedinlet,

17C132REGULATOR,pump

17C625REGULATOR,blast,125psi

17C133KIT,gaugeandtting

EQ5108

EQ5125

EQ5110KIT,airlter,3/8in.tube

EQ5181

EQ5119REGULATOR,xed,80psi

EQ1840HOSE,clear,braided,3/8in.

EQ1527FITTING,holder,fuse,ATM

EQ1844FUSE,ATM,bladetype,3

17B751

EQ5160

EQ1115

EQ1759FITTING,stem,reducer,1/4

EQ5179

EQ1122FITTING,elbow,stem,3/8in.

List

List List

Description

Description Description

ENCLOSURE,ss,el,30in.x

24in.x12in.

KIT,blastcontrol,return1

KIT,blastcontrol,output1

twist-lock

KIT,E-stop,3/8in.npt1

VALVE,rinse,3/8in.npt1

VALVE,selector,5–way1

ID

type

amp

LABEL,safety

NUT,ange,serrated,m5

SCREW,sems,#6–32,3/8in.

sst

VALVE,needle,dose1

FITTING,bulkhead,M14x

1/4tube

BULKHEAD,connector,

union3/8in.

in.x1/4in.tube

SCREW,sems,#10–32,1.5

in.sst

RELAY,airpilot,blastcontrol1

SPACER,blastcircuit,1.5

NUT,ange,serrated,1/4–20

ss

SCREW,cap,hex,hd

SPACER,washer,shim,ss

Qty.

Qty. Qty.

1

1

1

1

1

1

3

1

1

2

1

1

1

4

13

1

2

1

2

6

2

3

Part

Ref.

Part Part

Ref. Ref.

47111639

48111831

49127908

50

51

EQ1121FITTING,elbow,stem,1/4in.

53

55

56

57

58

59

6017B912

6317D685KIT,replacement,doorlatch2

64122030

66

6724A592KIT,smarts,cyclecountonly1

68

69

70121022

71

7417D686

75

EQ1846COUPLER,interchange,

90KIT,repair,externallypiloted

17C129EQ200T

17C131EQ400T

91KIT,repair,diaphragmvalve1

17C127EQ200T

17C128EQ400T

EQ5140EQ200T

EQ5142EQ400T

Replacement Danger and Warning labels are

▲

available at no cost.

Description

Description Description

SCREW,cap,hex,hd

SCREW,cap,skt,buttonhd

NUT,ange,serrated,

#10–32,ss

BRACKET,pump

FITTING,elbow,street,90

degree,not,ss

FITTING,nipple,hex,not,ss,

1.5in.

COUPLER,sandblast,tank,

brass

COUPLER,cam,lock,type

D,ss,1.5in.

FITTING,elbow,

push-to-connect,1/2in.

FITTING,adapter

GROMMET,pump,mounting

CABLE,GCA,M12–5P

GASKET,EcoQuip,enclosure

GASKET,EcoQuip,enclosure

GASKET,EcoQuip,enclosure

FITTING,elbow,male,1/4

npt

BRACKET,EcoQuip,

DataTrak

DOOR,stay

straight

airregulator

Diaphragmvalve,fullcanister

Qty.

Qty. Qty.

4

2

4

1

3

1

3

1

1

1

1

1

1

1

2

2

1

1

1

1

1

334666B 37

Page 38

Parts

Trailers

Trailers Trailers

EQ200

EQ200 EQ200

Trailers

Trailers Trailers

EQ200

EQ200 EQ200

Parts

List

Parts Parts

List List

Part

Ref.

Part Part

Ref. Ref.

1

2

3

EQ1152WASHER,at,1/2,sst

4

EQ1519BOLT,hexhd,1/2x1–1/2,

5

EQ1475

6

EQ5131VALVE,watertank,shutoff,

Description

Description Description

TRAILER,GL7,hydraulic,

210cfm

TRAILER,GL7,electric,210

cfm

SYSTEM,blast,200,trailer

module

sst

NUT,lock,nyloninsert,1/2,

sst

3/4in.

Qty.

Qty. Qty.

1

1

1

8

4

4

1

Part

Ref.

Part Part

Ref. Ref.

7

EQ1848HOSE,water,EQ2040,3/4

8

EQ1872HOSE,airsupply,air

9

10

11

13

14

Description

Description Description

in.ID

compressor

FITTING,bushing,1x3/4

npt,sst

LABEL,VRM,Gracologo

FITTING,elbow,90degree

FITTING,nipple,hex,1npt,

sst

FITTING,elbow,45degree,

ss,1in.

38 334666B

Qty.

Qty. Qty.

1

1

1

2

1

1

1

Page 39

Parts

EQ4E03

EQ4E03 EQ4E03

Trailer

Trailer Trailer

EQ4E03

EQ4E03 EQ4E03

Ref.

