Page 1

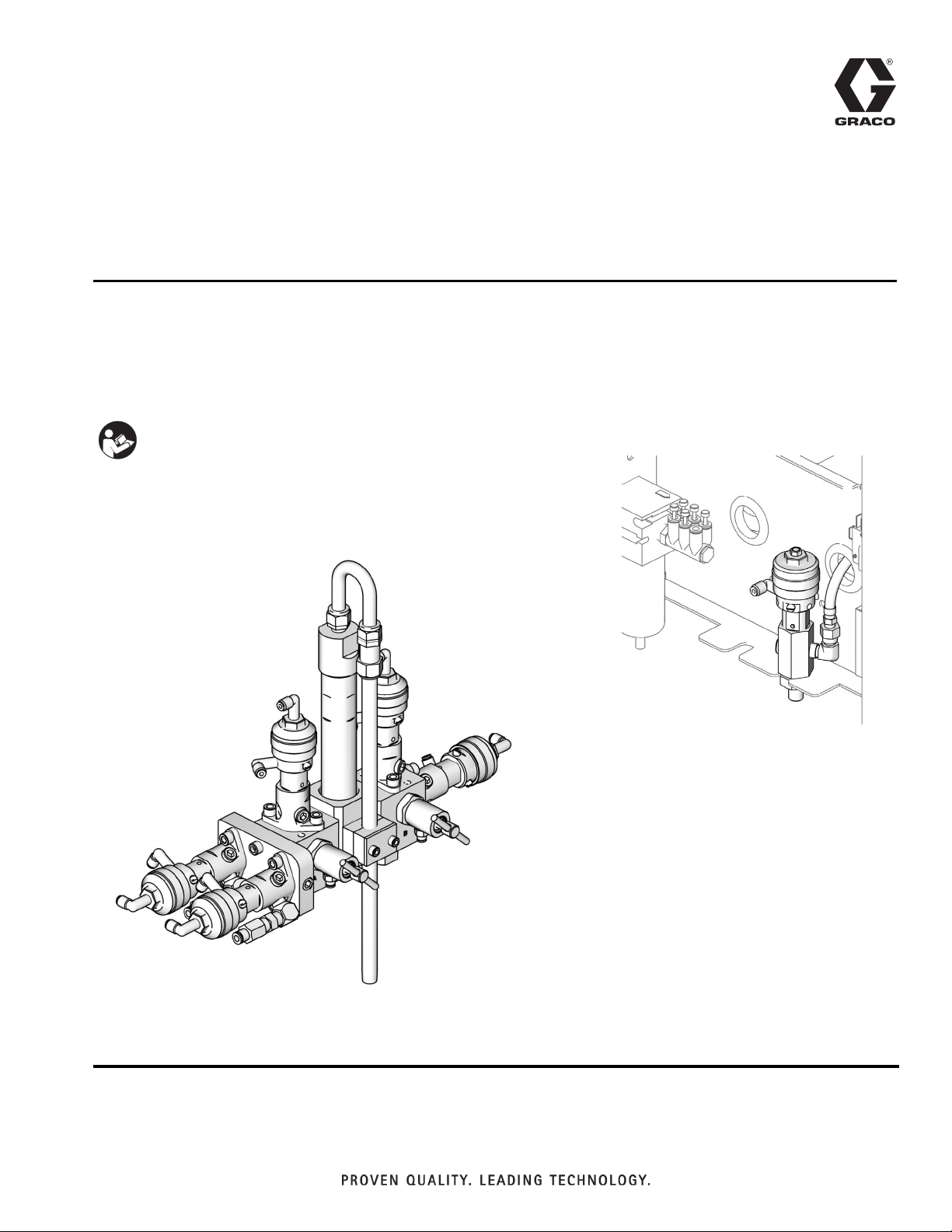

Instructions-Parts

Dump Valve and Third

Purge Valve Kits

For use with ProMix® 2KS Electronic Proportioners. For professional use only.

See page 2 for kit part numbers and maximum working pressure.

312786G

EN

Important Safety Instructions

Read all warnings and instructions in this manual. For complete

warnings and instructions see your proportioning system manual.

Hazard symbols refer to specific procedure risks. Save all instructions.

