Page 1

k.

"~

Thismanualcontains

IMPORTANT

1iV~RNINCSandiNSTRUCTlONS

..

~

READ

AND

RETAiN

FOR

REfERENCi

HYDRA-CLEAN'

225Opsi(155barl

MAXIMUM

WORKING PRESSURE

Model

800-101

1

INSTALLATION

Connect the quick coupler on the end of the tube to the

tip assembly. Connect the hose assembly to the quick

coupler at the fluid inlet of the

gun.

Then connect the

hose to the Hydra-Clean unit.

OPERATION

For cleaning with harsh chemicals,

see

the Chemical In-

jector Kit manual,

801-192. For cleaning with abrasives,

wood, hold the nozzle about

3

fl

(1 mm) from the

surface and gradually bring

it

closer, checking to see if

see

Water Smdblaster manual,

801-190.

the high pressure spray

is

damaging the surface.

For cleaning with clear water, test the distance you will

Always hold the nozzle at an angle to the surface and

need to hold the spray nozzle from the surface on

a

"chisel"

off

the dirt. When you have finished cleaning,

scrap piece of similar material. For soft surfaces such as

shut

off

the unit

and

trigger the spray gun to relieve

pressure.

SERVICE

WARM

Follow these precautions when r

1.

Shut

off

engine and trigger gun to release

4.

Do not let anyone

else

touch the spray valve

pressure. Engage trigger safety. while you are changing nozzles.

2. Keep the'nozzle and the tube pointed away

5.

Be sure the slip ring

is

pushed forward to lock

from you and everyone else.

the nozzle in place before triggering the spray

3.

Do

not put your hand over the tip to push the

nozzle into place. Grasp

it

from the side and

keep your fingers away from the tip.

gun,

Gun

1.

Remove the 9 screws and nuts from the body halves

4.

Remove sleeve nut

(J)

and O-ring IK) with the ac-

(3).

See Parts Drawing. Separate body halves. tuator rod.

2. Remove plug

(B),

seal washer

(C)

and ball (D) from

5.

After installing new seat (GI and ball

(Dl,

tap theball

lightly with a hammer to assure a proper seating

between the ball and seat.

the valve body

(E).

3.

Remove snap ring

(F).

Then remove valve seat (G)

.-

and O-ring (HI.

6.

Reassemble

in

reverse order, using remaining new

parts from repair kit.

GRACO

KWC.

P.0.

~QX

7441

MBMNEAPQRUS,

MN

55440

@COPYRIGHT

1981

GRACO

INC.

