Page 1

INSTRUCTIONS-PARTS

This

manual

WARNINGS

READ

AND RETAIN

conteins

and

IMPORTANT

INSTRUCTIONS

FOR

REFERENCE

LIST

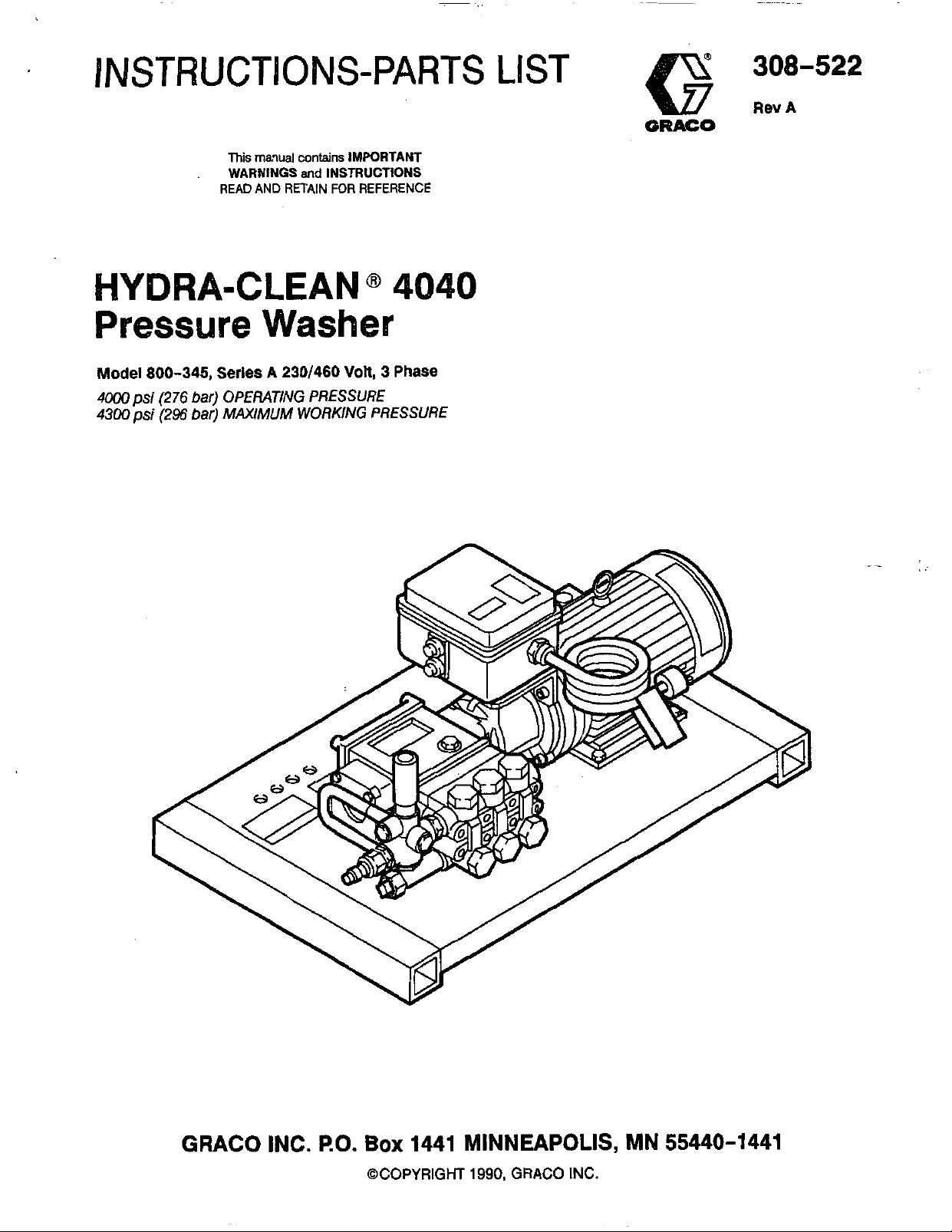

HYDRA-CLEAN

@

4040

Pressure Washer

Model

4ooo

4300psi

800-345,

psi

(276

(296

Series

bar)

bar)

A

230/460

OPERATING PRESSURE

MAXIMUM

WORKING PRESSURE

Volt,

3

Phase

GRACO INC.

RO.

Box

1441 MINNEAPOLIS, MN 55440-1441

@COPYRIGHT

1990,

GRACO

INC.

Page 2

~

BNG

Read

HIGH

FOR

and

PRESSURE SPRAY CAM CAUSE SERIOUS INJURY.

PROFESSIONAL

understand

all

USE

ONLY.

instruction

FLUID INJECTION HAZARD

General

This pressure washer generates very

pressure. Spray from the gun, leaks or ruptured

components can inject fluid through your skin and into

your body and cause extremely serious bodily injury

including theneedforamputation. Als0,fluid injectedor

splashed into the eyes or on the skin can cause serious

damage.

NNER

part of the body.

spray tip.

ALWAYS

cleaning or servicing any part of the sprayer.

NNER

body.

Be sure equipment safety devices are operating

properly before each use.

Safety

high

fluid

point the spray gun or wand at anyone

NNER

follow the Pressure Rellef Procedure, before

try

to

stop or deflect leaks with your hand or

put hand or fingers over the

of

at any

OBSERWE

manuals

Pressure

To

reduce the risk

injection and splashing in the eyes or on the skin,

always follow this procedure whenever you stop

spraying for more than

and before checking or repairing any part of the system.

1.

Engage the trigger safety latch.

2.

Turn the sprayer

3.

Disconnect the electrical supply.

4.

Shut

5.

Disengage the trigger safety latch and trigger the

gun

safety latch again.

6.

Before long-term (overnight) storage, disconnect

the water supply and disconnect the electricity.

ALL WARNINGS.

before

off

to

operating

Relief Procedure

of

serious bodily Injury, including fluid

10

off.

the water supply.

relieve pressure, and then engage the trigger

equipment.

minutes, when shutting down,

..

.

..

..

Medical

If

any

EMERGENCY MEDICALTREATMENTATONCE.

NOTTREAT AS A SIMPLE CUT. Tell the doctor exactly

what fluid was injected.