Ref. Ref.

Parts

List

Parts Parts

List List

Part

Part Part

1

2

3

EQ1152WASHER,at,1/2,sst

4

EQ1519BOLT,hexhd,1/2x1–1/2,

5

EQ1475

Description

Description Description

TRAILER,GL10,electric,

375cfm

SYSTEM,blast,400,trailer,

module

sst

NUT,lock,nyloninsert,1/2,

sst

Qty.

Qty. Qty.

1

1

8

4

4

Part

Ref.

Part Part

Ref. Ref.

6

EQ5131KIT,tank,shutoffvalve

7

EQ1848HOSE,water,EQ2040,3/4

8

EQ1941HOSE,aircompressorto

9

12

Description

Description Description

in.ID

control

LABEL,VRM,GracoLogo

FITTING,elbow,street,

1–1/2npt,ss

334666B 39

Qty.

Qty. Qty.

1

1

1

2

1

Page 40

Parts

EQ4E04

EQ4E04 EQ4E04

Trailer

Trailer Trailer

EQ4E04

EQ4E04 EQ4E04

Ref.

Ref. Ref.

Parts

List

Parts Parts

List List

Part

Part Part

1

2

3

EQ1152WASHER,at,1/2,sst

4

EQ1519BOLT,hexhd,1/2x1–1/2,

5

EQ1475

6

EQ5131KIT,tank,shutoffvalve

7

EQ1848HOSE,water,EQ2040,3/4

8

EQ1941HOSE,aircompressorto

9

Description

Description Description

TRAILER,GL10,electric,

425cfm

SYSTEM,blast400trailer

module

sst

NUT,lock,nyloninsert,1/2,

sst

in.ID

control

LABEL,VRM,Gracologo

Qty.

Qty. Qty.

1

1

8

4

4

1

1

1

2

Part

Ref.

Part Part

Ref. Ref.

12

13

14

15

16

17VALVE,ball,vented,.7501

18

19

Description

Description Description

FITTING,tee,1–1/4npt,sst

FITTING,elbow,street,

1–1/4npt,sst

FITTING,nipple,hex,1–1/4

npt,sst

FITTING,coupler,reducing,

fpt,sst

FITTING,reducer,1–1/4x

3/4in.

FITTING,hose,air,king,3/4

in.

FITTING,ball,vented

40 334666B

Qty.

Qty. Qty.

1

1

2

1

1

1

1

Page 41

Parts

1

Pressure

Pressure Pressure

Pot

Pot Pot

Pressure

Pressure Pressure

Ref.

Ref. Ref.

1

2

3KIT,pressurepot,dump

Pot

Parts

Pot Pot

Parts Parts

Part

Part Part

102901TEE,pipe

123724

166469NIPPLE,pipe,hex

EQ1034

EQ1500FITTING,elbow,swivel,

EQ1834FITTING,connector,

EQ1778FITTING,elbow,street,

115813

190724NIPPLE,sst

EQ1003VALVE,ball,fullport,

EQ1012FITTING,nipple,barb,

List

List List

Description

Description Description

PRESSUREPOT,blast,

6.5cubicft.

KIT,pressurepot,ll

port

FITTING,nipple,hex,

1/2in.nptx3/8in.npt

VALVE,check,in-line,

ss316

male,3/8in.

straight,male

1/2npt,sst

valve

FITTING,streetelbow,

3/4in.npt

npt,ss

hose,3/4in.

Qty.

Qty. Qty.

1

1

1

Ref.

Ref. Ref.

Part

Part Part

4KIT,pressurepot,

17D785KIT,replacement,valve

115813

17D789KIT,replacement,valve,

123514

516308

5

EQ5137KIT,pressurepot,ush

6

EQ5148

7

EQ1360HOSE,clear,braided,

817D790KIT,replacement,

917D741KIT,replacement,

Applythreadsealanttopipethreads.

Description

Description Description

auto-vent

FITTING,streetelbow,

3/4npt

auto-vent

FITTING,tee,run,3/4

in.,mff,ss,3k

FITTING,bushing,

reducer,sst

valve

KIT,pressurepot,

unequaltee

3/4in.ID

handway

pop-up

Qty.

Qty. Qty.

