Page 1

Instructions

™

G-Mini

For dispensing NLGI Grades #000 to #2 greases. For professional use only.

Not approved for use in explosive atmospheres or hazardous (classified) locations.

Models, page 3

4061 psi (28 MPa, 280 bar) Maximum Working Pressure

Important Safety Instructions

Read all warnings and instructions in this

manual before using the equipment.

Save these instructions.

Pump

3A6714C

EN

Page 2

Contents

Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . . 7

Divider Installation Remote............................. 7

CSP Direct Mount Installation......................... 7

Choose an Installation Location . . . . . . . . . . . . . . 8

Fuses.............................................................. 9

Recommendations for Pump Usage in

Harsh Environments................................. 9

Wiring and Installation Diagrams .................... 9

Manual Run Button . . . . . . . . . . . . . . . . . . . . . . 14

Proximity Switch. . . . . . . . . . . . . . . . . . . . . . . . . 14

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pressure Relief Procedure . . . . . . . . . . . . . . . . . 15

Disconnect and isolate all power supplies.... 15

Connect to Auxiliary Fittings . . . . . . . . . . . . . . . 15

Pressure Relief Valves ................................. 15

Pressure Relief Valves. . . . . . . . . . . . . . . . . . . . 15

Set Pump Outlet Volume . . . . . . . . . . . . . . . . . . 16

Load Grease . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Change Greases .......................................... 17

Priming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Non Controller Operation . . . . . . . . . . . . . . . . . . . . . 19

Low-Level Output Option .............................. 19

Controller Operation . . . . . . . . . . . . . . . . . . . . . . . . . 20

RUN MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

SETUP MODE . . . . . . . . . . . . . . . . . . . . . . . . . . 21

ON TIME Configuration (Minutes) ................ 21

ON TIME Configuration (Cycles) .................. 22

OFF TIME Configuration (Min./Hrs).............. 22

ADVANCED PROGRAMMING . . . . . . . . . . . . . 23

Advanced Programming Menu Descriptions 23

Alerts and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Alert and Alarm Scenarios . . . . . . . . . . . . . . . . . 27

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Reservoir Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Pump Element Kits . . . . . . . . . . . . . . . . . . . . . . . 30

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

CSP Valve Bracket Mount . . . . . . . . . . . . . . . . . 31

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Pump Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Universal Bracket Mount . . . . . . . . . . . . . . . . . . 35

