Page 1

INSTRUCTIONS–PARTS

LIST

308–188

This

manual contains IMPORT

W

ARNINGS AND INSTRUCTIONS

READ AND RET

AIN FOR REFERENCE

ANT

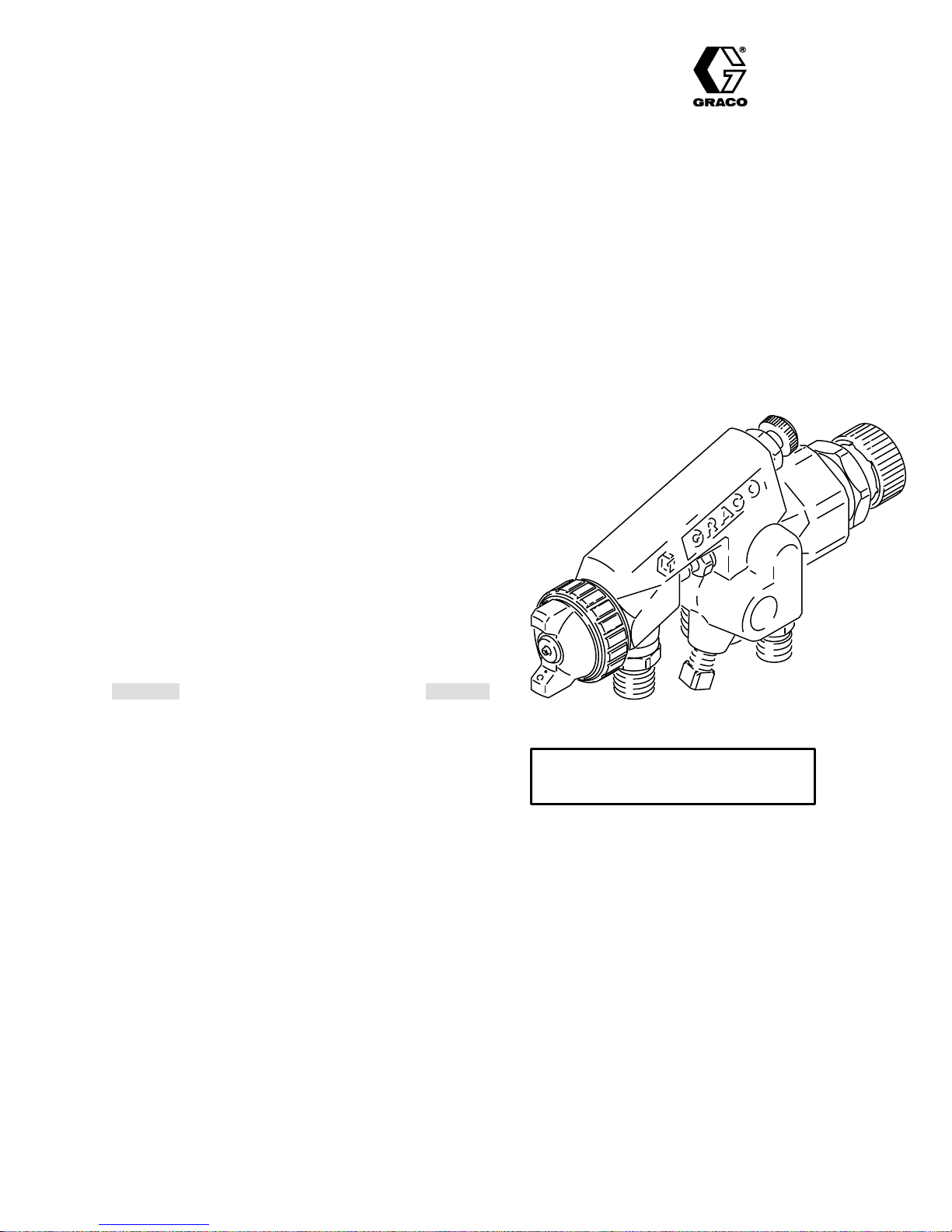

Model H.E.L.P. 1600B

HIGH EFFICIENCY

LOW PRESSURE

AUTOMATIC

STAINLESS STEEL FLUID PASSAGES

300

psi (21 bar) MAXIMUM WORKING FLUID PRESSURE

100

psi (7 bar) MAXIMUM WORKING AIR PRESSURE*

15

psi (1.05 bar) MAXIMUM OPERA

*The

Maximum Working Air Pressure

sure

the gun was designed to operate safely under

**The

Maximum Operating Air Pressure

pressure

pressures are maintained at or below 15 psi (1.05 bar), the

natural pressure drop through the gun will produce 10 psi

(0.7

allowable to guarantee HVLP compliance. If input

bar) maximum air cap pressure.

BLEEDER AIR SPRA

TING AIR PRESSURE**

is the maximum air pres

.

is the maximum inlet air

-

Rev A

Y GUN

TABLE OF CONTENTS

Warnings 2.