1

1

1

3

1

1

334666B

41

Page 42

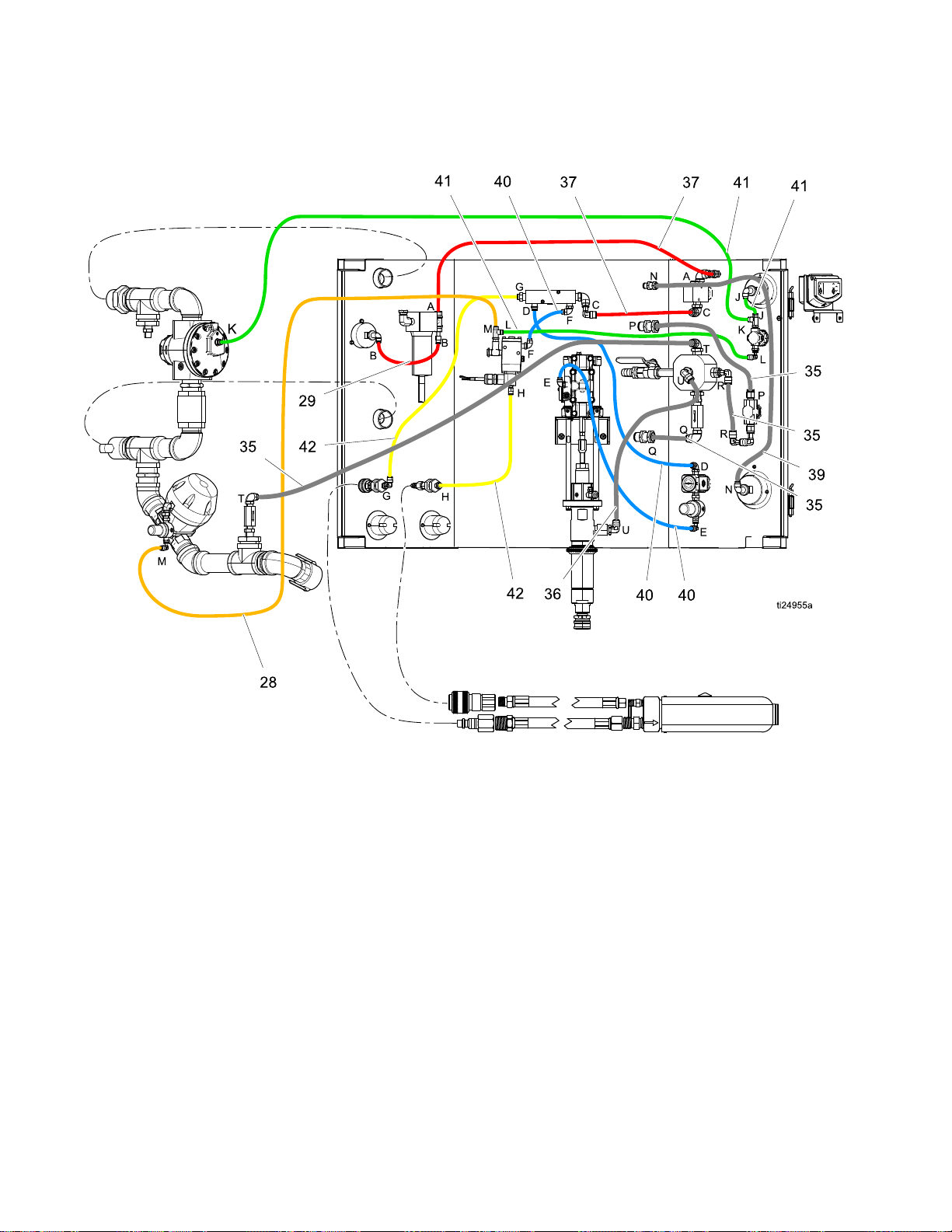

HoseSchematic

Hose

Hose Hose

Schematic

Schematic Schematic

Ref.

Ref. Ref.

28

29

35

35

35

35

37

37

39

Part

Part Part

EQ1296

EQ1882

EQ1273

EQ1273

EQ1273

EQ1273

EQ1297

EQ1273

EQ1881

Cut

Cut Cut

42.0in.

16.0in.

12.25in.

2.88in.

5.5in.

21.0in.

24.5in.

2.25in.

21.75in.

Length

Length Length

Ref.

Ref. Ref.

40

40

41

41

41

41

42

42

42

Part

Part Part

EQ1883

EQ1883

EQ1884

EQ1884

EQ1884

EQ1884

EQ1885

EQ1885

Cut

Cut Cut

20.75in.

11.25in.

19.88in.

32.0in.

7.38in.

10.5in.

34.5in.

17.0in.

