Page 1

This manual

WARNINGS

READ

AND

contains

and

INSTRUCTIONS-

RETAIN

FOR

IMPORTANT

REFERENCe

2104E.MODEL

2

150

psi

(1

50

bar) OPERA TlNG PRESSURE

2250

psi

(155

bar).MAXIMUM WORKING PRESSURE

800-053

SERIES

"A"

Page 2

~~JJj~~~~Q,&!

Fluids under high pressure from spray or leaks can

penetrate the skin and cause extremely serious

injury, including .the need for amputation.

NEVER

the body.

NEVER

NEVER

body.

point the spray

put hand or fingersover the spray tip.

try to stop or deflect leaks with your hand or

ALWAYS

MEDlCAL

[=;'b~~.j~~~

gun

at anyone or any part of

have the tip guard

in

TRE&TMEF%B

place when spraying.

DO

not use chemicals or agents which are not

compatible with Buna-N and PVC or neoprene cover

of hose.

Do

not leave a pressurized unit unattended. Shut off

the unit and release pressure before leaving.

FORE

Do

not spray flammable liquids.

engine where combustible fumes or 'dust may be

present.

Do

not operatethe

GENERAL

NEVER

Keep clear of moving parts when the unit is running.

run the unit with the belt guard removed.

.

'

If

any

fluid appears to penetrate your skin, get

treatment instructions have' your doctor call the

F.Sb,iTlONAE

Avena

Even after you shut

high pressure

release

the spray tip or servicing the unit, always shut offthe

unit and trigger the gun to release pressure.

Be sure that

components will withstand the pressure developed.

NEVER

in system.

personal safety, as well as the function of the

equipment,

Before each use, check hose for weak, worn or

damaged conditions caused by traffic, sharp corners,

pinching or kinking. Tighten

securely before.each

hose.

~QM?~HENT

it

exceed the pressure rating of any component

PQ@OM

(41

in

the pump, hose and gun until you

by triggering the gun.

.all

NEVER

alter or modify equipment -your

is

at stake.

CENTER

2)6$1-6669

off

the gasoline engine, there

accessory items and system

.use.

Replace any damaged

NETWORK

So

before removing

all

fluid connections

is

observe detergent manufacturer's safety

precautions. Avoid getting detergent or other liquids

in your eyes. Follow

regarding contact with eyes, nose, and skin,

breathing fumes, etc. Always wear full goggles to

protect your eyes from the spray as well as any debris

dislodged by the spray. If necessary, wear gloves or

other protective clothing. If. antidotes or treatment

are recommendbd, be prepared to use them.

DON'T

weed killer.

This unit is supplied with an 8-foot power cord made

up of four AWG

electric cord is connected to the unit chassis and

motor frame. The other three wires are connected to

the starter switch.

Be sure to connectthe power cord to the appropriate

approved plug to fit your requirements.

The starter switch has

will shut

circuit

Always check to be sure the switch is

hoses and electric cord are clear of moving parts

before plugging

spray toxic chemicals such as insecticide or

off

the power to the unit whenever the

is

overloaded.

the

directions on the container'

No.

12

wires. The green wire of the

a

built-in.circuit breaker that

in

the power cord.

off

and thatthe

IMPORTANT

United States Government safety standards have been adopted under the Occupational Safety and Health Act.

These standards

should

2

be

.

