Page 1

This

manual

WWARNINOS

READ

AND

contains

and

RETAIN FOR REFERENCE

IMPORTANT

INSTRUCTIONS

MODEL

2

150

psi

2250psi

800-048

(150

SERIES

"A"

bar) OPERATING PRESSURE

(155 bar) MAXIMUM WORKING PRESSURE

Page 2

~NJECTOQIM

Fluids under high pressure from spray or leaks can

penetrate the skin and cause extremely serious

injury, including the need for amputation.

NEVER

the body.

NEVER

NEVER

body.

point the spray gun

put hand or fingers over the spray tip.

try to stop or deflect leaks with your hand or

ALWAYS

MEDlCAU

HAZARD

at

anyone or any part of

have the tip guard in place when spraying.

TREATMENT

Do

not use chemicals or agents which are not

compatible with Buna-N and

of hose.

Do

not leave a pressurized unit unattended. Shut off

the unit and release pressure before leaving.

PVC

or neoprene cover

FORE

Do

not spray flammable liquids.

engine where combustible fumes or dust may be

present.

Do

not operate the

GENERAL

NEVER

Keep clear of moving parts when the unit is running.

run the unit with the belt guard removed.

If

any fluid appears to penetrate your skin. get

EMERGENCY

DO

MOK

Tell the doctor exactly what fluid was injected. For

treatment instructions have your doctor call the

RIAJIORIAU

MEDKAL

TREAT

POISON

CARE

AS

A

SIMPLE

CENTER

AB

ONCE.

GUT.

NETWORK

($a2w~-666~

AVOID

Even after you shut off the gasoline engine, there is

high pressure in the pump, hose and gun until you

release

the spray tip or servicing the unit,

unit

Be sure that all accessory items and system

components

NEVER

in

personal safety, as well as the function of the

equipment, is at stake.

Before each use, check hose for weak, worn or

damaged conditions caused by traffic, sharp corners,

pinching or kinking. Tighten all fluid connections

securely before each use. Replace any damaged

hose.

COMPONENT

it

by triggering the gun.

and

trigger the gun to release pressure.

will

withstand the pressure developed.

exceed the pressure rating of any component

system.

NEVER

alter or modify equipment -your

RUPTURE

So

before removing

always

shut off the

Observe detergent manufacturer's safety

precautions. Avoid getting detergent or other liquids

in your eyes. Follow the directions on the container

regarding contact with eyes, nose, and skin,

breathing fumes, etc. Always wear full goggles to

protect your eyes from the spray

dislodged by the spray. If necessary, wear gloves or

other protective clothing. If antidotes or treatment

are 'recommended, be prepared to use them.

DON'T

weed killer.

This unit is supplied with an 8-foot power cord made

up

electric cord is connected to the unit chassis and

motor frame. The other three wires are connected to

the starter switch.

Be sure to connect the power cord

approved plug to

The starter switch has a built-in circuit breaker that

will shut off the power to the unit whenever the

circuit

Always check to be sure the switch

hoses and electric cord are clear

before plugging in the power cord.

spray toxic chemicals such as insecticide or

of

three AWG No.

is

overloaded.

10

wires. The green wire of the

fit

your requirements.

as

well

as

any debris

to

the appropriate

is

off andthat the

of

moving parts

IMPORTANT

United States Government safety standards have been adopted under the Occupational Safety and Health Act.

These standards

Should be consulted

2

801-457

. . .

.

. .

-

particularly the General Standards, Part 1910. and the Construction Standards,Part 1926

in

connection with your use of airless spray equipment.

.

.

.

.

._i..

. . . ~.

. . . .. . ..

.

.-

.~.

.

..

:

..

~

..

