Page 1

Instructions-Parts

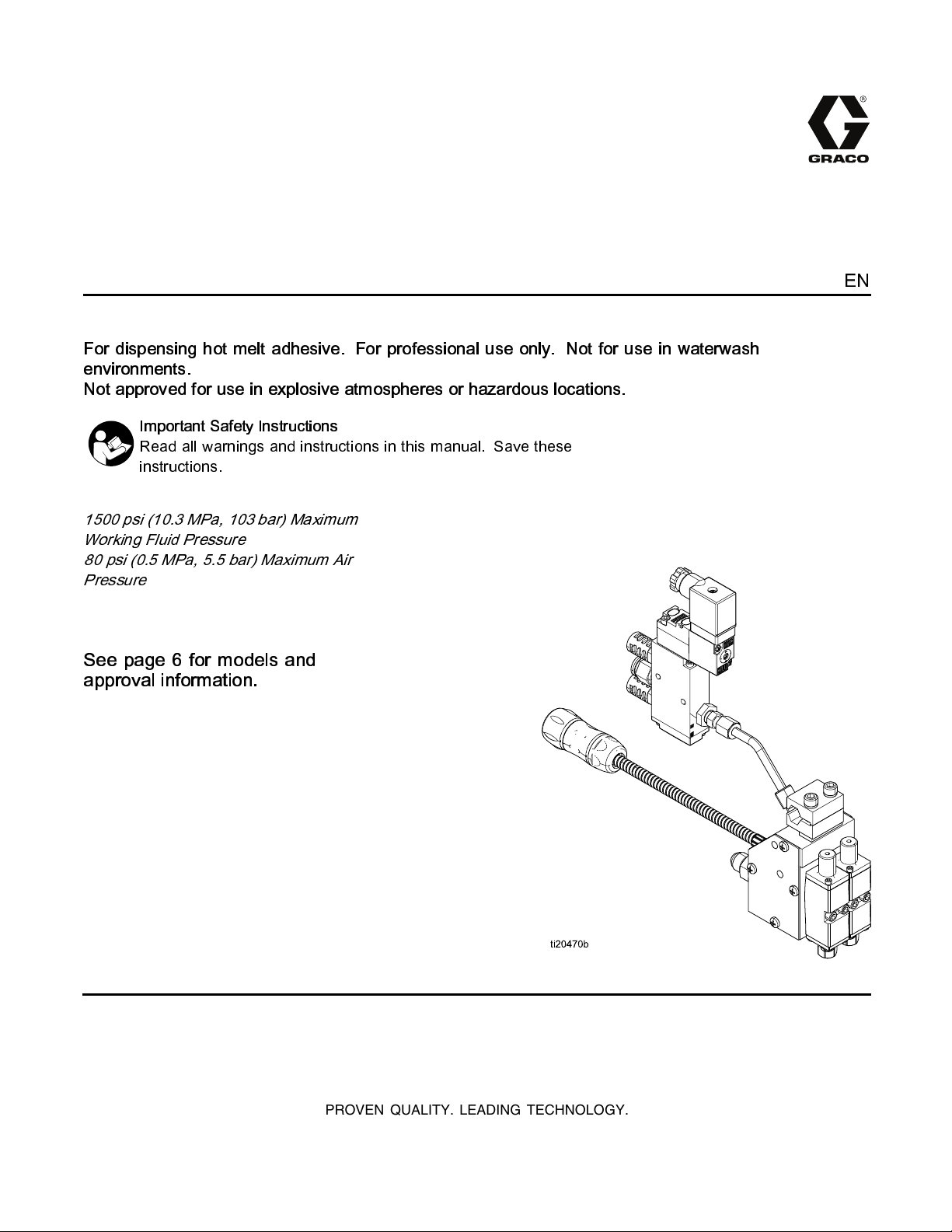

InvisiPac® GS35 Plug-Free™

Hot Melt Applicator

For dispensing hot melt adhesive. For professional use only. Not for use in waterwash

environments.

Not approved for use in explosive atmospheres or hazardous locations.

Important Safety Instructions

Read all warnings and instructions in this manual. Save these

instructions.

1500 psi (10.3 MPa, 103 bar) Maximum

Working Fluid Pressure

80 psi (0.5 MPa, 5.5 bar) Maximum Air

Pressure

See page 6 for models and

approval information.

3A2805K

EN

PROVEN QUALITY. LEADING TECHNOLOGY.

Page 2

Contents

Warnings ........................................................... 3

Approvals........................................................... 5

Models............................................................... 6

Component Identification..................................... 7

Overview............................................................ 8

Grounding.......................................................... 8

Installation.......................................................... 9

Mounting ..................................................... 9

Connect Heated Hose.................................. 9

Connect Solenoid Valve ............................... 9

Connect Triggering Device ........................... 10

Prime Before Using Equipment..................... 10

Flush........................................................... 11

Install Nozzle ............................................... 11

Select RTD.................................................. 11

Operation ........................................................... 12

Pressure Relief Procedure............................ 12

Maintenance ...................................................... 13

Replace Inlet Filter ....................................... 13

Filter Maintenance Guidelines....................... 13

Troubleshooting..................................................14

Check Module..............................................16

Check Nozzle and Module............................ 16

Check Heater .............................................. 17

Check RTD..................................................17

Check Thermal Cutoff .................................. 18

Repair................................................................ 19

Before Beginning Repair...............................19

Replace Heater Cartridge............................. 20

Replace RTD ............................................... 20

Replace Thermal Cutoff................................ 20

Replace Cordset.......................................... 22

Replace Solenoid Valve ............................... 24

Replace Module........................................... 24

Replace Applicator....................................... 24

Notes ................................................................ 25

Parts.................................................................. 26

Kits and Accessories...........................................44

Dimensions........................................................ 46

Technical Data...................................................50

Notes ................................................................ 51

Graco Extended Warranty ................................... 52

2

3A2805K

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The

exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific

risks. When these symbols appear in the body of this manual or on warning labels, refer back to these

Warnings. Product-specific hazard symbols and warnings not covered in this section may appear throughout

the body of this manual where applicable.

WARNING

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid

severe burns:

• Do not touch hot fluid or equipment.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can

cause electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before

servicing equipment.

• Connect only to grounded p ower source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes

and regulations.

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce

skin. This may look like just a cut, but it is a serious injury that can result in amputation.

immediate surgical treatment.

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

•Followthe

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

Pressure Relief Procedure

when you stop dispensing and before cleaning,

Get

3A2805K 3

Page 4

Warnings

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in

prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and

plastic drop cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn powe r or light switches on or off when flammable

fumes are present.

• Ground all equipment in the work area. See

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless

they are antistatic or conductive.

•

Stop operation immediately

equipment until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated

system component. See

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data

in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete

information about your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals

and create safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

if static sparking occurs or you feel a shock.Do not use

Technical Data

Pressure Relief Procedure

Grounding

in all equipment manuals.

work area

instructions.

canigniteorexplode.Tohelp

when equipment is not in use.

4

3A2805K

Page 5

Approvals

WARNING

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin,

inhaled, or swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable

guidelines.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury,

including eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective

equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent

manufacturer.

Approvals

4002346

Conforms to ANSI/UL Std.

499 Certified to CAN/CSA

Std. C22.2 No. 88

3A2805K 5

Page 6

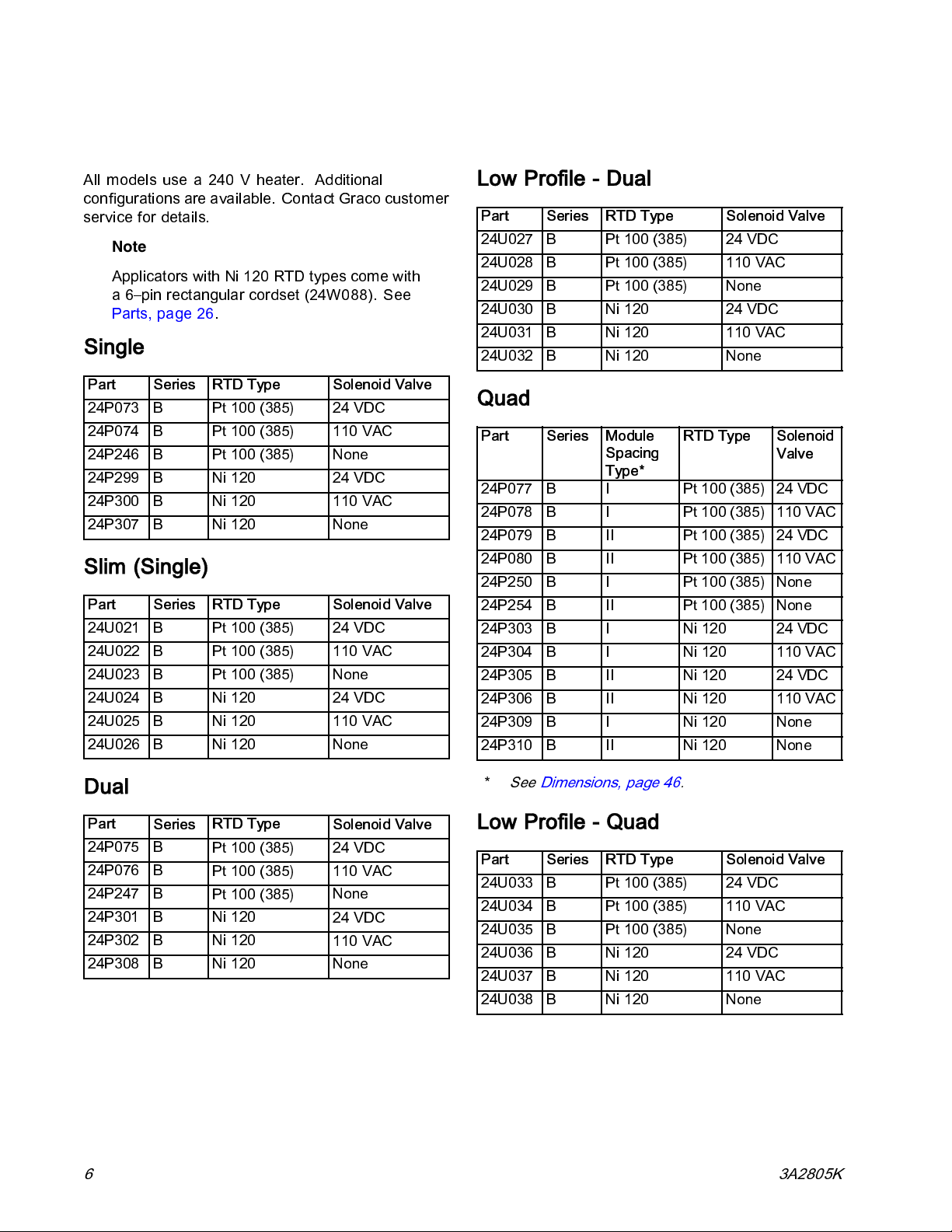

Models

Models

All models use a 240 V heater. Additional

configurations are available. Contact Graco customer

service for details.

Note

Applicators with Ni 120 RTD types come with

a 6–pin rectangular cordset (24W088). See

Parts, page 26.

Single

Part

24P073 B

24P074 B

24P246 B

24P299 B Ni 120

24P300 B Ni 120

24P307 B Ni 120 None

Series

RTD Type

Pt 100 (385) 24 VDC

Pt 100 (385) 110 VAC

Pt 100 (385)

Solenoid Valve

None

24 VDC

110 VAC

Slim (Single)

Part

24U021 B

24U022 B

24U023 B

24U024 B Ni 120

24U025 B Ni 120

24U026 B Ni 120 None

Series

RTD Type

Pt 100 (385) 24 VDC

Pt 100 (385) 110 VAC

Pt 100 (385)

Solenoid Valve

None

24 VDC

110 VAC

Low Profile - Dual

Part

24U027 B

24U028 B

24U029 B

24U030 B Ni 120

24U031 B Ni 120

24U032 B Ni 120 None

Series

RTD Type

Pt 100 (385) 24 VDC

Pt 100 (385) 110 VAC

Pt 100 (385)

Solenoid Valve

None

24 VDC

110 VAC

Quad

Part

24P077 B I

24P078 B I

24P079 B II

24P080 B II

24P250 B I

24P254 B II

24P303 B I Ni 120

24P304 B I Ni 120

24P305 B II Ni 120

24P306 B II Ni 120

24P309 B I Ni 120 None

24P310 B II Ni 120 None

Series

Module

Spacing

Type*

RTD Type

Pt 100 (385) 24 VDC

Pt 100 (385) 110 VAC

Pt 100 (385) 24 VDC

Pt 100 (385) 110 VAC

Pt 100 (385)

Pt 100 (385)

Solenoid

Valve

None

None

24 VDC

110 VAC

24 VDC

110 VAC

*

Dual

Part

24P075 B

24P076 B

24P247 B

24P301 B Ni 120

24P302 B Ni 120

24P308 B Ni 120 None

Series

RTD Type

Pt 100 (385) 24 VDC

Pt 100 (385) 110 VAC

Pt 100 (385)

Solenoid Valve

None

24 VDC

110 VAC

See Dimensions, page 46.

Low Profile - Quad

Part Series RTD Type Solenoid Valve

24U033 B Pt 100 (385) 24 VDC

24U034 B Pt 100 (385) 110 VAC

24U035 B Pt 100 (385) None

24U036 B Ni 120 24 VDC

24U037 B Ni 120 110 VAC

24U038 B Ni 120 None

6 3A2805K

Page 7

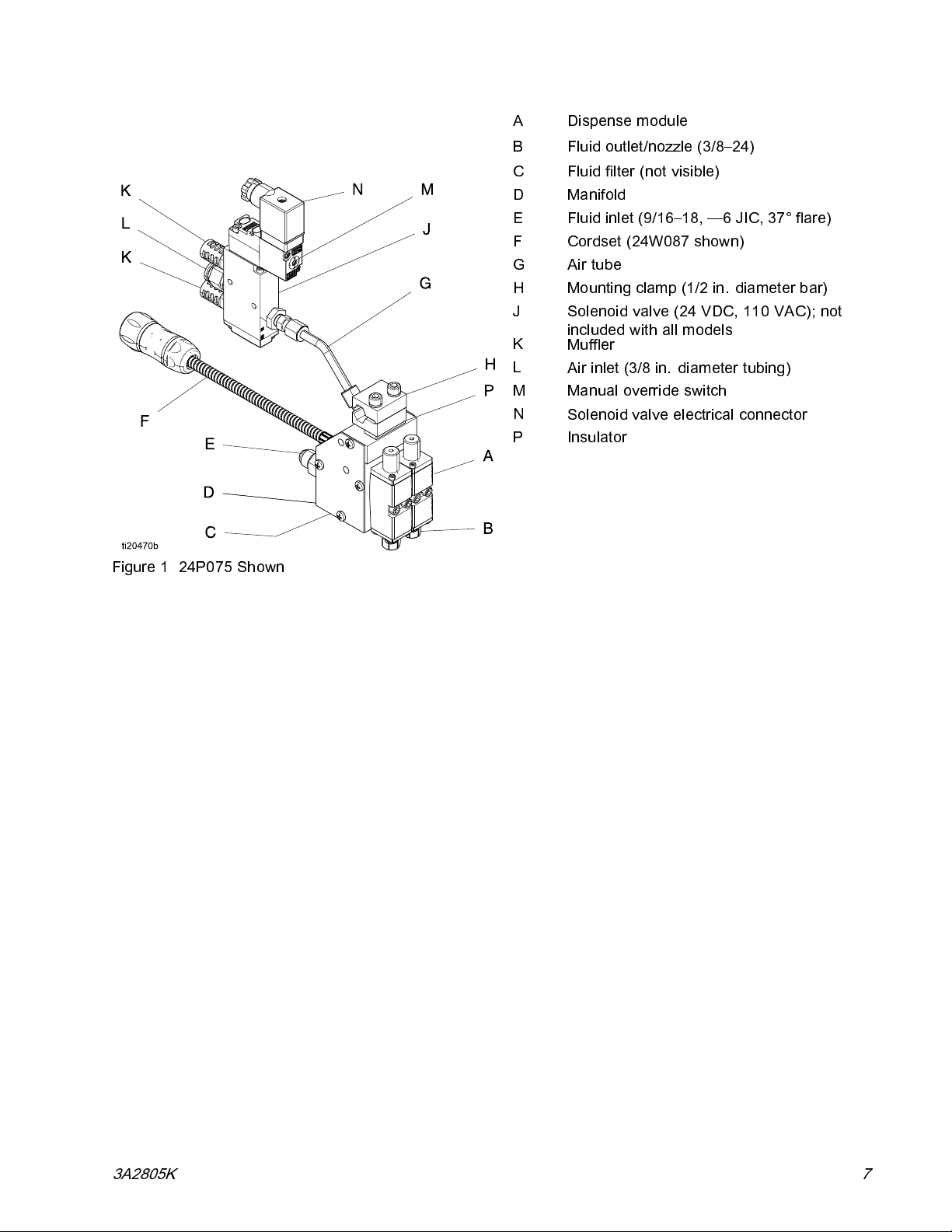

Component Identification

Component Identification

Figure 1 24P075 Shown

A Dispense module

B

C Fluid filter (not visible)

