Page 1

®

Reactor

A-25

Plural-Component Sprayer for Polyurethane Foams

Top quality and performance for spraying foam insulation

• Graco-engineered solution provides tested and proven reliability

• Maintains temperature setpoints for better yield

• Maintains consistent output pressure for uniform spray pattern

• Easy to operate and maintain

• Best choice for affordability and long-lasting durability

Page 2

© 2011 Graco Inc. 348581 Rev. A 09/11 All other brand names or marks are used

for identification purposes and are trademarks of their respective owners. All written

and visual data contained in this document are based on the latest product information

available at the time of publication. Graco reserves the right to make changes at any

time without notice.

Superior performance with

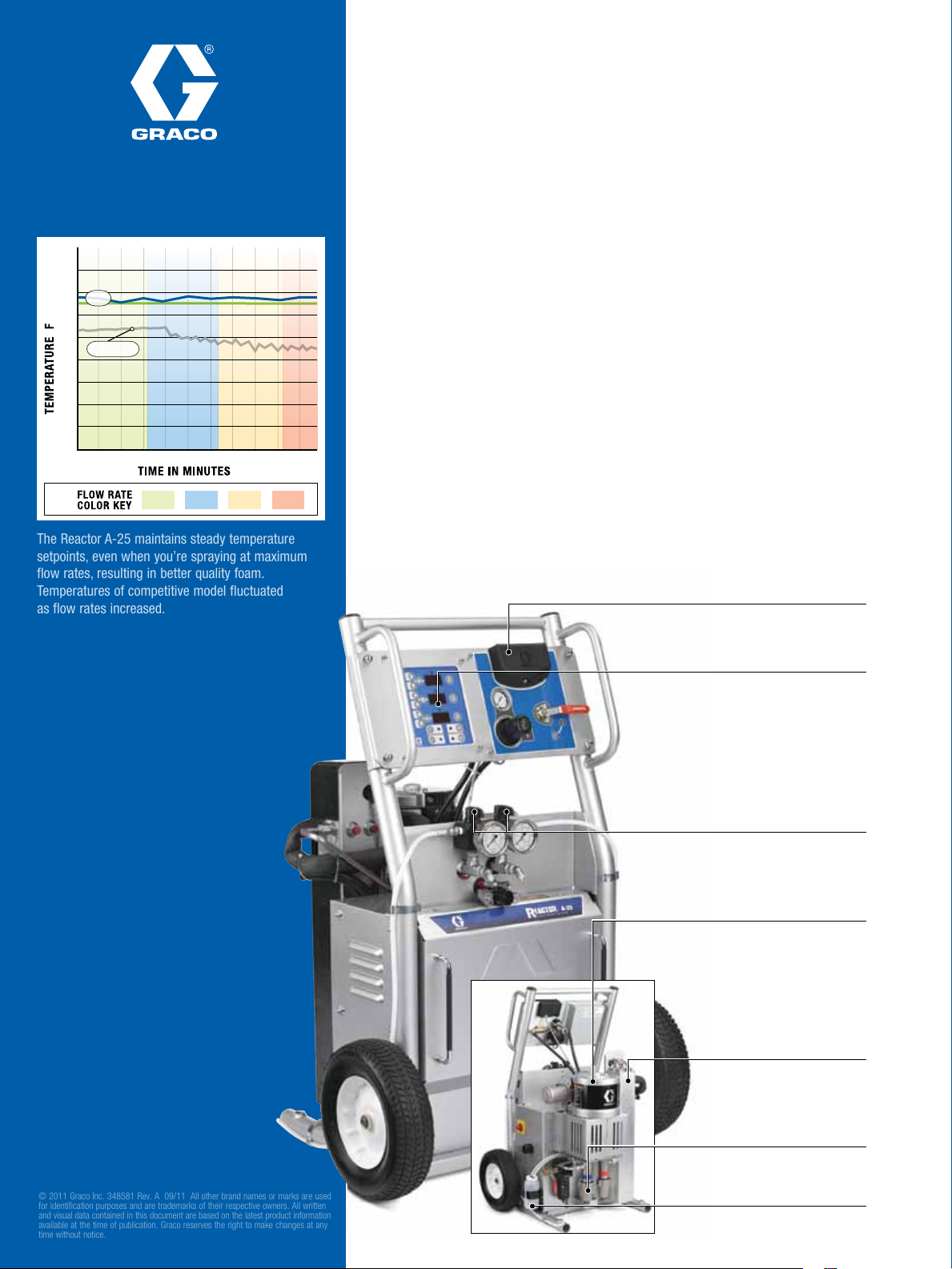

The Reactor A-25 maintains steady temperature

setpoints, even when you’re spraying at maximum

flow rates, resulting in better quality foam.

Temperatures of competitive model fluctuated

as flow rates increased.

long-lasting durability

Consistent Temperature Control Technical Specifications

HOSE OUTLET TEMPERATURES

140°

130°

A-25

Setpoint

120°

110°

COMPETITION

100°

90°

80°

70°

60°

1 2 3 4 5 6 7 8 9 10

1 GPM

.5 GPM

(

)

(

1.9 LPM

3.8 LPM

1.5 GPM

(

5.5 LPM

2 GPM

)

(

)

7.6 LPM

)

Max output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 lb/min (11.4 kg/min)

Max fluid working pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2000 psi (138 bar, 14 MPa)

Max air supply pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125 psi (9 bar, 0.9 MPa)

Air consumption

System air consumption

with 02 tip @ 1500 psi (103 bar, 10.3 MPa) stall pressure . . . . . . 28 scfm (0.8 m

with 2:1 feed pumps @ 100 psi . . 34 scfm (.96 m

Max heater fluid temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190°F (88°C)

Max hose fluid temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180°F (82°C)

Heater wattage . . . . . . . . . . . . . . . . . . 6,000 watts (

