Page 1

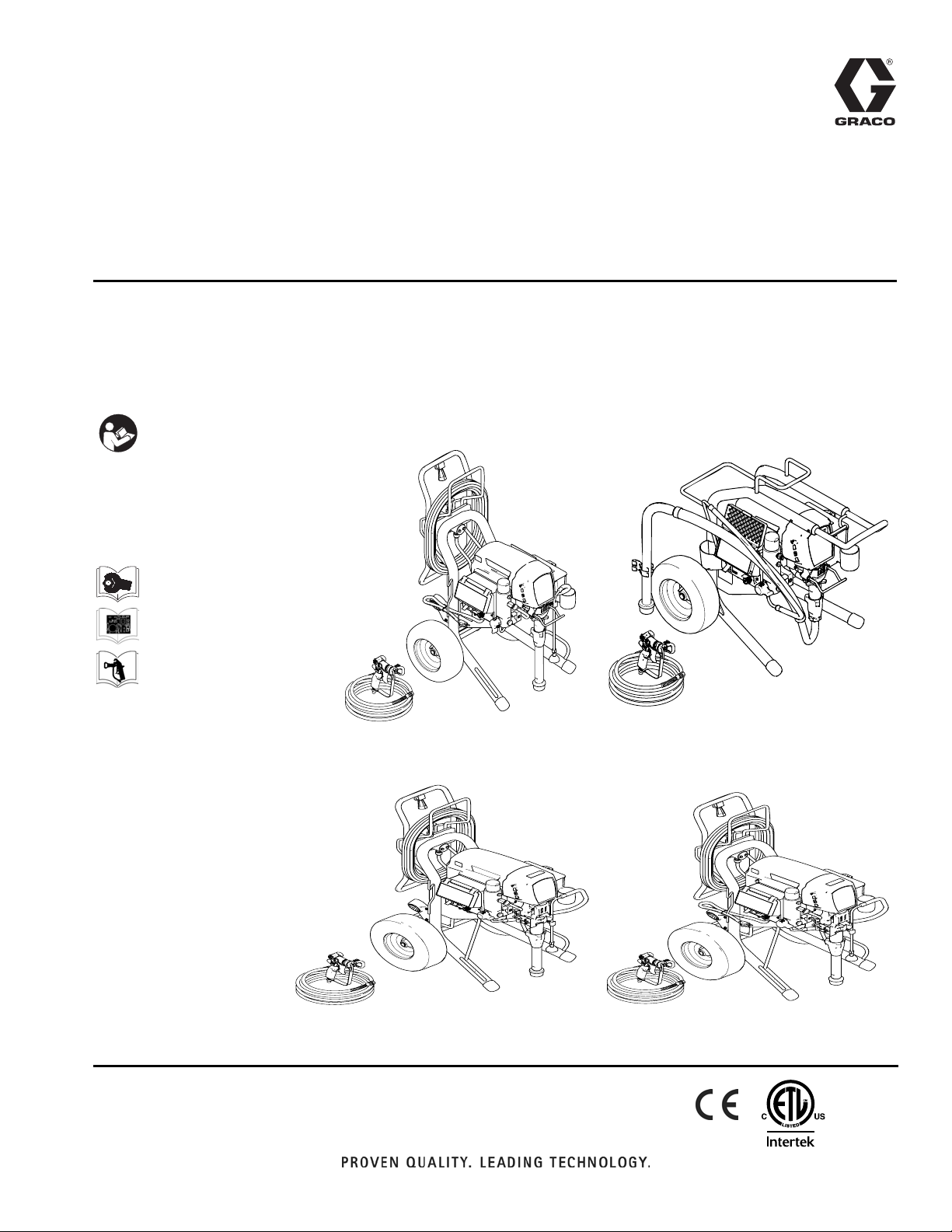

Repair

Electric Airless Sprayers

3A0157B

EN

For Portable Airless Spraying of Architectural Coatings and Paints. For professional use

only. Not approved for use in European explosive atmoshere locations.

3300 psi (227 bar, 22.7 MPa) Maximum Working Pressure

IMPORTANT SAFETY INSTRUCTIONS

Read all warnings and instructions in this

manual. Save these instructions.

Related Manuals:

3A0156

ti15034a

3A0158

Parts

311861

ti14838b

695/795

695/795 Premium Hi-Boy

ti15036b

MARK V

ti15035b

1095/1595 Premium Hi-Boy

Page 2

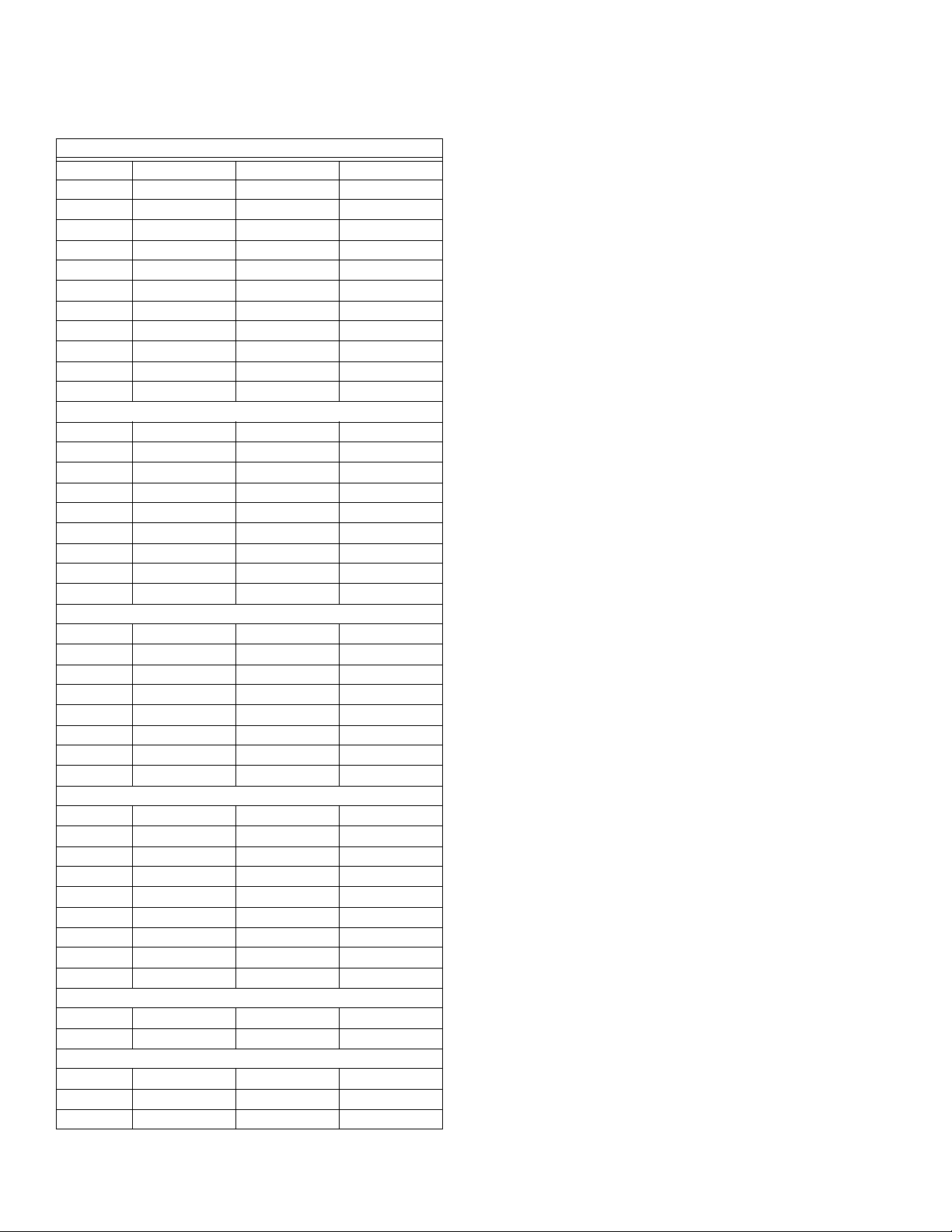

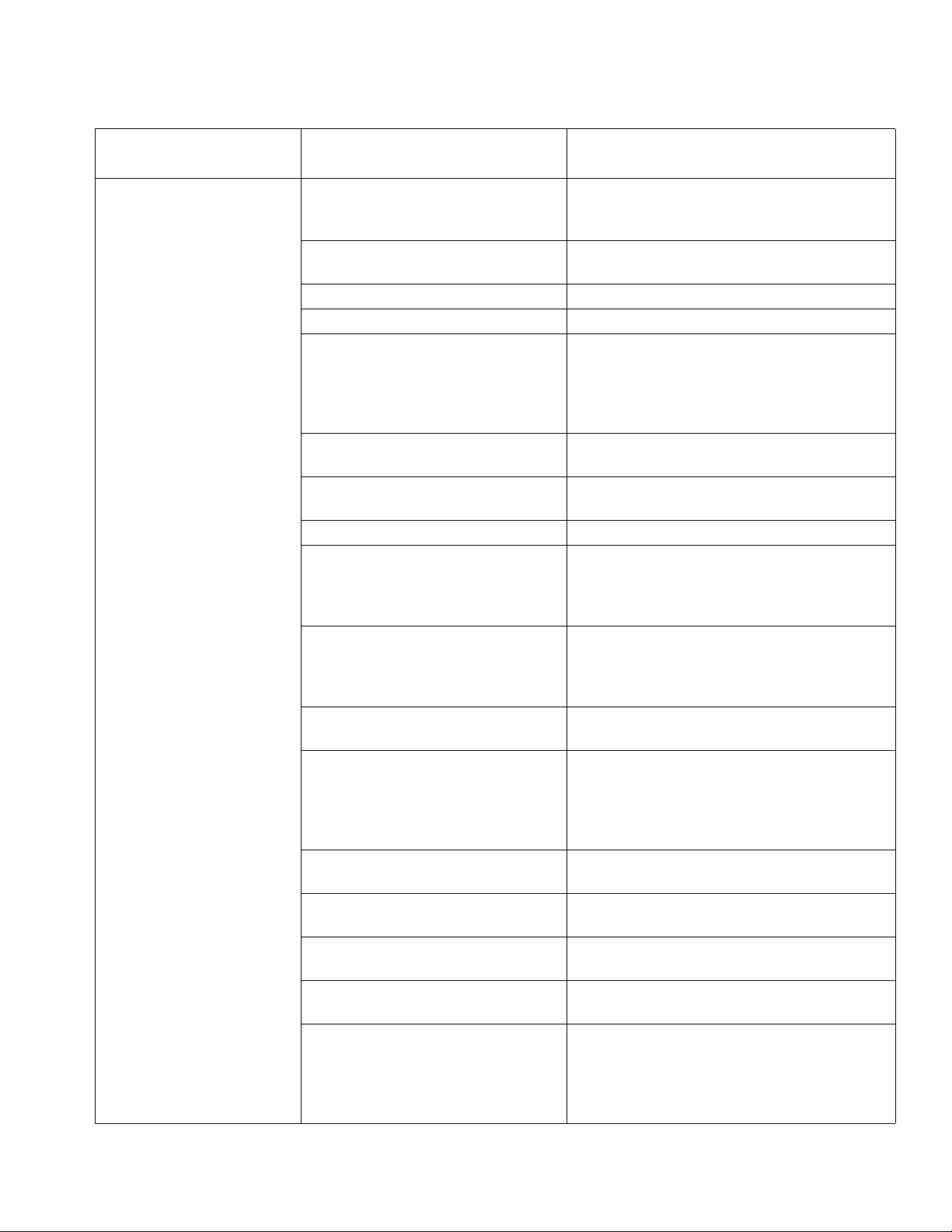

Models:

Models:

695 ULTRA MAX lIl

Model QuikReel Hi-Boy Lo-Boy

258719 ✓✓

258720 ✓

258722 ✓

258872 ✓

258873 ✓

258874 ✓

258876 ✓

258877 ✓✓

826124 ✓✓

826125 ✓

826127 ✓

795 ULTRA MAX III

Model QuikReel Hi-Boy Lo-Boy

258723 ✓✓

258724 ✓

258878 ✓✓

258879 ✓

258881 ✓

258882 ✓✓

826128 ✓✓

826129 ✓

1095 ULTRA MAX III

Model QuikReel Hi-Boy Lo-Boy

258727 ✓✓

258728 ✓

258883 ✓✓

258884 ✓

258886 ✓✓

826130 ✓✓

826131 ✓

1595 ULTRA MAX III

Model QuikReel Hi-Boy Lo-Boy

258763 ✓✓

258764 ✓

258765 ✓✓

258766 ✓

826132 ✓✓

826133 ✓

826134 ✓✓

826135 ✓

MARK IV

Model QuikReel Hi-Boy Lo-Boy

258729 ✓✓

MARK V

Model QuikReel Hi-Boy Lo-Boy

258730 ✓✓

258887 ✓✓

2 3A0157B

Page 3

Table of Contents

Table of Contents

Models: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Component Identification . . . . . . . . . . . . . . . . . . . . 7

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . 8

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Power Requirements . . . . . . . . . . . . . . . . . . . . . . 9

Extension Cord . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Mechanical/Fluid Flow . . . . . . . . . . . . . . . . . . . . 10

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

240 VAC and 110 VAC Motor Control Board . . . 21

240 VAC Filter Board . . . . . . . . . . . . . . . . . . . . 23

Pressure Adjust Potentiometer . . . . . . . . . . . . . 24

Pressure Control Transducer . . . . . . . . . . . . . . 25

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Drive and Bearing Housing Replacement . . . . . . 28

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Motor Replacement . . . . . . . . . . . . . . . . . . . . . . . . 30

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Displacement Pump Replacement for

695/795/Mark IV . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Displacement Pump Replacement

1095/1595/Mark V . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Hose Reel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Reed Switch Replacement . . . . . . . . . . . . . . . . . . 39

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

120V Models: . . . . . . . . . . . . . . . . . . . . . . . . . . 40

120V Models (with 15/20 Amp Switch): . . . . . . 41

240V Models: . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 44

3A0157B 3

Page 4

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance and repair of this equipment. The exclamation

point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risks. Refer back to

these warnings. Additional, product-specific warnings may be found throughout the body of this manual where applicable.