-

Page 3

INSTALLATION

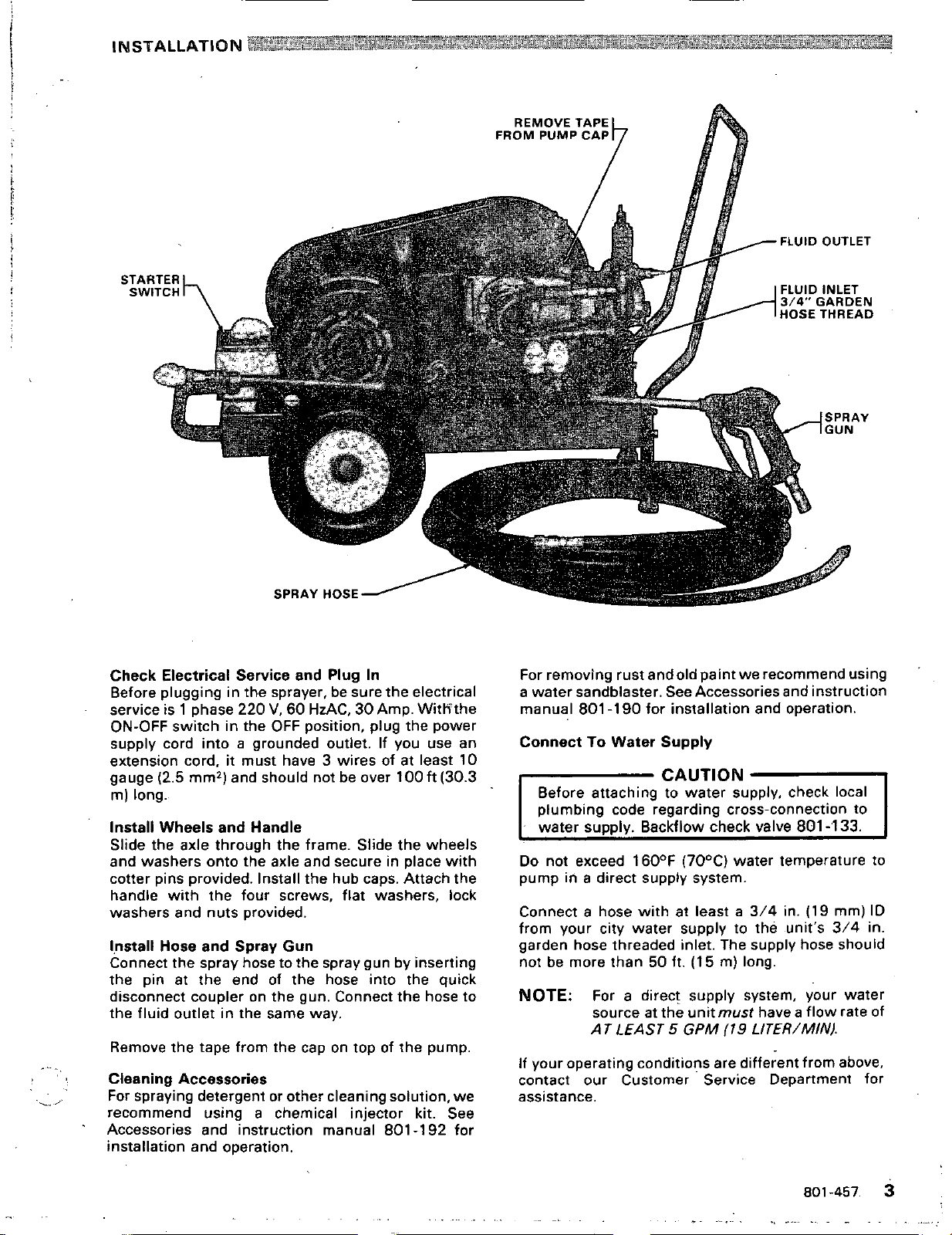

Check Electrical Service and Plug

in

Before plugging

service is 1 phase 220

ON-OFF switch

supply cord into

extension cord,

gauge (2.5

m) long.

