Page 1

Operation

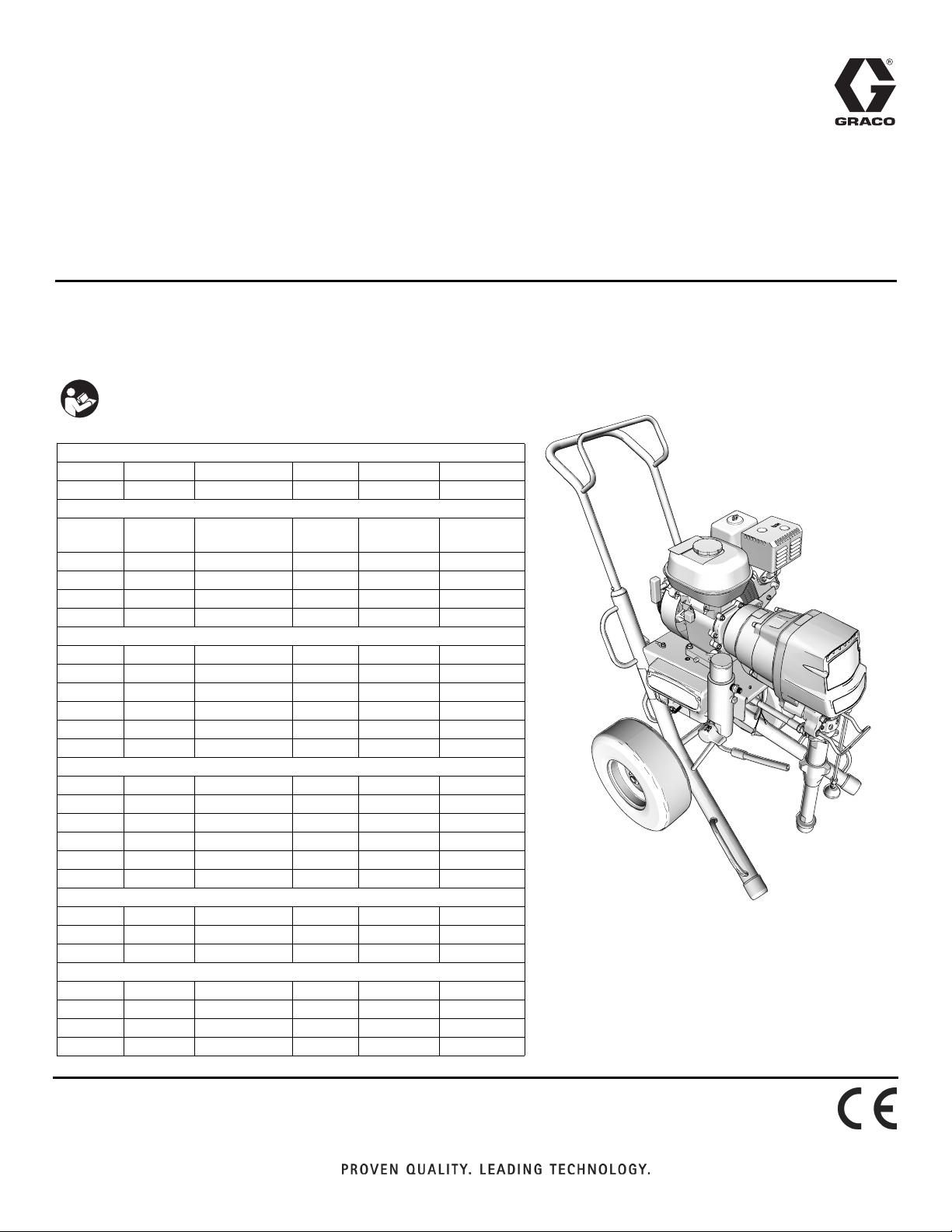

GMAX™ 3400, GMAX™ II 3900/5900/7900, and

TexSpray 5900HD/7900HD Airless Sprayers

332919C

EN

Not approved for use in European explosive atmosphere locations.

For professional use only.

For the application of architectural paints and coatings.

3300 psi (22.8 MPa, 228 bar) Maximum Working Pressure

Important Safety Instructions

Read all warnings and instructions in this manual

and in gas engine manual. Save these instructions.

GMAX 3400

Model: Standard

16W863 ✓

GMAX II 3900

Model: Standard ProContractor Lo-Boy RentalPro

360G

16W865 ✓

16W866 ✓

16W867 ✓

16W984 ✓

GMAX II 5900

Model: Standard ProContractor Lo-Boy Ironman Convertible

16W869 ✓

16W870 ✓

16W871 ✓

16W881 ✓

16W873 ✓

GMAX II 7900

Model: Standard ProContractor Lo-Boy Ironman Roof Rig

16W883 ✓

16W884 ✓

16W885 ✓

16W887 ✓

16W987 ✓

TexSpray 5900HD

Model: Standard ProContractor

16W889 ✓

16W882 ✓

TexSpray 7900HD

Model: Standard ProContractor Ironman

16W890 ✓

16W888 ✓

16X949 ✓

ti23055a

Related Manuals:

Parts 332921

Page 2

Table of Contents

Table of Contents

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Component Identification . . . . . . . . . . . . . . . . . . . . 5

Standard Models (3400, 3900, 5900, 5900HD,

7900, 7900HD) . . . . . . . . . . . . . . . . . . . . . . . 5

ProContractor Models (3900, 5900, 7900, 5900HD,

7900HD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Ironman Models (5900, 7900, 7900HD) . . . . . . . 7

Lo-Boy Models (3900, 5900, 7900) . . . . . . . . . . . 8

Convertible Models (5900) . . . . . . . . . . . . . . . . . 9

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 10

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Convertible Models Only: . . . . . . . . . . . . . . . . . 12

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Switch Tip

Spray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Clearing Tip Clogs . . . . . . . . . . . . . . . . . . . . . . . 15

WatchDog

Ironman units only) . . . . . . . . . . . . . . . . . . . . . 15

Hose Reel

(ProContractor units only) . . . . . . . . . . . . . . . 16

™

Guard Assembly . . . . . . . . . . . . . . 14

™

Protection System (ProContractor and

Digital Tracking System

(ProContractor and Ironman units) . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Pressure Relief Procedure . . . . . . . . . . . . . . . . 21

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Fluid Pump Runs Constantly . . . . . . . . . . . . . . . 24

Control Board Malfunction . . . . . . . . . . . . . . . . . 25

Control Board Malfunction (Steps) . . . . . . . . . . . 26

Convertible Electric Motor Will Not Run . . . . . . 27

Convertible Electric Motor Will Not Run (Steps) 28

Convertible Electric Motor Runs -

No AC Output to Sprayer Control Board . . . 29

Digital Display Messages . . . . . . . . . . . . . . . . . . . 31

Pinion Assembly/Clutch Armature/Clamp . . . . . . 32

Pinion Assembly/Clutch Armature Removal . . . 32

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Clamp Removal . . . . . . . . . . . . . . . . . . . . . . . . . 33

Clamp Installation . . . . . . . . . . . . . . . . . . . . . . . 33

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 38

2 332919C

Page 3

Warning

Warning

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation

point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these

symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific hazard

symbols and warnings not covered in this section may appear throughout the body of this manual where applicable.

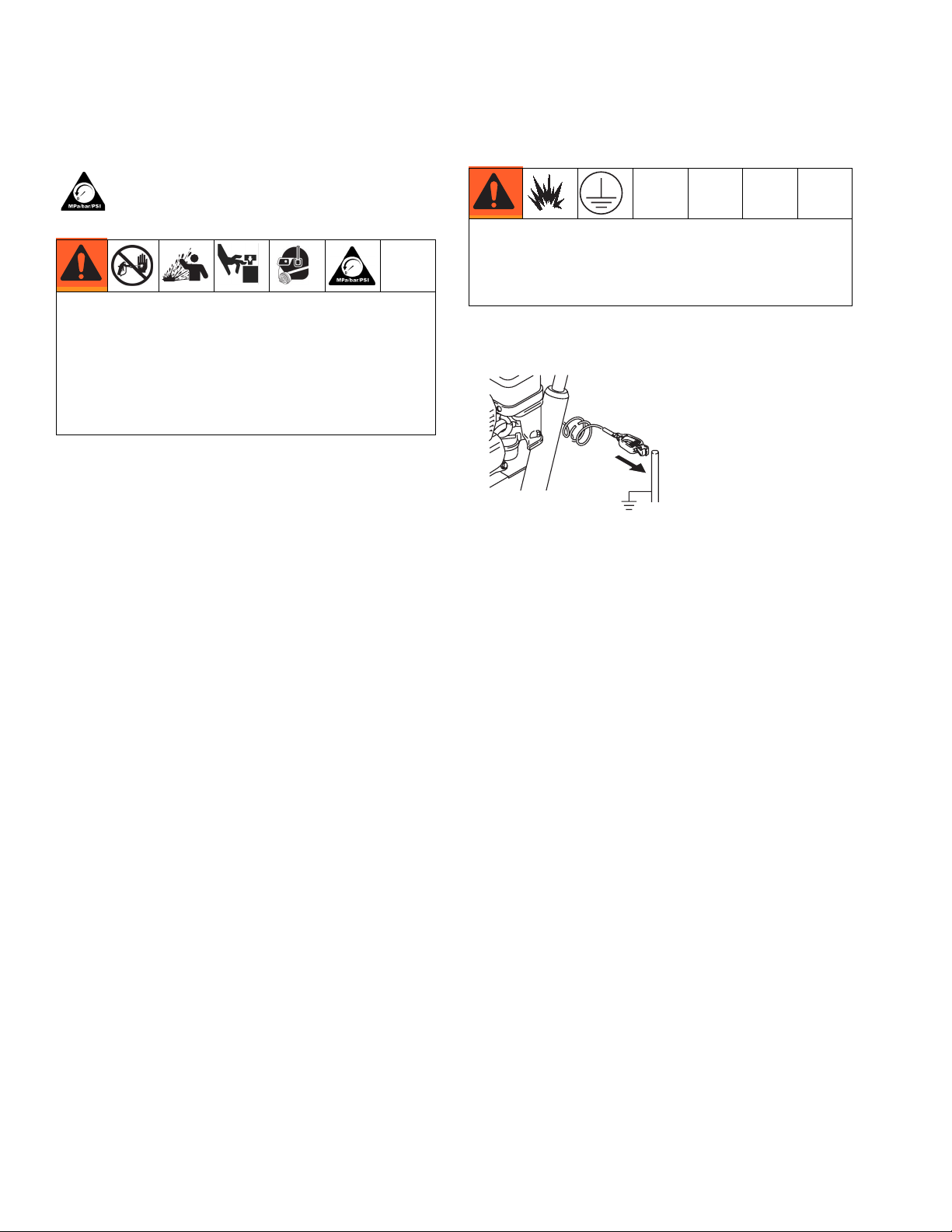

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire and

explosion:

• Use equipment only in well ventilated area.

