Graco GrindLazer Pro RC813 G, GrindLazer Pro Series, GrindLazer Pro RC813 G DCS, 25N669, 25M847 Operation, Repair, And Parts

Page 1

www.graco.com/techsupport

?? ??

Operation, Repair, Parts

25M847

25M847 (Series B)

25N669

™

GrindLazer

For removal of materials from flat horizontal concrete and asphalt surfaces. For

professional use only.

Pro Series - Rotary Cut

Model 25M847 - GrindLazer Pro RC813 G (390 cc / 13hp Electric Start)

Model 25M847 - GrindLazer Pro RC813 G (390 cc / 13hp Electric Start) (Series B)

Model 25N669 - GrindLazer Pro RC813 G DCS (390 cc / 13hp Electric Start)

Important Safety Instructions

Read all warnings and instructions in this manual before using the

equipment. Be familiar with the controls and the proper usage of the

equipment. Save these instructions.

3A5581C

EN

Page 2

Contents

Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Battery Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Component Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

25M847 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Component Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

25M847 (Series B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Component Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

25N669 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Handle Bar Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Engine Kill Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cutter Head Installation/Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Dust Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

DCS Control (DCS Models only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Machine Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Cutting Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Stop Cutting Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

DCS Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

DCS Control Translations (DCS Models only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Belt Replacement and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Drive Pulley Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Engine Pulley Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

DCS Models only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

DCS Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

DCS Actuator Rod Does Not Move . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Outer Frame Assembly - 25M847 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Outer Frame Assembly Parts List - 25M847 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Shock Assembly - 25M847 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Shock Assembly Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Adjustable Handles - 25M847 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Adjustable Handles Parts List - 25M847 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Adjustable Handles - 25M847 (Series B) & 25N669 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Adjustable Handles Parts List - 25M847 (Series B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Adjustable Handles Parts List - 25N669 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Drive System Assembly - 25M847 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Drive System Parts List - 25M847 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Drive System Assembly - 25M847 (Series B) & 25N669 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Drive System Parts List - 25M847 (Series B) & 25N669 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Front Assembly - 25M847 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Front Assembly Parts List - 25M847 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Assembly - 25M847 (Series B) & 25N669 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Front Assembly Parts List - 25M847 (Series B) & 25N669 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Controls Assembly - 25M847 (Series B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Controls Assembly Parts List - 25M847 (Series B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Controls Assembly - 25N669 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Controls Assembly Parts List - 25N669 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Spindle Cutter Assembly (24 pin) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Spindle Cutter Assembly Parts List - 25N363 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

DCS Control Box 18A790 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

25N669 only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

DCS System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

DCS Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

. . . . . . . . . . . . . . . . . . 45

2 3A5581C

Page 3

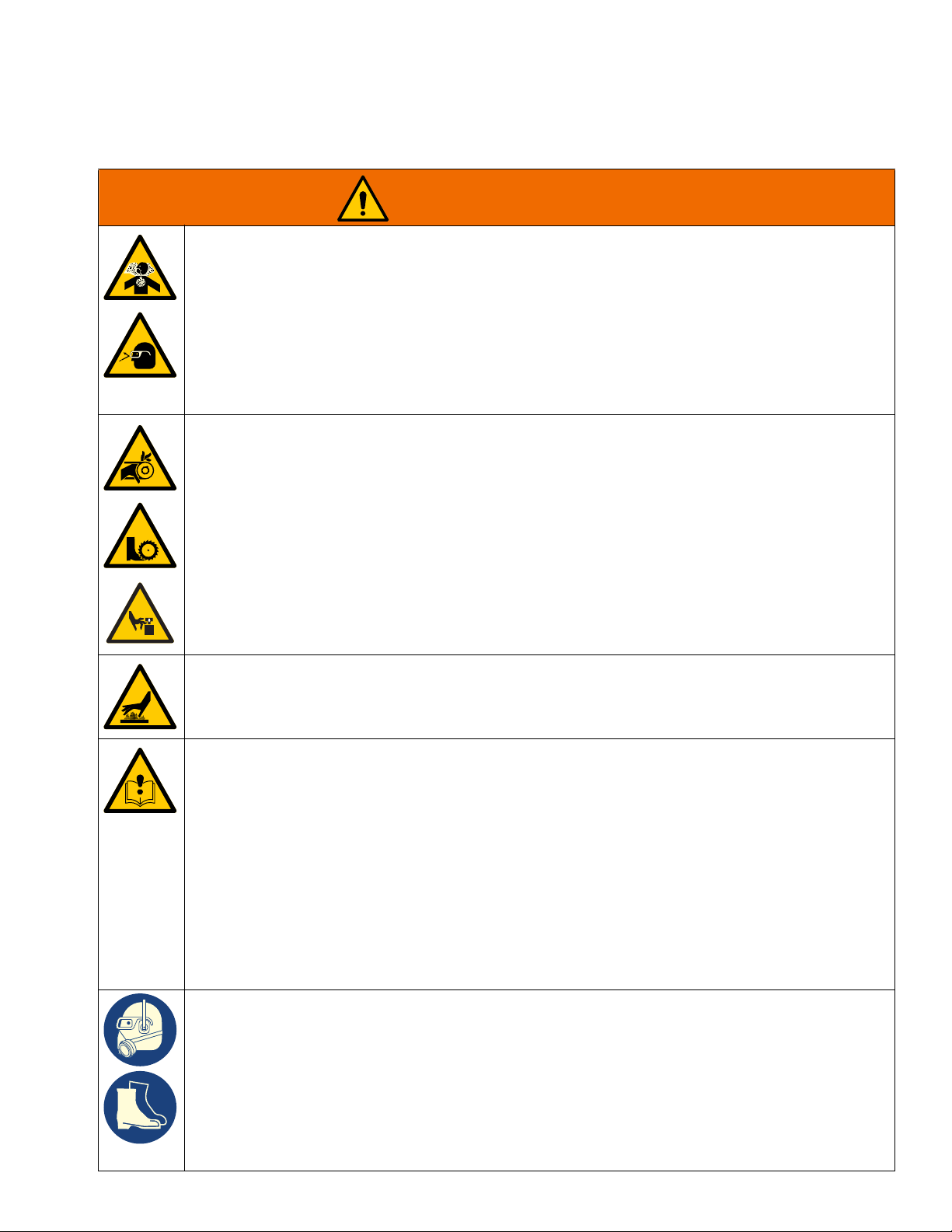

Warnings

WARNING

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation

point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these

symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific hazard

symbols and warnings not covered in this section may appear throughout the body of this manual where applicable.

DUST AND DEBRIS HAZARD

Grinding concrete and other surfaces with this equipment can create dust that contains hazardous

substances. Grinding can also create flying debris.

To reduce the risk of serious injury:

• Control the dust to meet all applicable workplace regulations.

• Wear protective eye wear and a properly fit-tested and government approved respirator suitable for

the dust conditions.

• Use equipment only in a well-ventilated area.

• Grinding equipment must be used only by trained personnel who understand the applicable workplace regulations.

ENTANGLEMENT AND MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Do not wear loose clothing, jewelry or long hair while operating equipment.

• Before checking, moving, or servicing equipment, disconnect battery.

Warnings

BURN HAZARD

Cutters and engine can become very hot during operation. To avoid severe burns, do not touch hot

equipment. Wait until equipment has cooled completely.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not leave the work area while equipment is energized. Turn off all equipment when equipment

is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

• Maintain a safe operating distance from other people in the work area.

• Avoid any pipes, columns, openings, or any other objects protruding from work surface.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of dust or

chemicals, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eye wear.

• Protective shoes.

• Gloves.

• Hearing protection.

• Properly fit-tested and government approved respirator suitable for the dust conditions.

3A5581C 3

Page 4

Warnings

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Do not fill fuel tank while engine is running or hot; shut off engine and let it cool. Fuel is flammable

and can ignite or explode if spilled on hot surface.

• Keep work area free of debris, including solvent, rags and gasoline.

• Keep a fire extinguisher in work area.

CARBON MONOXIDE HAZARD

Exhaust contains poisonous carbon monoxide, which is colorless and odorless. Breathing carbon

monoxide can cause death.

• Do not operate in an enclosed area.

BATTERY HAZARD

Lead-acid batteries produce explosive gases and contain sulfuric acid that can cause severe burns. To

avoid sparks and injury when handling or working with a lead-acid battery:

• Read and follow the battery manufacturer’s warnings.

• Exercise caution when working with metallic tools or conductors to prevent short circuits and sparks.

• Keep all sparks, flames, and cigarettes away from batteries.

• Always wear protective eyewear and protective equipment for face, hands, and body.

• If you have direct contact with battery fluid, flush with water and consult a physician immediately.

• Installation and maintenance must be performed by knowledgeable personnel only.

Battery Disposal

Do not place batteries in the trash. Recycle batteries according to local regulations. In the USA and Canada call

1-800-822-8837 to find recycling location or go to www.call2recycle.org.