Max heated hose length* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210 ft (64 m) of 3/8 ID

Power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40A at 230V, 1-ph

32A at 230V, 3-ph

18.5A at 380V, 3-ph

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250 lb (117.6 kg)

Dimensions (with wheels) . . . . . . . . . . . 43.5 H x 29 W x 30 D in (110 H x 74 W x 76 D cm)

Dimensions (without wheels) . . . . . . 43.5 H x 21.5 W x 24.5 D in (110 H x 55 W x 62 D cm)

Operation manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3A1569

*210 ft (64 m) of heated hose will produce the maximum allowable heat capacity. 310 ft (94 m) of heated hose may be

used, but will have 25% less heat capacity.

3

/min)

3

/min) at flow rate listed above

with the ability to easily reduce to 3,000 watts)

Ordering information

262614 Reactor A-25, includes DataTrak

and wheels

Packages include a proportioner, spray hose, whip hose

and spray gun.

AP2614 Reactor A-25 (262614) package

with Fusion

®

AP Gun (246101)

P22614 Reactor A-25 (262614) package

with P2 Gun (GCP2R1)

CS2614 Reactor A-25 (262614) package

with Fusion CS Gun (CS01RD)

Contact us today!

For more information, call

1-877-844-7226 or visit us

online at www.graco.com.

DataTrak™ Control

• Resettable counter tracks material usage

Three Heat Zones

• Three independent heat zones –

ISO, resin and hose heat

• Provide accurate heat control for reliable

spraying to handle different

chemical viscosities

• Digital temperature controls

Recirculation Manifold

• A quick, easy way to balance

system pressures

NXT® Air Motor

• Low air consumption for increased efficiency

• Muffler provides low operating noise levels

• Air valve provides smooth and

rapid changeover

Hybrid Heater

• Provides better temperature control

Quick Knockdown

Lower Pumps

• For easy disassembly and maintenance

ISO Pump Lube System

• Prevents isocyanate crystallization

on the pump seal and shaft

Loading...

Loading...