801-392

-

consulted

~~~

particulsrlythe.General Standards, Part

in

connection

with

your

use

.. ..

..

of

~~

airless

..

1910,

and the Construction Standards, Part

spray equipment.

.

..

1926

-

Page 3

,

..-..

:

:

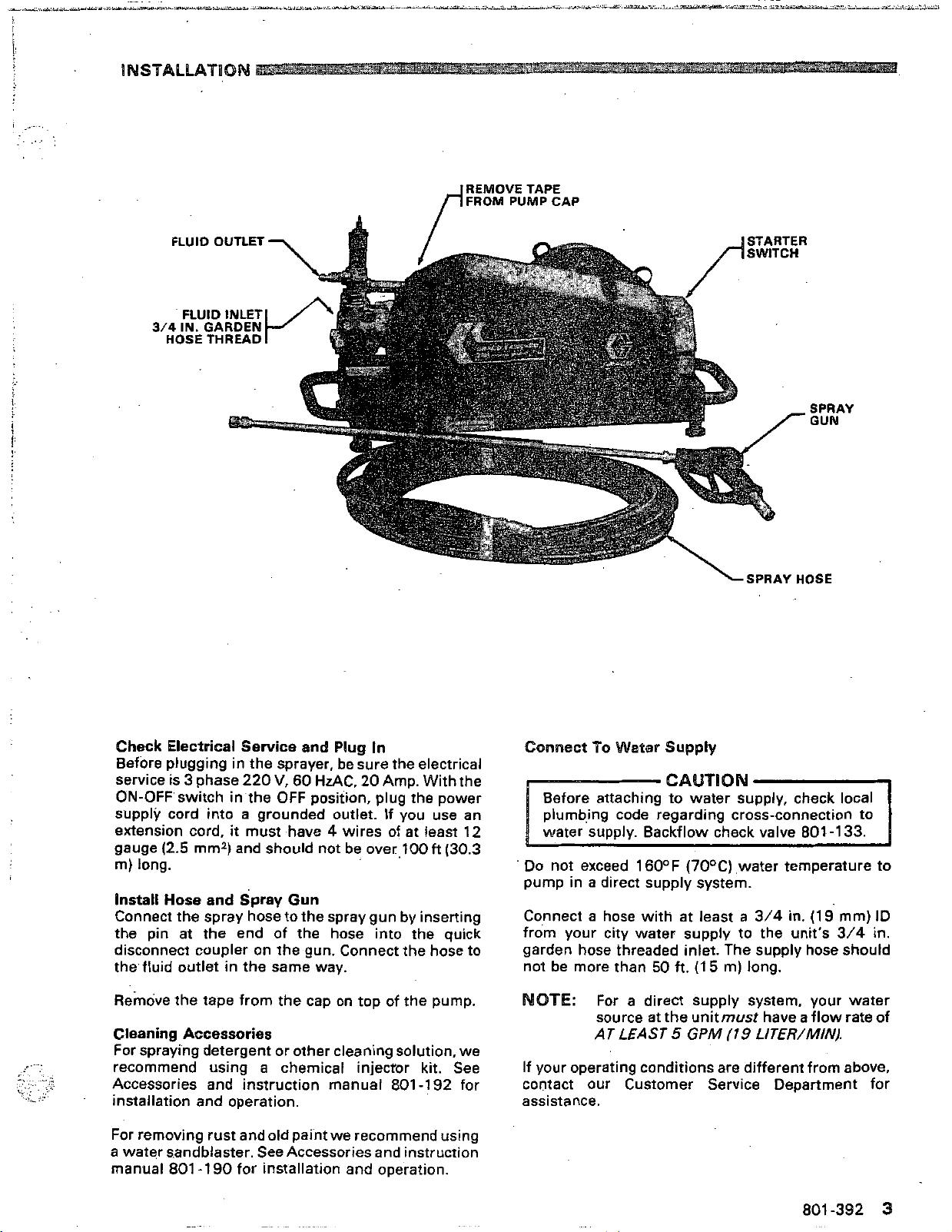

REMOVE

FROM

!’

TAPE

PUMP CAP

\SPRAY

I

SPRAY

GUN

HOSE

..

r

.

,

L:’:

..,<

.~

..

..

:,

...

Check Electrical Service and

Plug

In

Before plugging in the sprayer. be sure the electrical

service is

3

phase

220

V,

60 HAC.

20

Amp. With the

ON-OFF switch in the OFF position, plug the power

supplY cord into

extension cord,

gauge (2.5

m)

long.

Install

mm2)

Hose and Spray

a

grounded outlet. If you use an

it

must have 4 wires of

at

and should not be over.100ft

Gun

least

(30.3

12

Connect the spray hose to the spray gun by inserting

at

the pin

disconnect coupler

the end of the hose into the quick

on

the gun. Connect the hose to

the fluid outlet in the same way.

Remove the tape from the cap

on

top of the pump.

Cleaning Accessories

For spraying detergent or other cleaning solution, we

recommend using

chemical injecior

kit.

See

a

Accessories and instruction manual 801-192 for

installation and operation.

For removing rust and old paint we recommend using

a

water sandblaster. See Accessories and instruction

manual 801 -190 for installation and operation.

To

Connect

Do

not exceed 1 6OoF (7OOC) ,water temperature to

pump in

Wate~

a

direct supply system.

Connect a hose with at least

from your city water supply to the unit’s

Supply

a

3/4

in. (19 mm)

3/4

ID

in.

garden hose threaded inlet. The supply hose should

not

be more than

NOTE:

For a direct supply system. your water

source

AT

50

ft.

(1

5

m) long.

at

the unitmust have a flow rate of

LEAST 5 GPM

(19

LITER/MIN).

If your operating conditions are different from above,

contact our Customer Service Department for

assistance.

801-392

3

Page 4

OPERATlQM

:

Startup

'

.

Before starting, be sure'to read the safety warnings

and setup instructions.

in

Turn on the water supply.

Trigger the gun to release any back pressure.

CAUTION

Never run the cleaning unit dry. Costlydamage

',

to the pump

supply iscompletelyturned

Inspect

necessary.

Cleaning

For Hydra-Clean technique, see the Chemical

Injector manual, 801

'I

For abrasive cleaning, see the Water Sandblaster

manual, 801 -1

all

will

result. Always be sure water

on

before operating.

connections for any leaks. Tighten if

-1

92.

90.

I

Check the filter screen

as often as necessary,

the unit with the inlet and filter screen removed.

DO

NOTtrytoadjusttheunloadervalveorchangethe

engine speed. Changing these settings rnay cause

excessive pressure, intermittent unloader operation,

wasted fuel and increased wear

the warranty.

PUMP MUST

of water prior to exposure to freezing temperatures.

Use and store the unit where it

to freezing temperatures.

unit, thaw before trying to start.

solution rnay be pumped prior to cold weather

storage.

Use only spray tips that are matched to the unit to

avoid excessive cycling and wear of the unloader

valve. See Accessories.

NOT

BE

the water inlet connection

at

least daily.

RUN

DRY

If

water does freeze

Do

on

parts and

and must be drained

will

not be subjected

.A

50%

CAUTION

not operate

will

void

in

the

anti-freeze

WAffiNBNG

Follow

installing nozzles:

1.

2.

3.

4.

5.

Shutdown and. Care

When unit is not in use, turn off water supply.

When shutting down for the day or weekend, shut off

unit, shut off water supply valve, and trigger gun to

release pressure. Wipe off the unit with

these precautions when removing and

Shutoff the cleaning unit andtriggerthegun

to relieve pressure. Engage the triggersafety.

Keep the nozzle and the tube pointed

from you and everyone else.