Typical Installation 3.

Installation 3

Operation 4

Maintenance 6

Troubleshooting

Service 8

Important

Dimensional

Parts

Accessories 11

Technical

Air

Flow Charts

Warranty Back

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charts6. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phone Numbers8. . . . . . . . . . . . . . . . . . . . .

Drawing9. . . . . . . . . . . . . . . . . . . . . . . . . .

Drawing and List

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data

.

. . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

Back Cover

Back Cover

Cover

10.

Part No. 224–891

Includes

0.032 in. (0.8 mm) fluid nozzle

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

COPYRIGHT

1991 GRACO INC.

Page 2

WARNINGS

FOR PROFESSIONAL USE ONLY. OBSERVE ALL WARNINGS.

Read and understand all instruction manuals, tags,

and warning labels before operating equipment.

EQUIPMENT

MISUSE

HAZARD

General Safety

Any

misuse of the

as

over

pressurizing, modifying parts, using incompatible

chemicals and fluids, or using worn or damaged parts,

can cause them to rupture and result in serious bodily

injury,

fire, explosion or property damage.

NEVER point the spray gun at anyone or at any part of

the

body

. NEVER put hand or fingers over the spray noz

zle.

ALWAYS

before

any

NEVER try to stop or deflect leaks with your hand or

body.

NEVER

so

CHECK all spray equipment regularly and repair or

replace

follow the

cleaning or removing

system equipment.

alter or modify any part of this equipment; doing

could cause it to malfunction.

worn or damaged parts immediately

spray equipment or accessories, such

Pressure Relief Procedure

the fluid nozzle or servicing

, at

right,

.

Fluid Compatibility

BE SURE all fluids and solvents used are chemically

compatible

NICAL DATA on the back cover. Always read the fluid

and solvent manufacturer’s literature before using the

fluid

or solvent in this gun.

with the “W

etted Parts” shown in the

Pressure Relief Procedure

-

To reduce the risk of serious bodily injury, including

splashing

parts,

system,

system, when installing, cleaning or changing fluid nozzles,

1. T

2. Trigger the gun into a grounded metal waste con-

in the eyes or on the skin or injury from moving

always follow this procedure when shutting off the

when checking or servicing

and whenever you stop spraying.

urn of

f the air and fluid supply to the gun.

tainer

to relieve air and fluid pressure.

any part of the spray

TECH-

System Pressure

This gun has a

SURE

of 300 psi (21 bar), a

PRESSURE

AIR PRESSURE

ATING

ceed the maximum working pressure of the gun or any

other

component or accessory used in the system.

MAXIMUM WORKING FLUID PRES-

MAXIMUM WORKING AIR

of 100 psi (7 bar) and a

of 15 psi (1.05

MAXIMUM

bar). NEVER ex

OPER

-

-

HOSE SAFETY

TIGHTEN

NEVER use a damaged hose. Before each use, check

the

damage or movement of the hose couplings. If any of

these

United

all fluid connections securely before each use.

entire hose for cuts, leaks, abrasion, bulging cover

conditions exist, replace the hose immediately

, or

.

HANDLE AND ROUTE HOSES CAREFULLY. Do not

on hoses to move equipment. Do not use fluids or sol

pull

vents which are not compatible with the inner tube and

cover

of the hose.

IMPORTANT

States Government safety standards have been adopted under the Occupational Safety and Health Act. These stan

dards––particularly the General Standards, Part 1910 and the Construction Standards, Part 1926––should be consulted.

-

-

Page 3

TYPICAL INSTALLATION

Conveyor

Fluid

Supply

Pump

Sensing

Device

Fluid

Pressure

Regulator

Fluid

Line

H.E.L.P.

Bleeder Air Spray Gun

Cylinder Air

Supply Line

Atomizing Air

Supply Line

1600B Automatic

3-way

Air

Solenoid

Valve

Air Regulator

Air

Filter

0896

The

Model H.E.L.P

Bleeder Spray Gun

. 1600B High Ef

was

designed to produce the highest

ficiency Low

Pressure

quality finish with today’s fluids as well as the the Low

V.O.C.

(volatile organic compound)

fluids of tomorrow

.

This spray gun can spray most coatings or finishes currently

being used

for automotive refinish, industrial, aero

space, marine, wood, plastic and architectural applications,

while easily operating from any paint delivery sys

tem, including pressure pots of any size, or remote

pumps

for production line operation.

INSTALLATION

Ventilate the Spray Booth

WARNING

To prevent hazardous concentrations of toxic

and/or

flammable vapors, spray only in a properly

ventilated

gun unless ventilation fans are operating.

Check and follow all of the National, State and

Local codes regarding air exhaust velocity

requirements.

Check

spray booth. Never operate the spray

and follow all local safety and fire codes.