Install

Slide the axle through the frame. Slide the wheels

and washers onto the axle and secure

cotter pins provided. Install the hub caps. Attach the

handle

washers and nuts provided.

l,nstall

Connect the spray hose to the spray gun by inserting

the pin at the end of the hose into the quick

disconnect coupler on the gun. Connect the hose to

the fluid outlet

Remove the tape from the cap on top of the pump.

-

..

.

$.

Cleaning Accessories

'..

i

For spraying detergent or other cleaning solution, we

recommend

'

Accessories

installation and operation.

mm2)

Wheels and Handle

with

Hose

the sprayer, be sure the electrical

V,

60

HAC,

in

the OFF position, plug the power

a

grounded outlet. If you use an

it

must have 3 wires of at least 10

and should not be over

the four screws, flat washers, lock

and Spray

in

using

and instruction manual 801-192 for

Gun

the same way.

a

chemical injector kit. See

In

30

Amp. WitKthe

100

in

place

ft

(30.3

with

For removing rust andold paint we recommend using

a water sandblaster.

manual 801.190 for installation and operation.

To

Connect

Water Supply

See

Accessoriesand instruction

CAUTION

Before attaching to water supply. check local

plumbing code regarding cross-connection to

water supply. Backflow check valve 801-133.

Do

not exceed 1 6OoF (7OOC) water temperature to

in

a

pump

Connect a hose with at least a 3/4 in. (19 mm)

from your city water supply to the unit's

garden hose threaded inlet. The supply hose should

not be more than

NOTE:

If your operating conditions are different from above.

contact our Customer Service Department for

assistance.

direct supply system.

3/4

in.

50

ft.

(15

m) long.

For a direct supply system, your water

source at the

AT LEAST 5 GPM

unit

must

have a flow rate of

(19

LITER/MINI.

ID

Page 4

OPERATION

CAUTION

Startup

Before starting, be sure to read the safety warnings

and setup instructions.

Turn on the water supply.

Trigger the gun to release any back pressure.

1..

CAUTION

Never run the cleaning unit dry. Costlydamage

to the pump will result. Always be sure water

supplyiscompletelyturnedonbeforeoperating.

Inspect all connections for any leaks. Tighten if

necessary.

Cleaning

For cleaning technique, see the Chemical lniector

manual,

For abrasive cleaning, see the Water Sandblaster

manual,

801

801

-1

-1

92.

90.

spraying. for longer pump life. The pump

overheat if left running for over

in

Check the filter screen

as often as necessary, at least daily.

the unit with the inlet and filter screen removed.

DONOTtrytoadjusttheunloadervalveorchangethe

engine speed. Changing these settings may cause

excessive pressure, intermittent unloader operation,

wastedfuelandincreasedwearonpartsandwillvoid

the warranty.

PUMP MUST NOT BE RUN

of

water prior to exposure to freezing temperatures.

Use and store the unit where it

to freezing temperatures.

unit, thaw before trying to start. A

solution may be pumped prior to cold weather

storage.

Use only spray tips that are matched to the unit to

avoid excessive cycling and wear of the unloader

valve. See Accessories.

the water inlet connection

DRY

If

water does freeze

10

Do

and must bedrained

will

not be subjected

50%

will

minutes

not operate

in

the

anti-freeze

Follow these precautions when removing and

installing nozzles:

1.

Shut off the cleaning unit and trigger thegun

to relieve pressure. Engage the trigger safety.

2.

Keep the nozzle a.nd the tube pointed away

from you and everyone else.

3.

Do

not put your hand over the tip

nozzle into place. Grasp

keep your fingers away from the tip.

4.

Do

not let anyone else touch the spray'valve

while you are cleaning nozzles.

5.

Be

sure the slip ring

the nozzle in place beforetriggering thespray

gun.

.