WARNING

GROUNDING

This product must be grounded. In the event of an electrical short circuit, grounding reduces the risk of electric shock by providing an escape wire for the electric current. This product is equipped with a cord having a

grounding wire with an appropriate grounding plug. The plug must be plugged into an outlet that is properly

installed and grounded in accordance with all local codes and ordinances.

• Improper installation of the grounding plug is able to result in a risk of electric shock.

• When repair or replacement of the cord or plug is required, do not connect the grounding wire to either

flat blade terminal.

• The wire with insulation having an outer surface that is green with or without yellow stripes is the ground-

ing wire.

• Check with a qualified electrician or serviceman when the grounding instructions are not completely

understood, or when in doubt as to whether the product is properly grounded.

• Do not modify the plug provided; if it does not fit the outlet, have the proper outlet installed by a qualified

electrician.

• This product is for use on a nominal 120V circuit and has a grounding plug similar to the plug illustrated

in the figure below.

• Only connect the product to an outlet having the same configuration as the plug.

• Do not use an adapter with this product.

Extension Cords:

• Use only a 3-wire extension cord that has a 3-blade grounding plug and a 3-slot receptacle that accepts

the plug on the product.

• Make sure your extension cord is not damaged. If an extension cord is necessary, use 12 AWG

2

(2.5 mm

• An undersized cord results in a drop in line voltage and loss of power and overheating.

4 3A0157B

) minimum to carry the current that the product draws.

Page 5

Warnings

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire

and explosion:

• Do not spray flammable or combustible materials near an open flame or sources of ignition such as cig-

arettes, motors, and electrical equipment.

• Paint or solvent flowing through the equipment is able to result in static electricity. Static electricity cre-

ates a risk of fire or explosion in the presence of paint or solvent fumes. All parts of the spray system,

including the pump, hose assembly, spray gun, and objects in and around the spray area shall be properly grounded to protect against static discharge and sparks. Use Graco conductive or grounded

high-pressure airless paint sprayer hoses.

• Do not clean with materials having flash points lower than 70° F (21° C). Use water-based material or

mineral spirits-type material only. For complete information about your fluid, request the MSDS from the

fluid distributor or retailer.

• Verify that all containers and collection systems are grounded to prevent static discharge.

• Connect to a grounded outlet and use grounded extensions cords. Do not use a 3-to-2 adapter.

• Do not use a paint or a solvent containing halogenated hydrocarbons.

• Keep spray area well-ventilated. Keep a good supply of fresh air moving through the area. Keep pump

assembly in a well ventilated area. Do not spray pump assembly.

• Do not smoke in the spray area.

• Do not operate light switches, engines, or similar spark producing products in the spray area.

• Keep area clean and free of paint or solvent containers, rags, and other flammable materials.

• Know the contents of the paints and solvents being sprayed. Read all Material Safety Data Sheets

(MSDS) and container labels provided with the paints and solvents. Follow the paint and solvents manufacturer’s safety instructions.

• Fire extinguisher equipment shall be present and working.

• Sprayer generates sparks. When flammable liquid is used in or near the sprayer or for flushing or clean-

ing, keep sprayer at least 20 feet (6 m) away from explosive vapors.

SKIN INJECTION HAZARD

• Do not aim the gun at, or spray any person or animal.

• Keep hands and other body parts away from the discharge. For example, do not try to stop leaks with

any part of the body.

• Always use the nozzle tip guard. Do not spray without nozzle tip guard in place.

• Use Graco nozzle tips.

• Use caution when cleaning and changing nozzle tips. in the case where the nozzle tip clogs while spray-

ing, follow the Pressure Relief Procedure for turning off the unit and relieving the pressure before

removing the nozzle tip to clean.

• Do not leave the unit energized or under pressure while unattended. When the unit is not in use, turn off

the unit and follow the Pressure Relief Procedure for turning off the unit.

• High-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the event

that injection occurs, get immediate surgical treatment.

• Check hoses and parts for signs of damage. Replace any damaged hoses or parts.

• This system is capable of producing 3300 psi. Use Graco replacement parts or accessories that are

rated a minimum of 3300 psi.

• Always engage the trigger lock when not spraying. Verify the trigger lock is functioning properly.

• Verify that all connections are secure before operating the unit.

Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the controls.

3A0157B 5

Page 6

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Always wear appropriate gloves, eye protection, and a respirator or mask when painting.

• Do not operate or spray near children. Keep children away from equipment at all times.

• Do not overreach or stand on an unstable support. Keep effective footing and balance at all times.

• Stay alert and watch what you are doing.

• Do not leave the unit energized or under pressure while unattended. When the unit is not in use, turn off

the unit and follow the Pressure Relief Procedure for turning off the unit.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not kink or over-bend the hose.

• Do not expose the hose to temperatures or to pressures in excess of those specified by Graco.

• Do not use the hose as a strength member to pull or lift the equipment.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric

shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and regula-

tions.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical

reaction and equipment rupture. Failure to follow this warning can result in death, serious injury, or property

damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids

containing such solvents.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier

for compatibility.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, fol-

low the Pressure Relief Procedure and disconnect all power sources.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area of

the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of toxic

fumes, and burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

6 3A0157B

Page 7

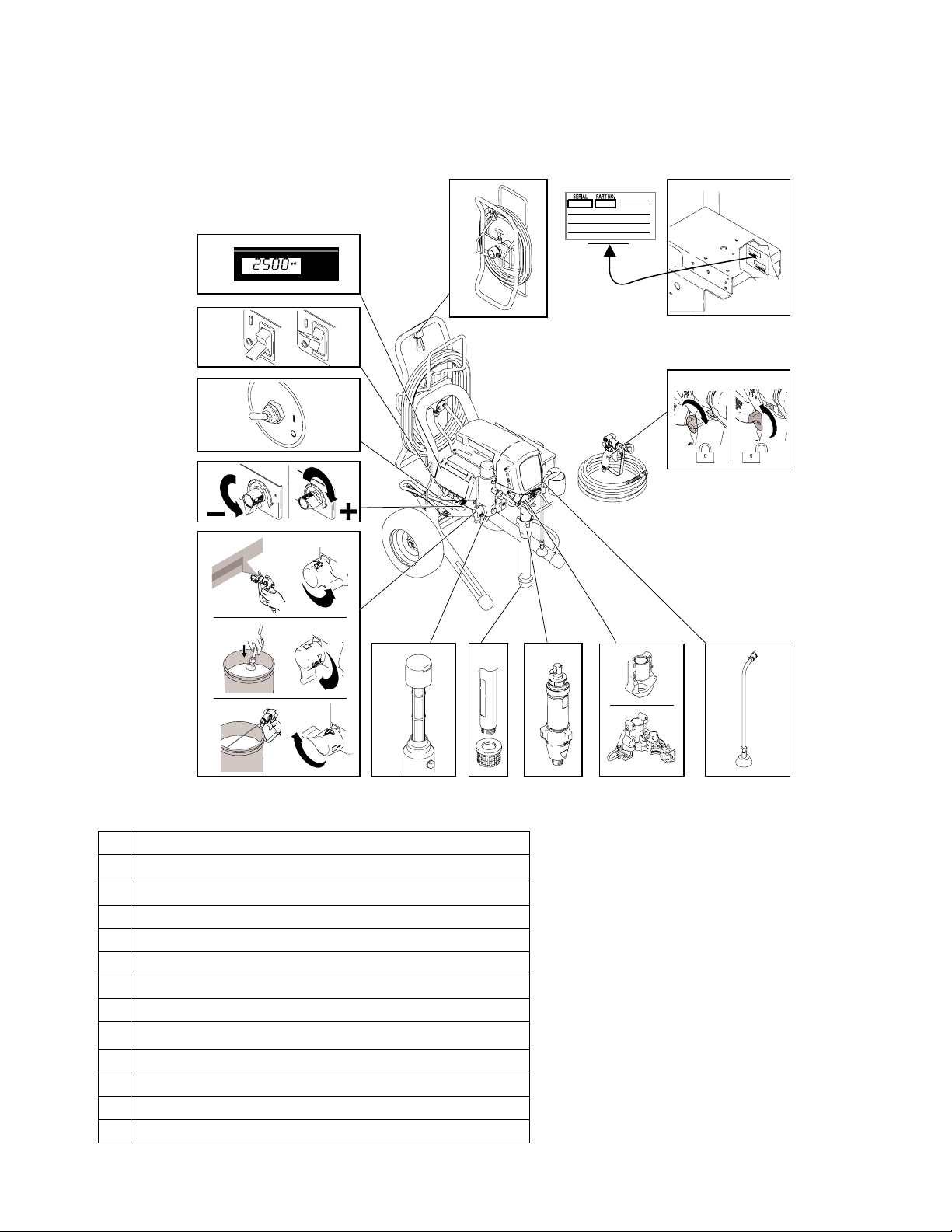

Component Identification

Component Identification

13.

1.

2.

3.

4.

5.

12.

11.

1 Premium Digital Display

2 ON/OFF switch

3

WatchDog

™

Switch (not available on Mark V)

4 Pressure Control

5 Prime / Spray Valve

6 Filter

7 Siphon Tube

8Pump

9

Bearing Housing / ProConnect

10 Drain Tube

11 Trigger Lock

12 Model/serial tag

13 Hose Reel

6. 7.

™

8.

9.

10.

ti14839b

3A0157B 7

Page 8

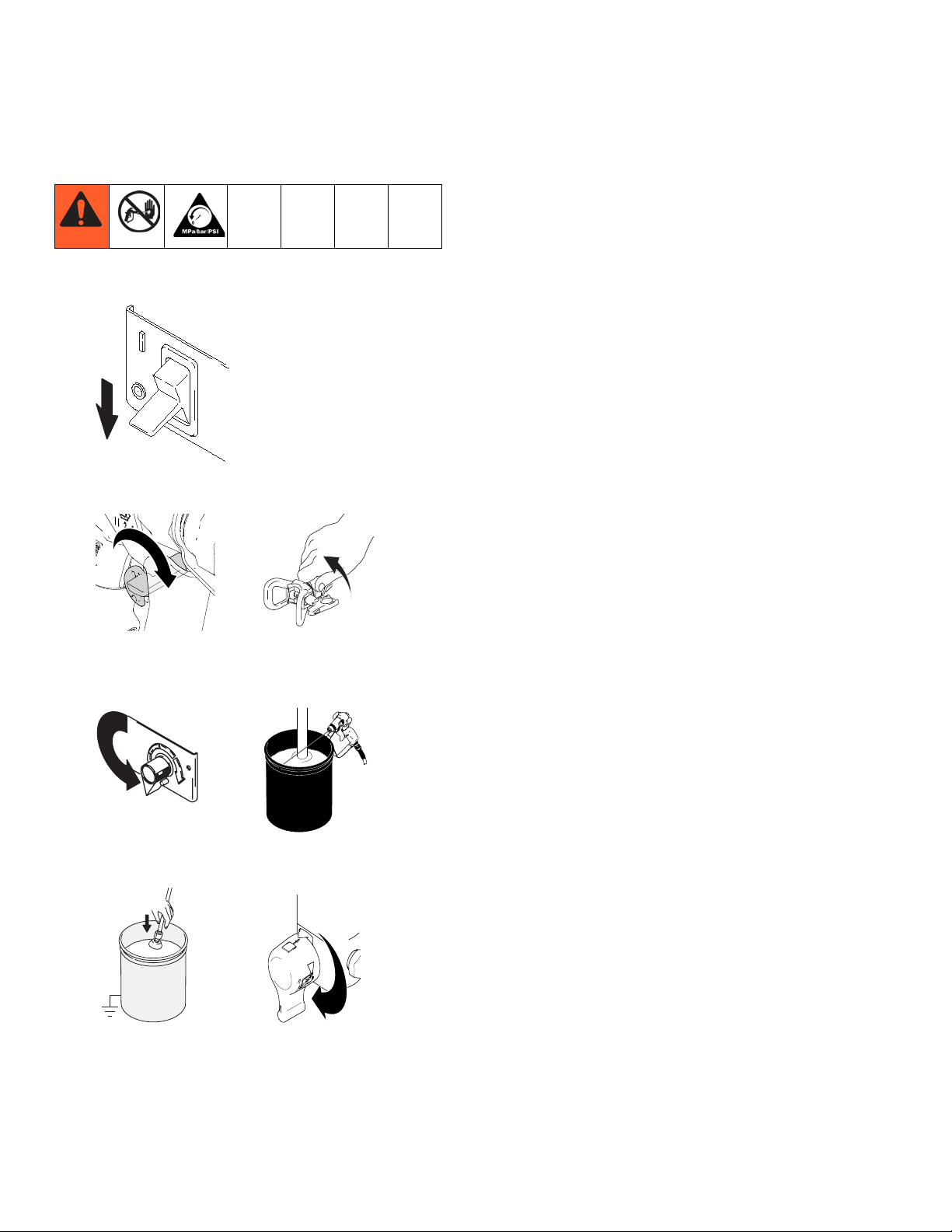

Pressure Relief Procedure

Pressure Relief Procedure

1. Turn power OFF. Wait 7 seconds for power to

dissipate.

