Page 1

Reactor® E-8p

Portable Plural-Component Sprayer

for No-Heat Polyurethane Foams

Page 2

Build Your Business by Re-insulating Existing Homes

1. American Housing Survey 2007 and Lawrence Berkeley Laboratory LBL-35700

2. NISTIR 7238 US DOE June 2005 by S.J. Emmerich, T. McDowell and W. Ains

Here’s your opportunity

Homeowners are looking for ways to cut energy costs. Proper sealing and insulating is

a long-term cost-effective way to make their homes more energy-efficient. With over

86 million existing homes in North America that require better insulation1, this is

a great opportunity for you to build your business.

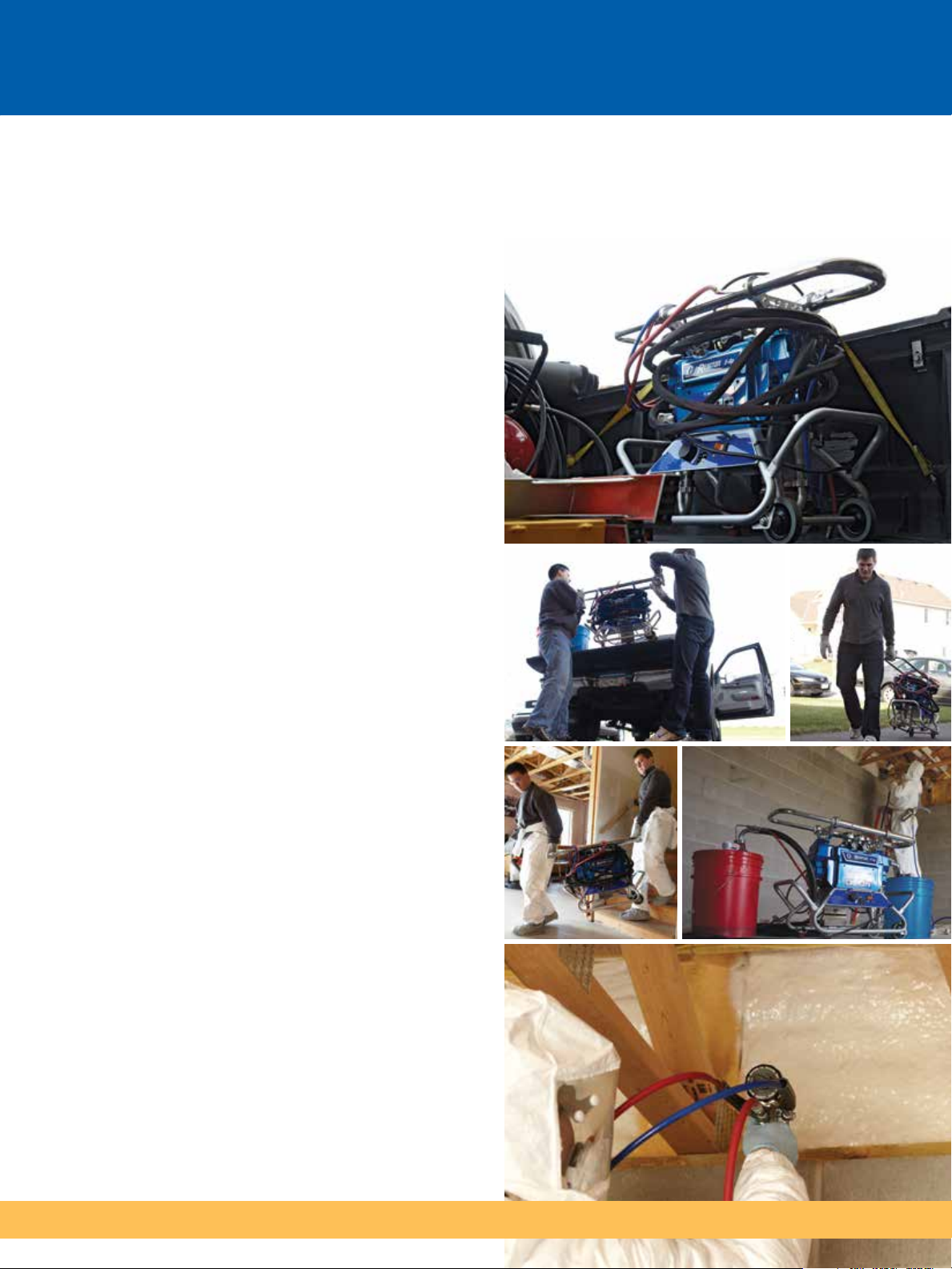

Use the Reactor E-8p in attics to create an air barrier under blown-in

insulation (above), or to seal and insulate rim joists (below).

A 2005 National Institute of Standards and Technology study2 indicates

that an air barrier system could reduce air leakage by up to 85%, and

realize a 40% savings in natural gas, and a 25% savings in electricity.

2

Page 3

The Reactor E-8p is the solution

The Reactor E-8p Portable Plural-Component Sprayer is among the first portable, professional foam insulation systems that produces foam

for air-sealing existing homes. In fact, it’s the first system that’s designed specifically for new no-heat polyurethane foam formulations. It

produces a proven air-seal solution that’s in demand by homeowners who want energy-efficient homes.

Expand your business

Become more competitive in today’s market with equipment

designed for the remodeling or small foam job. Whether you’re

expanding your existing insulation application opportunities or

just starting your business, the Reactor E-8p provides a quick

return on investment. As a touch-up system, the Reactor E-8p

frees up larger rigs for medium and large jobs while enabling

you to finish the job affordably.

Portable, lightweight

and easy to move

Haul it in your van, pickup or car. Take it anywhere – through