Shutdown and

When unit is not

When shutting down for the day or weekend,

unit, shut off water supply valve, and trigger gun to

release pressure. Wipe off the unit with

Care

Of

in

use, turn off water supply.

it

is

pushedforward to lock

Unit

to

push the

from the side and

shut

a

damp rag.

off

pour hot water on a frozen pump. A sudden

temperature change may crack the ceramic

plungers.

Do

not pump caustic materials.

Before extended storage, flush the pump with light

oil.

Avoiddragginghoseoveranabrasivesurfacesuchas

cement. This causes excessive wear and shorter

hose life.

Clean the intake line strainer daily

Lubrication and Care

Fill pump crankcase to dot on oil gauge window with

25

02.

(0.75

liters)

of

crankcase

or equivalent SAE

antiwear and rust inhibitor additives. Change initial

fill after

months or at

50

hour running period. Change oil every

500

40

hour intervals.

oil

(part

no.

weight hydraulic oil

801

-1

44)'

with

3

WARMING

I

NEVER

valve.

alter adiustment or modifv the unloader

1

I

Altering or adjusting unloader willnot increase

performance of unit.

I

4

..

801-457

. .

...

,

.

.. . .

.

.

._ . .

. .

.

. . ...

.

..

.. ~ . .

..

. .

.. .. . ..

I.

.

.

Page 5

PROBLEM

CAUSE

SOLUTION

Low pressure.

Pump runs extremely rough,

uressure low.

Worn nozzle.

Belt slippage.

in

Air leak

Relief valve stuck, partially

plugged or improperly adjusted

valve seat worn.

Inlet suction strainer clogged

improper size.

Worn packing. Abrasives in

pumped fluid or severe cavitation. Inadequate water supply.

Fouled or dim/ inlet or discharge

valves.

Worn inlet or discharge valves.

Leaky discharge hose.

Restricted inlet or air entering

the inlet plumbing.

inlet plumbing.

Replace

Tighten or replace; use correct belts and replac

both at same time.

Disassemble, reseal, and reassemble.

Clean. and adjust relief valve; check for worn

and dirty valve seats. Kit available.

Clean.

o

frequently.

Install proper filter. Check flow available to

pump.

Clean inlet and discharge valve assemblies.

Replace worn valves, valve seats and/or

discharge hose.

Proper size inlet plumbing; check for airtight

seal.

with

nozzle of proper size.

Use

adequate size. Check more

Water leakage from under

the manifold.

Water in pump crankcase.

Frequent or premature

failure of the packing.

Inlet restrictions and/or air

leaks. Stuck inlet or discharge

valve.

Leaking

Worn packing.

May

condensing into water inside the

crankcase.

Scored plungers.

Over pressure to inlet manifold

Damaged or worn plungers.

Abrasive material

being pumped.

Excessive pressure and/or tern

perature of fluid being pumped.

Over pressure of pumps.

H.P.

seals.

be caused by humid air

in

the fluid

Clean out foreign material, replace worn valve:

Replace seals.

Install new packing.

Change oil at

using Graco Crankcase

every month or

?eplace plungers.

?educe inlet pressure.

3eplace plungers.

nstall proper filtration on pump inlet plumbing

:heck pressures and fluid inlet temperature; bc

jure they are within specified range.

?educe pressure.

3

month or

200

500

Oil

(other approved

hours)

P.N.

hour interval

801-144.

o

Strong surging at the inlet

3nd low pressure on the

jischarge side.

Running pump dry.

Foreign particles

discharge valve, or worn inlet

and/or discharge valves.

in

the inlet or

10

not run pump without water.

:heck for smooth lap surfaces on inlet and

iischarge valve seats. Discharge valve seats

md inlet valve seats may be lapped on

ine oil stone.

a

very

Page 6

building circuit fuse blown.

SOLUTION

Check, replace.

Electric motor stops while

spraying.

Electric motor runs,

no output.

'This

unit

has an overload breaker built into the switch assembly. If

cool for

needed.