4 3A5581C

Page 5

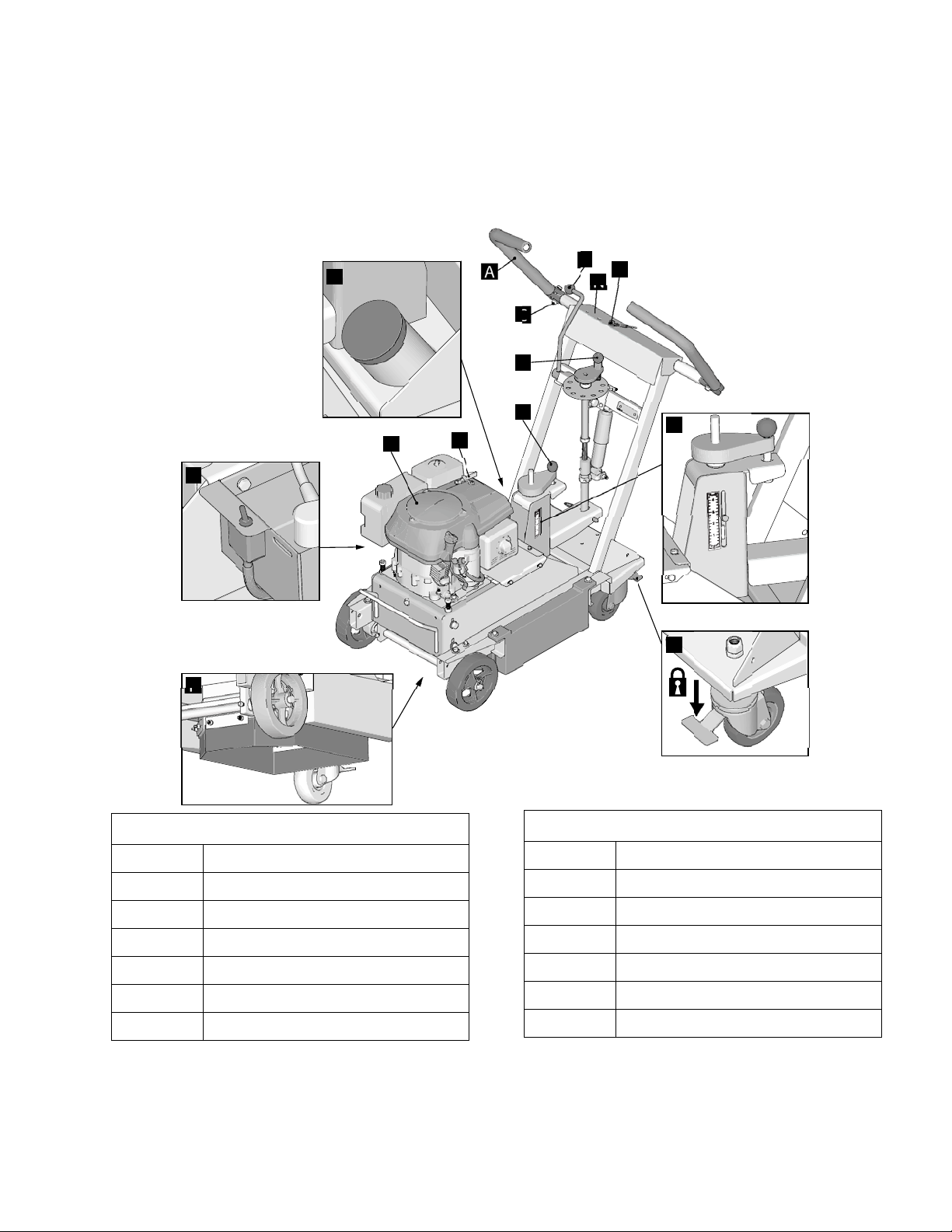

Component Identification

A

B

C

D

E

H

J

L

F

G

I

M

K

ti33805a

N

25M847

Component Identification

Component

Component

A Handlebar

B Cutter Head Engage Lever

C Handlebar Adjustment Bolts

D Cutter Head Adjustment Dial

E Pressure Control Dial

FDust Skirt

G Vacuum Port

H Engine

I Electric Start Engine Switch

J Engine Throttle

K Engine Kill Button

L Pressure Indicator

M Wheel Stop

N Hour Meter / Tachometer

3A5581C 5

Page 6

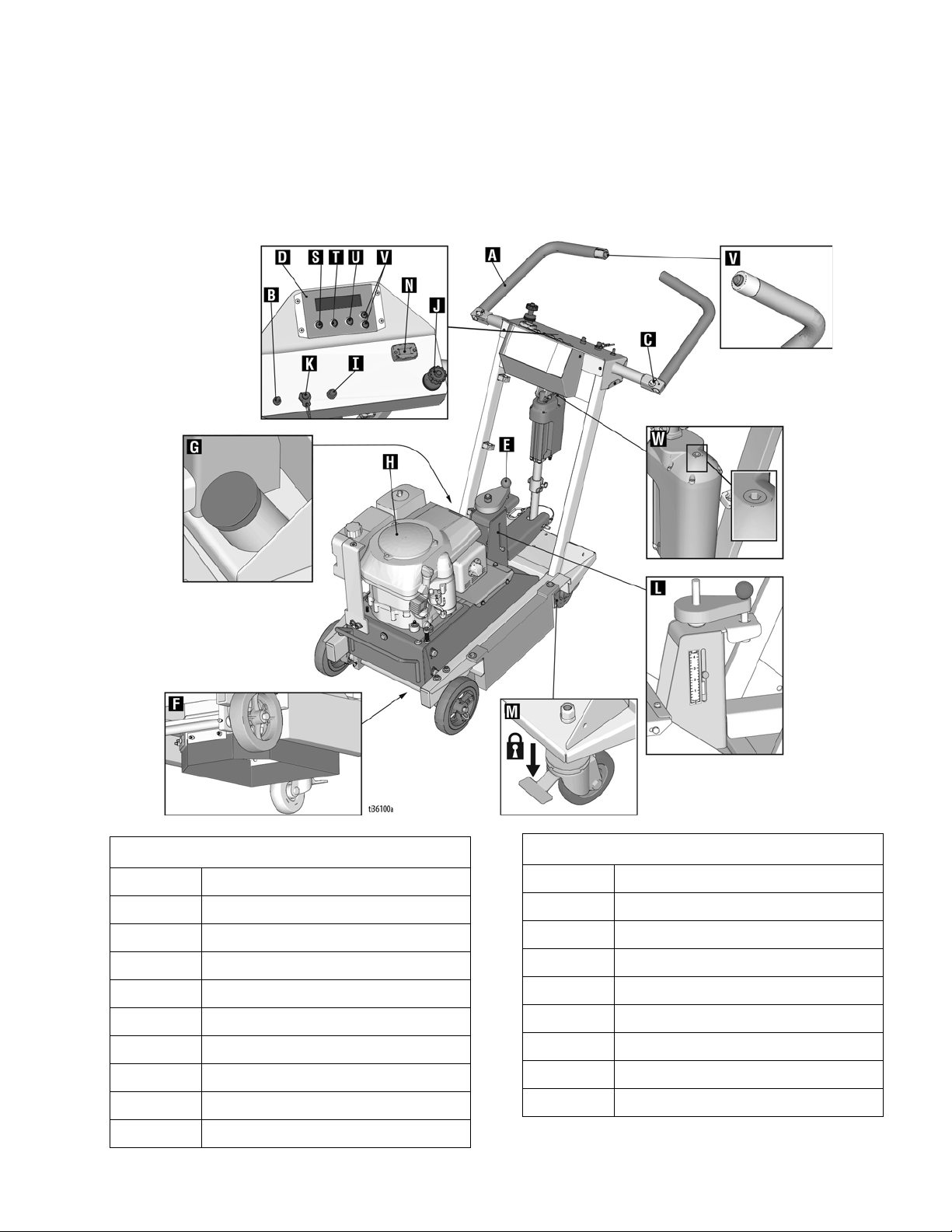

Component Identification

Component Identification

25M847 (Series B)

Component

A Handlebar

B Cutter Head Engage Lever

C Handlebar Adjustment Bolts

D Cutter Head Adjustment Dial

E Pressure Control Dial

FDust Skirt

G Vacuum Port

6 3A5581C

HEngine

I Electric Start Engine Switch

J Engine Throttle

K Engine Kill Button

L Pressure Indicator

M Wheel Stop

N Hour Meter/Tachometer

Component

Page 7

Component Identification

25N669

Component Identification

Component

A Handlebar

B Power Switch

C Handlebar Adjustment Bolts

DDCS Control

E Pressure Control Dial

FDust Skirt

G Vacuum Port

H Engine

I Electric Start Engine Switch

J Engine Throttle

3A5581C 7

K Engine Kill Button

L Pressure Indicator

M Wheel Stop

N Hour Meter/Tachometer

S Home Button

T Zero Button

U Cut Depth Button

V Up/Down Buttons

W Manual Height Adjustment

Component

Page 8

Setup

Setup

Handle Bar Adjustment

The handlebars are equipped with a high-density

vibration suppression material to reduce operator fatigue

when operating equipment. To adjust the handlebars to

a new position for different height operators please follow

these steps:

1. Using a 9/16” (14mm) wrench or socket, loosen the

bolts on both sides of the handlebars until the

handlebar moves freely.

2. Stand behind the machine and lightly tap the

handlebar to the desired position.

3. Re-tighten the bolts to 21.7 to 25 ft-lb (29-34 N•m)

to lock the handlebars into position.

NOTE: Never operate equipment with loose handlebars.

The bolts must be fastened tightly assuring the handle is

locked into position.

Cutter Head Installation/Replacement

Normal use will require periodic cutter head inspection

and may necessitate cutter replacement. Time of

replacement will vary according to usage and load

factors.

To avoid injury from unexpected start up, disconnect

spark plug wire and black battery cable before you

service your unit.

1. Non-DCS Models: Raise the Cutter Head Engage

Lever to the up position so the cutter head is off the

ground.

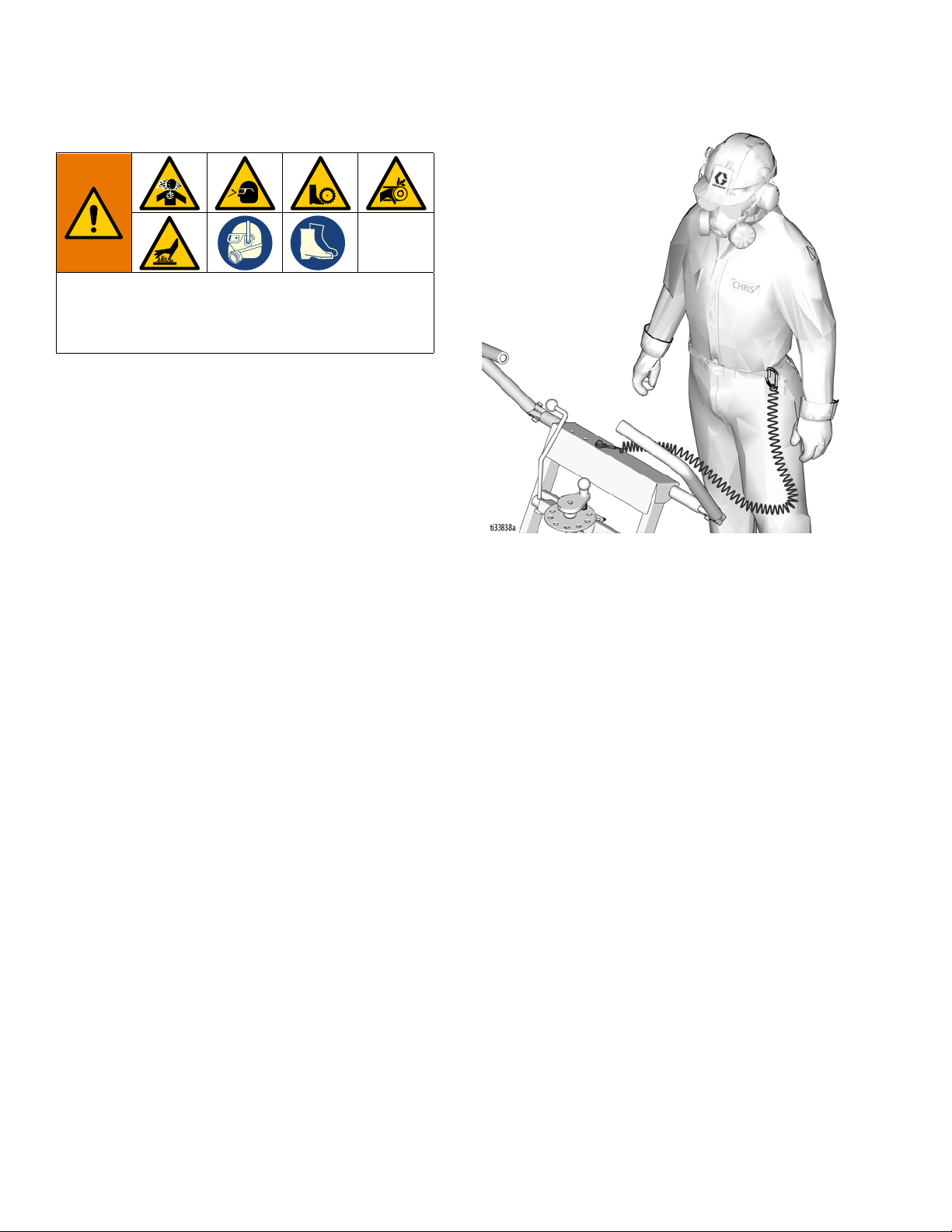

Engine Kill Button

In the event of a malfunction or an accident (such as the

machine operator falling or losing footing), the

GrindLazer is equipped with a corded Engine Kill Button.

Attach the end of the cord to the operator’s belt or wrist,

and snap the clip into place on the button by raising the

top of the Engine Kill Button and inserting the clip into the

gap. If the operator becomes distanced too far from the

machine, the cord will detach from the button and the

machine will stop running. The engine can also be

stopped by pressing down on the Engine Kill Button.

8 3A5581C

DCS Models: Press the Home Button on the DCS

Control so the cutter head is off the ground.

2. Remove Clevis Pin.

Page 9

Setup

3. Non-DCS Models: Rotate Cutter Head Engage

Lever to upwards position to release lower linkage

from inner frame.

5. Unhook spring from the spring plunger (bottom rear

section of machine).

6. Rotate the inner frame upwards to gain access to

the cutters.

DCS Models: Press the Home Button on the DCS

Control.

4. Turn the pressure control dial until the indicator is at

“0”. This releases tension from the pressure control

spring.

7. If there is a cutter head attached, it must be

removed. To do so, strike the cutters in a counter

clockwise direction with a rubberized mallet or wood

block.

3A5581C 9

Page 10

Setup

8. Install the new cutter assembly onto the machine by

spinning clockwise. Cutters will lock onto the

machine once surface removal is started.

10. Connect the spring to the spring plunger.

11. Lower the lower linkage into the slot in the inner

frame by rotating the Cutter Head Engage Lever

(non-DCS models), or by using the Down Button on

the DCS Control (DCS models).