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . 36

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . . . 38

2 3A6714C

Page 3

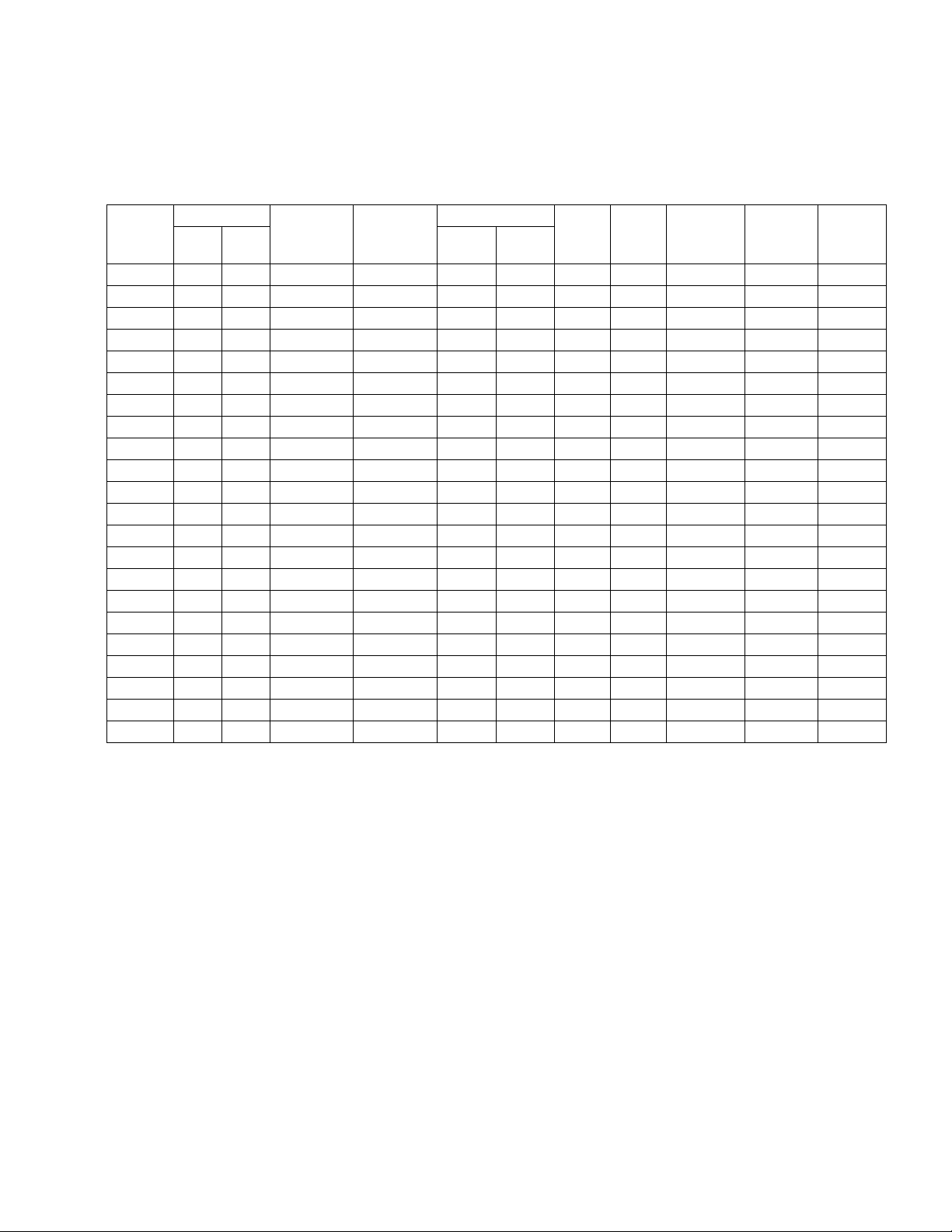

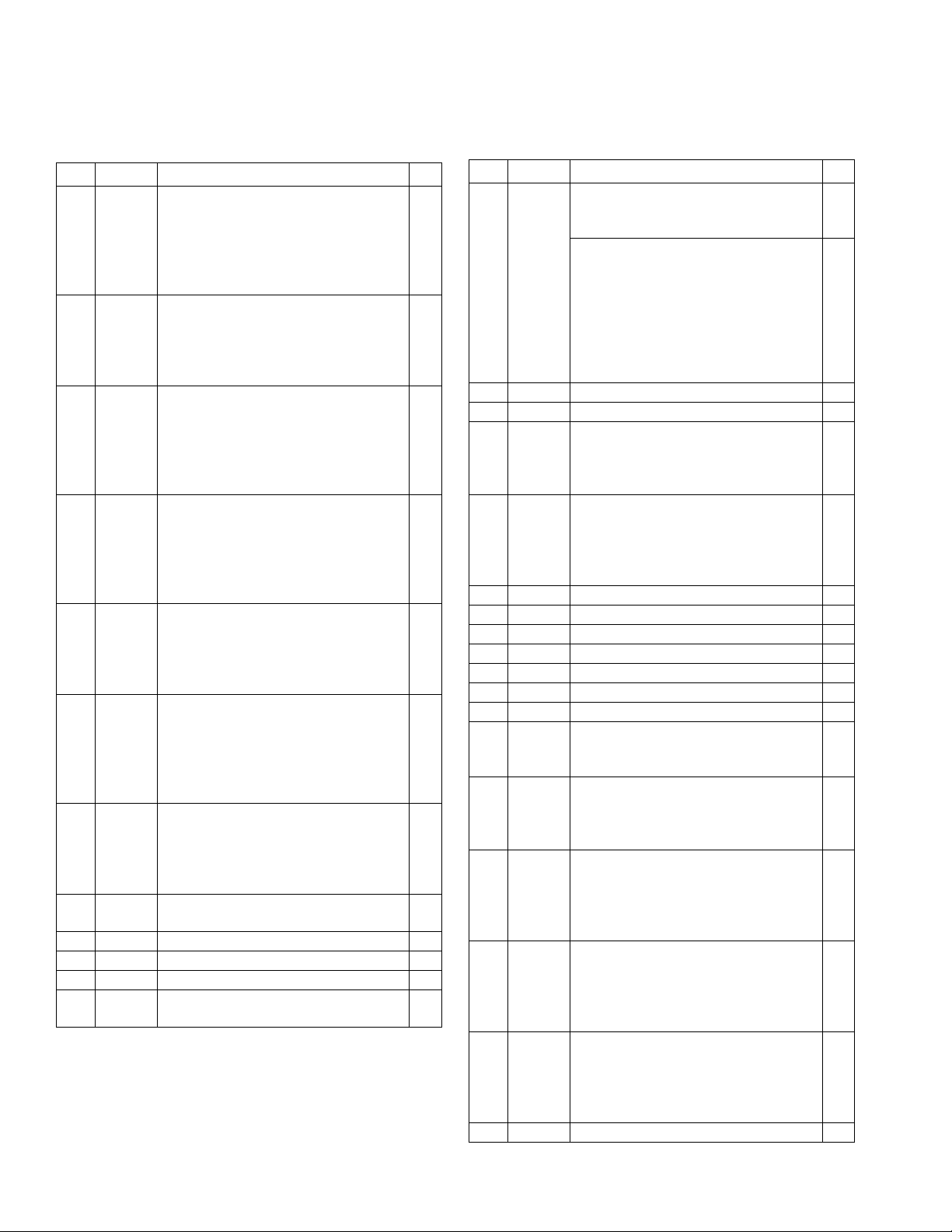

Models

Models

Reservoir

Non-

Model

25R800 X X X CPC X 1

25R801 X X X CPC X M12 1

25R802 X X X CPC X 1

25R803 X X X CPC X M12 1

25R804 X X X CPC X M12 1 X

25R805 X X X CPC X M12 2 X

25R806 X X X CPC X M12 1 X

25R807 X X X CPC X 1

25R808 X X X CPC X M12 1

25R809 X X X CPC X 1

25R810 X X X CPC X M12 1

25R820 X X X DIN X 1

25R821 X X X DIN X M12 1

25R822 X X X DIN X 1

25R823 X X X DIN X M12 1

25R824 X X X DIN X M12 1 X

25R825 X X X DIN X M12 2 X

25R826 X X X DIN X M12 1 X

25R827 X X X DIN X 1

25R828 X X X DIN X M12 1

25R829 X X X DIN X 1

25R830 X X X DIN X M12 1

Controller

Controller

Voltage

Power

Input

Low

Level

Cycle

Feedback

Input

Pump

Element

Quantity

Heater0.5 L 1 L 12VDC 24VDC

3A6714C 3

Page 4

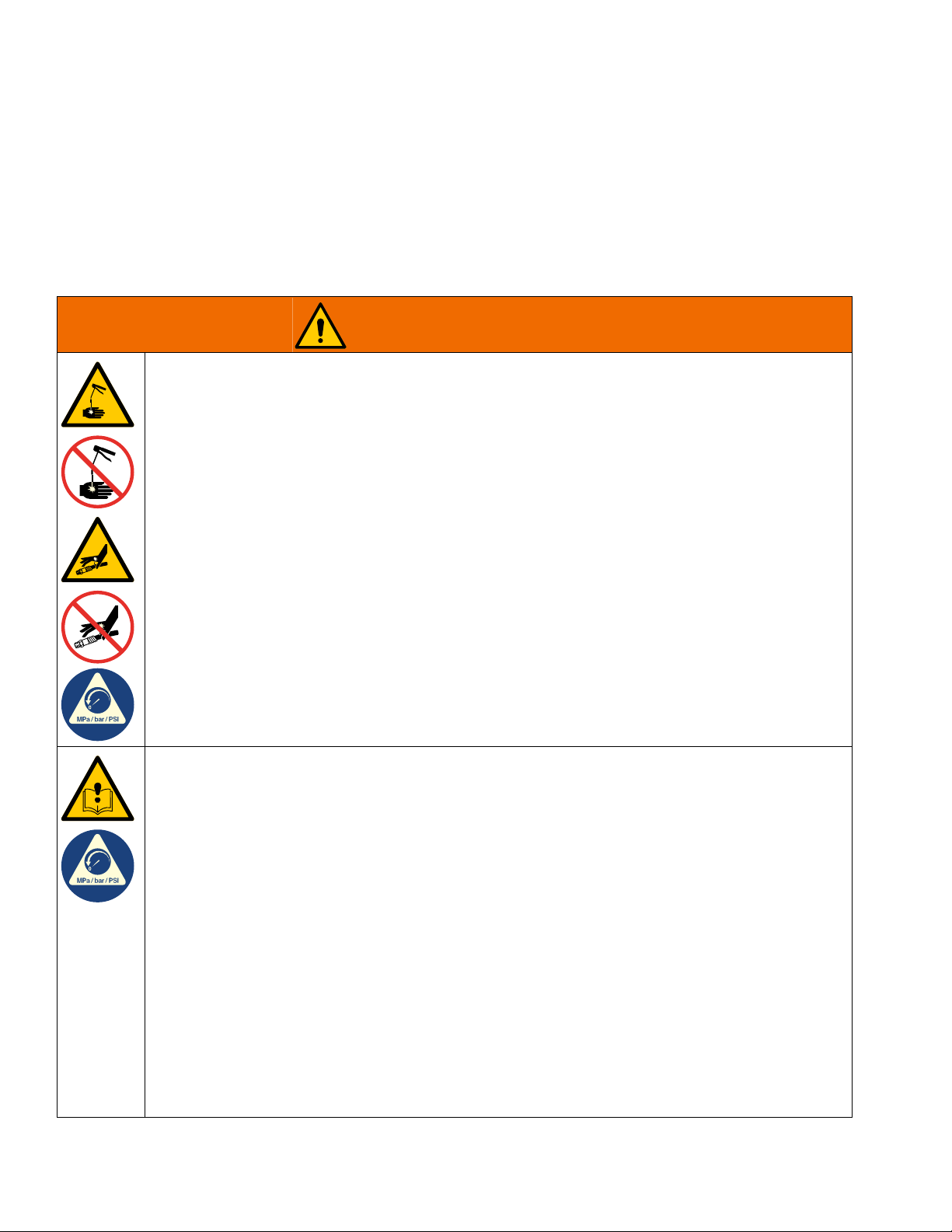

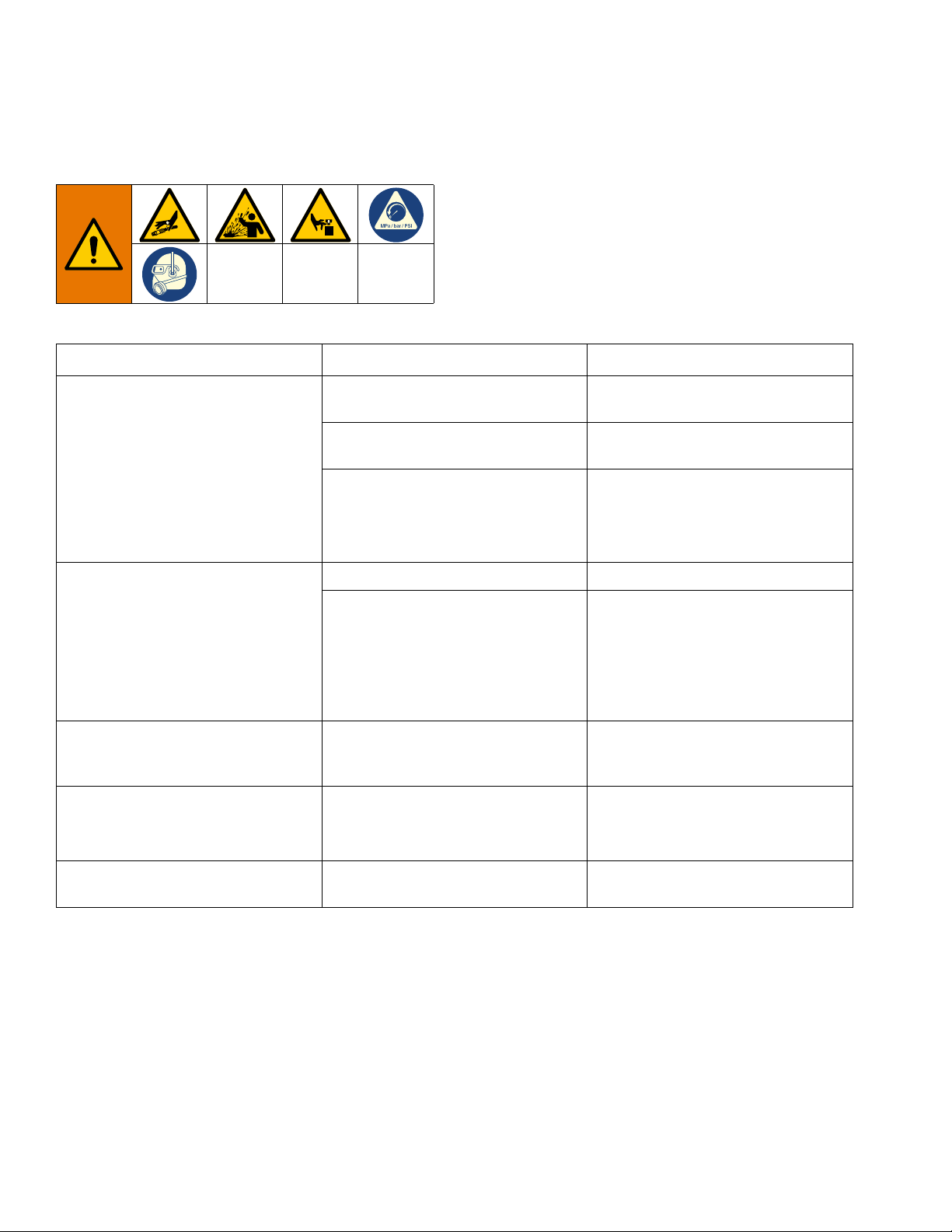

Warnings

WARNING

Warnings

The following warnings are for the setup, use, maintenance, and repair of this equipment. The exclamation point

symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these

symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Specifications in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical

Specifications in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For

complete information about your material, request Safety Data Sheets (SDSs) from distributor or

retailer.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

4 3A6714C

Page 5

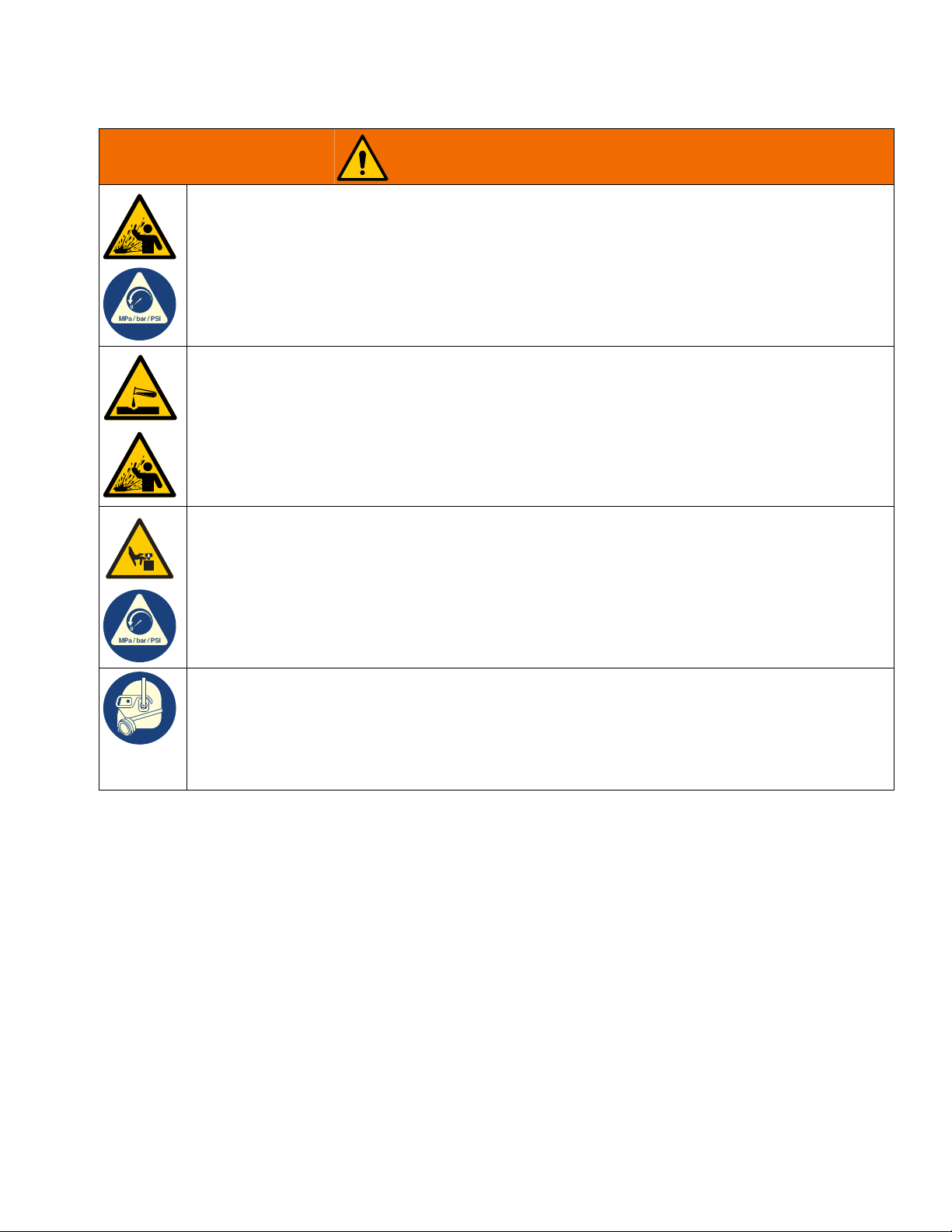

Warnings

WARNING

PRESSURIZED EQUIPMENT HAZARD

Over-pressurization can result in equipment rupture and serious injury.

• A pressure relief valve is required at each pump outlet.

• Follow the Pressure Relief Procedure in this manual when servicing equipment.

PLASTIC PARTS CLEANING SOLVENT HAZARD

Many cleaning solvents can degrade plastic parts and cause them to fail, which could cause serious

injury or property damage.

• Use only compatible solvents to clean plastic structural or pressure-containing parts.

• See Technical Specifications in all equipment manuals for materials of construction. Consult the

solvent manufacturer for information and recommendations about compatibility.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Equipment can start without warning. Before checking, moving, or servicing equipment, follow the

Pressure Relief Procedure and disconnect all power sources.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. Protective equipment includes but is not

limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

3A6714C 5

Page 6

Installation

D

A

B

C

F

G

E

H

J

J

V

W

Installation

Component Identification

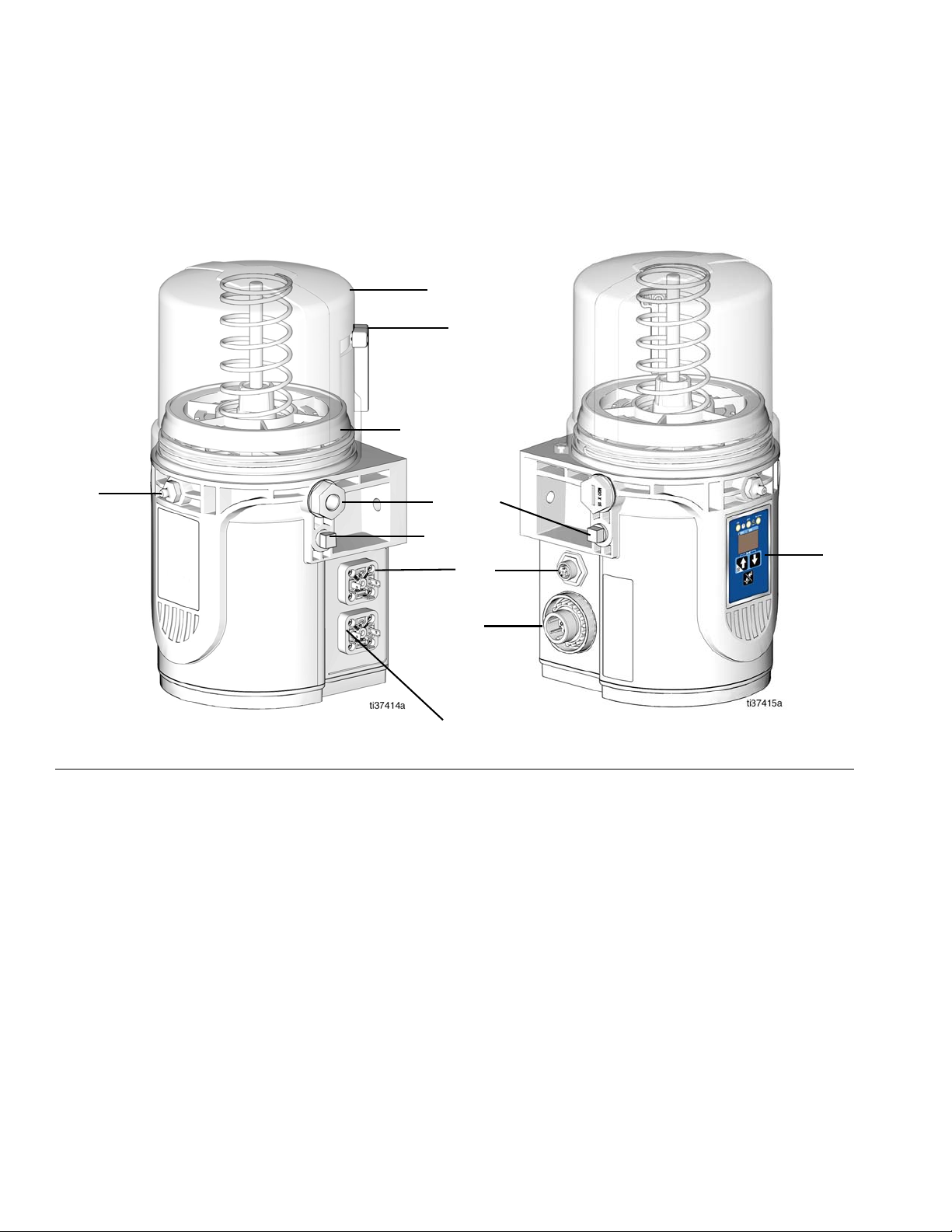

FIG. 1:

Key:

A Reservoir

B Venting Tube

C Follower Plate

D Pump Element

E Zerk Inlet Fill Fitting

F Cycle Indicator Connector (Controller model only)

G CPC Connector

H Controller

J Return to Reservoir

V DIN Connector (Power)

W DIN Connector (Low level/Manual run button)

6 3A6714C

Page 7

Typical Installation

K

R

P

N

M

L

X

R

S

L

K

T

U

Divider Installation Remote

Installation

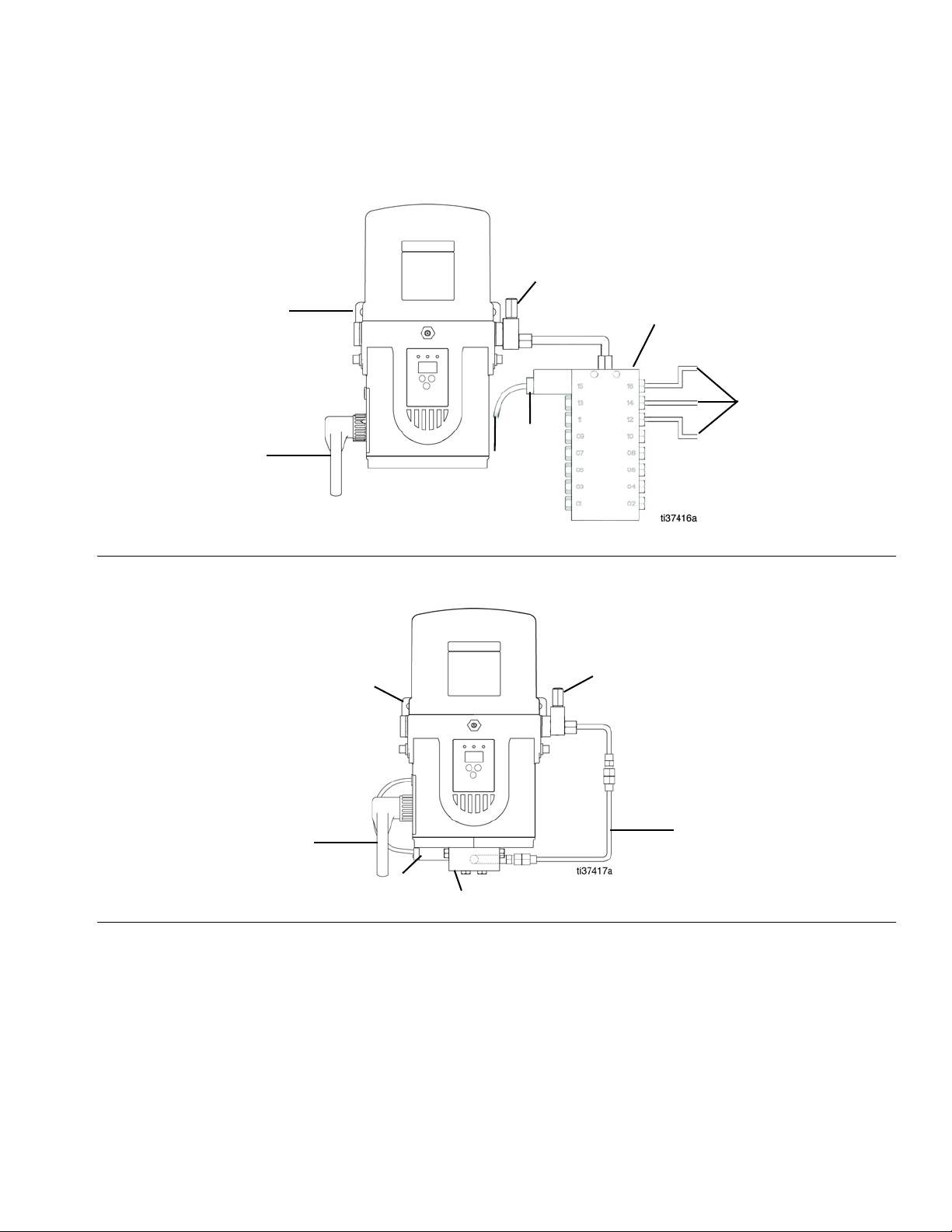

FIG. 2:

CSP Direct Mount Installation

FIG. 3:

K Connection to fused power source

L Pressure relief valve (required for each outlet)*

See Pressure Relief Valves, page 15

M Proximity switch cable

N Series progressive divider valves (Divider Installation)

P Connection to lube points

R Proximity switch, see page 14

S Direct Mount CSP Bracket, see page 8

T Direct Mount CSP Hose, see page 8

U CSP valves

X Universal Bracket, see page 8

*User Supplied

3A6714C 7

Page 8

Installation

Choose an Installation Location

AUTOMATIC SYSTEM ACTIVATION HAZARD

Unexpected activation of the system could result in

serious injury, including skin injection and amputation.

This device has an automatic timer that activates the

pump lubrication system when power is connected or

when exiting the programming function. Before you

install the lubrication pump or remove it from the system, disconnect and isolate all power supplies and

relieve all pressure.

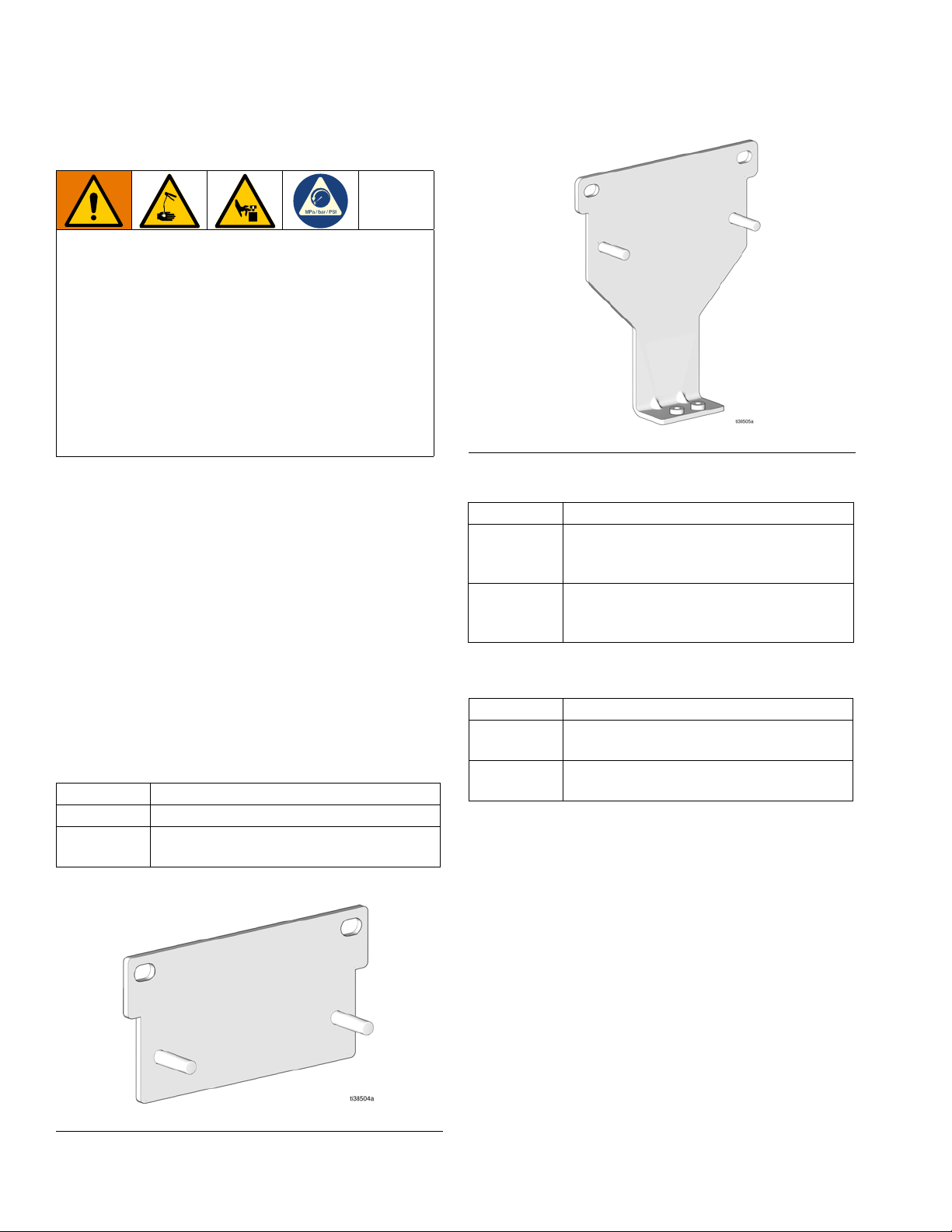

FIG. 5: 26C825

• Select a location that will support the weight of the

pump and lubricant, as well as all plumbing and

electrical connections.

• Refer to the two mounting hole layouts provided in

the Mounting Pattern section of this manual, page

35.

• Use designated mounting holes and provided configurations only.

• Use the two fasteners (included) to secure the pump

to the mounting surface.

Some installations may require an additional pump

bracket.

Mounting Bracket Kits

Part No Description

26C826 Universal Bracket (fastener included)

26C825

Direct Mount CSP Bracket (fastener

included)

Direct Mount CSP Hose Kits

Part No Description

1/4 NPT (Pressure Relief Outlet) to 1/8

26C956

26C957

Direct CSP Mount Kits

Part No Description

26C958

26C959

NPT (CSP Inlet), includes hose (25 cm

length), fitting 17T781and 17T783

1/4 NPT (Pressure Relief Outlet) to 1/8

BSPT (CSP Inlet), includes hose (25 cm

length), fitting 17L546 and 17T783

Kit, CSP Mount, NPT, includes 26C825

and 26C956

Kit, CSP Mount, BSPT, includes 26C825

and 26C957

F

IG. 4: 26C826

8 3A6714C

Page 9

System Configuration and Wiring

All electrical wiring must be done by a qualified

electrician and comply with all local codes and

regulations.

Installation

Recommendations for Pump Usage in

Harsh Environments

• Use pump with CPC style power cable.

• Use a corrosion preventative electrical grease on all

contacts.

Fuses

NOTICE

Fuses (user supplied) are required on all DC models.

To avoid equipment damage:

• Never operate pump DC models without a fuse

installed.

• A fuse of the correct amperage must be installed in

line with the power entry to the system.

Fuse kits are available from Graco. The following table

identifies the correct fuse to use for the input voltage

and the corresponding Graco Kit number.

Applicable

Fuse Value Graco Kit No.