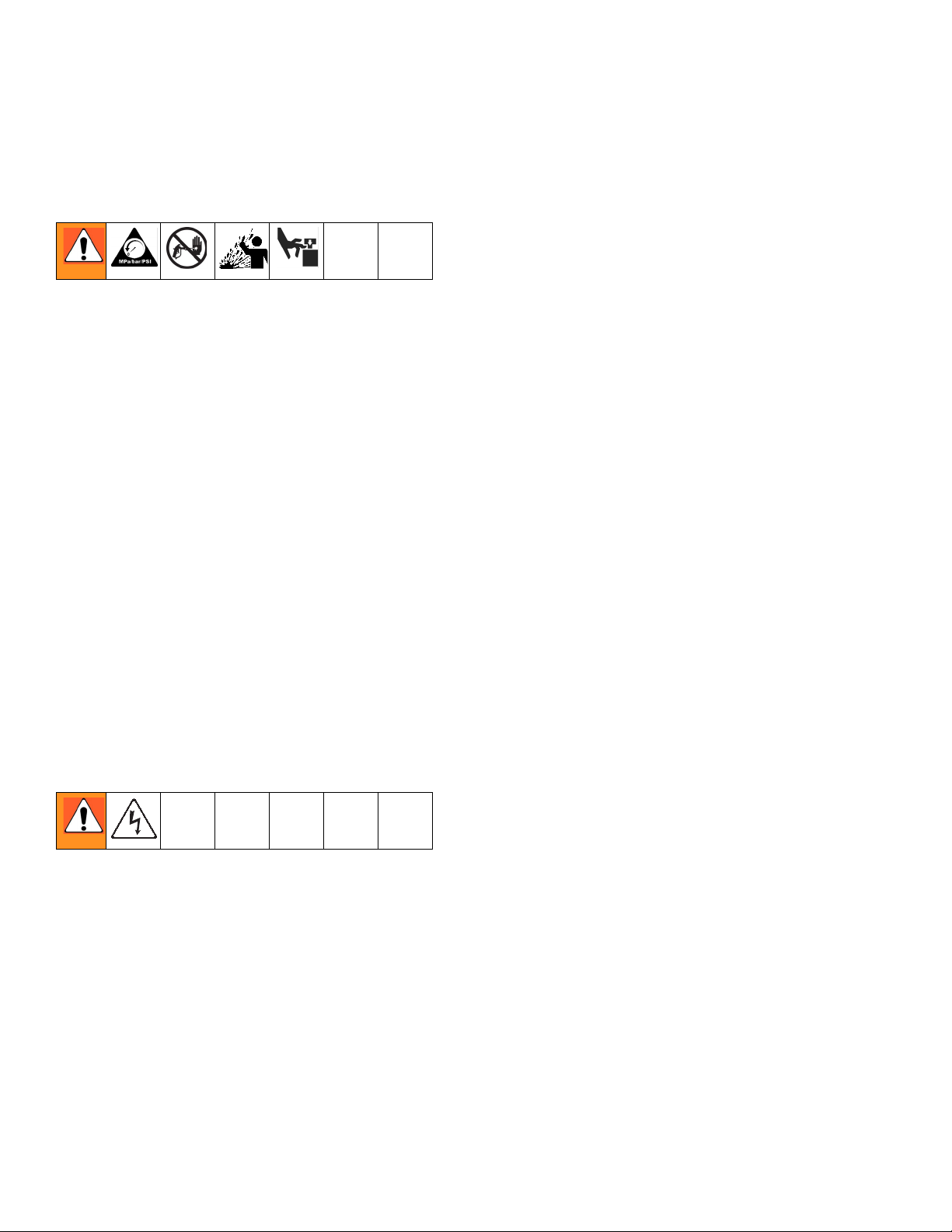

15V354 Third Flush Valve Kit

for Wall Panel, shown on

Fluid Mix Manifold

15V821 Dump Valve Kit

for Wall Panel

TI12743a

TI12954a

Page 2

Kits

Kits

15V821 Dump Valve Kit

For wall mount ProMix 2KS Electronic Proportioners

3000 psi (21 MPa, 210 bar) Maximum Fluid Working Pressure

100 psi (0.7 MPa, 7 bar) Maximum Air Working Pressure

See pages 3 and 14

15V822 Robo Dump Valve Kit

For robo mount ProMix 2KS Electronic Proportioners

300 psi (2.1 MPa, 21 bar) Maximum Fluid Working Pressure

100 psi (0.7 MPa, 7 bar) Maximum Air Working Pressure

See pages 6 and 16

15V354 Third Flush Valve Kit

For wall mount ProMix 2KS Electronic Proportioners

4000 psi (28 MPa, 280 bar) Maximum Fluid Working Pressure

100 psi (0.7 MPa, 7 bar) Maximum Air Working Pressure

See pages 5 and 15

15V202 Robo Third Flush Valve Kit

For robo mount ProMix 2KS Electronic Proportioners

300 psi (2.1 MPa, 21 bar) Maximum Fluid Working Pressure

100 psi (0.7 MPa, 7 bar) Maximum Air Working Pressure

See pages 7 and 17

15X247 Auto Dump Valve Kit

For wall mount ProMix 2KS Electronic Proportioners

3000 psi (21 MPa, 210 bar) Maximum Fluid Working Pressure

100 psi (0.7 MPa, 7 bar) Maximum Air Working Pressure

See pages 8 and 18

2 312786G

Page 3

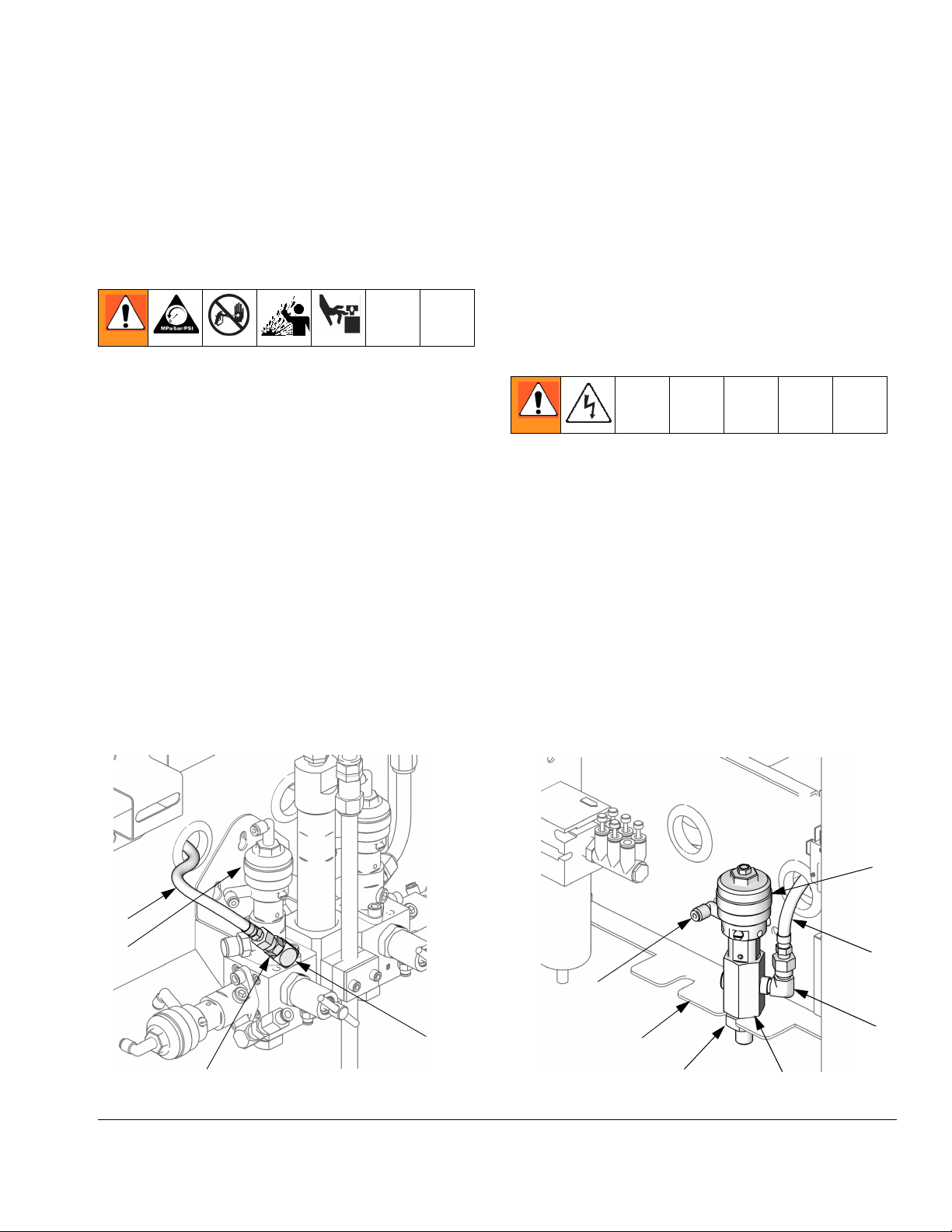