NOTE TO PHYSICIAN: lnjection

traumatic

surglcally

treatment

concern with some exotic coatings injected

directw into the bloodstream. Consultation with a

plastic surgeon or reconstructive hand surgeon

may be advisable.

Treatment

fluid

appears

injufg

as soon

to

to

penetrate your skin, get

in

the skin

It

Is

Important

as

research toxicip Toxicily

to

posslble.

treat the

Do

not delay

is

Injury

is

DO

a

a

Spray

Be sure all gun safety devices are operating properly

before each

the gun; this can cause a malfunction and result in

serious bodily

SAFm LATCH:

moment, always set the gun safety latch in the engaged

0r"safe" position, making the guninoperative. Failure

properly

triggering of the gun.

SPRAY

cleaning

while spraying, engage the gun safety latch

immediately.

Procedure and then remove the spray tip

Gun

Safety Devices

use.

Do not remove or modify any part of

injury.

Whenever you stop spraying for a

set

the safety latch can result in accidental

TIP

SAFm

or

changing spray

ALWAYS

Use extreme caution

tips.

If

a

spray tip

follow the Pressure Relief

to

to

when

clogs

clean it.

2

308-522

Page 3

This product must be grounded. If it should malfunction

or break down, grounding provides a path

resistance for electric cunent

to

reduce the risk of

of

least

electric shock. This equipment is equipped with a cord

having an equipment-grounding conductor and a

grounding plug. The plug must be plugged Into an

appropriate outlet that is properly installed and

grounded

in

accordance with all local codes

and

ordinances.

DANGER

Improper connection of the equipmentgrounding conductor can result in the risk of

electrocution. Check with a qualified electrician

or service person

whether the outlet is properly grounded. Do not

modify the plug provided with the product

will not

fit

the outlet, have a proper outlet

installed by a qualified electrician.

if

you are

in

doubt as

-

to

if it

GROUND

To

comply with the National Electrical Code (NFPA

and

to

electric shock, connect this pressure washer

FAULT

CIRCUIT INTERRUPTER PROTECTION

70)

provide additional protection from the risk of

to

a

EXTENSION CORDS

Use only 4-wire extension cords that have 4-prong

grounding-type plugs and 4-pole cord connectors that

accept the plug from the product. Use only extension

cords that are intended for outdoor

use.

These

extension cords are identified by a marking,

"Acceptable for use with outdoor appliances; store

use."

indook while not in

having an electrical rating not

Use only.extension cords

less

than the rating of the

product. Do not use damaged extension cords.

Examine extension cord before using and replace

Do

damaged.

EQUIPMENT MISUSE

not abuse extension cord and do not yank

HAZARD

if

General Safety

Any misuse of the pressure washer or accessories,

such as overpressurizing, modifying parts, using

incompatible chemicals and fluids, or using worn or

and

result in

repair or

to

damaged parts, can cause them

rupture and

fluid injection, splashing in the eyes or on the skin, or

other serious bodily injury, fire, -explosion or property

damage.

NNER

so

CHECK

alter or modify any part ofthis equipment; doing

could cause it

all

to

malfunction.

spray equipment regularly

replace worn or damaged park immediately.

ALWAYS

clothing.

wear protective eyewear and appropriate

If

using a chemical injector, read and follow

the chemical manufacturer's literature for

recommendations on additional protective equipment,

such as a respirator.

receptacle that is protected by a ground-fault

circuit-intempter (GFCI).

..

,

to

or pull on any cord

'

heat and sharp edges. Always disconnect the extension

disconnect. Keep cord awayfrom

cord from the receptacle before disconnecting the

Droduct from the extension cord.

1-

WARNING

-1

To reduce the risk of electrocution, keep all

connections dry and

off

the ground. Do not

touch plug with wet hands.

System Pressure

This sprayer can develop high operating pressure.

sure that all spray equipment and accessories are rated

to

withstand the maximum working pressure of this

sprayer.

DO

NOT

exceed the maximum working

pressure of any component or accessory used in the

system.

Be

Chemical Compatibility

BE

SURE

injector are compatible with the wetted parts of the

hose,

(inside back

manufacturer's literature before using any chemical in

this pressure washer.

that all chemicals used in the chemical

gun, wand and tip, as given in the Technical Data

cover).

Always read the chemical

"

308-522

3

Page 4

HOSE

SAFETY

High

pressure fluid

If

the hose develops a leak, split or rupture due

kind

of

wear, damage or misuse, the high pressure

spray emitted from it can cause a fluid injection injury or

other serious bodily injury or property damage.

ALL FLUID HOSES MUST HAVE STRAIN RELIEFS ON

BOTH ENDS.

from kinks or bends at or close

can result in hose rupture.

TlGHTEN

'use. High pressure fluid can dislodge a loose coupling

or allow high pressure spray

coupling.

all fluid connections securely before each

MOVING

Moving parts can pinch or amputate fingers or other

body parts.

or operating the pressure washer.

NNER

and interlocks installed and functioning. Follow the

KEEP

operate the pressure washer without all guards

in

the hoses can be very dangerous.

to

The strain reliefs help protect the hose

to

the coupling, which

to

be emitted from the

PARTS

HAZARD

CLEAR of moving parts when starting

any

TERMS

NNER

entire hose for

damage or movement of the hose couplings. If any of

these condRions exist, replace the hose immediately.

DO

with tape or any other device.

contain the high pressure fluid.

HANDLEAND

on hoses to move the pressure washer.

chemicals which are not compatible wlth the inner

and cover of the hose.

temperatwes above

(-400

Pressure Rellet Procedure

servicing the pressure washer

high pressure fluid from the gun.

use a damaged hose. Before each

cuts,

leaks, abrasion,

NOT

try

to

recouple high pressure hose or mend it

A

repaired hose cannot

ROUTEHOSES CAREFULLY

DO

NOT

expose Graco hose to

2M)"

F

(93'

G)

C).

before checking or

to

prevent discharging

bulging

Do

M

below

use,

cover,

Do

not pull

not use

-40'

check

or

tube

F

WARNING

conditions that could cause bodily injury.

CAUTION

that could cause damage

or

DANGER

Alerts user

Alerts user

to

avoid or correct conditions

to

the equipment.

to

avoid or correct

NOTE

Identifies helpful procedures and information.