10A 26C916

5A 26C917

7.5A 571039

Model

25R802

25R803

25R806

25R809

25R810

25R822

25R823

25R826

25R829

25R730

25R800

25R807

25R820

25R827

25R801

25R804

25R805

25R808

25R821

25R824

25R825

25R828

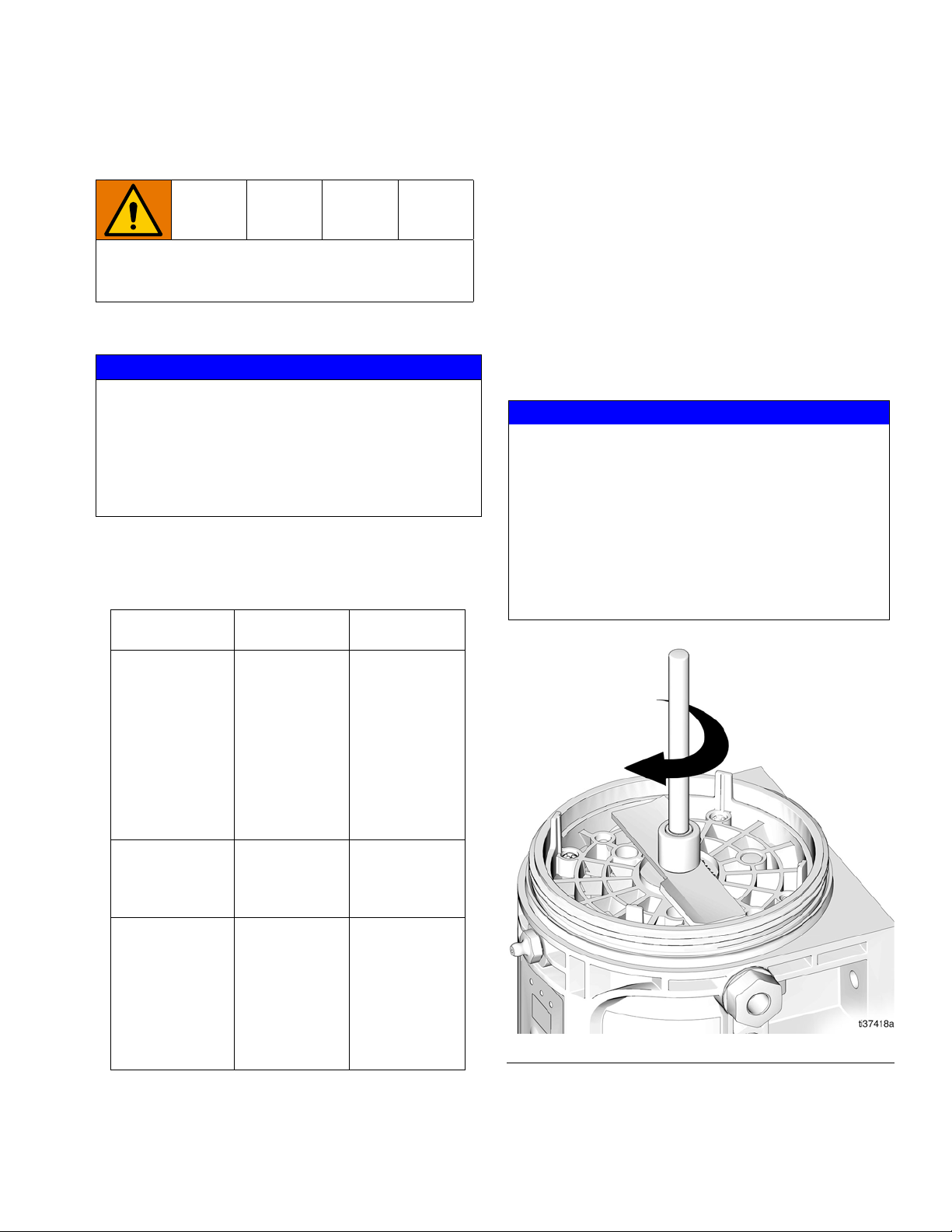

Wiring and Installation Diagrams

NOTE: Wire colors provided on these pages refer only

to the Graco power cable.

NOTICE

The stirring paddle should rotate clockwise (as viewed

from the top) (F

the stirring paddle to rotate counterclockwise damages the pump’s internal components.

If the stirring paddle is rotating counterclockwise, stop

the pump immediately. Check that the wiring is correct

and make any necessary changes.

If the motor does not run after power is supplied,

check the pump wiring.

FIG. 6

IG. 6) when power is applied. Allowing

3A6714C 9

Page 10

Installation

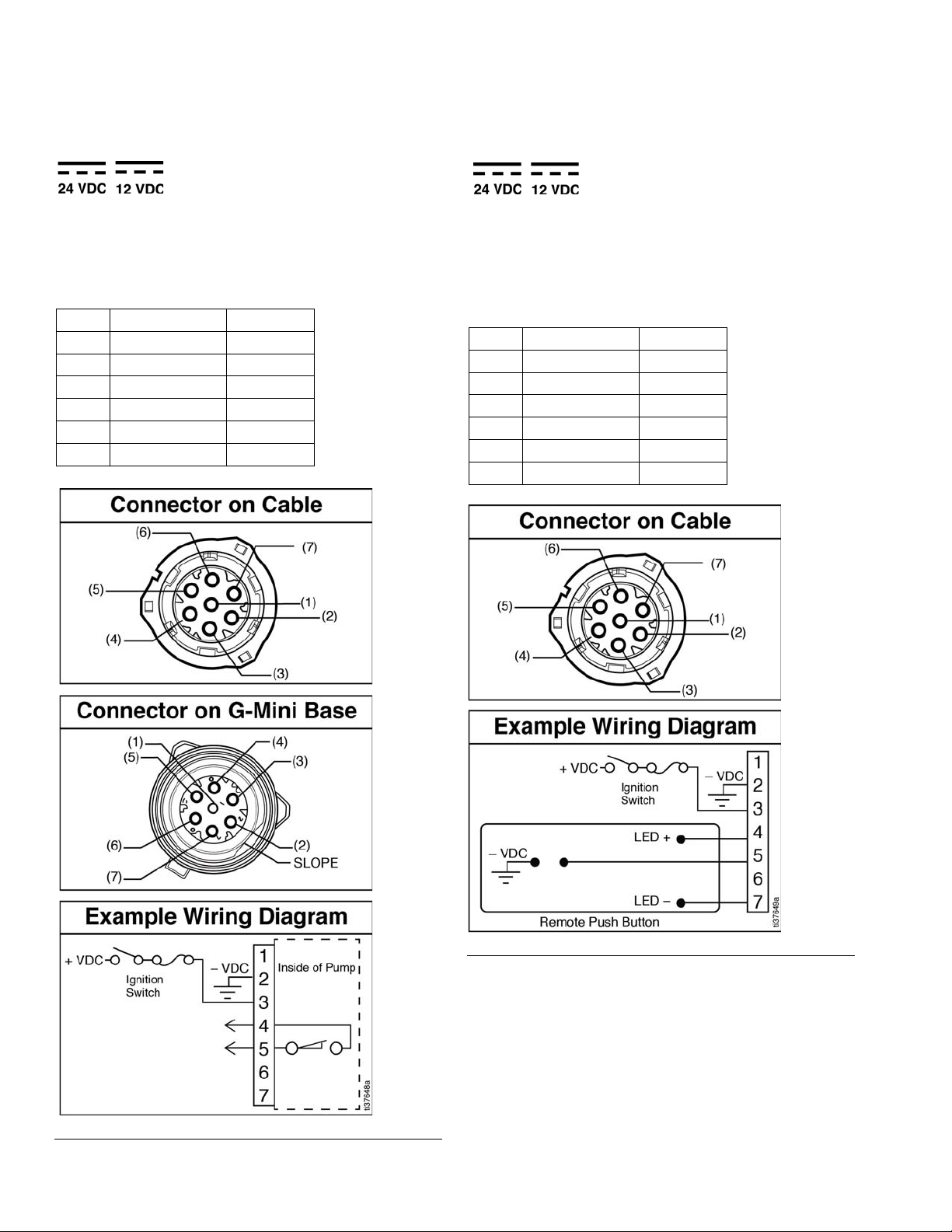

Power CPC DC - 5 Wire (Non-Controller)

Power Cable CPC DC

Part No.: 127780 - 15 ft. (4.5 m), 127781 - 20 ft. (6.1 m),

127782 - 30 ft. (9.1 m)

Pin Out

1 Not Used Not Used

2 -VDC Black

3+VDC Red

4 Low-Level White

5 Low-Level Orange

6 Not Used Not Used

7 Not Used Green

Power CPC DC - 5 Wire (Controller)

Power Cable CPC DC

Part No.: 127780 - 15 ft. (4.5 m), 127781 - 20 ft. (6.1 m),

127782 - 30 ft. (9.1 m)

Pin Out

1 Not Used Not Used

2 -VDC Black

3+VDC Red

4LED+ White

5 Button Orange

6 Not Used Not Used

7LED- Green

FIG. 8

FIG. 7

10 3A6714C

Page 11

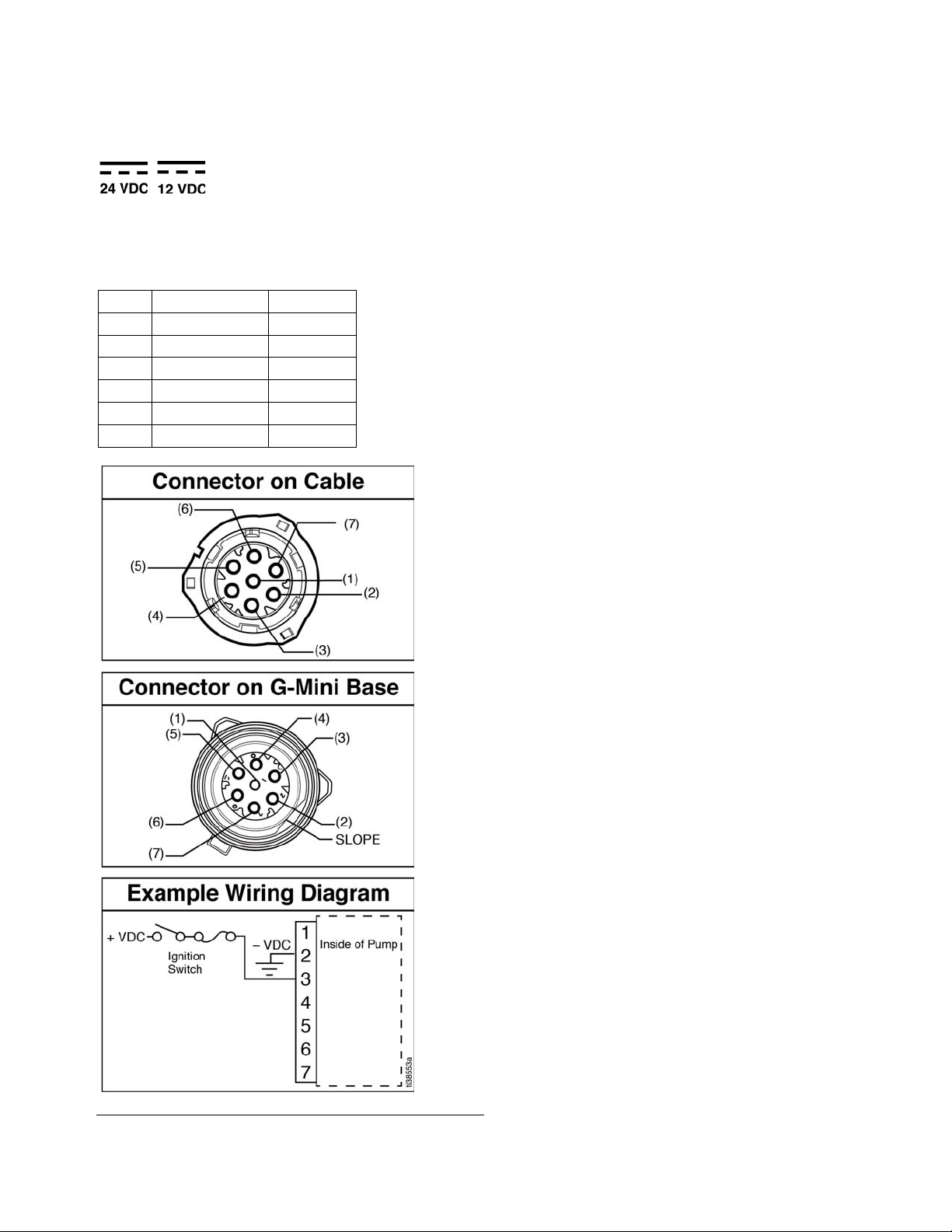

Power CPC DC - 3 Wire (Non-Controller)

Power Cable CPC DC

Part No.: 127783 - 15 ft. (4.5 m)