narrow doorways or halls, even up narrow stairways of older

homes. The Reactor E-8p’s compact design easily fits in tight

areas so you can spray foam with ease. Since no heaters are

required, the Reactor E-8p is small, lightweight and compact.

Designed for existing

home environments

The compact design is unobtrusive. Simply plug it into

a standard residential outlet. Material is drawn from handy

no-spill five-gallon pails. No feed pumps needed.

Applications

• Rim joists in existing homes

• Attics in existing homes – as an air barrier under blown-in insulation

• Alternative to froth kits

• Backup system for spray rig owners

• Touch-up projects in tight areas

• HVAC spray sealing of approved duct work

• Roofing applications – patching, applying select roofing adhesives

Visit www.graco.com/E-8p

3

Page 4

Best Choice for Portability and High-Quality Foam

Telescoping Handle

Easy handling from your vehicle to the home

Built-in Suction Lines

No need for feed pumps

Pressure Gauges

Easy to read gauges ensure you’re spraying on-ratio.

Holster for Suction Lines

Keeps tubes in place during transport; prevents drips.

Lightweight and Portable

Easy to maneuver up and down stairs,

wherever the job goes – only 95 lb (43 kg)

Desiccant Air Dryer

Allows air to be drawn into pail; protects material from

contamination.

4

Alarm / Status Indicator

Shuts down unit if off-ratio conditions exist –

assures good quality foam at the job site

Designed for new no-heat foam formulations

Page 5

Pressure Balance Valves

Quick and easy balancing of system pressures

enables correct start-up

Threaded Bucket Spout Connection

Keeps your connection secure

and prevents spills

Electric Motor

Proven motor performance and

reduced operating costs; plugs into

a standard residential outlet

Easy Controls

Intuitive start/stop with

single knob operation

Carrying Handle/Hose Wrap

Easy to transport, convenient hose storage.