D

E

F

G

H

J

K

L

M Manual override switch

N

P Insulator

Fluid outlet/nozzle (3/8–24)

Manifold

Fluid inlet (9/16–18, —6 JIC, 37° flare)

Cordset (24W087 shown)

Air tube

Mounting clamp (1/2 in. diameter bar)

Solenoid valve (24 VDC, 110 VAC); not

included with all models

Muffler

Air inlet (3/8 in. diameter tubing)

Solenoid valve electrical connector

3A2805K

7

Page 8

Overview

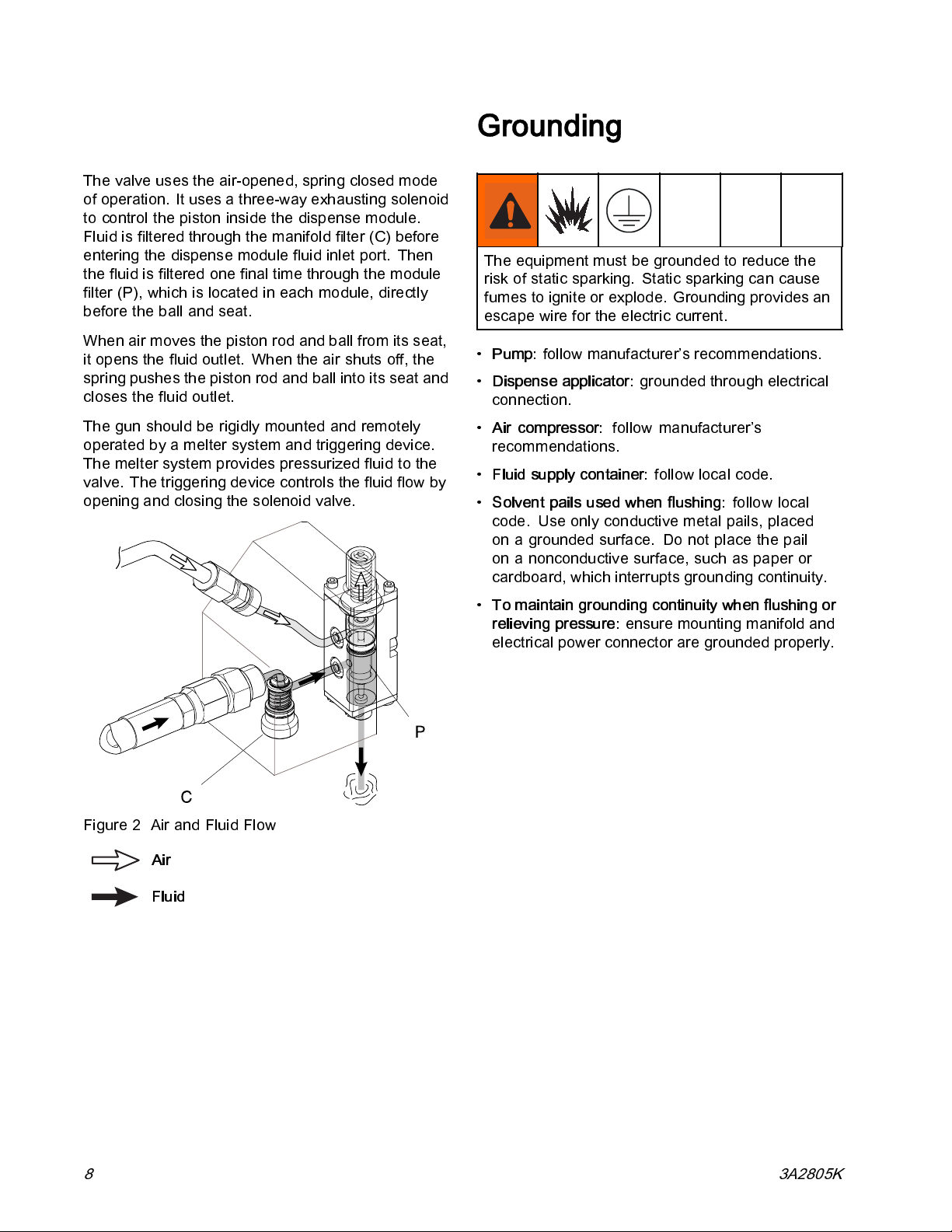

Overview

The valve uses the air-opened, spring closed mode

of operation. It uses a three-way exhausting solenoid

to control the piston inside the dispense module.

Fluid is filtered through the manifold filter (C) before

entering the dispense module fluid inlet port. Then

the fluid is filtered one final time t hrough the module

filter (P), which is located in each module, directly

before the ball and seat.

When air moves the piston rod and ball from its seat,

it opens the fluid outlet. When the air shuts off, the

spring pushes the piston rod and ball into its seat and

closes the fluid outlet.

The gun should be rigidly mounted and remotely

operated by a melter system and triggering device.

The melter system provides pressurized fluid to the

valve. The triggering device controls the fluid flow by

opening and closing the solenoid valve.

Grounding

The equipment must be grounded to reduce the

risk of static sparking. Static sparking can cause

fumes to ignite or explode. Grounding provides an

escape wire for the electric current.

•

Pump:

•

Dispense applicator:

connection.

•

Air compressor:

recommendations.

•

Fluid supply container:

•

Solvent pails used when flushing:

code. Use only conductive metal pails, placed

onagroundedsurface. Donotplacethepail

on a nonconductive surface, such as paper or

cardboard, which interrupts grounding continuity.

follow manufacturer’s recommendations.

grounded through electrical

follow manufacturer’s

follow local code.

follow local

Figure 2 Air and Fluid Flow

Air

Fluid

•

To maintain grounding continuity when flushing or

relieving pressure:

electrical power connector are grounded properly.

ensure mounting manifold and

8 3A2805K

Page 9

Installation

Installation

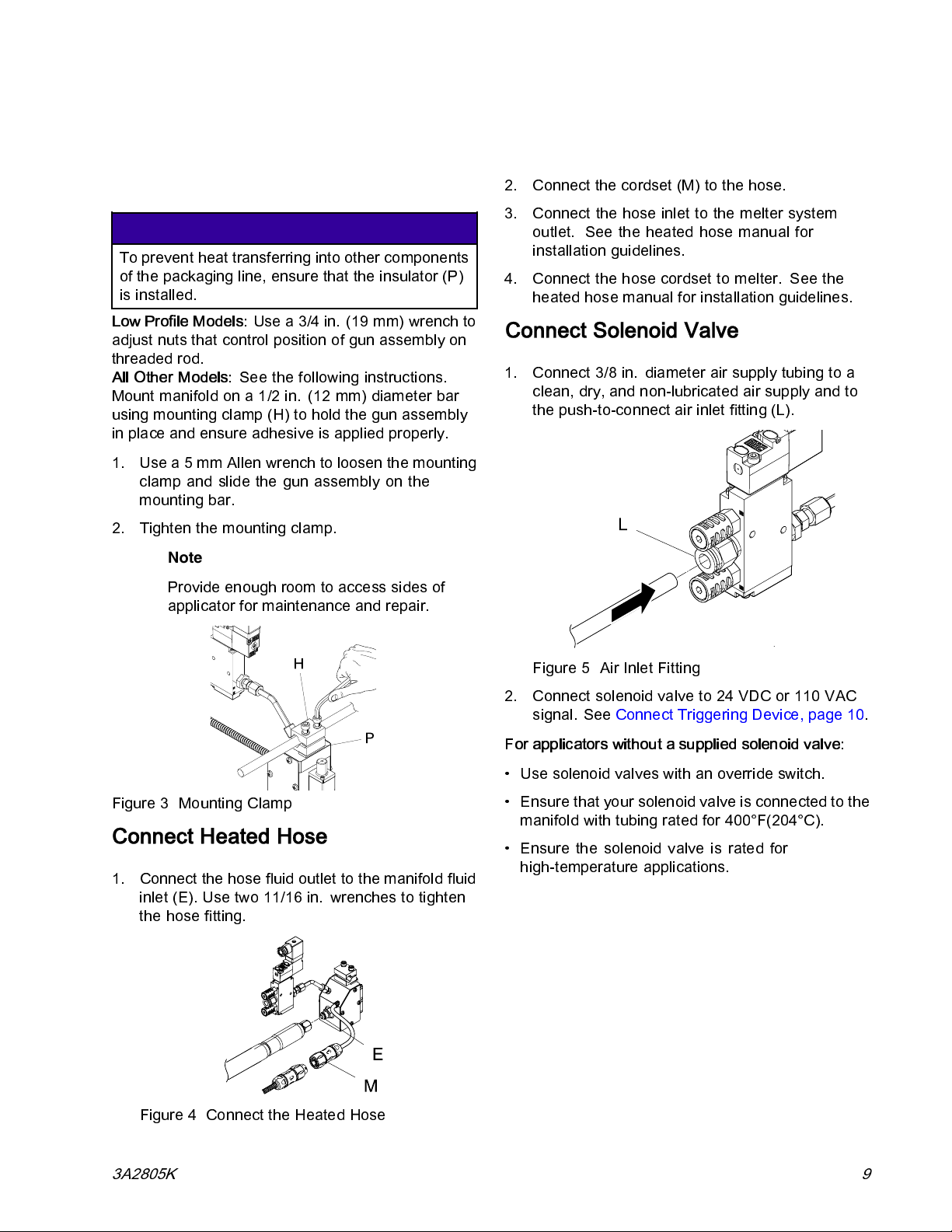

Mounting

NOTICE

To prevent heat transferring into other components

of the packaging line, ensure that the insulator (P)

is installed.

Low Profile Models:

adjust nuts that control position of gun assembly on

threaded rod.

All Other Models:

Mount manifold on a 1/2 in. (12 mm) diameter bar

using mounting clamp (H) to hold the gun assembly

in place and ensure adhesive is applied properly.

1. Use a 5 mm Allen wrench to loosen the mounting

clamp and slide the gun assembly on the

mounting bar.

2. Tighten the mounting clamp.

Note

Provide enough room to access sides of

applicator for maintenance and repair.

Usea3/4in.(19mm)wrenchto

See the following instructions.

2. Connect the cordset (M) to the hose.

3. Connect the hose inlet to the melter system

outlet. See the heated hose manual for

installation guidelines.

4. Connect the hose cordset to melter. See the

heated hose manual for installation guidelines.

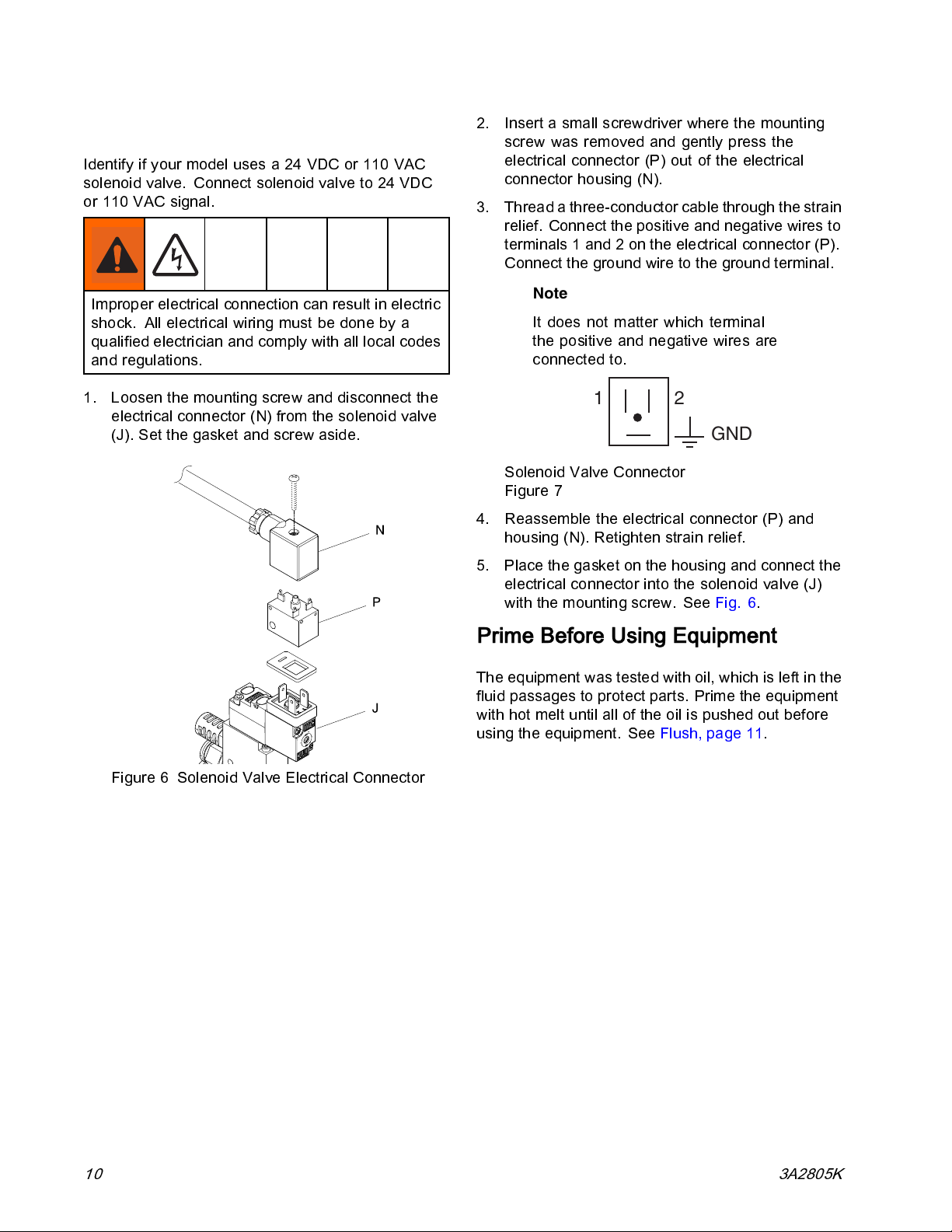

Connect Solenoid Valve

1. Connect 3/8 in. diameter air suppl y tubing to a

clean, dry, and non-lubricated air supply and to

the push-to-connect air inlet fitting (L).

Figure 3 Mounting Clamp

Connect Heated Hose

1. Connect the hose fluid outlet to the manifold fluid

inlet (E). Use two 11/16 in. wrenches to tighten

the hose fitting.

Figure 4 Connect the Heated Hose

Figure 5 Air Inlet Fitting

2. Connect solenoid valve to 24 VDC or 110 VAC

signal. See Connect Triggering Devi ce, page 10.

For applicators without a supplied solenoid valve:

• Use solenoid valves with an override switch.

• Ensure that your solenoid valve is connected to the

manifold with tubing rated for 400°F(204°C).

• Ensure the solenoid valve is rated for

high-temperature applications.