ti4265a

2. Lock gun trigger safety. Remove guard and

SwitchTip.

ti10166a

3. Turn pressure to lowest setting. Trigger gun to

relieve pressure.

ti2769a

ti14841a

-

4. Put drain tube in pail. Turn prime valve down to

DRAIN position.

ti2595a

ti14842a

8 3A0157B

Page 9

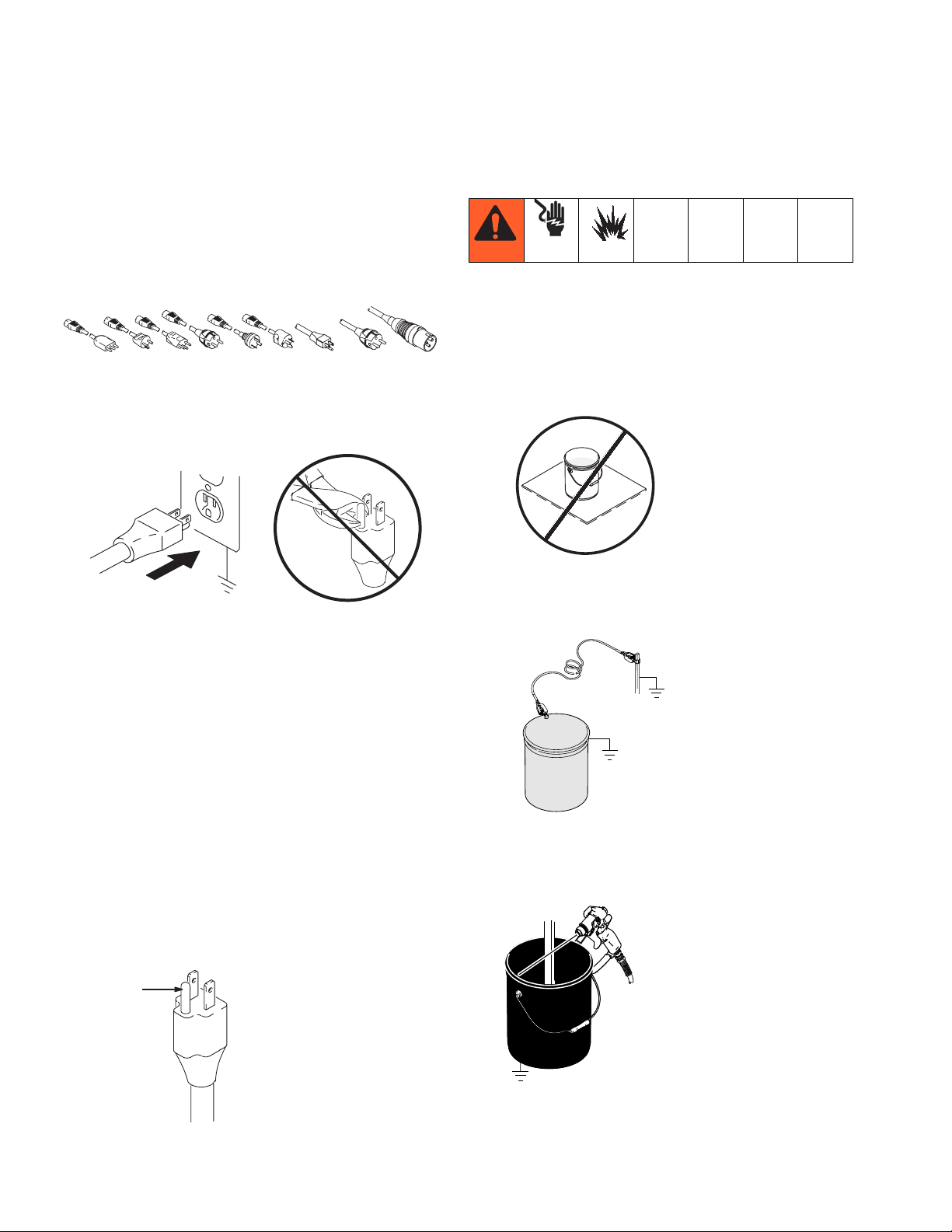

Grounding

Grounding

The sprayer must be grounded. Grounding reduces the

risk of static and electric shock by providing an escape

wire for the electrical current due to static build up or in

the event of a short circuit.

The sprayer cord includes a grounding wire with an

appropriate grounding contact.

The plug must be plugged into an outlet that is properly

installed and grounded in accordance with all local

codes and ordinances.

ti2810a

ti2810a

ti4297a

Do not modify plug! Tampering with the plug will result in

a voided warranty. If plug will not fit in outlet, have

grounded outlet installed by a qualified electrician. Do

not use an adapter.

Pails

Solvent and oil/based fluids: follow local code. Use

only conductive metal pails, placed on a grounded surface such as concrete.

Do not place pail on a nonconductive surface such as

paper or cardboard which interrupts grounding continuity.

ti5850a

Grounding a metal pail: connect a ground wire to the

pail by clamping one end to pail and other end to a true

earth ground.

Power Requirements

• 100-120V units require 100-120 VAC, 50/60 Hz,

15A, 1 phase.

• 230V units require 230 VAC, 50/60 HZ, 10A,

1 phase.

Extension Cord

Use an extension cord with an undamaged ground contact. If an extension cord is necessary, use a 3-wire, 12

2

AWG (2.5 mm

Ground

120 volt plug

) minimum.

ti14840a

To maintain grounding continuity when flushing or

relieving pressure: hold metal part of spray gun firmly

to side of a grounded metal pail. Then trigger gun.

ti13243a

3A0157B 9

Page 10

Troubleshooting

Troubleshooting

Mechanical/Fluid Flow

Perform Pressure Relief Procedure; page 8.

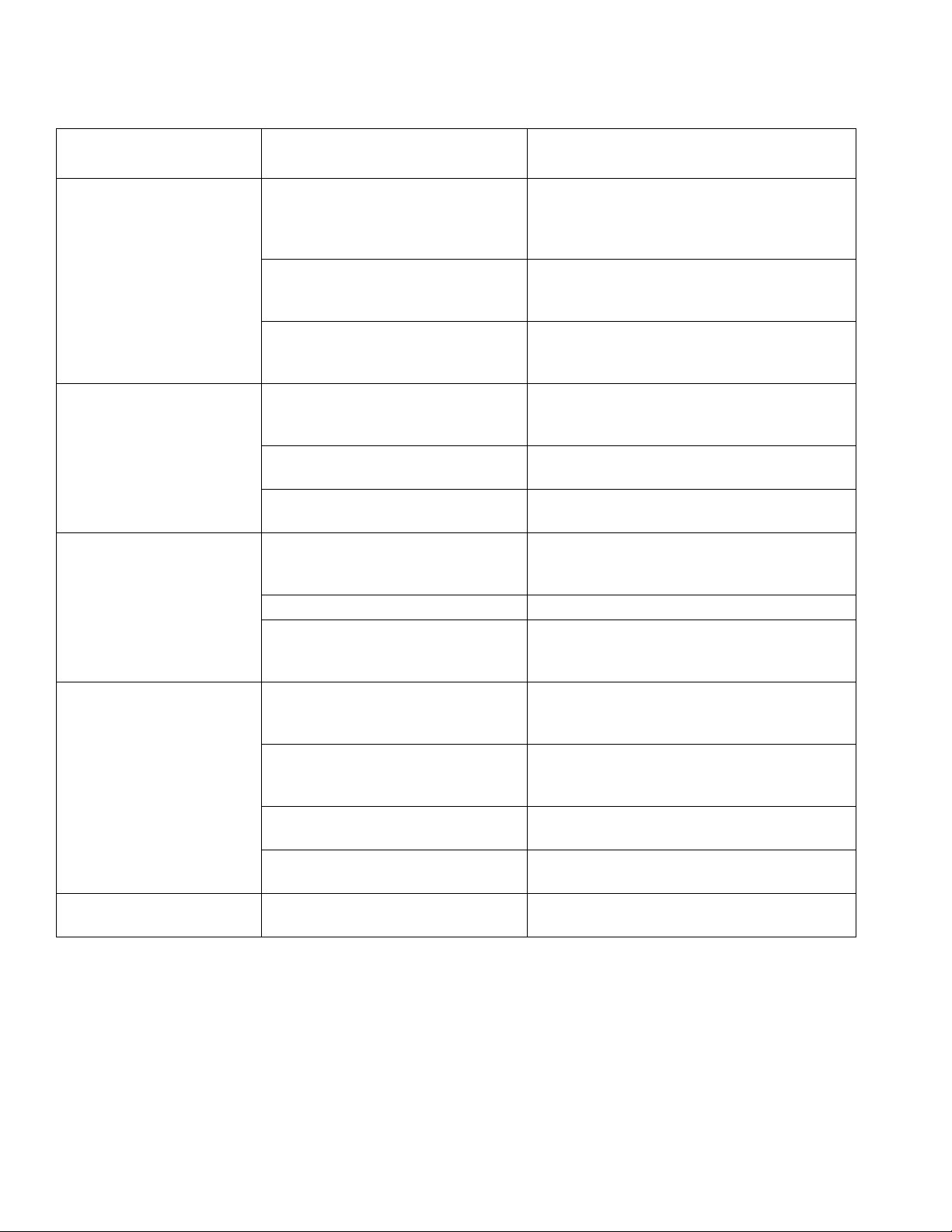

TYPE OF PROBLEM

E=XX is displayed

False tripping of WatchDog

system. EMPTY is displayed. Pump does not

run.

WHAT TO CHECK

If check is OK, go to next check

1. Fault condition exists 1. Determine fault correction from table,

1. Operating conditions out of

WatchDog parameters. Pump

output is low, see below.

When check is not OK, refer to this column

page 13.

1. Turn pressure down. Refer to operation

manual for adjusting. Operate without

WatchDog active; see operation manual.

WHAT TO DO

10 3A0157B

Page 11

Troubleshooting

TYPE OF PROBLEM

Pump output is low

WHAT TO CHECK

If check is OK, go to next check

When check is not OK, refer to this column

WHAT TO DO

1. Spray tip worn 1. Follow Pressure Relief Procedure on

page 8, then replace tip. See your separate gun or tip manual.

2. Spray tip clogged 2. Relieve pressure. Check and clean spray

tip.

3. Paint supply 3. Refill and reprime pump.

4. Intake strainer clogged 4. Remove and clean, then reinstall

5. Intake valve ball and piston ball

are not seating properly

5. Remove intake valve and clean. Check

balls and seats for nicks; replace if necessary; see pump manual 310643 or

310894. Strain paint before using to

remove particles that could clog pump.

6. Suction hose connections 6. Tighten any loose connections. Check for

missing or damaged seals.

7. Fluid filter, tip filter, or tip is

7. Clean filter; see operation manual.

clogged or dirty.

8. Prime valve leaking 8. Relieve pressure. Repair prime valve.

9. Verify pump does not continue to

stroke when gun trigger is

9. Service pump; see pump manual 310643

or 310894.

released. (Prime valve not leaking.)

10. Leaking around throat packing

nut which may indicate worn or

damaged packings.

10. Replace packings; see pump manual. Also

check piston valve seat for hardened paint

or nicks and replace if necessary. Tighten

packing nut/wet-cup.

11. Pump rod damage 11. Repair pump. See pump manual 310643

or 310894.

12. Low stall pressure 12. Turn pressure knob fully clockwise. Make

sure pressure control knob is properly

installed to allow full clockwise position. If

problem persists, replace pressure transducer.

13. Piston packings are worn or

damaged

14. O-ring in pump is worn or dam-

aged

15. Intake valve ball is packed with

material

13. Replace packings; see pump manual

310643 or 310894.

14. Replace o-ring; see pump manual 310643

or 310894.

15. Clean intake valve; see pump manual

310643 or 310894.

16. Pressure setting is too low 16. Increase pressure; see pump manual

310643 or 310894.

17. Large pressure drop in hose with

heavy materials

17. Use larger diameter hose and/or reduce

overall length of hose. Use of more than

100 ft of 1/4 in. hose significantly reduces

performance of sprayer. Use 3/8 in. hose

for optimum performance (50 ft minimum).

3A0157B 11

Page 12

Troubleshooting

TYPE OF PROBLEM

Motor runs but pump does

not stroke

Excessive paint leakage

into throat packing nut

Fluid is spitting from gun

Pump is difficult to prime

No display, sprayer operates

WHAT TO CHECK

If check is OK, go to next check

1. Displacement pump pin (32)

damaged or missing; see pump

manual 310643 or 310894.

When check is not OK, refer to this column

1. Replace pump pin if missing. Be sure

retainer spring (31) is fully in groove all

around connecting rod; see pump manual

WHAT TO DO

310643 or 310894.