Length

Length Length

334666B

Page 43

VaporAbrasiveBlastSystemsandAccessories

Vapor

Vapor Vapor

Systems

Systems Systems

EcoQuip

EcoQuip EcoQuip

Model

Model Model

EQ

EcoQuip

EcoQuip EcoQuip

Model

Model Model

EQ

Abrasive

Abrasive Abrasive

and

and and

Skid

Skid Skid

Series

Series Series

100M

1=100

3=300

6=600

Trailer

Trailer Trailer

Series

Series Series

2=200

series

4=400

series

Systems

Systems Systems

Package

Package Package

0=BarePackage(noblasthoseornozzle)M=Mobileunit(100seriesonly)

E=Completepackagewith15m(50ft)blasthose,

nozzle—ElectricBlastControl

P=CompletePackagewith15m(50ft)blasthose,

nozzle—PneumaticBlastControl

Systems

Systems Systems

Brakes

Brakes Brakes

2H03

H=HydraulicBrakes

available on 400 series)

E=ElectricBrakes

Blast

Blast Blast

Accessories

Accessories Accessories

(blast

hose

and

(blast (blast

hose hose

nozzle

and and

nozzle nozzle

Package

Package Package

(not

0=BarePackage

nozzle)

E=CompletePackage

m) blast hose, nozzle — Electric blast

control

P=CompletePackage

m) blast hose, nozzle — Pneumatic

blast control

type)

type) type)

(blasthoseandnozzletype)Compressor Compressor

(no blast hose or

Conguration

Conguration Conguration

S=SkidUnit(notavailableon

100series)

C=Nocrashframeorwatertank

(notavailableon100series)

with 50 ft (15

with 50 ft (15

Compressor

Conguration

Conguration Conguration

3=Tier3Compliant

(only available on

400 series)

4=Tier4iCompliant

334666B 43

Page 44

VaporAbrasiveBlastSystemsandAccessories

Mobile/Skid

Mobile/Skid Mobile/Skid

Model

Model Model

EQ100M100Series

EQ10EM100Series

EQ10PM100Series

Model

Model Model

EQ300S300Series

EQ300C300SeriesNoskid/crashframeorwatertank,barepackage

EQ30ES300SeriesCompletepackage,electricblastcontrol

EQ30EC300SeriesNoskid/crashframeorwatertank,completepackage,electricblastcontrol

EQ30PS300SeriesCompletepackage,pneumaticblastcontrol

EQ30PC300SeriesNoskid/crashframeorwatertank,completepackage,pneumaticblastcontrol

Model

Model Model

EQ600S600Series

EQ600C600SeriesNoskid/crashframeorwatertank,barepackage

EQ60ES600SeriesCompletepackage,electricblastcontrol

EQ60EC600SeriesNoskid/crashframeorwatertank,completepackage,electricblastcontrol

EQ60PS600SeriesCompletepackage,pneumaticblastcontrol

EQ60PC600SeriesNoskid/crashframeorwatertank,completepackage,pneumaticblastcontrol

Units

Units Units

Series

Series Series

Series

Series Series

Series

Series Series

Description

Description Description

Mobileunit,barepackage

Mobileunit,completepackage,electricblastcontrol

Mobileunit,completepackage,pneumaticblastcontrol

Description

Description Description

Barepackage

Description

Description Description

Barepackage

100/300 complete packages include 1 in. ID, 4 –ply hose (15 meter long) and #7 standard nozzle.

600 complete packages include 1.25 in. ID, 2–ply hose and #8 high performance nozzle.

Trailer

Trailer Trailer

Model

Model Model

EQ2H04

EQ2HE4

EQ2HP4

EQ2E04

EQ2EE4

EQ2EP4

EQ4E03

EQ4EE3

EQ4EP3

EQ4E04

EQ4EE4

EQ4EP4

Units

Units Units

Description

Description Description

200series,hydraulicbrakes,barepackage,Tier4i

200series,hydraulicbrakes,completepackage,electricblastcontrol,Tier4i

200series,hydraulicbrakes,completepackage,Tier4i

200series,electricbrakes,barepackage,Tier4i

200series,electricbrakes,completepackage,electricblastcontrol,Tier4i

200series,electricbrakes,completepackage,pneumaticblastcontrol,Tier4i

400series,electricbrakes,barepackage,Tier3

400series,electricbrakes,completepackageelectricblastcontrol,Tier3

400series,electricbrakes,completepackagepneumaticblastcontrol,Tier3

400series,electricbrakes,barepackage,Tier4i

400series,electricbrakes,electricblastcontrol,Tier4i

400series,electricbrakes,completepackage,pneumaticblastcontrol,Tier4i

44

334666B

Page 45

VaporAbrasiveBlastSystemsandAccessories

Hoses

Hoses Hoses

Model

Model Model

EQ5237

EQ5235

EQ5236

EQ5234

EQ5077

EQ5084

EQ5082

EQ5073

EQ5071

EQ5080

Model

Model Model

17D786Hoserestraint

17D787

17C459

17C124

17C125Gasket,cam/groove,abrasiveblastline–1.25in.ID(EQ300)

17C453Gasket,cam/groove,abrasiveblastline–1.5in.ID(EQ600)

EQ5183Cable,battery

17D788Replacementhandle,pneumaticblastcontrol

17D791Replacementhandle,electricblastcontrol

Description

Description Description

BlastHoseExtension

BlastHoseExtension

BlastHoseReplacement

BlastHoseReplacement

BlastHoseExtension

BlastHoseExtension

BlastHoseExtension

BlastHoseExtension

BlastHoseReplacement

BlastHoseReplacement

Description

Description Description

Couplerpin

Blasthosecouplergasket,hoseend

Blasthosecouplergasket,machineend

Type

Type Type

Length

Length Length

15m(50ft)

15m(50ft)

15m(50ft)

15m(50ft)

30m(100ft)

30m(100ft)

15m(50ft)

15m(50ft)

15m(50ft)

15m(50ft)

Blast

Control

Blast Blast

Control Control

Pneumatic1.0in.