Installation

15V821 Dump Valve Kit for Wall Panel

Installation

NOTE: These instructions show this kit being installed

on the A side. It may also be installed on the B side.

1. Shut off the fluid supply to the dose valve (V) at the

front of the wall panel.

2. Actuate the dose valve to relieve fluid pressure in

the valve.

3. Relieve fluid pressure upstream and downstream of

the dose valve. See your ProMix 2KS Operation

Manual.

4. See F

IG

. 1. Remove the plug from the dose valve

adapter. Install the street elbow (18) in this port.

Install the nipple (19) in the elbow.

5. Install the dump valve assembly (includes 1, 2, 4,

and 11) in a slot of the flange (F) at the back of the

wall panel. Secure with the nut (8).

6. Install the elbow (6) in the open port of the dump

valve adapter (2). Connect a 1/4 npsm(f) hose (12)

between the elbow (6) and nipple (19).

7. Shut off all power to the fluid panel. Open the fluid

panel. See the Wall Panel detail in F

solenoid (9) at the correct position (Dump Valve A

or Dump Valve B) on the solenoid manifold. Connect the solenoid wires to the fluid panel control

board as shown in F

Electrical Schematic on page 13.

8. Connect the tubing (7) between the solenoid manifold and the tube fitting (T) on the dump valve (1).

See System Pneumatic Schematic, page 10.