-

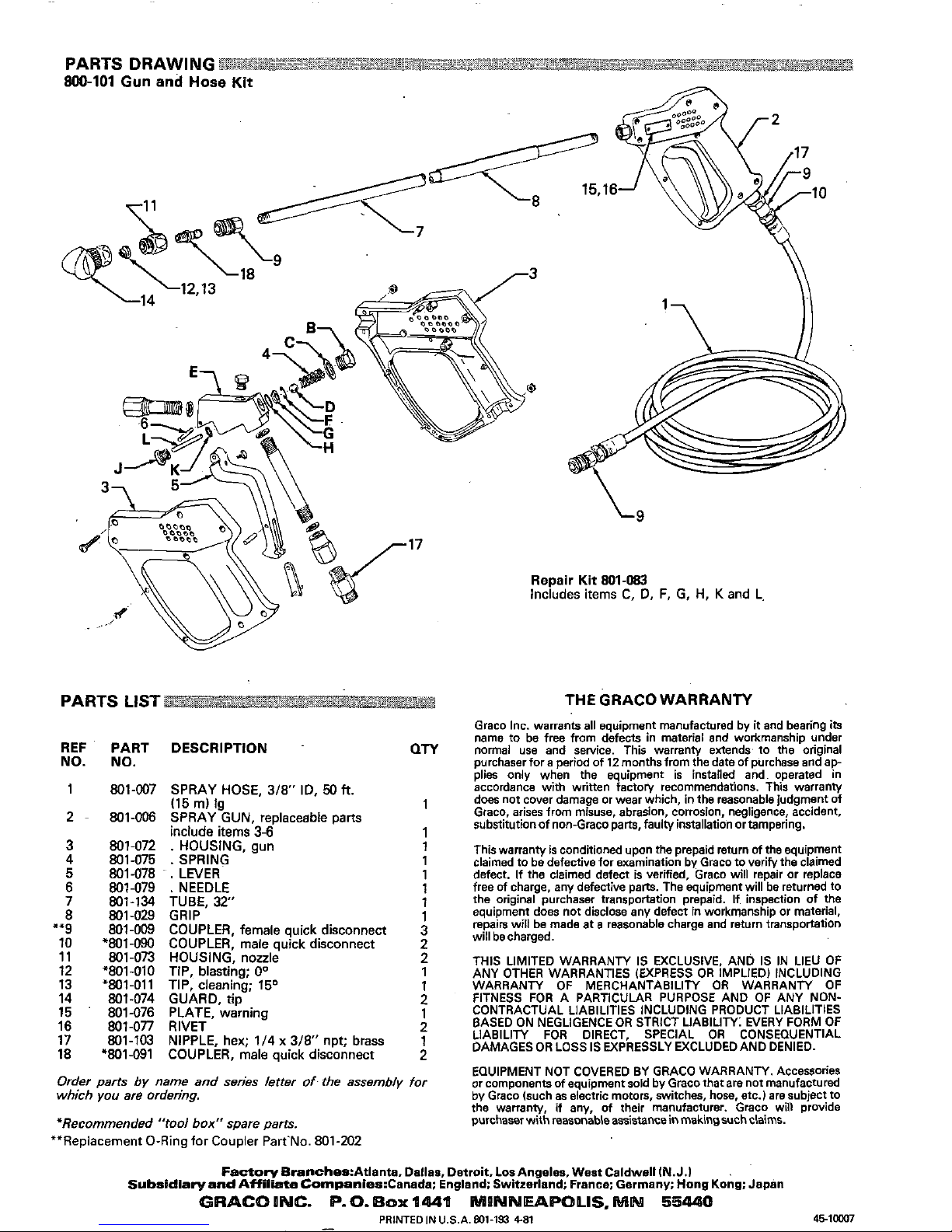

Page 2

PARTS

LIST

THE

GRACO WARRANTY

REF

NO.

1

2

3

4

5

6

7

8

""9

10

11

13

12

14

15

16

17

18

PART DESCRIPTION

NO.

801-007 SPRAY HOSE,

3/8"

ID,

50

ft.

(15

rn)

lg

801-006 SPRAY GUN, replaceable parts

include

item$

3-6

801-072 . HOUSING, gun

801675

.

SPRING

801-078

~.

LEVER

801-079

.

NEEDLE

801-029 GRIP

801-134 TUBE,

32"

801-009 COUPLER, female quick disconnect

801-073 HOUSING. nozzle

'801-090

COUPLER, male quick disconnect

~~ ~ ~ ~ ~ ~~

*801-010 TIP, blasting;

Oo

'801-011 TIP, cleaning; 15O

801-074 GUARD,

tip

801-076 PLATE, warning

801477

RIVET

801-103 NIPPLE, hex; 1/4

x

3/8"

npt;

brass

~_,

'801-091

COUPLER. male ouick disconnect

QTY

1

2

2

1

1

2

1

2

2

1

Graco Inc. warrants a11 equipment manufactured by

it

and bearing

its

name to be free from defects in material and workmanship under

normal use and service. This warranly extends to the original

purchaserforaperiodof12monthsfromlhedateofpurchaseandap-

plies only when the equipment is installed and operated in

accordance with written factory recommendations, This warranly

does not cover damage or wear which,

in

the reasonable judgment

of

substitutionof

non-Gracoparts,faullyinstallationortampering.

Graco, arises from misuse, abrasion, corrosion, negligence, accident,

This warranty is conditioned upon the prepaid return

of

the equipment

claimed to be defective for examination by Graco to verify the claimed

defect. If the claimed defect is verified, Graco will repair or replace

free of charge, any defective parts. The equipment will be returned to

the original purchaser transportation prepaid.

if

inspection of the

equipment does not disclose any defect

in

workmanship or material,

will becharged.

repaim will be made at

a

reasonable charge and return transportation

. ~~

~.~

~~

~~~

-

EQUIPMENT NOT COVERED

BY

GRACO

WARRANN.

Accessories

Order parts

by

name and series lerter

of.

the assembly for

which

you

are

ordering.

or

components

of

equipment sold by Graco that are

not

manufactured

by Graco (such as electric motors, switches, hose, etc.) are subject

to

*Recommended

"tool

box" spare parts.

the warranty,

if

any, of their manufacturer. Graco will provide

purchaser with reasonable assistancein making such claims.

**Replacement

0-Ring

for Coupler Part'No. 801-202

FaGtDlyeranches:Atianta,

Dallas, Detroit. LOSAngeles. West Caldwell

IN.J.1

Subsidla~andA*iliateCompanies:Canada:

England; Switzerland: France; Germany: Hong

Kong:

Japan

Loading...

Loading...