Page 1

Instructions/Parts

MODEL 7004

2-QUART PRESSURE CUP

FOR PRODUCT INFORMATION CALL:

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

DESCRIPTION

The Model 7004 2-quart pressure cup is designed to be used with

any pressure feed manual spray gun where more than one quart

of material is to be used. Pressure cups will provide a better

degree of control over atomizing air and fluid pressure than

siphon feed equipment. The Model 7004 will enable you to spray

a wider range of refinish materials and has a full 2-quart capacity

when needed.

SPECIFICATIONS

Max. regulated cup pressure

(fluid pressure)

50 psi

311417D

1 (800) SHARPE 1

ENG

Max. air inlet pressure 160 psi

Relief valve release 40 psi

Weight (empty) 3 lbs 3 oz

Hose connections:

Air 1/4 in. NPS (M)

Fluid 3/8 in. NPS (M)

Regulator Assembly: Controls pressure of material in cup 0-50

psi.

Pressure Release Valve: Manual operation, allows air pressure to

bleed from cup.

MODEL 7004

2-QUART PRESSURE CUP

Page 2

2-QUART PRESSURE CUP

• Air pressure in the cup never to exceed 50 PSI.

• Never tamper with the relief valve. The relief valve limits the maximum air pressure entering the cup. If the relief

valve does not work properly, over-pressurization may occur and cause the cup to rupture or explode.

• Always disconnect cup assembly from air supply and release pressure in cup (open release valve counterclockwise) before installing or removing the canister from the lid assembly.