If input air pressures are maintained at or below 15 psi

(1.05

bar), maximum air

bar),

which is required to meet all new regulations.

cap pressure will be 10 psi (0.7

The Typical Installation shown above is only a guide for

selecting

tomatic spray system. It is not an

-

and installing the equipment needed for an au

actual system design.

For assistance in designing a system, contact your

-

representative.

Graco

Mount the Gun

Mount

the gun on a 0.50 in. (12 mm) diameter rod mount

ing fixture that allows adjustment of the spray pattern

direction

and the distance from the workpiece.

Connect the Fluid Line

1. Before connecting the fluid line, blow it out with air

and flush it with solvent. Use solvent which is compatible

with the fluid to be sprayed.

2. Install

a fluid regulator on the fluid line to control fluid

pressure

to the gun.

-

-

3. Connect

gun

fluid inlet.

the fluid line to the 3/8–18 npsm (R 3/8–19)

Page 4

INSTALLATION

Connect the Air Lines

1. Install

2. Install

3. Connect

4. Install

Pressure Relief Procedure

To

splashing in the eyes or on the skin or injury from

moving parts, always follow this procedure when

shutting

any part of the spray system, when installing,

cleaning or changing fluid nozzles, and whenever

you

1. T

2. Trigger the gun into a grounded metal waste

an air filter to provide a clean, dry air supply to

the

gun. Dirt and moisture in the air line can af

appearance

the

cylinder air supply line. Connect an air hose from

the solenoid valve to the 1/4–18 npsm (R 1/4–19)

gun

air inlet marked CYL.

NH (standard garden hose fitting) gun air inlet

marked ATOM.

and

cylinder air

reduce the risk

stop spraying.

urn of

container

of your finished workpiece.

a normally closed, 3-way air solenoid valve in

an

atomizing air supply line to the 3/4–1

separate air regulators to control atomizing air

.

WARNING

of serious bodily injury

of

f the system, when

f the air and fluid supply to the gun.

to relieve fluid pressure.

checking or servicing

, including

Recommended Hose Sizes

fect the

FLUID HOSE

Length

Needed

0–35

1.5

(0–11 m)

35–100 ft

(11–30 m)

100–20

(30–6

OPERATION

ft

0 f

0 m

(general purpose)

CYLINDER

AIR HOSE

ID

Length

(in.)

t

)

3/8

1/2

in.

3/4

in.

Needed

0–100 ft

(0–30 m)

100–20

0 m

(30–6

(in.)

5/16

0 f

t

3/8

)

Vertical Pattern

ID

in.

in.

ATOMIZING

AIR HOSE

Length

Needed

0–25 ft

(0-7.63

m)

ID

(in.)

3/4

in.

Filter the Fluid and Check Viscosity

Filter the fluid to remove coarse particles and sediment

which

could clog the spray nozzle, then check the viscos

ity of your fluid. This gun is best suited for light to medium

fluids.

Light Fluid:

Furniture, Appliances, Fine Finish Metallics, Top Coats,

Lacquer,

Medium

tact Adhesive, Latex, Maintenance Paints, Textures,

Primers,

Heavy Fluid:

Polyurethanes, Heavy W

solid

19 to 24 seconds (No. 2 Zahn cup). Auto,

Enamel Primer

Fluid:

22 to 41 seconds

Epoxies, V

2.8 Volatile Organic Compounds, High-

.

(No. 2 Zahn cup). Con

inyls, High Flow High V

aterborne Enamels

iscosity.