3A2805K 9

Page 10

Installation

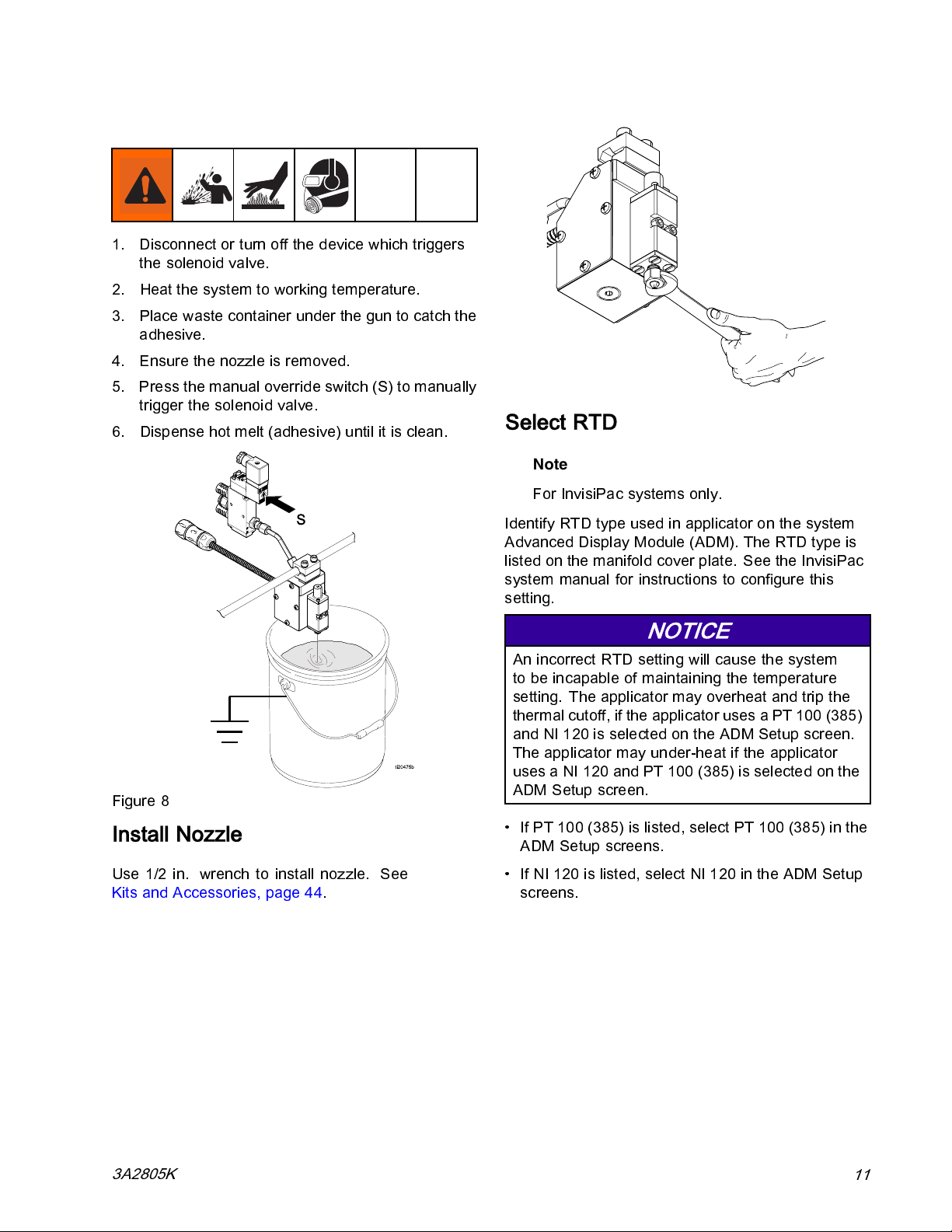

Connect Triggering Device

Identify if your model uses a 24 VDC or 110 VAC

solenoid valve. Connect solenoid valve to 24 VDC

or 110 VAC signal.

Improper electrical connection can result in electric

shock. All electrical wiring must be done by a

qualified electrician and comply with all local codes

and regulations.

1. Loosen the mounting screw and disconnect the

electrical connector (N) from the solenoid valve

(J). Set the gasket and screw aside.

2. Insert a small screwdriver where the mounting

screw was removed and gently press the

electrical connector (P) out of the electrical

connector housing (N).

3. Thread a three-conductorcable through the strain

relief. Connect the positive and negative wires to

terminals 1 and 2 on the electrical connector (P).

Connect the ground wire to the ground terminal.

Note

It does not matter which terminal

the positive and negative wires are

connected to.

21

GND

Solenoid Valve Connector

Figure 7

4. Reassemble the electrical connector (P) and

housing (N). Retighten strain relief.

5. Place the gasket on the housing and connect the

electrical connector into the solenoid valve (J)

with the mounting screw. See Fig. 6.

Figure 6 Solenoid Valve Electrical Connector

Prime Before Using Equipment

The equipment was tested with oil, which is left in the

fluid passages to protect parts. Prime the equipment

with hot melt until all of the oil is pus hed out before

using the equipment. See Flush, page 11.

10 3A2805K

Page 11

Flush

1. Disconnect or turn off the device which triggers

the solenoid valve.

2. Heat the system to working temperature.

3. Place waste container under the gun to catch the

adhesive.

4. Ensure the nozzle is removed.

5. Press the manual override switch (S) to manually

trigger the solenoid valve.

6. Dispense hot melt (adhesive) until it is clean.

Installation

Select RTD

Note

For InvisiPac systems only.

Figure 8

Install Nozzle

Use 1/2 in. wrench to install nozzle. See

Kits and Accessories, page 44.

Identify RTD type used in applicator on the system

Advanced Display Module (ADM). The RTD type is

listed on the manifold cover plate. See the InvisiPac

system manual for instructions to configure this

setting.

NOTICE

An incorrect RTD setting will cause the system

to be incapable of maintaining the temperature

setting. The applicator may overheat and trip the

thermal cutoff, if the applicator uses a PT 100 (385)

and NI 120 is selected on the ADM Setup screen.

The applicator may under-heat if the applicator

uses a NI 120 and PT 100 (385) is selected on the

ADM Setup screen.

• If PT 100 (385) is listed, select PT 100 (385) in the

ADM Setup screens.

• If NI 120 is listed, select NI 120 in the ADM Setup

screens.

3A2805K

11

Page 12

Operation

Operation

Pressure Relief Procedure

Follow the Pressure Relief Procedure

whenever you see this symbol.

This equipment stays pressurized until pressure

is manually relieved. To help prevent serious

injury from pressurized fluid, such as skin injection,

and splashing fluid, follow the Pressure Relief

Procedure when you stop spraying and before

cleaning, checking, or servicing the equipment.

1. Depressurize system.

2. Close the bleed-type master air valve.

3. Actuate the applicator repeatedly until no fluid

flows.

Material inside the module and hose may still

be near setpoint temperature. Wear protective

clothing to avoid severe burns.

4. If you suspect the module nozzle is clogged,

remove nozzle and then actuate the module to

relieve pressure.

5. If you suspect the module or fluid hose is

clogged or that pressure has not been fully

relieved after following the steps above, VERY

SLOWLY loosen inlet fitting, inlet filter, or hose

end coupling to relieve pressure gradually,

then loosen completely. Clear hose or module

obstruction.

6. Turn off air pressure to the solenoid valve.

12

3A2805K

Page 13

Maintenance

Material inside the applicator can be near setpoint

temperature. Wear protective clothing to avoid

severe burns.

Daily:

Clean hot melt from exterior of gun.

Weekly:

Inspect the applicator, fluid lines, cordset,

and solenoid cable for wear or damage. See

Repair, page 19 for instructions.

Replace Inlet Filter

Maintenance

NOTICE

Remove the filter when the gun is hot. If the gun is

cold, the adhesive will be hard and the filter may

be difficult to remove or damaged.

1. Disable gun assembly. See

Before Beginning Repair, page 19.

Material inside the applicator can be near

setpoint temperature. Wear protective clothing

to avoid severe burns.

2. Remove dirty filter (16) from manifold (1).

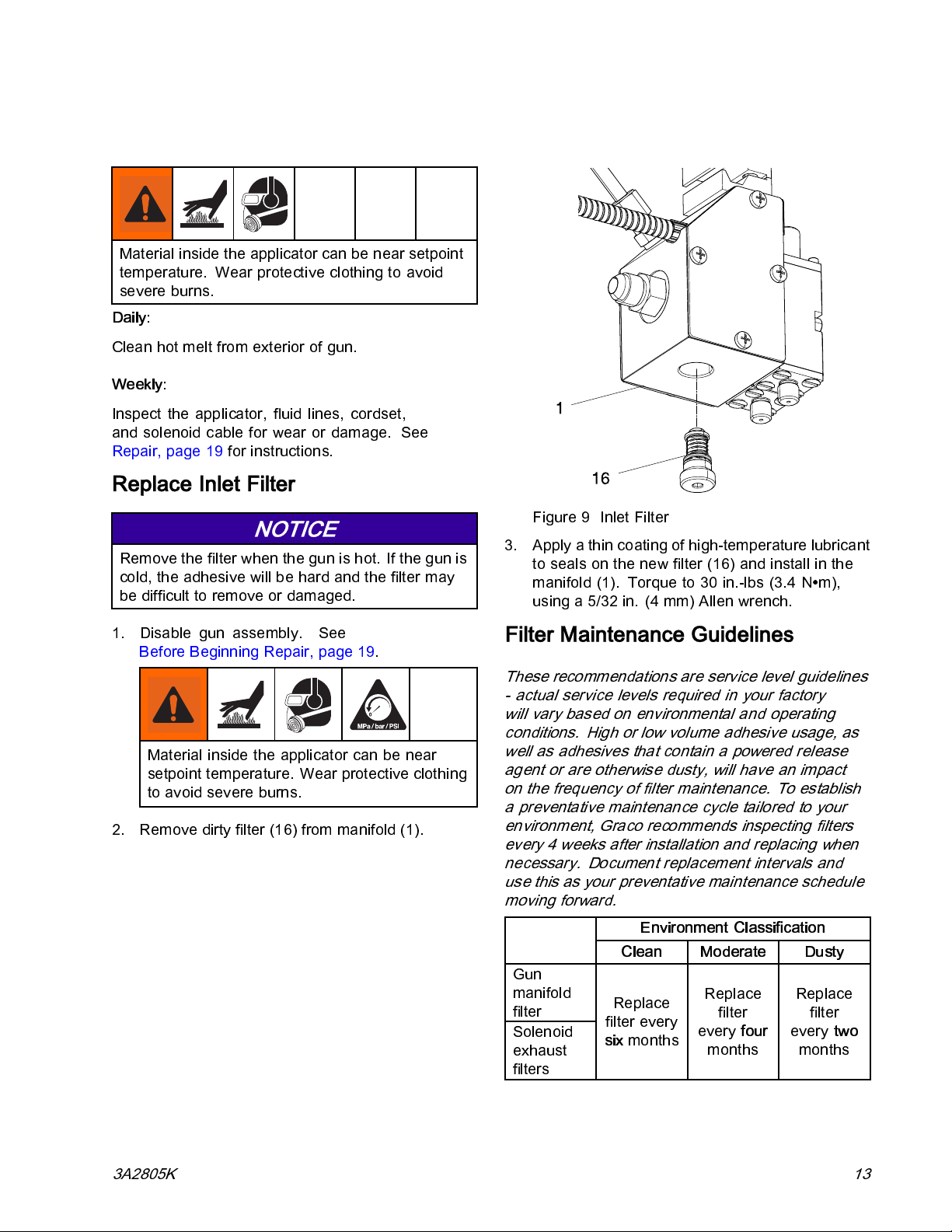

Figure 9 Inlet Filter

3. Apply a thin coating of high-temperature lubricant

to seals on the new filter (16) and install in the

manifold (1). Torque to 30 in.-lbs (3.4 N∙m),

using a 5/32 in. (4 mm) Allen wrench.

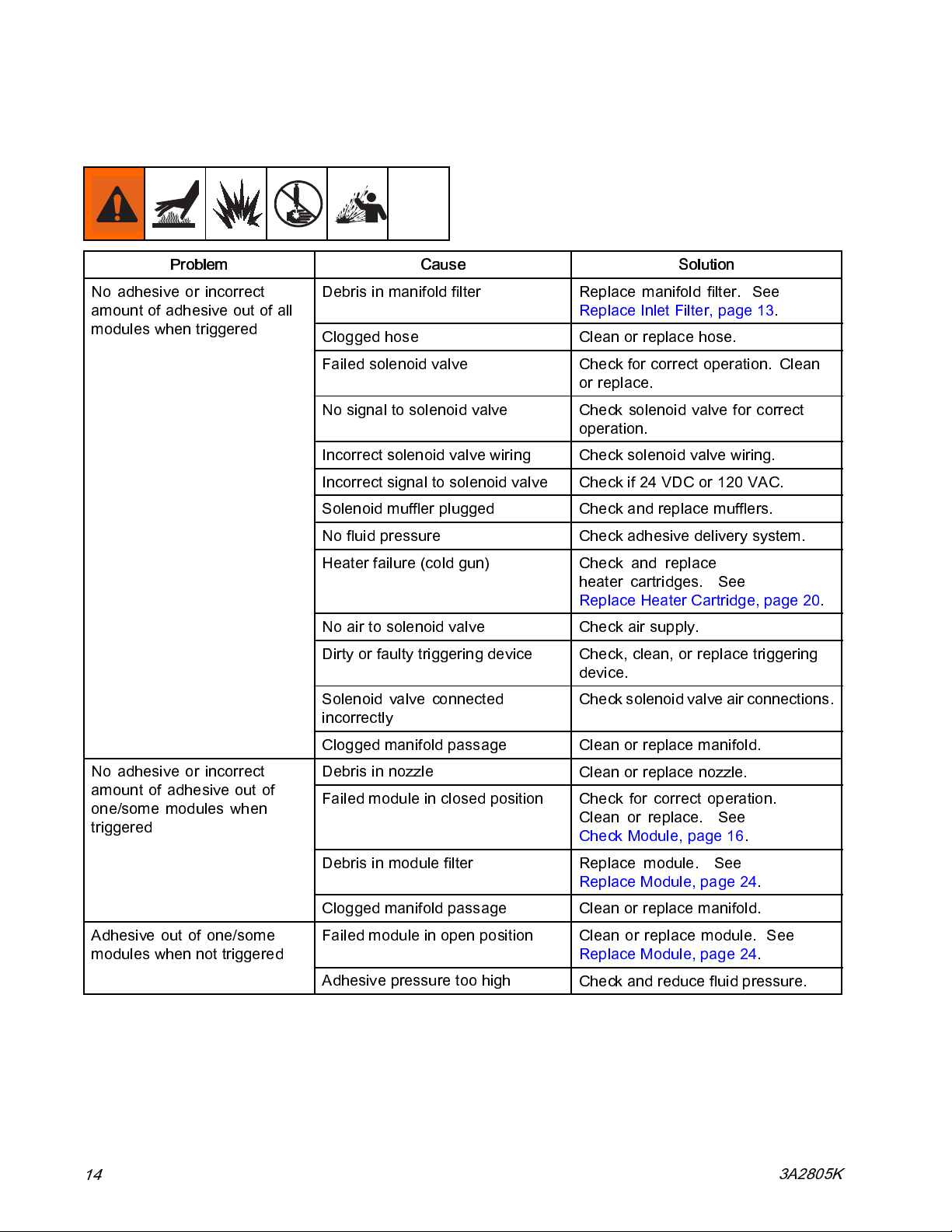

Filter Maintenance Guidelines

These recommendations are service level guidelines

- actual service levels required in your factory

will vary based on environmental and operating

conditions. High or low volume adhesive usage, as

well as adhesives that contain a powered release

agent or are otherwise dusty, will have an impact

on the frequency of filter maintenance. To establish

a preventative maintenance cycle tailored to your

environment, Graco recommends inspecting filters

every 4 weeks after installation and replacing when

necessary. Document replacement intervals and

use this as your preventative maintenance schedule

moving forward.

Environment Classification

Moderate Dusty

Replace

filter

every

months

four

Replace

filter

every

months

two

Gun

manifold

filter

Solenoid

exhaust

filters

Clean

Replace

filter every

six

months

3A2805K 13

Page 14

Troubleshooting

Troubleshooting

Problem Cause Solution

No adhesive or incorrect

amount of adhesive out of all

modules when triggered

Debris in manifold filter Replace manifold filter. See

Replace Inlet Filter, page 13.

Clogged hose Clean or replace hose.

Failed solenoid valve Check for correct operation. Clean

or replace.

No signal to solenoid valve

Incorrect solenoid valve wiring

Incorrect signal to solenoid valve

Solenoid muffler plugged Check and replace mufflers.

No fluid pressure Check adhesive delivery system.

Heater failure (cold gun) Check and replace

No air to solenoid valve

Dirty or faulty triggering device Check, clean, or replace triggering

Solenoid valve connected

incorrectly

Check solenoid valve for correct

operation.

Check solenoid valve wiring.

Check if 24 VDC or 120 VAC.

heater cartridges. See

Replace Heater Cartridge, page 20.

Check air supply.

device.

Check solenoid valve air connections.

No adhesive or incorrect

amount of adhesive out of

one/some modules when

triggered

Adhesive out of one/some

modules when not triggered

14

Clogged manifold passage Clean or replace manifold.

Debris in nozzle

Failed module in closed position Check for correct operation.

Debris in module filter Replace module. See

Clogged manifold passage Clean or replace manifold.