9. Lower the inner frame back to a horizontal position.

12. Connect Clevis Pin.

10 3A5581C

Page 11

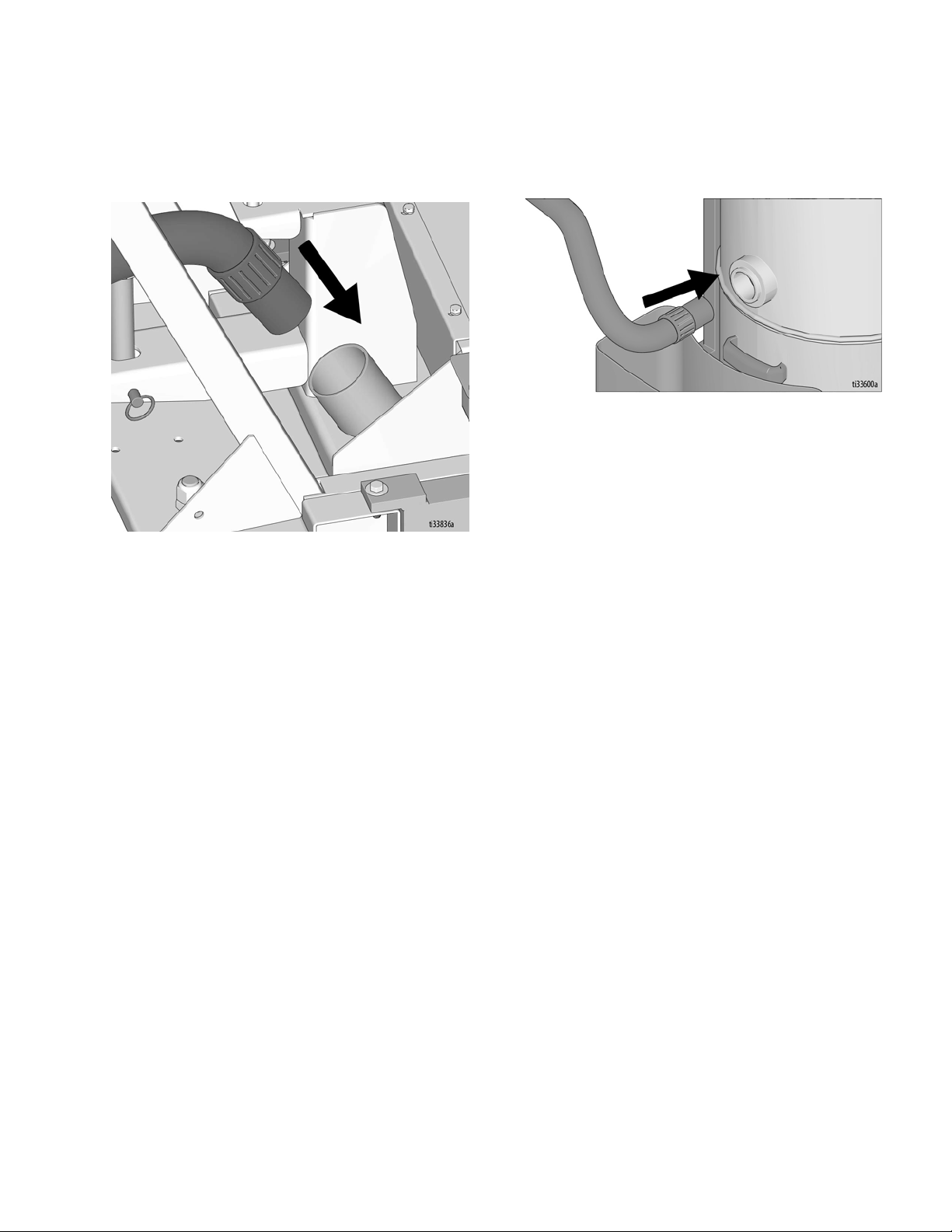

Dust Control

Vacuum Attachment

Setup

1. If using a vacuum, attach vacuum hose to the

Vacuum Port.

2. Attach vacuum hose to the Inlet Port on the Cyclone

Separator (optional) or vacuum.

3A5581C 11

Page 12

Setup

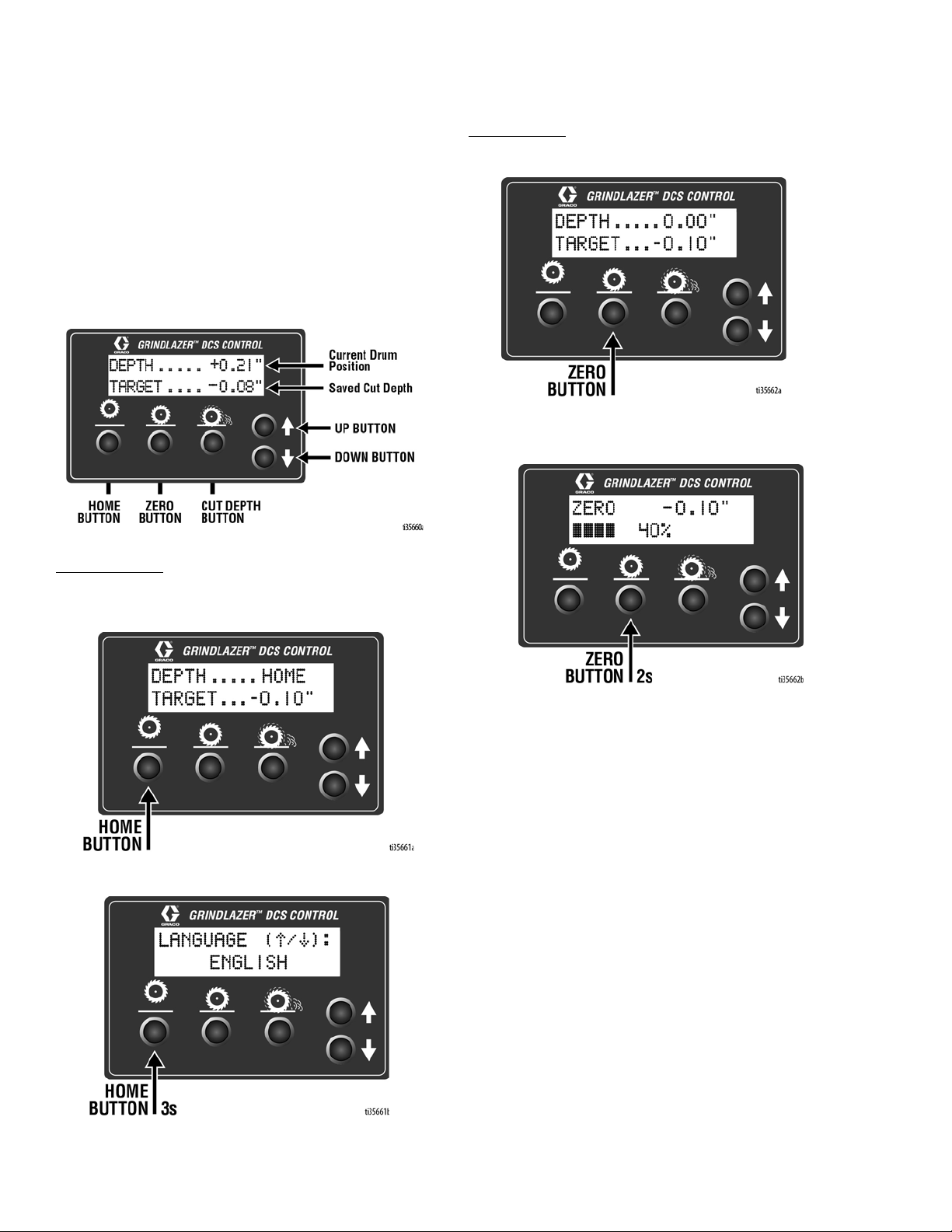

DCS Control (DCS Models only)

Buttons on the DCS Control have two functions, quick

press and long press. Quick press refers to pressing the

button and releasing the button quickly, while long press

is pressing the button and holding the button for two or

more seconds.

NOTE: “+” (plus) refers to above pavement surface. “-”

(minus) refers to below pavement surface.

Run Screen

Home Button

Zero Button

Quick Press: Takes the cutter head to the surface.

Long Press: Reprograms the zero point to the current

cutter head position.

Quick Press: Takes the cutter head to its highest

position.

Long Press: Brings up Menu Screen.

12 3A5581C

Page 13

Cut Depth Button

Quick Press:

get.

Long Press:

- If at or above zero point: Opens new screen to

select desired cut depth using up/down buttons.

Takes the cutter head to the Cut Depth Tar-

•To exit without saving, quick press the Cut Depth

Button.

•To exit with saving, long press the Cut Depth Button.

Setup

Up Arrow Button*

Quick Press: Raises the cutter head by 0.01” (0.25mm,

10 mil).

Long Press: Raises the cutter head to Home position.

- If below zero point: Reprograms the Cut Depth Target to the current cutter head position.

Down Arrow Button*

Quick Press: Lowers the cutter head by 0.01” (25mm, 10

mil).

Long Press: Lowers the cutter head to Cut Depth Target.

*Handlebar Rocker Switch has the same functions as Up

and Down Arrow Buttons.

3A5581C 13

Page 14

Setup

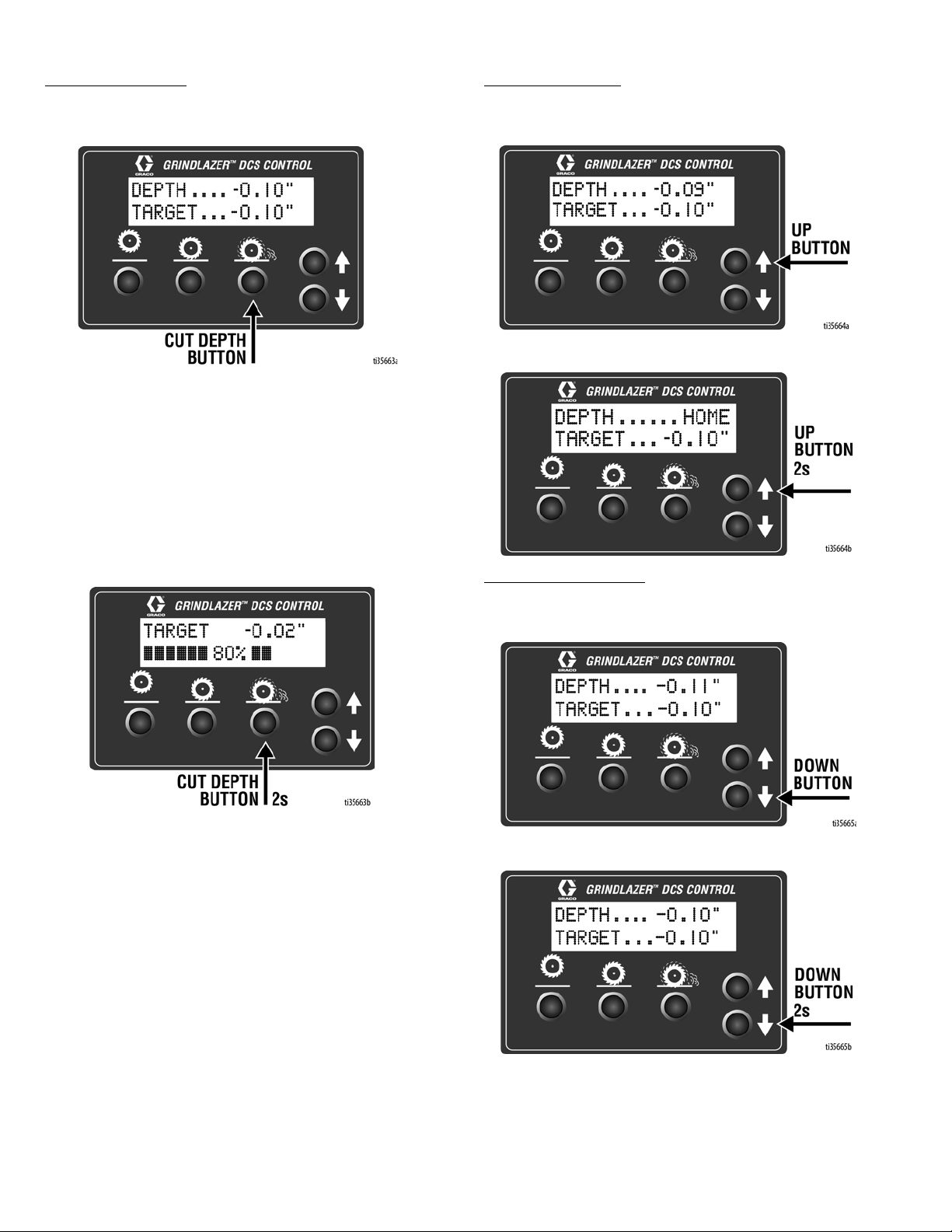

Menu Screens

To display the Menu Screens, hold down Home Button

from the Run Screen. To save menu settings and return

to Run Screen, hold down Home Button from any Menu

Screen.