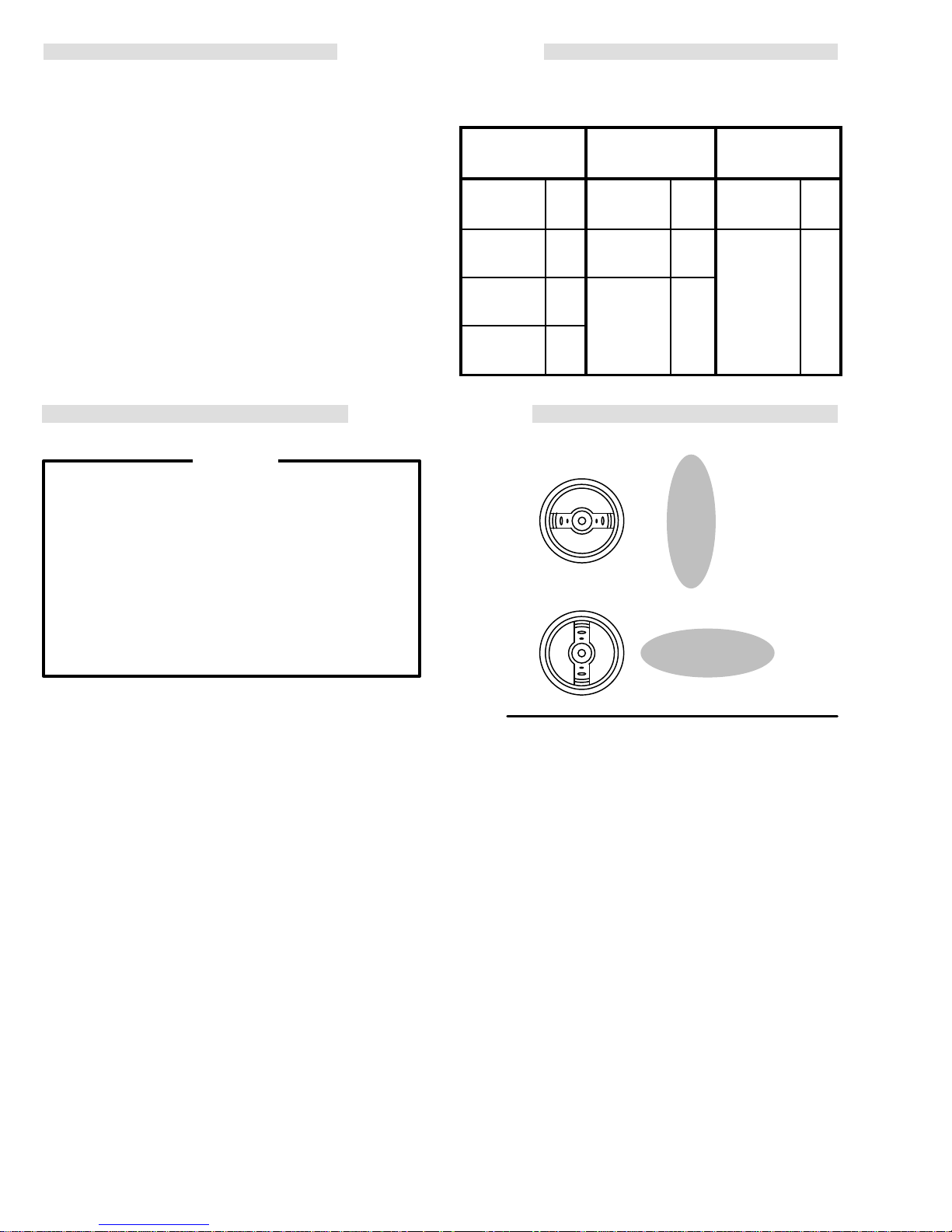

Position the Air Cap

The direction of the spray pattern is controlled by the

position

cap

securely.

of the air cap. See Fig 1. Loosen and

to the desired position, then

hand tighten the air cap

turn the air

Adjust the Spray Pattern

Follow these steps to establish the correct fluid flow

air

flow:

4308-188

and

-

-

Horizontal Pattern

Fig

1

1. Adjust

NOTE:

2. T

NOTE: If

the pattern size by turning the pattern adjust

ing

valve

OUT (counterclockwise)

or

IN (clockwise)

2.

The pattern width at the widest adjustment is 10

to 11 in. (254 to 279 mm) at 350 grams/min. fluid

flow

and 10 in. (254 mm) target distance with 15

psi

(1.05 bar) inlet air pressure. (Measurements

taken using a 23 sec. Zahn #2 viscosity fluid.)

pattern length will vary with the fluid flow

The

pressure,

o adjust the volume of fluid output:

a. Turn the fluid adjusting valve all the way out

(counterclockwise)

b. Adjust the fluid regulator for the desired pres-

sure.

c. For final adjustment, turn the fluid adjusting

in

valve

output

the fluid adjusting valve is turned in all the way

the

gun will only emit air

for a narrower pattern

fluid viscosity

.

Refer to Fig 2.

(clockwise)

and obtain the desired results.

to

reduce the volume of fluid

for a wider pattern

.

Refer

, and other factors.

.

to

0897

-

Fig

, air

Page 5

3.

For

continuous spraying,

valve and fluid adjusting valve in the full open position.

This provides maximum fluid flow and prevents

premature

4. Test

the

gun about 6 to 8 inches (150 to 200 mm) from the

test piece. Adjust the air pressure to the gun until

proper

possible atomizing air pressure to obtain the de

est

sired

wear on the fluid nozzle.

the spray pattern and atomization while

atomization is achieved. Always use the low

results.

leave the pattern adjusting

OPERATION

To Operate the Gun

Adjust the system’s sensing device so the gun starts

spraying

the

holding

Air and Fluid Pressure

The gun requires 71 psi (4.9 bar) air pressure to the

-

-

The

The fluid pressure normally does not exceed 15 psi

just before meeting the workpiece

workpiece has passed.

cylinder.

atomizing air pressure must be set at or below 15

psi

(1.05 bar) for compliant operation.

(1.0 bar).