IMPORTANT

United States Government safety standards have been adopted under the Occupational Safety and Health Act. These

standards-particularly the General Standards, Part 1910, and the Construction Standards, Part 1926-should be

consulted.

4

308-522

Page 5

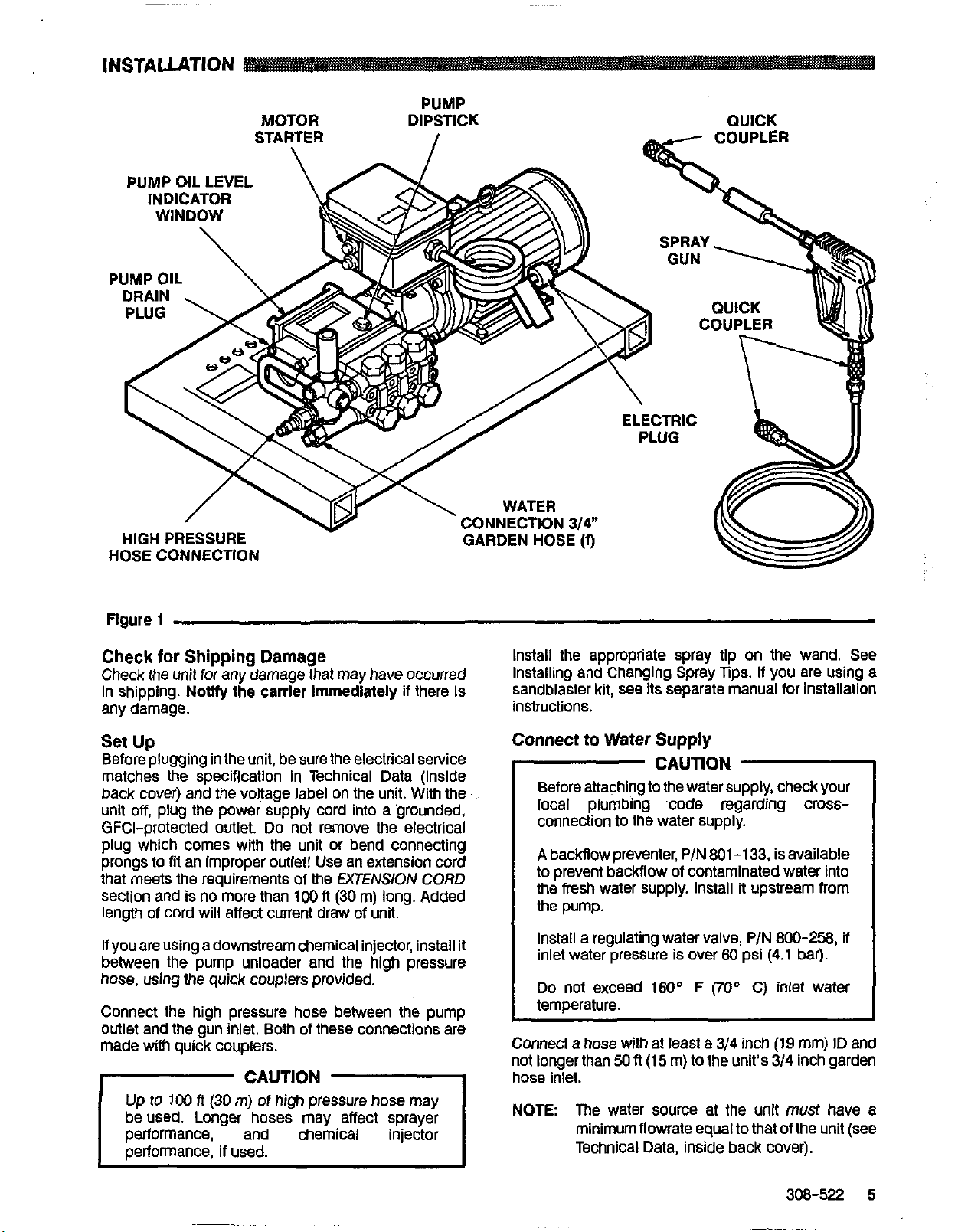

INSTALLATION

PUMP OIL LEVEL

INDICATOR

PUMP

MOTOR DIPSTICK QUICK

CONNECTION

GARDEN

Figure

Check

Check the unit for any damage that may have occurred

in shipping. Not@ the carrier Immediately

any damage.

1

for

Shipping Damage

if

there is

Set Up

Before plugging in the unit, be sure the electrical service

matches the specification

back cover) and the voltage label on the unit. With the

unit

off,

plug the power supply cord into a grounded,

GFCi-protected

plug which comes with the unit or bend connecting

prongs to fit an improper outlet! Use an extension cord

that meets the requirements

section and is no more than

length of cord will affect current draw of unit.

If you are using a downstream chemical injector, install it

between the pump unloader and the high pressure

hose, using the quick couplers provided.

Connect the high pressure hose between the pump

outlet and the gun inlet. Both of these connections

made with quick couplers.

outlet.

in

Technical Data (inside

Do not remove the electrical

of

the

100

fl(30

EXTENS/ON

m) long. Added

CORD

are

.

CAUTION

Up

lo 100

beused. Longer hoses may affect sprayer

performance, if used.

ft

(30

m)

and

of

high

pressure hose may

-1

chemical injector

314"

HOSE

Install the appropriate spray tip on the wand. See

lnstaliing and Changing Spray

sandblaster kit, see its separate manual for installation

instructions.

(9

Tips.

If

you

are

Connect to Water Supply

CAUTION

,

Before attaching to the water supply, check your

local plumbing code regarding

connection

A

backilow preventer,

to

prevent backflow of contaminated water Into

the fresh water supply. Install it upstream from

the pump.

Install a regulating water valve,

inlet water pressure is over

Do

not exceed

temperature.

Connect a hose with at least a

not longer than

hose inlet.

NOTE

to

the water supply.

P/N

801

-1

33,

is available

P/N

800-258,

€0

psi

(4.1

bar).

160°

F

(70"

C) inlet water

3/4

inch

(19

mm) ID

50

fl(15

m)

to

the unit's

me water source at the unit

minimum flowrate equal

Technical Data, inside back cover).