Pin Out

1 Not Used Not Used

2 -VDC Black

3+VDC White

4 Not Used Not Used

5 Not Used Not Used

6 Not Used Not Used

7 Not Used Not Used

Installation

FIG. 9

3A6714C 11

Page 12

Installation

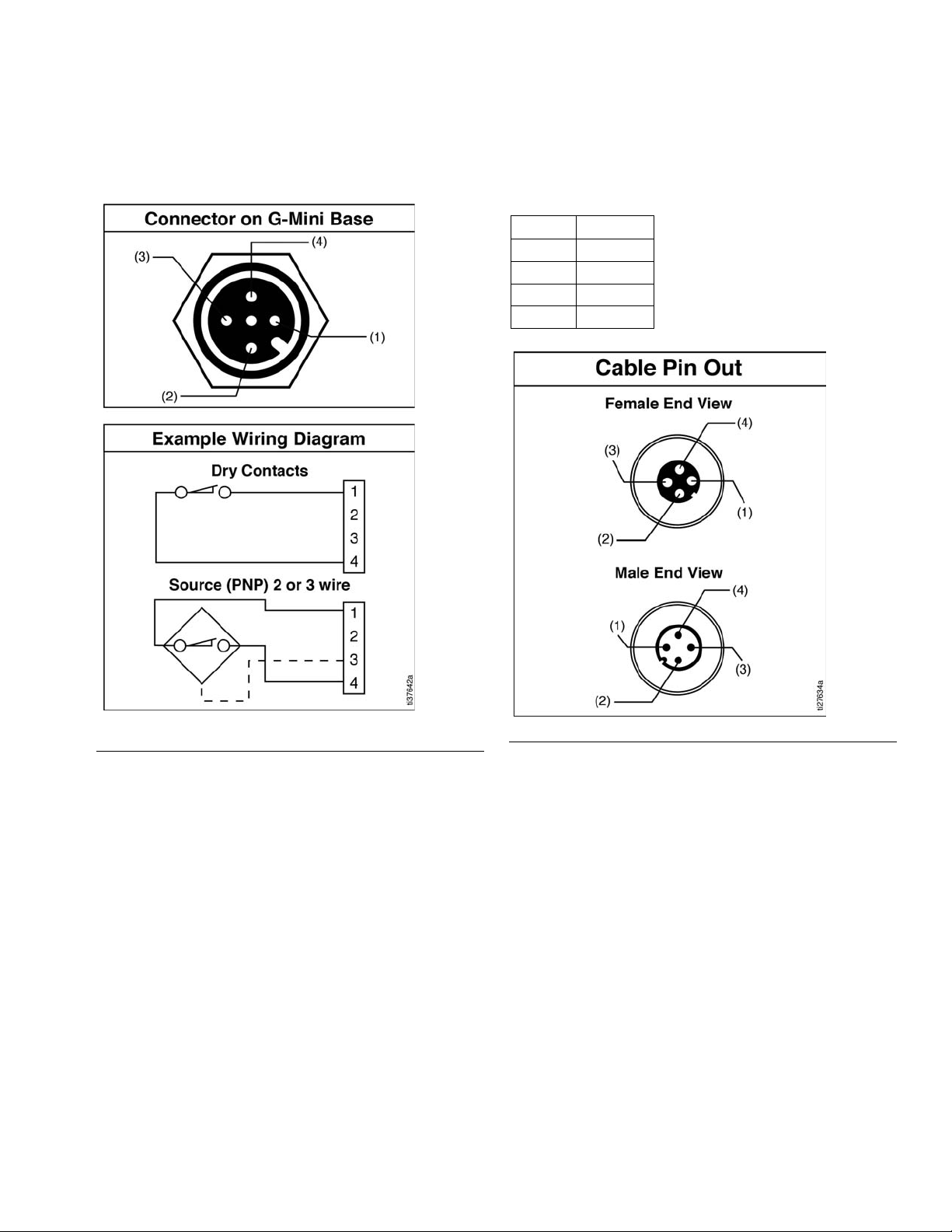

Power DIN DC - 15 ft Power Cable: Part No, 16U790

Pin Out

1 -VDC Black

2+VDC White

3 Not Used Not Used

4 Not Used Green

Low Level DIN DC

See Technical Specifications, page 36 for ratings

Pin Out

1 LL N.O.

2 LL Com

3Not Used

4Not Used

FIG. 10

FIG. 11

12 3A6714C

Page 13

Installation

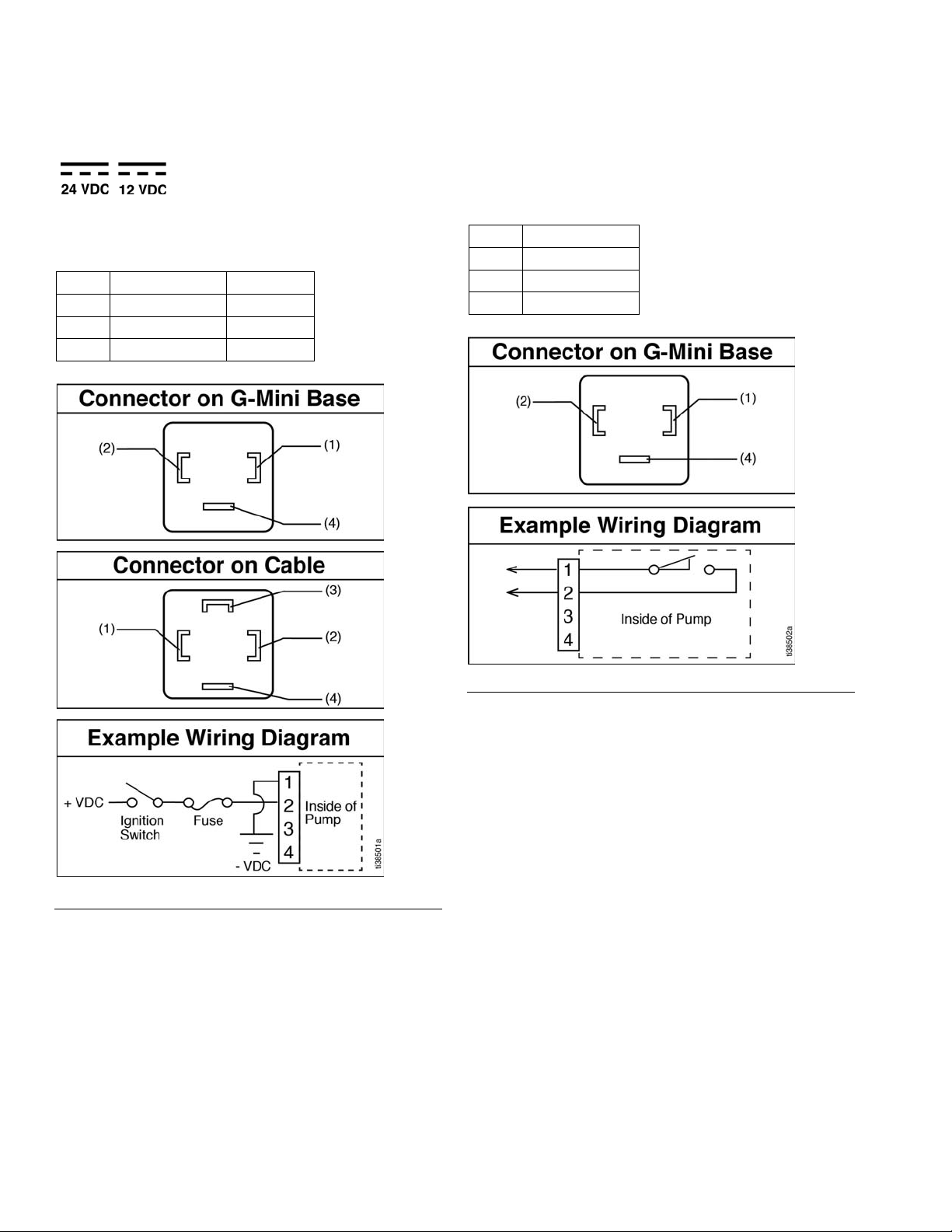

Divider Valve Indicator Cycle Inputs (M12)

See Technical Specifications, page 36 for ratings.

Part No. 124333: Cable Pin Out (M12) for

5 m Cable

Wire Colors (F

IG. 13)

Item No. Color

1Brown

2White

3Blue

4Black

FIG. 12

3A6714C 13

FIG. 13

Page 14

Installation

Manual Run Button

Part No. Description

25C981 Manual Run Button, 12V

25C982 Manual Run Button, 24V

Manual Run Button DIN DC

See Technical Specifications, page 36 for ratings

Pin Out

1LED2LED +

3Button

4 Not Used

FIG. 14

Proximity Switch

NOTE: Reference ILE buyer’s guide for appropriate PNP

proximity switches and cables.

14 3A6714C

Page 15

Setup

Setup

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, splashing

fluid and moving parts, follow the Pressure Relief

Procedure when you stop dispensing and before

cleaning, checking, or servicing the equipment.

Disconnect and isolate all power supplies.

Relieve pressure in the system using two wrenches

working in opposite directions on the pump element and

pump element fitting to slowly loosen fitting only until the

fitting is loose and no lubricant or air is leaking from

fitting.

Connect to Auxiliary Fittings

NOTICE

Do not attach unsupported equipment to auxiliary fittings such as fill ports and pump element. Attaching

unsupported equipment to these fittings can result in

irreparable housing damage.

• Always use two wrenches working in opposite directions when connecting anything to pump element or

auxiliary fittings. See F

• Torque pump element fittings to 50 in-lb (5.6 N•m).

• Torque pump element to 65 in-lb (7.3 N•m) when

connecting to the housing.

Pressure Relief Valves

IG. 15 for an example.

NOTE: When loosening the pump element fitting, do not

loosen the pump element. Loosening the pump element

changes the output volume.

F

IG. 15

To prevent over-pressurization, which can result in

equipment rupture and serious injury, a pressure

relief valve appropriate for the lubrication system

must be installed close to each pump outlet to alleviate unintended pressure rises in the system and protect the pump from damage.

• Only use a pressure relief valve that is rated for

no more than the working pressure of any component installed in the system.

• Install a pressure relief valve before any auxiliary

fitting.

NOTE: A pressure relief valve may be purchased from

Graco. See Pressure Relief Valves, page 15.

Pressure Relief Valves

Part No. Description

571028 Kit, Adj. Pressure Relief

3A6714C 15

Page 16

Setup

Set Pump Outlet Volume

1. Follow the Pressure Relief Procedure, page 15.

2. Use a wrench and turn the pump element counterclockwise to remove the entire pump element.

4. Re-install the pump element into the pump base,

ensuring that the first thread of the element

engages correctly.

NOTE: It may be necessary to repeat the pump outlet

volume setup procedure after the pump is operating to

adjust the volume of the dispensed fluids.

5. Use a wrench and tighten the pump element fitting.

Torque to 50 in-lb (5.6 N•m).

NOTE:

• The dispensed volume amount varies depending

upon external conditions, such as lubricant

temperature and back pressure from downstream

connections.

• Use the volume adjustment process in conjunction

with setting the ON time of the pump to control the

output volume.

• The volume adjustment process should be used as

a starting point for dispensing the desired lubrication

volume.

FIG. 16

3. Replace the current spacer with the desired spacer.

Thickness Output Volume/Minute

Spacers

25N814 1.5 0.183 3.0

18A317 4.6 0.0915 1.5

NOTE: A spacer is required for operation. Only one

Graco spacer can be used at a time. The pumps from

the factory have a spacer (25N814) installed on the

pump element. Pump Element Kits (page 30) come

with a spacer. The spacer may be replaced depending

upon the required output volume.

mm Cubic In. Cubic cm

Load Grease

To ensure optimal performance from the pump:

• Use only NLGI #000 - #2 greases appropriate for

the application, automatic dispensing, and the

equipment’s operating temperature. Consult with the

machine and lubrication manufacturers for details.

• Fill the reservoir using a hand operated pump,

pneumatic pump or electric transfer pump.

• Do not overfill.

• Do not operate the pump without having a reservoir

attached.

NOTICE

• Always clean fitting (E) with a clean dry cloth

prior to filling the reservoir. Dirt and/or debris

can damage pump and/or lubrication system.

• Use care when filling the reservoir using a pneumatic or electric transfer pump to avoid pressurizing and breaking the reservoir.

16 3A6714C

Page 17

Setup

E

B

1. Connect the fill hose to the Zerk Inlet Fill Fitting (E)

(F

IG. 17).

FIG. 17

NOTE: The venting tube (B) should not be used as an

overfill indicator (F

IG. 18).

2. For higher viscosity fluids, start the pump, per the

controller instructions, to rotate the stirring paddle

during filling to prevent air pockets from forming in

the grease.

For models using an external controller, start the pump

operation following the controller instructions.

3. Fill the reservoir with NLGI grease to the MAX line

(F

IG. 18).

FIG. 18

4. Remove the fill hose.

Change Greases

Always use compatible grease when changing grease.

3A6714C 17

Page 18

Setup

Priming

It is not necessary to prime the pump every time the

pump is filled. The pump only requires priming the first

time it is used, or if it is allowed to run dry.

1. Loosen the pump element fitting (F

IG. 19).

NOTE: When loosening the pump element fitting, do not

loosen the pump element. Loosening the pump element

changes the output volume and causes leakage.

FIG. 19

FIG. 20

3. Tighten the pump element fitting using two

wrenches working in opposite directions (F

IG. 21).

2. Only run the pump until air is no longer dispensed

with the lubricant out of element fitting (F

IG. 20).

FIG. 21

18 3A6714C

Page 19

Non Controller Operation

Non Controller Operation

The pump can be controlled using an external, user supplied, controller.

NOTE:

• When using an external controller, Pump ON (Run)

Time should be set for no longer than 30 minutes.

• In most cases, Pump OFF (Rest) Time should be

twice as long as Pump ON (Run) time. If alternative

ON / OFF times are required, contact Graco Customer Service for assistance.

Typical Low-Level Output Response with Low-Level Fluid

Low-Level Output Option

Models 25R800, 25R802, 25R807 and 25R809

Pumps without controllers include a Low-Level Output

Option. The low-level signal is monitored across PINS 4

and 5. For the locations and wiring information for PINS

4 and 5, see the Wiring and Installation Diagrams,

page 9.

Model 25R820, 25R822, 25R827 and 25R829

See the Wiring and Installation Diagrams, page 9.