Failed module in open position

Adhesive pressure too high

Clean or replace nozzle.

Clean or replace. See

Check Module, page 16.

Replace Module, page 24.

Clean or replace module. See

Replace Module, page 24.

Check and reduce fluid pressure.

3A2805K

Page 15

Troubleshooting

Problem

Gun will not heat

Gun overheats

Cause Solution

Heater failure Check and replace

heater cartridge. See

Replace Heater Cartridge, page 20.

Loose cord set connection

RTD failure Check and replace RTD. See

Incorrect RTD for adhesive delivery

system

Thermal cutoff failure Check and replace

Wrong RTD type selected

Heater failure Check and replace

RTD failure Check and replace RTD. See

Incorrect RTD for adhesive delivery

system

Check connection.

Check RTD, page 17.

Check delivery system RTD

requirement

thermal cutoff. See

Replace Thermal Cutoff, page 20.

Check RTD type settings on the

system. Change if necessary. See

Select RTD, page 11.

heater cartridge. See

Replace Heater Cartridge, page 20.

Check RTD, page 17.

Check delivery system RTD

requirement.

Gun under-heats

Adhesive leaking from gun

Incorrect power to heater

Wrong RTD type selected Check RTD type settings on the

Heater failure Check and replace

RTD failure Check and replace RTD.

Incorrect RTD for adhesive delivery

system

Incorrect power to heater

Wrong RTD type selected

Module o-ring failure Check and replace o-ring. See

Inlet fitting loose Tighten fitting.

Manifold filter o-ring failure Check and replace o-ring.

Nozzle loose Tighten nozzle.

Module seal failure Check and replace module. See

Check and correct power.

system. Change if necessary. See

Select RTD, page 11.

heater cartridge. See

Replace Heater Cartridge, page 20

Check delivery system RTD

requirement.

Check and correct power.

Check RTD type settings on the

system. Change if necessary. See

Select RTD, page 11.

Replace Module, page 24.

Check Module, page 16.

3A2805K 15

Page 16

Troubleshooting

Problem

Adhesive out of all modules

when not triggered

Solenoid valve failure Check and replace solenoid valve.

Adhesive pressure too high

Solenoid valve connected

incorrectly

Module failure Check and replace all modules. See

Cause Solution

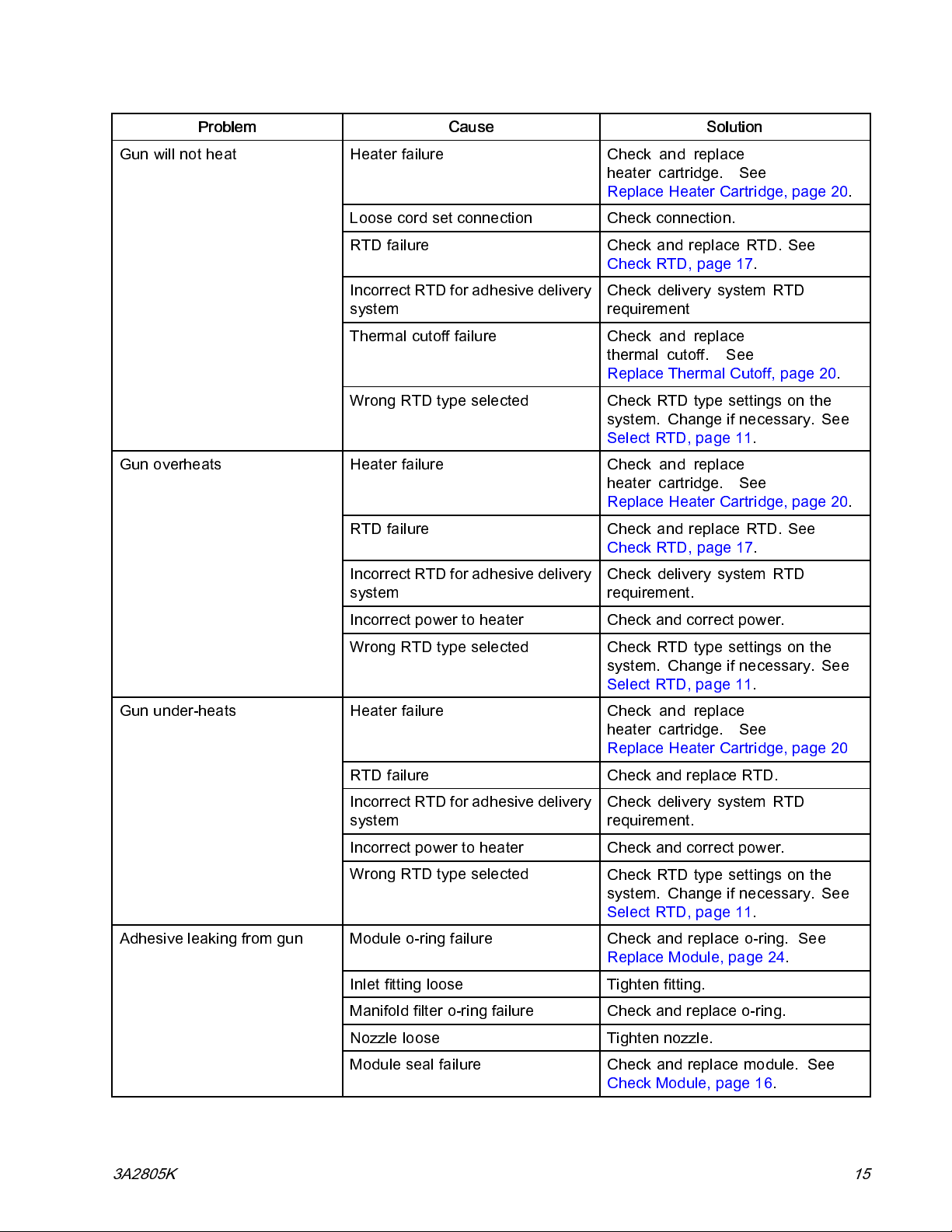

Check Module

Check the module operation to verify if the m odule

has failed and needs to be replaced.

1. InsertasmallAllenwrenchintothetopofthe

module.

2. Press the solenoid valve override switch (S ) to

manually trigger the gun.

Check and reduce fluid pressure.

Check solenoid valve air connections.

Check Module, page 16.

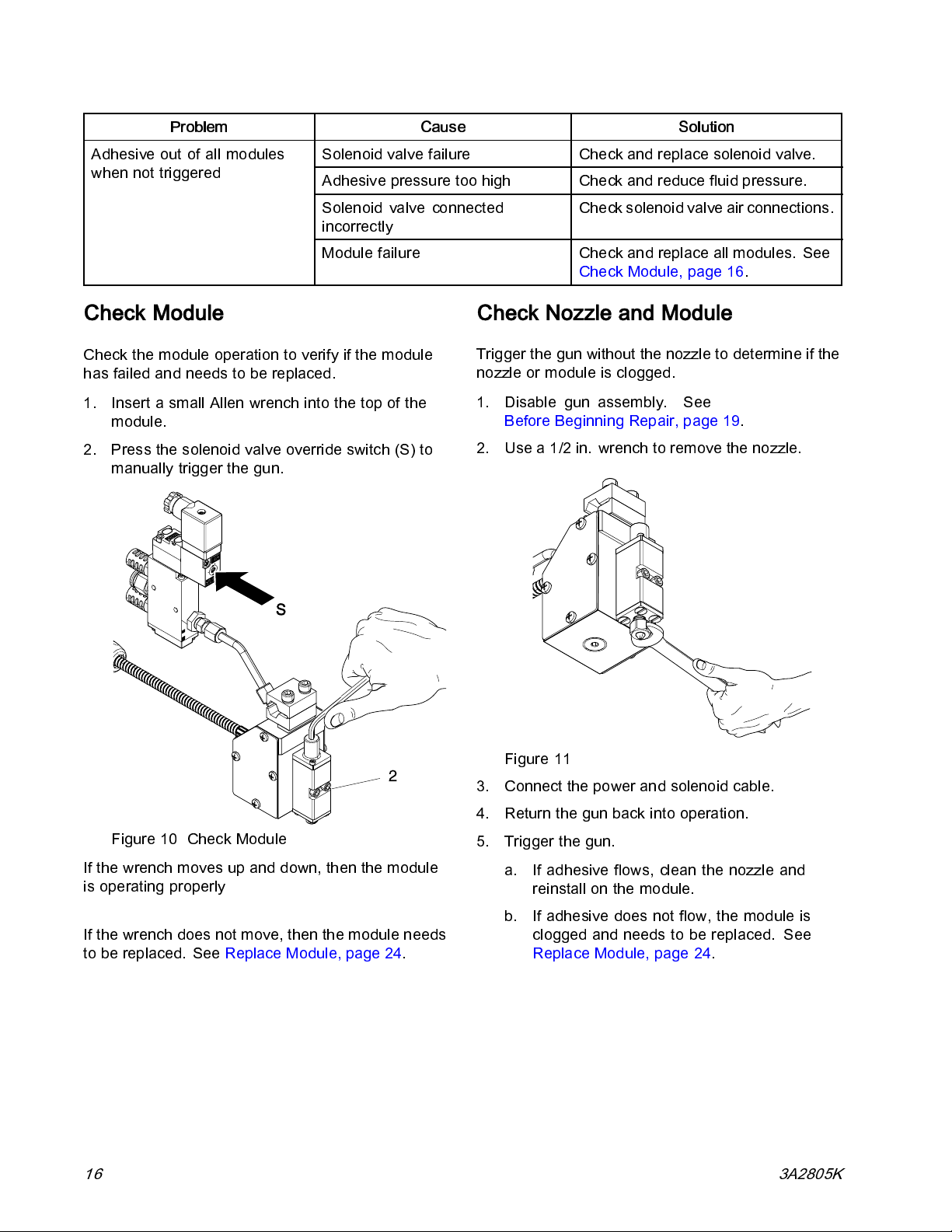

Check Nozzle and Module

Trigger the gun without the nozzle to determine if the

nozzle or module is clogged.

1. Disable gun assembly. See

Before Beginning Repair, page 19.

2. Usea1/2in.wrenchtoremovethenozzle.

Figure 11

3. Connect the power and solenoid cable.

4. Return the gun back into operation.

Figure 10 Check Module

If the wrench moves up and down, then the module

is operating properly

If the wrench does not move, then the module needs

to be replaced. See Repl ace Module, page 24.

16 3A2805K

5. Trigger the gun.

a. If adhesive flows, clean the nozzle and

reinstall on the mo dule.

b. If adhesive does not flow, the module is

clogged and needs to be replaced. See

Replace Module, page 24.

Page 17

Troubleshooting

Check Heater

Check the continuity of the heater to verify proper

resistance. If there is no continuity, the heater

may have failed and need to be replaced. See

Wiring Diagram, page 21, and parts illustrations.

1. Disable gun assembly. See

Before Beginning Repair, page 19.

2. Check resistance of the heater using a multimeter

between the pins of the cordset connector. See

connectors illustrations in cordset pin tables.

• If there is no continuity measure resistance of

the heater at the butt splice terminals (52b).

• If the resistance is outside the range listed

below replace the heater cartridge. See

Replace Heater Cartridge, page 20.

Cordset Check

Pins

24W087,

Pt 100

(385) RTD

Cordset

24W088,

Ni 120

RTD

Cordset

A and C

1 and 2

Gun Model Resis-

tance

Values

24U021–24U0

26

24U027–24U-

032

All other

models

24U021–24U0

26

24U027–24U-

032

All other

models

260–280

ohms

130–140

ohms

260–280

ohms

130–140

ohms

Table 1 24W087, Pt 100 (385) RTD Cordset

Pin Description

A

B

C

D

E

Table 2 24W088, Ni 120 RTD Cordset

Pin Description

1

2Heat-

3

5

G Ground

Thermal Cutoff

Ground

Heat -

RTD (White)

RTD (Red)

Thermal Cutoff

RTD (White)

RTD (Red)

Check RTD

Check the continuity of the RTD to verify proper

resistance. If there is no continuity, the RTD has

failed and needs to be replaced.

1. Disable gun assembly. See

Before Beginning Repair, page 19.

2. Check resistance of the RTD using a multimeter

between the pins of the cordset connector. See

connectors illustrations in cordset pin tables.

Cordset Check Pins

Resistance

Values

At Room

Temperature

70–72°F

(21–22°C)

3A2805K

24W087, Pt

100 (385)

RTD Cordset

24W088, Ni

120 RTD

Cordset

3. Replace the RTD if the resistance reading is

outside the range, or if there is no continuity. See

Replace RTD, page 20.

D and E 107-115

ohms

3 and 5 130-140

ohms

17

Page 18

Troubleshooting

Check Thermal Cutoff

If working properly, the cutoff will trip at 450°F

(232°C) and resets at 370°F (187°C). If failure is

suspected, allow gun to cool and then check the

continuity of the thermal cutoff to verify it has not

failed. If there is no continuity, the cutoff has failed

andneedstobereplaced.

1. Disable gun assembly. See

Before Beginning Repair, page 19.

2. Remove cover plate.

3. Check for continuity using a multimeter between

pin of cordset connector and the wires from the

thermal cutoff that connects to the heater lead.

Cordset Check Pins

24W087, Pt 100 (385)

RTD Cordset

A

Thermal Cutoff

WLD

24W088, Ni 120 RTD

Cordset

1

18 3A2805K

Page 19

Repair

Required Tools

• Phillips screw driver

•Flatbladescrewdriver

• 5/64in(2mm)and5/32in.(4mm)Allenwrenches

• 1/2 in. and 7/16 in. wrenches

• Torque wrench

• Waste container

• High-temperature anaerobic thread sealant (110110)

• High-temperature lubricant (24T156)

• Anti-sieze (24T179)

• Crimp tool (24W086)

Repair

Before Beginning Repair

1. Turn off the melter system. See melter manual

for shutdown instructions.

2. Relieve pressure. See

Pressure Relief Procedure, page 12.

3. Disconnect the cordset from the heated hose.

4. Loosen the mounting screw and disconnect the

solenoid valve power connector (N) from the

solenoid valve (J).

Figure 13 Disconnect Solenoid Valve Power

Connector

Figure 12 Disconnect Cordset

3A2805K 19

Page 20

Repair

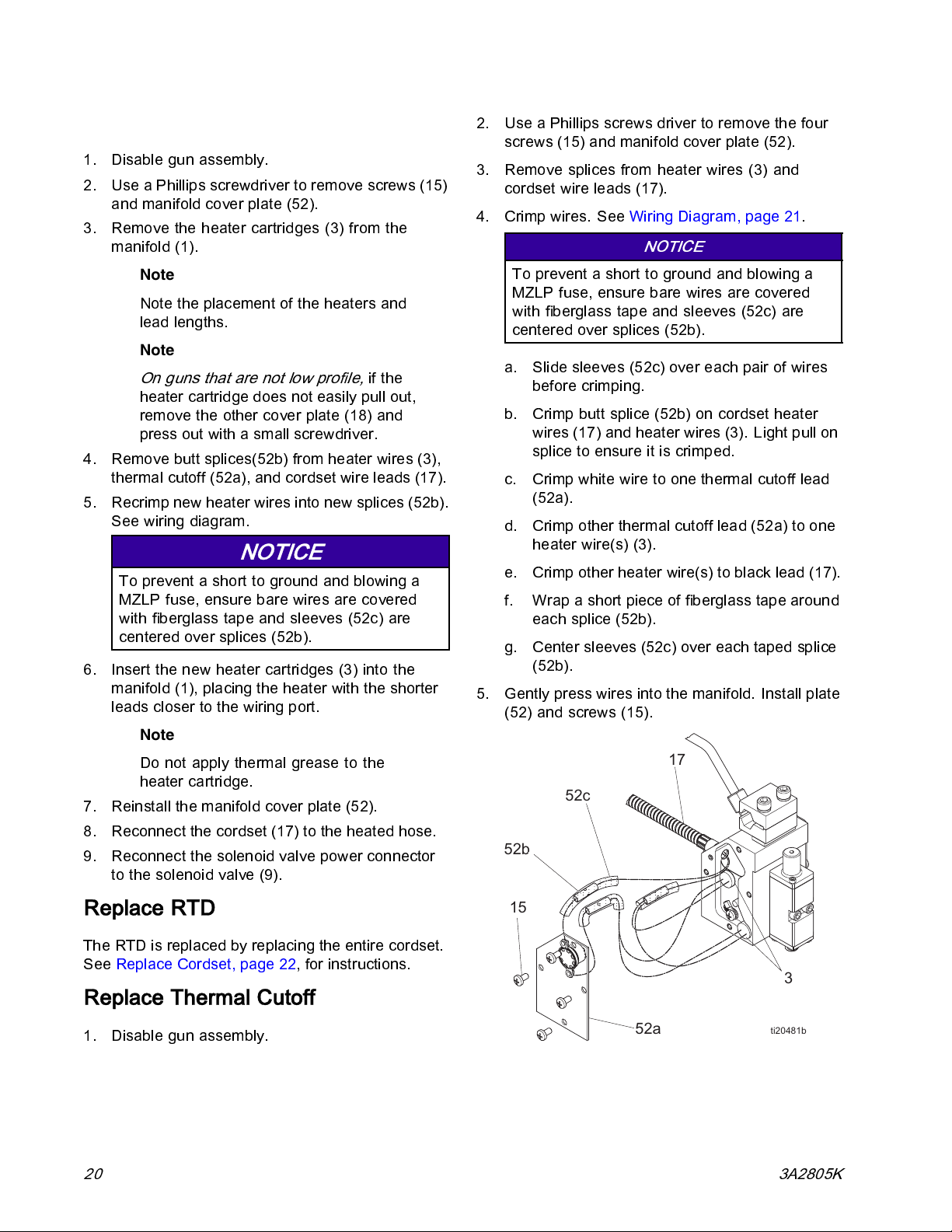

Replace Heater Cartridge

1. Disable gun assembly.

2. Use a Phillips screwdriver to remove screws (15)

and manifold cover plate (52).