• Do not fill fuel tank while engine is running or hot; shut off engine and let it cool. Fuel is flammable and can

ignite or explode if spilled on hot surface.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop cloths

(potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless they are antistatic

or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment until you iden-

tify and correct the problem.

• Keep a working fire extinguisher in the work area.

SKIN INJECTION HAZARD

High-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the event that injection

occurs, get immediate surgical treatment.

• Do not aim the gun at, or spray any person or animal.

• Keep hands and other body parts away from the discharge. For example, do not try to stop leaks with any part

of the body.

• Always use the nozzle tip guard. Do not spray without nozzle tip guard in place.

• Use Graco nozzle tips.

• Use caution when cleaning and changing nozzle tips. In the case where the nozzle tip clogs while spraying, fol-

low the Pressure Relief Procedure for turning off the unit and relieving the pressure before removing the nozzle tip to clean.

• Do not leave the unit energized or under pressure while unattended. When the unit is not in use, turn off the unit

and follow the Pressure Relief Procedure for turning off the unit.

• Check hoses and parts for signs of damage. Replace any damaged hoses or parts.

• This system is capable of producing 3300 psi (22.8 MPa, 228 bar). Use Graco replacement parts or accessories

that are rated a minimum of 3300 psi (22.8 MPa, 228 bar).

• Always engage the trigger lock when not spraying. Verify the trigger lock is functioning properly.

• Verify that all connections are secure before operating the unit.

• Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the controls.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, follow the

Pressure Relief Procedure and disconnect all power sources.

332919C 3

Page 4

Warning

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component.

See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all equipment

manuals. Read fluid and solvent manufacturer’s warnings. For complete information about your material,

request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s

replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create safety

hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical reaction

and equipment rupture. Failure to follow this warning can result in death, serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids contain-

ing such solvents.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier for com-

patibility.

CARBON MONOXIDE HAZARD

Exhaust contains poisonous carbon monoxide, which is colorless and odorless. Breathing carbon monoxide can

cause death.

• Do not operate in an enclosed area.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

BURN HAZARD

Equipment surfaces and fluid that is heated can become very hot during operation. To avoid severe burns:

• Do not touch hot fluid or equipment.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including eye injury,

hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

RECOIL HAZARD

Gun may recoil when triggered. If you are not standing securely, you could fall and be seriously injured.

CALIFORNIA PROPOSITION 65

The engine exhaust from this product contains a chemical known to the State of California to cause

cancer, birth defects or other reproductive harm.

This product contains a chemical known to the State of California to cause cancer, birth defects or other reproductive harm. Wash hands after handling.

4 332919C

Page 5

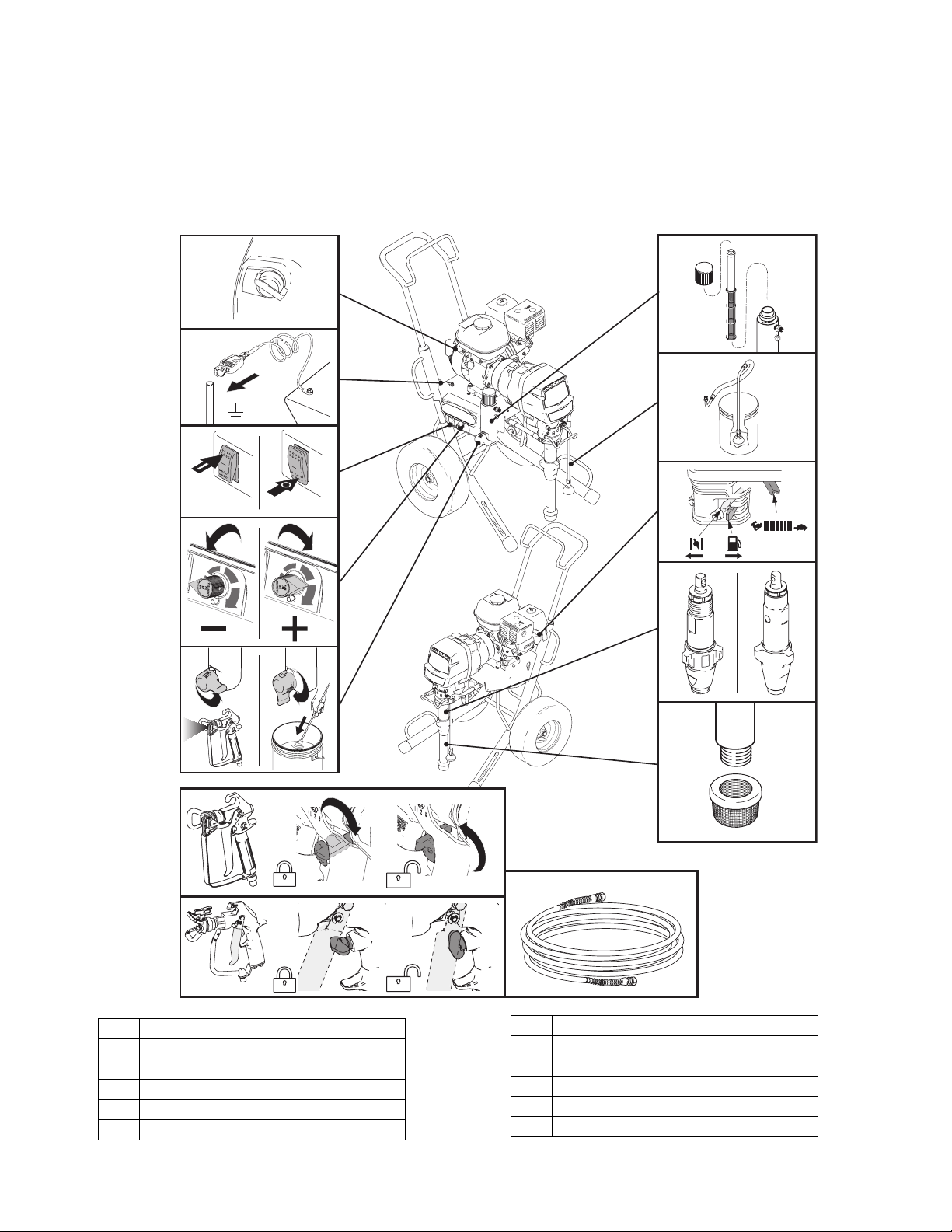

Component Identification

Component Identification

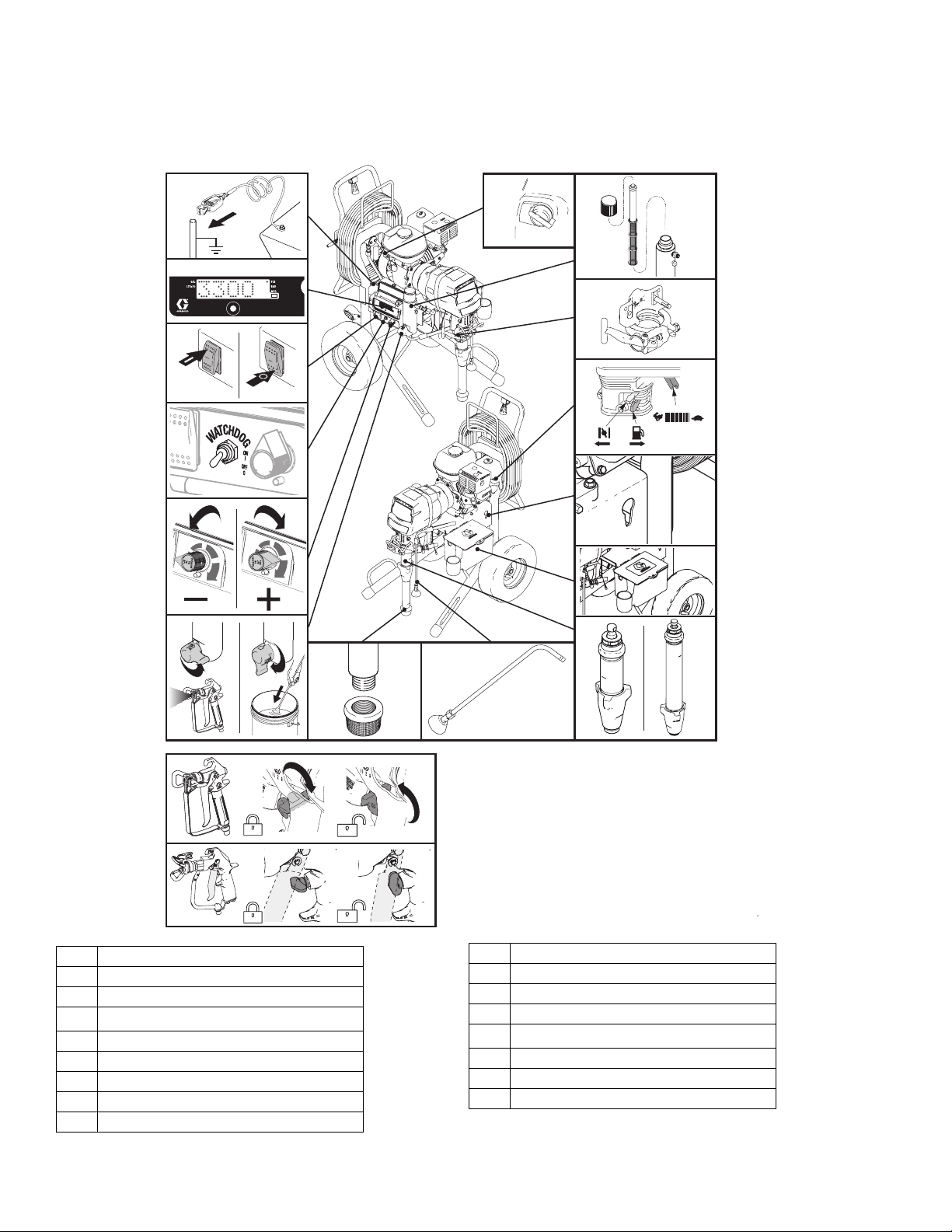

Standard Models (3400, 3900, 5900, 5900HD, 7900, 7900HD)