2. Connecting rod assembly (43)

damaged; see pump manual

2. Replace connecting rod assembly; see

pump manual 310643 or 310894.

310643 or 310894.

3. Gears or drive housing damaged, page 28.

3. Inspect drive housing assembly and gears

for damage and replace if necessary; see

pump manual 310643 or 310894.

1. Throat packing nut is loose 1. Remove throat packing nut spacer.

Tighten throat packing nut just enough to

stop leakage.

2. Throat packings are worn or

damaged

3. Displacement rod is worn or

damaged

2. Replace packings; see pump manual

310643 or 310894.

3. Replace rod; see pump manual 310643 or

310894.

1. Air in pump or hose 1. Check and tighten all fluid connections.

Cycle pump as slowly as possible during

priming.

2. Tip is partially clogged 2. Clear tip; see tip guard manual 309640.

3. Fluid supply is low or empty 3. Refill fluid supply. Prime pump; see pump

manual 310643 or 310894. Check fluid

supply often to prevent running pump dry.

1. Air in pump or hose 1. Check and tighten all fluid connections.

Cycle pump as slowly as possible during

priming.

2. Intake valve is leaking 2. Clean intake valve. Be sure ball seat is not

nicked or worn and that ball seats well.

Reassemble valve.

3. Pump packings are worn 3. Replace pump packings; see pump manual 310643 or 310894.

4. Paint is too thick 4. Thin the paint according to supplier recommendations.

1. Display is damaged or has bad

1. Check connections. Replace display.

connection

12 3A0157B

Page 13

Electrical

Symptom: Sprayer does not run or stops running.

Perform Pressure Relief Procedure; page 8.

• Plug sprayer into correct voltage, grounded outlet

• Set power switch OFF for 30 seconds and then ON

again (this ensures sprayer is in normal run mode).

• Turn pressure control knob clockwise 1/2 turn

• View digital display

Troubleshooting

To avoid electrical shock or moving parts hazards when

covers are removed for troubleshooting, wait 30 seconds after unplugging power cord for stored electricity

to dissipate. Keep clear of electrical and moving parts

during troubleshooting procedures.

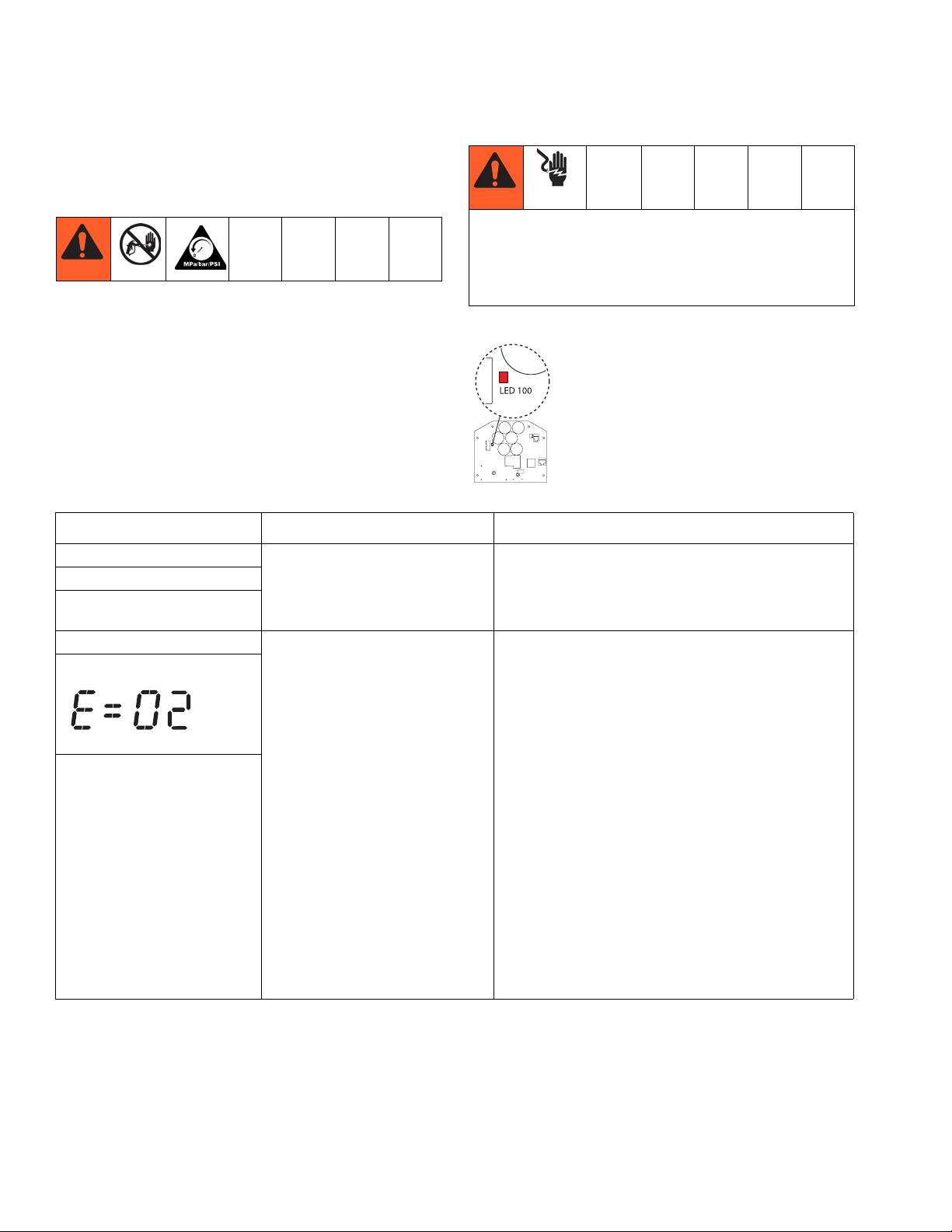

WARNING

If no digital display is available, use control

board status light to troubleshoot problems: Turn ON/OFF switch OFF, remove

control cover and then turn power back

ON. Observe status light. Blinking LED total count equals digital error code i.e., two

blinks equals E=02.

TYPE OF PROBLEM WHAT TO CHECK HOW TO CHECK

Sprayer does not run at all See flow chart, page 19.

Digital display is blank

Control board status light never

lights

Sprayer does not run at all Check transducer or transducer

Digital display shows E=02

Control board status light blinks

2 times repeatedly

connections

1. Make sure there is no pressure in the system (see

Pressure Relief Procedure, page 8). Check fluid

path for clogs, such as clogged filter.

2. Use airless paint spray hose with no metal braid

1/4 in. x 50 ft minimum. Smaller hose or metal braid

hose may result in high-pressure spikes.

3. Set sprayer to OFF and disconnect power to

sprayer.

4. Check transducer and connections to control board.

5. Disconnect transducer from control board socket.

Check that transducer and control board contacts

are clean and secure.

6. Reconnect transducer to control board socket.

Connect power, set sprayer ON and control knob

1/2 turn clockwise. If sprayer does not run properly,

set sprayer to OFF and go to next step.

7. Install new transducer. Connect power, set sprayer

ON and control knob 1/2 turn clockwise. Replace

control board if sprayer does not run properly.

3A0157B 13

Page 14

Troubleshooting

TYPE OF PROBLEM WHAT TO CHECK HOW TO CHECK

Sprayer does not run at all Check transducer or transducer

Digital display shows E=03

Control board status light blinks

3 times repeatedly

connections (control board is not

detecting a pressure signal).

1. Set sprayer to OFF and disconnect power to

sprayer.

2. Check transducer and connections to control board.

3. Disconnect transducer from control board socket.

Check to see if transducer and control board

contacts are clean and secure.

4. Reconnect transducer to control board socket.

Connect power, set sprayer ON and control knob

to 1/2 turn clockwise. If sprayer does not run,

set sprayer to OFF and go to next step.

5. Connect a confirmed working transducer to control

board socket.

6. Set sprayer ON and control knob to 1/2 turn

clockwise. If sprayer runs, install new transducer.

Replace control board if sprayer does not run.

7. Check transducer resistance with ohmmeter (less

than 9k ohm between red and black wires and 3-6k

ohm between green and yellow wires).

14 3A0157B

Page 15

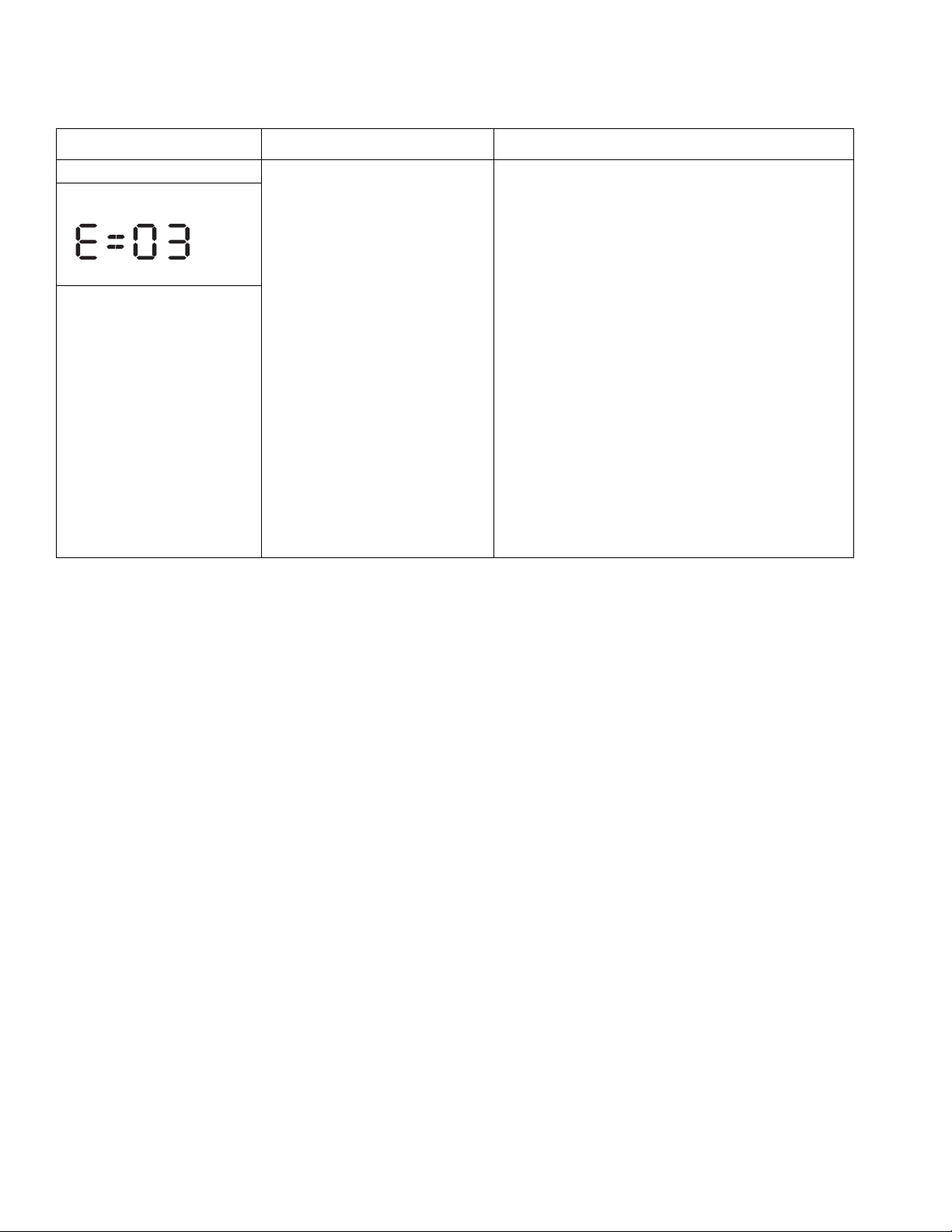

TYPE OF PROBLEM WHAT TO CHECK HOW TO CHECK

Troubleshooting

Sprayer does not run at all Control is commanding motor to run

Digital display shows E=05

Control board status light blinks

5 times repeatedly

but motor shaft does not rotate.

Possibly locked rotor condition, an

open connection exists between

motor and control, there is a

problem with motor or control board,

or motor amp draw is excessive.

1. Remove pump and try to run sprayer. If motor runs,

check for locked or frozen pump or drive train.

If sprayer does not run, continue to step 2.

2. Set sprayer to OFF and disconnect power to

sprayer.

3. Disconnect motor connector(s) from control board

socket(s). Check that motor connector and control

board contacts are clean and secure. If contacts

are clean and secure, continue to step 4.

4. Set sprayer to OFF and spin motor fan 1/2 turn.

Restart sprayer. If sprayer runs, replace control

board. If sprayer does not run, continue to step 5.

5. Perform Spin Test: Test at large 4-pin motor field

connector. Disconnect fluid pump from sprayer. Test

motor by placing a jumper across pins 1 & 2. Rotate

motor fan at about 2 revolutions per second. A cogging

resistance to motion should be felt at the fan.

The motor should be replaced if no resistance is felt.

Repeat for pin combinations 1 & 3 and 2 & 3. Pin 4

(the green wire) is not used in this test. If all spin test

is positive, continue to step 6.

Green Blue Red Black

STEP 1:

STEP 2:

STEP 3:

Green Blue Red Black

Green Blue Red Black

3A0157B 15

Page 16

Troubleshooting

TYPE OF PROBLEM WHAT TO CHECK HOW TO CHECK

Sprayer does not run at all Control is commanding motor to run

Digital display shows E=05

but motor shaft does not rotate.