Pattern

Adjusting Valve

and stops as

Air Cap

Fig

2

Fluid

Needle

Fluid

Nozzle

Fluid Inlet

OM Air Inlet

AT

Fluid

Adjusting

Valve

308-1885

Page 6

Daily Care and Cleaning

WARNING

Pressure

To

reduce the risk

splashing in the eyes or on the skin or injury from

moving parts, always follow this procedure when

shutting

any part of the spray system, when installing,

cleaning or changing fluid nozzles, and whenever

you

1. T

2. Trigger the gun into a grounded metal waste

Clean all parts with a solvent compatible with the

fluid

parts.

Relief Procedure

of serious bodily injury

of

f the system, when

stop spraying.

urn of

f the air and fluid supply to the gun.

container

being sprayed and compatible with gun wetted

See TECHNICAL DATA

to relieve fluid pressure.

CAUTION

checking or servicing

on the back page.

, including

MAINTENANCE

1.

After operation, flush the gun with a compatible sol

vent

passages. Follow the Pressure Relief Procedure

Warning,

2. Wipe the outside of the gun clean with a solvent

dampened

3. Remove the air cap and fluid nozzle from the gun.

Soak them in solvent and scrub them with a fine,

bristled

4. To

clean out air

as a toothpick, to avoid damaging critical surfaces.

Clean the air cap and fluid nozzle daily, minimum.

(Some

5. Lubricate

daily

the needle spring (7) and cylinder with light-weight

grease

-

until all traces of paint are removed from the gun

at left, before proceeding.

cloth.

brush (provided with the gun).

cap holes, use a soft implement, such

applications require more frequent cleaning.)

the exposed portion of the fluid needle (1)

with Graco TSL or light oil. Periodically lubricate

or petroleum jelly

. See Fig 3, page 9.

To avoid getting solvent in the gun air passages,

NEVER

To avoid scratches that can distort the spray pattern,

in the air cap or fluid nozzle .

To

splashing

always follow the Pressure Relief Procedure

Warning,

ing or repairing the gun or any part of the system.

Disconnect

PROBLEM CAUSE SOLUTION

Leakage from fluid pack

ing nut.

immerse the gun in solvent

NEVER use metal instruments

GUN OPERA

WARNING

reduce the risk of serious bodily injury

fluid or solvent in the eyes or on the

above, before checking, adjusting, clean

the fluid hose from the gun.

Loose needle packing nut(s) (9).

W

orn needle packings (10, 16).

.

to clean holes

TION TROUBLESHOOTING CHART

, including

skin,

-

NOTE: The shield (24) helps to minimize over-spray

buildup on the fluid needle (1). Refer to the

PARTS

NOTE: Check all possible remedies in the T

ing

DRA

WING.

Charts before disassembling the gun.

T

ighten packing nut(s).

Replace packing assemblies.

See page 8.

roubleshoot-

Fluid leakage from

front of gun.

6308-188

Fluid needle (1) worn or damaged.

W

orn fluid needle and fluid nozzle seat

Fluid packing nuts (9) too tight.

Replace fluid needle. See page 8.

Replace fluid nozzle (2) and needle (1).

See page 8.

Lubricate packings (10, 16) and adjust

packing nuts (9). See page 8.

Page 7

SPRAY PA

TTERN TROUBLESHOOTING CHART

PROBLEM: CAUSE SOLUTION

IMPROPER SPRA

PATTERN

Fluttering or spitting

spray

Y

Insuf

ficient fluid supply

Loose fluid nozzle or damaged fluid

nozzle taper seat.

Dirt between fluid nozzle, taper seat

and body

Loose or cracked fluid inlet fitting (4a).

Loose fluid tube in pressure tank.

Dry or worn fluid needle packings (10, 16)

or loose packing nuts (9) permit air to get

into fluid passage.

Fluid build-up on air cap; partially

clogged horn holes. Full air pressure

from clean horn hole forces fan pattern

toward clogged end.

Damaged fluid nozzle or air cap holes.

Fluid build-up on the perimeter of fluid

nozzle orifice, or partially clogged fluid

nozzle orifice.

.

.

Adjust fluid regulator or fill fluid tank.

T

ighten or replace fluid nozzle (2) and

needle (1).

Clean.

T

ighten or replace fitting.

T

ighten fluid tube.

Lubricate or replace packings;

tighten packing nuts.

Clean with soft implement or

submerge in suitable solvent and

wipe clean.

Replace damaged part.

Remove obstruction. Never use wire

or hard instruments.

Streaks

NOTE:

T

oo high atomization air pressure.

Fluid too thin.

Not enough fluid pressure.

Low atomization air pressure.

Fluid too thick.

oo much fluid. Reduce fluid pressure.

T

Last coat of fluid applied too wet.

oo much air pressure.

T

ficient air pressure.

Insuf

Non-uniform spray pattern.

Some improper patterns are caused by the improper balance between air and fluid.

Reduce air pressure or adjust air

adjusting valve (5).

Regulate fluid viscosity

Increase fluid pressure.

Increase air pressure or adjust air

adjusting valve (5).

Regulate fluid viscosity

Adjust fluid adjusting valve (6) until

proper pattern is obtained.