OFF

A

ON

B

ON

C

ti22694a

L

K

OFF

J

D

H

E

G

F

M

A Engine ON/OFF Switch

B Grounding Clamp

C Pump On/Off Switch

D Pressure Control

E Prime Valve

F Gun Trigger Lock

332919C 5

GStrainer

HPump

J Engine Controls

K Drain Hose

L Easy Out Pump Filter

MHose

Page 6

Component Identification

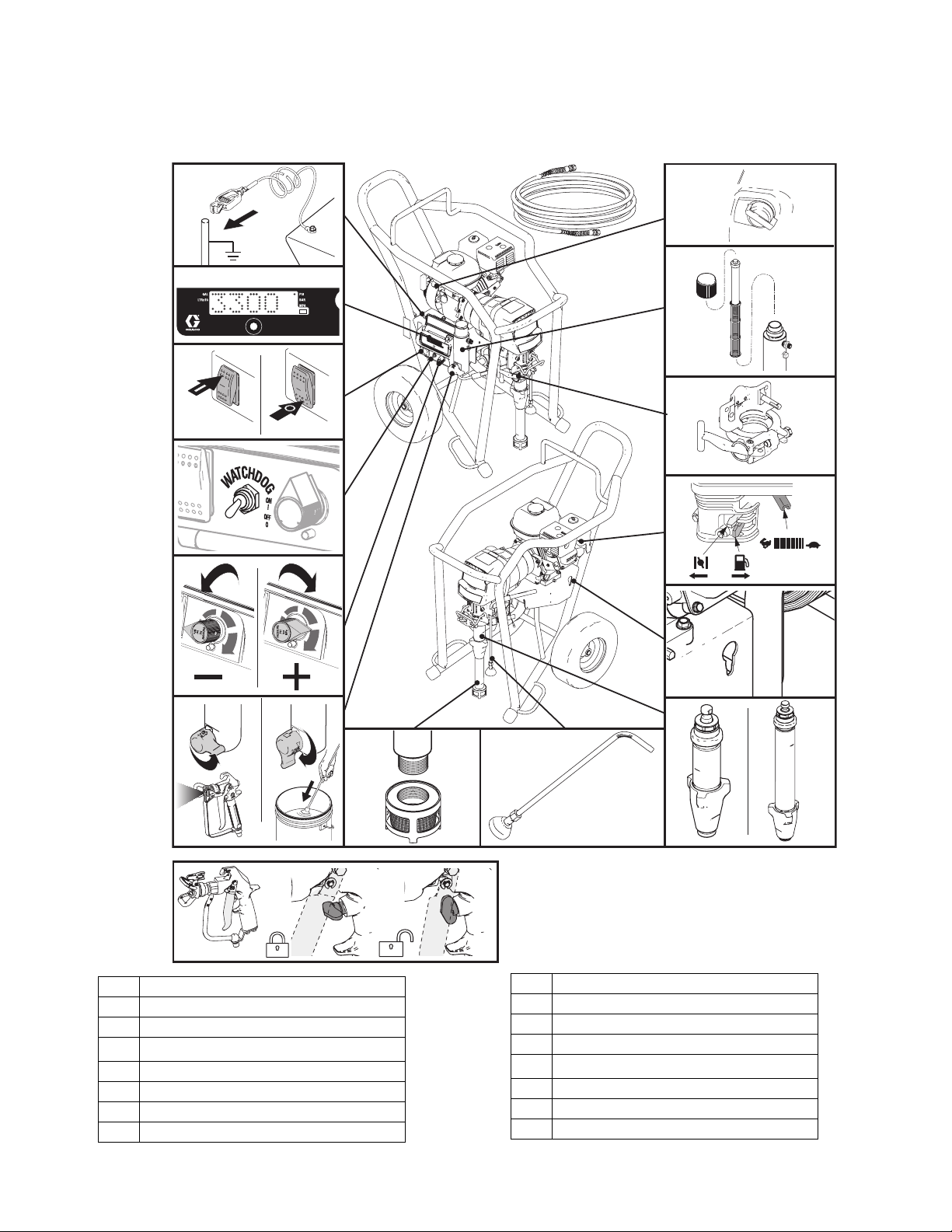

ProContractor Models (3900, 5900, 7900, 5900HD, 7900HD)

T

A

S

OFF

ON

R

B

P

ON

C

OFF

ti22742a

N

D

ti22742a

M

E

L

F

G

A Grounding Coil

B Smart Control 3.0 Display

C Pump ON/OFF Switch

D

WatchDog

E Pressure Control

F Prime Valve

G Gun Trigger Lock

HStrainer

J Drain hose

TM

Switch

HJ

KPump

L Toolbox

M Rod Pull Feature

N Engine Controls

P

ProConnect

R Filter

S Engine ON/OFF Switch

T Hose Reel

TM

II Pump Clamp

K

6 332919C

Page 7

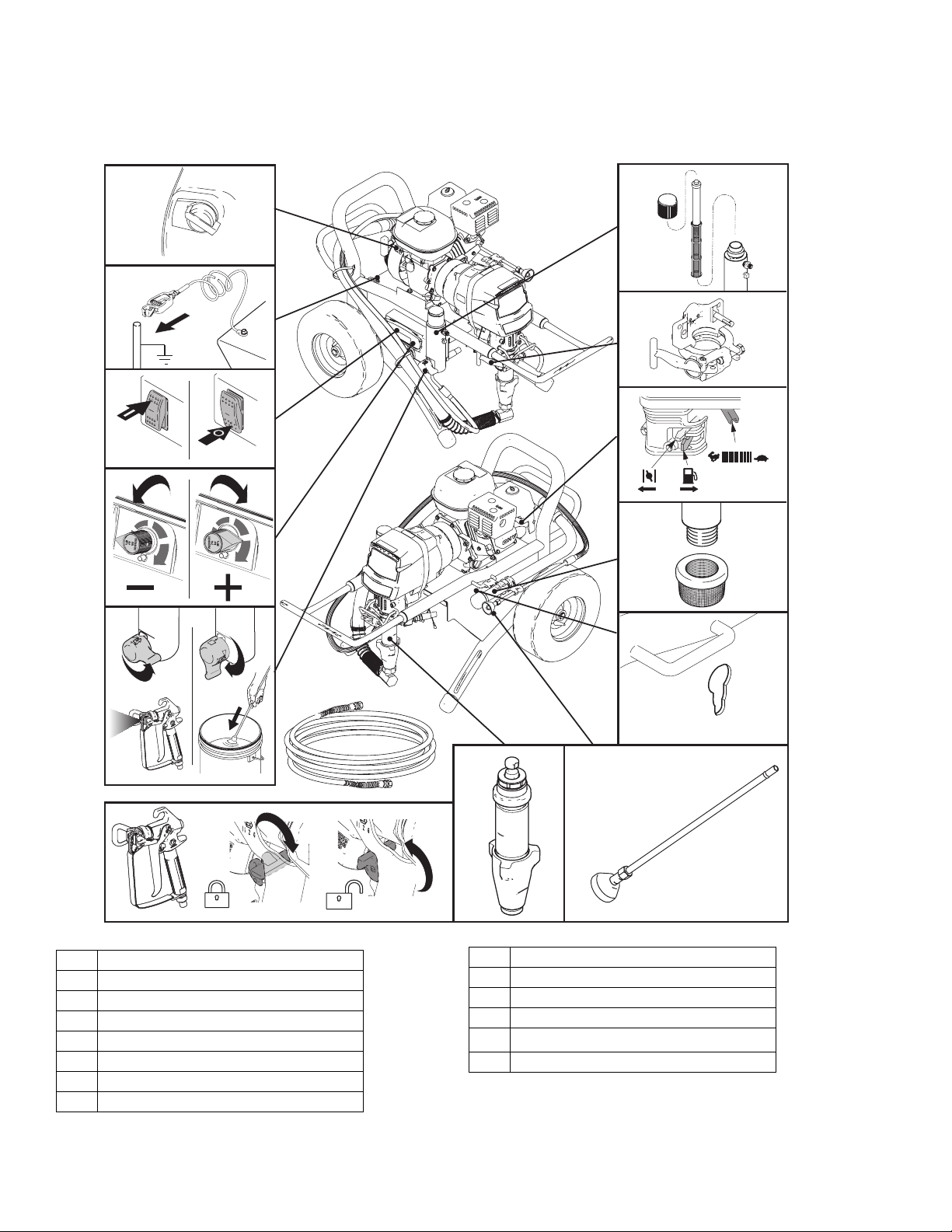

Ironman Models (5900, 7900, 7900HD)