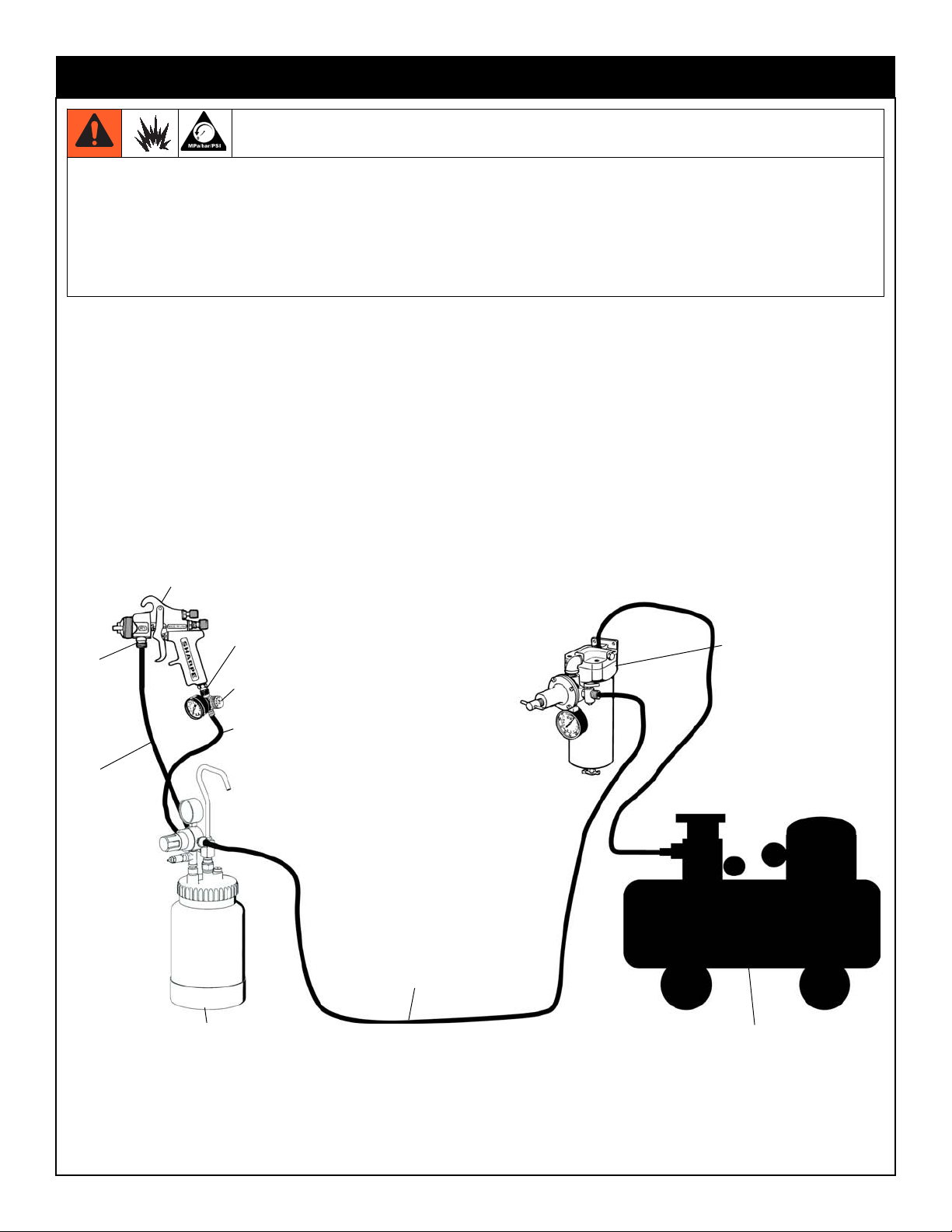

SET-UP FOR SPRAYING

1. Connect air hose to air inlet of gun and to air outlet on cup regulator as shown.

2. Connect fluid hose to fluid inlet of gun and to cup fluid outlet as shown.

3. Connect handle to top of cup as shown.

4. It is best for the air supply line to pass through a SHARPE Air Control Unit to filter dirt from the air and extract water

and oil. Connect the air supply hose to the air inlet fitting on cup regulator.

Note: Follow the manufacturer’s directions for the mixing and preparation of material. Strain material using a fine mesh

screen in order to prevent the entry of foreign matter and the clogging of fluid passageways.

Pressure Spray Gun

Gun

Fluid

Inlet

Fluid

Hose

Gun Air Inlet

Air Adjusting Valve (Optional)

Air Hose

Air Supply Hose

Air Control Unit

Model 7004

2-Quart Pressure Cup

Air Compressor

2 311417C

Page 3

2-QUART PRESSURE CUP

OPERATION

1. Pull out regulator knob and turn fully counter-clockwise. Open

release valve on cup lid (counter-clockwise).

2. Open lid and fill cup with desired sprayable material.

3. Close lid and seal by turning clockwise hand-tight.

4. Close release valve on cup lid hand-tight turning clockwise.

5. Set wall-mounted regulator (not supplied) to desired PSI (this

is your atomizing air).

6. Slowly turn the cup regulator knob clockwise while pulling the

gun trigger fully back to commence material flow. Continue

clockwise until desired material flow is achieved. Push in regulator knob to lock. Maximum cup pressure is 50 PSI.

7. To decrease paint flow, pull out regulator knob and turn counter-clockwise to lower cup pressure. Open the release valve to

bleed off excess pressure. Reseal release valve. Repeat step

6. The cup lid has a check valve that prevents the cup from

losing pressure until the release valve is opened.

8. Atomizing air for the spray gun can be adjusted at the gun by

means of an air adjusting valve on the spray gun.

Note: To achieve desired cup pressure you must always start at a

lower pressure and adjust up to the desired setting.

MAINTENANCE

Cup Pressure

Regulator

Knob

Pressure

Relief Valve

Fluid Outlet

Cup Air Outlet

Pressure

Release

Val ve

TI7063

Cleaning your cup.

1. After relieving cup pressure and turning cup pressure regulator to the full “off ” position (counter-clockwise), open cup

lid by turning counter-clockwise.

2. Pour out any remaining material and add a compatible solvent.

3. Repeat steps 3, 4, and 6 in OPERATION section above and spray until clean solvent appears. Cup and gun material

passages should be clean now.

4. Depressurize cup (OPERATION step 1) and empty remaining solvent from cup and wipe clean with a solvent soaked

cloth.

NOTICE

Never clean your Model 7004 in a gun washer. The

safety valve, regulator body and gauge will be damaged by use in a gun washer. The canister only can be

cleaned in a gun washer.