314

Inch garden

must

to

that of the unit (see

using a

cross-

if

and

have a

308-522 5

Page 6

STARTUP

Always

is started safely and properly.

1.

2.

use

this start up procedure

Check the oil level.

Pump: Add SAE

as necessary.

Tum on

the

XI

water supply.

to

ensure that the unit

or

30

weight non-detergent oil

CAUTION

Never

run

the

unit dry. Costly damage

pump will result. Always be sure the water

supply

operating.

I

3.

Trigger the gun until water sprays from the tip

indicating that

4.

Plug the electrical cord into proper, grounded,

GFCI-protected

5.

ALWAYS

whenever you stop spraying,

reduce the risk of fluid injection or splashing in the

eyes or on the skin

accidentally.

is

completely tumed on before

the

air is purged from the system.

outlet.

engage the gun’s trigger safety latch

even

if

the gun is bumped or triggered

to

for a moment

the

to

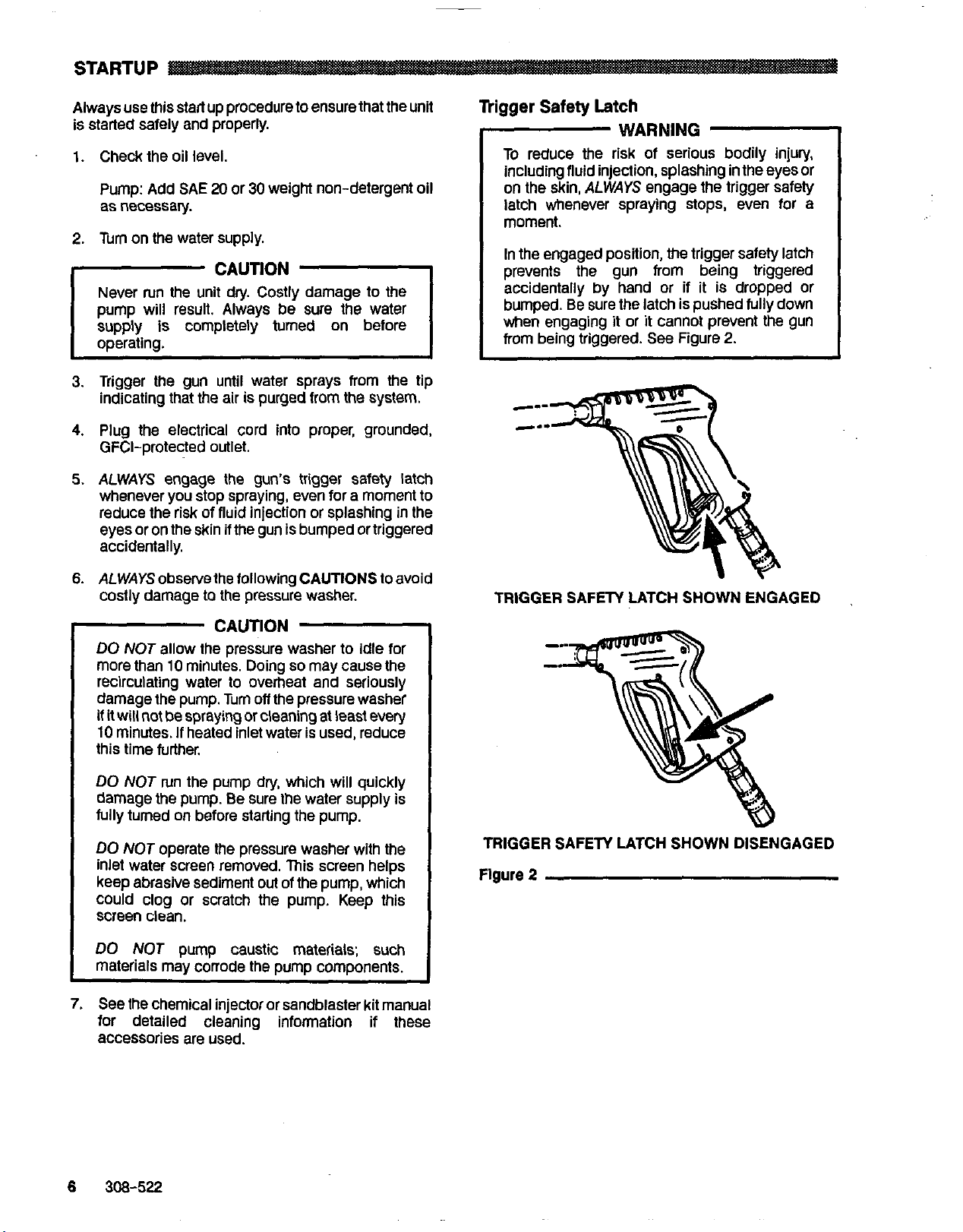

Trigger

Safety

Latch

WARNING

To reduce

including fluid injection, splashing in the eyes or

on the skin,

latch whenever spraying

moment.

In

the

prevents the gun from being triggered

accidentally by hand or if it is dropped or

bumped.

when engaging it or it cannot prevent the gun

from being triggered.

the

risk of serious bodily injury,

ALWAYS

engaged position, the trigger safety latch

Be

sure the latch is pushed fully down

engage the trigger safety

See

stops,

Figure

even for a

2.

6.

ALWAYS

costly damage

observe

to

the following CAUTIONS to avoid

the pressure washer.

CAUTION

DO

NOT

allow the pressure washer

more than

recircuiating water

damage the pump. Tum

if it will not

10

minutes.

this time further.

DO

damage the pump.

fully tumed on before starting the pump.

DO

inlet water screen removed. This screen helps

keep abrasive sediment

could clog or scratch the pump, Keep this

screen clean.

DO

materials may corrode the pump components.

7.

See

for detailed cleaning information if these

accessories are used.