A

Component Identification

S

OFF

R

ON

B

ON

P

C

OFF

N

D

M

E

L

ti22741a

HJ

F

K

G

A Grounding Coil

B Smart Control 3.0 Display

C Pump ON/OFF Switch

D

WatchDog

E Pressure Control

F Prime Valve

G Gun Trigger Lock

H Heavy Duty Strainer

332919C 7

TM

Switch

J Drain Hose

K MaxLife Pump

L Rod Pull Feature

M Engine Controls

N

ProConnect

P Easy Out Pump Filter

R Engine ON/OFF Switch

SHose

TM

II Pump Clamp

Page 8

Component Identification

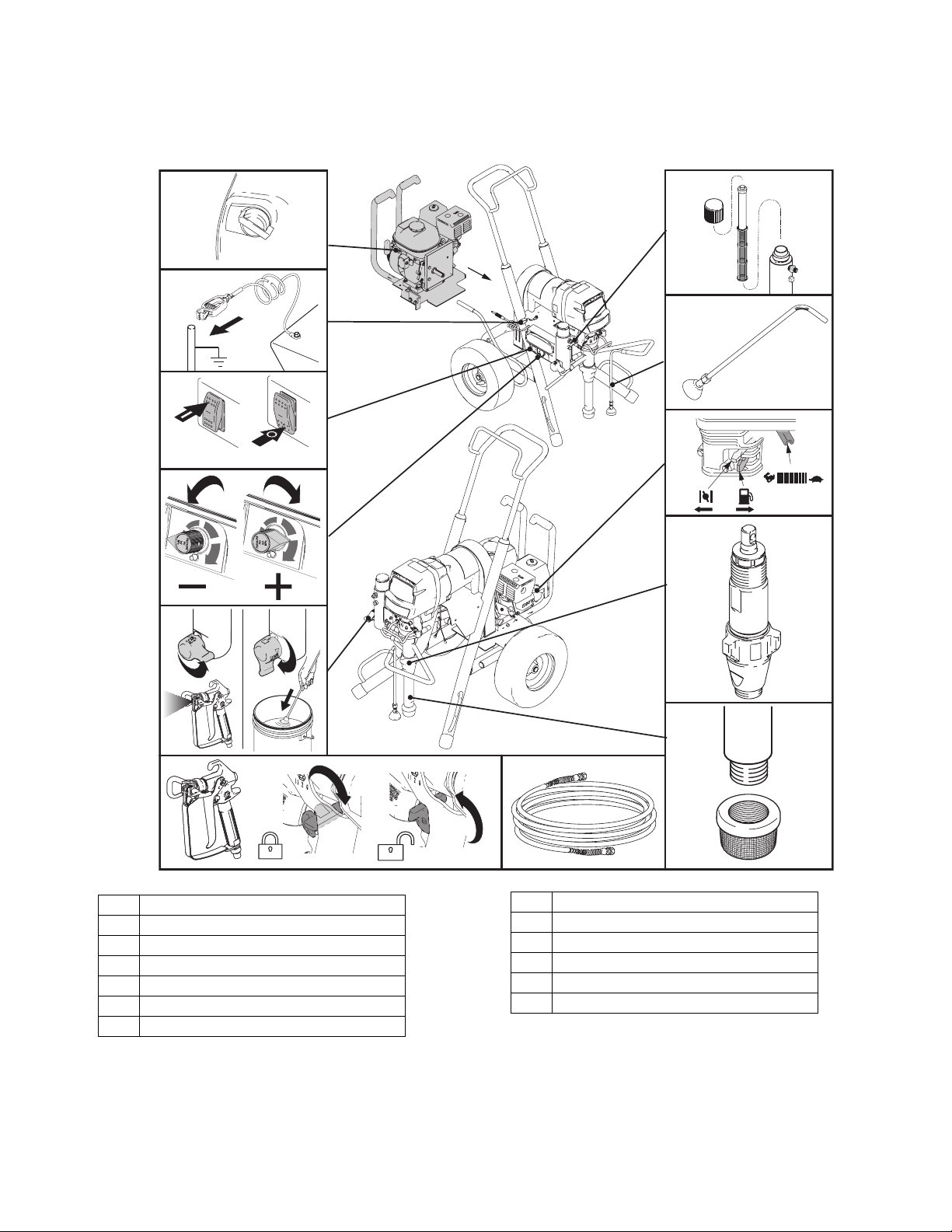

Lo-Boy Models (3900, 5900, 7900)

OFF

A

ON

B

ON

C

O

N

ti22737a

OFF

M

D

L

E

K

G

J

F

H

A Engine ON/OFF Switch

B Grounding Coil

C Pump ON/OFF Switch

D Pressure Control

E Prime Valve

F Gun Trigger Lock

GHose

HPump

8 332919C

J Drain Hose

K Rod Pull Feature

LStrainer

M Engine Controls

N

ProConnectTM II Pump Clamp

O Easy Out Pump Filter

Page 9

Convertible Models (5900)

OFF

A

ON

N

B

ON

C

OFF

Component Identification

M

L

ti22696a

K

D

E

F

A Engine ON/OFF Switch

B Grounding Coil

C Pump On/Off Switch

D Pressure Control

E Prime Valve

F Gun Trigger Lock

GHose

J

G

H

HStrainer

JPump

K Engine Controls

L Drain Hose

M Easy Out Pump Filter

NPower Pack

332919C 9

Page 10

Pressure Relief Procedure

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the

Pressure Relief Procedure when you stop spraying

and before cleaning, checking, or servicing the

equipment.

1. Engage trigger lock.

2. Turn engine ON/OFF switch to OFF.

3. Move pump switch to OFF and turn pressure control

knob fully counterclockwise.

4. Disengage trigger lock. Hold metal part of gun firmly

to side of grounded metal pail, and trigger gun to

relieve pressure.

5. Engage gun trigger lock.

6. Turn prime valve down to DRAIN position. Leave

prime valve down until ready to spray again.

7. If you suspect the spray tip or hose is clogged or

that pressure has not been fully relieved after following the steps above, VERY SLOWLY loosen tip

guard retaining nut or hose end coupling to relieve

pressure gradually, then loosen completely. Clear

hose or tip obstruction.

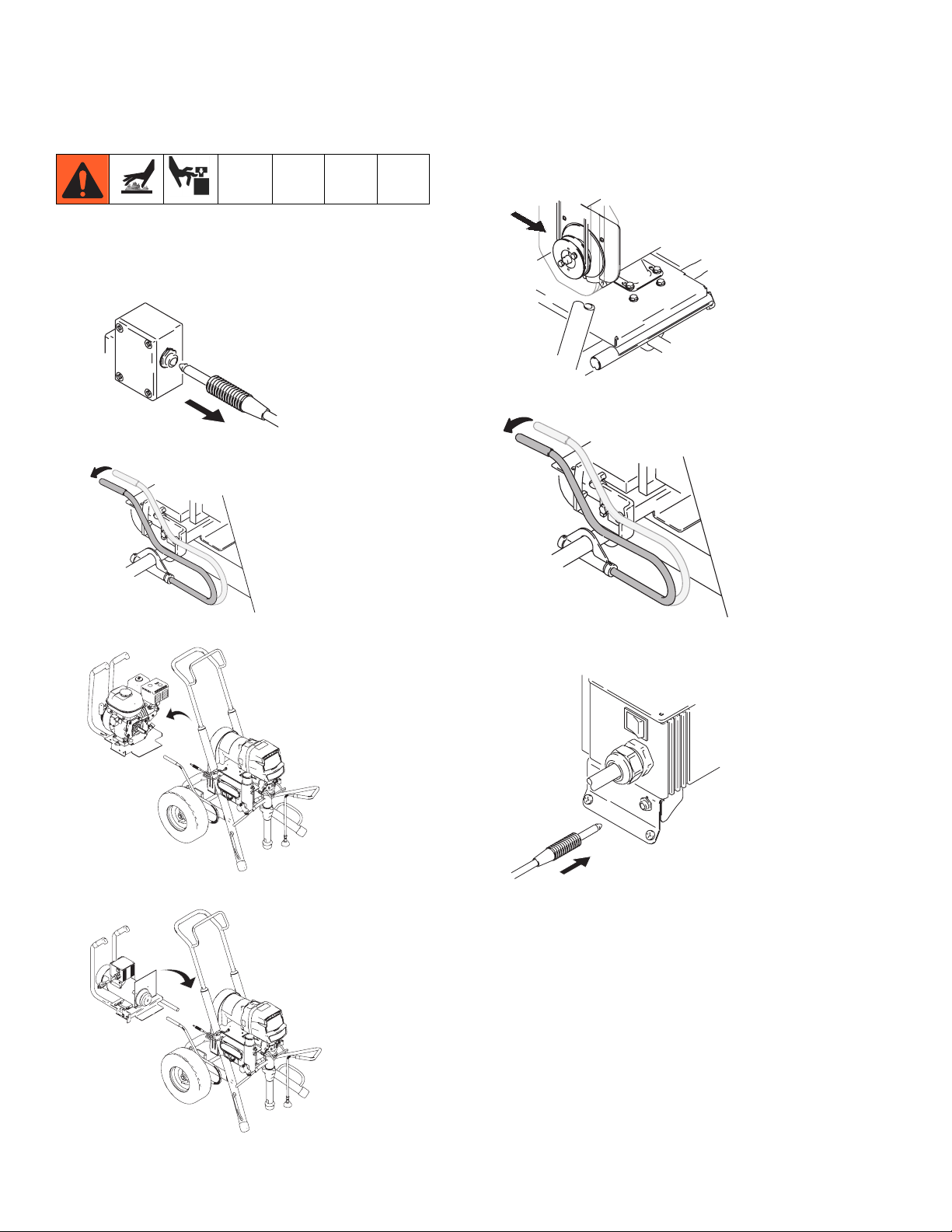

Grounding

The equipment must be grounded to reduce the risk

of static sparking. Static sparking can cause fumes

to ignite or explode. Grounding provides an escape

wire for the electric current.

To ground sprayer: Attach sprayer grounding clamp to

earth ground.

ti5787a

Air and fluid hoses: Use only electrically conductive

hoses with a maximum of 500 ft. (150 m) combined

hose length to ensure grounding continuity. Check electrical resistance of hoses. If total resistance to ground

exceeds 29 megohms, replace hose immediately.

Spray gun: Ground through connection to a properly

grounded fluid hose and pump.

Solvent pails used when flushing: Follow local code.

Use only conductive metal pails, placed on a grounded

surface. Do not place the pail on a nonconductive surface, such as paper or cardboard, which interrupts

grounding continuity.

To maintain grounding continuity when flushing or

relieving pressure: Hold metal part of the spray gun

firmly to the side of a grounded metal pail, then trigger

the gun.

10 332919C

Page 11

Setup

1.

All sprayers except ProContractor:

appropriate Graco high-pressure hose to sprayer.

2.

Select Units:

Install whip hose to fluid inlet of spray

gun and tighten securely.

ti22698a

Connect

Setup

5. Fill throat packing nut with TSL to prevent premature packing wear. Do this each time you spray.

ti22743a

6. Check engine oil level. Add SAE 10W-30 (summer)

or 5W-20 (winter), if necessary.