Do

not put your hand over the tip to push the

nozzle into place. Grasp

keep your fingers away from the tip.

Do

not let anyone else touch the spray valve

while you are cleaning nozztes.

Be sure the slip ring

the nozzle in place before triggering the spray

gun.

Of

it

from the side and

is

pushedforward to lock

Unit

away

a

damp rag.

pour hot water

temperature change may crack the ceramic

Do

not pump caustic materials.

Before extended storage, flush the pump with light

oil.

Avoid dragging hoseoveranabrasivesurfacesuch as

cement. This causes excessive wear and shorter

hose life.

Clean the intake line strainer daily.

Lubrication

Fill

pump crankcase to dot

25

oz.

or equivalent SA€

antiwear and rust inhibitor additives. Change initial

fill after

months or

and

(0.75

liters) of crankcase oil (part

50

hour running period. Change oil every

at

on

Care

40

500

hour intervals.

a

frozen pump. A sudden

on

oil,gauge window

no.

801

weight hydraulic

oil

with

-1

44)

with

WARNONG

NEVER

1

valve.

alter adlustment or modify the unloader

3

.

~i

.. .

.. . .

..

..

.:

.

~. ..

..

i

,.

Page 5

PROBLEM

CAUSE

SOLUTION

-0w~pressure.

’ump runs extremely rough,

Iressure low.

Worn nozzle.

Belt slippage.

Air leak in inlet plumbing.

Relief valve stuck, partially

plugged or improperly adjusted,

valve seat worn.

Inlet suction strainer clogged

01

improper size.

Worn packing. Abrasives in

pumped fluid or severe cavitation. Inadequate water supply.

Fouled

or dirty inlet or discharge

valves.

Worn inlet or discharge valves.

Leaky discharge hose.

Restricted inlet or air entering

the inlet plumbing.

Replace with nozzle of proper Size.

Tighten or replace; use correct belts and replacl

both

at

same time.

Disassemble, reseal, and reassemble

Clean, and adjust relief valve; check for worn

Kit

and dirty valve seats.

available.

Clean. Use adequate size. Check more

frequently.

..

Install proper filter. Check flow available

to

pump.

Clean inlet and discharge valve assemblies.

Replace worn valves, valve seats and/or

discharge hose.

Proper size inlet plumbing; check for airtight

seal.

.. .

.

:

”

-.

Inlet restrictions and/or air

Clean out foreign material, replace worn valves

‘eaks. Stuck inlet or discharge

talve.

Replace seals.

Install new packing

Nater leakage from under

-caking

H.P. seals.

vVorn packing.

:he manifold.

Nater in pump crankcase.

:requent or premature

May be caused by humid air

:ondensing into water inside the

:rankcase.

Scored plungers.

Change oil

Graco Crankcase Oil (other approved oil evenl

month or

Replace plungers,

at

200

3

month or

hours)

500

hour intervals usins

P.N.

801-144.

ailure of the packing.

3ver pressure to inlet manifold.

lamaged or worn plungers.

4brasive material in the fluid

Reduce inlet pressure.

Replace plungers.

Install proper filtration

on

pump inlet plumbing,

)eing pumped.

ixcessive pressure-and/or tem.

)erature of fluid being pumped.

.

..

.I

..

..

:

.

her pressure of pumps.

lunning pump dry.

Check pressures and fluid inlet temperature; be

sure they are within specified range.

Reduce pressure.

Do

not run DumD without water.

;trow surging

at

lnd low pressure

lischarge side.

the inlet

on

the

:oreign particles in the inlet or

lischarge valve, or worn inlet

Ind/or discharge valves.

Check for smooth lap surfaces

on

inlet and.

discharge valve seats. Discharge valve seats

and inlet valve seats may be lapped

on

a

very

fine oil stone.

801-392

5

Page 6

CAUSE

ectrtc motor wont run.

Electric motor runs, but

no output.

*This unit has an overload breaker built into the switch assembly. If

60

cool for 30 to

needed.

NOTE:

minutes. Also, try to correct the cause of overheating. Always use the lowest pressure setting

A

M11 and M30 metric wrenches are