Spray Guns

Uses standard Graco Fusion or P2 Guns;

provides consistent spray patterns

Non-heated Hose

Easy to maneuver – 70% lighter than standard

Reactor heated hose

5

Page 6

A

B

C = A / B

D

E = C x D

FORMULA

F

G = E x F

H = G -

ANNUAL MAT’L COST

OF NO-HEAT FOAM

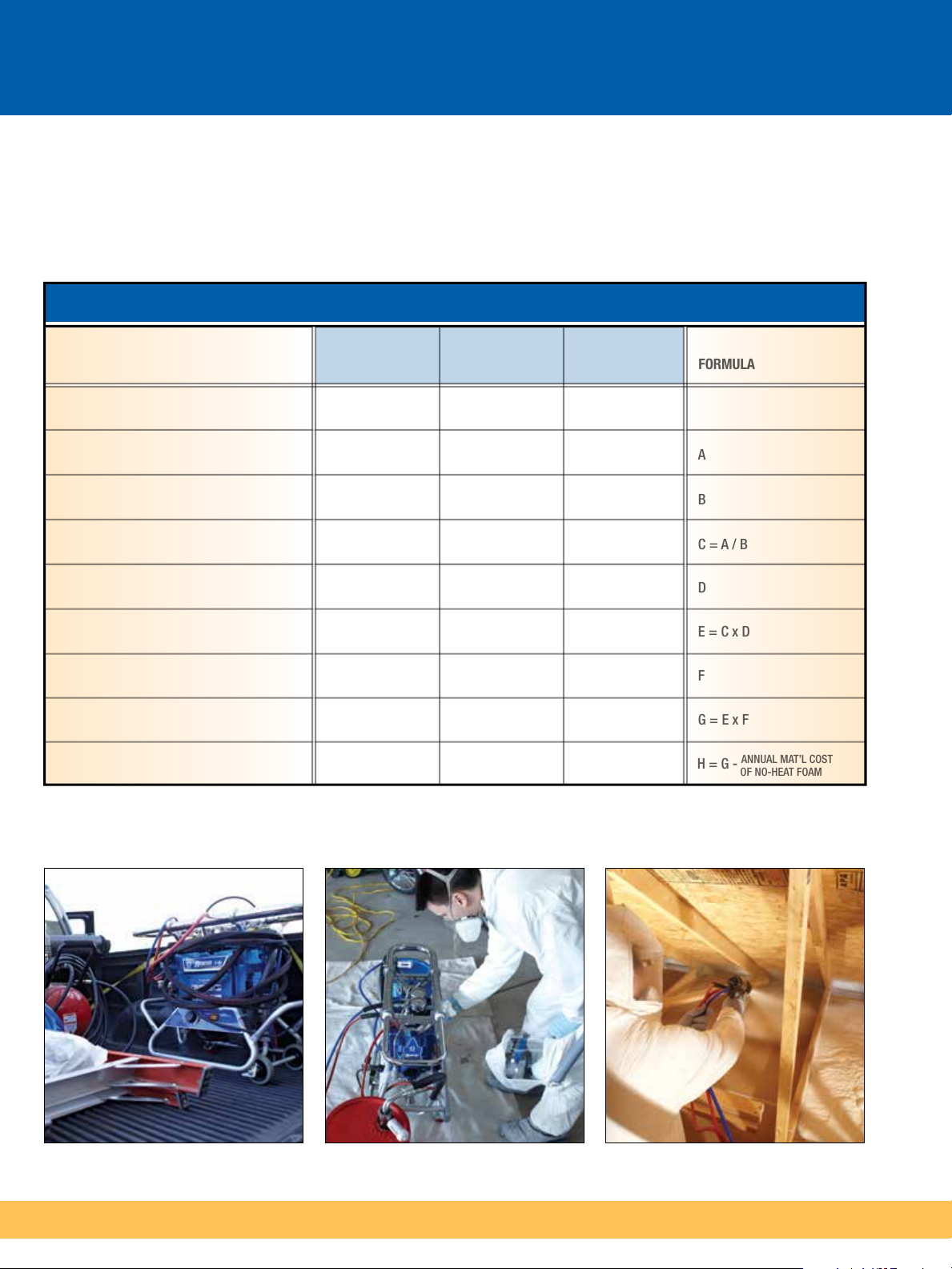

Reactor E-8p: An Economical Alternative to Froth Kits

A quick return on your investment

Many small projects that are ordinarily completed with froth kits can now be accomplished more economically with the

Reactor E-8p and no-heat polyurethane foams. In fact, froth kits can cost up to three times the cost of five-gallon pails

of no-heat foam polyurethane materials.