IG

. 3. Also see the System

IG

. 2. Install the

At Front of Wall Panel

A SIDE B SIDE

12

V

19

FIG. 1: 15V821 Kit Installation

TI12744a TI12743a

18

At Back of Wall Panel

T

F

8

1

12

6

2

312786G 3

Page 4

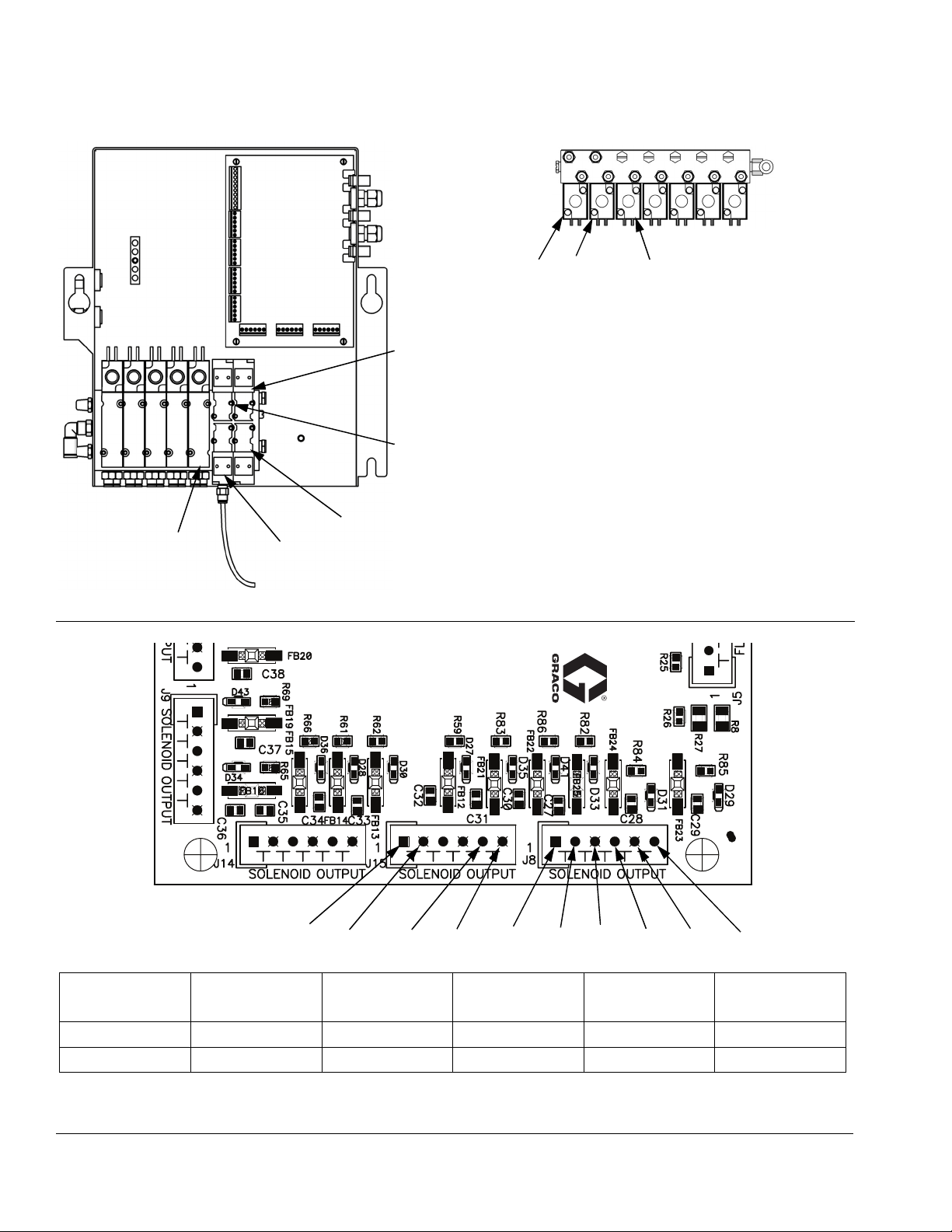

Installation

3rd Flush

Valve

Wall Panel

GFB1

GFB2

TI13116a

Dump

Valve B

Dump

Valve A

Dump

Valve B

RoboMix Panel

Dump

Valve A

3rd Flush

Valve

TI12655a

FIG. 2: Solenoid Manifolds

J15-1 J15-2 J15-6J15-5 J8-6J8-5

3rd Purge Valve Dump Valve A Dump Valve B

J15-1 J15-5 J8-5 J8-3 J8-1 Red

J15-2 J15-6 J8-6 J8-4 J8-2 Black

J8-1 J8-2 J8-3 J8-4

Auto Dump

Valve A (GFB1)

Auto Dump

Valve B (GFB2) Wire Color

F

IG

. 3: 255765 Fluid Panel Control Board, Detail View of Solenoid Connections

4 312786G

Page 5

15V354 Third Flush Valve Kit for Wall Panel

7. Connect the tubing (13, 14) between the solenoid

manifold and the tube fittings (T) on the flush valve

(2). See System Pneumatic Schematic, page 10.

1. Shut off the air and fluid supply to the ProMix 2KS.

2. Relieve pressure. See your ProMix 2KS Operation

Manual.

Installation

3. See F

IG

. 4. Remove the air flush valve (AFV) from

the fluid mix manifold (FM) and set it aside.

FM

AFV

FIG. 4: Disconnect Air Flush Valve

IG

4. See F

. 5. Install the o-ring (6), double valve

mounting block (1), and screws (8).

IG

5. See F

. 6. Install the air flush valve (AFV) on the

double valve block (1). Assemble the third flush

valve kit parts (2, 3, 4, 6, 9, 10, 11) as shown on

page 15. Install on the mounting block using the

screws (7). See F

IG

. 6.

TI12955a

6

1

8

F

IG

. 5: Install Double Valve Mounting Block

1

AFV

7

2

IG

. 6: Install Third Flush Valve

F

TI12956a

TI12957a

6. Shut off all power to the fluid panel. Open the fluid

IG

panel. See the Wall Panel detail in F

. 2. Install the

solenoid (12) and two tube connectors (15) at the

correct position (3rd Flush Valve) on the solenoid

manifold. Connect the solenoid wires to the fluid

panel control board as shown in F

312786G 5

IG

. 3.