required for servicing pump.

Power cord unplugged, or

building circuit fuse blown

Overload switch has opened.

Power.cord unplugged, or

building circuit fuse blown,

Overload breaker has opened.

Extension cord.

Tip plugged.

Displacement pump frozen or

gear train damage.

Check, replace

Unplug power cord+, decrease pressure.

Check, replace.

Unplug power cord*, relieve pressure-allow

tO.CO01.

Don't

Remove and clean.

Thaw.

use

more than

it

opens, unplug power cord and let sprayer

100

ftof 12

ga

extension cord.

PUMP

Valves

Photo

Pumping

Photo

1

and

2.

1)

Remove the hex plug using an M30 wrench.

2) Examine O-ring under plug and replace if

evidence of cuts or distortion.

3)

Remove valve assembly including retainer,

spring, valve and valve seat from valve cavity.

NOTE:

4)

Replace valve parts

including retainer, spring, valve, valve seat,

ring and back-up-ring.

5)

Replace valve cover and torque to

Nm).

Valve assembly may come apart during

removal.

with

service

kit

75

Section

3.

1)

Remove the four

2)

Separate the manifold from the crankcase.

NOTE:

It

lightly with mallet to loosen.

(4)

hex nuts from the manifold.

may be necessary to tap manifold

(801-041)

o-

ft-lb (100

CAUTION

Keep manifold properly aligned with ceramic

plungers when removing to avoid damage to

either plungers or seals.

3)

Carefully examine each plunger for any scoring

and replace if necessary.

6

801-392

Page 7

Plungers

Photo

4.

1)Using an M1 1 wrench,

remove the plunger retainer.

2)

Slide out the seal retainer with

oil wick and rubber barrier

slinger.

3)

With a slight twisting motion,

loosen the plunger from the

plunger rod and remove.

NOTE:

4)

Replace O-ring 'and back up

ring on plunger retainer.

5)

Saturate new oil wick by

soaking in oil.

6)

Install new plunger.

7)

Replace plunger retainer and

torque to

8)

Install new

retainer.

9)

Replace barrier slinger over

new plunger.

10) Lubricate each plunger sleeve

and carefully slide manifold

onto crankcase.

Seals

or

Photo

5,

)

Remove C-ring from seal case:

1

2)

Then remove the low pressure

seal from the seal case.

3)

Unscrew the seal case from

the manifold using

key wrench (801-044).

4)

Remove the high pressure

seal and examine. Before

replacing, lubricate

of new high-pressure seal and

press into manifold.

The stud may remain

with the retainer

when removed.

Disassemble and

screw stud into

plunger rod finger

tight.

80

in-lb

(9

oil

wick in seal

V-Packings

6,

7

and

8.

ID

Nm).

a

special'

and

OD

,.

,

:.

.

,.

..,,.

MOTE:

5)

Install new O-ring on sealcase

and lubricate

6)

Screw

7)

Lubricate

pressure seal and press into

seal case.

8)

Replace C-ring holding low

pressure seal in place.

A

socket and extension may be used to

pressure seal from

manifold.

OD

of O-ring.

seal

case into manifold.

ID

and

OD

of low

9)

Lubricate each plunger sleeve

and carefully slide manifold

onto crankcase.

.NOTE:

When replacing

manifold

ememe caution should

be

damage

onto

plungers,

exercised to avoid

to

the seals.

k

10)

Torqueallfour(4)boltsto240in-lb

(27

Nm).

NOTE:

Carefully study the

order of respective

parts and note

position of seals to

assure proper reassembly and operation.

801-392

7

Page 8

8

801-392

Page 9

i

!

Ref.

No.

50

Includes items

,

51-66

62

63

-52

PARTS

LIST

REF PART DESCRIPTION

NO.

NO.

1 HOSE & GUN ASSY.

detail'for parts

2

3

4

5

6

8

9

10

11

13

14

16

17

18

19

20

801-001

800-01 5

800-036

800-037

801-390

801 -285

801 -231

801-140

801-129

801-131

801-221

801 -379

801-382

801 -380

801-292

801 -021

PUMP, REPLACEMENT PARTS,

includes items

ANTI VIBRATION FOOT

CHASSIS

ELECTRIC MOTOR ASSY

BRACKET.

BELT,

drive

LABEL.

LABEL.

LABEL,

PLATE,

CONNECTOR,

SWITCH^