ANNUAL MATERIAL SAVINGS WITH E-8p

SMALL

FROTH KIT

PACKAGE SIZE

AVERAGE COST PER KIT

TYPICAL YIELD

COST PER BOARD FOOT

AVERAGE SIZE JOB

FOAM COSTS OF AVERAGE SIZE JOB

ESTIMATED NUMBER OF JOBS ANNUALLY

ANNUAL MATERIAL COST

ANNUAL MATERIAL SAVINGS WITH E-8p

* Per The Dow Chemical Company for Froth Kits: The theoretical yield has become an industry standard for identifying certain sizes of two-component kits. Theoretical yield calculations are done in perfect laboratory conditions, without taking

into account the loss of blowing agent or the variation in application methods and types. This chart is an example only and should be reviewed for each application. Dollar savings are not guaranteed. Actual results may vary.

(in board feet)*

(in board feet)

39 lb

$374

170

$2.20

850

$1,870

LARGE

FROTH KIT

118 lb

$828

510

$1.62

850

$1,380

5050

$69,000$93,500

$38,643$63,143

NO-HEAT FOAM

5-GAL PAIL SET

80 lb

$320

450

$0.71

850

$604

50

$30,200

Ready - Easy to transport to the job site. Set - Get ready to spray in a matter of minutes. Spray - Ideal for attics and rim joists.

6

Page 7

Technical Specifications and Ordering Information

Technical Specifications

Max fluid working pressure ......................................... 2000 psi (140 bar, 14 MPa)

Electrical requirements ................. Model 259082: 120 Vac, dedicated 15 A-circuit,

1 phase, 50/60 Hz

Max output ............................................... 12 lb/min (5.4 kg/min) at 340 cycles/min

Max chamber size .................................................................00 (orifice size 0.029)

Output per cycle (A and B) ................................................. .00352 gal (0.0133 liter)

Sound power (per ISO 9614-2) ................. 94.4 dB(A) at 2000 psi (140 bar, 14 MPa)

0.5 gpm (1.9 lpm)

Sound pressure (1 m from equipment) ...... 84.5 dB(A) at 2000 psi (140 bar, 14 MPa)

0.5 gpm (1.9 lpm)

For best results, use specially formulated no-heat polyurethane foam and follow chemical manufacturer’s application recommendations.

Fluid outlets ............................................................ Component A (ISO):-5 JIC male

Fluid circulation return ........................................... Component A (ISO):-5 JIC male

Hose markings .................................................................. A side: Red; B side: Blue

Wetted parts ......................... Aluminum, stainless steel, carbon steel, brass, carbide,

Dimensions (Bare sprayer) ......................... 35 L x 24 H x 15 W in (89 x 61 x 38 cm)

Weight (Bare sprayer, no hose, no gun) ................................................. 95 lb (43 kg)

Operation manual .................................................................................. 3A1602A

Ordering Information

Sprayers – Packages include gun and 35 ft (10.6 m) of non-heated hose

259082 Bare proportioner, 240V, 15 amp cord

AP9082 Proportioner package with Fusion AP Gun (246100)

and non-heated hose (24M653)

CS9082 Proportioner package with Fusion CS Gun (CS00RD)

and non-heated hose (24M653)

P29082 Proportioner package with P2 Gun (GCP2R0)

and non-heated hose (24M653)

259083 Bare proportioner, 240V, 10 amp cord

AP9083 Proportioner package with Fusion AP Gun (246100)

and non-heated hose (24M653)

CS9083 Proportioner package with Fusion CS Gun (CS00RD)

and non-heated hose (24M653)

P29083 Proportioner package with P2 Gun (GCP2R0)

and non-heated hose (24M653)