Page 6

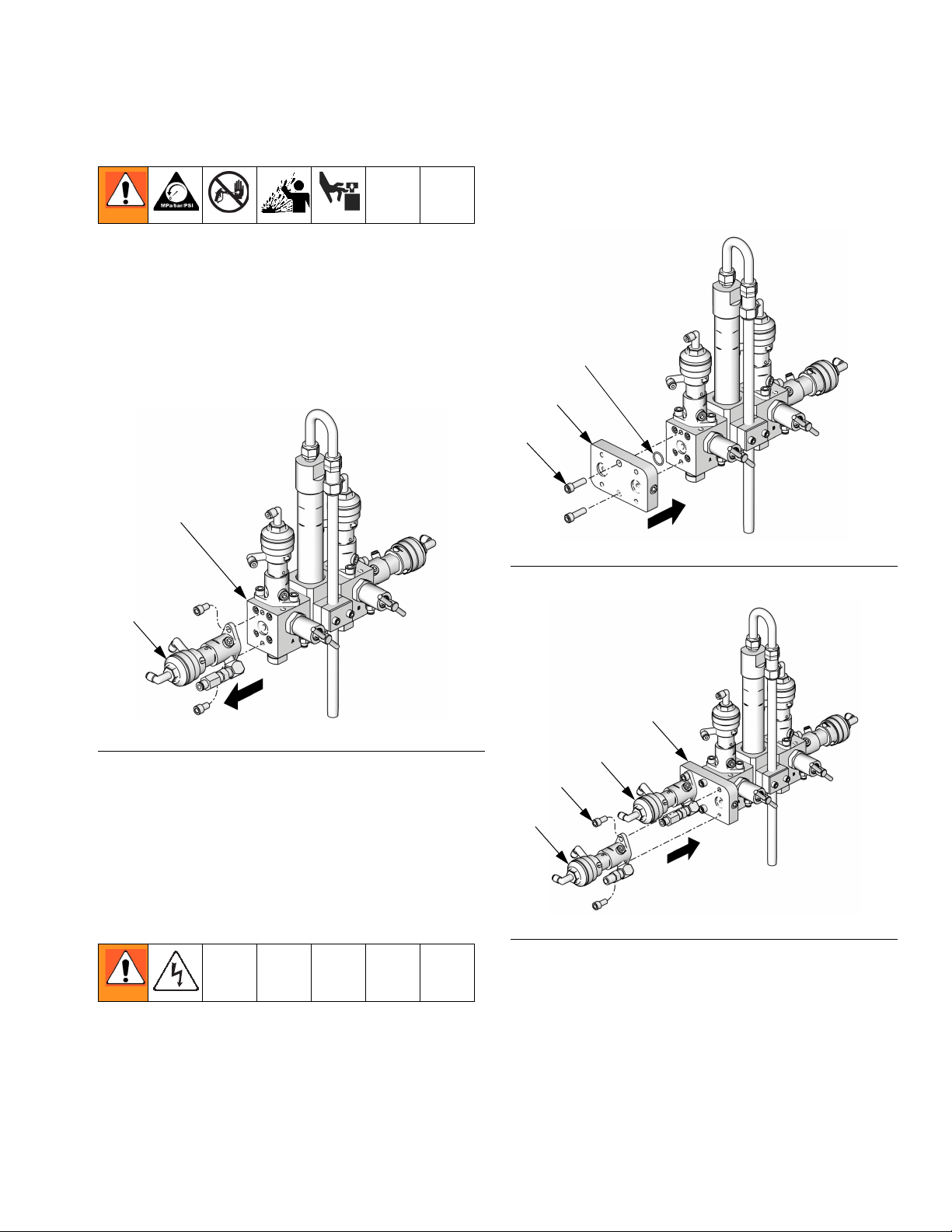

Installation

15V822 Dump Valve Kit for RoboMix

NOTE: These instructions show this kit being installed

on the B side. It may also be installed on the A side.

IG

1. See F

valve (V) in the RoboMix.

2. Actuate the dose valve to relieve fluid pressure in

the valve.

3. Relieve fluid pressure upstream and downstream of

the dose valve. See your ProMix 2KS Operation

Manual.

4. Remove the plug from the dose valve adapter.

Apply thread sealant and install the elbow (8) in this

port.

. 7. Shut off the fluid supply to the dose

5. Install the valve adapter (3) in the RoboMix. Secure

with four screws (11). Apply thread sealant and

install the nipple (9) through the back of the RoboMix and into the adapter. Install the swivel (6) in the

opposite side of the adapter.

6. Install the seat (2), o-ring (10), and dump valve (1)

in the adapter (3).

7. Connect the hose (5) between the swivel (6) and

elbow (8).

8. Shut off all power to the fluid panel. Open the fluid

panel. See the RoboMix Panel detail in F

IG

. 2.

Install the solenoid (4) at the correct position (Dump

Valve A or Dump Valve B) on the solenoid manifold.

Connect the solenoid wires to the fluid panel control

board as shown in F

IG

. 3. Also see the System

Electrical Schematic on page 13.

9. Connect the tubing (13) between the solenoid manifold and the tube fitting (T) on the dump valve (1).

See System Pneumatic Schematic, page 10.

6 312786G

Page 7

Installation

1

10

2

T

3

6

5

Dump

Valve B

8

V

TI13045a

F

IG

. 7: 15V822 Kit Installation

15V202 Third Flush Valve Kit for RoboMix

TI12655a

Dump

Valve A

4

11

9

TI13047a

1. Shut off the air and fluid supply to the ProMix 2KS.

2. Relieve pressure. See your ProMix 2KS Operation

Manual.

3. See F

IG

. 8. Remove the plug (A) from the air flush

valve (AFV). Install an o-ring (6) in this port.

4. Install the third flush valve adapter (3) in the RoboMix. Ensure that the o-ring (6) remains in place to

seal between the adapter and the air flush valve

adapter.

5. Secure the adapter (3) to the air flush valve adapter

with four screws (10) inserted through the side wall

of the RoboMix. Torque to 70 in-lb (8 N•m).

6. Apply thread sealant and install the check valve (4)

through the back of the RoboMix and into the third

flush valve adapter (3).

7. Install the o-ring (2), seat (1), o-ring (6), and third

flush valve (5) in the adapter (3).

8. See F

IG

. 8. Shut off all power to the fluid panel.

Open the fluid panel. Install the solenoid (8) in the

third flush valve position on the solenoid manifold.

Install the tube connector (9). Connect the solenoid

wires to the fluid panel control board as shown in

F

IG

. 3. Also see the System Electrical Schematic

on page 13.

9. Connect the tubing (13) between the solenoid manifold and the tube fitting (T) on the third flush valve

(5). See System Pneumatic Schematic, page 10.

10. Connect the third flush fluid supply line to the check

valve (4).

312786G 7

Page 8

Installation

5

6

1

2

10

F

IG

. 8: 15V202 Kit Installation

9

T

3

6

TI12655a

8

4

TI13046a

TI13047a

15X247 Auto Dump Valve Kit

1. Close the component A and component B shutoff

valves on the fluid manifold.

2. Trigger the gun to relieve fluid pressure downstream

of the fluid manifold.

3. See F

4. Install the valve adapter (2) in the mixed material

NOTE: Connect the static mixer to one 1/4 npt port of

the valve adapter.

5. Install the nipple (8) in the other port of the adapter

IG

. 9. Install the small o-ring (3), seat retainer

(6), large o-ring (7), and dump valve (1) in the valve

adapter (2).

line, downstream of the static mixer and as close to

the gun as possible.

(2). Connect the gun line to this nipple.

6. Connect a 1/4 npsm(f) dump hose (not supplied) to

the 1/4 npsm(m) threaded stud at the bottom of the

adapter (2). When the gun closes, the dump valve

opens and fluid is dumped through the stud.