~~~~~

CORD,

STRAIN RELIEF

SCREW,

no.

6-32 NC

BOLT.

carriage,

5/16-18 NCx 5"

21

801

22

23

24

-088

801-298

801 -302

801-082

SCREW,

5/16-18

hd.

SCREW,

hd.

5/16-18 NC x 2-1/2"

SCREW,

5/16-18

.

. . . .

SCREW,

M6 x 30

25

801-081

SCREW.

M8

x

20

77-90

spacer

warning

identification

warning

serial

no.

crimp

starter

power

(8

fi

lg)

self tapping,

x

1

/2

NC

1"

~

x

1-1/2"

machine, hex hd.

machine, hex hd.

machine hex hd.

NCr

-

.

. - . . .

machine, hex hd.

mm

machine, hex hd.

mm

see

aun

~

QTY

2

2

4

4

4

2

REF PART DESCRIPTION

NO,

NO.

26

801 -023

27

801

28

29

30

31

32

34

35

36

37

40

41

42

44

46

47

1

48

50

1

4

1

.1

1

2

2

1

1

1

2

1

1

2

51

52

53

54

55

56

57

58

59

60

61

62

63

64

-01

-1

801

801.025

80.1 -024

801 -01

801-367

801

-004

801 -381

801-135

801-137

-01

801

801-364

801 -365

801 -132

801 -008

801 -388

801-389

801 -084

801 -045

801 -046

801 -047

801 -048

801 -049

801-050

800-012

,801-059

801-060

801

-OB1

65

66

67

68

801-105

801-106

.69

70

1

71

72

73

74

75

76

801-236

801-108

801-109

801-110

801

-1

801-11~2

801-113

WASHER,

5

WASHER,

WASHER,

39

WASHER,

NUT,

2

GROMMET

BUMPER

PULLEY,

PULLEY.