Apply drier finish with multiple

strokes.

Use least air pressure necessary

Increase air pressure.

Clean or replace air cap.

.

.

.

308-1887

Page 8

SERVICE

Air and Fluid Fitting Replacement

When

replacing the fluid fitting (4a),

the gasket and washer included with the fitting (gasket

and

washer are not sold separately). Apply Loctite 242

sealant or equivalent on the fluid fitting threads and

torque

the fitting to 20 ft-lb (27 N

When replacing the cylinder (CYL) air fitting (4b), apply

Loctite PST pipe sealant or equivalent on the threads

before installing the new fitting. DO NOT remove the

atomizing

air fitting as it is press fit.

m).

BE

SURE

to reinstall

Piston Service

1. Follow

2.

3. Carefully pull the fluid needle (1) out of the piston

4. Clean

5. Apply a few drops of light-weight machine oil to the

the

Pressure Relief Procedure W

page

6 to relieve fluid pressure.

Unscrew and remove the fluid needle guide (8).

(12).

and inspect the fluid needle (1),

(12), and piston packings (13, 15) for damage or

ton

wear.

Replace if needed.

fluid

needle and reassemble the parts.

arning

spring (7), pis

on

4. Unscrew

ings

5. Clean and inspect the fluid needle (1); replace the

needle

6. Reinstall

and

7. Slide the rear packings (16) onto the fluid needle;

orientate

8. Slide

onto

9. Slide

needle

10. Slide the fluid needle (1) into the front fluid packing

cavity.

11. Push

-

12. Screw

16)

the

NOTE: For the best packing life, lubricate the fluid

the packing nuts (9) and remove the pack

(10, 16); use a pick if needed.

if damaged or worn.

the fluid needle (1) through the piston

the rear packing cavity

them as shown in

the packing

the fluid needle.

the

remaining four packings (10) onto the fluid

in the order shown in

the fluid needle (1) and piston (12) fully forward.

in both packing nuts (9) until the packings (10,

are fully compressed, then

fluid needle moves freely

needle daily as explained in MAINTENANCE,

step

5.

nuts (9), threads facing oppositely

.

Packing Detail 16

Packing Detail 10

back of

.

-

(12)

.

,

.

f the nuts until

Fluid Packing Replacement

If

fluid leakage cannot be stopped by tightening the pack

ing nuts (9), replace the

as instructed below; refer to Fig 3.

1. Follow

2.

3. Carefully pull the fluid needle (1) out of the piston

the

Pressure Relief Procedure W

page

6 to relieve fluid pressure.

Unscrew and remove the fluid needle guide (8).

(12).

fluid packings (10, 16). Service

arning

on

-

IMPORTANT

TO

PLACE AN ORDER

or call this number to identify the distributor closest to

you:

FOR TECHNICAL ASSISTANCE

mation

equipment:

or assistance regarding the application of Graco

PHONE NUMBERS

, contact your Graco distributor

1–800–328–0211 T

1–800–543–0339 T

oll Free

, service repair infor-

oll Free

,

Page 9

SERVICE

0900

PACKING

P

DET

ACKING DET

AIL 10

AIL 16

16

5

1

Lubricate daily

12

with light-oil

15

13

6

8

7, 1

1

Lubricate

periodically

with

light-

grease

Fig

3

3.375” (86.7 mm)

Apply

4a

Loctite 242 or

equivalent. T

to 20 ft-lb (27 N

orque

m).

10

DIMENSIONAL

6.78”

(174.6 mm)

DRA

9

WING

NOTE:

If replacing CYL air fitting (4b)

[

not shown here; see Parts Drawing

apply Loctite PST Pipe Sealant or

equivalent.

0.56” (14.2 mm)

],

0898

1.88” 47.8 mm)

3.56” 90.4 mm)

0.50” (12.75 mm) DIA. MOUNTING HOLE

MAX. WIDTH: 2.03” (51.6 mm)

2.37” (60.2 mm)

0901

308-1889

Page 10

PARTS

DRA

WING

HOW T

1. To

accessories,

chart

2. Check

use

3.

Order all parts from your nearest Graco distributor

6 digit

Part

Number Qty

O ORDER REPLACEMENT P

be sure you receive the correct replacement parts, kits or

the ref. no. when ordering.

always give all of

below

.

the parts list to identify the correct part number; do not

the information requested in the

Part Description

(label)

4c

4

2

3

ARTS

.

24

10*

13

Model H.E.L.P. 1600B

Automatic

5

1

12*

15

16*

9

Bleeder

7

18

11

Air Spray Gun

14

8

19

21

6

4a

REF

NO. P

1 599–599

2 187–271

ART NO.