FIG. 22

3A6714C 19

Page 20

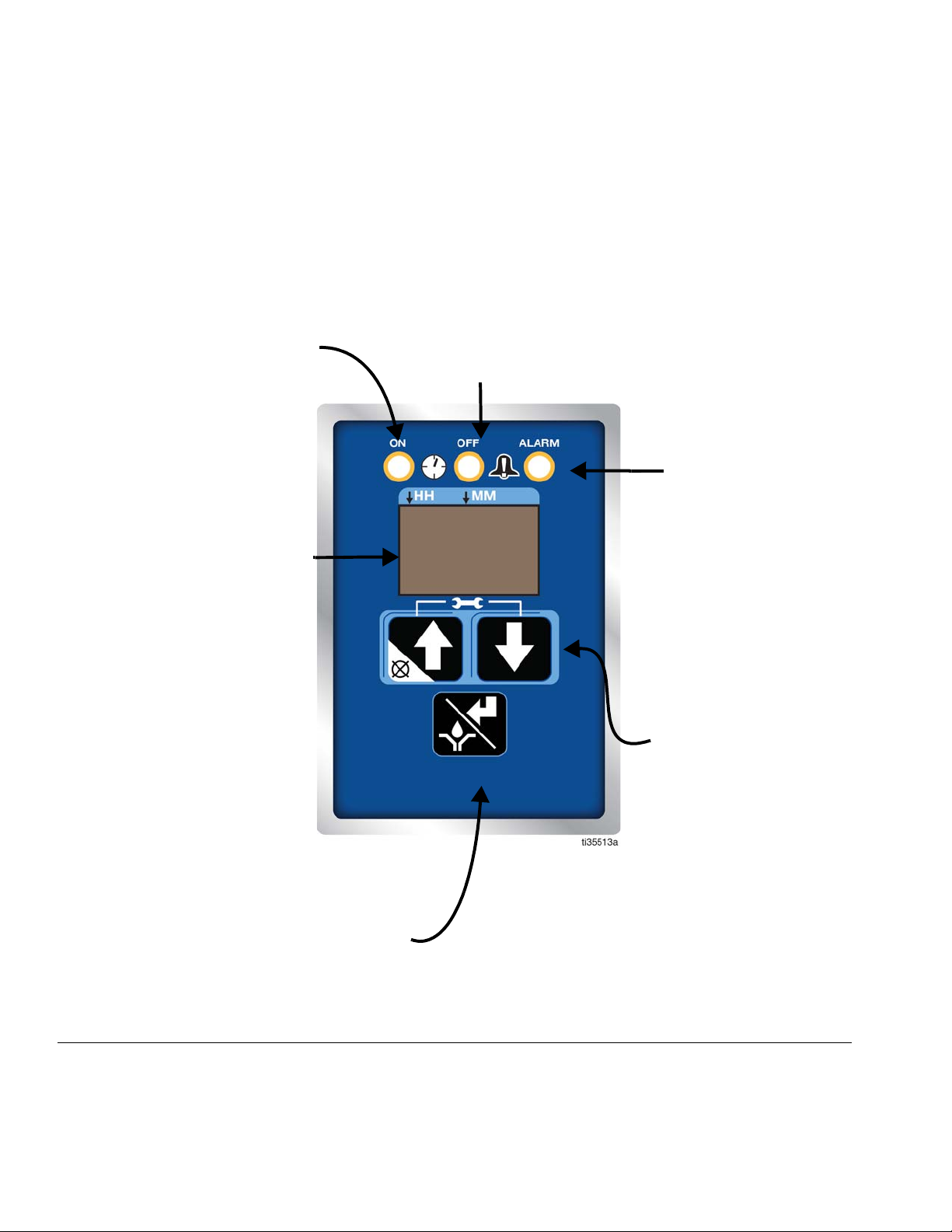

Controller Operation

DISPLAY

• Upon entering SETUP MODE, the

first digit in the display begins to

blink.

• In RUN MODE, the programmed

ON TIME, CYCLES or OFF TIME

displays and counts down to zero.

ON TIME

• In SETUP MODE, the LED illumi-

nates when ON TIME duration or

cycles are set up.

• A dot illuminates under MM on the

display.

• The ON TIME range is 1 to 30

minutes, or 1 to 99 cycles.

• In RUN MODE, the LED illuminates

during the ON TIME sequence.

ALARM

The LED illuminates when

an alert / alarm event occurs.

Most alerts/alarms occur

during ON TIME MODE.

However, if a Low-Level alert

triggers near the end of an

ON TIME cycle, the alert will

display while the controller is

in OFF TIME MODE. A software error occurring when

the controller is operating in

the OFF TIME MODE will

also activate the alarm LED.

MANUAL RUN / ENTER

• In SETUP MODE, press this button to save the

entry, move the cursor in the display one field to the

right or to the next setup step.

• In RUN MODE, press this button to start a manual

run cycle.

UP and DOWN ARROWS

• Hold both the UP and

DOWN arrow buttons

together for 3 seconds to

enter SETUP MODE.

• In SETUP MODE, the UP

and DOWN arrows

increase or decrease time

and cycle setting values

shown on the display.

• In RUN TIME MODE,

pressing the UP

arrow/CANCEL button terminates the lubrication

period.

OFF TIME

• In SETUP MODE, the LED illuminates when OFF TIME duration is

set up.

• A dot illuminates under HH on the display.

• The OFF TIME range is 15 / 30 / 45 min or 1 to 99 hours.

• The LED illuminates when OFF TIME sequence is running.

Controller Operation

Control Panel Overview (FIG. 23)

FIG. 23

20 3A6714C

Page 21

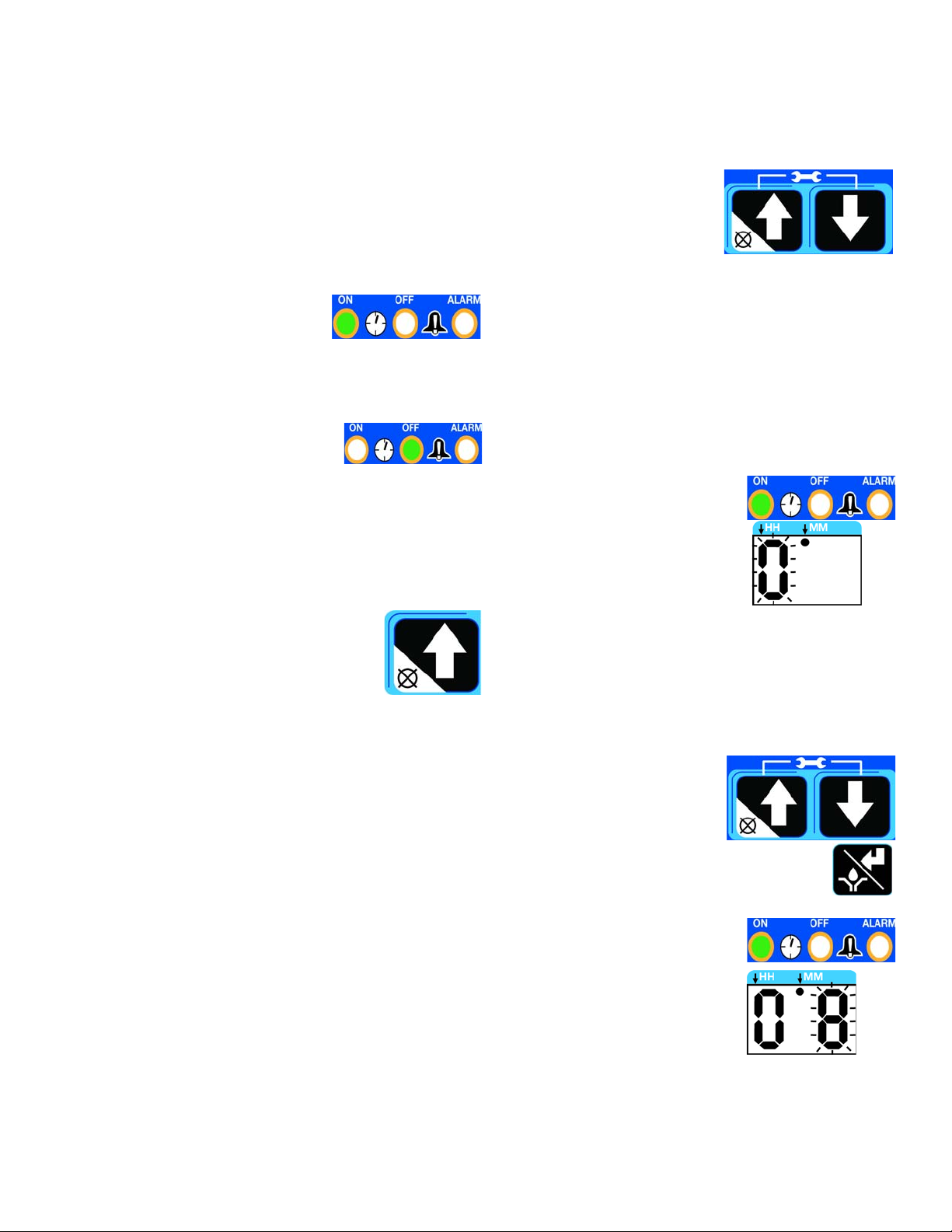

Controller Operation

The controller operates in two modes; RUN MODE and

SETUP MODE. Each mode has multiple functions.

RUN MODE

RUN MODE performs two functions while monitoring

Alert/Alarm conditions: ON TIME and OFF TIME.

• In ON TIME the motor is

running and the lubrication

is delivered. ON TIME can

be configured to be active

for a period of time in minutes or a period of lube

cycles (cycle or proximity switch is required).

• In OFF TIME the motor is not

running. This is a period

where no lubrication is delivered. OFF TIME can be configured for 15 / 30 / 45 min. or 1 to 99 hours.

By default, units with controllers are set to operate with

an ON TIME period of five (5) minutes and an OFF

TIME period of one (1) hour.

Once an ON TIME lubrication period

begins, it can be terminated by pressing

the UP arrow/CANCEL button.

While in RUN MODE the controller

monitors Alert/Alarm conditions. See

Alert and Alarm Scenarios, page 27 for full descriptions.

SETUP MODE

Press both the UP and

DOWN arrow buttons

together for 3 seconds to

enter SETUP MODE.

The first digit on the display

begins to blink. This indicates SETUP MODE. After

entering SETUP Mode, if no activity is detected, after 60

seconds a timeout occurs and the controller resumes in

RUN MODE.

ON TIME Configuration (Minutes)

The first configuration in SETUP MODE is programming

the ON TIME.

Notice the following on the controller:

- The LED next to the

Clock in the ON field illuminates.

- The first digit on the display begins to blink.

- A dot on the display

under the MM illuminates.

This confirms that the controller is ready for the first digit

to be configured for ON TIME in Minutes (MM).

NOTE: The ON TIME can be configured between 1 to

30 minutes.

1. Press the UP or DOWN

arrows to select the first

digit.

2. Press the ENTER button

to save the selection.

After the ENTER button is

pressed, the second digit begins

to blink. The ON LED and MM

dot remains lighted.

This confirms that the second

digit for ON TIME is being configured in Minutes (MM).

3A6714C 21

Page 22

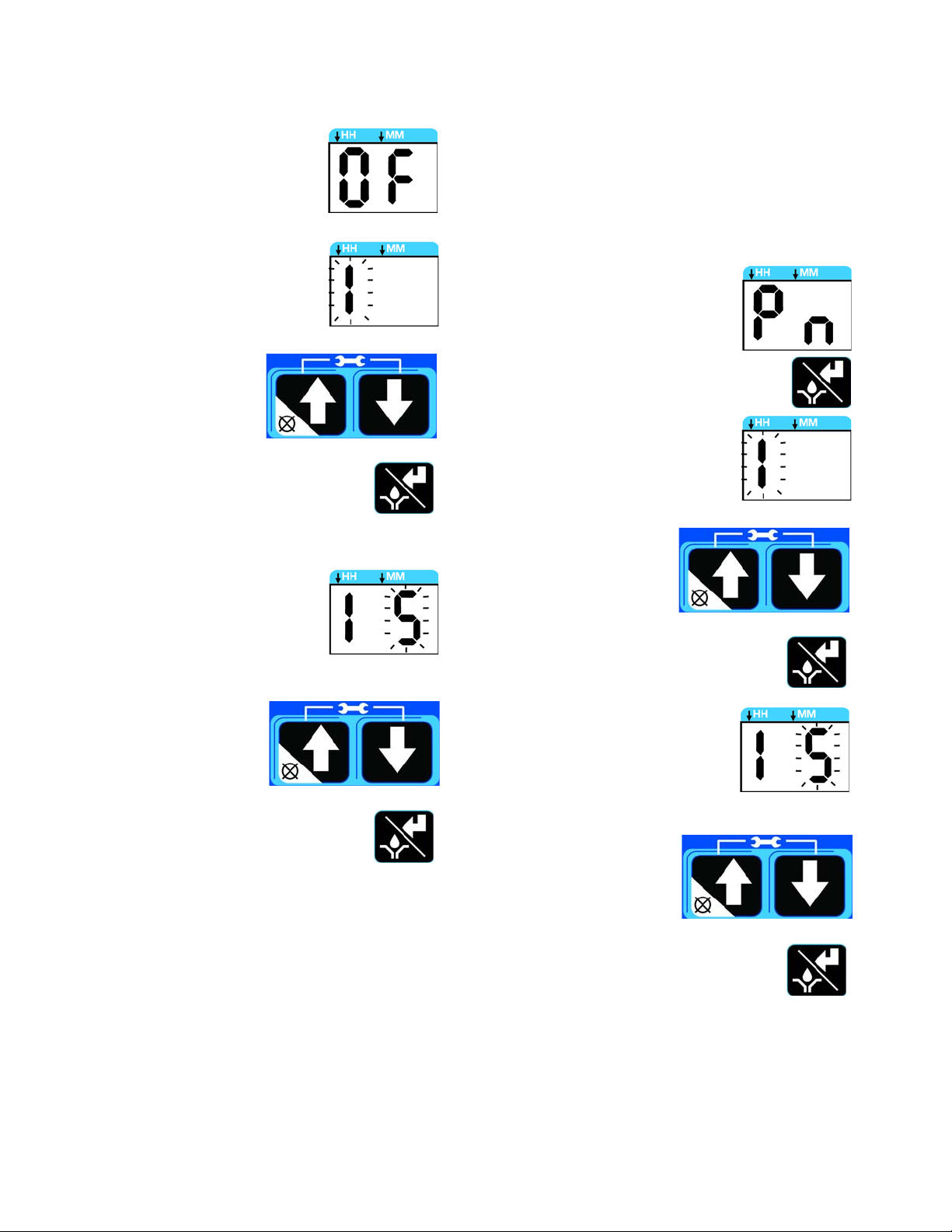

Controller Operation

3. Press the UP or DOWN

arrows to select the second digit.