3. Engage gun trigger lock.

ti22700a

4. When spraying texture, remove inlet strainer and filter bowl screen when spraying materials.

ti22701a

ti5952a

7. Fill fuel tank.

ti5953a

8. Attach sprayer grounding clamp to earth ground.

ti5787a

332919C 11

Page 12

Setup

Convertible Models Only:

Change Engine to Motor

1. Disconnect engine power cord.

5. Look through side vent holes and ensure drive belt

is in motor pulley.

ti5772a

ti5774a

2. Release tension bar.

ti5775a

3. Remove engine; tilt and slide back.

ti22702a

6. Secure motor with tension bar.

ti5775a

7. Plug in pressure control power cord.

ti5779a

4. Install motor; drop in and push forward.

ti22703a

12 332919C

Page 13

Startup

Startup

c. Set throttle to fast.

1. Place suction tube and drain tube in grounded metal

pail partially filled with flushing fluid. Attach ground

wire to pail and to earth ground.

ti14844a

2. Turn prime valve down to DRAIN position. Turn

pressure control counterclockwise to lowest pressure.

ti14842a

ti22708a

3. Set pump switch OFF.

ti5250a

d. Set engine switch to ON.

ti5262a

5. Pull rope to start engine.

ti5263a

6. Increase pressure enough to start pump stroking

and allow fluid to circulate for 15 seconds; turn pressure down and turn prime valve forward to SPRAY

position.

ti5790a

4. Start Engine

ti22709a

a. Move fuel valve to open.

ti14845a

ti5248a

7. Disengage spray gun trigger lock.

b. Move choke to closed.

ti22818a

ti5249a

332919C 13

Page 14

Startup

8. Hold gun against grounded metal flushing pail. Trigger gun and increase fluid pressure slowly until

pump runs smoothly.

ti13243a

ti22710a

Inspect fittings for leaks. Do not stop leaks with your

hand or a rag! If leaks occur, turn sprayer OFF

immediately. Perform Pressure Relief Procedure

steps 1-3, page 10. Tighten leaky fittings. Repeat

Startup procedure steps 1 - 5. If no leaks, continue

to trigger gun until system is thoroughly flushed.

Proceed to step 6.

9. Place siphon tube in material pail.

Switch Tip™ Guard Assembly

1. Perform Pressure Relief Procedure, page 10.

2. Engage gun trigger lock. Insert Switch Tip. Insert

seat and OneSeal

C

3. Insert Switch Tip.

4. Screw assembly onto gun. Tighten.

™

.

B

A

ti13023a

ti13024a

ti5797a

10. Trigger gun again into flushing fluid pail until material appears.

ti13243a

ti2710a

Spray

1. Spray test pattern. Increase pressure to eliminate

heavy edges. Use smaller tip size if pressure adjustment can not eliminate heavy edges.

ti13030a

2. Hold gun perpendicular, 10-12 in. (25-30 cm) from

surface. Spray back and forth. Overlap by 50%.

Trigger gun after moving and release before stopping.

ti13025a

14 332919C

Page 15

WatchDog™ Protection System (ProContractor and Ironman units only)

Clearing Tip Clogs

To avoid injury, never point gun at your hand or into a

rag!

1. Release trigger, engage trigger lock. Rotate Switch

Tip. Disengage trigger lock. Trigger gun to clear

clog.

ti10166a

ti13033a

ti13033a

2. Engage trigger lock. Return Switch Tip to original

position. Disengage trigger lock and continue spraying.

ti10166a

ti13034a

ti10167a

ti10167a

WatchDog™ Protection System

(ProContractor and Ironman units only)

Pump stops automatically when material pail is empty.

To Activate:

1. Perform Startup.

2. Turn WatchDog switch ON and WD ON displays.

EMPTY displays/flashes and pump stops when

Watchdog protection system detects an empty

material pail.

ti22711a

3. Turn WatchDog switch OFF. Add material or reprime

sprayer. Turn pump switch OFF and ON to reset

WatchDog protection system. Turn WatchDog

switch back ON to continue to monitor material

level.

ti22712a

332919C 15

Page 16

Hose Reel (ProContractor units only)

Hose Reel

(ProContractor units only)

To avoid injury, keep your head clear of hose reel

while winding up hose.

1. Make sure hose is routed through hose guide.

3. Pull reel handle down and turn clockwise to reel in

hose.

ti22745a

NOTE: The hose reel can be locked into two positions: Usage (A) and Storage (B).

ti13504a

2. Lift and turn pivot lock 90 to unlock hose reel. Pull

on hose to remove it from hose reel.

ti22744a

(A)

(B)

ti22746a

16 332919C

Page 17

Digital Tracking System

(ProContractor and Ironman units)

Digital Tracking System (ProContractor and Ironman units)

Operation Main Menu

Short press to move to next display. Press and hold (5

seconds) to change units or reset data.

ti22713a

1. Turn pressure to lowest setting. Trigger gun to

relieve pressure. Turn prime valve down to DRAIN

position.

ti22714a

ti13243a

2. Turn power ON. Pressure display appears. Dashes

will not appear unless pressure is less than 200 psi

(14 bar, 1,4 MPa).

Job Gallons

1. Short press DTS button to move to Job Gallons (or

liters x 10).

ti22717a

NOTE: JOB scrolls past, then the number of gallons

sprayed above 1000 psi (70 bar, 7 MPa) displays.

Lifetime Gallons

1. Short press DTS button to move to Lifetime Gallons

(or liters x 10).

NOTE: LIFE scrolls briefly, then the number of gallons sprayed above 1000 psi (70 bar, 7 MPa) displays.

OFF

ON

ti22715a

Change Display Units

Press and hold DTS button for 5 seconds to change

pressure units (psi, bar, MPa) to desired units. Selection of bar or MPa changes gallons to liters x 10. To

change display units DTS must be in pressure display

mode and pressure must be at zero.

FT

M

ti22716a

ti22718a

332919C 17

Page 18

Digital Tracking System (ProContractor and Ironman units)

Secondary Menu - Stored Data and

WatchDog Pump Protection Modes

1. Perform Pressure Relief, steps 1 - 4 if they have

not already been done.

2. Turn power switch on while holding DTS button

down.

ti22719a

3. The sprayer model briefly displays (e.g. 5900),

SERIAL NUMBER scrolls past and then serial number (e.g. 00001) displays.

ti22720a

4. Short press DTS button and MOTOR ON scrolls

past and then total motor run hours are displayed.

7. Short press DTS button. W-DOG scrolls past then

OFF displays if watchdog switch is OFF. ON dis-

plays if Watchdog switch is ON.

ti22724a

8. Press and hold (8 seconds) DTS button to move to

WatchDog Trigger % menu. Continue to hold DTS

button and Watchdog can be set to trigger at 30, 40,

50, or 60% of current sprayer pressure setting.

Release DTS button when desired % is displayed.

default is 50%.

ti22725a

9. Short press to move to SOFTWARE REV.

ti22721a

5. Short press DTS button. LAST ERROR CODE

scrolls by and last error code is displayed; e.g.

E=07. See sprayer Repair manual for additional

information.

ti22722a

6. Press and hold DTS button to clear error code to

zero.

ti22723a

ti22726a

18 332919C

Page 19

Cleanup

1. Perform Pressure Relief Procedure (page 10),

steps 1 - 4. Remove siphon tube set from paint and

place in flushing fluid. Remove tip guard from gun.

ti14844a

NOTE: Use water for water-base paint, mineral spirits for oil-base paint, or other solvents recommended by manufacturer.

2. Start Engine

Cleanup

3. Pull rope to start engine.

ti5263a

4. Turn pump switch ON. Turn prime valve forward to

SPRAY position.

OFF

ON

ti22729a

5. Increase pressure to 1/2. Hold gun against paint

pail. Disengage trigger lock. Trigger gun until flushing fluid appears.

a. Move fuel valve to open.

ti5248a

b. Move choke to closed.

ti5249a

c. Set throttle to fast.

ti5250a

d. Set engine switch to ON.

ti22730a

ti14846a

6. Move gun to waste pail, hold gun against pail, trigger gun to thoroughly flush system. Release trigger

and engage trigger lock.

ti14847a

7. Turn prime valve down to DRAIN position and allow

flushing fluid to circulate until flushing fluid appears

clear.

8. Turn prime valve forward to SPRAY position. Trigger

gun into flushing pail to purge fluid from hose.

ti5262a

ti14845a

332919C 19

ti14847a

Page 20

Cleanup

9. Raise siphon tube above flushing fluid and run

sprayer for 15 to 30 seconds to drain fluid. Turn

pump switch and engine OFF

ti22731a

10. Turn prime valve down DRAIN position.

ti14842a

11. Remove filters from gun and sprayer, if installed.

Clean and inspect. Install filters.

12. If flushing with water, flush again with mineral spirits,

or Pump Armor, to leave a protective coating to prevent freezing or corrosion.

13. Wipe sprayer, hose and gun with a rag soaked in

water or mineral spirits.

ti2776a

ti15018a

20 332919C

Page 21

Maintenance

Maintenance

Pressure Relief Procedure

1. Lock gun trigger safety.

2. Turn engine ON/OFF switch to OFF.

3. Move pump switch to OFF and turn pressure control

knob fully counterclockwise.

4. Unlock trigger safety. Hold metal part of gun firmly to

side of grounded metal pail, and trigger gun to

relieve pressure.

5. Lock gun trigger safety.

6. Open pressure drain valve. Leave valve open until

ready to spray again.

If you suspect that the spray tip or hose is completely

clogged, or that pressure has not been fully relieved

after following the steps above, VERY SLOWLY loosen

tip guard retaining nut or hose end coupling to relieve

pressure gradually, then loosen completely. Now clear

tip or hose.

NOTE: For detailed engine maintenance and specifications, refer to separate Honda Engines Owner's Manual,

supplied.

DAILY: Check level of TSL in displacement pump packing nut. Fill nut, if necessary. Keep TSL in nut to help

prevent fluid buildup on piston rod and premature wear

of packings and pump corrosion.