HUB.

KEY,

8

BRACKET,

BELTGUARD,

BELTGUARD.

RIVET,

LABEL.

LABEL,

LABEL.

UNLOADER.

.

CAGE,

.

O-RING

.

SPRING

,

BALL

.

SEAT

,

O-RING.

.

UNLOADER SUB-

.

O-RING

HOUSING

.

CYLINDER

O-RING

.

PLUG

HOUSING

.

SPRING

.

VALVE'

.

SEAT

COUPLER,

NIPPLE,

1

/2

TEE,

NIPPLE,

NIPPLE,

PLUG,

ADAPTER, 1 /2

1

1

NUT,

SCREEN,

HOSE,

17-1

flat,

1/4

flat,

5/16

IocIc

1

lock,

hex,

pulley

pulley

drive

identification

warning

identification

valve

5/16

5/16-18 NC

pump

rnntnr

(2"

lg)

tensioner

cover

baseplate

includes itkms

VALVE

male quick disconnect

straight, brass,

NPT x 3- 1 /2"

brass,

1

/2 NPT

hex, steel,

hex, brass,.l/4x

hex, brass,

brass, adapter

coupled,

/2"

inlet

Ig

hose

1

/2

/4

1

/2

z

3/8 NPT

NPT (MBE)

51-66

3/8 NPT

1/2 NPT

QN

8

16

4

10

7

4

1

1

1

1

1

1

1

1

2

1

1

1

1

1

2

1

1

1

2

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

801

-392

9

Page 10

REF

NO.

Items

PART

NO.

77-90

See exploded view of pump for details.

DESCRIPTION

are pump internal replacement parts.

ELECTRICAL SCHEMATIC

Qn

77 801-027

78 801-028

79 801-267

CAP

,

. O-RING,

.

DISCHARGE

MANIFOI

cap

n

80

81

82

83

84

85

86

87

.

. . .

-

88

801-038

. . - .

89 801-039

90 801-040

Order parts by name and number. Always give the model

number and series letter

ordering.

-

-

RING,

.

.

O-RING

.

RETAINER,

of

backup

plunge1

the assembly for which

you

are

801-042

INCLUDES

1

1

1

3

3

3

3

3

3

3

3

3

3

3

SEAL KIT

3

SETS

'80

801-392

SERVICE TOOLS

KEY WRENCH

EXTRACTOR TOOL 801-205

801-044

Page 11

PARTS

Gun and Hose

14

DWAVVlMG

5

A

Assern

'7

I-3

8

Repair

Includes items

Kit

801

-083

A,

B,

C.

D,

E

and

F

SERVICE

1.

Re'move the 8 screws from the body halves

(4).

See the Parts Drawing. Separate the body

halves.

2.

Remove the Plug

the valve body

3.

Remove

seat

4.

Remove the sleeve

actuator rod

the

(C)

and'o-ring

(14).

(G).

snap ring

(0).

nut

(F).

spring

(6).

(1 1)

(5)

Then remove

and O-ring

and ball

5.Afterinstallingthenewseat(C)andball(A),tapthe

ball lightly

seating between the ball and seat.

6.

Reassemble

new parts from the repair kit.

with

a hammer to assure a proper

in

reverse order, using the remaining

(A)

the

(E)

with'the

(3)

from

valve

and

REF

PART

NO.

NO.

1

801")7

2 800-017

3 801-244

4

'

801-245

5 801-249

6

801-254

7 801-256

8 801-262

9 801-261

10 801-247

11

801-253

12 801-246

13 801-263

14 801-250

15 801.264

16 801-265

17 801-134

18 801-029

19 801-009

20 '801 -090

21 801-073

22 "801 -010

23 '801 -01 1

24 801-074

25 801-076

26 801-077

27 801-103

28 '801 -091

Order

parts

you

by

are

which

DESCRIPTION

SPRAY HOSE, 3/8" ID. 50

(15

ml

SPRAY GUN,

include items 3-1 6)

.