NOTE:

PUMP

30

to

60

A

M11

required for servicing pump.

but

minutes. Also, try to correct the cause of overheating. Always use the lowest pressure setting

and

Overload switch has opened.

Power cord unplugged, or

building circuit fuse blown.

Overload breaker.has opened.

Extension cord

Tip plugged.

Displacement pump frozen or

gear train damage.

M30

metric wrenches are

Unplug power cord'. decrease pressure

~ ~~~

Check, replace.

Unplug powei cord'. relieve pressure-allow

to cool.

DonZ use more than

Remove and clean

Thaw,

it

opens, unplug power cord and let sprayer

loOftoi

8

ga extension cord.

Valves

Photo 1 and

1)

Remove the hex plug using an

2)

Examine O-ring under plug and replace

evidence of cuts or distortion.

3)

Remove valve assembly including, retainer.

spring, valve and valve seat from valve cavity.

MOTE:

41

Replace valve parts

including retainer, spring, valve, valve seat,

ring and back-up-ring.

5)

Replace valve cover and torque to

2.

M30

Valve assembly may come apart during

removal.

with

service kit

75

Nm).

Pumping

Photo

1)

2)

I

3)

Section

3.

Remove the four

Separate the manifold from the crankcase.

NOTE:

Keep manifold properlyaligned with ceramic

plungers when removing to avoid damage to

either Dlunclers or seals.

Carefully examine each plunger for any scoring

and replace if necessary.

It may be necessary to tap manifold

lightly with mallet to loosen.

{4)

hex nuts from the manifold.

~ ~~

1

wrench.

(801-041)

ft-lb

(100

~~ ~

if

o-

6

..

801-457

....

~

..

......

...

~ ..

Page 7

Plungers

Photo

4.

1)Using .an

M1

1

wrench,

remove the plunger retainer.

2)

Slide out the seal retainer with

oil wick and rubber barrier

slinger.

3).

With a slight twisting motion,

loosen the plunger from the

plunger rod and remove.

MOTE:

The stud may remain

with the retainer

when removed.

Disassemble and

screw stud into

plunger rod finger

tight.

4)

Replace O-ring and back up

ring on plunger retainer.

5)

Saturate new oil wick by

in

soaking

6)

Install new plunger.

7)

Replace plunger retainer and

torque to

8)

Install new oil wick in seal

oil.

80

in-lb

(9

Nm).

retainer.

9)

Replace barrier slinger over

new plunger.

10) Lubricate each plunger sleeve

and carefully slide manifold

onto crankcase.

Seals or V-Packings

Photo

5,

6,

7

and

8.

1) Remove C-ring from seal case.

2)

Then remove the low pressure

seal from the seal case.

3)

Unscrew the seal case from

the manifold using a special

key wrench (801

4)

Remove the high pressure

-044).

seal and examine. Before'

replacing, lubricate

ID

and

OD

of new high-pressure seal and

press into manifold.

NOTE:

A

socket and extension may be used to

pressure seal from

manifold.

5)

Install

new O-ring on seal case

and lubricate OD of O-ring.

6)

Screw seal case into manifold.

7)

Lubricate

ID

and

OD

of low

pressure seal and press into

seal case.

8)

Replace C-ring holding

pressure seal in place.

..

~.

..

..~ - . , ..

.,

low

,...

9)

Lubricate each plunger sleeve

and carefully slide manifold

onto crankcase.

NOTE:

When replacing

manifold onto plungers,

enreme caution should

be

exercised to avoid

damage to the seals.

.

~..

.

. . . ..

_.

.

10)

Torqueallfour(4)bltsto240ir-lb

(27

Nm).

NOTE:

Carefully study the

order of respective

parts and note

position of seals to

assure proper reassembly and opera-

tion.

801-457

..

..

.

7

"

. .

.

. . .

.,

Page 8

8

801-457

-

..,

"..