10

minutes. Doing

lo

De

spraying or cleaning at least every

If

heated inlet water is used, reduce

NOT

run the pump dry, which will quickly

Be

NOT

operate the pressure washer with the

NOT

the chemical injector or sandblaster kit manual

pump caustic materiais; such

so

overheat and seriously

off

the pressure washer

sure the water supply is

out

of the pump, which

to

idle for

may cause

the

TRIGGER SAFETY LATCH SHOWN ENGAGED

TRIGGER SAFETY LATCH

Figure

2

SHOWN

DISENGAGED

6

308-522

Page 7

Installing

and

Changing Spray lips

WARNING

To

reduce the risk of serious bodily injury,

including fluid injection

or onto the skin, use extreme caution when

changing spray tips.

procedure below.

1.

Follow

2.

Point the gun and wand away

anyone

3.

Without holding your hand over the spray tip

pull back the quick coupler ring

and then release the ring.

4.

Be

again.

5.

Tip holding holes are provided on the chassis.

the

Pressure

else.

sure the tip is secure before starting to spray

or

splashing in the eyes

ALWAYS

Rellet

Procedure.

follow the

from

(B),

remove the tip

See

Figure

yourself and

(A),

3.

CAUTION

To

avoid blowing the O-ring

coupler, due to the high pressure

never operate

securely mounted in the quick coupler.

Figure

3

the

pressure washer without a tip

out

in

of

the

the

qulck

system,

308-522

7

Page 8

SHUTDOWN, FLUSHING

AND STORAGE

MAINTENANCE

WARNING

Pressure Rellef Procedure

To reduce the risk of serious bodily injury,

including fluid injection and splashing in the

eyes, or on the skin, always follow this

procedure whenever you stop spraying for more

10

than

before checking or repairing any part of the

system.

1.

2.

3.

4.

5.

6.

1.

If

the pressure washer will be exposed

temperatures, drain all water out of the pump. If it

must be stored in freezing temperatures, flush the

unit with a

pressure. Flush the pressure washer before using

again

minutes, when shutting down, and

Engage the trigger safety latch.

Tum the sprayer

Disconnect the electrical supply.

Shut

off

the water supply.

Disengage the trigger safety latch and

trigger the gun to relieve pressure, and then

engage the trigger safety latch again.

Before long-term (overnight) storage,

disconnect

disconnect the electricity.

to

remove the anti-freeze.

off.

the

water supply and

50%

anti-freeze solution. Relieve

to

freezing

Observing regular maintenance intervals helps ensure

that you get maximum performance and life from the

pressure washer.

There is a break-in period for the pump. Afler changing

the oil initially, the interval between required changes

longer.

WARNING

To reduce the risk

includingfluid injection, splashing in the eyes or

on

the

skin or injury from moving parts, always

follow the

interval

Daily Clean water inlet screen and

After first

hours of SAE

operation

500

Each

of operation or

6

months

it

Pressure Relief Procedure

50

hours Change pump oil.

of

What

to do

filter. Check pump oil level. Fill

as necessary.

Change pump break-in oil.

20

or

30

non-detergent oil.

-I

serious bodily injury,

Warning

30

non-detergent oil.

Use

SAE

Use

20

Is

or

I

NOTE:

An anti-freeze flush kit

to

available

make flushing easier.

P/N

CAUTION

If water does freeze in the pressure washer,

thaw it

DO

2.

After each

washer with a clean, damp cloth.

3.

Perform

maintenance chart.

in

a warm room before trying to start it.

NOT

pour hot water on or into the pump; it

use,

wipe all surfaces of the pressure

the appropriate maintenance.

802-327

See

the

is

E

308-522

Page 9

TROUBLESHOOTING CHART

To

reduce

injury

from

the

risk of serious bodily injury,

moving

parts,

always fallow

including

the

Pressure

WARNING

fluid

injection,

Relief

splashing

Procedure

in

the eyes

or

on

the

skin,

Warning before proceeding.

or

PROBLEM

DW

pressure and/or

ump runs rough

rater leakage from

nder pump manifolc

rater

in

pump

'eqequent

or

emature failure of

18

packings

lrong surging at the

let

and low pressurt

1

the

discharoe side

nit

will

nd

start

CAUSE

Wom or wrong size

tip.

Inlet filter clogged.

Wom packings, abrasives

in

water or

I

Replace with tip

SOWTION

of

proper size.

Clean. Check more frequently.

Checlc filter. Replace packings.

See

PUMP SERVICE.

natural wear.

rate

to

Inadequate water supply.

Coupling slippage.

or

dirty

Fouled

inlet or discharge valves.

Even a small particle can cause the valve

lo

stick.

Reslricted inlet.

Worn inlet or discharge valves.

Leakina hiah msure hose.

Wom packings.

Check water flow

Tighten or replace.

Clean Inlet and discharge valve assemblies. Check

filter.

Check

Replace

Reolace hlah mwre hose.

Install new packings.

garden

worn

hose. may

valves.

pump.

be

collapsed or

See

PUMP SERVICE.

kinked.

Humid air condensing inside crankcase. Change oil as specified in MAINTENANCE.

Wom packings.

Install new packings.

Install new oil seals.

Scored, damaged or worn plungers. Install new plungers.

fluid

being

Abrasive material in the

Inlet water temperature

too

Overpressurizing pump.

high.

pumped.

Install proper filtration on pump inlet plumbing.

Check water temperature; may

Do

not modify any factory-set adjustments.

EQUIPMENT MISUSE

Excessive pressure due

to

partially plugged or replace

tip.

See

PUMP SERVICE.

See

PUMP SERVICE. Oil seals leaking.

See

PUMP SERVICE.

not

exceed

HAZARD.

See

Installing and Changing Spra)

or damaged tip.

Pump running

long without spraying.

Never run pump more than

Do not

run

pump without water.

10

minutes without spraying

too

Running pump dry.

in

Foreign particles

the inlet or discharge

Clean or replace valves.

See

PUMP SERVICE.

valve or wom inlet and/or discharge valves.

Unit not plugged

Electrical service off/GFCI activated.

mermai overload has tripped.

in.

Check power cord.

Check fuse/circuit breaker. Check for proper

grounding.

Press

stop button on

the

motor starter.

160°F.