3. Remove the heater cartridges (3) from the

manifold (1).

Note

Note the placement of the heaters and

lead lengths.

Note

On guns that are not low profile,

heater cartridge does not easily pull out,

remove the other cover plate (18) and

press out with a small screwdriver.

4. Remove butt splices(52b ) from heater wires (3),

thermal cutoff (52a), and cordset wire leads (17).

5. Recrimp new heater wires into new splices (52b).

See wiring diagram.

if the

NOTICE

To prevent a short to ground and bl owing a

MZLP fuse, ensure bare wires are covered

with fiberglass tape and sleeves (52c) are

centered over splices (52b).

6. Insert the new heater cartridges (3) into the

manifold (1), placing the heater with the shorter

leads closer to the wiring port.

Note

Do not apply thermal grease to the

heater cartridge.

7. Reinstall the manifold cover plate (52).

8. Reconnect the cordset (17) to the heated hose.

9. Reconnect the solenoid valve power connector

to the solenoid valve (9).

2. Use a Phillips screws driver to remove the four

screws (15) and manifold cover plate (52).

3. Remove splices from heater wires (3) and

cordset wire leads (17).

4. Crimp wires. See Wiring Diagram, page 21.

NOTICE

To prevent a short to ground and blowing a

MZLP fuse, ensure bare wires are covered

with fiberglass tape and sleeves (52c) are

centered over splices (52b).

a. Slide sleeves (52c) over each pair of wires

before crimping.

b. Crimp butt splice (52b) on cordset heater

wires (17) and heater wires (3). Light pull on

splice to ensure it is crimped.

c. Crimp white wire to one thermal cutoff lead

(52a).

d. Crimp other thermal cutoff lead (52a) to one

heater wire(s) (3).

e. Crimp other heater wire(s) to black lead (17).

f. Wrap a short piece of fiberglass tape around

each splice (52b).

g. Center sleeves (52c) over each taped splice

(52b).

5. Gently press wires into the manifold. Install plate

(52) and screws (15).

F

E

Replace RTD

The RTD is replaced by replacing the entire cordset.

See Replace Cordset, page 22, for instructions.

Replace Thermal Cutoff

1. Disable gun assembly.

20 3A2805K

D

WLE

Page 21

Wiring Diagram

Thermal Cutoff

Repair

17

17

52b

52b

52a

52b

33

Note

Slim (24U021–24U026) and Low Profile Dual (24U026–24U032) applicators use one heater (3).

3A2805K

21

Page 22

Repair

Replace Cordset

See Fig 14, page 24.

Note

There are two types of cordsets (17):

24W087 is for PT100 (385) RTD controlled

guns and 24W088 is for NI 120 Ohm

RTD controlled guns. Ensure you have

the correct cordset before replacing. See

Parts, page 26.

1. Disable gun assembly. See

Before Beginning Repair, page 19.

2. Use a Phillips screwdriver to remove the four

screws (15) and manifold cover plate (52).

3. Usea2mmAllenwrenchtoremovetheset

screw (8) holding the cordset (17) on the manifold

(1).

4. Use a Phillips screwdriver to remove the ground

screw (15) and star washer (20) from the

manifold (1).

5. Remove the RTD (R) from the manifold (1).

Note

On guns that are not low profile,

RTD does not easily pull out, remove the

other cover plate (19) and press out with

a small screwdriver.

6. Disconnect thermal cutoff (52).

7. Remove the cordset (17) from the manifold (1).

8. Install the new cordset, RTD, and ground (17 in

the manifold (1). Recrimp thermal cutoff wires.

See Wiring Diagram, page 21, for connections.

Note

Ensure the cordset bushing is fully

inserted into the manifold.

9. Install set screw (8) against the cordset bushing

to secure the cordset (17) to the manifold (1).

if the

22

3A2805K

Page 23

Repair

10. Reinstall the ground lead onto the manifold (1).

Note

Ensure the star washer (20) is placed

below the ground ring terminal.

11. Insert the plug (P), RTD (R) and thermal cutoff

(52) into the manifold ports. See Fig 14.

Note

Do not apply grease on the RTD or

thermal cutoff.

12. Insert the heater cartridges (3) in the manifold (1).

NOTICE

To prevent removing wire insulation or

disconnecting wires, do not pinch any wires

when inserting wire in the manifold. If wire

insulation is removed, the RTD or heaters

could short out and need to be replaced.

13. Reinstall the manifold cover plate (52).

14. Reconnect the cordset (17) to the heated hose.

15. Return to service.

Figure 14 Repair Parts

3A2805K 23

NOTE:

of the Parts chapter ( Parts, page 26).

See Slim and Low Profile GS35 subsections

Page 24

Repair

Replace Solenoid Valve

1. Disable gun assembly. See

Before Beginning Repair, page 19.

2. Remove solenoid valve fitting (102) and solenoid

valve (9) from tube (7).

3. Use a 1/2 in. and 7/16 in. wrench to tighten new

connector (102) to tube (7).

Figure 15 Replace Solenoid Valve

Replace Module

NOTICE

Do not allow adhesive to enter the air ports,

to allow air to flow through valve. Adhesive in

the air ports will obstruct the flow of air and

damage the valve.

Figure 16 Remove Module From Manifold

3. Apply high temperature lubricant to o-rings in

module (2).

4. Apply anti-seize to two screw threads (22). Use

a5/32in. (4mm)Allenwrenchtoinstallnew

module(2)onmanifoldwithtwoscrews(22).

Torque to 28–32 in.-lbs (3.2–3.6 N•m).

1. Disable gun assembly. See

Before Beginning Repair, page 19.

Material inside the applicator can be near

setpoint temperature. Wear protective clothing

to avoid severe burns.

2. Use a 5/32 in. (4 mm) Allen wrench to remove

the two mounting screws (22) and module (2)

from manifold (1).

5. Connect cordset (17) to the heated hose.

Replace Applicator

Material inside the applicator can be near setpoint

temperature. Wear protective clothing to avoid

severe burns.

1. Disable gun assembly. See

Before Beginning Repair, page 19.

2. Loosen the mounting bar clamp and remove the

applicator from the mounting bar.

3. Install new applicator. See Installat ion, page 9 .

24

3A2805K

Page 25

Notes

Notes

3A2805K 25

Page 26

Parts

Parts

Single GS35

ply anti-seize to first 1/2 in. of threads. Torque

Apply thread sealant to threads.

1

Apply a thin coating of lubricant to seals.

2

Ap

3

4

28-32 in-lbs (3.2-3.6 N∙m).

to

See Wiring Diagram, page 21.

26 3A2805K

Page 27

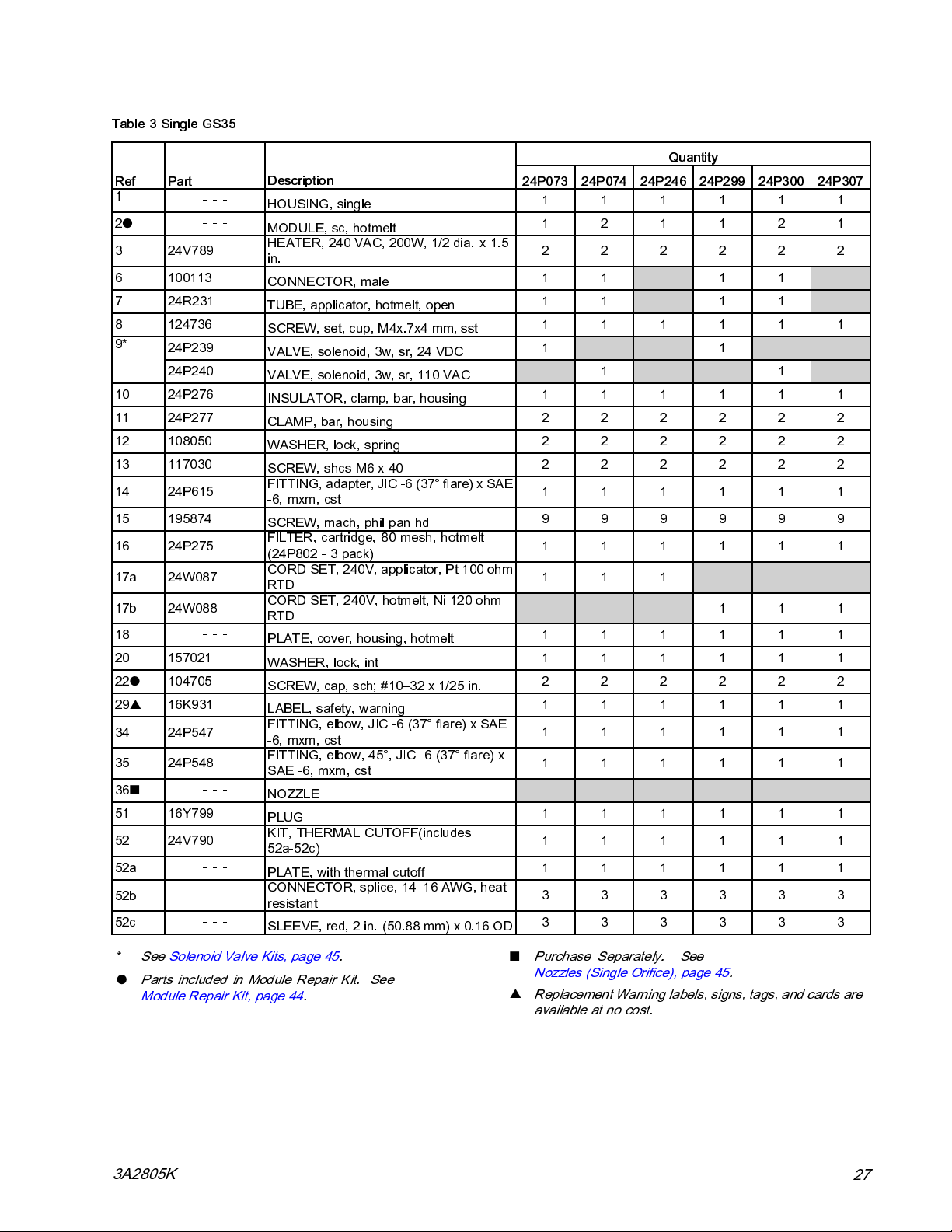

Table3SingleGS35

Ref Part

1

2

●

3 24V789

6 100113

7 24R231

8 124736

9*

10 24P276

11 24P277

12 108050

13 117030

14 24P615

15 195874

16 24P275

17a 24W087

17b 24W088

18

20 157021

22

●

29

▲

34 24P547

35 24P548

36

■

51 16Y799

52 24V790

52a

52b

52c

---

---

24P239

24P240

---

104705

16K931

---

---

---

---

Description

HOUSING, single

MODULE, sc, hotmelt

HEATER, 240 VAC, 200W, 1/2 dia. x 1.5

in.

CONNECTOR, male

TUBE, applicator, hotmelt, open

SCREW, set, cup, M4x.7x4 mm, sst

VALVE, solenoid, 3w, sr, 24 VDC

VALVE, solenoid, 3w, sr, 110 VAC

INSULATOR, clamp, bar, housing

CLAMP, bar, housing

WASHER, lock, spring

SCREW, shcs M6 x 40

FITTING, adapter, JIC -6 (37° flare) x SAE

-6, mxm, cst

SCREW, mach, phil pan hd

FILTER,

(24P802

CORD SET, 24 0V, applicator, Pt 100 ohm

RTD

CORD SET, 240V, hotmelt, Ni 120 ohm

RTD

PLATE, cover, housing, hotmelt

WASHER, lock, int

SCREW, cap, sch; #10–32 x 1/25 in.

LABEL, safety, warning

FITT

-6,

FITTING, elbow, 45°, JIC -6 (37° flare) x

SAE -6, mxm, cst

NOZZLE

PLUG

KIT, THERMAL CUTOFF(includes

52a-52c)

PLATE, with thermal cutoff

C

resistant

SLEEVE, red, 2 in. (50.88 mm) x 0.16 OD

cartridge, 80 mesh, hotmelt

- 3 pack)

ING, elbow, JIC -6 (37° flare) x SAE

mxm, cst

ONNECTOR, splice, 14–16 AWG, heat

Parts

Quantity

24P073 24P074 24P246 24P299 24P300 24P307

111111

121121

222222

11 11

11 11

111111

11

11

111111

222222

222222

222222

111111

999999

111111

111

111

111111

111111

222222

111111

111111

111111

111111

111111

111111

333333

333333

*

See Solenoid Valve Kits, page 45.

●

Parts included in Module Repair Kit. See

Module Repair Kit, page 44.

3A2805K

■

Purchase Separately. See

Nozzles (Single Orifice), page 45.

▲

Replacement Warning labels, signs, tags, and cards are

available at no cost.

27

Page 28

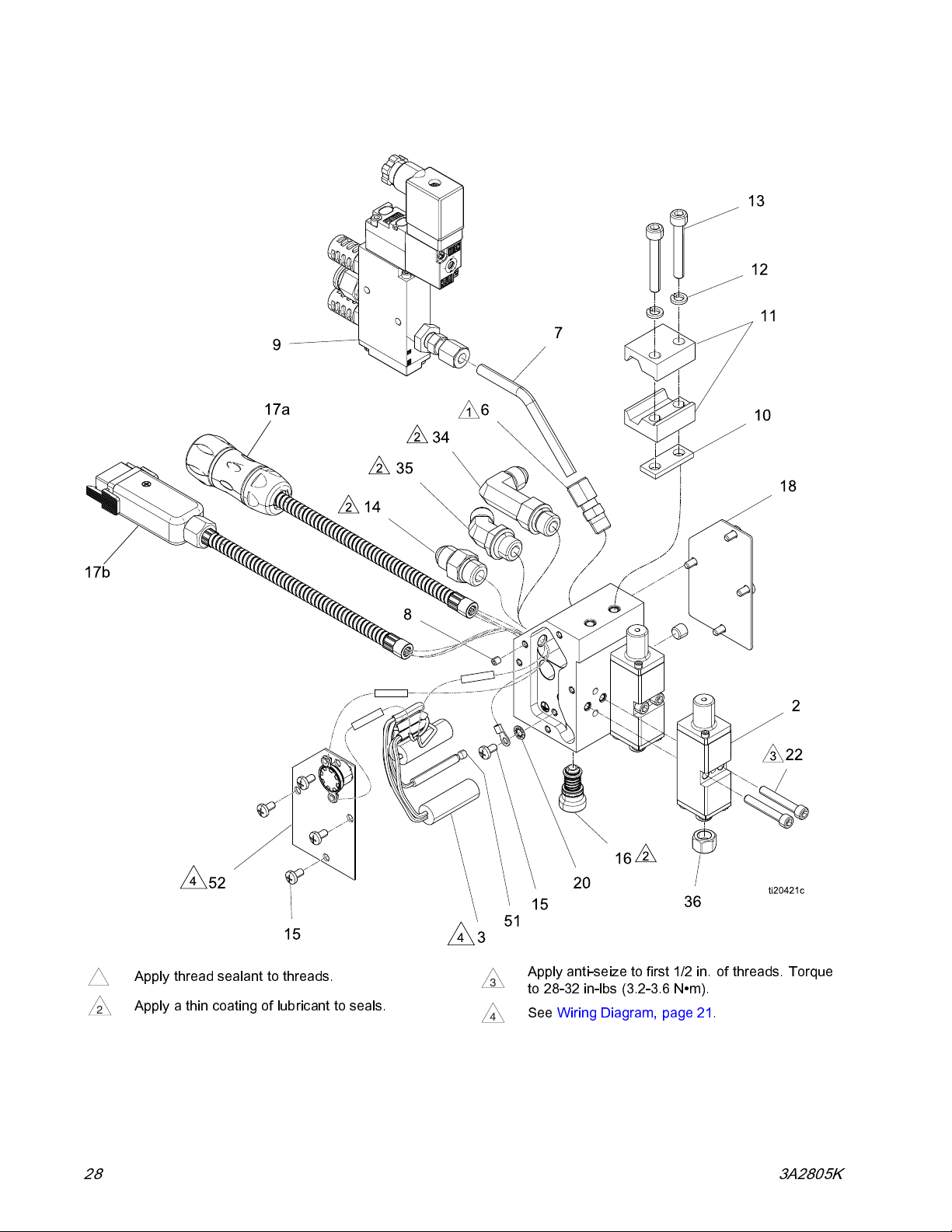

Parts

DUAL GS35

Apply thread sealant to threads.