Electric1.0in.

Pneumatic1.0in.

Electric1.0in.

Pneumatic1.25in.

Electric1.25in.

Electric1.25in.

Pneumatic1.25in.

Pneumatic1.25in.

Electric1.25in.

ID

ID ID

Model

Model Model

EQ100,

EQ200,

EQ300

EQ400,

EQ600

Nozzles

Nozzles Nozzles

Model

Model Model

EQ1710Standard#7(EQ100,EQ300,EQ200T)

EQ1711Standard#8(EQ600,EQ400T)

EQ7073*Highperformance#7(EQ100,EQ300,EQ200T)

EQ7074*Highperformance#8(EQ600,EQ400T)

EQ5166

Description

Description Description

Nozzleextension,24in.

*Performance nozzles require 100 psi (7 bar, 0.7

MPa) or more air pressure at nozzle.

334666B 45

Page 46

VaporAbrasiveBlastSystemsandAccessories

Common

Common Common

Model

Model Model

17B186KIT,repair,pump

17C124

17C125

17C127KIT,repair,diaphragmvalve(EQ300)

17C128KIT,repair,diaphragmvalve(EQ100,EQ600)

17C129KIT,repair,regulator,air(EQ100)

17C131KIT,repair,regulator,air(EQ600)

17C453

17C459

17D790

17D789VALVE,auto-vent,3/4in.