7. Shut off all power to the fluid panel. Open the fluid

panel. See the Wall Panel detail in F

IG

. 9. Install the

solenoid (5) at the correct position (GFB1 or GFB2)

on the solenoid manifold. Connect the solenoid

wires to J8 on the fluid panel control board as

shown in F

IG

. 3. Also see the System Electrical

Schematic on page 13.

8. Install the tube connector (9) in the solenoid manifold. Connect the tubing (4) between the connector

and the tube fitting (T) on the dump valve (1). See

System Pneumatic Schematic, page 10.

8 312786G

Page 9

Installation

T

7

6

3

2

FIG. 9: 15X247 Kit Installation

TI14283b

1

8

GFB1

GFB2

9

J8 (see FIG. 3

for details)

5

4

TI13116a

Wall Panel

312786G 9

Page 10

Schematic Diagrams

Schematic Diagrams

System Pneumatic Schematic

AIR INPUT

COLOR

CHANGE

AIR EXHAUST MUFFLER

12 VDC

4-WAY SOLENOID

12 VDC

4-WAY SOLENOID

12 VDC

4-WAY SOLENOID

12 VDC

4-WAY SOLENOID

12 VDC

4-WAY SOLENOID

AIR EXHAUST MUFFLER

12 VDC

3-WAY SOLENOID

3/8 AIR FILTER

MANUAL DRAIN

5 MICRON

WALL MOUNT ONLY

05

AIR INPUT

TO MANIFOLD 1/4 TUBE

CONTROL AIR

PURGE AIR

12 VDC

3-WAY SOLENOID

12 VDC

3-WAY SOLENOID

12 VDC

3-WAY SOLENOID

MANIFOLD

A

B

A

B

A

B

A

B

A

B

A

A

A

A

MANIFOLD

CLOSE

5/32 TUBE

OPEN

CLOSE

5/32 TUBE

OPEN

CLOSE

5/32 TUBE

OPEN

CLOSE

5/32 TUBE

OPEN

CLOSE

5/32 TUBE

OPEN

5/32 TUBE

OPEN

5/32 TUBE

OPEN

5/32 TUBE

OPEN

5/32 TUBE

OPEN

DOSE A

VALV E

DOSE B

VALV E

PURGE A

VALV E

PURGE B

VALV E

PURGE C

VALV E

(OPTIONAL)

DUMP A

VALV E

(OPTIONAL)

DUMP B

VALV E

(OPTIONAL)

GFB 1

VALV E

(OPTIONAL)

GFB 2

VALV E

(OPTIONAL)

FLUSH AIR TO FLUID INLET 1/4 TUBE

CONTROL

36 SERIES SOLENOID VALVES

COLOR

VALV E

STACKS

COLOR 1

COLOR 2

COLOR 3

COLOR 4

COLOR 5

COLOR 6

COLOR 7

COLOR 8

COLOR SOLVENT

COLOR 9

COLOR 10

COLOR 11

COLOR 12

CATALYST 1

CATALYST 2

CATALYST 3

CATALYST 4

CATALYST SOLVENT

COLOR 13

COLOR 14

COLOR 15

COLOR 16

COLOR 17

COLOR 18

COLOR 19

COLOR 20

COLOR 21

COLOR 22

COLOR 23

COLOR 24

COLOR 25

COLOR 26

COLOR 27

COLOR 28

COLOR 29

COLOR 30

MAC

10 312786G

Page 11

Tubing Schematic

Schematic Diagrams

B3

B1

A2

A6

B5

AT

A4

B1 B3 B5 B7

13

13

GFB1-P

GFB2-P

B7

DADB

A8

TI13857a TI13858a

GFB1-C GFB2-C

TI13862a

A2 A4 A6 A8

DA DB

GFB1-P

GFB1-A

ATOM-1

GFB1-A GFB2-A

GFB1

GFB1-C

GFB1-S

GFB1-S GFB2-S

GFB2-P

GFB2-A

GFB2

312786G 11

GFB2-S

TI13863a

GFB2-C

ATOM-1 ATOM-2

TI13861a

ATOM-2

TI13860a

Page 12

Schematic Diagrams

Table 1: Tubing Chart

Color Description Starting Point

Ending

Point

Tube OD

in. (mm) Tube Ref. No.

Green Dose A On A2 A2 5/32 (4) 336

Green Dose B On A4 A4 5/32 (4) 336

Green Purge A On A6 A6 5/32 (4) 336

Green Purge B On A8 A8 5/32 (4) 336

Green Dump A DA DA 5/32 (4) Included in optional

Green Dump B DB DB 5/32 (4)

Dump Valve Kit

15V821

Red Dose A Off B1 B1 5/32 (4) 337

Red Dose B Off B3 B3 5/32 (4) 337

Red Purge A Off B5 B5 5/32 (4) 337

Red Purge B Off B7 B7 5/32 (4) 337

Natural Solenoid Air Supply 13 13 1/4 (6) 334

Natural Gun Flush Box 1 Pressure

GFB1-A GFB1-A 5/32 (4)

Switch Signal

Natural Gun Flush Box 2 Pressure

GFB2-A GFB2-A 5/32 (4)

Switch Air

Natural Gun Flush Box 1 Trigger

GFB1-C GFB1-C 5/32 (4)

Air

Natural Gun Flush Box 2 Trigger

Air

GFB2-C GFB2-C 5/32 (4)

Included in optional

Gun Flush Box Kit

Natural Gun Flush Box 1 Supply

GFB1-P GFB1-P 5/32 (4)

15V826

Air

Natural Gun Flush Box 2 Supply

GFB2-P GFB2-P 5/32 (4)

Air

Natural Gun Flush Box 1 Safety

GFB1-S GFB1-S 5/32 (4)

Interlock

Natural Gun Flush Box 2 Safety

GFB2-S GFB2-S 5/32 (4)

Interlock

Natural Gun 1 Atomizing Air ATOM-1 ATOM-1 1/4 (6) User supplied. Con-

Natural Gun 2 Atomizing Air ATOM-2 ATOM-2 1/4 (6)

nects air flow switch to

gun air shutoff valve.