See

308-522

9

Page 10

PARTS

800-345

For wiring diagram, see page

DRAWING

Hvdra-Clean@

4040

Pressure Washer

14

~~~~~

10

308-522

Page 11

PARTS

800-345

LIST

Hydra-Clean@

4040

Pressure Washer

REF

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

27

28

29

30

31

32

33

34

PART

NO.

DESCRIPTION

QN

800-579 PUMP & MOTOR ASSEMBLY

(see

page 15)

803-554 BRACKET, Pump Support

801-382 CORD, Power 10/4

803-263 BRACKET. Starter.

left

159-239 NIPPLE, Hex 1/2 x 3/8

802-732 WASHER. Flat

802-731 WASHER: Lock

#6

#6

1

1

48

1

2

4

4

803-484 SCREW, Cap, pan hd. 4

803-517 LABEL, Keep From Freezing

800-427 UNLOADER,

4ooo

psi

1

1

800-450 HOSE ASSEMBLY, w/Quick

Couplers (includes 14, 18,

20)

1

801-009 QUICK COUPLER, Femaie 1/4

1

154-594 O-RING, (includes Quic 13L Coupler 1/4 1

801-568 QUICK COUPLER, Male 3/8

802-534 NIPPLE, Hex 1/2 NPSM

112 NPT

803-141 HOSE, Bvoass

X

2

1

1

803-395 LABEL, Model 4040 1

803-519 HOSE, High Pressure 3/8 x

50

ft 1

800-429 GUN &WAND ASSEMBLY

fincl. 12. 20. 28. 29. 34. 35) 1

803-157 QUiCK COUPLER, Femaie 318

(includes 21) 2

156-082 OkNG, Quicik Coupler 3/8 2

402-278 PLUG. Plastic

1

804-051 STRAiNEWFiLTER 1

801-110 ADAPTER, Garden Hose

801-1 11 NUT, Garden Hose

801-106

801-957

TEE. 112 1

SLERIE,

18”

1

1

1

801 -1 34 WAND, 32 1

803-262 BRACKET, Starter, right 1

800-441 CHASSiS 1

802-993 PLUG,-Locking 15 hp, 460 volt 1

803-186 LABEL, Cordset

803-351 GUN, Spray, SST

(See

1

Instruction Manual 308-51 1) 1

in

REF

NO.

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

PART

NO. DESCRIPTION

ON

156-849 NIPPLE, Hex 3/8

803-591 WASHER, Flat 1/2

802-784 WASHER, Lock 112 4

803-592 SCREW, Cap, hex hd.

1/2-13

X

1-1/2 4

801-012 GROMMET., Rubber

800-124 TIP ASSEMBLY,

(includes

45,

OOO4

60)

800-125 TIP ASSEMBLY, 1504

(includes

45,

61) 1

800-126 TIP ASSEMBLY, 2504

(includes

800-127 TIP ASSEMBLY.

~~~

45,

62) 1

4004

(includes 45,’63)~

801-WB DECAL. Graco G

Soi-Os0

QUICKCOUPLER,

Male 1/4 4

2

~

176-250 LABEL, Warning, chassis

176-981 LABEL, Warning. chassis

803-396 LABEL, WamingICavtion 1

100-527 WASHER, Flat 5/16

100-21 4

WASHER, Lock 5/16

100-188 NUT, Hex 5/16-18

2

2

2

803-007 LABEL, Caution, 230 volt,

3 phase

803-006 LABEL, Caution, 460 volt,

3 phase 152

801-226 CONNECTOR, Wire 4

801-382 CORD. Power 12/4

1

802-81

CORD’GRiP

804-043 SWITCH. Starter. 15

803-749 SWITCH: Starter: 15

hD

hp

230

460

8n

3

Volt

Volt

801-937 NUT. Lock. electrical 1

801-523

NIPPLE,

1i2 X 2

801-221 TERMINAL. Rina

801 -599 TIP, Spray

6004’

80-600 TIP SDrav 1504

801-661

TIP;

sprai, 2504

801-602 TIP SDrav 4004

801-304

TERMINAL, Ring

1

4

5

1

1

1

1

1

1

1

308-522

11

Page 12

I

53

Model 4040

Wirlng Diagram

230

Volt.

3

Phase

Model 4040

Wring Diagram

Volt,

3

460

Phase

12

308-522

Page 13

PARTS

DRAWING

800-579 Pump

and

Motor Assembly

PARTS

LIST

800-579 Pump

REF

NO.

10

11

1

2

3

4

5

6

7

8

9

PART

NO.

803-584

802-698

802-540

802-784

803-750

802-508

100-527

801 -559

802-783

802-794

803-552

and

Motor Assembly

DESCRIPTION

MOTOR,

COUPLER, 15 hp

15.0 hp TEFC, 3 phase

HOUSING

WASHER, Lock 1/2

SCREW, Cap, socket hd.

1/2-13

PUMP (see page 16)

WASHER, Lock 5/16

SCREW, Cap,

KM,

KM,

RING,

X

Motor

Pump

Adapter

3

hex

hd.

M8

x

30

QTY

1

1

1

4

4

1

4

4

1

1

1

308-522

13

Page 14

PARTS

803-508

DRAWING

Pump Assembly,

4000

psi

45

1

-/-

/

/-

14

308-522

Page 15

PARTS

803-508

LIST

Pump

Assembly,

4000

psi

REF

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

PART

.

.....

NO.

801 -647 MANIFOLD

~~ ~

DESCRIPTION

~~ ~~~

~-

801-468 SCRNV, Cap, hex hd.

801-469 WASHER. Lock

KIT 1

KIT 1

KIT

KIT 1

KIT 1

KIT 106

KIT

KIT

803-283

803-506

802-500

803-324

KIT 2

803-286

803-501

801 -475

803-1

803-287

803-288

802-794

803-289

803-503

803-291

803-292

O-RING

SEAT, Valve

1

PLATE, Valve

SPRING

GUIDE, Valve

O-RING

CAP

106

1

VALVE ASSEMBLY

SCREW, Cap, socket hd.

COVER, Crankcase

O-RING, Crankcase Cover

BEARING, Tapered Roller

SEAL, Oil

BUSHING, Piston

CRANKCASE

DIPSTICK

44

GASKET, Cover

CRANKSHAFT

RING, Retaining

KEY

PIN, Wrist

GUIDE, Piston

ROD,

Connecting

SCREW, Cap, socket hd.