AFTER THE FIRST 20 HOURS OF OPERATION:

Drain engine oil and refill with clean oil. Reference

Honda Engines Owner's Manual for correct oil viscosity.

WEEKLY: Remove engine air filter cover and clean element. Replace element, if necessary. If operating in an

unusually dusty environment: check filter daily and

replace, if necessary.

Replacement elements can be purchased from your

local HONDA dealer.

AFTER EACH 100 HOURS OF OPERATION:

Change engine oil. Reference Honda Engines Owner's

Manual for correct oil viscosity.

SPARK PLUG: Use only BPR6ES (NGK) or

W20EPR-U (NIPPONDENSO) plug. Gap plug to 0.028

to 0.031 in. (0.7 to 0.8 mm). Use spark plug wrench

when installing and removing plug.

Use the supplied engine oil funnel when draining oil.

DAILY: Check engine oil level and fill as necessary.

DAILY: Check hose for wear and damage.

DAILY: Check that all hose fittings are secure.

DAILY: Check gun safety for proper operation.

DAILY: Check pressure drain valve for proper opera-

tion.

DAILY: Check and fill the gas tank.

OIL FUNNEL

ti23054a

332919C 21

Page 22

Troubleshooting

Troubleshooting

Problem Cause Solution

E=XX is displayed Fault condition exists. Determine fault correction from table, page 31.

Engine will not start Engine switch is OFF. Turn engine switch ON.

Engine is out of gasoline. Refill gas tank. Honda Engine Manual.

Engine oil level is low. Try to start engine. Replenish oil, if necessary.

Honda Engine Manual.

Spark plug disconnected or damaged. Connect spark plug cable or replace spark

plug.

Engine is cold. Use choke.

Fuel shutoff lever is OFF. Move lever to ON position.

False tripping of WatchDog system.

EMPTY is displayed. Pump does not

run.

Engine operates, but displacement

pump does not operate

Oil is seeping into combustion chamber.

Operating conditions out of WatchDog

parameters.

Pump output is low, page 23.

Error code displayed. See Digital Display Messages, page 31.

Pump switch is OFF. Turn pump switch ON.

Pressure setting too low. Turn pressure adjusting knob clockwise to

Fluid filter is dirty. Clean filter.

Tip or tip filter is clogged. Clean tip or tip filter (see gun manual).

Displacement pump piston rod is stuck

due to dried paint.

Connecting rod is worn or damaged. See Parts manual.

Drive housing is worn or damaged. See Parts manual.

Electrical power is not energizing clutch

field.

Remove spark plug. Pull starter 3 to 4 times.

Clean or replace spark plug. Start engine.

Keep sprayer upright to avoid oil seepage.

Turn pressure down. Contact Graco Technical

Assistance to adjust WatchDog parameters.

Operate without WatchDog active (see Opera-

tion manual).

increase pressure.

Repair pump (see pump manual).

See Parts manual.

See Digital Display Messages, page 31.

With pump switch ON and pressure turned to

MAXIMUM, use a test light to check for power

between clutch test points on control board.

Remove clutch wires from control board and

measure resistance across clutch coil. At 70°

F, the resistance must be between for 3900 -

1.2 + 0.2 Ω, for 5900/7900 1.7 ± 0.2 Ω; if not,

replace pinion housing.

Have pressure control checked by authorized

Graco dealer.

Clutch is worn, damaged, or incorrectly

positioned.

Pinion assembly is worn or damaged. Repair or replace pinion assembly. Page 32.

22 332919C

Adjust or replace clutch. See page 32.

Page 23

Troubleshooting

Problem Cause Solution

Pump output is low Strainer is clogged. Clean strainer.

Piston ball is not seating. Service piston ball (see pump manual).

Piston packings are worn or damaged. Replace packings (see pump manual).

O-ring in pump is worn or damaged. Replace o-ring (see pump manual).

Intake valve ball is not seating properly. Clean intake valve (see pump manual).

Intake valve ball is packed with mate-

rial.

Engine speed is too low. Increase throttle setting (see operation man-

Clutch is worn or damaged. Adjust or replace clutch. Page 32.

Pressure setting is too low. Increase pressure (see operation manual).

Fluid filter, tip filter or tip is clogged or

dirty.

Large pressure drop in hose with heavy

materials.

Excessive paint leakage into throat

packing nut

Fluid is spitting from gun Air in pump or hose. Check and tighten all fluid connections. Rep-

Pump is difficult to prime Air in pump or hose. Check and tighten all fluid connections.

Throat packing nut is loose. Remove throat packing nut spacer. Tighten

Throat packings are worn or damaged. Replace packings (see pump manual).

Displacement rod is worn or damaged. Replace rod (see pump manual).

Tip is partially clogged. Clear tip (see gun manual).

Fluid supply is low or empty. Refill fluid supply. Prime pump (see operation

Clean intake valve (see pump manual).

ual).

Clean filter (see gun manual).

Use larger diameter hose and/or reduce overall

length of hose. Use of more than 100 ft of 1/4

in. hose significantly reduces performance of

sprayer. Use 3/8 in. hose for optimum performance (50 ft minimum).

throat packing nut just enough to stop leakage.

rime pump (see operation manual).

manual). Check fluid supply often to prevent

running pump dry.

Reduce engine speed and cycle pump as

slowly as possible during priming.

Intake valve is leaking. Clean intake valve. Be sure ball seat is not

nicked or worn and that ball seats well. Reas-

semble valve.

Pump packings are worn. Replace pump packings (see pump manual).

Paint is too thick. Thin the paint according to the supplier's rec-

ommendations.

Engine speed is too high. Decrease throttle setting before priming pump

(see operation manual).

Clutch squeaks each time clutch

engages

High engine speed at no load Misadjusted throttle setting. Reset throttle to 3300 engine rpm at no load.

Gallon counter not working Bad sensor, broken or disconnected

No display, sprayer operates Display damaged or has bad connec-

Clutch surfaces are not matched to

each other when new and may cause

noise.

Worn engine governor. Replace or service engine governor.

wire. Displaced or missing magnet.

tion.

Clutch surfaces need to wear into each other.

Noise will dissipate after a day of run time.

Check connections. Replace sensor or wire.

Reposition or replace magnet.

Check connections. Replace display.

332919C 23

Page 24

Troubleshooting

Fluid Pump Runs Constantly

Troubleshooting Procedure:

1. Perform Pressure Relief Procedure (page 21),

turn prime valve forward to SPRAY position, and

turn power switch OFF.

2. Remove control box cover.

With a pressure gauge plumbed into the paint

hose, start the engine. Turn pump switch ON.

Does sprayer exceed maximum pressure?

YES

Disconnect clutch wires from control board (see

diagram, page 29). Does the pump stop running?

YES

Make sure clutch wires are plugged in (see diagram, page 29). Do the clutch test points read

10-18 DC volts?

YES

NO

NO

NO

Pump problem. See the proper fluid pump

manual for the sprayer for further troubleshooting procedures.

Mechanical problem in the clutch pinion assembly (clutch may be close to the rotor).

Check for a short from the two clutch wires

to the frame. If shorted, repair or replace

faulty wire.

Unplug transducer from control board.

YES

Bad transducer.

Replace and test with a new one.

24 332919C

NO

Replace the control board.

Page 25

Control Board Malfunction

Troubleshooting Procedure

(see following page for actual steps):

Remove control box cover. Turn

sprayer ON. Observe control board

Green and Red LED lights.

No light

Once Normal operation

Red light on

continuously

Green light on

continuously

Flashing See error code

Red light on

continuously with

potentiometer

OFF after a

replacement

board is installed

Go to step 4.

Is 1-3 Ohms

reading present?

YES

Control board

commanding

engine to run

WatchDog

enabled

section for further

troubleshooting

Model not

selected

YES

If low resistance is

NO

present in step 4,

the problem is a

shorted field.

Replace pinion.

If an open in the

wiring is present,

check pinion

wiring

connections.

Go to step 3.

Is 10-12

VDC

present?

NO

Go to step 1.

Does switch

test positive?

YES

Go to step 2.

Do you have

proper engine

voltage?

YES

Go to step 5.

Does the

clutch

engage?

YES

Replace the

potentiometer.

NO

NO

NO

Troubleshooting

Replace the

switch.

Check wiring

from J1 and J2

for proper connection. If proper

connection is

detected, repair

or replace engine

generator.

Connect

a test

transducer to

the board.

Does the

clutch

engage?

Replace

YES

the

control

board.

NO

Mechanical

problem. Repair

or replace

clutch/pinion

assembly.

332919C 25

Replace

the

transducer.

Page 26

Troubleshooting

Control Board Malfunction (Steps)

BEEP

-

-

+

STEP 1.

Turn engine

OFF and set

meter to

continuity.

ti14938a

Pump

On/Off

Switch

To Engine

To Ground

ti14939a

Engine

Generator

J1J2

J4J3

12 -20 AC

V

-

-

Control

Board

STEP 2.

Turn engine

ON. Set meter

to AC volts and

connect wires

to control

board.

Control

Board

+

J1

J2

To C l u tc h

Field

Clutch Test Points

J10

LED

D12

J5

J9

STEP 3.

10-12 DC

V

-

ti14940a

Clutch

Field

Pinion

Assembly

+

ti14943a

-

Drive

Housing

Leave engine

running and turn

switch ON. Turn

potentiometer to

high and set

meter to DC

volts.

+

Control

Board

Clutch

Field

On/Off Switch

1-3 ohms

-

ti14942a

-

Clutch Test Points

WatchDog

STEP 4.

Turn engine

OFF and

unplug

clutch wires.

Set meter to

Ohms.

+

Control

Board

Premium Display Board

Transducer

Potentiometer

STEP 5.

Turn engine

ON and turn

switch ON.

Control

Board

J5

ti14941a

26 332919C

Page 27

Convertible Electric Motor Will Not Run

Troubleshooting Procedure

(see following page for actual steps):

Troubleshooting

See Step 1. Is there

over 100 AC volts?

YES

See Step 3. Is there

over 100 DC volts?

YES

See engine test section.

NO

NO

See step 2. Is there

over 100 AC volts?

YES

Replace the power switch.

See Step 4. Is there

continuity through the

thermal sensor?

YES

Replace engine

control board.