17D785

17D786KIT,replacement,hoserestraint

17D787KIT,replacement,couplerpin

206994

Other

Other Other

Spare

Spare Spare

Accessories

Accessories Accessories

Parts

Parts Parts

Description

Description Description

KIT,gasket,hosecoupler

KIT,gasket,quickcoupler

KIT,gasket,quickcoupler

KIT,gasket,hosecoupler

GASKET,handway6in.x8in.blackne

KIT,replacement,pressurereliefvalve

ThroatSealLiquid

Model

Model Model

17C126PumpRetrotKit

24A592

Description

Description Description

DataTrakModuleandReedSwitch

46 334666B

Page 47

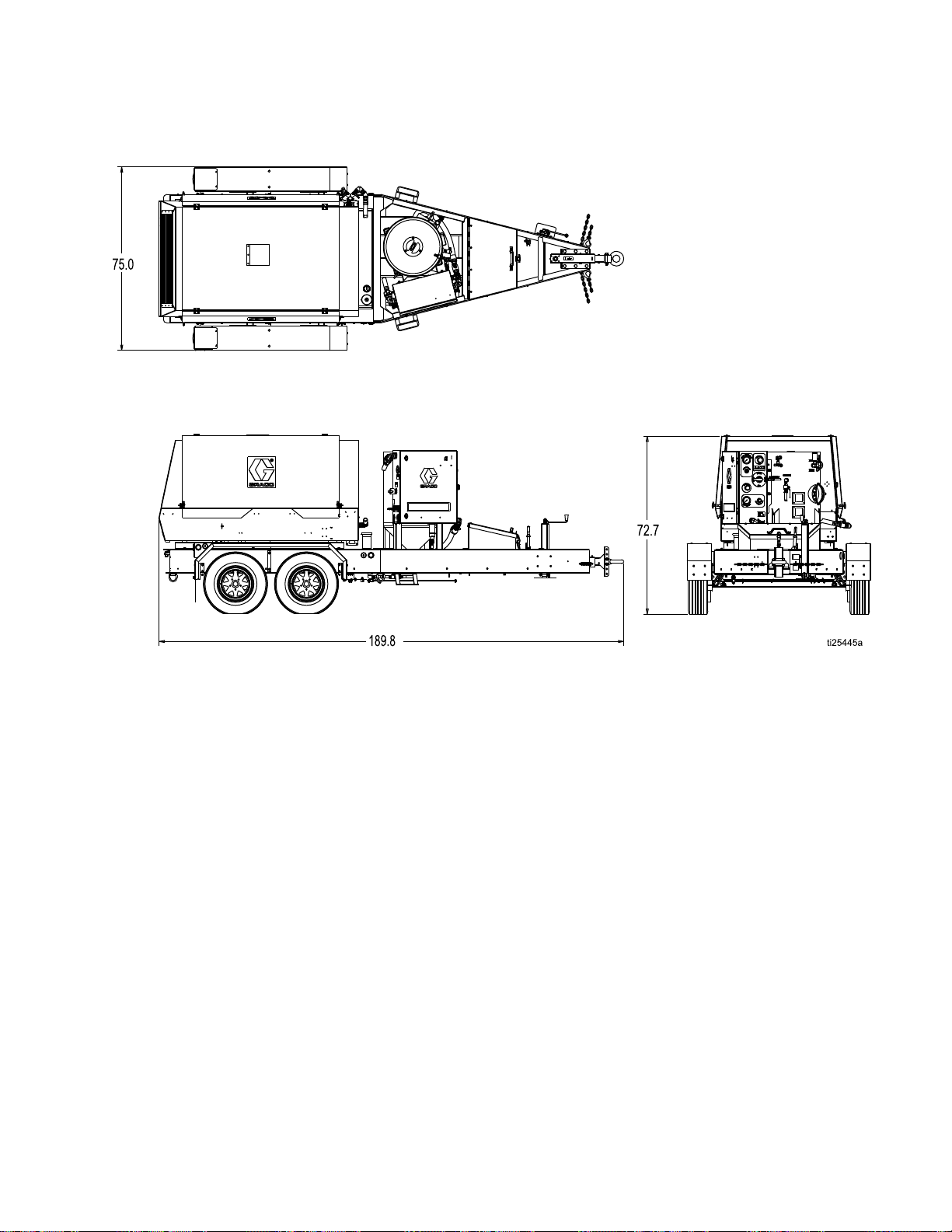

Dimensions

Dimensions

Dimensions Dimensions

334666B

47

Page 48

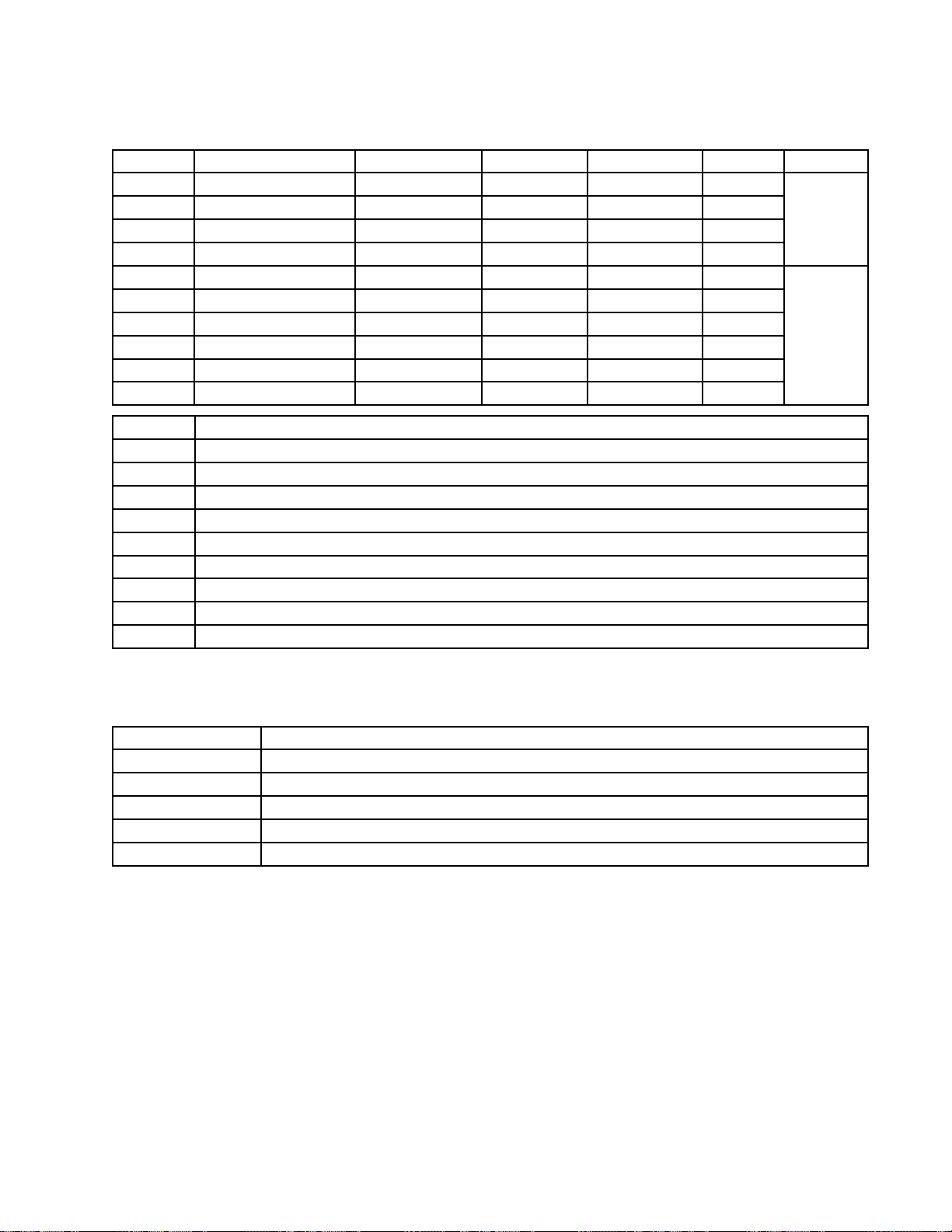

TechnicalSpecications

Technical

Technical Technical

EQ200T

EQ200T EQ200T

MaximumWorkingPressure125psi8.6bar,0.86MPa

OperatingTemperature35°–110°F1.6°–43.3°C

AirConsumption165–375cfm

BlastHoseSize

AbrasiveCapacity

GVWR

PressurePotVolume

WaterTankVolume100gallon378liters

Sound

Sound Sound

SoundPressureLevel133dB(A)133dB(A)

SoundPowerLevel139dB(A)139dB(A)

InstantaneousSoundPressureLevel131dB(C)131dB(C)

*All readings were taken at the maximum system blast pressure 125 psi (8.6 bar, 0.86 MPa) from the operator

position. The abrasive used was garnet and the substrate was steel. Tested in accordance with ISO 9614–2.

EQ400T

EQ400T EQ400T

MaximumWorkingPressure125psi8.6bar,0.86MPa

OperatingTemperature35°–110°F1.6°–43.3°C

AirConsumption375–600cfm

BlastHoseSize

AbrasiveCapacity

GVWR

PressurePotVolume

WaterTankVolume130gallon492liters

Sound

Sound Sound

SoundPressureLevel133dB(A)133dB(A)

SoundPowerLevel139dB(A)139dB(A)

InstantaneousSoundPressureLevel131dB(C)131dB(C)

*All readings were taken at the maximum system blast pressure 125 psi (8.6 bar, 0.86 MPa) from the operator

position. The abrasive used was garnet and the substrate was steel. Tested in accordance with ISO 9614–2.

Data*

Data* Data*