DESCRIPTION QTY

NEEDLE, fluid

FLUID NOZZLE; 0.032” (0.8 mm);

See ACCESSORIES for other sizes

3 110–864 AIR

4 223–282

GUN BODY

Includes items 4a & 4b

4a 106–786

FITTING, fluid; includes gasket

& washer

4b 106–690

4c 185–771

FITTING, air 1

LABEL, instruction

5 107–824 VAL

6 107–818

7 107–817

8 107–825

KNOB, fluid adjusting valve

SPRING, compression, needle

GUIDE, fluid needle

9 106–781 NUT

4b

17

CAP

VE, fan adjusting

, packing, needle

PARTS LIST

REF

NO. P

10* 106–885 KIT

1

1

11 107–821

1

12* 187–550 PISTON 1

13 107–822 P

14 107–819

1

15 107–828

1

16* 107–829 KIT

17 107–823

1

18 107–826

19 100–172 BALL 1

1

1

20 BRUSH 1

1

21 110–765 WRENCH 1

1

24 106–780

2

*Recommended “tool box” replacement parts.

ART NO.

20

DESCRIPTION QTY

, packing, fluid needle;

(2) leather, (2) PTFE 1

SPRING, compression, air valve

ACKING, u-cup; buna-n

SPRING, compression, fluid adj.

O-RING; buna-n

, packing, needle; leather

SCREW SET

RING, retaining

SHIELD, tube

1

1

1

1

1

1

1

1

Page 11

ACCESSORIES

THROAT SEAL LIQUID (TSL) 206–995

1 quart (0.97 liter) non-evaporating lubricant for air and

fluid

packings.

WRENCH 179–764

Open-end

assembly

type wrench with openings for all required dis

and adjustments of this gun.

AIR PRESSURE REGULATOR 207–755

10–125 psi (1–9 bar) Regulated Pressure

npt(f) inlet and outlet

3/4

AIR PRESSURE GAUGE

101–180

0–200

psi (0–14 bar) Pressure Range

AIR PRESSURE VERIFICATION

KIT 224–133

For

use in checking air cap

pressures. Do not use the air cap for spraying.

Assemble the kit as shown in the drawing below. Install

the

air cap on the gun. T

ger

the gun and read the resulting air cap pressure.

The

air cap

the position (rotation) of the air cap on the gun, but with

on

15

psi (1.05 bar) inlet atomizing air pressure, the average

air

cap pressure will be 10 psi (0.7

is

+/– 2% over the middle half of the gauge scale, +/– 3%

over

pressure reading will vary slightly

the remainder of the gauge scale.

NOTE: To be “HVLP compliant”, the atomizing inlet air

pressure

must not exceed 15 psi (1.05 bar).

pressure at various gun inlet

urn on the air to the

gun, then trig

,depending

bar). Gauge accuracy

AIR FILTER & MOISTURE SEPARATOR

250

psi (17.5 bar) MAXIMUM WORKING PRESSURE

For cleaning and drying air in air spray system.

40 micron filtration

-

106–146

1/2 npt(f), with gauge

5–125 psi (0.35–9 bar)

pressure range, 4 oz. bowl

106–148

3/8 npt(f), without gauge,

5 oz. bowl

FILTER (AIR OR PAINT) 202–271

750

psi (52 bar) MAXIMUM WORKING PRESSURE

With 250 micron (60 mesh) element,

3/8 npt(f) inlet, 3/8 npt(m) outlet

FLUID REGULATOR

250

psi (18 bar) MAXIMUM WORKING PRESSURE

To reduce and regulate fluid pressure to one air spray

gun.

3/8 npsm(m) and 3/8 npt(f) fluid outlets

-

203–831 0–60

204–500 0–15

205–425 0–60

psi (0–4 bar)

pressure

psi (0–1 bar)

pressure

psi (0–4 bar)

pressure

range

range

range

(for viscous fluid)

FLUID NOZZLE/NEEDLE COMBINATIONS

Order

Part Number

1

2a

2c

2d

2e

2b

REF

NO. PART NO. DESCRIPTION QTY

1 186–789 AIR CAP

2 224–187 GUAGE ASSEMBLY;

Includes items 2a–2e

2a 108–294 CONNECTOR,

2b 054–177 TUBE,

(order by length needed)

2c 110–552 CONNECT

2d 104–192

2e 102–730

COUPLING, pipe, 1/8 npt(f)

GAUGE, 0 to 15 psi (0 to 1 bar)

pressure range

, tapped

tube

bulk

10 in.

OR, elbow; 1/8 npt(m)

Orifice

Type

0N/0N 0.032”

02N/02N 0.047”

03N/02N 0.055”

04N/04N 0.070”

Needles

and fluid nozzles are manufactured in matched,

should

be

fluid

nozzle.