1

Apply a thin coating of lubricant to seals.

2

Apply anti-seize to first 1/2 in. of threads. Torque

3

to 28-32 in-lbs (3.2-3.6 N∙m).

See Wiring Diagram, page 21.

4

28 3A2805K

Page 29

Table 4 Dual GS35

Parts

Ref Part

1

2

●

324V789

6 100113

724R231

8 124736

9*

10 24P276

11 24P277

12 108050

13 117030

14 24P615

15 195874

16 24P275

17a 24W087

17b 24W088

18

20 157021

22

●

29

▲

34 24P547

35 24P548

36

■

51 16Y799

52 24V790

52a

52b

52c

---

---

24P239

24P240

---

104705

16K931

---

---

---

---

Description

HOUSING, dual

MODULE, sc, hotmelt

HEATER, 240 VAC, 200W, 1/2 dia. x

1.5 in.

CONNECTOR, male

TUBE, applicator, hotmelt, open

SCREW, set, cup, M4 x .7 x 4 mm, sst

VALVE, solenoid, 3w, sr, 24 VDC

VALVE, solenoid, 3w, sr, 110 VAC

INSULATOR, clamp, bar, housing

CLAMP, bar, housing

WASHER, lock, spring

SCREW, shcs M6 x 40

FITTING, adapter, JIC -6 (37° flare) x

SAE -6, mxm, cst

SCREW, mach, phil pan hd

FILTER,

(24P802

CORD SET, 240V, applicator, Pt 100

ohm RTD

CORD SET, 240V, hotmelt, Ni 120 ohm

RTD

PLATE, cover, housing, hotmelt

WASHER, lock, int

SCREW, cap, sch; #10–32 x 1/25 in.

LABEL, safety, warning

FITT

SAE

FITTING, elbow, 45°, JIC -6 (37° flare)

x SAE -6, mxm, cst

NOZZLE

PLUG

KIT, THERMAL CUTOFF (includes

52a-52c)

PLATE, with thermal cutoff

C

heat resistant

SLEEVE, red, 2 in. (50.88 mm) x 0.16

OD

cartridge, 80 mesh, hotmelt

-3pack)

ING, elbow, JIC -6 (37° flare) x

-6, mxm, cst

ONNECTOR, splice, 14–16 AWG,

24P075 24P076 24P247 24P301 24P302 24P308

111111

222222

222222

11 11

11 11

111111

11

11

111111

222222

222222

222222

111111

999999

111111

111

111

111111

111111

444444

111111

111111

111111

111111

111111

111111

333333

333333

*

See Solenoid Valve Kits, page 45.

●

Parts included in Module Repair Kit. See

Module Repair Kit, page 44.

■

Purchase Separately. See

Nozzles (Single Orifice), page 45.

▲

Replacement Warning labels, signs, tags, and cards are

available at no cost.

3A2805K 29

Page 30

Parts

Quad GS35

24P077 Type I Shown

Apply thread sealant to threads.

1

Apply a thin coating of lubricant to seals.

2

Apply anti-seize to first 1/2 in. of threads. Torque

3

to 28-32 in-lbs (3.2-3.6 N∙m)).

See Wiring Diagram, page 21.

4

30 3A2805K

Page 31

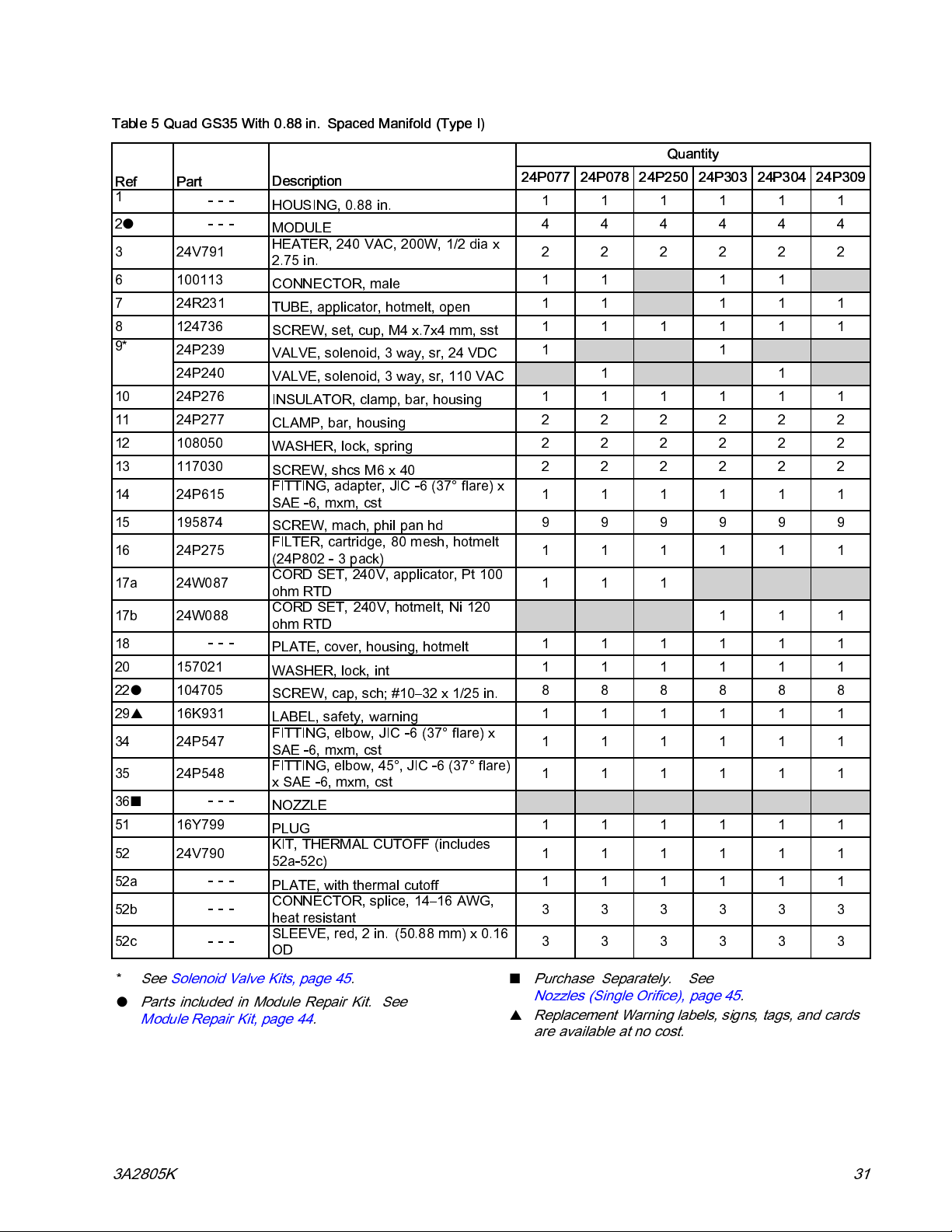

Table 5 Quad GS35 With 0.88 in. Spaced Manifold (Type I)

Ref Part

1

2

●

3 24V791

6 100113

7

8 124736

9*

10 24P276

11 24P277

12 108050

13 117030

14 24P615

15 195874

16 24P275

17a 24W087

17b 24W088

18

20 157021

22

●

29

▲

34 24P547

35 24P548

36

■

51 16Y799

52 24V790

52a

52b

52c

---

---

24R231

24P239

24P240

---

104705

16K931

---

---

---

---

Description

HOUSING, 0.88 in.

MODULE

HEATER, 240 VAC, 200W, 1/2 dia x

2.75 in.

CONNECTOR, male

TUBE, applicator, hotmelt, open

SCREW, set, cup, M4 x.7x4 mm, sst

VALVE, solenoid, 3 way, sr, 24 VDC

VALVE, solenoid, 3 way, sr, 110 VAC

INSULATOR, clamp, bar, housing

CLAMP, bar, housing

WASHER, lock, spring

SCREW, shcs M6 x 40

FITTING, adapter, JIC -6 (37° flare) x

SAE -6, mxm, cst

SCREW, mach, phil pan hd

FILTER, cartridge, 80 mesh, hotmelt

(24P802-3pack)

CORD SET, 240V, applicator, Pt 100

ohm RTD

CORD SET, 240V, hotmelt, Ni 120

ohm RTD

PLATE, cover, housing, hotmelt

WASHER, lock, int

SCREW, cap, sch; #10–32 x 1/25 in.

LABEL, safety, warning

FITTING, elbow, JIC -6 (37° flare) x

SAE -6, mxm, cst

FITTING, elbow, 45°, JIC -6 (37° flare)

x SAE -6, mxm, cst

NOZZLE

PLUG

KIT, THERMAL CUTOFF (includes

52a-52c)

PLATE, with thermal cutoff

CONNECTOR, splice, 14–16 AWG,

heat resistant

SLEEVE, red, 2 in. (50.88 mm) x 0.16

OD

Parts

Quantity

24P077 24P078 24P250 24P303 24P304 24P309

111111

444444

222222

11 11

11 111

111111

11

11

111111

222222

222222

222222

111111

999999

111111

111

111

111111

111111

888888

111111

111111

111111

111111

111111

111111

333333

333333

*

See Solenoid Valve Kits, page 45.

●

Parts included in Module Repair Kit. See

Module Repair Kit, page 44.

■

Purchase Separately. See

Nozzles (Single Orifice), page 45.

▲

Replacement Warning labels, signs, tags, and cards

are available at no cost.

3A2805K 31

Page 32

Parts

Table 6 Quad GS35 with 1.5 in. Spaced Manifold (Type II)

Ref Part

1

2

●

3 24V791

6 100113

7

8 124736

9*

10 24P276

11 24P277

12 108050

13 117030

14 24P615

15 195874

16 24P275

17a 24W087

17b 24W088

18

20 157021

22●104705

29▲16K931

34 24P547

35 24P548

36

51 16Y799

52 24V790

52a

52b

52c

---

---

24R231

24P239

24P240

---

■

---

---

---

Description

HOUSING, 1.5 in.

MODULE

HEATER, 240 VAC, 200W, 1/2 dia x

2.75 in.

CONNECTOR, male

TUBE, applicator, hotmelt, open

SCREW, set, cup, m4 x.7x4 mm, sst

VALVE, solenoid, 3 way, sr, 24 VDC

VALVE, solenoid, 3 way, sr, 110

VAC

INSULATOR, clamp, bar, housing

CLAMP, bar, housing

WASHER, lock, spring

SCREW, shcs M6 x 40

FITTING, adapter, JIC -6 (37° flare)

x SAE -6, mxm, cst

SCREW, mach, phil pan hd

FILTER, cartridge, 80 mesh, hotmelt

(24P802-3pack)

CORD SET, 240V, applicator, Pt 100

ohm RTD

CORD SET, 240V, hotmelt, Ni 120

ohm RTD

PLATE, cover, housing, hotmelt

WASHER, lock, int

SCREW,

LABEL, safety, warning

FITTING, elbow, JIC -6 (37° flare) x

SAE -6, mxm, cst

FITTING, elbow, 45°, JIC -6 (37°

flare) x SAE -6, mxm, cst

NOZZLE

PLUG

KIT, THERMAL CUTOFF (includes

52a-52c)

PLATE, with thermal cutoff

CONNECTOR, splice, 14–16 AWG,

heat resistant

SLEEVE, red, 2 in. (50.88 mm) x

0.16 OD

cap, sch; #10–32 x 1/25 in.

24P079 24P080 24P254 24P305 24P306 24P310

Quantity

11 1111

44 4444

22 2222

11 11

11 11

11 1111

11

11

11 1111

22 2222

22 2222

22 2222

11 1111

99 9999

11 1111

111

11 1

11 1111

11 1111

88 8888

11 1111

11 1111

11 1111

11 1111

11 1111

11 1111

33 3333

33 3333

*

See Solenoid Valve Kits, page 45.

●

Parts included in Module Repair Kit. See

Module Repair Kit, page 44.

■

Purchase Separately. See

Nozzles (Single Orifice), page 45.

▲

Replacement Warning labels, signs, tags, and cards

are available at no cost.

32 3A2805K

Page 33

Notes

Parts

3A2805K 33

Page 34

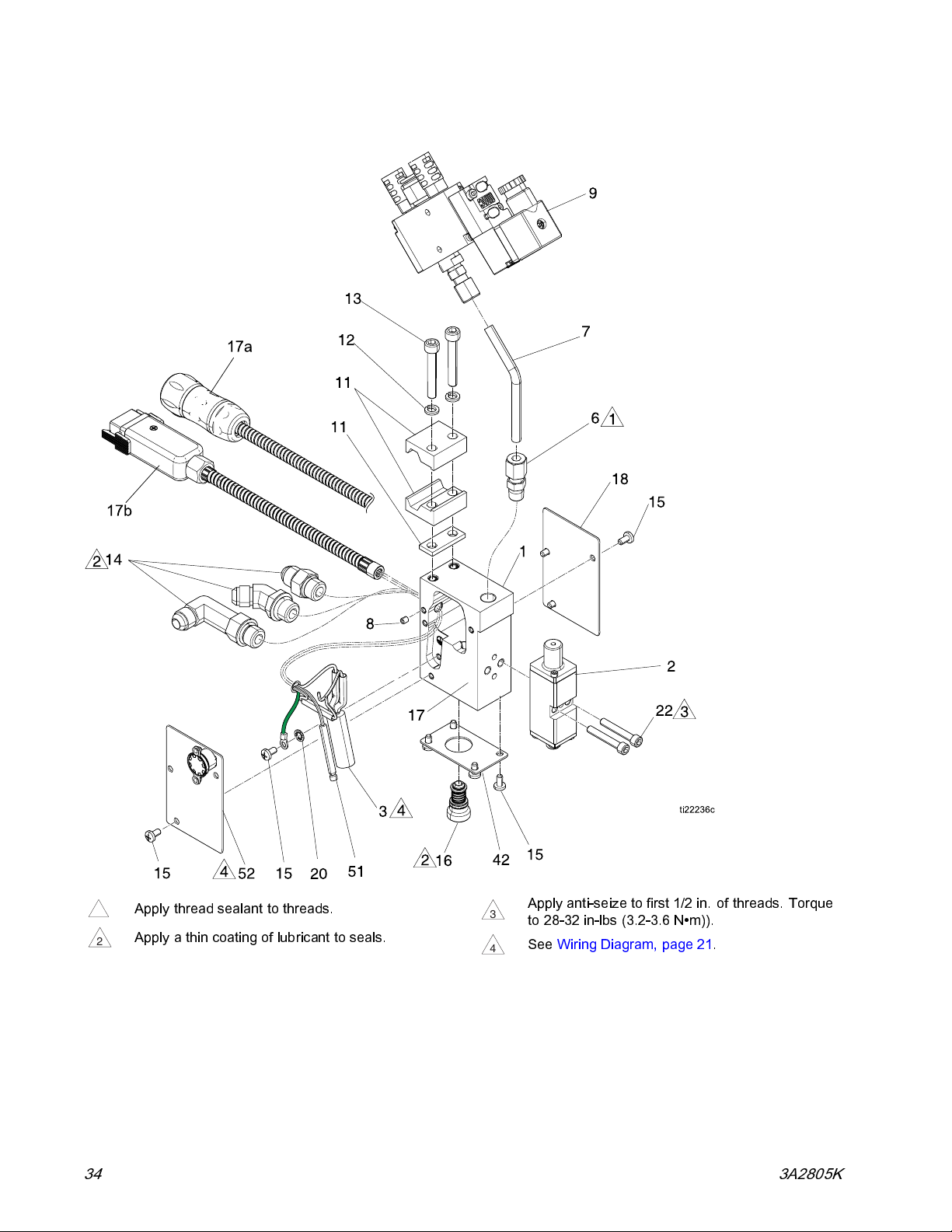

Parts

Slim GS35

Apply thread sealant to threads.