Possibly locked rotor condition,

an open connection exists between

motor and control, there is a problem

with motor or control board, or

motor amp draw is excessive.

Control board status light blinks

5 times repeatedly

6. Perform Field Short Test: Test at large 4-pin motor

field connector. There should not be continuity from

pin 4, the ground wire, and any of the remaining

3 pins. If motor field connector tests fail,

replace motor.

7. Check Motor Thermal Switch: Unplug thermal

wires. Set meter to ohms. Meter should read the

proper resistance for each model (see table below).

-

ti13140a

Resistance Table:

695 0 ohms

795 2k ohms

1095 3.9k ohms

1595 6.2k ohms

MARK IV 2k ohms

MARK V 120V 6.2k ohms

MARK V 240V 3.9k ohms

16 3A0157B

Page 17

TYPE OF PROBLEM WHAT TO CHECK HOW TO CHECK

Troubleshooting

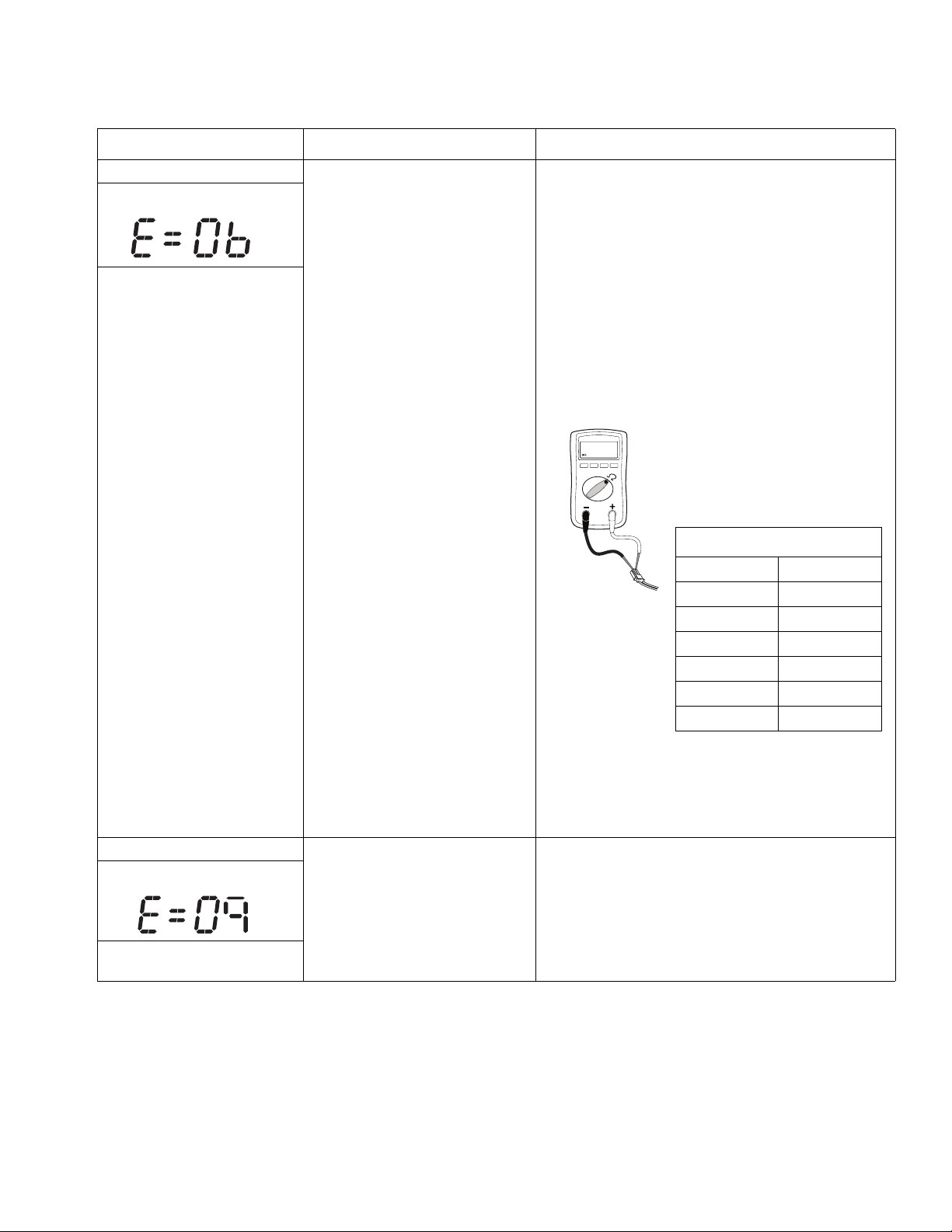

Sprayer does not run at all Allow sprayer to cool. If sprayer runs

Digital display shows E=06

when cool, correct cause of

overheating. Keep sprayer in cooler

location with good ventilation. Make

sure motor air intake is not blocked.

If sprayer still does not run, follow

Control board status light blinks

Step 1.

6 times repeatedly

NOTE: Motor must be cooled down for the test.

1. Check thermal device connector (yellow wires)

at control board.

2. Disconnect thermal device connector from control

board socket. Make sure contacts are clean and

secure.

Measure resistance of the thermal device. If reading

is not correct, replace motor.

Check Motor Thermal Switch: Unplug thermal

wires. Set meter to ohms. Meter should read the

proper resistance for each model (see table below).

-

Resistance Table:

ti13140a

695 0 ohms

795 2k ohms

1095 3.9k ohms

1595 6.2k ohms

MARK IV 2k ohms

MARK V 120V 6.2k ohms

MARK V 240V 3.9k ohms

3. Reconnect thermal device connector to control

board socket. Connect power, turn sprayer ON and

control knob 1/2 turn clockwise. If sprayer does not

run, replace control board.

Sprayer does not run at all Check the connections. Control

Digital display shows E=09

is not receiving a motor position

sensor signal

1. Turn power OFF.

2. Disconnect motor position sensor and inspect for

damage at connectors.

3. Reconnect sensor.

Control board status light blinks

4. Turn power ON. If error continues, replace motor.

9 times repeatedly

3A0157B 17

Page 18

Troubleshooting

TYPE OF PROBLEM WHAT TO CHECK HOW TO CHECK

Sprayer does not run at all Check to see if control board is over

Digital display shows E=10

Control board status light blinks

10 times repeatedly

heating.

Sprayer Will Not Shut Off

1. Perform Pressure Relief Procedure; page 8. Leave

prime valve open and power switch OFF.

Troubleshooting Procedure

Plumb pressure gauge into paint

hose, plug sprayer in, and turn power

switch ON. Does sprayer reach or

exceed its maximum pressure?

NO

1. Make sure motor air intake is not blocked.

2. Make sure fan has not failed.

3. Make sure control board is properly connected

to back plate and that conductive thermal paste

is used on power components.

4. Replace control board.

5. Replace motor.

2. Remove control box cover so the control board

status light can be viewed if available.

Mechanical problem: See the proper

fluid pump manual for the sprayer for

further trouble shooting procedures.

YES

Unplug the transducer from control

board. Does motor stop running?

YES

Bad transducer. Replace and test

with a new one.

NO

Replace the control board.

18 3A0157B

Page 19

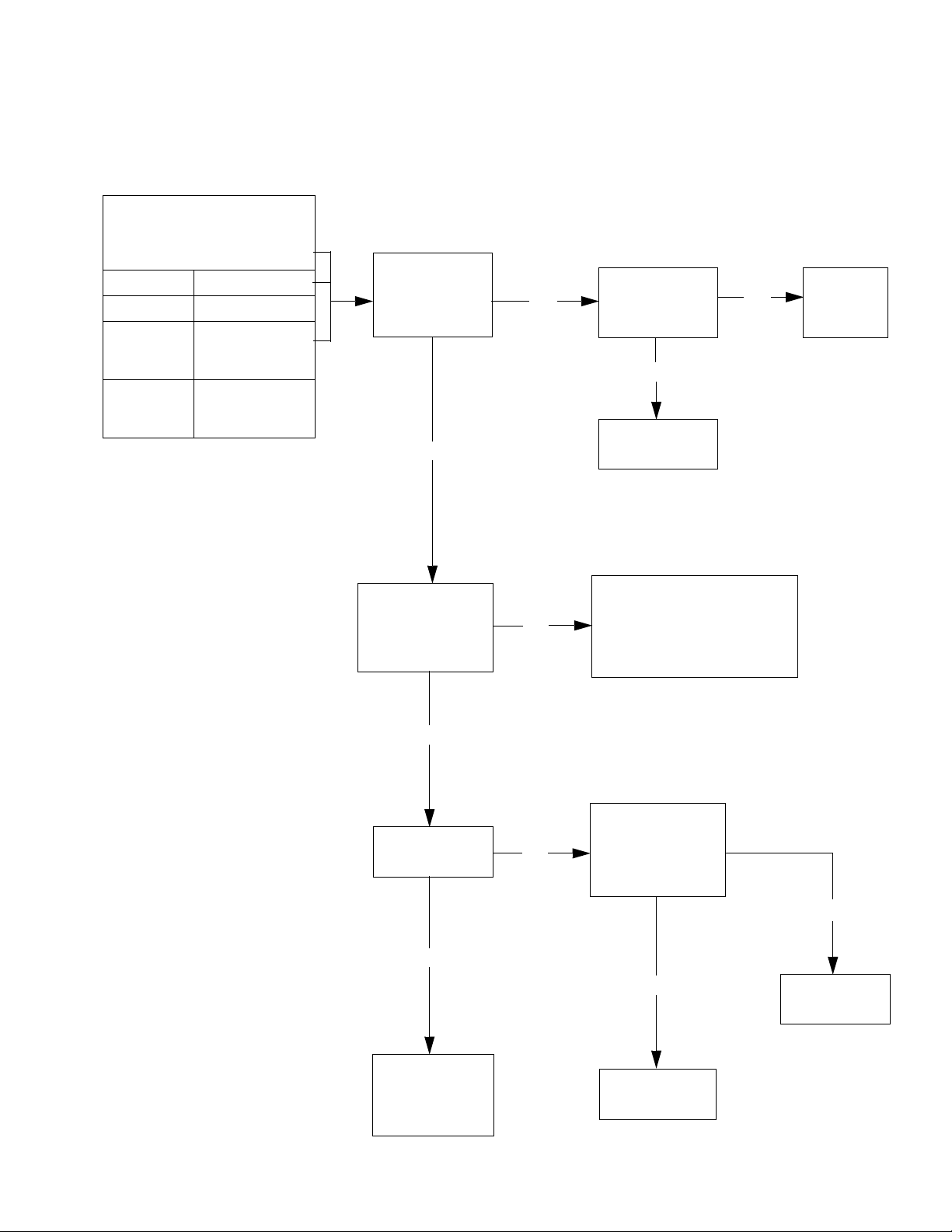

Sprayer Will Not Run

(See following page for steps)

Remove control box cover. Turn

sprayer ON. Observe control

board status light on control board

(see page 13).

No light

Once Normal operation

Light on

Continuously

Flashing See Error Code

Control board

commanding

motor to run

section for further

troubleshooting

See Step 1. Do

you have over

100 AC volts (200

for 220V units)?

YES

NO

See Step 2. Do

you have over

100 AC volts?

YES

Replace the

ON/OFF switch.

NO

Troubleshooting

Repair or

replace

power cord.

See Step 3. Is the

proper reading

present through the

thermal switch

wires?.

YES

See step 4. Does

the motor run?

YES

NO

NO

If motor is hot, let cool and

retest. If Step 4 still shows

incorrect resistance, replace

motor. The motor has

a defective thermal device.

Connect a test

transducer to the

board. Does the

motor run?

YES

NO

Replace the

control board.

Replace

potentiometer.

Pressure switch.