To cycle through selections in each Menu Screen, use

Up and Down Arrow Buttons.

To advance to next Menu Screen, quick press the Home

Button.

Menu Screen #1 - Language

Select your desired language (English, Spanish,

French, German, or International Symbols).

Menu Screen #3 - Model Select

Your GrindLazer model name can be found on the handlebar dashboard label. Select the model on the DCS

Control which matches the model you have. This

ensures accurate depth readings. Hold down Up or

Down Arrow Buttons to cycle through models.

Menu Screen #4 - Software revision

Displays the revision of the software on the DCS Control.

Menu Screen #2 - Units

Select your desired depth units (inches, millimeters, or

mils).

14 3A5581C

Page 15

Setup

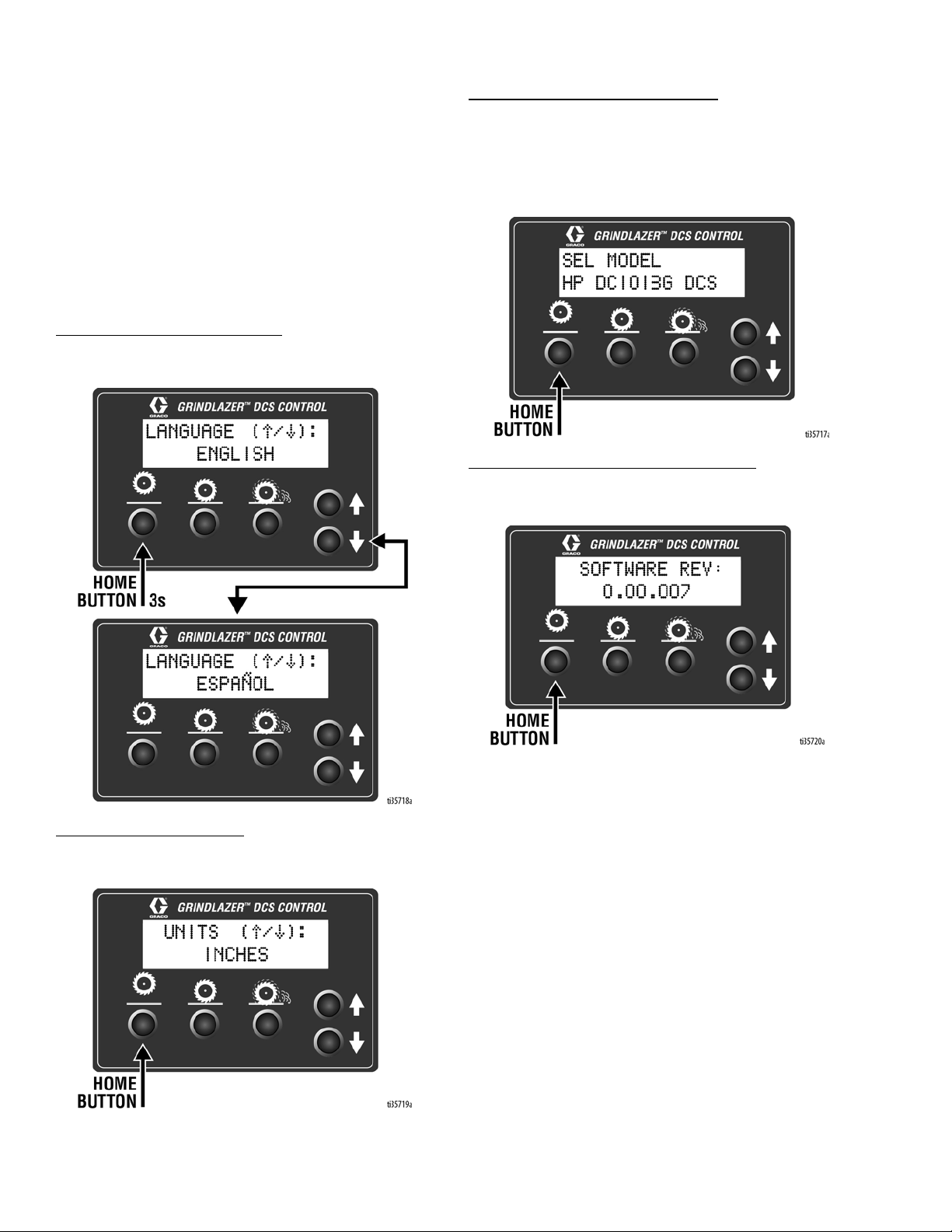

Menu Screen #5 - Error Codes

Displays the most recent error code and the total number of times that error has occured. Cycle through previous error codes using Up/Down Buttons.

Error Codes

E04: High Voltage

E05: High Motor Current

E08: Low Voltage

E09: Hall Sensor Error

E12: High Current (short circuit)

E31: Home Button Error

E32: Zero Button Error

E33: Cut Depth Button Error

E34: Up Button Error

E35: Down Button Error

To clear an error code that appears while on the Run

Screen:

1. Turn DCS Power Switch OFF.

2. Address/Fix the issue.

3. Turn DCS Power Switch ON.

NOTE: See Repair Manual for more information on

Error Codes and Troubleshooting.

3A5581C 15

Page 16

Operation

Operation

Do not start machine while cutter head is in contact

with the ground. Doing so can cause the operator to

lose control of the machine, resulting in property

damage and/or personal injury.

Machine Start Up

Before starting engine, perform the following:

• Read and understand engine manual.

• Make sure all guards are in place and secure.

• Make sure all mechanical fasteners are secure.

• Inspect for damage to engine and other exterior

surfaces.

• Inspect work area to locate any pipes, columns,

deck inserts, or other objects protruding from work

surface. Avoid these objects during operation.

Starting the Engine

• Connect Engine Kill Button Cord to operator and

machine.

• Open the fuel shut off on the gas tank and then

place the throttle lever at the “fast idle” position.

• Move the choke to closed.

• Push the Electric Start Engine Switch to start the

engine.

• After the engine starts, move choke to open.

• Set throttle to desired setting.

If the Engine Does Not Start

• Check engine for proper gas level.

• Check the spark plug. Make sure socket areas are

clean and clear of debris, and the proper gap is set.

Replace if needed.

• Battery might be dead. Try pulling the starter cord.

• Engine may have tilted backwards. If so, allow oil to

drain after removing spark plug.

• If engine still does not start, refer to the engine

manual.

• The engine will not start without the Corded Engine

Kill Clip securely in place.

16 3A5581C

Page 17

Operation

C

B

A

Cutting Material

Maintain a safe operating distance from other people

in the work area. Avoid any pipes, columns, openings,

or any other objects protruding from your work surface.

1. Start Engine, see page 16.

2. Turn vacuum on, if using a vacuum.

Adjusting Cutter Head Angle

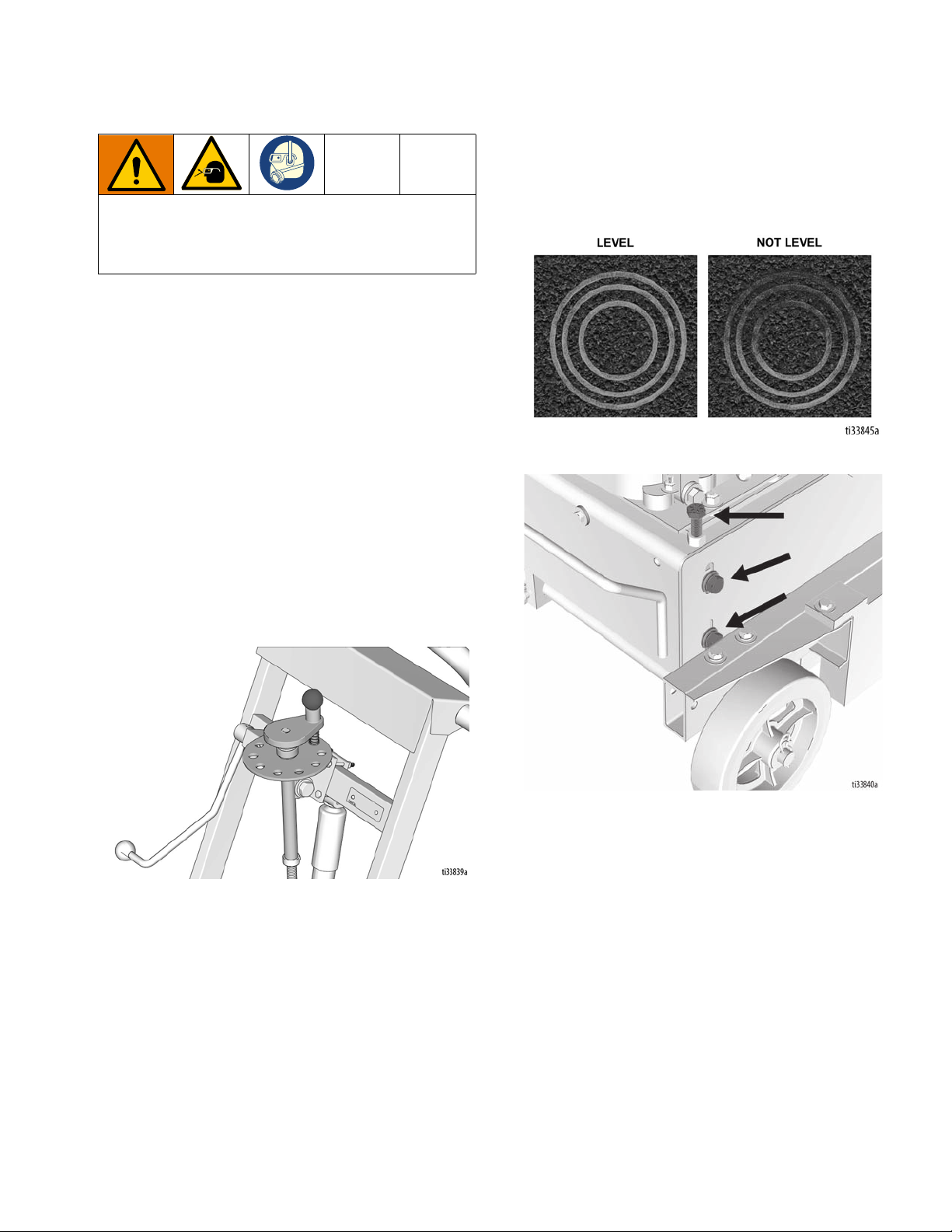

1. Locate a level surface for cutter adjustment. All four

wheels should be on a level surface for setup.

2. Run at about 1/3 engine throttle.

3. Non-DCS Models: Lower the Cutter Head Engage

Lever.

5. Move the machine away from the current position to

inspect the cut. Use the elevation screws in the front

of the machine to pitch the cutter to the correct

plane to create the desired cut pattern. Loosen bolts

A and B, then adjust bolt C to modify the cutter head

angle. Tighten bolts A and B when the desired

cutter angle is achieved.

4. Non-DCS Models: Slowly lower the Cutter Head

Adjustment Dial and at first sign of dust from the

cutters, raise the depth control knob up a couple of

turns and then lift the Cutter Head Engage Lever

back up.

DCS Models: Slowly lower the cutter head by pressing

the Down Button on the DCS Control repeatedly until the

first sign of dust from the cutters. Then raise the cutter

head off of the surface by pressing the Home Button.

3A5581C 17

Page 18

Operation

Max

Min

Concrete Cutting Setup

The machine set-up required when cutting

concrete is as follows:

1. Cutters should be parallel to the ground when

engaged.

2. Use the Pressure Control Dial to set the Pressure

Indicator to 0-1.

3. The cutting mark left by the machine should be an

even circle.

4. If the mark left by the machine is not as shown, adjust

the elevation screws accordingly. See page 17.