.

...

~,

~.

~

.

.

.

..

..

.

.

-~

..

.

..

..

.

.

Page 9

Ref.

No.

50

Includes items

51-66, 79 & 81

62

fj/7g

63

52

64

65

REF

66

56

59

PARTS

REF

NO.

1

2 801-001

3 800-015

4 800-038

5 800-047

6 801-390

8

9 801-231

10 801-140

11

12 801-022

13 801-131

14 801-221

15 801.394

16 801-379

17 801-448

18 801-446

19 801-292

20 800-039

21 801-088

.’

..

22

23

LIST

PART

NO.

801-285

801-129

801-298

801-302

.DESCRIPTION CITY

HOSE

&

detail for parts

PUMP, REPLACEMENT PARTS,

include items

ANTI VIBRATION FOOT

CHASSIS

ELECTRIC MOTOR ASSY

BRACKET. spacer

BELT. drive

LABEL. warning

LABEL, identification

LABEL. warning

.SCREW, machine, hex hd..

5/16-18

PLATE, serial

CONNECTOR, crimp

HANDLE

SWITCH, starter

CORD. power

STRAIN RELIEF

SCREW, self tapping.

no.

RAIL STIFFNER ASSY

SCREW, machine, hex hd,

5/16-18

SCREW, machine. hex hd.

5/16-18

SCREW, machine hex tid,

5/16-18

GUN ASSY. see gun

77-90

NC

x

1-3/4”

no.

(8

6-32

NC

x

1/2 2

NCx

1-1/2” 4

NC

x

2-1/2”

NCx

1”

ft

Ig)

2

2

2

1

1

4

1

2

1

1

1

2

1

1

4

8

1

1

1

1

1

NO.

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

PART

NO.

801 -082

801-081

801 -023

801

-01 5

801

-1

39

801 -025

801 -024

801 -01 2

801 -367

801.241

801 -004

801-381

801-135

801

-1

37

801 -393

801 -235

801 -01

801 -364

801.365

801 -242

801 -243

801-132

801-130

801 -388

801-141

801 -41 7

800-045

801 -045

801 -046

801 -047

801 -048

801 -049

801 -050

801 -046

801 -059

801 -41 2

801-432

801 -062

801

-063

801 -068

801-069

801 -070

801-071

801 -090

801-105

801-106

801 -41 6

801-108

801-109

801-110

801

-1

11

801-112

801-113

801 -445

801 -450

800-044

801

-008

801 -465

DESCRIPTION

SCREW, machine. hex hd,

..6 x 30

r!A

CREW. machine, hex hd.

S

MB

WASHER.

WASHER. flat,

WASHER, lock,

WASHER. lock,

NUT, hex.

GROMMET

BUMPER

WHEEL

PULLEY, pump

PULLEY, motor

HUE. pulley

KEY, pulley

AXLE

WASHER,

8

BRACKET, tensioner

BELTGUARD. cover

BELTGUARD. baseplate

HUBCAP

PIN, cotter

RIVET, drive

LABEL, warning

LABEL. warning

LABEL. warning

LABEL, starting

UNLOADER, includes

items

CAGE, valve

O-RING

SPRING

BALL

SEAT

.

O-RING

UNLOADER SUE-ASSY.

n.m~G

HOUSSG

CYLINDER

O-RING

PLUG

HOUSING VALVE

SPRING

VALVE

SEAT

COUPLER, male quick disconnect.

NIPPLE, straight. brass,

1 /2

TEE, brass,

NIPPLE, hex, steel,

NIPPLE, hex, brass,

PLUG. hex. brass.

ADAPTER,

NUT. brass, adapter

SCREEN, inlet

HOSE, coupled,

17-1 /2”

LABEL. caution

O-RING

SLEEVE ASSY

LABEL

SCREW, button hd,

#6-32

mm

x

20

mm

flat.