3A0157B 19

Replace the

transducer

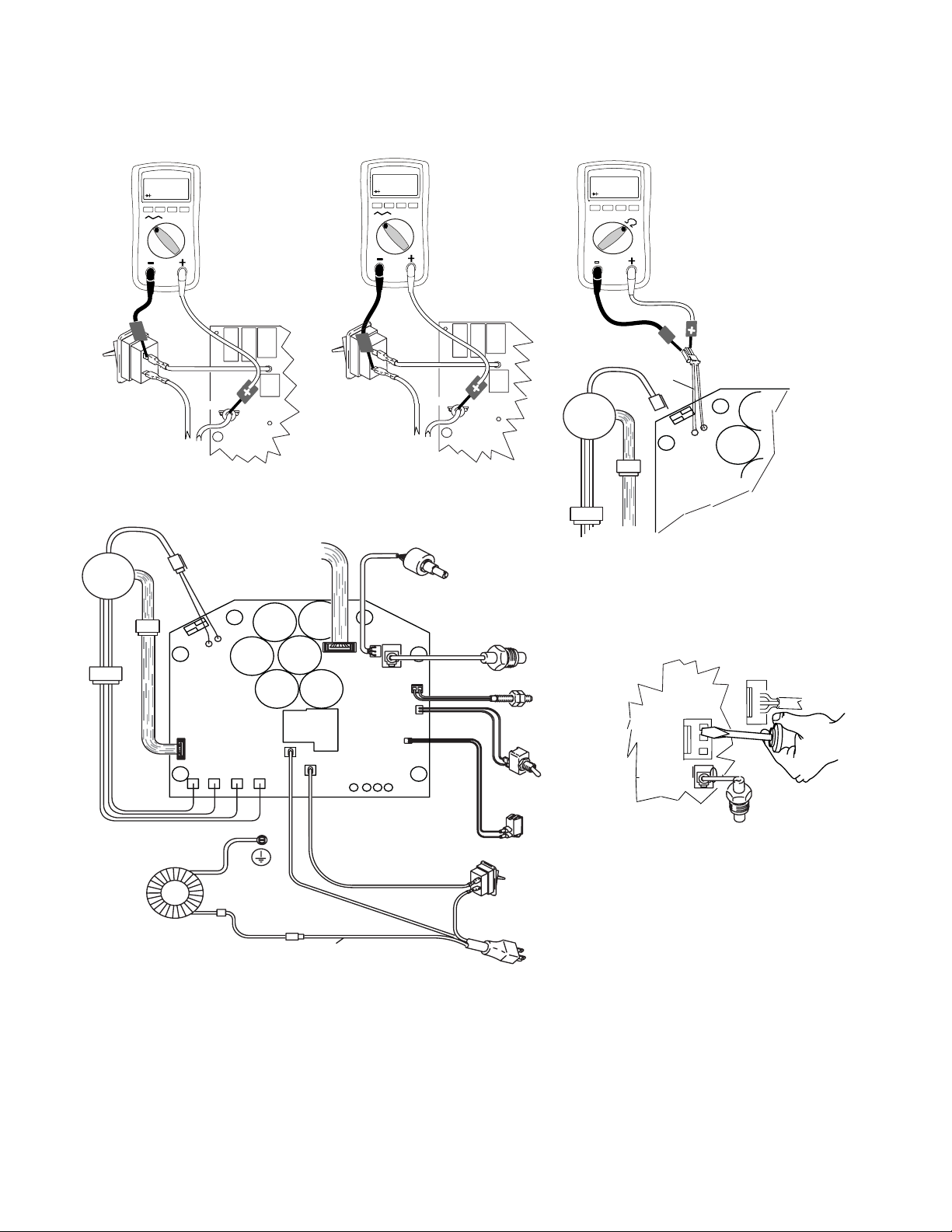

Page 20

Troubleshooting

Motor

Leads

On/Off

Switch

Thermal

Switch

Motor

110-120 AC

V

-

-

Black

Power Cord

Motor

Sensor

Leads

Green/Ground

GFI Filter Coil

STEP 1:

Plug power cord in

and turn switch ON.

Connect wires to

control board and

on/off switch. Turn

meter to AC Volts.

Black

+

White

Control

Board

To Optional

Display

Neutral

-

On/Off

Switch

White

Green/Ground

110-120 AC

V

-

Black

Black

Power Cord

Potentiometer

Black

STEP 2:

Plug power cord in

and turn switch ON.

Connect wires to

control board and

on/off switch. Turn

meter to AC Volts.

+

White

Control

Board

Pressure

Transducer

Black

AutoClean

WatchDog Switch:

On - Open

Off - Closed

Switch:

15 Amp - Closed

20 Amp - Open

On/Off

Switch

Black +

Powe r Plug

100k ohm

-

Thermal

Switch

Motor

STEP 3:

Check motor thermistor.

Unplug yellow wires. Meter

should read according to

Resistance Table on page 17.

NOTE: Motor should be cool

during reading.

+

-

Ye l l o w

Control

Board

STEP 4:

Plug power cord

in and turn switch

ON. Disconnect

potentiometer.

Control

Board

Black

20 3A0157B

Page 21

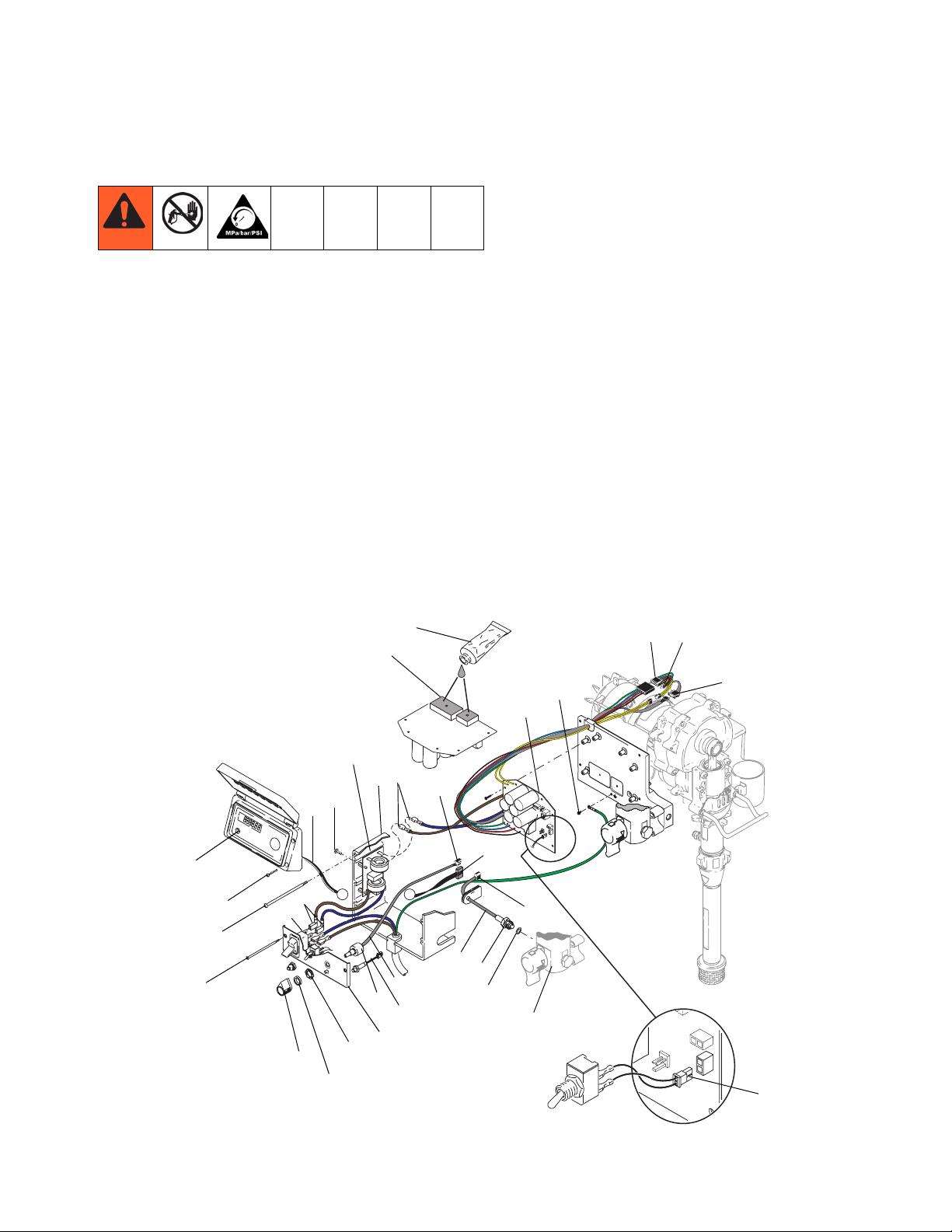

240 VAC and 110 VAC Motor Control Board

Troubleshooting

Removal

Perform Pressure Relief Procedure; page 8. Wait 5

minutes before servicing.

1. Remove Motor Shroud (for units equipped with

Hose Reel only):

a. Remove bolts from motor shroud.

b. Remove pressure tube from sprayer.

c. Remove bottom screw from toolbox.

d. Loosen (but do not remove) four nuts on shelf.

Carefully slide shelf forward.

e. Remove shroud.

f. Slide shelf back and tighten four nuts on shelf.

2. Remove all four screws (38) and cover (96).

3. Disconnect display connector (A) from motor control

board (52).

4. Remove bottom two screws (39). disconnect potentiometer connector (C) from motor control board

(52). Disconnect power cord connectors (D) and filter board connectors (J) from ON/OFF switch (33)

and remove control panel (68).

Installation

1. Use acetone or equivalent cleaner to thoroughly

remove thermal paste from pockets on powerbar.

ti14695a

2. Apply new thermal paste into both pockets of powerbar.

ti14693a

3. Replace two inner screws to control board and

torque to 17 in-lb (1 N•m).

5. Disconnect WatchDog switch connector (X) and

reed switch connector (L) from motor control board.

ti14696a

6. Disconnect motor control board power connectors

(K) from filter board (146).

4. Replace six outer screws to control board and

7. Remove top two screws (39) and control box (61).

torque to 11 in-lb (1.25 N•m).

8. Disconnect transducer connector (E) from motor

control board.

9. Disconnect motor connectors (F, G and H).

10. Remove six screws (27), two screws (102) and control board.

3A0157B 21

ti14697a

Page 22

Troubleshooting

5. Make switch dip switch is moved to the left (toward

inside of board). See Wiring Diagram, page 40.

6. Connect motor connectors (F, G and H) and install

into baffle.

7. Connect transducer connector (E) to motor control

board.

8. Connect motor control board power connectors (K)

to filter board (146).

9. Install control box (61) with top two screws (39).

10. Connect filter board power connectors (J) and

power cord connectors (D) to ON/OFF switch (33).

11. Connect potentiometer connector (C) to motor control board.

12. Connect WatchDog switch (X) and reed switch connector (L) to motor control board.

5

52

13. Install control panel (68) with two screws (39).

14. Connect display connector (A) to motor control

board (52).

15. Install cover (96) with four screws (38)

16. Install Motor Shroud (for units equipped with Hose

Reel only):

a. Loosen (but do not remove) four nuts on shelf

and slide shelf forward.

b. Replace shroud.

c. Slide shelf back and tighten four nuts on shelf.

d. Replace bottom screw from toolbox and tighten.

e. Replace pressure tube from sprayer.

f. Replace bolts from motor shroud.

96

39

38

39

68

33

61

146

A

27

C

J

D

E

52

E

80

20

82

82

115

67

34

X

Fast Flush

1595

MARK V

ti14891a

22 3A0157B

Page 23

240 VAC Filter Board

Perform Pressure Relief Procedure; page 8.

Removal

1. Remove four screws (38) and cover (96).

2. Disconnect display connector (A) from motor control

board (52).

Troubleshooting

6. Remove four screws (163) from filter board (146).

Installation

1. Install filter board (146) with four screws (163).

2. Connect motor control board power connectors (K)

to filter board (146).

3. Connect filter board power connectors (J) to top two

terminals of ON/OFF switch (33) and power cord

connectors (D) to bottom two terminals of ON/OFF

switch.

3. Remove bottom two screws (39). disconnect potentiometer connector (C) from motor control board

(52). Disconnect power cord connectors (D) and filter board connectors (J) from ON/OFF switch (33)

and remove control panel (68).

4. Disconnect WatchDog switch connector (X) and

reed switch connector (L) from motor control board.

5. Disconnect motor control board power connectors

(K) from filter board (146).

96

240 VAC

146

163

A

61

52

5

K

C

4. Connect potentiometer connector (C) to motor control board (52).

5. Connect WatchDog switch (X) and reed switch connector (L) to motor control board.

6. Install control panel (68) with two screws (39).

7. Connect display connector (A) to motor control

board (52).

8. Install cover (96) with four screws (38).

F

H

26

52

A

G

82

68

A

E

E

C

L

80

20

67

ti14890a

X

A

38

39

39

3A0157B 23

33

34

J

82

115

Page 24

Troubleshooting

Pressure Adjust Potentiometer

Removal

Perform Pressure Relief Procedure; page 8. Wait 5

minutes before servicing.

1. Remove four screws (38) and cover (96).

96

38

2. Remove two screws and control panel.

3. Disconnect potentiometer connector (C) from motor

control board (95).

95

C

ti13493a

Installation

1. Install gasket (115), nut and potentiometer (82) on

control panel (68). Torque nut to 30-35 in-lb (3.25 -

4.0 N•m).

68

82

82

115

ti13674a

2. Rotate new potentiometer shaft to highest pressure

setting (fully clockwise) and install knob (34). Use

allen wrench to tighten two screws on knob.

34

ti13338a

ti12997a

4. Use allen wrench to loosen two screws on knob

(34).

34

ti13207a

5. Remove gasket (115), nut and potentiometer (82)

from control panel (68).