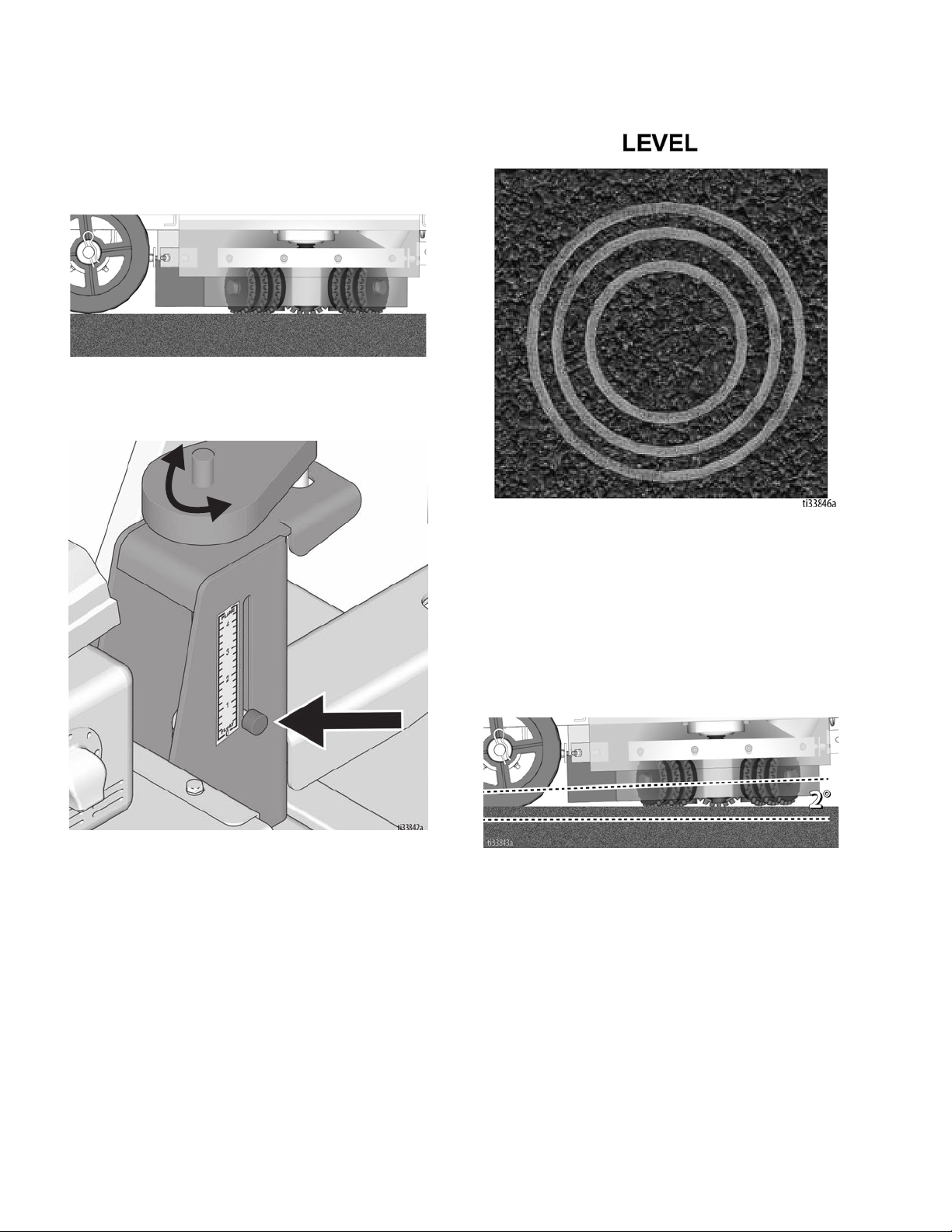

Asphalt Cutting Setup

The machine set-up required when cutting

asphalt is as follows:

1. Cutters should be at an angle no more than 2

degrees to the ground when engaged.

18 3A5581C

Page 19

Operation

2. Use the Pressure Control Dial to set the Pressure

Indicator to 2-3.

Cutting Technique

These are recommended settings only. Increasing

spring tension, depth of cut and pitch will increase the

removal speed at the expense of reduced life and

surface finish.

NOTICE

Care must always be taken to lift up the rotating

heads over any significant obstruction, including steel

or concrete expansion joints that can cause the cutters or spindle components to break.

NOTICE

NOTICE

Should you desire to tilt the machine, always tilt

forward. Tilting the machine backwards at any time

will flood the spark plug with oil and may cause

damage to your engine.

NOTE: On harder surfaces, it may be best to make

several passes in increments of 1/32 in. (0.8 mm) to get

to the desired depth.

3. The cutting mark left by the machine should be an

uneven circle.

4. If the mark is in the wrong direction, adjust the

elevation screws to pitch the cutter head to the

correct plane. See page 17.

• Make certain that the cutter head is positioned to

where only the cutter tips strike the surface.

• The cutter head will not withstand substrate contact.

NOTE: Contacting the removal surface too deeply

will cause premature wear to the cutter head and

other components. The correct depth setting is

indicated by relatively little machine vibration.

• Cutting too deep only has negative results. Try to

remove materials in several passes rather than one,

deep pass. Several tests will show the best, most

appropriate cutter impact. Use a forward, backward

and/or circular pattern to achieve your desired

finish.

NOTE: Positioning the machine over the surface in

many directions, as well as dialing the hand wheel up or

down can help create desirable surface patterns. After

several hours of practice, the operator will become

comfortable and should be able to remove materials

faster with enhanced results.

NOTE: The engine should not labor. Run engine at full

speed and adjust the forward speed to fit the work being

performed. Harder concrete surfaces will have to be cut

at a slower pace than asphalt or other softer surfaces.

3A5581C 19

Page 20

Operation

Stop Cutting Material

1. Non-DCS Models: Raise Cutter Head Engage

Lever so that the cutter head is off the ground.

2. Adjust Engine Throttle to low setting.

3. Depress Engine Kill Button.

DCS Models: Press the Home Button on the DCS

Control.

4. Clean the entire exterior of the machine after it has

cooled. Check for worn or damaged parts and

perform any required Maintenance on page 23.

20 3A5581C

Page 21

Operation

DCS Instructions

Each time the DCS Control is turned on, the DCS actuator will travel to the Home position.

Once the DCS Control finds Home, ensure the correct

model is selected as well as your desired language and

units. See Menu Screens, page 14, for instructions on

changing these settings.

Set Zero Point:

With the engine on, lower the cutter head by pressing

the Down Arrow Button until you hear the cutters make

contact with the pavement surface. Hold down the Zero

Button for 2 seconds. Your Zero Point has now been

saved.

NOTE: The Cut Depth Target is based off of the Zero

Point. Re-program the Zero Point if the cutter head is

changed or worn.

Set Cut Depth Target:

Quick press the Zero Button to take the cutter head to

the pavement surface. Set the Cut Depth Target by:

1. Quick pressing the Down Arrow Button as many

times as needed to achieve your target. Then long

press the Cut Depth Button to save your target.

NOTE: This method will lower the cutter head into

the pavement surface as you set your cut depth.

OR

2. From the Zero Point, long press the Cut Depth Button until a new screen pops up. Use the Down

Arrow Button to enter your Cut Depth Target. Then

long press the Cut Depth Button to save your target

and return to the Run Screen.

NOTE: This method will keep the cutter head stationary as you set your Cut Depth Target.

3A5581C 21

Page 22

Operation

The DCS Control is now ready to grind/scarify. Long

press down on the Handlebar Rocker Switch to lower

the cutter head to your Cut Depth Target. Short press up

or down on the switch to adjust your Cut Depth on the

fly. When finished with your cut, long press up on the

switch to raise the cutter head to the Home position.

NOTE: The Zero Point and Cut Depth are referenced

from the Home position. Recalibrate your DCS Control

periodically by pressing the Home button or long pressing up on the Handlebar Rocker Switch.

NOTE: Pressing any button while the cutter head is

moving to Zero or Cut Depth will stop the command and

halt the cutter head from moving any further up or down

until another button is pressed.

Manual Height Adjustment

If the DCS Control is not usable (dead battery, etc.), the

cutter head height can be adjusted using the Manual

Height Adjustment feature.

1. Remove fuse from fuse holder near positive battery

terminal. This will protect the battery from damage.

3. Insert 6mm hex key into the port the screw plug was

removed from.

- One revolution of the hex key results in 0.10”

(2.5mm, 100 mil) of adjustment at the cutter

head.

- Rotate counterclockwise to lower the cutter

head cutter head; rotate clockwise to raise the

cutter head. Max rotation speed of 1 revolu-

tion per second. Do not use power tools in

the Manual Height Adjustment port.

4. Once the desired depth is achieved, replace the

screw plug in order to keep water and dust out.

2. Use a 6mm hex key to remove the screw plug on

the top of the linear actuator.

22 3A5581C

Page 23

Maintenance

Avoid touching engine and cutter head after use until

they have completely cooled. To avoid injury from

unexpected start up, disconnect spark plug wire and

black battery cable before you service your unit.

The following steps should be performed to maintain

proper operation and sustain the life of the GrindLazer.

Maintenance

AFTER THE FIRST 20 HOURS OF

OPERATION:

• Drain engine oil and refill with clean oil. See engine

manual for correct viscosity.

EVERY 40-50 HOURS OF OPERATION:

• Change engine oil (see engine manual).

• Grease wheel bearings.

BEFORE OPERATION:

• Visually inspect the entire unit for damage or loose

connections.

• Check engine oil (see engine manual).

• Check bushings and cutters.

• Check cutter for uneven wear.

DAILY:

• Check all fasteners and re-tighten.

• Clean dust and debris from exterior of unit (do NOT

use pressure washer or other high pressure

cleaning equipment).

• Inspect dust skirts for damage. Repair or replace

damaged skirts in order to help dust and debris

containment.

• Check engine oil level and fill as necessary.

• Check and fill gas tank.

• Remove air filter cover and clean element. Replace

element if necessary. Replacement elements can

be purchased from your local engine dealer.

AS REQUIRED:

• Check drive belt and tension and tighten or replace

as needed.

For additional information about engine maintenance,

see engine manual.

• Grease the Cutter Head Engage Lever and lower

linkage (non-DCS models only).

3A5581C 23

Page 24

DCS Control Translations (DCS Models only)

DCS Control Translations (DCS Models only)

English Español Français Deutsche International

FINDING HOME ENCONTRANDO INICIO

HOME INICIO

DEPTH ALTURA

TARGET OBJETIVO

ZERO CERO

TROUVER LE DÉBUT

DÉBUT

HAUTEUR

OBJECTIF

ZÉRO

START FINDEN

START

TIEFE

ZIEL

NULL

SEL MODEL MODELO

LANGUAGE IDIOMA

UNITS UNIDAD DE MEDIDA

INCHES PULGADAS

MILLIMETERS MILIMETROS

MILS MILS

SOFTWARE REV SOFTWARE REV

ERROR ERROR

MODELE

LA LANGUE

UNITÉ DE MESURE

POUCES

MILLIMETRES

MILS

REVUE SOFTWARE

ERREUR

MODELL

SPRACHE

MAßEINHEIT

ZOLL

MILLIMETER

MILS

SOFTWARE REV

FEHLER

INCH

MM

MIL

24 3A5581C

Page 25

DCS Control Translations (DCS Models only)