1

Apply a thin coating of lubricant to seals.

2

Apply anti-seize to first 1/2 in. of threads. Torque

3

to 28-32 in-lbs (3.2-3.6 N∙m)).

See Wiring Diagram, page 21.

4

34 3A2805K

Page 35

Parts

Table7SlimGS35

Quantity

Ref Part

---

1

---

2

●

324V793HEATER,240VAC,200W,1/2diax1.5in.111111

6 100113 CONNECTOR, male 1 1 1 1

7

16P769 TUBE, applicator, hotmelt, open 1 1 1 1

8124736SCREW,set,cup,M4x0.7x4mm,sst111111

24P239 VALVE, solenoid, 3 way, sr, 24 VDC 1 19*

24P240 VALVE, solenoid, 3 way, sr, 120 VAC 1 1

1024P276INSULATOR,clamp,bar,housing 111111

1124P277CLAMP,bar,housing 222222

12108050WASHER,lock,spring 222222

13 117030

14 24P615

15 195874

16 24P275

17a 24W087

24W088 CORD SET, 240V, hotmelt, Ni 120 ohm

17b

---

18

20157021WASHER,lock,int 111111

22●104705SCREW,cap,sch 222222

3424P547FITTING,elbow,JIC06xSAE06,mm,cs111111

35 24P548 FITTING, elbow, 45, JIC06 x SAE06, mm,

---

36

■

42 16W708PLAT

Description

HOUSING,slim 111111

MODULE 111111

SCREW, shcs M6 x 40

FITTING, adapter, JIC 06 x SAE 06, mm,

cs

SCREW, mach, phil pan hd

FILTER, gun, 80 mesh (3–pack: 24P802)

CORD SET, 240V, applicator, Pt 100 ohm

RTD

RTD

PLATE,cover,side,slim 111111

c

NOZZLE (not shown)

E, cover, bottom, slim

24U021 24U022 24U023 24U024 24U025 24U026

222222

111111

11 11 11 11 11 11

111111

111

111

111111

111111

51 16Y799

52 24V792

52a

52b

52c

*

●

--

---

---

e Solenoid Valve Kits, page 45.

Se

arts included in Module Repair Kit. See

P

odule Repair Kit, page 44.

M

PLUG

KIT, THERMAL CUTOFF (includes

52a-52c)

-

PLATE, with thermal cutoff

CONNECTOR, splice, 14–16 AWG, heat

resistant

SLEEVE, red, 2 in. (50.88 mm) x 0.16 OD

111111

111111

111111

333333

333333

■

urchase Separately. See

P

ozzles (Single Orifice), page 45.

N

▲

Replacement Warning labels, signs, tags, and cards are

available at no cost.

3A2805K 35

Page 36

Parts

Low Profile Dual GS35

Apply thread sealant to threads.

1

Apply a thin coating of lubricant to seals.

2

Apply anti-seize to first 1/2 in. of threads. Torque

3

to 28-32 in-lbs (3.2-3.6 N∙m)).

See Wiring Diagram, page 21.

4

36 3A2805K

Page 37

Table 8 Low Profile Dual GS35

Ref Part

1

2

3 24V793

6 100113

7

8 124736

9*

10 24P276

---

---

●

16P769 TUBE, applicator, hotmelt, open 1 1 1 1

24P239

24P240

Description

HOUSING, double

MODULE, sc

HEATER, 240 VAC, 200W, 1/2 dia x 1.5 in.

CONNECTOR, male

SCREW, set, cup, M4 x 0.7 x 4 mm, sst

VALVE, solenoid, 3 way, sr, 24 VDC

VALVE, solenoid, 3 way, sr, 120 VAC

INSULATOR, clamp, bar, housing

Parts

Quantity

24U027 24U028 24U029 24U030 24U031 24U032

111111

222222

111111

11 11

111111

11

11

111111

11

12 108050 WASHER, lock, spring 2 2 2 2 2 2

13 117029 SCREW, shcs, M6 x 25 2 2 2 2 2 2

14 24P615 FITTING, adapter, JIC06 x SAE06, mm, cs 1 1 1 1 1 1

15 195874 SCREW, mach, phil pan hd

16 24P275 FILTER, gun, 80 mesh (3–pack: 24P802) 1 1 1 1 1 1

17a 24W087 CORD SET, 240V, applicator, Pt 100 ohm

17b 24W088 CORD SET, 240V, hotmelt, Ni 120 ohm

18

20 157021 WASHER, lock, int 1 1 1 1 1 1

21 103147 PLUG, pipe 3 3 3 3 3 3

22

34 24P547 FITTING, elbow, JIC06 x SAE06, mm, cs 1 1 1 1 1 1

35 24P548 FITTING, elbow, 45, JIC06 x SAE06, mm, c 1 1 1 1 1 1

36

42 16W70

44 24U69

45

46

47

48

49

50 1005

---

---

●

104705 SCREW, cap, sch 4 4 4 4 4 4

---

■

10259

10002

1095

1000

---

70

18

08

BLOCK 111111

555555

111

RTD

111

RTD

PLATE, s

NOZZLE (not shown)

9

PLATE

8

ROD, mtg, threaded 1 1 1 1 1 1

8

SCREW, cap, socket head 1 1 1 1 1 1

0

WASHER, lock 1 1 1 1 1 1

WASHER, plain 2 2 2 2 2 2

WASHER, lock, spring 2 2 2 2 2 2

NUT,

SCREW, drive 4 4 4 4 4 4

ide

, cover, end

1/2-13 hex

111111

111111

222222

51 16Y799

PLUG

111111

3A2805K 37

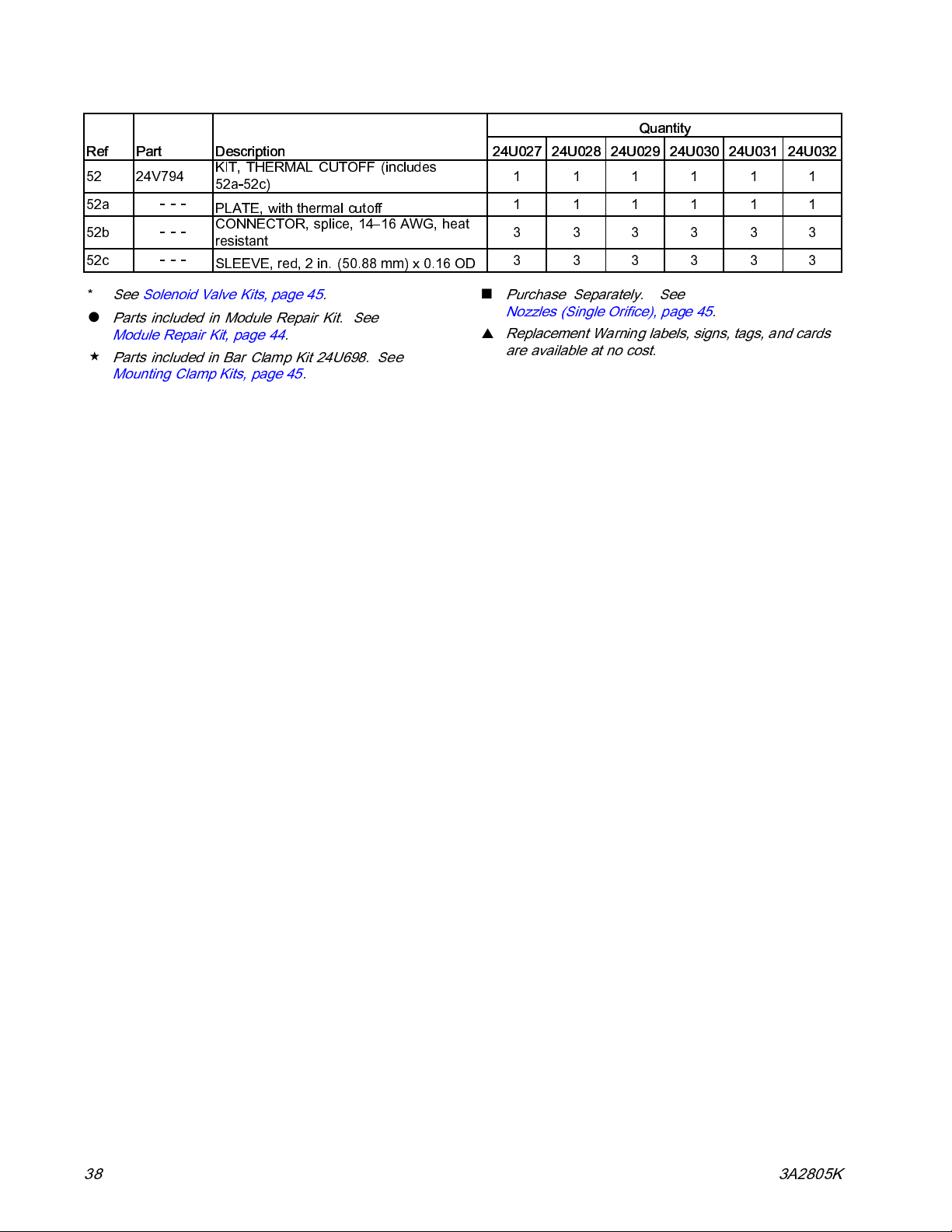

Page 38

Parts

Ref Part

52 24V794

52a

52b

52c

---

---

---

Description

KIT, THERMAL CUTOFF (includes

52a-52c)

PLATE, with thermal cutoff

CONNECTOR, sp

resistant

SLEEVE, red, 2 in. (50.88 mm) x 0.16 OD

lice, 14–16 AWG, heat

Quantity

24U027 24U028 24U029 24U030 24U031 24 U032

111111

111111

333333

333333

*

See Solenoid Valve Kits, page 45.

●

Parts included in Module Repair Kit. See

Module Repair Kit, page 44.

Parts included in Bar Clamp Kit 24U698. See

Mounting Clamp Kits, page 45.

■

Purchase Separately. See

Nozzles (Single Orifice), page 45.

▲

Replacement Warning labels, signs, tags, and cards

are available at no cost.

38 3A2805K

Page 39

Notes

Parts

3A2805K 39

Page 40

Parts

Low Profile Quad GS35

Apply thread sealant to threads.

1

Apply a thin coating of lubricant to seals.

2

Apply anti-seize to first 1/2 in. of threads. Torque

3

to 28-32 in-lbs (3.2-3.6 N∙m)).

See Wiring Diagram, page 21.

4

40 3A2805K

Page 41

Table 9 Low Profile Quad GS35

Ref Part

1

2

●

3

6

7

8

9*

10

11

12

13

14

15

16

17a 24W087

17b 24W088

18

20

21

22

●

34

35

36

■

38

▲

39

42

44

45

46

47

48

49

50

51

---

---

24V795

100113

16P769 TUBE, applicator, hotmelt, open

124736

126407 VALVE, solenoid, 3 way, sr, 24

126408 VALVE, solenoid, 3 way, sr, 120

16P848

---

108050

117029

126544

195874

24P275

---

157021

103147

104705

126748

126749

---

16K931

103473

16V721 PLATE, cover, applicator

24U698

102598

100020

109570

100018

-

--

100508

16Y799

Description

HOUSING, quad

MODULE, sc, invisipac

HEATER, 240 VAC, 200W, 1/2

dia x 1.5 in.

CONNECTOR, male

SCREW, set, cup, M4x 0.7 x 4

mm, sst

VDC

VAC

INSULATOR, clamp, bar, housing

BLOCK, mtg

WASHER, lock, spring

SCREW, shcs M6 x 25

FITTING, adapter, JIC06 x

SAE06, mm, cs

SCREW, mach, phil pan hd

FILTER, gun, 80 mesh (3-pack:

24P802)

CORD SET, 240V, applicator, Pt

100 ohm RTD

CORD SET, 240V, hotmelt, Ni

120 ohm RTD

PLATE, side, quad

WASHER, lock, int

PLUG, pipe

SCREW, cap, sch

FITTING, elbow, JIC06 x SAE06,

mm, cs

FITTING, elbow, 45, JIC06 x

SAE06, mm, c

NOZZLE (not shown)

TAG, warning, turbo

STRAP, tie, wire

ROD, mtg, threaded

SCREW, cap, socket head

WASHER, lock

WASHER, plain

WASHER, lock, spring

NUT, 1/2-13 hex

SCREW, drive

PLUG

Parts

Quantity

24U033 24U034 24U035 24U036 24U037 24U038

111111

444444

222222

11 11

11 11

111111

11

11

111111

111111

222222

222222

111111

666666

111111

111

111

111111

111111

333333

888888

111111

111111

111111

111111

111111

111111

111111

111111

222222

222222

222222

222222

111111

3A2805K

41

Page 42

Parts

Ref Part

52

52a

52b

52c

24V796 KIT, THERMAL CUTOFF

---

---

---

Description

(includes 52a-52c)

PLATE, with th

CONNECTOR, sp

AWG, heat res

SLEEVE, red, 2 in. (50.88 mm)

x0.16OD

ermal cutoff

lice, 14–16

istant

Quantity

24U033 24U034 24U035 24U036 24U037 24U038

111111

111111

333333

333333

*

See Solenoid

●

Parts includ

Module Repai

Parts included in Bar Clamp Kit 24U698. See

Mounting Clamp Kits, page 45.

Valve Kits, page 45.

ed in Module Repair Kit. See

r Kit, page 44.

■

Purchase Sep

Nozzles (Si

▲

Replacement Warning labels, signs, tags, and cards

are available at no cost.

arately. See

ngle Orifice), page 45.

42

3A2805K

Page 43

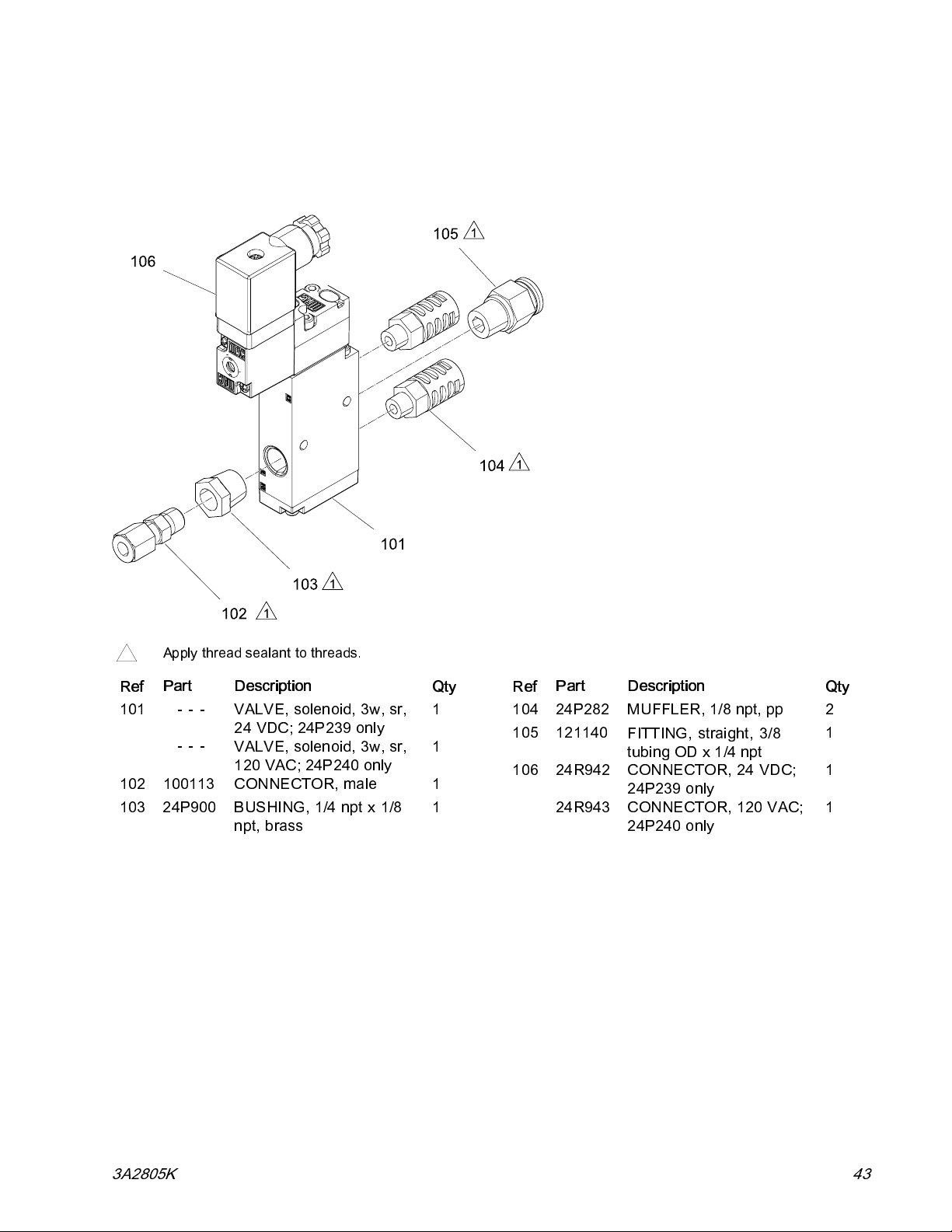

Solenoid Valve Kits

24P239, 24 VDC Solenoid Valve 24P240, 110 VAC Solenoid Valve

Parts

Apply thread sealant to threads.