Component B (RES):-6 JIC male

Component B (RES):-6 JIC male

chrome, chemically resistant o-rings, PTFE,

ultra-high molecular weight polyethylene

Accessories

119974 Dryer, desiccant

249855 Repair kit, displacement pump; includes seals, balls, bearings, intake valve seat

246010 Suction hose, pump to 5 gal pail

24J155 Adapter, spout, pour, assembly A

24J766 Adapter, spout, pour, assembly B

16H615 Tube, recirculation

249633 Hose bundle, 35 ft (10.6 m), non-insulated

Guns – Refer to brochure 300615 for complete spray gun listings, plus wide and flat chamber sizes

246099 Fusion AP: AR2020 (000) mix chamber (0.020 orifice size)

246100 Fusion AP: AR2929 (00) mix chamber (0.029 orifice size)

GCP2RA P2: GC250A mix chamber with GC251A tip (0.020 orifice size)

GCP2RO P2: GC2500 mix chamber with GC2510 tip (0.029 orifice size)

CS20RD Fusion CS: RD2020 (000) round mix chamber (0.020 orifice size)

CS00RD Fusion CS: RD0000 (00) round mix chamber (0.029 orifice size)

7

Page 8

ABOUT GRACO

Founded in 1926, Graco is a world leader in fluid handling systems and components. Graco products

move, measure, control, dispense and apply a wide range of fluids and viscous materials used

in vehicle lubrication, commercial and industrial settings.

The company’s success is based on its unwavering commitment to technical excellence, world-class

manufacturing and unparalleled customer service. Working closely with qualified distributors, Graco

offers systems, products and technology that set the quality standard in a wide range of fluid handling

solutions. Graco provides equipment for spray finishing, protective coating, paint circulation, lubrication,

and dispensing sealants and adhesives, along with power application equipment for the contractor

industry. Graco’s ongoing investment in fluid management and control will continue to provide

innovative solutions to a diverse global market.

GRACO LOCATIONS

MAILING ADDRESS

P.O. Box 1441

Minneapolis, MN 55440-1441

Tel: 612-623-6000

Fax: 612-623-6777

AMERICAS

MINNESOTA

Worldwide Headquarters

Graco Inc.

88 -11th Avenue N.E.

Minneapolis, MN 55413

EUROPE

BELGIUM

European Headquarters

Graco N.V.

Industrieterrein-Oude Bunders

Slakweidestraat 31

3630 Maasmechelen,

Belgium

Tel: 32 89 770 700

Fax: 32 89 770 777

ASIA PACIFIC

AUSTRALIA

Graco Australia Pty Ltd.

Suite 17, 2 Enterprise Drive

Bundoora, Victoria 3083

Australia

Tel: 61 3 9468 8500

Fax: 61 3 9468 8599

CHINA

Graco Hong Kong Ltd.

Shanghai Representative Office

Building 7

1029 Zhongshan Road South

Huangpu District

Shanghai 200011

The People’s Republic of China

Tel: 86 21 649 50088

Fax: 86 21 649 50077

INDIA

Graco Hong Kong Ltd.

India Liaison Office

Room 443, Augusta Point

Regus Business Centre 53

Golf Course Road

Gurgaon, Haryana

India 122001

Tel: 91 124 435 4208

Fax: 91 124 435 4001

JAPAN

Graco K.K.

1-27-12 Hayabuchi

Tsuzuki-ku

Yokohama City, Japan 2240025

Tel: 81 45 593 7300

Fax: 81 45 593 7301

KOREA

Graco Korea Inc.

Shinhan Bank Building

4th Floor #1599

Gwanyang-Dong, Dongan-Ku,

Anyang-si, Korea 431-060

Tel: 82 31 476 9400

Fax: 82 31 476 9801

SALES/

DISTRIBUTION/

SERVICE

North America

Customer Service

800-328-0211

Fax 877-340-6427

Call today for product information or to request a demonstration.

877-84GRACO (1-877-844-7226) or visit us at www.graco.com.

Graco Inc. is registered to I.S. EN ISO 9001

©2011-2014 Graco Inc. ELECTRONIC ONLY Rev. C 5/14 All written and visual data contained in this document are based on the latest product information

available at the time of publication. Graco reserves the right to make changes at any time without notice. All other brand names or marks are used for

identification purposes and are trademarks of their respective owners.

Loading...

Loading...