QTY

1

8

8

8

1

2

2

1

1

1

1

1

6

1

3

3

3

5

REF PART

NO.

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

51

52

53

54

NO. DESCRIPTION

803-507 COVER, Crankcase

802-345 GAUGE, SigM

802-793 PLUG, Oil Drain

KIT 107 O-RING

803-294 SCREW, Cap,

socket

801-652 WASHER, Lock

KIT 107 WASHER, Flinger

801-490 PLUNGER, Ceramic

803-502 PLUNGER, Ceramic

KIT 107 RING, Backup

KIT 107 WASHER

KIT 107 SCREW, Piston

803-505 COVER, Crankcase

803-296 SHIM

KIT 3 SEAL, Oil

KIT 109

KIT 109

KIT 109

KIT 112

KIT 109

KIT 109

KIT

801 -482

801

-483

801 -484

801 -485

O-RING

RETAINER. Packing

PACKING

PACKING

RING, Head

RETAINER, Packing

RING, Long Life

109

PLUG, Hex

WASHER, Flat

PLUG, Hex

WASHER, Flat

hd.

QTY

1

1

1

6

6

3

3

1

2

1

1

1

1

Klt

No.

1

2

3

106

Repalr Kit

Part No.

801-472

Valve

801-473

Oil Seal Kit

802-511

Crankshaft

Seal

802-509

Valve Cap

4000

psi

Ret.

No.

4

5

Descrlption

O-RING

SEAT,

Valve

6 PLATE, Valve

7

8

16

41

9

10

SPRING

GUIDE, Valve

11

VALVEASSEMBLE

SEAL. Oil

SEAL,

O-RING

CAP

Oil

.

QW

6

6

6

6

6

6

3

2

6

6

Repalr Kit

Kk

Part

No.

No.

Plunger WASHER, Flinger

Plunger WASHER, Flinger

Repair RING, Backup

Repair RING, Backup

Retainer

Ref.

No.

Descrlptlon

Packing

QiY.

PACKING

RING. Head

It

II

112

803-512

I46 I RETAINER,

44

PACKING

I1

.

6

Packing

4ooo

psi

308-522

15

Page 16

PUMP

I

I

NOTE:

NOTE

SERVICE

To reduce the risk Of serious bodily injury,

including

on the skin, or injury from moving parts, always

follow the

before proceeding.

fluid

injection, splashing in the eyes or

Pressure

The following metric wrenches are needed:

M10,

M13 ani M30. ReDair kits are available. screw.

Refer

to

pump parts page for more details. For the best

results, use all parts in the kits.

There are

servicing the pump. P/N 800-298 is used

ease installation of packings. P/N 800-271

includes

in the removal of packing retainers.

Relief

WARN'NG

the individual repair sections and

two

the

items

Procedure

different

in

800-298 and

Warning

1

tool

kits

to

tools

Valves

NOTE

1.

2.

3.

4.

NOTE

For a

set

of six valves, order P/N 801 -472.

Remove the hex plug from the manifold using an

M30 wrench.

Examine the O-ring under the hex plug and replace

it if it is cut or distorted.

Remove the valve assembly from the cavity; the

assembly may come apart.

lnslall the newvalve. Install the O-ring and hex plug;

torque

to

75

Retorque the plug after 5 hours of operation.

.-

ft-lb (103 Nm).

the

aid in

to

aid

to

I

Servicing the Plungers

NOTE

1. Loosen the plunger retaining screw five

2. Remove the screw from the plunger and examine

3. Remove the plunger and flinger from the plunger

4.

5.

6.

NOTE:

Plunger repair kit, P/N 803-510 is available

replace retainers, O-rings, washers and

backup rings for three cylinders.

(19.5

'

to

is

available

Nm).

-

using an M10 wrench. Push the plunger towards the

to

crankcase

the O-ring, backup ring and copper bearindgasket

washer. Replace these parts,

803-510.

shaft. Clean, examine and replace parts as

necessary.

Inspect the plunger shaft for oil leakage from the

crankcase. If leaking is obvious, replace the oil

seals. Otherwise,

they cannot be reused.

replace the seals.

Lightly grease the oil seal,

and the flinger and replace them on the plunger

shaft. Then install the plunger.

Lightly grease the retaining screw and the outer end

of the plunger. Place the washer, O-ring and backup

ring around the screw and install the screw through

the plunger. Torque

If

vou plan

Sitvicing the V-backings.

separate the plunger and retaining

DO

to

to

replace the Packinas. refer

..

if

necessary, using kit

NOT

remove these seals as

An

oil seal kit

if

it is being replaced,

14.4

ft-lb

to

six tums,

-

to

to

Pumping Section

1. Remove the eight capscrews and lockwashers from

the manifold using an M13 wrench.

2. Carefully separate themanifold

NOTE:

3. Carefully examine each plunger

It

may be necessary

a

soft

mallei

with

Keep

the

manifold properly aligned with the

ceramic plungers when removing

damage to the plunger or seals.

cracking and replace as necessary.

to

from

the crankcase.

to

tap the manifold lightly

loosen.

to

avoid

for

any scoring or

7.

Lubricate the outside of each plunger. Slide the

manifold

damage the seals.

8. Install the capscrews and washers finger-tight.

Torque the screws

tightening pattem (Figure 4). Uneven tightening

may cause the manifold

Figure

4

onto

the crankcase, being careful not

to

21.7 ft-lb

I

(29

Nm) following the

to

bind or jam.

I

to

16

308-522

Page 17

Servicing the V-Packings

NOTE

1.

2.

3.

4.

There

are

two

lypes

of

packing kits: one is

pacltlngs only, the other includes the

packings, rings

Remove the manifold as outlined In the Pumping

Section.

Carelully pull the packing retainer from the

manifold. Examine the O-ring and replace

cut or damaged.

Remove the v-packing and head ring. Pull out the

intermediate retainer ring. Remove the second

v-packing and second head ring.

inspect all parts and replace as necessary.

and

retainers.

It

if it is

5.

Thoroughly clean the packing cavities and examine

for debris and damage.

6.

Lightly grease the packing cavities and then

replace the packings in the following order: head

ring, v-packing. intermediate ring, head ring,

v-packing and packing retainer with. the O-ring

installed In the retainer groove.