1

Part Description

Ref

101

102 100113 CONNECTOR, male 1

103 24P900 BUSHING, 1/4 npt x 1/8

---

---

VALVE, solenoid, 3w, sr,

24 VDC; 24P239 only

VALVE, solenoid, 3w, sr,

120 VAC; 24P240 only

npt, brass

Qty

1

1

1

Part Description

Ref

104 24P282 MUFFLER, 1/8 npt, pp 2

105 121140

106 24R942

24R943

FITTING, straight, 3/8

tubing OD x 1/4 npt

CONNECTOR, 24 VDC;

24P239 only

CONNECTOR, 120 V AC;

24P240 only

Qty

1

1

1

3A2805K 43

Page 44

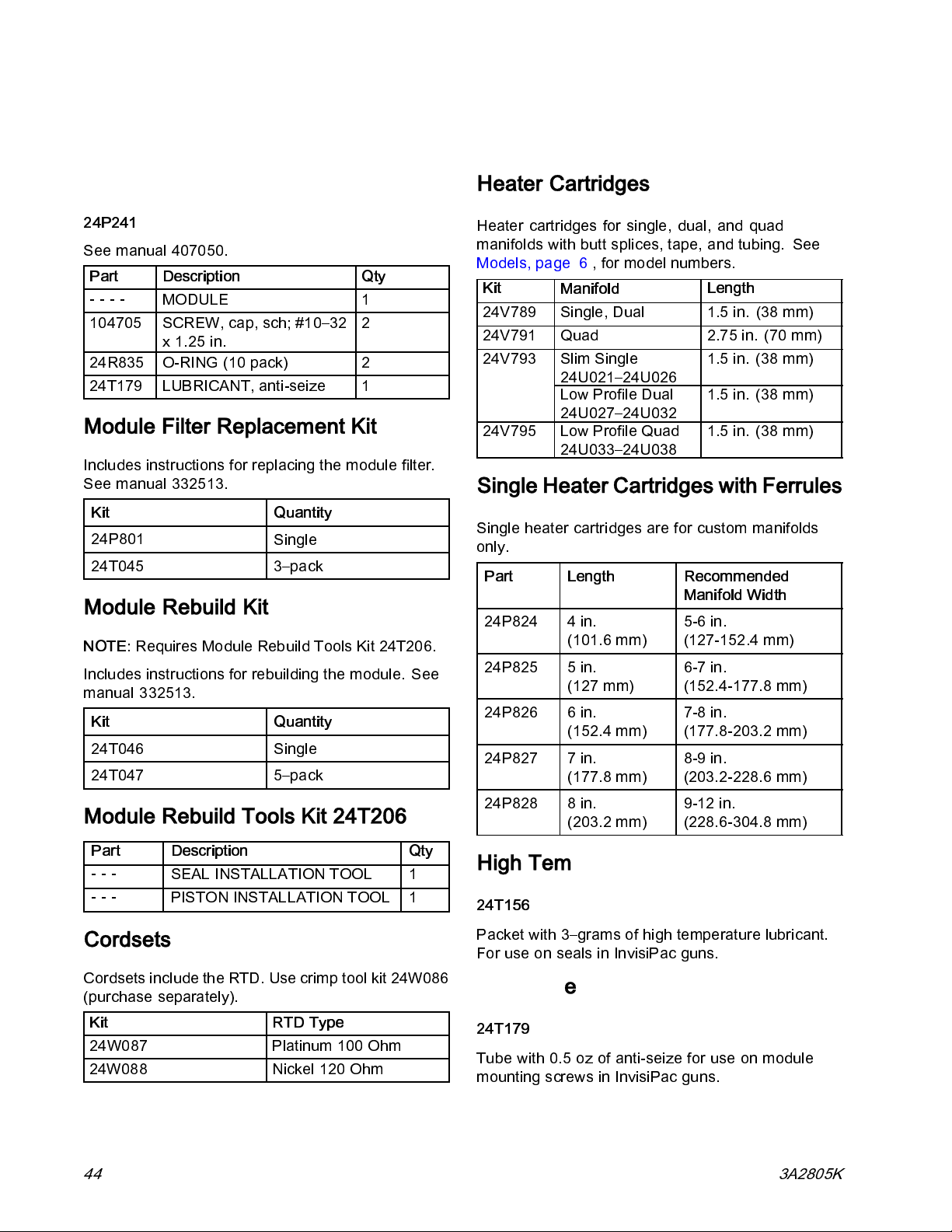

Kits and Accessories

Kits and Accessories

Module Replacement

24P241

See manual 407050.

Part Description

----

104705

24R835

24T179

MODULE

SCREW, cap, sch; #10–32

x1.25in.

O-RING (10 pack )

LUBRICANT, anti-seize

Qty

1

2

2

1

Module Filter Replacement Kit

Includes instructions for replacing the modul e filter.

See manual 332513.

Kit

24P801

24T045 3–pack

Quantity

Single

Module Rebuild Kit

NOTE:

Includes instructions for rebuilding the module. See

manual 332513.

Requires Module Rebuild Tools Kit 24T206.

Kit

24T046 Single

24T047 5–pack

Quantity

Heater Cartridges

Heater cartridges for single, dual, and quad

manifolds with butt splices, tape, and tubing. See

Models, page 6 , for model numbers.

Kit

24V789

24V791

24V793

24V795

Manifold

Single, Dual 1.5 in. (38 mm)

Quad 2.75 in. (70 mm)

Slim Single

24U021–24U026

Low Profile Dual

24U027–24U032

Low Profile Quad

24U033–24U038

Length

1.5in.(38mm)

1.5in.(38mm)

1.5in.(38mm)

Single Heater Cartridges with Ferrules

Single heater cartridges are for custom manifolds

only.

Part Length Recommended

Manifold Width

24P824 4 in.

(101.6 mm)

24P825 5 in.

(127 mm)

24P826 6 in.

(152.4 mm)

24P827 7 in.

(177.8 mm)

5-6 in.

(127-152.4 mm)

6-7 in.

(152.4-177.8 mm)

7-8 in.

(177.8-203.2 mm)

8-9 in.

(203.2-228.6 mm)

Module Rebuild Tools Kit 24T206

Part Description Qty

---

---

SEAL INSTA LLA TIO N TOOL 1

PISTON INSTALLATION TOOL 1

Cordsets

Cordsets include the RTD. Use crimp tool kit 24W086

(purchase separately).

Kit RTD Type

24W087 Platinum 100 Ohm

24W088 N icke l 120 Ohm

44

24P828 8 in.

(203.2 mm)

9-12 in.

(228.6-304.8 mm)

High Temperature Lubricant

24T156

Packet with 3–grams of high temperature lubricant.

For use on seals in InvisiPac guns.

Anti-Seize

24T179

Tubewith0.5ozofanti-seizeforuseonmodule

mounting screws in InvisiPac guns.

3A2805K

Page 45

Kits and Accessories

Mufflers

24P282

Includes two mufflers that can be used with solenoid

valve kits.

Blanking Plate Kit

24P810

Use to run two or three modules on a quad applicator

or one module on a dual applicator. See manual

407051.

Solenoid Valve and Fitting Kits

3–Way (air open - spring close) Solenoid Valves

Kit Description

24P239

24P240

24 VDC

110 VAC

Inlet Filter

Kit

24P275

24P802 3 Pack

Qty

Single

Material Inlet Fittings

Mounting Clamp Kits

See Models, page 6 , for model numbe rs.

24P277 (Single, Dual, and Quad GS35)

Part Description

Ref

10 24P276

11

12 108050

13 117030

24U698 (Low Profile GS35, 24U027–24U038))

Ref

10 24P276

11

12 108050

13 117029

44

45

46

47

48

49

---

Part Description

---

---

---

---

---

---

---

INSULATOR, clamp, bar,

housing

CLAMP, bar housing

WASHER, lock, spring

SCREW, shcs, M6 x 40

INSULATOR, clamp, bar,

housing

BLOCK, mating, low

profile

WASHER, lock, spring

SCREW, shcs, M6 x 25

ROD

SCREW, cap, socket head

WASHER, lock

WASHER, plain

WASHER, lock, spring

NUT, 1/2–13 2

Qty

1

2

2

2

Qty

1

1

2

2

1

1

1

2

2

Single Kit

24P615

24P548

24P547

Thermal Cutoff Replaceme

For Series A and Series B Models.

Kit Models Description

24V790 See Models,

page 6

24V792 24U021-

24U026

24V794 24U027-

24U032

24V796 24U033-

24U038

Description

Straight

45°

90°

nt Kits

Standard

Slim Single

Dual Low

Profile

Quad Low

Profile

Nozzles (Single Orifice)

Single

24P636 24P794 0.008 straight

24P637 24P795 0.010 straight

24P638 24P796 0.012 straight

24P639 24P797 0.016 straight

24P640 24P798 0.018 straight

24P641 24P799 0.020 straight

24P642 24P800 0.024 straight

24P643 24P803

24P644 24P804

24P645 24P805

24P646 24P806

24P647 24P807

24P648 24P808

24P649 24P809

5 Pack Description

0.008 90°

0.010 90°

0.012 90°

0.016 90°

0.018 90°

0.020 90°

0.024 90°

3A2805K 45

Page 46

Dimensions

Dimensions

Single, Dual, and Quad GS35

24P075 Shown

0.79 in.

(20.0 mm)

24P077 Type I Shown

0.72 in.

(18.16 mm)

9.3 in. (236.2 mm)

7.93 in. (201.42 mm)

5.01 in.

(127.25 mm)

1.00 in.

(25.4 mm)

1.14 in.

(28.96 mm)

3.07 in.

(77.98 mm)

3.94 in.

(100.1 mm)

24P079 Type II Shown

3.63 in.

(92.2 mm)

0.5 in.

(12.7 mm)

4.24 in.

(107.7 mm)

0.31 in.

(7.9 mm)

0.625 in.

(15.8 mm)

A

A

A

C

B

Applicator A

in. (mm)

Single 2.23 (56.6)

Dual 0.88 (22.4) 2.23 (56.6)

Quad - Type I 0.88 (22.4) 3.74 (95) 0.88 (22.4)

Quad - Type II 0.88 (22.4) 4.36 (111) 1.5 (38)

See Models, page 6 , for applicator model numbers.

46 3A2805K

C

B

B

in. (mm)

A

0.25 in.

(6.25 mm)

C

in. (mm)

Page 47

Slim GS35

(24U021-24U026)

24U021 Shown

0.79 in.

(20.0 mm)

Dimensions

11.68 in.

(296.67 mm)

0.67 in.

(17.02 mm)

1.35 in. (34.29 mm)

5.01 in.

(127.25 mm)

4.24 in.

(107.70 mm)

3.63 in.

(92.20 mm)

1.0 in.

(25.4 mm)

2.41 in.

(61.21 mm)

2.86 in.

(72.64 mm)

3.16 in.

(80.26 mm)

4.04 in.

(102.62 mm)

3A2805K

47

Page 48

Dimensions

Low Profile Double GS35

(24U027-24U033)

24U027 Shown

0.88 in.

(22.35 mm)

1.94 in.

(49.28 mm)

0.79 in.

(20.1 mm)

1.0 in.

(25.4 mm)

6.29 in.

(159.77 mm)

11.69 in.

(296.93 mm)

1.5 in.

(38.1 mm)

0.13 in.

(3.30 mm)

5.66 in.

(143.76 mm)

3.18 in.

(80.77 mm)

2.30 in.

(58.42 mm)

48 3A2805K

Page 49

Low Profile Quad GS35

(24Ubob 033-24U038)

24U033 Shown

Dimensions

0.88 in.

(22.35 mm)

(92.20 mm)

(22.35 mm)

3.63 in.

0.88 in.

0.79 in.

(20.1 mm)

0.88 in.

(22.35 mm)

6.29 in.

(159.77 mm)

1.0 in.

(25.4 mm)

11.69 in.

(296.93 mm)

1.5 in.

(38.1 mm)

0.13 in.

(3.30 mm)

5.16 in.

(131.06 mm)

3.18 in.

(80.77 mm)

2.30 in.

(58.42 mm)

3A2805K 49

Page 50

Technical D ata

Technical Data

InvisiPac™GS35 Plug-Free Hot Melt Adhesive Applicator

US Metric

Speed

Heat up Time

Electrical Service

Maximum Working Fluid Pressure 1500 psi 10.3 MPa, 103 bar

Maximum Air Pressure 80 psi 0.5 MPa, 5.5 bar

Minimum Air Pressure 40 psi 0.3 MPa, 2.7 bar

Maximum O p erati ng Temperature 400°F 204°C

Ambient Storage Temperature

Range

Ambient Operating Temperature

Range

Solenoid Air Flow Rating 1.0 Cv

Wetted Parts Aluminum, carbon steel, stainless steel, carbide, brass,

Cordsets

24W087

24W088 Ni 120 RTD

Solenoid Control Voltages

< 10 minutes to 350°F at 240 VAC < 10 minutes to 176°C at 240 VAC

32-122°F 0-50°C

32-122°F 0-50°C

> 3,500 cycles/minute

200-240V, 50–60 Hz, 400W

chemically resistant seals, chrome

Pt 100 (385) RTD

24P239

24P240

Noise

Sound pressure measured 6.5 ft

(2m) from gun at 80 psi (550kPa,

5.5 bar)

24 VDC

110 VAC

75.6 dB(A)

50 3A2805K

Page 51

Notes

Notes

3A2805K 51

Page 52

Graco Extended Warranty

Graco warrants all equipment referenced in this document whic h is manufactured by Graco and bearing its

name to be free from defects in material and workmanship on the date of sale to the original purchaser for use.

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of

eighteen months from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance

with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction,

damage or wear caused by faulty installation, misapplication, abrasion, corrosion, inadequate or improper

maintenance, negligence, accident, tampering, or substitution of non-Graco component parts. Nor shall Graco

be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with structures,

accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation,

operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized

Graco distributor for verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace

free of charge any defective parts. The equipment will be returned to the original purchaser transportation

prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will be

made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS

FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The

buyer agrees that no other remedy (including, but not limited to, incidental or consequential damages for lost

profits, lost sales, injury to person or property, or any other incidental or consequential loss) shall be available.

Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT,

MATERIALS OR COMPONENTS SOLD BUT NOT MANUFACTURED BY GRACO.

manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of

their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of

these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco

supplying equipment hereunder, or the furnishing, performance, or use of any products or other goods sold

hereto, whether due to a breach of contract, breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices

and legal proceedings entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be

drawn up in English. Les parties reconnaissent avoir conv enu que la rédaction du présente document sera en

Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite de ou

en rapport, directement ou indirectement, avec les procédures concernées.

These items sold, but not

Graco Information

For more information about InvisiPac, visit www.InvisiPac.com or email InvisiPac@graco.com.

To place an order,

For technical assistance or customer service, call toll free: 1–800–458–2133.

All written and vis ual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

contact your Graco Distributor or call to identify the nearest distributor.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original Instructions. This manual contains English. MM 3A2805

Graco Headquarters:

International Offices:

Copyright 2012, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Belgium, China, Japan, Korea

www.graco.com

Revised August 2014

Minneapolis

Loading...

Loading...