1/4

5/16

1 /4

5/16

5/16-18

(2”

lg)

flat

51-66. 79. 81

~~

.

NPT

x

3-1 /2” 1

1/2

NPT

1/2

1/4 x 1/2

3/8

.~ ~

1

/2

hose

1

/2

5/16

NC

lg

x

NC

NPT

x

3/8

NPT

(MBE)

NPT

NPT

QTY

4

2

8

18

4

12

9

4

1

2

1

1

1

1

1

2

1

1

1

1

1

1

1

1

..

801-457

. . .

. . .

.

..

. . .

9

.

..

.

Page 10

PARTS LIST

REF PART D.ESCRlPTlON

NO.

NO.

Items

77

~nl-nn

".

?E

801.028

79 801-267

80

801-030

81 801-031

82

801-032

83 801-033

84 801-034

85

801-035

86 801-036

87 801-037

88 801-038

89 801-039

90 801-040

Order parrs by name and number. Always give the model

number andseries letter

ordering.

(continued)

77-90

See exploded view of pump for details.

are pump internal replacement parts.

".

CAP

.

_.

..

.

O-RING,

.

DISCHARGE

MANIFOLD

.

WASHER

.

SEAL

.

RETAINER

.

WASHER

~

WICK

.

.

RING, retaining

.

PLUNGER

.

STUD

.

RING, backup

.

O-RING

.

RETAINER, plunger

cap

.

of

the assembly for which you are

QTY

ELECTRICAL SCHEMATIC

1

1

1

3

3

3

3

3

3

3

3

3

3

3

801-042

INCLUDES

-r

OF

PARTS

SEAL KIT

3

SETS

90

77.

-86

SERVICE

KEY

.

. - .

EXTRACTOR

TOOLS

WRFNCH

. . . .

-.

-

-

Rnl-nAA

.

.

-

- . -

TOOL

801-205

.

.

10

..

..

.

.....

801-457

. , .

~

.. .

.

. . . . .

-.

,

.

..

......

~. ~ ..

.

.

..

..

..

..

.

..

~..~

Page 11

ij

Repair

Includes items

Kit

801

-083

A,

B.

C,

D,

E

and

F

/A)

k21

SERVICE

1.

Pressaccesspin(17)fromgunhandleandremove

access plate

handle. Unscrew both short and long tubes with

fittings (12 and

body should now slide out

the access plate opening.

2. Remove the cap (14). spring

the valve body

3.

Remove the snap ring

seat

(C)

4.

Remove the sleeve nut

actuator rod

5.

."

...

.

.

.

..

_.

Afterinstallingthenewseat(C)andball(A),tapthe

ball lightly

seating between the ball and seat.

6.

Reassemble

pipe threads on both short and long tubes(l2 and

151.

(4)

by sliding plate towards back

15)

(10).

and O-ring

(F).

with

in

reverse order. Use pipe sealant on

from

valve body

of

(5)

(e).

Then remove the valve

(13).

(1 1)

and O-ring

a

hammer to assure a proper

))

L

(10);

Valve

the handle through

and ball

(E)

(A)

with

from

the

of

@

PARTS LIST

RE

:F

PART

).

NO. DESCRIPTION

N<

801

800-043

5

6

7

8

9

10

11

12

13

801-250

14

15

16

17

..

18

19

20

21

'801 -090

22

23

801 -073

'801 -01

24

25

"801 -01 1

26

801 -074

801-103

27

*a01

28

Order parts by name

which

you

*Recommended

-007

-091

are

.

.

.

.

TUBE,

GRIP

COUPLER,

COUPLER,

HOUSING,

0

TIP,

TIP,

GUARD,

NIPPLE,

COUPLER,

ordering.

"tool

SPRAY HOSE,

(1

5

m)

IQ

SPRAY GUN,

include

HANDLE

ACCESS PLATE

SPRING

TRIGGER

.

NEEDLE

.