4. Press the ENTER button

to save the selection.

The controller automatically switches to OFF TIME configuration.

ON TIME Configuration (Cycles)

NOTE: The proximity switch accessory must be installed

and Cycle Count enabled in Advanced Programming

(page 23) before the number of cycles can be configured in SETUP MODE.

Notice the following on the controller:

- The LED next to the

Clock in the ON field illuminates

- The display reads “CY”

to identify that the ON

TIME is configured for

Cycles Counts.

NOTE: The number of cycles counts can range from 1

to 99.

1. Press the ENTER button to

advance the display.

After the ENTER button is

pressed, the second digit

begins to blink. The ON LED

remains lighted.

This confirms that the second

digit for ON TIME is being configured in Minutes (MM).

4. Press the UP or DOWN

arrows to select the second digit.

5. Press the ENTER button to save the

selection.

The controller automatically switches to OFF TIME configuration.

OFF TIME Configuration (Min./Hrs)

Notice the following on the controller:

- The LED next to the

Clock in the OFF

field is lighted.

- The first digit on the

display begins to

blink.

- A dot on the display

under the HH illuminates.

The first digit on the display

begins to blink. This confirms

that the controller is ready for

the cycle count to be configured.

2. Press the UP or DOWN

arrows to select the first

digit.

3. Press the ENTER button to save the

selection.

22 3A6714C

This confirms that the controller is ready for the first digit

to be configured for OFF TIME in Hours (HH).

NOTE: The OFF TIME must be configured between 15

min, and 99 hours.

1. Press the UP or Down

arrows to select the first

digit.

2. Press the ENTER button

to save the selection.

Page 23

Controller Operation

After the ENTER button is

pressed, the second digit

begins to blink. The OFF

LED and HH dot remain

lighted.

This confirms that the second digit for OFF TIME is

being configured in Hours

(HH).

3. Press the UP or DOWN

arrows to select the second digit.

4. Press the ENTER button

to save the selection.

The controller automatically switches to RUN MODE.

ADVANCED PROGRAMMING

The Seven Advanced Programming Menu Descriptions

are:

• A1 - PIN Entry Enable/Setting Up the PIN Code,

page 23

• A2 - Prelube and Delay, page 25

• A3 - Low-Level Alert Duration, page 25

• A4 - Missed Cycle Threshold, page 25

• A5 - Low-Level Power Cycle Retry, page 25

• A6 - Low-Level Alert Enable, page 25

• A7 - Cycle Count Enable, page 25

To access ADVANCED PROGRAMING:

1. Press both the UP and

DOWN arrow buttons for

3 seconds to enter

SETUP MODE.

After entering ADVANCED PROGRAMMING, if no activity is detected for 60 seconds, a timeout occurs and the

controller resumes RUN MODE.

Press the ENTER button to advance to the

configurable portion of the specific settings.

1. Press the UP or DOWN

arrows to configure the

selection.

For ON or OFF selection:

-ON: UP arrow

- OFF: DOWN arrow

2. After completing configuration, press the

ENTER button to save and proceed to

the next ADVANCED PROGRAMMING

settings.

After all of the ADVANCED PROGRAMMING settings

are configured, press the ENTER button to return the

controller to RUN MODE.

Advanced Programming Menu Descriptions

A1 – PIN Entry Enable/Setting Up the PIN Code

A PIN Code provides additional controller security by

requiring that a PIN Code be entered before gaining

access to SETUP MODE.

NOTE: The PIN Code can be configured to be any number between (and including) 00 and 99.

To set up the PIN Code:

1. Follow Steps 1 and 2 of ADVANCED PROGRAMMING, (page 23).

2. When A1 appears on the display, press

the ENTER button. Either On (PIN Code

ON) or OF (PIN Code OFF) displays.

2. In SETUP MODE, press and hold

the UP arrow for 10 seconds.

The display reads A1. This confirms

that the controller is in the

ADVANCED PROGRAMMING settings.

3A6714C 23

• On (ON) - Select On to configure the controller to

require that a PIN Code be entered prior to

accessing SET UP Mode.

-

Page 24

Controller Operation

- OF (OFF) - Select OF to configure the controller to not

require a PIN code. Press the

ENTER button again to set

the OF (OFF) option.

3. The first digit on the display

begins to blink. This confirms

that the controller is ready to

select the first number of the PIN

Code.

4. Press the UP or Down

arrows to select the first

digit.

5. Press the ENTER button to save the

selection.

After the ENTER button is pressed,

the second digit begins to blink.

Entering a PIN Code in the Controller

After the controller is configured for PIN entry, to access

SETUP MODE:

1. Follow Steps 1 and 2 of ADVANCED PROGRAM-

MING, (page 23).

2. Pn appears on the display.

3. Press the ENTER button to

advance the display.

4. The first digit on the display

begins to blink. This confirms

that the controller is ready for the

first number of the PIN Code to

be entered.

5. Press the UP or Down

arrows until the first digit

of the PIN Code displays.

This confirms that the second digit for

the PIN Code is ready to be configured.

6. Press the UP or Down

arrows to select the second digit.

7. Press the ENTER button to save the

selection.

8. The controller automatically advances to the A2

screen.

6. Press the ENTER button to save the

entry.

7. After pressing the ENTER button, the second digit begins to

blink. This confirms that the controller is ready for the second

number of the PIN Code to be

entered.

8. Press the UP or Down

arrows until the second

digit of the PIN Code displays.

9. Press the ENTER button to save the

entry.

10. The ON TIME configuration screen displays. See

SETUP MODE, ON TIME Configuration (Minutes), page 21 for additional information.

24 3A6714C

Page 25

Controller Operation

A2 – Prelube and Delay

The Prelube Delay option configures the controller to set

the amount of time before the Prelube cycle begins. The

duration of time begins after power has been restored to

the controller. This value can range from 0 to 60 minutes

(default: 0).

The Prelube function determines operation of the pump

when power is applied. It can be set to ON or OFF.

• OF (OFF) (default) – The unit resumes at the point

in the lubrication cycle it was at when power was

disengaged.

• On (ON) – The unit begins a pump cycle once

power is restored.

When On is selected and the Enter button is pressed,

the controller is ready for a Prelube delay to be configured. See ADVANCED PROGRAMMING instructions,

page 23.

A3 – Low-Level Alert Duration

The Low-Level Alert Time configures the controller to

set the duration of time that a Low-Level Alert exists with

the pump running before escalating to an Alarm.

The Low-Level Auto Clear is an OF (OFF) or On (ON)

selection.

• OF (OFF) (default) – Upon power cycle, the controller will remain in its current Low-Level Alarm state.

• On (ON) – Upon power cycle, the controller will

begin a lubrication cycle to determine if a Low-Level

condition still exists.

See ADVANCED PROGRAMMING instructions, page

23.

A6 – Low-Level Alert Enable

The Low-Level Warning Enable feature configures the

controller to trigger a Low-Level Alert prior to the escalation of an Alarm.

The Low-Level Warning Enable is an OF (OFF) or On

(ON) selection.

• OF (OFF) (default) – Low-Level conditions are

immediately escalated to Alarm status.

• On (ON) – Low-Level conditions are first reported as

an Alert for the duration of setting A3, at which point

they escalate to an Alarm.

The Low-Level Alert Time can range from 1 to 5 minutes

(default: 3). To configure the Low-Level Alert Time, see

ADVANCED PROGRAMMING instructions, page 23.

A4 – Missed Cycle Threshold

While operating in Cycle Mode, the Cycle Alarm Threshold configures the controller to set the number of consecutively missed Cycles allowed before activating an

alarm.

The Cycle Alarm Threshold can range from 0-99 cycles

(default:0). To configure the Cycle Alarm Threshold, see

ADVANCED PROGRAMMING instructions, page 23.

A5 – Low-Level Power Cycle Retry

When set to ON, the Low-Level Auto Clear feature

allows the controller to attempt to automatically clear a

Low-Level Alarm during the power cycle. This feature is

only used when a controller has the power removed

while in a Low-Level Alarm state.

See ADVANCED PROGRAMMING instructions, page

23.

A7 – Cycle Count Enable

The Cycle Lubrication Enable feature configures the

controller to use Cycle Counts to monitor the duration of

a lubrication period and enables the M12 Cycle Indicator

Connector.

The Cycle Lubrication Enable is an OF (OFF) or On

(ON) selection.

• OF (OFF) (default) – The lubrication period will be

monitored in minutes.

• On (ON) – The lubrication period is monitored in

cycles. This requires the addition of a proximity

switch. The number of cycles must also be configured in SET UP mode (page 21).

See ADVANCED PROGRAMMING instructions, page

23.

3A6714C 25

Page 26

Alerts and Alarms

Alerts and Alarms

The controller monitors and displays two types of

events: Alerts and Alarms.

Alerts

Alerts do not cause the lubrication cycle to stop. These

events are automatically cleared based upon the alert

received.

An amber LED illuminates under ALARM on

the display when an

Alert occurs. See Alert

and Alarm Scenarios on page 27 for a description of

Alerts that could occur.

Alarms

Alarms cause the lubrication cycle to stop. Alarms can

trigger immediately or can be the result of an escalated

Alert. Alarms must be cleared immediately.

A red LED illuminates

under ALARM on the

display when an Alarm

occurs. See the Alert

and Alarm Scenarios table on page 27 for a description of Alarms that could occur.

When an Alarm is triggered, any active lubrication cycle

will be terminated. The display begins to count up to

identify how long the Alarm condition has been present.

The counter begins in minutes, then changes to hours,

with a limit of 99 hours.

See ADVANCED PROGRAMMING, page 23 for additional information about configuring the controller for

Alerts and Alarms.

26 3A6714C

Page 27

Alert and Alarm Scenarios

The following pages describe the most likely alerts and alarms:

Alarm Type Display What it Indicates Solution

Low-Level There is a low-level of lubricant in

the reservoir

Add lubricant to reservoir.

An alert will auto-clear.

An alarm must be reset by

pressing and holding the

Cancel Button for 4 seconds.

Alerts and Alarms

Cycle The cycle was not completed in 4

minutes.

Over

Current

The measured motor current is

above the maximum operating level.

The motor turns off and a new lube

cycle is not allowed to be initiated.

Check for a plugged or broken line, or

other component failure such as a divider

valve.

An alert will auto-clear.

An alarm must be reset by

pressing and holding the

Cancel Button for 4 seconds.

Check to make sure that the system is

operating correctly. A blocked line could

create excessive motor current.

Examine the pump to verify it is rotating

properly.

An alarm must be reset by

pressing and holding the

Cancel Button for 4 seconds.

System

Fault

3A6714C 27

An internal fault has occurred.

The controller may not be recoverable from this state.

Attempt a power cycle of the device.

If the alarm does not clear, contact Graco

Customer Service.

Page 28

Troubleshooting

Troubleshooting

1. Follow Pressure Relief Procedure, page 15,

before checking or repairing.

Problem Cause Solution

Unit does not power on. Incorrect/loose wiring Refer to Installation instructions,

page 6.

Lubricant leaks past the seal located

on the bottom of the reservoir.

The external controller is

functioning, but the unit is not

pumping during the ON cycle.

The follower plate is not moving

downward.

After wiring and installing the

equipment, the pump is not working.

Tripped external fuse due to internal

component failure.

Tripped external fuse from using

grease with an inadequate

temperature rating in a cold

environment.

Seal was not installed correctly. Replace seal.

Reservoir is being pressurized

during filling.

Motor failure. Replace the motor.