68

82

115

ti13674a

82

3. Connect potentiometer connector (C) to motor control board.

95

C

ti12997a

4. Install control panel and tighten two screws.

5. Install cover (96) with four screws (38).

96

38

ti13493a

24 3A0157B

Page 25

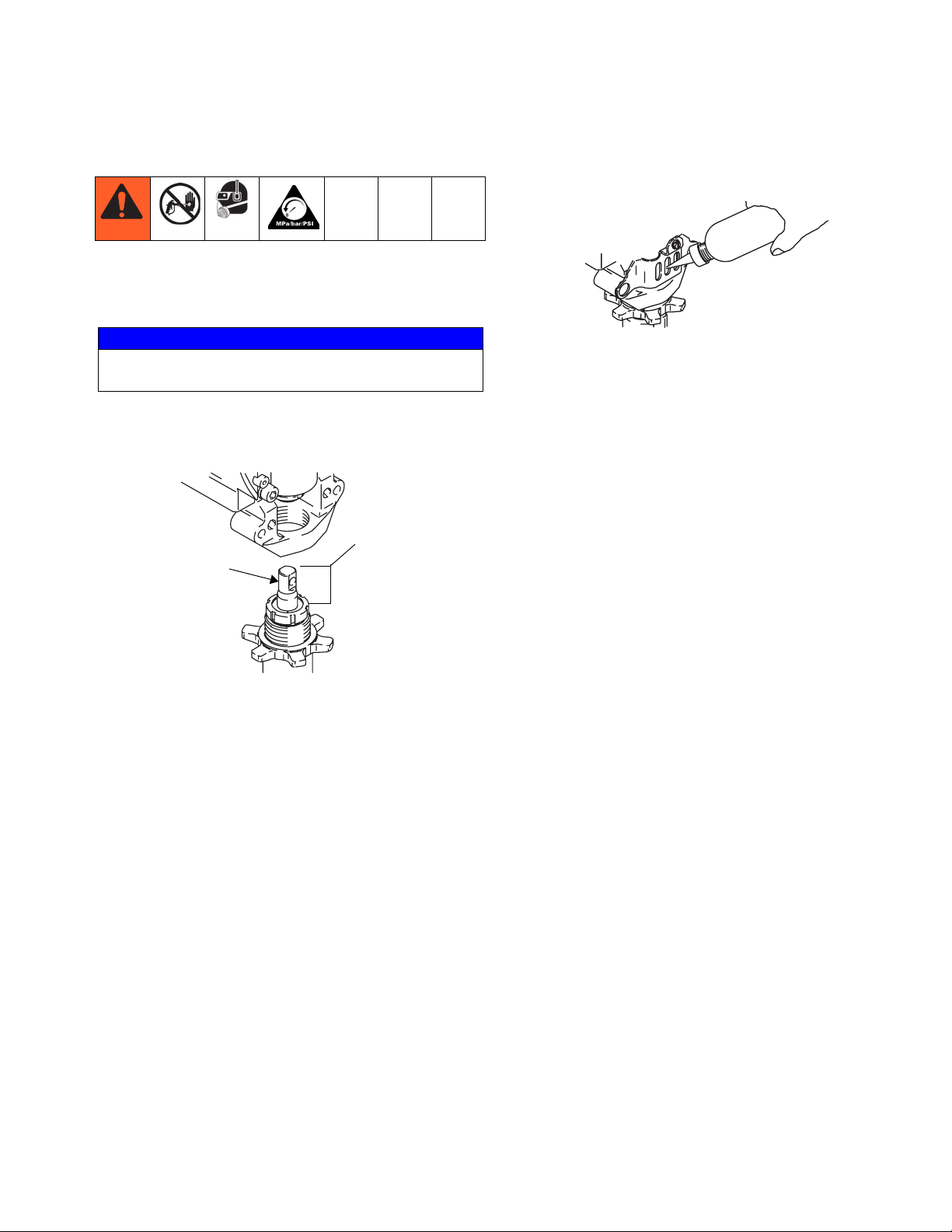

Pressure Control Transducer

Removal

Perform Pressure Relief Procedure; page 8. Wait 5

minutes before servicing.

Troubleshooting

4. Remove four screws (39) and control box (61). Allow

control panel (68) to hang down freely.

1. Remove four screws (38) and cover (96).

96

38

ti13493a

2. Disconnect transducer connector (E) from motor

control board (95).

E

ti12999a

95

ti7458a

68

39

ti13494a

61

5. Remove grommet (40) from control box then

remove transducer (86) and o-ring (20) from filter

base (67).

ti7260a

40

67

86

20

ti13495a

3. Disconnect potentiometer connector (C), WatchDog

switch, and reed switch connector from motor con-

6. Remove grommet (40) from transducer and save for

reuse.

trol board.

40

C

ti13722a

ti13495a

3A0157B 25

Page 26

Troubleshooting

Installation

1. Install o-ring (20) and transducer (86) in filter base

(67). Torque to 35-45 ft-lb (47-61 N•m). Install grommet onto transducer (86) and transducer into control

box.

40

67

ti7447a

86

20

ti13496a

2. Connect transducer connector (E), WatchDog

switch, and reed switch connector to control board

(95).

4. Connect potentiometer connector (C), WatchDog

switch, and reed switch connector to control board.

C

ti13722a

5. Install cover (96) with four screws (38).

96

38

ti13493a

E

95

ti12999a

3. Install control box (61) and control panel (68) with

four screws (39).

ti7458a

39

ti13494a

61

68

26 3A0157B

Page 27

Notes

Notes

3A0157B 27

Page 28

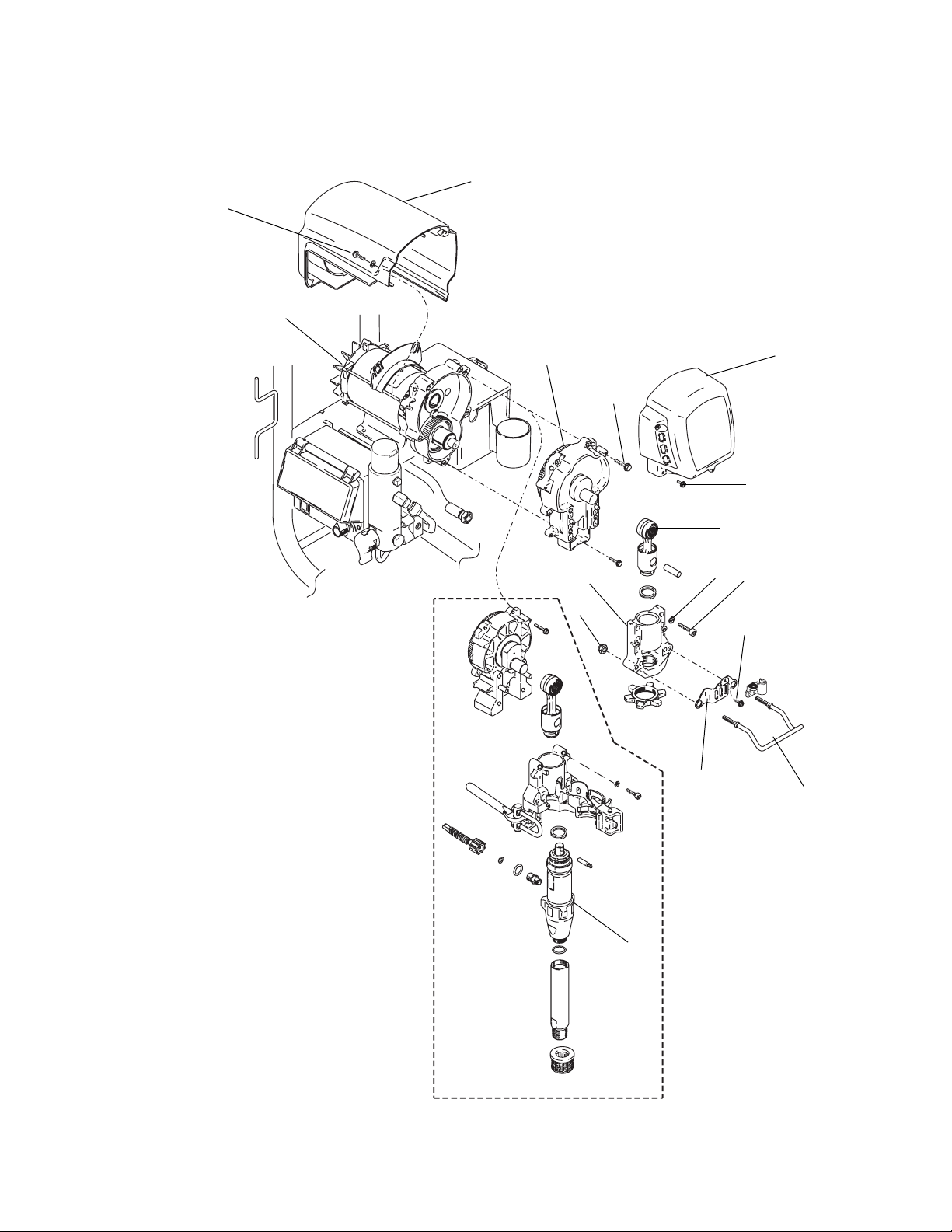

Drive and Bearing Housing Replacement

Drive and Bearing Housing Replacement

NOTICE

Do not drop gear cluster (89) when removing drive

housing (90). Gear cluster may stay engaged in motor

front end bell or drive housing.

Disassembly

Perform Pressure Relief Procedure; page 8.

1. Remove screw (31), two nuts (24), pail hanger (55)

and pump rod cover (108).

2. Remove pump (91); see Displacement Pump

Replacement, page 32 (695/795) page 34

(1095/1595/Mark V).

Assembly

Make sure gear (89) and thrust washers (28, 30, 90a,

36; see page 29) are in place. Brush grease onto gear

teeth.

1. Push drive housing (90) onto motor (84) and install

with five screws (6). Torque to 190-210 in-lb (21-23

N•m).

3. Remove two screws (158) and shroud (72).

4. Remove four screws (31) and front cover (51).

5. Remove four screws (14) and washers (12) to

remove bearing housing (83) and connecting rod

(85).

6. Remove five screws (6) and pull drive housing (90)

off motor (84).

2. Install bearing housing (83) with four screws (14)

and washers (12). Torque to 25-30 ft-lb (34-40 N•m).

3. Install front cover (51) with four screws (31).

4. Install shroud (72) with two screws (158).

5. Install pump (91); see Displacement Pump

Replacement, page 32 (695/795) page 34

(1095/1595/Mark V).

6. Install pump rod cover (108) and pail hanger (55)

with screw (31) and two nuts (24).

28 3A0157B

Page 29

Drive and Bearing Housing Replacement

158

84

Drive and Bearing Housing Replacement

72

90

24

83

51

6

31

85

12

14

31

108

55

91

ti14892a

3A0157B 29

Page 30

Motor Replacement

Motor Replacement

Removal

Perform Pressure Relief Procedure; page 8.

1. Remove pump (91); see Displacement Pump

Replacement, page 32 (695/795) page 34

(1095/1595/Mark V).

NOTICE

Do not drop gear cluster (89) when removing drive

housing (90). Gear cluster may stay engaged in motor

front end bell or drive housing.

2. Remove drive housing (90); see Drive Housing

Replacement, page 28.

1. Remove Motor Shroud:

a. Remove bolts from motor shroud.

b. Remove pressure tube from sprayer.

9. Remove two screws (23) and nuts (19) on side

opposite control.

10. Loosen two nuts (19) on side near control and

remove motor (84) from cart frame (62).

Installation

1. Slide new motor (84) under two screws (23) in cart

frame (62) near control.

2. Install two screws (23) and nuts (19) on motor side

opposite control.

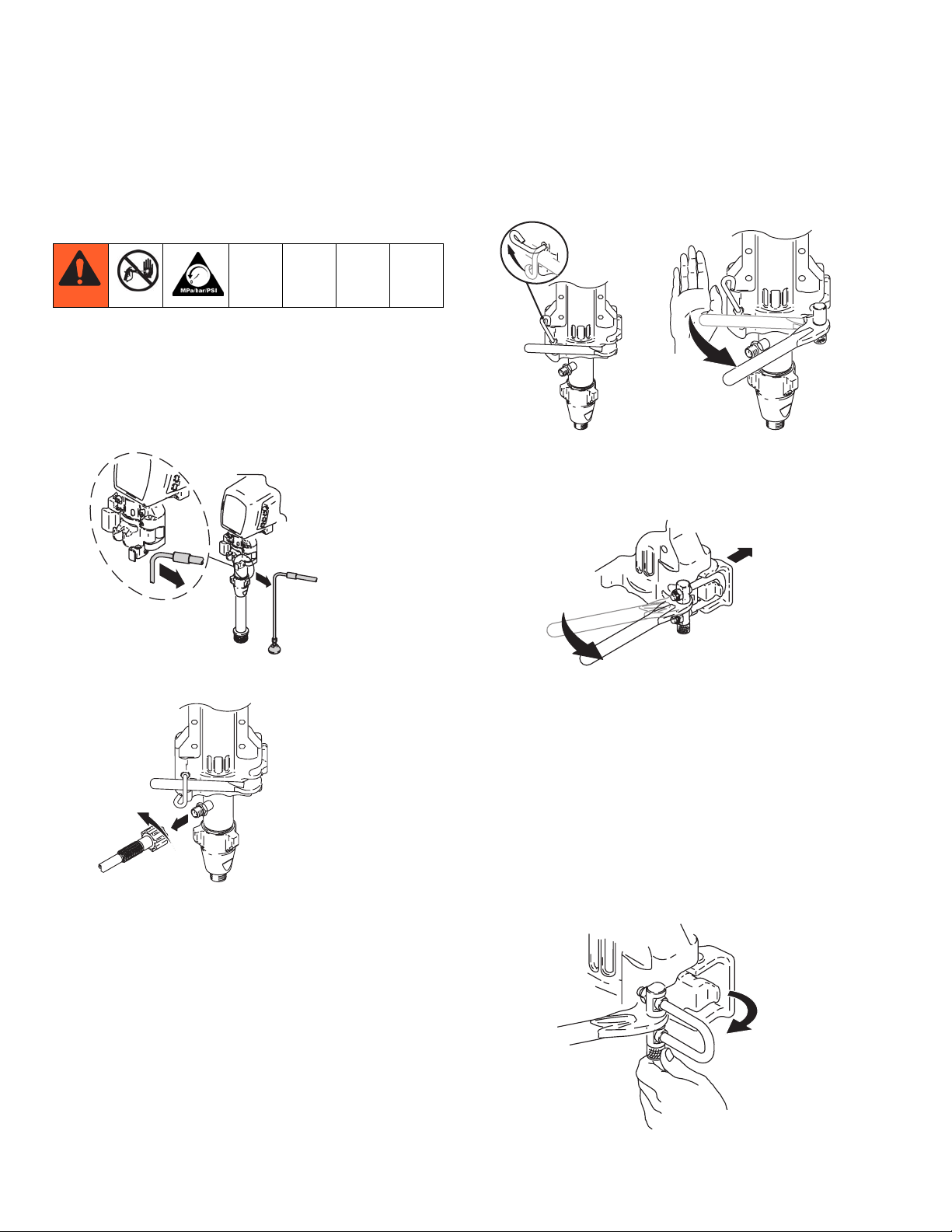

3. Install baffle and connect motor wires.

4. Tighten all four screws (23) and nuts (19). torque

nuts to 115-135 in-lb (13-15 N•m).