.

.

.

.

.

. -.

.

.

TUBE.

GRIP

COUPLER,femalequickdisconnea

COUPLER, male quick disconnect

HOUSING, nozzle

TIP,

TIP, cleaning; 15O

GUARD,

PLATE,

RIVET

NIPPLE, hex: 1/4

COUPLER, male quick disconnect

name

ordering.

Ig

(replaceable

HANDLE, left

HANDLE,

;PRING

EVER

IEEDLE

IEX PLUG

IISCHARGE FIlTING

VALVE BODY

GUIDE SLEEVE

TUBE

INLET FllTlNG

CAP

..

SCREW

SCREW

blasting;

and

32"

tip

warning

series

right

Oo

x

letter

3/8" npc

ft.

parts

of

the assembly

brass

QTY

1

1

1

1

1

1

1

1

1

1

1

1

1

1

7

1

1

1

3

1

2

1

1

2

1

2

1

2

for

*Recommended

.'tool

box"

spare parts.

801

-392

1

d

Page 12

ACCESSORIES

(Must

be

purchased

separately)

CHECK VALVE

Prevent back up

supply. lnstatl upstream from pump.

WATER SANDBLASTER

For

abrasive cleaning of stubborn dirt and paint. For adjusting sand

801

-1

33

of

contaminated water into fresh For injecting harsh cleaning chemicals downstream

CHEMICAL INJECTOR

from pump.

800-103

ADJUSTABLE SAND SAVER

TECHNICAL DATA

MOTOR:

WATER PUMP:

WETTED PARTS:

WEIGHT:

OVERALL DIMENSION:

5

hp, 3 phase,

220

V,

60

50

PSI (1

21

pressure;

(15

liter/min).

Stainless Steel, Aluminum,

Phenolic Plastic, Ceramic

Liners, Nitrile Rubber.

Ibs

140

Length: 36

Width:

Height:

18

17

Hz, 17 Amp

50

bar) rnax.

4

GPM

in

(914 mrn)

in

(457

in

(432.rnm)

flow.

mm)

KIT

800-182

800-031

6OoF

MAX. WATER TEMPERATURE:

INLET HOSE CONNECTION:

THE

GRACO

GracoInc.warrantsa1Iequipmentmanufacturedbyitandbearingitsnametobefreefromdefectsin

material and workmanship under normal use and service. This warranty extends

purchaserforaperiodof

is installed and operated

not cover damage or wear which.

abrasion. corrosion, negligence. accident, substitution of non-Graco parts, faulty installation or

tampering.

This warranty is conditioned

examination by Gram

or

replace free

purchaser transportation prepaid. If inspection of the equipment does

workmanshipormaterial,repairswill

be

charged.

EOUIPMENT NOT COVERED BY GRACO WARRANTY. Accessories or components of equipment

sold by Graco that are

subiect to the warranty,

assistance

of

in

making such claims.

12monthsfromthedateofpurchaseandappliesonlywhentheequipment

in

accordance with written

to

verify the claimed defect. If the claimed defect

charge. any defective parts. The equipment will be returned to the original

not

manufactured

if

any. of their manufacturer. Graco will provide purchaserwith reasonable

in

the reasonable judgment of Graco. arises from misuse,

upon

the prepaid return of the equipment claimed

bemadeatareasonablechargeandreturntransportationwill

by

Graco (such as electric motors. switches, hose. etc.)are

1

3/4-in. garden hose

WARRANTY

factoryrecommendations.Thiswarrantydoes

(70°C)

is

not

(f)

to

the original

to

verified, Gram will repair

be defective for

disclose any defect in

Subsidiary

FaEtory

and

GRACO

AMIIata

BNC.

Branches:

Companies:

P.O.

Atlanta. Dallas, Detroit,

Canada: England: Switzerland; France; Germany; Hong Kong:'Japan

~QX

IWT

PRINTED IN U.S.A.

Los

Angeles. West Caldwell

MBNMEAIPOLQS.

801-392

9-82

MN

[N.J.)

%wo-na

. .

45-10043A

Loading...

Loading...