English Español Français Deutsche International

FREQUENCY FRECUENCIA

HIGH CURRENT ALTA CORRIENTE

LOW VOLTAGE BAJO VOLTAJE

HIGH VOLTAGE ALTO VOLTAJE

HALL SENSORS SENSORES DE HALL

HOME BUTTON BOTÓN DE INICIO

FRÉQUENCE

COURANT ÉLEVÉ

BASSE TENSION

HAUTE TENSION

CAPTEURS DE HALL

BOUTON DE DÉBUT

ANZHAL

HOHER STROM

NIEDERSPANNUNG

HOCHSPANNUNG

HALL-SENSOREN

START KNOPF

ZERO BUTTON BOTÓN CERO

CUT BUTTON BOTÓN DE CORTAR

UP BUTTON BOTÓN ARRIBA

DOWN BUTTON BOTÓN DE ABAJO

BOUTON ZÉRO

BOUTON DE COUPE

BOUTON HAUT

BOUTON BAS

NULLTASTE

SCHNITT TASTE

NACH OBEN TASTE

NACH UNTEN TASTE

3A5581C 25

Page 26

Repair

Max

Min

Repair

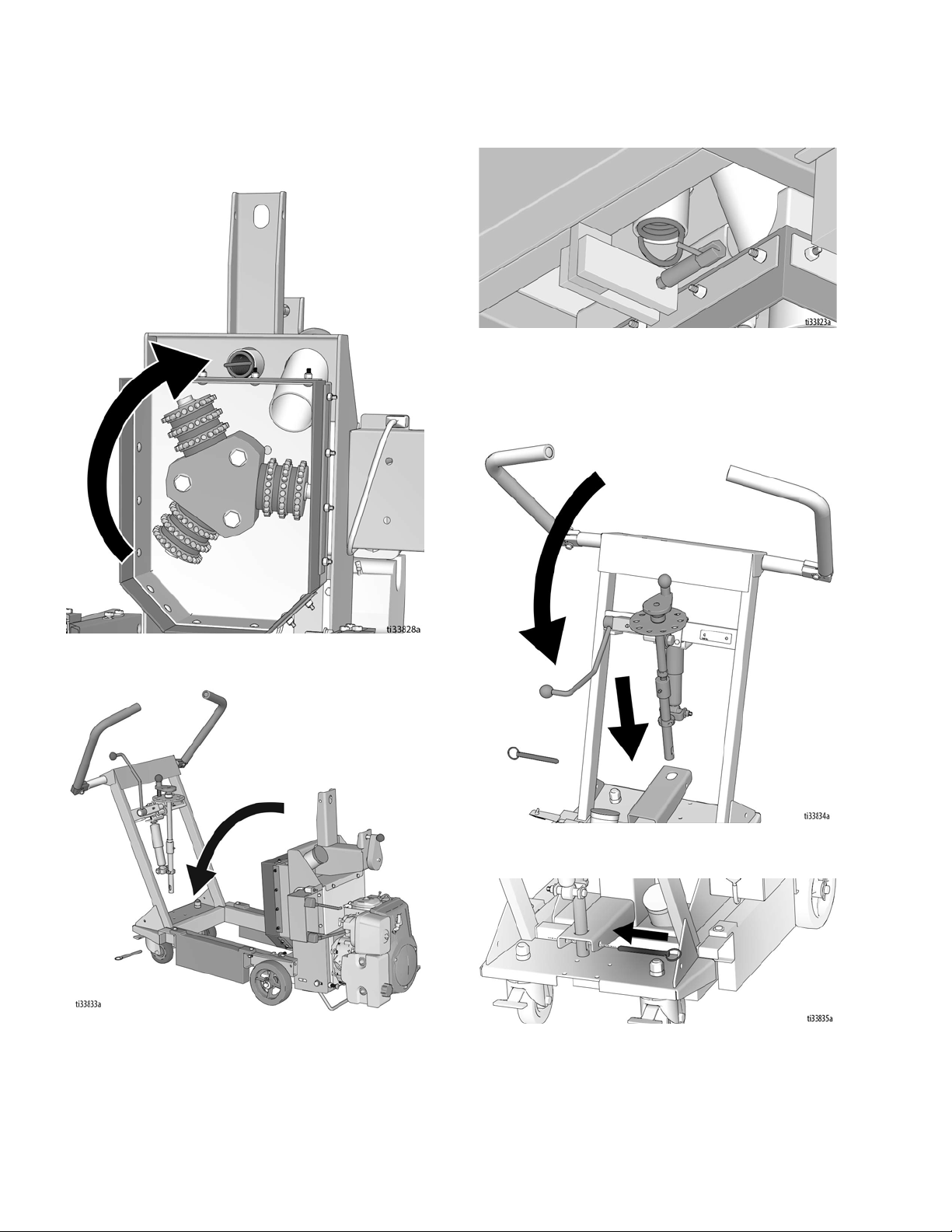

Belt Replacement and Adjustment

To avoid injury from unexpected start up, disconnect

spark plug wire and black battery cable before you

service your unit.

1. Remove Clevis Pin.

2. Non-DCS Models: Rotate Cutter Head Engage

Lever to upwards position to release lower linkage

from inner frame.

3. Use the Pressure Control Dial to set the Pressure

Indicator to 0. This releases tension from the

pressure control spring.

DCS Models: Press Home Button on the DCS Control.

4. Unhook spring from the spring plunger (bottom rear

section of machine).

26 3A5581C

Page 27

Repair

5. Remove belt guards using a 7/16” socket or wrench.

8. To tighten belts, reverse step 6 until desired tension

is achieved.

Drive Pulley Replacement

1. After the belts have been removed, remove the 3

hex bolts using a 7/16” socket.

2. Screw those 3 hex bolts into the threaded holes

shown below and turn equally to remove pulley from

bushing.

6. Unscrew tension bolt using a 9/16” socket or wrench

until belts are loose (do not remove entirely).

7. At this point the belts should be loose enough to be

removed and replaced.

3. To remove bushing, use 1/8” hex key to loosen the

set screw.

***RECOMMENDED***

Use medium strength thread locker or equivalent on set

screws when reinstalling bushing.

3A5581C 27

Page 28

Repair

Engine Pulley Replacement

1. Remove the lock nuts that hold the engine plate to

the inner frame using a 9/16” socket or wrench.

2. Lift the engine off the machine.

3. Remove the hex bolt below the pulley using the 5/8”

socket, followed by the set screws using the 5/32”

hex key.

4. When reinstalling, adjust the pulley so that the

distance between the bottom face of the engine

plate and the uppermost edge of the V-belt groove

is 2 inches.

***RECOMMENDED***

Use medium strength thread locker or equivalent on set

screws when reinstalling pulley.

28 3A5581C

Page 29

Troubleshooting

To avoid injury from unexpected start up, disconnect

spark plug wire and black battery cable before you

service your unit.

Problem Cause Solution

Cutter head is too low Raise the cutter head

Cutters wearing unevenly/prematurely

Cutters Shaft Breakage

unevenly/prematurely

Material build up Clean the cutters

Bearings may be worn Replace bearings

Wrong cutters for application Contact Tech Services

Cutter head is too low Raise the cutter head

Over 40 hours service life Replace shafts

Troubleshooting

Excess Vibration

Machine jumps erratically

Drive belt wearing prematurely

Cutter Head Engage Lever will not

raise/lower (non-DCS models

only)

Cutter Head Adjustment Dial will

not turn (non-DCS models only)

Bearings may be worn Replace bearings

Drive shaft worn Replace drive shaft

Improper cutter set-up Contact Tech Services

Spindle contacting the ground Raise the cutter head

Wheels worn out Replace the wheels

RPM is too low Turn engine throttle to highest setting

Surface is severely uneven Move to smoother surface

Pulley is misaligned Re-align pulley, see

Engine Pulley Replacement, page 28

Wrong belt Order new belt

Cutter Head Adjustment Dial is set too high

or low

Threads are not greased Clean and grease threads

Linkage may be bent Replace linkage

Cutter Head Adjustment Dial may be out of

position

Raise or lower the Cutter Head Adjustment

Dial

Raise or lower cutter head adjustment dial

3A5581C 29

Page 30

Troubleshooting

DCS Models only

Problem Cause Solution

DCS Control not turning onBlown fuse on DCS Power wire. Replace fuse on DCS Power wire.

Power Switch is OFF or damaged. Turn Power Switch ON. Replace Power

Switch if damged.

Battery is dead. Charge Battery.

DCS Control Board is damaged. Replace DCS Control Board.

DCS Control runs for

short time, then turns off

DCS Control is on, but

actutator and/or cutter

head housing does not

move

Engine is not charging the battery. Battery voltage is

14.0-15.0 VDC when engine is full throttle and

charging correctly.

Actuator is disconnected from DCS Control. Check all connections.

A DCS Control Switch is pressed or defective. Ensure all switches are not stuck. Replace

Actuator rod is stuck. Manually move the actuator rod using the

Check engine charging coil and voltage rectifier/regulator. Replace or repair if needed.

switches if defective.

Manual Height Adjustment feature. Remove

screw plug on top of the actuator, then use

6mm hex key to move the rod.

DCS display does not

match Cut Depth.

DCS Control Buttons

work, but display is

blank

Actuator or DCS Control Board is damaged. See flow chart, page 33.

Battery is low. Charge battery.

DCS Control needs to recalibrate its position. Restart the DCS Control.

Zero Position is not set to the pavemet surface. Reprogram the Zero Position. See DCS

Instructions, page 21.

The wrong GrindLazer model is selected on the DCS

Control.

The display is unplugged or damaged. Check that the display ribbon cable and

Select the correct model on DCS Control.

See Menu Screens, page 14.

red/white wire are connected inside Control

Box. Replace if damaged.

30 3A5581C

Page 31

DCS Error Codes

To clear an error code on the DCS Control: 1. Turn DCS Power Switch to OFF.

2. Address/Fix the issue.

3. Turn DCS Power Switch to ON.

Error Cause Solution

Troubleshooting

E04: High Voltage

(20VDC or greater, measured across battery

posts)

E05: High Motor Current (15 Amps or

greater, measured on

blue or brown actuator

wire)

E08: Low Voltage

(7VDC or lower, measured across battery

posts)

E09: Hall Sensor Error Actuator Signal Cable is disconnected from DCS

E12: High Current (short

circuit, 60 amps or

greater, measured on

red or black wire

between battery and

DCS Control)

E31: Home Button Error The Home Button is stuck or shorted. Check to see if Home Button is stuck. If not

E32: Zero Button Error The Zero Button is stuck or shorted. Check to see if Zero Button is stuck. If not

Battery is damaged. Replace battery.

Engine voltage rectifier/regulator is damaged. Replace engine voltage rectifier/regulator.

Actuator rod is stuck. Manually move the actuator rod using the

Manual Height Adjustment feature.

Too high of load. Ensure there is no binding anywhere on the

unit when the actuator is moving.

Battery is low/dead. Charge battery.

Engine is not charging the battery. Check the engine charging coil and voltage

rectifier/regulator. Replace or repair if

needed.

Check all connections. Repair or replace if

Control or is damaged.

Actuator or DCS Control Board is damaged. See flow chart, page 33.

A wire or board component has shorted. Check all wires for shorts. If all wires are

needed.

okay, the DCS Control board may be damaged and need to be replaced.

stuck, replace the Home Button switch.

stuck, replace the Zero Button switch.

E33: Cut Depth Button

Error

3A5581C 31

The Cut Depth Button Error is stuck or shorted. Check to see if Cut Depth Button is stuck. If

not stuck, replace the Cut Depth Button

switch.

Page 32

Troubleshooting

Error Cause Solution

E34: Up Button Error The Up Button or Handlebar Rocker Switch is stuck

or shorted.

E35: Down Button Error The Down Button or Handlebar Switch is stuck or

shorted.

Disconnect Handlebar Rocker Switch from

the DCS Control. Clear the error code.

If the error code reappears 30 seconds

after turning the Power Switch back ON,

the problem is the Up Button on the DCS

Control. Check to see if the Up Button is

stuck. If not stuck, replace the Up Button

Switch.

If the error code does not reappear 30

seconds after turning the Power Switch

back ON, the problem is the Handlebar

Rocker Switch. Check to see if the switch

is stuck. If not stuck, replace the Handlebar Rocker Switch.

Disconnect Handlebar Rocker Switch from

the DCS Control. Clear the error code.

If the error code reappears 30 seconds

after turning the Power Switch back ON,

the problem is the Down Button on the

DCS Control. Check to see if the Down

Button is stuck. If not stuck, replace the

Down Button Switch.

If the error code does not reappear 30

seconds after turning the Power Switch

back ON, the problem is the Handlebar

Rocker Switch. Check to see if the switch

is stuck. If not stuck, replace the Handlebar Rocker Switch.

32 3A5581C

Page 33

DCS Actuator Rod Does Not Move

YES NO

Turn power switch to OFF. Remove the blue shroud behind the DCS Control.

Ensure you have a good 12V battery installed. Disconnect the actuator motor

wires and signal cable from the DCS Control. Connect a multimeter between

the blue and brown wires on the DCS Control. Turn the power switch to ON.

Measure the voltage (DC) within 10 seconds of turning the power on. Does it

measure at least 3.0 VDC?

Connect the blue and brown wires on the

actuator to a good 12VDC battery. First try with

the blue wire on positive post and brown wire

on negative post. If the actuator rod does not

move, put the blue wire on the negative post

and the brown wire on the positive post. Does

the rod move in either case?

REPLACE

ACTUATOR

REPLACE

ACTUATOR

REPLACE DCS

CONTROL BOARD

REPLACE DCS

CONTROL BOARD

NO

NO

NO

YES

Within 10 seconds of turning the power switch to ON (while connected to

a good battery), measure the voltage (DC) between the red and black

wires on the actuator signal cable coming from the DCS Control. Does it

measure at least 10 VDC?

Reconnect the actuator motor wires and signal cable from the actuator to

the DCS Control. Turn the power switch to ON. Does the DCS Control

display the Run Screen within 5 seconds?