5. Install strain relief (29) onto motor wires and into

power bar plate (69).

6. Install control housing (61) with top two screws (39).

7. Connect all three motor connectors to motor.

c. Remove bottom screw from toolbox.

d. Loosen (but do not remove) four nuts on shelf.

Carefully slide shelf forward.

e. Remove shroud.

2. Slide shelf back and tighten four nuts on shelf.

3. Remove four screws (38) and control cover (96).

4. Remove bottom two screws (39) and allow control

panel (68) to hang down freely.

5. Disconnect all three motor connectors from motor.

6. Remove top two screws (39) and control housing

(61).

7. Remove strain relief (29) from motor wires and

power bar plate (69).

8. Remove motor wires from baffle 278075 and

remove baffle.

8. Install control panel (68) with two screws (39).

9. Install control cover (96) with four screws (38).

10. Install drive housing (90); see Drive Housing

Replacement, page 28.

11. Install pump (91); see Displacement Pump

Replacement, page 32 (695/795) page 34

(1095/1595/Mark V).

12. Install Motor Shroud.

a. Loosen (but do not remove) four nuts on shelf

and slide shelf forward.

b. Replace shroud.

c. Slide shelf back and tighten four nuts on shelf.

d. Replace bottom screw from toolbox and tighten.

e. Replace pressure tube from sprayer.

f. Replace bolts from motor shroud.

30 3A0157B

Page 31

Motor Replacement

Motor Replacement

96

39

68

61

158

84

58

19

89

36

90a

30

28

23

90

51

6

158

12

14

31

19

90

6

12

14

91

ti14893a

3A0157B 31

Page 32

Displacement Pump Replacement for 695/795/Mark IV

Displacement Pump Replacement for 695/795/Mark IV

See pump manual 310643 or 310894 for pump repair

instructions.

See manual 3A0158 for applicable sprayer part number

references.

Removal

1. Flush pump.

2. Perform Relieve Pressure Procedure; page 8.

3. Remove screw (31) and slide pump rod shield (108)

forward.

31

6. Loosen pump jam nut (56). Unscrew pump.

94

ti7167b

56

76

ti14894a

4. Increase pressure slightly to cycle pump in JOG

mode until pump pin (44) is in position to be

removed. Turn power switch OFF and unplug power

cord. Push up retaining ring (43) and push pump pin

out.

44

43

5. Remove suction tube (76), hose (94) and any washers and o-rings.

32 3A0157B

108

Page 33

Installation

If pump pin works loose, parts could break off due to

force of pumping action. Parts could project through the

air and result in serious injury or property damage.

NOTICE

If the pump jam nut loosens during operation, the

threads of the drive housing will be damaged.

1. Extend pump piston rod 1.5 in. Apply grease to top

of pump rod at (A) or inside connecting rod.

Displacement Pump Replacement for 695/795/Mark IV

8. Fill packing nut with Graco TSL until fluid flows onto

top of seal.

ti7169a

1.5 in.

A

ti7171a

2. Install pump pin (44). Verify retaining spring (43) is

in groove of connecting rod (85).

3. Push pump up until pump threads engage.

4. Screw in pump until threads are flush with drive

housing opening. Align pump outlet to back.

5. Install washers, o-rings and suction tube (76) and

hose (94).

6. Screw jam nut (56) up onto pump until nut stops.

Tighten jam nut by hand, then tap 1/8 to 1/4 turn

with a 20 oz (maximum) hammer to approximately

75± 5 ft-lb (102 N•m).

7. Install pump rod shield (108) with screw (31).

3A0157B 33

Page 34

Displacement Pump Replacement 1095/1595/Mark V

Displacement Pump Replacement 1095/1595/Mark V

Removal

1. Flush pump.

2. Stop pump with piston rod in its lowest position.

3. Perform Pressure Relief Procedure, page 8.

4. Separate drain hose from sprayer.

6. Raise latch lock. Push latch open.

ti6369a

ti6370a

7. Ratchet open pump door.

a. Ratchet pump door forward.

ti6373a

5. Disconnect paint hose from pump.

ti6300a

b. Twist latch u-bolt out of pump door recess.

c. Place u-bolt on pump door outer edge.

d. If pump door is stuck, do steps e, f, and 8, other-

wise go to step 9.

e. Twist latch u-bolt back from pump door outer

edge.

ti6374a

34 3A0157B

Page 35

Displacement Pump Replacement 1095/1595/Mark V

f. Place u-bolt on pump door protrusion.

ti6375a

8. Ratchet pump door forward.

ti6377a

9. Open pump door.

Installation

1. Adjust piston rod with pin holder to pull out piston

rod. Tap piston rod on hard surface to push in piston

rod.

2. Push pump collar flush with bearing housing ledge

to be able to close pump door.

ti6325a

ti5492a

3. Slide pump into connecting rod. Push pump pin until

it is fully retained.

NOTE: Pin will snap into position.

10. Pull out pump pin and place in pin holder.

ti7327a

ti6378a

ti7328a

3A0157B 35

Page 36

Displacement Pump Replacement 1095/1595/Mark V

4. Close pump door and rotate latch into position. Do

not tighten latch.

ti7329a

ti6313a

5. Rotate pump to align with paint hose. Connect paint

hose and hand tighten to 70 in-lb.

ti6299a

7. Attach drain hose to sprayer.

ti7330a

8. Fill pump with Graco TSL until fluid flows onto top of

seal.

6. Tighten latch and rotate latch lock into locked position.

ti6204a

TI6312a

ti5493a

36 3A0157B

Page 37

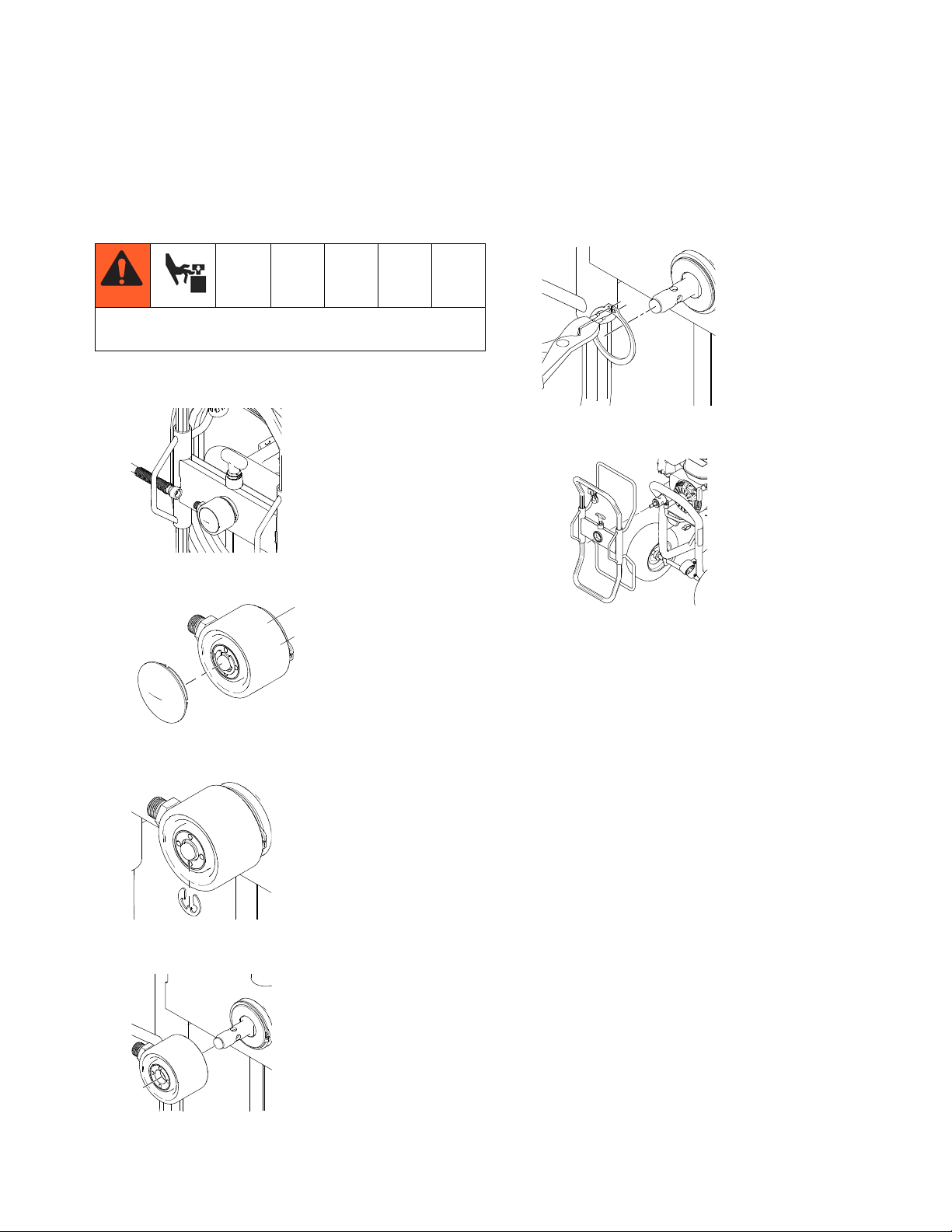

Hose Reel

Removal

Be sure to keep your head clear of hose reel while

winding up hose.

1. Remove hose fitting from swivel cap and completely

remove hose.

Hose Reel

5. Remove snap ring.

ti13542a

6. Remove hose reel.

ti13539a

2. Remove cap from swivel.

ti13675a

3. Remove E-clip from swivel shaft.

ti13538a

4. Remove swivel.

ti15024a

ti13543a

3A0157B 37

Page 38

Hose Reel

Installation

1. Grease shaft.

ti13537a

2. Make sure two washers and wave spring are on hub

before hose reel is installed.

ti13545a

3. Install hose reel onto frame. Place C-clamp on reel

and frame to allow snap ring to fit into place. Install

snap ring.

6. Install hose to swivel. Make sure to route hose

through side arm of hose reel.

ti13539a

7. Turn hose reel clockwise to wrap up hose. Make

sure hose is routed through hose guide.

ti13504a

ti13536a

4. Install swivel.

ti13543a

5. Install E-clip and swivel cap.

ti13538a

38 3A0157B

Page 39

Reed Switch Replacement

Reed Switch Replacement

Removal

1. Remove four screws and remove display cover.

ti13568a

2. Remove two screws and remove control panel.

Installation

1. Apply thread sealant to end of reed switch. Hand

tighten reed switch until it is tight against control

panel.

ti13574a

2. Add thread sealant and tighten jam nut against

threaded bus.

ti13576a

3. Connect reed switch to control board.

ti13571a

3. Unplug reed switch from control board.

ti13572a

4. Unscrew reed switch from control panel.

ti13573a

ti13572a

4. Replace control panel and tighten two screws.

ti13571a

5. Replace display cover and tighten four screws.

ti13568a

3A0157B 39

Page 40

Wiring Diagram

Wiring Diagram

120V Models:

Motor

Leads

Motor

Thermal

Switch

Motor

Sensor

Leads

Potentiometer

Digital Display

Pressure

Transducer

Black

Dip Switch

ON

AutoClean

Watchdog

ti13484b

green/ground

ON/OFF

Switch

ti13485a

Black

white

Black +

Power Plug

green/ground

40 3A0157B

Page 41

120V Models (with 15/20 Amp Switch):

Digital Display

Wiring Diagram

Motor

Potentiometer

Pressure

Transducer

Black

ON

Dip Switch

Watchdog

ti12980b

green/ground

white

green/ground

Black

20A 15A

1595 Switch

ON/OFF

Switch

Black +

Power Plug

3A0157B 41

Page 42

Wiring Diagram

240V Models:

Thermal

Switch

Digital Display

Potentiometer

Motor

Leads

ti13485a

Motor

Motor

Sensor

Leads

Black

Pressure

Transducer

Black

Dip Switch

ON

AutoClean

Watchdog

Blue

Blue

Brown

Blue

ON/OFF

Switch

Brown +

green/ground

42 3A0157B

Power Plug

Page 43

Notes

Notes

3A0157B 43

Page 44

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES y P.O. BOX 1441 y MINNEAPOLIS MN 55440-1441 y USA

Copyright 2009, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 3A0157

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised 09/2011

Loading...

Loading...