Natural Purge Air Supply Use as a separate line

AT 1/4 (6) 338

connected directly to the

main shop air line. Do

not connect to the unit’s

main air supply or to the

air manifold (335).

12 312786G

Page 13

System Electrical Schematic

Hazardous Area

Schematic Diagrams

FO OUT

(BLU)

FO IN

(BLK)

FLUID PANEL CONTROL BOX

FLUID

PANEL

CONTROL

BOARD

J10

+12VDC I/S

1

COM

2

SHIELD

3

J4

J6

J15

J14

J13

MH2

HAZARDOUS AREA

1

2

3

J3

4

5

6

1

2

3

J12

4

5

6

UNUSED

1

UNUSED

2

UNUSED

3

UNUSED

4

UNUSED

5

UNUSED

6

1

2

3

J5

4

5

6

3

2

J11

5

4

1

3

2

J7

5

4

1

6

5

4

J8

3

2

1

6

5

4

3

2

1

6

5

4

3

2

1

6

5

4

J9

3

2

1

1

2

3

4

5

6

J1

7

8

9

10

6' STD.

(3'-100' OPTIONS)

50' STD.

GRD (BLK)

+12VDC (RED)

SHIELD (BARE)

CAN H (WHT)

CAN L (BLU)

BLACK

RED

BLACK

RED

BLACK

RED

BLACK

RED

BLACK

RED

BLACK

RED

BLACK

RED

BLACK

RED

BLACK

RED

BLACK

RED

BLACK

RED

BLACK

RED

SIG

COM

SIG

COM

SIG

COM

SIG

COM

SIG

COM

PWR (RED)

COM (BLACK)

SIG (WHITE)

SHIELD/GRN

PWR (RED)

COM (BLACK)

SIG (WHITE)

SHIELD/GRN

PWR (RED)

COM (BLACK)

SIG (WHITE)

SHIELD/GRN

GROUND

TERMINAL

MANIFOLD

MANIFOLD

3X CABLE

(10')/

(40')

GRD (BLK)

+12VDC (RED)

SHIELD (BARE)

CAN H (WHT)

CAN L (BLU)

BOOTH

3

CONTROL

2

BOARD

5

4

1

DUMP B

GFB #1

GFB #2

DUMP A

NOT USED

PURGE C

PURGE B

PURGE A

NOT USED

NOT USED

DOSE B

DOSE A

AIR FLOW SWITCH 1

AIR FLOW SWITCH 2

SOLVENT FLOW SWITCH

GFB 1 PRESSURE SWITCH

GFB 2 PRESSURE SWITCH

FLOW METER A

FLOW METER B

FLOW METER SOLVENT

12 VDC

3-WAY SOLENOID

12 VDC

4-WAY SOLENOID

V/P ANALOG OUT (WHT)

PRESS. (GRN)

+12 V (RED)

GND (BLK)

CHASSIS (BARE)

MANIFOLD

CLR 8

CLR 7

CLR 6

CLR 5

CLR 4

CLR 3

CLR 2

CLR 1

SOL CLR

MANIFOLD

CLR 21

CLR 20

CLR 19

CLR 18

CLR 17

CLR 16

CLR 15

CLR 14

CLR 13

I.S. METERS

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

COM

COM

COM

COM

COM

COM

COM

COM

COM

COM

COM

COM

COM

COM

COM

COM

COM

COM

J1

1

2

3

4

5

J7/J11

FLOW

CONTROL

BOARD

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

J7/J11

J7/J11

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

J2

1

2

J4

1

2

3

4

5

1 4 5 2 3

COLOR

BOARD 1

(COLORS

1 THRU 12,

CATALYST

1 THRU 4)

J8

J16

J15

J10

J14

1 4 5 2 3

1 4 5 2 3

COLOR

BOARD 2

(COLORS

13 THRU 30)

J8

J15

J16

J14

J10

SIG (RED)

COM (BLK)

+ PRESSURE (GRN)

COM (RED)

EX+ (WHT)

- PRESSURE (BLK)

SHIELD (BARE)

6

5

4

3

J9

2

1

6

5

4

3

2

1

6

5

4

3

2

1

6' STD.

6

5

4

J9

3

2

1

6

5

4

3

2

1

6

5

4

3

2

1

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

MANIFOLD

MANIFOLD

TECNO

V/P

FLUID

PRESS.

SENS.

CLR 9

CLR 10

CLR 11

CLR 12

CAT 4

CAT 3

CAT 2

CAT 1

SOL CAT

CLR 22

CLR 23

CLR 24

CLR 25

CLR 26

CLR 27

CLR 28

CLR 29

CLR 30

312786G 13

Page 14

Parts

Parts

15V821 Dump Valve Kit for Wall Panel

18

1*

*14

*11

*4

*2

19

12

AB

15

8

Ref.

No. Part No. Description Qty

1* 24W310 VALVE, dispense; includes 14; see

manual 312782

2* 15T717 ADAPTER, dump valve 1

4*† 111457 O-RING; ptfe 1

6 114342 ELBOW; 1/4 npt (mbe) 1

7 n/a TUBE; nylon; 5/32 in. (4 mm) OD;

2 ft (0.61 m)

8* n/a NUT, hex; 9/16-18 1

9 121324 VALVE, solenoid, dump valve 1

11*† n/a SEAT, dump valve; sst 1

6

TI12742b

13

7

Ref.