NO

NO

Repair or replace

the power cord.

If engine is hot, let

cool and retest. If

step 4 still shows an

open, replace engine.

332919C 27

Page 28

Troubleshooting

Convertible Electric Motor Will Not Run (Steps)

STEP 1.

Plug in cord and turn

switch ON. Connect

V

wires to control board

and turn meter to AC

volts.

-

ti14920a

+

-

Black

Electric Engine Control Board

L1

L2

White

Ground

Black

Black

Transformer

White

Black

Black

STEP 2.

Plug in cord and turn

switch ON. Connect

wires to control board

and turn meter to AC

volts.

power cord

Jack

Power Cord

AC power to

control board

Black to

V

-

ti14921a

-

Black

Electric Engine Control Board

White to Barrel

Black to Tips

L1

L2

+

White

100 + DC

V

-

+

ti14923a

+M -M

STEP 3.

Plug in cord and turn

switch ON. Turn

meter to DC volts.

Engine

-

TS TS

Control

Board

Engine Control Board

Black

+M -M

ti14924a

Electric

Engine

White

L1

L2

TS TS

STEP 4.

BEEP

Check the engine thermal sensor (meter

should read continuity).

Note: engine should

-

ti14922a

be cooled down. Turn

meter to continuity test.

Engine

Control

+M

-M

TS

-

Board

TS

Electric

Engine

Yellow Yellow

Electric

Engine

28 332919C

Page 29

Convertible Electric Motor Runs No AC Output to Sprayer Control Board

Troubleshooting Procedure

(see following page for actual steps):

Troubleshooting

See step 1.

Is there over 10-20

AC volts?

YES

See the sprayer

control board troubleshooting in this

manual.

NO

See step 2.

Is there continuity?

YES

See step 3.

Is there continuity?

YES

See step 4.

Is there over 100

AC volts?

YES

See step 5.

Is there over

10-20 AC volts.

NO

NO

NO

NO

Repair or replace

the power cord.

Repair or replace

the power cord.

Repair or replace

wire splice(s) on

the power cord

wires.

Replace transformer.

YES

Replace cord jack.

332919C 29

Page 30

Troubleshooting

Convertible Electric Motor Runs - No AC Output to Sprayer Control Board (Steps)

10-20 AC

V

-

ti14925a

Jack

Transformer

STEP 1.

Plug in cord and turn

switch ON. Connect

wires to transformer

and power cord. Turn

meter to AC volts.

-

Power Cord

AC power to

control board

Ground

Black

+

Black

White to barrel

Black to tips

Transformer

Black

Black

White

Engine Control Board

Jack

Power Cord

AC power to

control board

ti14926a

White to barrel

Black to tips

-

BEEP

-

-

STEP 2.

Check AC power cord

for an open wire. Turn

meter to continuity

test. Meter should

read continuity.

Power Cord

AC power to

control board

STEP 3.

BEEP

Check AC power

cord for an open

wire. Turn meter to

continuity test.

-

Meter should read

continuity.

Power Cord

White to barrel

Black to tips

White to barrel

Power

Cord

V

-

-

Black

Black

Electric

Engine

STEP 4.

Plug in cord and turn

switch ON. Partially

connect wires to

splice. Turn meter to

AC volts.

Transformer

+

White

L1

ti14929a

L2

+M -M

White

White

L2

L1

TS TS

ti14930a

ti14927a

AC power to

control board

Black to tips

STEP 5.

10-20 AC

Plug in cord and

turn switch ON.

V

Partially connect

wires to splice.

Transformer

Turn meter to AC

-

ti14928a

volts.

Black

Black

-

+

Jack

Black

Electric Engine Control Board

30 332919C

Page 31

Digital Display Messages

Digital Display Messages

• Digital messages are not available on all sprayers

• Blinking LED total count equals digital error code

i.e., two blinks is the same as E=02

DISPLAY* SPRAYER OPERA-

TION

No Display Sprayer may be

pressurized.

Sprayer may be

pressurized.

Sprayer is pressurized.

Power is applied.

(Pressure varies with

tip size and pressure

control setting).

Sprayer stops. Engine

is running.

Sprayer stops. Engine

is running.

Sprayer stops. Engine

is running.

Sprayer stops. Engine

is running.

(with constant

green LED)

Sprayer stops. Engine

is running.

INDICATION ACTION

Loss of power or display

not connected.

Pressure less than

200 psi (14 bar, 1.4 MPa).

Normal operation. Spray

Exceeded pressure limit. 1. Check fluid path for clogs, such as clogged filter.

Pressure transducer faulty,

bad connection or broken

wire.

High clutch current. 1. Check wiring connections.

Loss of paint to pump or

severe pressure loss.

Pressure greater than

2000 psi (138 bar, 14 MPa)

while in Flush Timer Mode.

Check power source. Relieve pressure before repair

or disassembly. Verify display is connected.

Increase pressure as needed.

2. Open prime valve and gun if running AutoClean.

3. Use Graco paint hose, 1/4 in. x 50 ft minimum.

Smaller hose or metal braid hose may result in

pressure spikes.

4. Replace transducer if fluid path is not clogged

and proper hose is used.

1. Check transducer connection.

2. Disconnect and reconnect transducer plug to

ensure good connection with control board

socket.

3. Open prime valve. Replace sprayer transducer

with known good transducer and run sprayer.

Replace transducer if sprayer runs or control

board if sprayer does not run.

Measure: 1.2 + 0.2 Ω (GMAX II 3900);

2.

1.7 + 0.2 Ω (GMAX II 5900/ 7900 & TexSpray

7900HD) across clutch field at 70°F.

3. Replace clutch field assembly.

1. Check for empty paint condition, clogged inlet

strainer, failed pump or severe leak.

2. Reduce pressure and turn pump switch OFF

and ON to restart pump.

3. WatchDog function can be deactivated by

turning WatchDog switch OFF.

1. Open prime valve and gun.

2. Verify no flow obstructions or clogged filter.

* Error codes also appear on control board as a blinking red

LED. LED is an alternate to digital messages.

1. Remove two screws (71) and swing down cover (130).

2. Start engine. Blink count is the same as error code(E=0X).

332919C 31

After a fault, follow these steps to restart sprayer:

1. Correct fault condition

2. Turn sprayer OFF

3. Turn sprayer ON

Page 32

Pinion Assembly/Clutch Armature/Clamp

Pinion Assembly/Clutch Armature/Clamp

Pinion Assembly/Clutch Armature Removal

Pinion Assembly

If pinion assembly (29) is not removed from clutch housing (19), do 1. through 3. Otherwise, start at 4.

1. Remove drive housing.

2. Disconnect clutch cable connectors from inside of

pressure control.

a. Remove two screws (71) and swing down cover

(130a).

b. Disconnect engine leads from board to engine.

c. Remove strain reliefs 130r and 123.

3. Remove four screws (36) and pinion assembly (29).

36

37

19

29

6. Remove retaining ring (29b).

7. Turn pinion assembly over and tap pinion shaft

(29a) out with plastic mallet.

27

29b

29a

29d

ti5482a

Clutch Armature

8. Use an impact wrench or wedge something

between clutch armature (25) and clutch housing to

hold engine shaft during removal.

9. Remove four screws (23) and lock washers (24).

36

37

ti5480a

4. Place pinion assembly (29) on bench with rotor side

up.

5. Remove four screws (28) and lock washers (24).

Install two screws in threaded holes (E) in rotor.

Alternately tighten screws until rotor comes off.

28

24

E

29

ti5481a

E

ti5987b

10. Remove armature.

TIA

32 332919C

Page 33

Installation

Pinion Assembly/Clutch Armature/Clamp

Clutch Armature

1. Lay two stacks of two dimes on smooth bench surface.

2. Lay armature (25) on two stacks of dimes.

3. Press center of hub (26) down to bench surface.

25

ti6321a

26

0.12+01 in (3.0+.25 mm)

dimes

4. Install armature (25) on engine drive shaft.

5. Install four screws (23) and lock washers (24) with

torque of 125 in-lb.

Pinion Assembly

1. Check o-ring (29d) and replace if missing or damaged.

2. Tap pinion shaft (29a) in with plastic mallet.

3. Install retaining ring (29b) with beveled side facing

up.

4. Place pinion assembly on bench with rotor side up.

5. Apply thread sealant to screws. Install four screws

(28) and lock washers (24). Alternately torque

screws to 125 in-lb until rotor is secure. Use

threaded holes to hold rotor.

6. Install pinion assembly (29) with four screws (36)

and washers (37).

7. Connect clutch cable connectors to inside of pressure control.

4. Loosen two screws (24) on clamp (22),

5. Push screwdriver into slot in clamp (22) and remove

clamp.

ti6199a

Clamp Installation

1. Install engine shaft key (18).

2. Tap clamp (22) onto engine shaft (A). Maintain

dimension shown note 2. Chamfer must face

engine.

3. Check dimension: Place rigid, straight steel bar (B)

across face of clutch housing (19). Use accurate

measuring device to measure distance between bar

and face of clamp. Adjust clamp as necessary.

Torque two screws (24) to 125 ±10 in-lb (14 ±1.1

N•m).

1

Face of clutch housing

1.550 ± .010 in. (39.37 ± .25 mm) - GMAX 3400 and 3900

2

2.612 ± .010 in. (66.34 ± .25 mm) - GMAX 5900 and 7900

Torque to 125 ±.10 in-lb (14 ±1.1 N•m)

3

Chamfer this side

4

19

Clamp Removal

"

1. Remove engine.

2. Drain gasoline from tank according to Honda manual.

3. Tip engine on side so gas tank is down and air

TIA

!

cleaner is up.