Air is trapped in the reservoir

between the follower plate and the

lubricant.

The pump is wired incorrectly. Rewire the pump following Wiring

Contact Graco Customer Service.

Replace lubricant with a lubricant

rated for environmental conditions

and application.

Replace fuse.

Ensure that the vent tube is not

plugged.

If the problem persists, contact

Graco Customer Service or your

local Graco distributor for

assistance.

Add grease following the Load

Grease instructions, page 16.

Purge any air from the reservoir.

and Installation Diagrams, page 9.

28 3A6714C

Page 29

Maintenance

Maintenance

Frequency Component Required Maintenance

Daily and at Refill Fill Fittings Keep all of the fittings clean using a clean dry cloth.

Dirt and/or debris can damage the pump and/or the

lubrication system.

Daily Pump Unit and Reservoir Keep pump unit and reservoir clean using a clean dry

cloth.

Monthly External Wiring Harness Verify external harnesses are secure.

3A6714C 29

Page 30

Repair

Repair

All electrical wiring must be done by a qualified

electrician and comply with all local codes and

regulations.

Reservoir Kits

Kit No. Description

26C943 Kit Replacement, Reservoir, 1L

26C945 Kit Replacement, Reservoir, 0.5L

Kit Replacement, Reservoir, Follower

26C944

26C946

Plate, 1L

Kit Replacement, Reservoir, Follower

Plate, 0.5L

Pump Element Kits

Kit No. Description

Standard G-Mini Pump Element;

26C947

26C948

Output: 3 cc/min.

Alternative G-Mini Pump Element;

Output: 1.5 cc/min.

30 3A6714C

Page 31

Parts

Torque to 23 in-lb (2.6 N•m)

3

Torque to 13 in-lb (1.5 N•m)

1

Torque to 65 in-lb (7.3 N•m)

2

1a

1b

2

3a

3b

4a, 4b

46

6

12

11

19

20

22

23

24

25a, 25b

28

32a, 32b

33

34

38

39

41a, 41b

42

43

44

45

19

19

1

1

2

3

3

4

50

Torque to 7 in-lb (0.8 N•m)

4

63a, 63b

65

64

4

66

Parts

3A6714C 31

Page 32

Parts

Part No./Description

Ref. Part Description Qty.

Reservoir, 1.0 Liter, included in kits

26C943, 26C944

1a

1b

2

3a

3b

4a

4b

6

11 Blade, agitator

12 Washer, paddle, ID8/OD16

19 Screw, ST4.2

20

Model 25R800, 25R801, 25R802,

25R803, 25R804, 25R805, 25R806,

25R820, 25R821, 25R822, 25R823,

25R824, 25R825, 25R826

Reservoir, 0.5 Liter, included in kits

26C945, 26C946

Model 25R807, 25R808, 25R809,

25R810, 25R827, 25R828, 25R829,

25R830

Label, max fill, included in kits

26C943, 26C944

Model 25R800, 25R801, 25R802,

25R803, 25R804, 25R805, 25R806,

25R820, 25R821, 25R822, 25R823,

25R824, 25R825, 25R826

Label, branding, 1L, included in kits

26C943, 26C944

Model 25R800, 25R801, 25R802,

25R803, 25R804, 25R805, 25R806,

25R820, 25R821, 25R822, 25R823,

25R824, 25R825, 25R826

Label, branding, 0.5 Liter, included in

kits 26C945, 26C946

Model 25R807, 25R808, 25R809,

25R810, 25R827, 25R828, 25R829,

25R830

Spring, compr., 1.0 Liter Reservoir,

included in kit 26C944

Model 25R800, 25R801, 25R802,

25R803, 25R804, 25R805, 25R806,

25R820, 25R821, 25R822, 25R823,

25R824, 25R825, 25R826

Spring, compr., 0.5 Liter Reservoir,

included in kit 26C946

Model 25R807, 25R808, 25R809,

25R810, 25R827, 25R828, 25R829,

25R830

Plate, follow, included in kits 26C944,

26C946

Seal, Reservoir, included in kits

26C943, 26C944, 26C945, 26C946

1

1

1

1

1

1

1

1

1

3

10

1

Ref. Part Description Qty.

Pump element, assy, included in kits

26C947, 26C948

Model 25R805, 25R825

Pump element, assy, included in kits

26C947, 26C948

22

23 100721 Plug, 1/4 npt, HEX socket

24 555888 Nipple

25a

25b

28 PCB, Board, assy, Compact Pump

32a Motor, 24VDC

32b Motor, 12VDC

33 Seal, bottom cover

34 Cover, bottom

38 111139 O-ring

39 Label, Series

41a

41b

42

43

44

45 Base, Pump

Model 25R800, 25R801, 25R802,

25R803, 25R804, 25R806, 25R807,

25R808, 25R809, 25R810, 25R820,

25R821, 25R822, 25R823, 25R824,

25R825, 25R826, 25R827, 25R828,

25R829, 25R830

Label, overlay, BLK

Model 25R800, 25R802, 25R807,

25R809, 25R820, 25R822, 25R827,

25R829

Label, overlay, controller version

Model 25R801, 25R803, 25R804,

25R805, 25R806, 25R808, 25R810,

25R821, 25R823, 25R824, 25R825,

25R826, 25R828, 25R830

CPC connector, Power and Low Level

Model 25R800, 25R802, 25R807,

25R809

CPC connector, Power and Manual

Run Button

Model 25R801, 25R803, 25R804,

25R905, 25R806, 25R808, 25R810

Washer, lock, M12

Model 25R801, 25R803, 25R804,

25R805, 25R806, 25R808, 25R810,

25R821, 25R823, 25R824, 25R825,

25R826, 25R826, 25R830

M12 connector, cycle feedback input

Model 25R801, 25R803, 25R804,

25R805, 25R806, 25R808, 25R810,

25R821, 25R823, 25R824, 25R825,

25R826, 25R828, 25R830

Plug, M12

Model 25R801, 25R803, 25R804,

25R805, 25R806, 25R808, 25R810,

25R821, 25R823, 25R824, 25R825,

25R826, 25R828, 25R830

2

1

2

1

1

1

1

1

1

1

1

4

1

1

1

1

1

1

1

32 3A6714C

Page 33

Ref. Part Description Qty.

Plug, M20

Model 25R800, 25R801, 25R802,

25R803, 25R804, 25R806, 25R807,

46

50 16A579 Label, Warning

63a

63b

64 DIN connector, Power Input

65

66

25R808, 25R809, 25R810, 25R820,

25R821, 25R822, 25R823, 25R824,

25R826, 25R827, 25R828, 25R829,

25R830

DIN connector, Low Level

Model 25R820, 25R822, 25R827,

25R829

DIN connector, Manual Run Button

Model 25R821, 25R823, 25R824,

25R825, 25R826, 25R828, 25R830

Screw, Self-Tap

Model 25R820-25R830

Cap

Model 25R820-25R830

1

1

1

1

1

8

2

Parts

Replacement safety labels, tags, and cards are

available at no cost.

3A6714C 33

Page 34

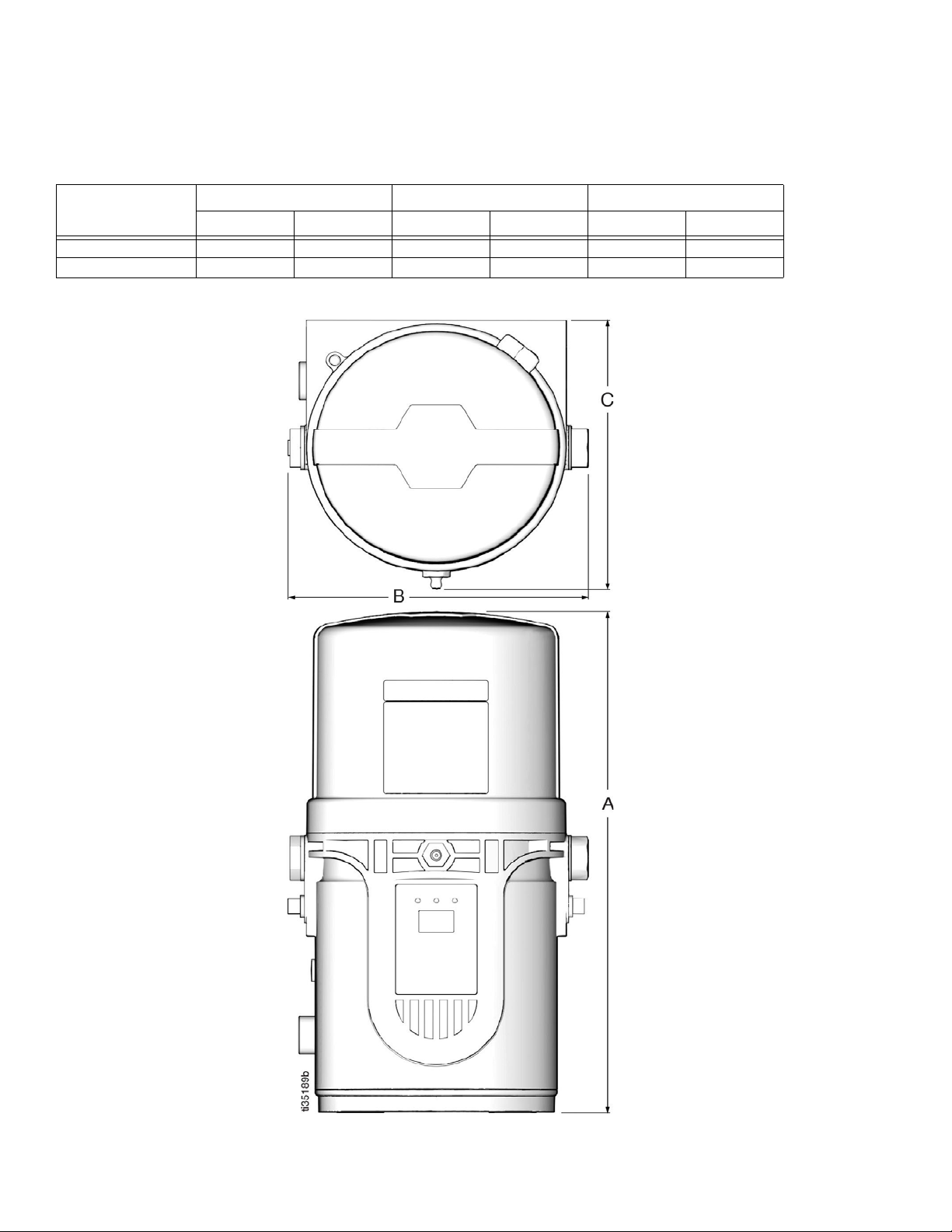

Dimensions

Dimensions

Model

0.5L 10.9 27.7 6.97 17.7 6.57 16.7

1L 12.2 31.0 6.97 17.7 6.57 16.7

Height - A Width - B Depth - C

Inches cm Inches cm Inches cm

34 3A6714C

Page 35

Dimensions

Pump Mount

Universal Bracket Mount

CSP Valve Bracket Mount

3A6714C 35

Page 36

Technical Specifications

Technical Specifications

G-Mini Pump

US Metric

Maximum fluid working pressure 4061 psi 28 MPa, 280 bar

Power

12 VDC 9-16 VDC; 9.5 A current, 114 W, inrush/locked rotor 12 A

24 VDC 18-32 VDC; 6.5 A current, 156 W, inrush/locked rotor 7.5 A

Inputs - Proximity Switch PNP Style Switch and Cable Only

Pump Voltage: 12 VDC 11 mA at 12 VDC

Pump Voltage: 24 VDC 22 mA at 24 VDC

Outputs - Low Level

Contact Rating

Switch Rating

Switching Current 0.5 A maximum

Carry Current 1.2 A maximum

Outputs - Manual Run Button

Pump Voltage: 12 VDC 11 mA at 12 VDC

Pump Voltage: 24 VDC 22 mA at 24 VDC

Pump Output

Pump Outlet 1/4 in. NPT female

Reservoir Size 0.5 L

IP Rating IP69K

Working Temperature*

Non-Heater Model

Heater Model

Weight

Wetted parts

Sound data

100 W maximum

200 VDC maximum

3.0 cc minute at room temperature with 4061 psi (28 MPa,

280 bar) back pressure

1.0 L

5°F to 158°F -15°C to 70°C

-40°F to 158°F -40°C to 70°C

8.8 lb 4 kg

carbon steel, alloy steel, stainless steel, nitrile rubber

(buna-N), bronze, nickel plated alnico, chemically lubricated

acetal, aluminum, PTFE, amorphous polyamide, nylon 6/6

(PA)

<60dB

*Achieving the minimum working temperature is contingent on using a temperature compliant grease in an appropriately designed

system.

36 3A6714C

Page 37

Technical Specifications

California Proposition 65

WARNING: This product can expose you to chemicals known to the State of California to

cause cancer and birth defects or other reproductive harm. For more information, go to

www.P65warnings.ca.gov.

3A6714C 37

Page 38

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2020, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A6714

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revision

C, July 2020

Loading...

Loading...