YES

YES

BLUE

BROWN

12V

Use this flow chart if the DCS Actuator Rod does not

move or if the DCS displays error code E09 (Hall Sensor

Error). Reference Wiring Diagram, page 54.

Troubleshooting

ti36057a

3A5581C 33

Page 34

Parts

*Use industry standard torques when not specified.

Ref. Torque

20-22 ft-lb (27.1-30.0 N•m)

72-84 in-lb (8.1-9.5 N•m)

1

2

2

1

Parts

Outer Frame Assembly - 25M847

34 3A5581C

Page 35

Outer Frame Assembly Parts List - 25M847

Item: P/N Description Qty

1 17W049 Ball Knob 2

2 17Y998 Handwheel Assembly 1

3 17W111 Spring 1

4 17W119 Locater Pin 1

5 17W127 E-Clip 1

6 17W054 Thrust Bearing 1

7 17W105 5/8” Structural Washer 2

8 17Y022 Upper Linkage 1

9 119563 5/8” Belleville Spring Washer 2

10 17W113 Bronze Washer 2

11 C19075 5/8-11x2.5” Hex Head Bolt 1

12 17W056 Locking Collar 1

13 17W045 Grease Fitting, straight 2

14 17Y114 Lower Linkage 1

15 17W217 Pin Detent 1

16 17W243 Damper Kit 1

17 17W230 Spring Plunger 1

18 17W185 Outer Frame 1

19 17W189 Caster Wheel 2

20 17W234 3/4-10 Jam Nut 6

21 17W261 3/4-10 Nylon Nut 2

22 17W186 Weight 2

23 100023 3/8” Flat Washer 8

24 100003 3/8-16x1.5” Hex Head Bolt 4

25 101566 3/8-16 Nylon Nut 4

26 17W302 Height Control Lever Sheathing 1ft

29

16C393 Warning Label, Foot Cut 2

30

16D646 Warning Label, Hot Surface 2

31 15H108 Warning Label, Pinch 2

32 194126 Warning Label, Fire and Explosion 1

33

17W264 Warning Label, Multiple 1

34 16C394 Warning Label, Entanglement 2

35 17W284 Tachometer (not shown) 1

Replacement warning, safety labels, tags, and cards are

available at no cost.

Parts

3A5581C 35

Page 36

Parts

*Use industry standard torques when not specified.

Ref. Torque

72-84 in-lb (8.1-9.5 N•m)

1

1

Shock Assembly - 25M847

Shock Assembly Parts List

Item: P/N Description Qty

1 17W247 Upper Shock Mount Clamp 1

2 17W246 Upper Shock Mount Bracket 1

3 17W248 1/4-20x2.25” Hex Cap Screw 4

4 17W020 1/4” Flat Washer 8

5 17W126 Shock Absorber 1

36 3A5581C

6 17W125 3/8-16x1.5” Hex Cap Screw 1

7 100023 3/8 Flat Washer 2

8 17W123 Lower Shock Mounting Bracket 1

9 101566 3/8-16 Nylon Nut 1

10 102040 1/4” Nylon Nut 4

Page 37

Adjustable Handles - 25M847

*Use industry standard torques when not specified.

Ref. Torque

20-22 in-lb (27.1-30.0 N•m)

1

1

Parts

Adjustable Handles Parts List - 25M847

Item: P/N Description Qty

1 100003 3/8-16x1.5” Hex Cap Screw 4

2 100133 3/8” Lock Washer 4

3 120454 5/16” Flat Washer 4

4 17W003 Handle Clamps 4

5 17W268 3/16 x 1-1/4 Roll Pin 2

6 17W216 Adjustable Handle Bars 2

7 17W195 Long Handle Bar Grips (24” Long) 2

8 17W269 Short Handle Bar Grips (4.5” Long) 2

9 17W009 Small Black Tube Caps 4

3A5581C 37

Page 38

Parts

Ref. Torque

20-22 in-lb (27.1-30.0 N•m)

72-84 in-lb (8.1-9.5 N•m)

1

2

25M847 (Series B)

25N669

Adjustable Handles - 25M847 (Series B) & 25N669

38 3A5581C

Page 39

Adjustable Handles Parts List - 25M847 (Series B)

Item: P/N Description Qty

1 17Y113 Cable, Vernier Control 1

2 18A137 Starter Assembly 1

3 18A143 Kill Switch Assembly 1

4 18A133 Tachometer Assembly 1

5 17W269 Grip, Foam, Handlebar, 4.5” 2

6 17W003 Clamp, Handlebar Locking 4

7 100003 Screw, Cap, Hex Head, 3/8-16x1.5” 4

8 100133 Washer, Lock, 3/8” 4

9 120454 Washer, Flat, 5/16” 4

10 17W268 Pin, Roll, 3/16” DIA x 1-1/4” 2

11 18A331 Handle, Adjustment, Bar, right 1

12 17W216 Handle, Adjustment, Bar, left 1

13 17W195 Grip, Foam, Handlebar, 24” 2

14 17W009 Plug, Cap, 3/4” 4

15

17W264 Warning Label, Multiple 1

Replacement warning, safety labels, tags, and cards are

available at no cost.

Parts

Adjustable Handles Parts List - 25N669

Item: P/N Description Qty

1 17Y113 Cable, Vernier Control 1

2 18A137 Starter Assembly 1

3 18A143 Kill Switch Assembly 1

4 18A142 Power Switch Assembly 1

5 18A133 Tachometer Assembly 1

6 17W269 Grip, Foam, Handlebar, 4.5” 2

7 17W003 Clamp, Handlebar Locking 4

8 100003 Screw, Cap, Hex Head, 3/8-16x1.5” 4

9 100133 Washer, Lock, 3/8” 4

10 120454 Washer, Flat, 5/16” 4

11 17W268 Pin, Roll, 3/16” DIA x 1-1/4” 2

12 18A331 Handle, Adjustment, Bar, right 1

13 17W216 Handle, Adjustment, Bar, left 1

14 17W195 Grip, Foam, Handlebar, 24” 1

15 18A424 Grip, Foam, Handlebar, 23” 1

16 17Y120 Housing, control switch 1

17 17Y999 Switch, Rocker 1

18 17W009 Plug, Cap, 3/4” 3

19

17Y160 Warning Label, Multiple 1

Replacement warning, safety labels, tags, and cards are

available at no cost.

3A5581C 39

Page 40

Parts

*Use industry standard torques when not specified.

Ref. Torque

28-30 ft-lb (38.0-40.0 N•m)

144-180 in-lb (16.2-20.0 N•m)

72-84 in-lb (8.1-9.5 N•m)

123

2

3

3

2

2

1

3

Drive System Assembly - 25M847

40 3A5581C

Page 41

Drive System Parts List - 25M847

Item: P/N Description Qty

1 17W089 Hex Slotted Screw - Self Tapping 2

2 17X251 Throttle Cable Assembly 1

3 17W143 #10 Flat Washer 2

4 17W262 #10-32 Nylon Nut 2

5 17W194 13HP Engine 1

6 110838 5/16” - 18 Nylon Nut 2

7 120454 5/16” - Flat Washer 6

8 17W211 Engine Pulley 1

9 17W088 Key for Engine Pulley 1

10 17W212 Drive Pulley 1

11 17W213 Bushing for Drive Pulley 1

12 17W146 7/16” Fender Washer 1

13 17X252 Key for Drive Pulley 1

14 116645 7/16-20x1” Hex Head Bolt 1

15 17W210 Drive Belt 2

16 17W057 1/2-20x4” Hex Head Bolt 4

17 101566 3/8-16 Nylon Nut 4

18 100023 3/8” Flat Washer 4

19 17W218 1/2” Hardened Spacer 8

20 17W191 Engine Mount Plate 1

21 17W238 Driveshaft Housing Assembly 1

22 108843 6/16-18x1 3/4” Hex Head Bolt 2

23 17W197 Rubber Bushing 4

24 17W193 Engine Mount Spacer 2

25 100214 5/16” Lock Washer 2

26 109031 5/16”-24x1” Hex Head Bolt 2

27 17W220 Cap Plug 1

28 17W175 Inner Frame 1

29 17W192 Engine Tensioner 1

30 17W183 Cutter Head Guard 1

31 17W222 Skirt Retainer (med) 1

32 17W223 Skirt Retainer (small) 2

33 17W184 Rubber Skirt 1

34 17W224 Skirt Retainer (large) 3

35 17W020 1/4” Flat Washer 18

36 102040 1/4-20 Nylock Nut 18

37 107139 1/4-20x1” Carriage Bolt 18

38 101926 1/2-20 Nylock Nut 4

40* 17W029 Deflector for Engine 1

41 17W964 Self Tapping Screws for Deflector 3

* Not Shown

Parts

3A5581C 41

Page 42

Parts

*Use industry standard torques when not specified.

Ref. Torque

28-30 ft-lb (38.0-40.0 N•m)

144-180 in-lb (16.2-20.0 N•m)

72-84 in-lb (8.1-9.5 N•m)

123

Drive System Assembly - 25M847 (Series B) & 25N669

42 3A5581C

Page 43

Drive System Parts List - 25M847 (Series B) & 25N669

Parts

Item: P/N Description Qty

1 18A394 Frame, Inner 1

2 17W235 Bearing, Axle, Ball, 1” 2

3 17W232 Shaft, Axle, Front 1

4 17W187 Holder, Axle, Front 2

5 17W190 Wheel, Front, 8 x 2-5/8 x 3/4 2

6 17W238 Bearing, Assembly, Drive Shaft 1

7 120454 Washer, Flat, 5/16” 6

8 110838 Nut, Lock, 5/16”-18 2

9 17Y158 Grommet, push in 1

10 17W220 Plug, Cap, 3” 1

11 558673 Screw, cap, socket head, 5/16-18 x

0.75”

12 17W188 Spacer, Axle, Front 2

13 169468 Washer, Flat, 3/4” 2

14 17W226 Shim, 3/4” ID x 1-1/2” OD x .048”

THK

15 17W229 Pin, Cotter, Hitch 2

16 100023 Washer, Flat, 3/8” 4

17 17W223 Screw, Cap, Hex Head, 1/2-13 x 1.5” 4

18 17W098 Washer, Flat, 1/2” 4

19 101911 Washer, Lock, 1/2” 4

20 17W215 Screw, Cap, Hex Head, 1/2-13 x 3 2

21 555395 Nut, Hex, 1/2-13 2

22 17W195 Screw, Cap, Hex Head, 3/8-16 x 3 1

23 101566 Nut, Lock, 3/8”-16 4

24 17W192 Belt, Tensioner, engine 1

25 17W193 Spacer, Engine, Mount 2

26 17W197 Grommet, Rubber 4

27 17W191 Plate, Engine, Mount 1

28 17W194 Engine, Honda GX390V, 13HP 1

2

4

29 108843 Screw, Cap, Hex Head, 5/16-18 x

30 17W183 Guard, Head Cutter 1

31 17W184 Gasket, Rubber, Skirt 1

32 17W222 Retainer, Medium 5-12”, Skirt 1

33 107139 Bolt, Round Head, 1/4 - 20 x 1” 18

34 17W020 Washer, flat, 1/4” 18

35 102040 Nut, Lock, 1/4”-20 18

36 17W223 Retainer, Small, 3-14”, Skirt 2

37 17W224 Retainer, Large, 12”, Skirt 3

38 17W057 Screw, Cap, Hex Head, 1/2-20 x 4” 4

39 17W218 Spacer, Hardened, 1/2” 8

40 101925 Nut, Lock, 1/2”-20 4

41 17X252 Key, Way, Drive Pulley 1

42 17W213 Bushing, 35mm Bore, w/ Key Slot 1

43 17W212 Pulley, Engine, 2-groove 1

44 109031 Screw, Cap, Hex Head 5/16 - 24x1” 2

45 100214 Washer, Lock, 5/16” 2

46 17W211 Pulley, Engine 1

47 17W088 Key, Drive, 1/4” SQ x 2-1/4” 1

48 16Y269 Washer, Flat, M12 3

49 17W146 Washer, Fender, 7/16” 1

50 100052 Washer, Lock, 7/16” 1

51 116645 Screw, Cap, Hex Head, 7/16-20x1” 1

52 17W210 Belt, Drive, Heavy-Duty 2

53

15H108 Warning Label, Pinch 2

54

194126 Warning Label, Fire & Explosion 1

Replacement warning, safety labels, tags, and cards are

available at no cost.