• Paint can erupt from the cup due to rapid depressurization. Never open the cup prior to turning cup pressure

regulator knob to the full “off” position (counter-clockwise) and relieving cup pressure by opening (counterclockwise) release valve.

3 311417C

Page 4

2-QUART PRESSURE CUP

TROUBLE SHOOTING

CONDITION CAUSE CORRECTION

Excess pressure in cup.

Insufficient pressure in cup.

FLUID PRESSURE REGULATOR

PART NO. 9985

PUSH/PULL

ADJUSTING KNOB

Leak at regulator valve assy.

Gauge registering wrong.

Relief valve setting too high.

Valve spring broken or distorted.

Diaphragm damaged.

Check valve stuck shut.

Relief valve setting too low.

Gauge registering incorrectly.

Leak at cup lid threads.

Pressure release valve partially open.

Replace.

Replace.

Replace.

Replace.

Replace.

Clean or Replace.

Replace.

Replace.

Tighten cup or replace gasket.

Tighten.

REPAIR KIT

PART NO. 10000

• Diaphragm Assy

• Inner Valve Assy

• Bottom Plug and

O-Ring Assy

• Valve Spring

SPRING CAGE

ADJUSTING

SCREW AND

NUT ASSEMBLY

TOP SPRING

DIAPHRAGM

ASSEMBLY

BODY

INNER

VALVE

ASSEMBLY

VALVE

SPRING

BOTTOM PLUG

AND O-RING

ASSEMBLY

4 311417C

Page 5

2-QUART PRESSURE CUP

MODEL 7004 PARTS LIST

REF. NO. PART NO. DESCRIPTION

1 8215 FLUID PRESSURE GAUGE

2 9985 FLUID PRESSURE REGULATOR

3 U42000 FLUID TUBE

4 U42001 CUP LID

4a 120122 LID FITTING

5 U42002 LID GASKET (pkg of 5)

6 U42003 VALVE/FITTING KIT

6a CHECK VALVE ASSEMBLY

6b PRESSURE RELIEF VALVE

6c PRESSURE RELEASE VALVE

6d INLET FITTING

6e TEE FITTING

7 U42005 CUP HANDLE/NUT/

FLUID OUTLET

8 U42004 2-QUART CANISTER

9 9993 NIPPLE - 1/4 in.

1

7

2

6e

9

6b

6d

5

6c

4a

4

6a

3

8

MODEL 7004

2-QUART PRESSURE CUP

5 311417C

Page 6

1 Year Limited Warranty

Sharpe warrants this product to the original user against defective material or workmanship for a period of 1 year from the

date of purchase.

Sharpe reserves the right to determine whether the part or parts failed because of defective material, workmanship, or

other causes. Failures caused by accident, alteration, or misuse are not covered by this warranty.

Sharpe, at its discretion, will repair or replace products covered under this warranty free of charge. Repairs or replacements

of products covered under this warranty are warranted for the remainder of the original warranty period.

Sharpe or its authorized service representatives must perform all warranty repairs. Any repair to the product by unauthorized service representatives voids this warranty. The rights under this warranty are limited to the original user and may not

be transferred to subsequent owners.

This warranty is in lieu of all other warranties, expressed or implied, including warranties of merchantability and fitness for a

particular purpose. Some states do not allow the exclusion or limitations of incidental or consequential damages, so the

above limitations may not apply to you.

Sharpe Information

TO PLACE AN ORDER, contact your SHARPE distributor or call 1-800-742-7731 or visit our website at www.sharpe1.com.

Product Registration

Thank you for the purchase of your Sharpe® product. We greatly appreciate your business.

Important reasons to register your product:

• Registration enables Sharpe to notify you if there is a problem with your product.

• Improved Product Development - Your input helps us continue to design products that meet your needs.

For the most up-to-date information and to register your product, please go to www.sharpe1.com and click on “Register

Product.”

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 311417

SHARPE MANUFACTURING • P.O. BOX 1441, MINNEAPOLIS, MN 55440-1441

1-800-742-7731, www.sharpe1.com

Copyright 2005, Graco Inc. is registered to ISO 9001

Revised 02/2011

Loading...

Loading...