Data*

Data* Data*

Specications

Specications Specications

U.S.

U.S. U.S.

4.67–10.62m^3/min

1in.ID25.4mmID

400–500lb181–227kg

6160lb2794kg

6.5cubicfeet

U.S.

U.S. U.S.

10.62–17.0m^3/min

1.25in.ID31.75mmID

400–500lb181–227kg

11000lb4990kg

6.5cubicfeet

Metric

Metric Metric

184liters

Metric

Metric Metric

184liters

48 334666B

Page 49

Notes

Notes

Notes Notes

334666B 49

Page 50

Graco

Graco Graco

Components

Components Components

GracowarrantsallequipmentreferencedinthisdocumentwhichismanufacturedbyGracoandbearingthe

GracoorEcoQuipnametobefreefromdefectsinmaterialandworkmanshiponthedateofsaletotheoriginal

purchaserforuse.Gracowill,forthree(3)yearsfromthedateofsale,repairorreplaceanypartofthe

equipmentdeterminedbyGracotobedefective.Thiswarrantyappliesonlywhentheequipmentisinstalled,

operatedandmaintainedinaccordancewithGraco’swrittenrecommendations.

Thiswarrantydoesnotcover,andGracoshallnotbeliableforgeneralwearandtear,oranymalfunction,

damageorwearcausedbyfaultyinstallation,misapplication,abrasion,corrosion,inadequateorimproper

maintenance,negligence,accident,tampering,orsubstitutionofnon-Gracocomponentparts.NorshallGraco

beliableformalfunction,damageorwearcausedbytheincompatibilityofGracoequipmentwithstructures,

accessories,equipmentormaterialsnotsuppliedbyGraco,ortheimproperdesign,manufacture,installation,

operationormaintenanceofstructures,accessories,equipmentormaterialsnotsuppliedbyGraco.

Thiswarrantyisconditionedupontheprepaidreturnoftheequipmentclaimedtobedefectivetoanauthorized

Gracodistributorforvericationoftheclaimeddefect.Iftheclaimeddefectisveried,Gracowillrepairorreplace

freeofchargeanydefectiveparts.Theequipmentwillbereturnedtotheoriginalpurchasertransportation

prepaid.Ifinspectionoftheequipmentdoesnotdiscloseanydefectinmaterialorworkmanship,repairswillbe

madeatareasonablecharge,whichchargesmayincludethecostsofparts,labor,andtransportation.