No. Part No. Description Qty

12 206966 HOSE; 1-1/2 ft (0.46 m) 1

1

13 111328 CONNECTOR; 10-32 x 5/32 in. (4

mm) OD tube

14*† n/a O-RING; ptfe 1

15 101970 PLUG 1

18 166866 ELBOW, street; 1/4 npt (m x f) 1

1

19 C20482 NIPPLE; 1/4 npt 1

9

* Parts included in 16A079 Dump Valve Replacement

Kit (purchase separately).

†

Order Kit 16A560 to replace a single seat. The kit

includes a seat (11) and o-rings (4 and 14).

TI13116a

1

NOTE:

The standard valve seat (11) is SST. To install a

carbide seat, order Kit 24U054. The kit includes a single

carbide seat and o-rings 4 and 14.

Parts labeled n/a are not available separately.

14 312786G

Page 15

15V354 Third Flush Valve Kit for Wall Panel

6

8

‡11

3

7

5

Parts

1

2‡4

10

‡6

9

Ref.

No. Part No. Description Qty

1 15U673 BLOCK, double valve mount 1

2 15X303 VALVE, dispense; includes item 4;

see manual 312782

3 15T600 ADAPTER, valve 1

4‡ n/a O-RING; ptfe 2

5 101970 PLUG, pipe; 1/4 npt 3

6‡ 109450 O-RING; ptfe 5

7 n/a SCREW, cap, socket-hd; 5/16-24 x

3/4 in. (19 mm)

8 109031 SCREW, cap, socket-hd; 5/16-24 x

1 in. (25 mm)

9 166866 ELBOW, street; 1/4 npt (m x f) 1

10 501867 VALVE, check 1

TI12953a

12 15

Ref.

No. Part No. Description Qty

11‡ n/a SEAT, valve 1

12 121374 VALVE, solenoid, 4-way 1

1

13 n/a TUBE; nylon; 5/32 in. (4 mm) OD; 3

ft (0.9 m); green

14 n/a TUBE; nylon; 5/32 in. (4 mm) OD; 3

ft (0.9 m); red

15 114263 CONNECTOR; 1/8 npt(m) x 5/32 in.

2

2

‡

Parts included in Valve Seat Kit 24A861 (purchase

(4 mm) OD tube

separately).

Parts labeled n/a are not available separately.

TI12652a

1

1

2

312786G 15

Page 16

Parts

15V822 Dump Valve Kit for RoboMix

1

TI12655a

10

2

3

6

5

TI13045a

Ref.

No. Part No. Description Qty

1 15X304 VALVE, dispense; includes item 10;

see manual 312782

2 15V888 RETAINER, seat, RoboMix 1

3 15U713 VALVE, adapter; RoboMix 1

4 121795 VALVE, solenoid, 4-way 1

5 15U720 HOSE; 1/4 npt (mbe); 15-1/2 in.

(394 mm); ptfe

6 114339 UNION, swivel; 1/4 npt 1

8 114446 ELBOW; 1/4 npt(m) x 1/4 npsm(f) 1

9 166421 NIPPLE; 1/4 npt 1

10 n/a O-RING; ptfe 1

Dump

Valve B

Dump

Valve A

4

8

11

9

Ref.

No. Part No. Description Qty

11 C19979 SCREW, cap, socket-hd; 10-24 x

1

3/8 in. (10 mm)

12 111328 CONNECTOR; 10-32 x 5/32 in. (4

mm) OD tube

13 n/a TUBE; nylon; 5/32 in. (4 mm) OD; 3

1

ft (0.9 m); green

14 114342 ELBOW; 1/4 npt (mbe) 1

15 104644 PLUG, screw 1

16 104640 GASKET; buna-N 1

Parts labeled n/a are not available separately.

TI13047a

4

1

1

16 312786G

Page 17

15V202 Third Flush Valve Kit for RoboMix

Parts

10

5

9

6

1

3

2

TI12655a

8

4

TI13046a

TI13047a

Ref.

No. Part No. Description Qty

1 15V888 RETAINER, seat, RoboMix 1

2 109450 O-RING; ptfe 1

3 15U715 VALVE, adapter; RoboMix 1

4 501867 VALVE, check 1

5 15X304 VALVE, dispense; includes item 6;

see manual 312782

6 n/a O-RING; ptfe 2

8 121795 VALVE, solenoid, 4-way 1

9 111328 CONNECTOR; 10-32 x 5/32 in. (4

mm) OD tube

10 110420 SCREW, cap, socket-hd; 10-24 x

1-1/2 in. (38 mm)

13 n/a TUBE; nylon; 5/32 in. (4 mm) OD; 2

ft (0.61 m); green

Parts labeled n/a are not available separately.

1

1

4

1

312786G 17

Page 18

Parts

15X247 Auto Dump Valve Kit

1

7

6

3

2

8

GFB1

GFB2

TI14283a

Ref.

No. Part No. Description Qty

1 24W310 VALVE, dispense; includes 7 ; see manual 312782 1

2 15T717 ADAPTER, dump valve 1

3† 111457 O-RING; ptfe 1

4 n/a TUBE; nylon; 5/32 in. (4 mm) OD; 5 ft (1.52 m) 1

5 121324 VALVE, solenoid, dump valve 1

6† n/a SEAT, dump valve; sst 1

7† n/a O-RING; ptfe 1

8 C20482 NIPPLE; 1/4 npt 1

9 111328 CONNECTOR; 10-32 x 5/32 in. (4 mm) OD tube 1

†

Order Kit 16A560 to replace a single seat. The kit

includes a seat (6) and o-rings (3 and 7).

NOTE:

The standard valve seat (6) is SST. To install a

carbide seat, order Kit 24U054. The kit includes a single

carbide seat and o-rings 3 and 7.

Parts labeled n/a are not available separately.

9

5

4

TI13116a

18 312786G

Page 19

Notes

Notes

312786G 19

Page 20

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS, MN 55440-1441 • USA

Copyright 2008, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM

312786

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revision G, August 2014

Loading...

Loading...