HEX

PLUG

.

DISCHARGE FllTlNG

.

VALVE BODY

.

GUIDE SLEEVE

.

TUBE

.

INLET FllTlNG

.

CAP

SAFETY LATCH

ACCESS PIN

LATCH PIN

32"

blasting;

cleaning;

and

box" spare

3/8"

(replaceable

items

3-18)

female quick disconnect

male

quick disconnect

nozzle

0"

150

tip

hex; 1/4 x 3/8"

male quick disconnect

series

letter

parts.

ID,

50

ft.

parts

npt;

brass

of

the assembly

801.457

an

1

1

1

1

1

1

1

1

1

1

1

1

1

for

11

Page 12

ACCESSORIES

(Must

be

purchased

separately)

CHECK VALVE

801

-1

33

CHEMICAL INJECTOR

KIT

800-102

Prevent back up of contaminated water into fresh For injecting harsh cleaning chemicals downstream

supply. Install upstream from pump.

WATER SANDBLASTER 800-1

03

from pump.

ADJUSTABLE SAND SAVER 801-031

For abrasive cleaning of stubborn dirt and paint. For adjusting sand flow.

TECHNICAL DATA

MOTOR: 5 hp, 1 phase

220 V.

WATER PUMP: 2150 PSI (150 bar) max

pressure;

(15 liter/min).

WETTED PARTS: Stainless Steel, Aluminum,

Phenolic Plastic, Ceramic

Liners, Nitrile Rubber.

WEIGHT: 195 Ibs

OVERALL DIMENSION: Length:

Width: 27

Height: 26

60

Hz, 27.5 Amp

4

G,PM

(88

kg)

38

in

(965 mm)

in

(686 mm)

in

(660

mm)

MAX. WATER TEMPERATURE: 1 6OoF

INLET HOSE CONNECTION: 3/4-in. garden hose

THE

GRACO

GracoInc.warrantsallequipmentmanufacturedbyitandbear~ngitsnametobefreeframdefectsin

material and workmanship under normal use and service. This warranty extends to the original

purchaserforaperiodof12monthsfromthedateofpurchaseandappliesanlywhentheequipment

is installed and operated in accordance with

not

cover damage

abrasion. corrosion. negligence, accident. substitution of non-Graco parts. faulty installation

tampering.

This warranty is conditioned upon the prepaid return of the equipment clatmed

examination by Graco toverify the claimeddefect. If the claimed defect is verified. Graco will repair

or

replace free

purchaser transportation prepaid. If inspection

workmanship

be charged.

EOUIPMENT NOT COVERED

sold bv Graco that

subject

to

assistance in making such

the warranty.

or

wear which.

of

charge. any defective parts. The equipment will be returned

or

material, repairs will be madeata reasonablechargeandreturntranspartation will

PURPOSE AND

..............

are

not

manufactured byGraco(such aselectric motors. switches. hose.etc.)are

if

any.

claims.

in

the reasonable judgment

OF

ANY NON-CONTR

BY

GRACO WARRANTY. Accessories

of

their manufacturer. Graco will provide purchaser wcth reasonable

WARRANTY

writtenfactaryrecommendations.This

of

the equipment does

(70°C)

of

or

(f)

Graco. arises

to

not

disclose any defect

components

warrantydoes

from

misuse.

or

be defective for

IO

the original

of

equipment

in

Subsidiary and Affiliate Companies:

Factory

GRACO

.

.~

.

INC.

Branches:

P.Q.

-

..

PRINTED

Atlanta. Pallas, Detroit,

Canada: England; Switzerland;

BOX

1441

IN

U.S.A.

........

MORIRIEAPQLIS,

801.457

Lo6

Angeles.

West

France;

Caldweli

Germany;

MRI

Rev A

7/83

..........

1N.J.l

Hong

55440-1444

Kong: Japan

45-10051A

.....

."

.....

Loading...

Loading...