CAUTION

the

Install the parts in

the

correct direction. Improperly installed parts

will cause a malfunction.

7.

Reassemble ¶he manifold

the Plungers.

proper order and facing

as

instructed in Servicing

308-522

17

Page 18

~

ACCESSORIES

(Must

be

purchased separately)

DOWNSTREAM CHEMICAL INJECTOR KIT WATER SANDBLASTING KIT 800-120

800-649

For injecting harsh cleaning chemicals downstream

from the pump. Stainless steel construction.

For abrasive cleaning

Requires a spray tip

kit.

of

stubborn dirt and paint.

(801-600)

which

is not included

in

UPSTREAM CHEMICAL INJECTOR

KIT

800-257

For

injecting mild cleaning chemicals upstream into the

Pump.

BACKFLOW PREVENTOR 801-133 INLET PRESSURE REGULATOR 800-258

Prevent back-up

supply. Install upstream

TECHNiCAL

of

contaminated water into fresh Regulates inlet water pressure to

of

pump. maximum.

DATA

ANTI-FREEZE FLUSH

For flushing system with

to

transporting or storing pressure washer

KIT

802-327

50%

anti-freeze solution prior

freezing temperatures.

60

psi

in

below

(4

bar)

High

Pressure

Hase

Acrylonitrile

and

Buna-N cover and tube

Synthetic yam and

EPDM

Pressure Washer Anodized aluminum, Aluminum or Bronze alloys,

(including fittings)

Ceramic, Buna-N,

Conon

Phenolic.

Thermoplastic. Teflono, Carbon

303,304,

Steel,

Zinc

with

and

or

Brass,

Copper, Nylon-TefionQ composite.

316

Stainless

without

Yellow

Steel.

Polymide-12

Chromare

Plate

Page 19

THE GRACO WARRANTY

WARRANTY AND DISCLAIMERS

Gram warrants ail equipment manufachrred by

andwo~manshiponthedateofsaiebyanauthorizedGramdistnbutortotheonginalpurchaserforuse.

As purchaser's

dateofsale,repairorreplaceanypartoftheequipmentpmvendefscthe.Thiswarran~appliesonlywhen

the

equipment

recommendations.

This warranty does not cover. and Gram

tauily

by

negligence. accident, tampering, or substihltion

liableform~nction,damageorwearcausedbytheinmmpatibilitywithGramequipmentofsfruchrres,

accessories. equipment or materials not supplied by Graco. or the improper design, manufacture,

installation. operation or maintenance

Grm.

Thii

warranty is conditioned upon

examination by Gram

replace

transportation prepaid.

workmanship. repairs will

labor and transportation.

DISCLAIMERS AND LIMITATIONS

METERMSOFTHlSWARRANPlCONSTiTUTETHEPURCHASER'SSOLEANDEXCLUSlVEREMEDY

ANDAREINLlEUOFANYOTHERWARRANTIES(EXPRESSORIMPLIED),lNCLUDlNGWARRANTYOF

MERCHANTABILITY

NON-CONTRACTUALLIABILITIES.

STRICT LIABILITY:

DAMAGES

LIABILITY EXCEED THE AMOUNT OF THE PURCHASE PRICE.

WARRANTY MUST BE BROUGHT WITHIN THREE

sole

remedy for breach ofthis warranty, Graco will,

is

installed. operated

installation. misapplication. abrasion, corrosion, inadequate or Improper maintenance,

of

the

the

claimed defect.

defecthe

madeata reasonable charge. which charges may include thecosts

FORM OF UABiLlTY

parts.

of

INCLUDING PRODUCTLIABILITIES. BASEDON NEGLIGENCEOR

free

of

OR

charge

EVERY

LOSS

to

verify

any

If

inspection

be

OR

WARRANTY

IS

EXPRESSLY EXCLUDED AND DENIED. IN NO CASE SHALL GRACOS

fi

and bearing its name to

and

maintained

shall

not

be

liable for, any malfunction. damage or

of

non-Graco component parts Nor shall Graco

sfruotures. accessories. equipmentor materials not supplied by

prepaid return

the equipment does not disclose any defect in material or

OF

If

The equipment will be returned

FITNESS FOR A PARTICULAR PURPOSE, AND

me

FOR

(3)

in

of

the

equipment claimed

claimed defect is verified. Graco will repair or

DIRECT SPECIAL

YEARS OF THE DATE OF SALE.

be

frea

from defects

for

a period

of

twenty four months

accordancB with Gram's written

to

to

the

in

material

wear

caused

be

defective for

original purchaser

of

parts.

OF

OR

CONSEQUENTIAL

ANY

ACTION FOR BREACH

from

be

ANY

OF

EQUIPMENT NOT COVERED

BY

GRACO WARRANTY

GRACOMAKESN0WARRANPl.ANDDiSCLAlMSALLIMPLIEDWARRANTIESDFMERCHANTABlLlTY

AND FITNESS FOR

MATERIALS

A

OR

COMPONENTS

PARTICULAR PURPOSE, WITH RESPECT TO ACCESSORIES, EQUIPMENT

SOLD

BUT

NOT MANUFACTURED BY GRACO. These

items

sold, but

notmanufacturedbyGraw(suchaselectricmotor,switches,hose,etc.)aresubjecttothewarranty,ifany.

of

their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim

breach

of

these warranties.

for

IMPORTANT PHONE NUMBERS

TO PLACE AN ORDER,

distributor

FOR

application

Subsldlary and Affiliate Companies:

closest

TECHNICAL ASSISTANCE,

of

Graw

Factory Branches:

GRACO INC.

wntacd

to

you:

1-800-328-021 1

equipment:

Atlanta, Chicago. Dallas,

Canada; England; Swiizeriand; France; Germany; Hong Kong:

PO.

BOX

PRINTED IN U.S.A.

your

Graw

distributor,

Toll

Free

service repair information

1-800-543-0339

Delmi.

Toll

Free

Los

or

call

this

or

assistance

Angeles. West

number to

Caldwell

identify

regarding

(N.J.)

1441 MINNEAPOLIS, MN 55440-1441

308-522

1/91

the

the

Japan:

Korea

Loading...

Loading...