ATOMIZING AIR HOSE ASSEMBLY

1

15

psi (1 bar) MAXIMUM WORKING PRESSURE

0.75

1

1

in. (19 mm) ID, 3/4–1

Male

x female swivel fittings, natural-color

223–263 15

1

1

223–265

Size

(0.8

mm)

(1.2 mm)

(1.4 mm)

(1.8 mm)

ordered as a kit to ensure perfect seating of the needle in the

ft (4.575 m) long

25 ft (7.625 m) long

Kit

224–581 187–271 599–599

224–582 187–272 107–801

224–583 187–273 107–801

224–584 187–274 107–802

1.5 NH (standard garden hose)

H.E.L.P. 1500 SYSTEM 223–293

See

1

Manual 308–057

Nozzle

Only

Needle

Only

lapped sets and

polyurethane

Page 12

TECHNICAL

PTFE

DA

TA

Weight 1.4

Maximum Working Fluid Pressure

Maximum Working Air Pressure

Maximum

Typical

Cylinder

.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. .

.

. . . . . .

Operating Air Pressure

Pattern Width

Air Inlet

.

. . . . . .

.

. . . . . . . . . . .

.

. .

10–1

1 in. (254–279 mm)

1/4-18 npsm (R1/4-19)

AIR

300 psi (21 bar)

100 psi (7 bar)

15 psi (1.05 bar)

CHARACTERISTICS CHART

GUN

INLET AIR PRESSURE (psi)

lb (0.64 kg)

Atomizing

Fluid

Inlet

Wetted

Parts

is a registered trademark of Du Pont Company

Loctite

is a registered trademark of Loctite Corporation.

Air Flow (scfm)

Cap Pressure (psi)

Horn Pressure (psi)

Air Inlet

.

. . . . . . . . . . . . . . . .

. . . . . .

NOTE:

air

pressure ranges are shown.

3/4-1

.

. . .

Stainless Steel,

The maximum and

flow

, cap pressure, and horn

1.5 NH (std. garden hose)

3/8–18 npsm (R3/8–19)

PTFE, Leather .

.

minimum

THE

GRACO W

WARRANTY

Graco

warrants all equipment manufactured by it and bearing its name to be free from defects in material and workmanship on the date

of

sale by an authorized Graco distributor to the original purchaser for use. As purchaser’s sole remedy for breach of this warranty

Graco

will, for a period of twelve months from the date of sale, repair or replace any part of the equipment proven defective. This war

applies only when the equipment is installed, operated and maintained in accordance with Graco’

ranty

This

warranty does not cover

plication,

component

structures,

maintenance

This

verification

equipment

in

transportation.

DISCLAIMERS AND LIMITATIONS

THE

OTHER WARRANTIES (EXPRESS OR IMPLIED), INCLUDING WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS

BASED

DAMAGES OR LOSS IS EXPRESSLY EXCLUDED AND DENIED. IN NO CASE SHALL GRACO’S LIABILITY EXCEED THE

AMOUNT OF THE PURCHASE PRICE. ANY ACTION FOR BREACH OF WARRANTY MUST BE BROUGHT WITHIN TWO (2)

YEARS OF THE DATE OF SALE.

EQUIPMENT NOT COVERED BY GRACO WARRANTY

GRACO

PURPOSE,

These

their

abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non–Graco

parts. Nor shall Graco be liable for malfunction,

accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

of structures, accessories, equipment or materials not supplied by Graco.

warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor and

will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

TERMS OF THIS W

FOR A PARTICULAR PURPOSE, AND OF ANY NON–CONTRACTUAL LIABILITIES, INCLUDING PRODUCT LIABILITIES,

ON NEGLIGENCE OR STRICT LIABILITY

MAKES NO W

WITH RESPECT T

items sold, but not manufactured by Graco (such as electric motor

manufacturer

ARRANTY

. Graco will provide purchaser with reasonable assistance in making any claim for breach of these warranties.

, and Graco shall not be liable for

ARRANTY CONSTITUTE PURCHASER’S SOLE AND EXCLUSIVE REMEDY AND ARE IN LIEU OF ANY

, AND DISCLAIMS ALL IMPLIED W

O ACCESSORIES, EQUIPMENT

ARRANTY AND DISCLAIMERS

, any malfunction, damage or wear caused by faulty installation, misap

damage or wear caused by the incompatibility with Graco equipment of

. EVER

Y FORM

, MA

OF LIABILITY FOR DIRECT

ARRANTIES OF MERCHANT

TERIALS, OR COMPONENTS SOLD BUT NOT MANUF

, switches, hose, etc.) are subject to the warranty

, SPECIAL OR CONSEQUENTIAL

ABILITY AND FITNESS FOR A P

s written recommendations.

ARTICULAR

ACTURED BY GRACO.

, if any, of

,

-

-

Factory

Branches:

Atlanta, Chicago, Dallas, Detroit, Los Angeles, W

Subsidiary and Affiliate Companies:

GRACO INC.P.O. BOX 1441

est Caldwell (N.J.)

Canada; England; Switzerland; France; Germany; Hong Kong; Japan;

Korea

PRINTED

MINNEAPOLIS, MN

IN U.S.A. 308–188 1

1/91

55440–1441

Loading...

Loading...