332919C 33

Page 34

Technical Data

Technical Data

3400 Models

U.S. Metric

Engine

Honda GX120 Engine

ANSI Power Rating @ 3600 rpm 4.0 Horsepower 3.0 kW

Sprayer

Maximum Working Pressure 3300 psi 228 bar, 22.8 MPa

Maximum Delivery Rating 0.75 gpm 2.84 lpm

Inlet Paint Strainer

Outlet Paint Filter

Pump Inlet Size 1 1/4-12 UNF-2A 1 1/4-12 UNF-2A

Fluid Outlet Size 1/4 npsm from fluid filter 1/4 npsm from fluid filter

Maximum Tip Size: 1 Gun with 0.027 in. tip 1 Gun with 0.027 in. tip

Dimensions

Weight: 89 lb 40.5 kg

Height (handle extended): 40.8 in. 103.6 cm

Length (handle extended): 35.0 in. 88.9 cm

Width: 22.3 in. 56.6 cm

12 mesh (1523 micron)

stainless steel screen, reusable

60 mesh (250 micron)

stainless steel screen, reusable

12 mesh (1523 micron)

stainless steel screen, reusable

60 mesh (250 micron)

stainless steel screen, reusable

zinc- and nickel-plated carbon steel, PTFE, nylon, polyurethane, UHMW,

Wetted parts

Noise Level:

Sound Power 100 dBa per ISO 3744 100 dBa per ISO 3744

Sound Pressure 86 dBa measured at 3.1 ft 86 dBa measured at 1 m

fluoroelastomer, acetal, leather, aluminum, tungsten carbide,

stainless steel, chrome plating

34 332919C

Page 35

3900 Models

U.S. Metric

Engine

Honda GX120 Engine

ANSI Power Rating @ 3600 rpm 4.0 Horsepower 3.0 kW

Sprayer

Maximum Working Pressure 3300 psi 228 bar, 22.8 MPa

Maximum Delivery Rating 1.25 gpm 4.73 lpm

Inlet Paint Strainer

Outlet Paint Filter

Pump Inlet Size 1-5/16-12 UN-2A 1-5/16-12 UN-2A

Fluid Outlet Size 1/4 npsm from fluid filter 1/4 npsm from fluid filter

Maximum Tip Size:

Dimensions

Weight:

GMAX 3900 Standard 106 lb 48.2 kg

GMAX 3900 Lo-Boy 123 lb 55.9 kg

GMAX 3900 ProContractor 133 lb 60.5 kg

GMAX 3900 Rental Pro 360G 106 lb 48.2 kg

Height:

GMAX 3900 Standard 40.8 in. 103.6 cm

GMAX 3900 Lo-Boy 26.4 in. 67.1 cm

GMAX 3900 ProContractor 38.3 in. 97.3 cm

GMAX 3900 Rental Pro 360G 40.8 in. 103.6 cm

Length:

GMAX 3900 Standard 38.3 in. 97.3 cm

GMAX 3900 Lo-Boy 46.9 in. 119.1 cm

GMAX 3900 ProContractor 32.3 in. 82.0 cm

GMAX 3900 Rental Pro 360G 38.3 in. 97.3 cm

Width:

GMAX 3900 Standard 22.3 in. 56.6 cm

GMAX 3900 Lo-Boy 24.4 in. 62.0 cm

GMAX 3900 ProContractor 22.3 in. 56.6 cm

GMAX 3900 Rental Pro 360G 22.3 in. 56.6 cm

8 mesh (2589 micron)

stainless steel screen, reusable

60 mesh (250 micron)

stainless steel screen, reusable

1 Gun with 0.036 in. tip 1 Gun with 0.036 in. tip

2 Guns with 0.023 in. tip 2 Guns with 0.023 in. tip

3 Guns with 0.018 in. tip 3 Guns with 0.018 in. tip

8 mesh (2589 micron)

stainless steel screen, reusable

60 mesh (250 micron)

stainless steel screen, reusable

Technical Data

Wetted parts

Noise Level:

Sound Power 105 dBa per ISO 3744 105 dBa per ISO 3744

Sound Pressure 96 dBa measured at 3.1 ft 96 dBa measured at 1 m

zinc- and nickel-plated carbon steel, PTFE, nylon, polyurethane, UHMW,

fluoroelastomer, acetal, leather, aluminum, tungsten carbide,

stainless steel, chrome plating

332919C 35

Page 36

Technical Data

5900 Models

U.S. Metric

Engine

Honda GX160 Engine

ANSI Power Rating @ 3600 rpm 5.5 Horsepower 4.1 kW

Sprayer

Maximum Working Pressure 3300 psi 228 bar, 22.8 MPa

Maximum Delivery Rating 1.6 gpm 6.06 lpm

Inlet Paint Strainer

Outlet Paint Filter

Pump Inlet Size 1-5/16-12 UN-2A 1-5/16-12 UN-2A

Fluid Outlet Size 1/4 npsm from fluid filter 1/4 npsm from fluid filter

Fluid Outlet Size (5900 IronMan and 5900HD) 3/8 npsm from fluid filter 3/8 npsm from fluid filter

Maximum Tip Size:

Dimensions

Weight:

GMAX 5900 Standard 138 lb 62.7 kg

GMAX 5900 Lo-Boy 144 lb 65.5 kg

GMAX 5900 ProContractor 160 lb 72.7 kg

GMAX 5900 Convertible, Standard 167 lb 75.9 kg

GMAX 5900 IronMan 160 lb 72.7 kg

TexSpray 5900HD ProContractor 164 lb 74.5 kg

TexSpray 5900HD Standard 142 lb 64.5 kg

Height:

GMAX 5900 Standard 40.5 in. 102.9 cm

GMAX 5900 Lo-Boy 27.2 in. 69.1 cm

GMAX 5900 ProContractor 38.0 in. 96.5 cm

GMAX 5900 Convertible, Standard 43.8 in. 111.3 cm

GMAX 5900 IronMan 38.8 in. 98.6 cm

TexSpray 5900HD ProContractor 38.0 in. 98.6 cm

TexSpray 5900HD Standard 40.5 in. 102.9 cm

Length:

GMAX 5900 Standard 37.7 in. 95.8 cm

GMAX 5900 Lo-Boy 46.9 in. 119.1 cm

GMAX 5900 ProContractor 32.7 in. 83.1 cm

GMAX 5900 Convertible, Standard 33.0 in. 83.8 cm

GMAX 5900 IronMan 40.4 in. 102.6 cm

TexSpray 5900HD ProContractor 32.7 in. 83.1 cm

TexSpray 5900HD Standard 37.7 in. 95.8 cm

Width: 24.4 in. 62.0 cm

8 mesh (2589 micron)

stainless steel screen, reusable

60 mesh (250 micron)

stainless steel screen, reusable

1 Gun with 0.043 in. tip 1 Gun with 0.043 in. tip

2 Guns with 0.029 in. tip 2 Guns with 0.029 in. tip

3 Guns with 0.023 in. tip 3 Guns with 0.023 in. tip

4 Guns with 0.019 in. tip 4 Guns with 0.019 in. tip

8 mesh (2589 micron)

stainless steel screen, reusable

60 mesh (250 micron)

stainless steel screen, reusable

Wetted parts

Noise Level:

Sound Power 105 dBa per ISO 3744 105 dBa per ISO 3744

Sound Pressure 96 dBa measured at 3.1 ft 96 dBa measured at 1 m

zinc- and nickel-plated carbon steel, PTFE, nylon, polyurethane, UHMW,

fluoroelastomer, acetal, leather, aluminum, tungsten carbide,

stainless steel, chrome plating

36 332919C

Page 37

7900 Models

U.S. Metric

Engine

Honda GX200 Engine

ANSI Power Rating @ 3600 rpm 6.5 Horsepower 6.5 kW

Sprayer

Maximum Working Pressure 3300 psi 228 bar, 22.8 MPa

Maximum Delivery Rating 2.2 gpm 8.33 lpm

Inlet Paint Strainer

Outlet Paint Filter

Pump Inlet Size 1-5/16-12 UN-2A 1-5/16-12 UN-2A

Fluid Outlet Size 3/8 npsm from fluid filter 3/8 npsm from fluid filter

Maximum Tip Size:

Dimensions

Weight:

GMAX 7900 Standard 148 lb 67.3 kg

GMAX 7900 Lo-Boy 154 lb 70.0 kg

GMAX 7900 ProContractor 167 lb 75.9 kg

GMAX 7900 IronMan 168 lb 76.4 kg

TexSpray 7900HD Pro 182 lb 82.7 kg

TexSpray 7900HD Standard 153 lb 69.5 kg

TexSpray 7900HD IronMan 175 lb 79.5 kg

Height:

GMAX 7900 Standard 40.5 in. 102.9 cm

GMAX 7900 Lo-Boy 27.2 in. 69.1 cm

GMAX 7900 ProContractor 38.0 in. 96.5 cm

GMAX 7900 IronMan 38.8 in. 98.6 cm

TexSpray 7900HD Pro 38.0 in. 96.5 cm

TexSpray 7900HD Standard 40.5 in. 102.9 cm

TexSpray 7900HD IronMan 38.8 in. 98.6 cm

Length:

GMAX 7900 Standard 38.1 in. 96.8 cm

GMAX 7900 Lo-Boy 46.9 in. 119.1 cm

GMAX 7900 ProContractor 33.3 in. 84.6 cm

GMAX 7900 IronMan 40.4 in. 102.6 cm

TexSpray 7900HD Pro 33.3 in. 84.6 cm

TexSpray 7900HD Standard 38.1 in. 96.8 cm

TexSpray 7900HD IronMan 40.4 in. 102.6 cm

Width: 24.4 in. 62.0 cm

8 mesh (2589 micron)

stainless steel screen, reusable

60 mesh (250 micron)

stainless steel screen, reusable

1 Gun with 0.048 in. tip 1 Gun with 0.048 in. tip

2 Guns with 0.035 in. tip 2 Guns with 0.035 in. tip

3 Guns with 0.027 in. tip 3 Guns with 0.027 in. tip

4 Guns with 0.023 in. tip 4 Guns with 0.023 in. tip

8 mesh (2589 micron)

stainless steel screen, reusable

60 mesh (250 micron)

stainless steel screen, reusable

Technical Data

Wetted parts

Noise Level:

Sound Power 105 dBa per ISO 3744 105 dBa per ISO 3744

Sound Pressure 96 dBa measured at 3.1 ft 96 dBa measured at 1 m

zinc- and nickel-plated carbon steel, PTFE, nylon, polyurethane, UHMW,

fluoroelastomer, acetal, leather, aluminum, tungsten carbide,

stainless steel, chrome plating

332919C 37

Page 38

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2014, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 332919

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised July 2014

Loading...

Loading...