1.75”

2

3A5581C 43

Page 44

Parts

*Use industry standard torques when not specified.

Ref. Torque

28-30 ft-lb (38.0-40.0 N•m)

20-22 ft-lb (27.1-30.0 N•m)

144-180 in-lb (16.2-20.0 N•m)

72-84 in-lb (8.1-9.5 N•m)

123

4

2

3

1

4

4

1

4

Front Assembly - 25M847

44 3A5581C

Page 45

Front Assembly Parts List - 25M847

Item: P/N Description Qty

1 100022 1/4-20x3/4” Hex Head Bolt 4

2 100016 1/4” Lock Washer 4

3 17W020 1/4” Flat Washer 4

4 17W176 Belt Cover (top) 4

5 17W177 Belt Cover (back) 1

6 101712 5/8-11 Nylock Nut 1

7 17W049 Ball Knob 1

8 17W181 Handwheel 1

9 17W141 1/2-13x4” Socket Head Cap Screw 1

10 17W054 Thrust Bearing 1

11 17W105 5/8” Structural Washer 2

12 17W215 1/2-13x3” Hex Head Bolt (full thread) 2

13 555395 1/2-13 Hex Nut 2

14 17W196 3/8-16x3” Hex Head Bolt (full thread) 1

15 100023 3/8” Flat Washer 7

16 17W192 Belt Tension 1

17 17W232 Axle Shaft 1

18 558673 5/16-18x3/4” Socket Head Cap Screw 2

19 17W187 Axle Holder 2

20 17W229 Cotter Pin 2

21 17W188 Spacer 2

22 17W235 Axle Bearing 2

23 169468 3/4” Flat Washer 2

24 17W226 Shim 4

25 17W190 Front Wheel 2

26 17X253 5/16-18 Hex Nut 1

27 108843 5/16-18x1 3/4” Hex Head Bolt 1

28 17W056 Locking Collar 1

29 17W182 Pressure Control Linkage 1

30 17W221 Pressure Control Spring 1

31 17W098 1/2” Flat Washer 4

32 17W064 1/2” Lock Washer 4

33 17W233 1/2-13x1.5” Hex Head Bolt 4

34 17W231 3/8-16x3.5” Hex Head Bolt 4

35 100133 3/8” Lock Washer 4

36 17W237 Tapered Sleeve 1

Parts

3A5581C 45

Page 46

Parts

*Use industry standard torques when not specified.

Ref. Torque

28-30 ft-lb (38.0-40.0 N•m)

20-22 ft-lb (27.1-30.0 N•m)

144-180 in-lb (16.2-20.0 N•m)

72-84 in-lb (8.1-9.5 N•m)

123

4

Front Assembly - 25M847 (Series B) & 25N669

46 3A5581C

Page 47

Front Assembly Parts List - 25M847 (Series B) & 25N669

Parts

Item: P/N Description Qty

1 17Y118 Frame, Outer 1

2 17W189 Wheel, Caster 2

3 17W234 Nut, Jam, 3/4”-10 6

4 108540 Nut, Lock, 3/4”-10 2

5 17W186 Ballast, Weight 2

6 100003 Screw, Cap, Hex Head, 3/8-16 x 1.5” 4

7 100023 Washer, Flat, 3/8” 12

8 101566 Nut, Lock, 3/8”-16 6

9 17W230 Plunger, Spring 1

10 555396 Nut, Hex, 5/8”-11 1

11 17W181 Wheel, Hand, Large 1

12 17W182 Link, Pressure Control 1

13 17W056 Collar, Locking, 5/8” 1

14 17W105 5/8” Structural Washer 2

15 17W054 Bearing, Thrust 1

16 101712 Nut, Lock, 5/8”-11 1

17 17X254 Nut, Hex, 5/16”-18 1

18 108843 Screw, Cap, Hex Head, 1/4-20 x 0.75” 4

19 17W221 Spring, Control, Pressure 1

20 17W141 Screw, Cap, Socket Head, 1/2-13 x 4” 1

21 17W237 Sleeve, Tapered, Aluminum 1

22 17W049 Knob, Ball 1

23 17W176 Belt, Cover, Top 1

24 100022 Screw, Cap, Hex Head, 1/4-20 x 0.75” 4

25 100016 Washer, Lock, 1/4” 4

26 17W020 Washer, Flat, 1/4” 4

27 17W177 Belt, Cover, Back 1

28 17Y121 Box, Battery 1

29 18A435 Rubber, Backing Skirt 1

30 110823 1/4-20 x 1” Low Profile Screw 2

31 115753 Battery, 33AH, Sealed 1

35 100021 Screw, Cap, Hex Head, 1/4-20 x 1” 2

36 100015 Nut, Hex, 1/4”-20 2

37 17W231 Screw, Cap, Hex Head, 3/8-16 x 3.75” 4

38 100133 Washer, Lock, 3/8” 4

39 168117 3” x 1.5” Rectangular Plug 2

40 18A115 Support, Tubing 5

41 17W089 Screw, Self-Tap, 10-32 x 0.5” 5

42 17Y117 Bracket, Vernier Control 1

43 120454 Washer, Flat, 5/16” 4

44 113956 Bolt, Carriage, 3/8-16 x 1” 2

45 17W861 Label, Made in USA 1

46

16C394 Warning Label, Entanglement 2

47 16D646 Warning Label, ISO, Hot Surface 2

48

16C393 Warning Label, ISO, Cut Foot Hazard 2

49 17W751 Label, Pro Series 1

50 17W241 Label, Depth Control 1

51 17W263 Label, Pressure Control 1

52 17P925 Label, A+ Service 1

200 18Y704 Foam, 1/2”, under battery 1

201 18A786 Strap, velcro, 2” 1

202 18Y705 Foam, 1/4”, front of battery 1

203 18Y701

Foam,1/4”, side and back of battery

Replacement warning, safety labels, tags, and cards are

available at no cost.

3

3A5581C 47

Page 48

Parts

*Use industry standard torques when not specified.

Ref. Torque

28-30 ft-lb (38.0-40.0 N•m)

20-22 in-lb (2.3-2.5 N•m)

1

2

Controls Assembly - 25M847 (Series B)

48 3A5581C

Page 49

Controls Assembly Parts List - 25M847 (Series B)

Item: P/N Description Qty

1 17W108 Handle, Assembly, Cam Lever 1

2 17Y115 Bracket, Shock 1

3 120454 Washer, Flat, 5/16” 6

4 17W081 Screw, Cap, Hex Head, 5/16”-18 x 2.5” 4

5 110838 Nut, Lock, 5/16”-18 4

6 17W049 Knob, Ball 2

7 17W045 FItting, Grease 2

8 17Y822 Link, Upper 1

9 17W113 Washer, Flat, Bronze 2

10 119563 Washer, Belleville 2

11 C19075 Screw, Cap, Hex Head, 5/8-11 x 2.5” 1

12 M71149 Screw, Set, SCH, 10-32 x 0.25” 1

13 17Y998 Wheel, Assembly, Hand 1

14 17W119 Pin, Locator 1

15 17W127 Ring, Retainer 1

16 17W146 Washer, Fender, 7/16” 1

17 17W111 Spring, Compression 1

18 17W105 Washer, Structural, 5/8” 2

19 17W054 Bearing, Thrust 1

20 17W056 Collar, Locking, 5/8” 1

21 17Y114 Link, Lower 1

22 17W123 Link, Attachment, Lower 1

23 100023 Washer, Flat, 3/8” 2

24 17W125 Screw, Cap, Hex Head, 3/8-16 x 3.5” 1

25 101566 Nut, Lock, 3/8-16 1

26 17W126 Shock, Absorber 1

27 17W217 Pin, Detent 1

28 17Y116 Plate, Handlebar, Front 1

29 117501 Screw, Hex Washer Head, 8-32 x 0.5” 6

30 18A154 Cover, Backing 1

31 17W053 Label, Info, Control 1

32 17W240 Label, Brand 1

Parts

3A5581C 49

Page 50

Parts

*Use industry standard torques when not specified.

Ref. Torque

28-30 ft-lb (38.0-40.0 N•m)

20-22 in-lb (2.3-2.5 N•m)

1

2

Controls Assembly - 25N669

50 3A5581C

Page 51

Controls Assembly Parts List - 25N669

Item: P/N Description Qty

1 17Y112 Bracket, Control Mounting 1

2 17Y111 Bracket, Upper Linkage 1

3 120454 Washer, Flat, 5/16” 8

4 17W081 Screw, Cap, Hex Head, 5/16-18 x 2.5” 4

5 110838 Nut, Lock, 5/16’ 4

6 18A790 Control, Assembly, DCS 1

7 128990 Screw, Cap, Button Head, 10-32 x

0.75”

8 17W886 Washer, Flat, M6 4

9 115483 Nut, Lock, 10-32 4

10 17Y237 Actuator, Linear, 12V 1

11 18A114 Pin, Clevis 2

12 17Y962 Pin, Cotter, Bow Tie 2

13 17Y110 Bracket, Lower Linkage 1

14 17W217 Pin, Detent 1

15 18A151 Cover, Shroud 1

16 117501 Screw, Hex Washer Head, 6-32 x 0.5” 9

17 18A154 Cover, Backing 1

18 17Y823 Label, Brand 1

19 18A330 Label, Instruction 1

4

Parts

3A5581C 51

Page 52

Parts

Spindle Cutter Assembly (24 pin)

Spindle Cutter Assembly Parts List - 25N363

Item: P/N Description Qty

1* 17W324 Spindle Assembly 1

2 17X257 Rubber Bushing 6

3 17W258 Steel Bushing 3

4 17X259 Hub Connector 1

5 17X260 Hub Plate 1

6 17W299 Lock Washer 3

7 17W297 Hex Cap Screw 3

8 19A087 24 Pin Cutter (set of 3) 1

9 17W267 Backing Plate 3

10 17X266 Belleville Washer 3

11 17W265 Left Handed Hex Nut 3

* Item 1 includes items 1-7, 9-11

52 3A5581C

Page 53

DCS Control Box 18A790

25N669 only

DCS Control Box 18A790

Parts List

Ref. Part Description Qty.

300 18A690 KIT, DCS Control Box, machined

includes 300a - 300f

301 17Y686 LABEL, control, GrindLazer DCS

302 18A691 KIT, potted DCS Control PCB

303 18A692 KIT, display board, DCS control

3A5581C 53

Ref. Part Description Qty.

304 18A693 KIT, home button, DCS

1

305 18A694 KIT, zero button, DCS

1

306 18A695 KIT, cut cutton, DCS

1

307 18A696 KIT, up button, DCS

1

308 18A697 KIT, down button, DCS

1

1

1

1

1

Page 54

Wiring Diagram

17Y999

17Y237

18A790

Wiring Diagram

DCS System

54 3A5581C

Page 55

DCS Control Box

Powers Display

Wiring Diagram

3A5581C 55

Page 56

Technical Data

WARNING: This product can expose you to chemicals known to the State of California to cause cancer

and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

CALIFORNIA PROPOSITION 65

Technical Data

GrindLazer Pro RC813 G (25M847)

Noise level (dBa)

Sound power

Sound pressure

Vibration level*

Right/Left Hand

* Vibration measured per ISO 5349 based on 8 hr daily exposure

Dimensions/Weight (unpackaged) US Metric

Height 50 in. 127 cm

Length 48 in. 122 cm

Width 27 in. 69 cm

Weight 450 lb 204 kg

GrindLazer Pro RC813 G DCS (25N669)

Noise level (dBa)

Sound power

Sound pressure

Vibration level*

Right/Left Hand

* Vibration measured per ISO 5349 based on 8 hr daily exposure

Dimensions/Weight (unpackaged) US Metric

Height 50 in. 127 cm

Length 48 in. 122 cm

Width 27 in. 69 cm

Weight 475 lb 216 kg

109 dBa per ISO 3744

94 dBa measured at 3.1 feet (1m)

18.1 m/sec

109 dBa per ISO 3744

94 dBa measured at 3.1 feet (1m)

18.1 m/sec

2

2

56 3A5581C

Page 57

Graco Standard Warranty

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

3A5581C 57

Page 58

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2018, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A5581

International Offices: Belgium, China, Japan, Korea

Graco Headquarters: Minneapolis

www.graco.com

Revision

C, April 2019

Loading...

Loading...