THIS

WARRANTY

THIS THIS

WARRANTY WARRANTY

INCLUDING

INCLUDING INCLUDING

FOR

FOR FOR

A AAPARTICULAR PARTICULAR

Graco’ssoleobligationandbuyer’ssoleremedyforanybreachofwarrantyshallbeassetforthabove.The

buyeragreesthatnootherremedy(including,butnotlimitedto,incidentalorconsequentialdamagesforlost

prots,lostsales,injurytopersonorproperty,oranyotherincidentalorconsequentialloss)shallbeavailable.

Anyactionforbreachofwarrantyhereundermustbebroughtwithinthelatteroftwo(2)yearsofthedateofsale,

orone(1)yearafterthewarrantyperiodexpires.

GRACO

GRACO GRACO

AND

FITNESS

AND AND

FITNESS FITNESS

MATERIALS

MATERIALS MATERIALS

manufactured

manufactured manufactured

hose

hose hose

or ororother other

provide

provide provide

InnoeventwillGracobeliableforindirect,incidental,specialorconsequentialdamagesresultingfromGraco

supplyingequipmenthereunder,orthefurnishing,performance,oruseofanyproductsorothergoodssold

hereto,whetherduetoabreachofcontract,breachofwarranty,thenegligenceofGraco,orotherwise.

FORGRACOCANADACUSTOMERS

ThePartiesacknowledgethattheyhaverequiredthatthepresentdocument,aswellasalldocuments,notices

andlegalproceedingsenteredinto,givenorinstitutedpursuantheretoorrelatingdirectlyorindirectlyhereto,be

drawnupinEnglish.Lespartiesreconnaissentavoirconvenuquelarédactionduprésentedocumentseraen

Anglais,ainsiquetousdocuments,avisetprocéduresjudiciairesexécutés,donnésouintentés,àlasuitedeou

enrapport,directementouindirectement,aveclesprocéduresconcernées.

Extended

Extended Extended

IS

EXCLUSIVE,

IS IS

BUT

BUT BUT

PARTICULAR

MAKES

MAKES MAKES

OR

OR OR

by

by by

other

hose

hose hose

purchaser

purchaser purchaser

EXCLUSIVE, EXCLUSIVE,

NOT

LIMITED

NOT NOT

LIMITED LIMITED

PURPOSE.

PURPOSE. PURPOSE.

NO

WARRANTY,

NO NO

WARRANTY, WARRANTY,

FOR

FOR FOR

PARTICULAR

A AAPARTICULAR PARTICULAR

COMPONENTS

COMPONENTS COMPONENTS

Graco

(such

Graco Graco

(such (such

and

blast

and and

with

with with

nozzles),

blast blast

nozzles), nozzles),

reasonable

reasonable reasonable

Warranty

Warranty Warranty

AND

IS

IN

AND AND

TO

WARRANTY

TO TO

WARRANTY WARRANTY

AND

AND AND

PURPOSE,

PURPOSE, PURPOSE,

SOLD

SOLD SOLD

as

electric

as as

electric electric

are

are are

assistance

assistance assistance

LIEU

IS IS

IN IN

LIEU LIEU

OF

OF OF

DISCLAIMS

DISCLAIMS DISCLAIMS

BUT

BUT BUT

motors,

motors, motors,

subject

subject subject

IN

IN IN

NOT

NOT NOT

switches,

switches, switches,

making

in ininmaking making

for

for for

OF

ANY

OF OF

ANY ANY

MERCHANTABILITY

MERCHANTABILITY MERCHANTABILITY

ALL

ALL ALL

CONNECTION

CONNECTION CONNECTION

MANUFACTURED

MANUFACTURED MANUFACTURED

the

warranty,

to totothe the

warranty, warranty,

any

any any

EcoQuip

EcoQuip EcoQuip

OTHER

OTHER OTHER

IMPLIED

IMPLIED IMPLIED

compressors,

compressors, compressors,

claim

claim claim

WARRANTIES,

WARRANTIES, WARRANTIES,

OR

OR OR

WARRANTIES

WARRANTIES WARRANTIES

WITH

ACCESSORIES,

WITH WITH

ACCESSORIES, ACCESSORIES,

BY

GRACO.

BY BY

GRACO. GRACO.

engines,

engines, engines,

any,

if ififany, any,

of ofoftheir their

for

breach

for for

breach breach

™

™ ™

EXPRESS

EXPRESS EXPRESS

WARRANTY

WARRANTY WARRANTY

OF

MERCHANTABILITY

OF OF

MERCHANTABILITY MERCHANTABILITY

These

These These

trailer

components,

trailer trailer

their

manufacturer.

manufacturer. manufacturer.

these

of ofofthese these

components, components,

warranties.

warranties. warranties.

OR

IMPLIED,

OR OR

OF

OF OF

EQUIPMENT,

EQUIPMENT, EQUIPMENT,

items

items items