Graco G3-G-24NC-2L0000-00C00000, 96G000, G3-G-24NC-2LFA00-L0C00000, G3-G-ACNC-2L0000-0D000000, G3-G-24NC-2L0A00-L0C00000 Instructions Manual

...

Instructions

Conforms to ANSI/UL 73

Certified to CAN/CSA

Std. 22.2 No 68-09

3132066

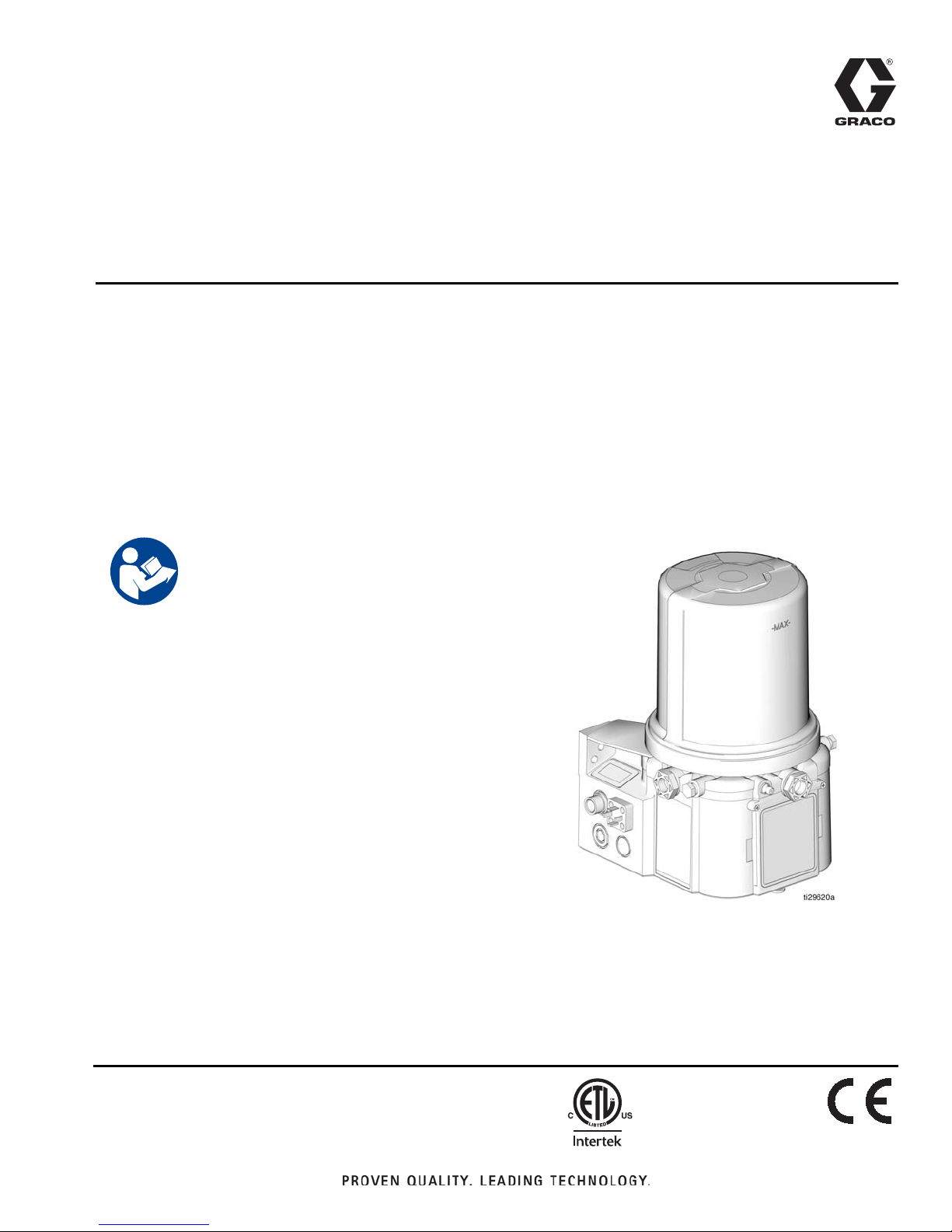

G3 Standard Automatic

332291G

Lubrication Pump

For dispensing of NLGI Grades #000 to #2 greases and oil with at least 40cSt. For

Professional Use Only.

Not approved for use in explosive atmospheres or hazardous locations.

Part Nos., page 3

5100 psi (35.1 MPa, 351.6 bar) Pump Output Pressure

5000 psi (34.4 MPA, 344.7 bar) Fill Inlet Pressure

EN

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

Contents

Part / Model Numbers . . . . . . . . . . . . . . . . . . . . . . . 3

2 Liter Models . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4 Liter Models . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

8 Liter Models . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

12 Liter Models . . . . . . . . . . . . . . . . . . . . . . . . . . 3

16 Liter Models . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Understanding the Model Number . . . . . . . . . . . 4

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . . 8

Typical Installation - With Remote Fill Manifold . . 9

Optional Installation -

Without Remote Fill Manifold . . . . . . . . . . . 10

Choosing an Installation Location . . . . . . . . . . . 11

System Configuration and Wiring . . . . . . . . . . . 12

Wiring and Installation Diagrams . . . . . . . . . . . 13

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Connecting to Auxiliary Fittings . . . . . . . . . . . . . 18

Setting Pump Outlet Volume . . . . . . . . . . . . . . . 19

Loading Grease . . . . . . . . . . . . . . . . . . . . . . . . 19

Auto-Fill Shut Off . . . . . . . . . . . . . . . . . . . . . . . . 21

Filling Oil Unit . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Priming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Pump Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Parts - 2 Liter Models . . . . . . . . . . . . . . . . . . . . . . 29

Parts - 4 Liter and Larger Models . . . . . . . . . . . . . 30

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Mounting Pattern . . . . . . . . . . . . . . . . . . . . . . . . 35

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 36

Graco Information . . . . . . . . . . . . . . . . . . . . . . . 36

2 332291G

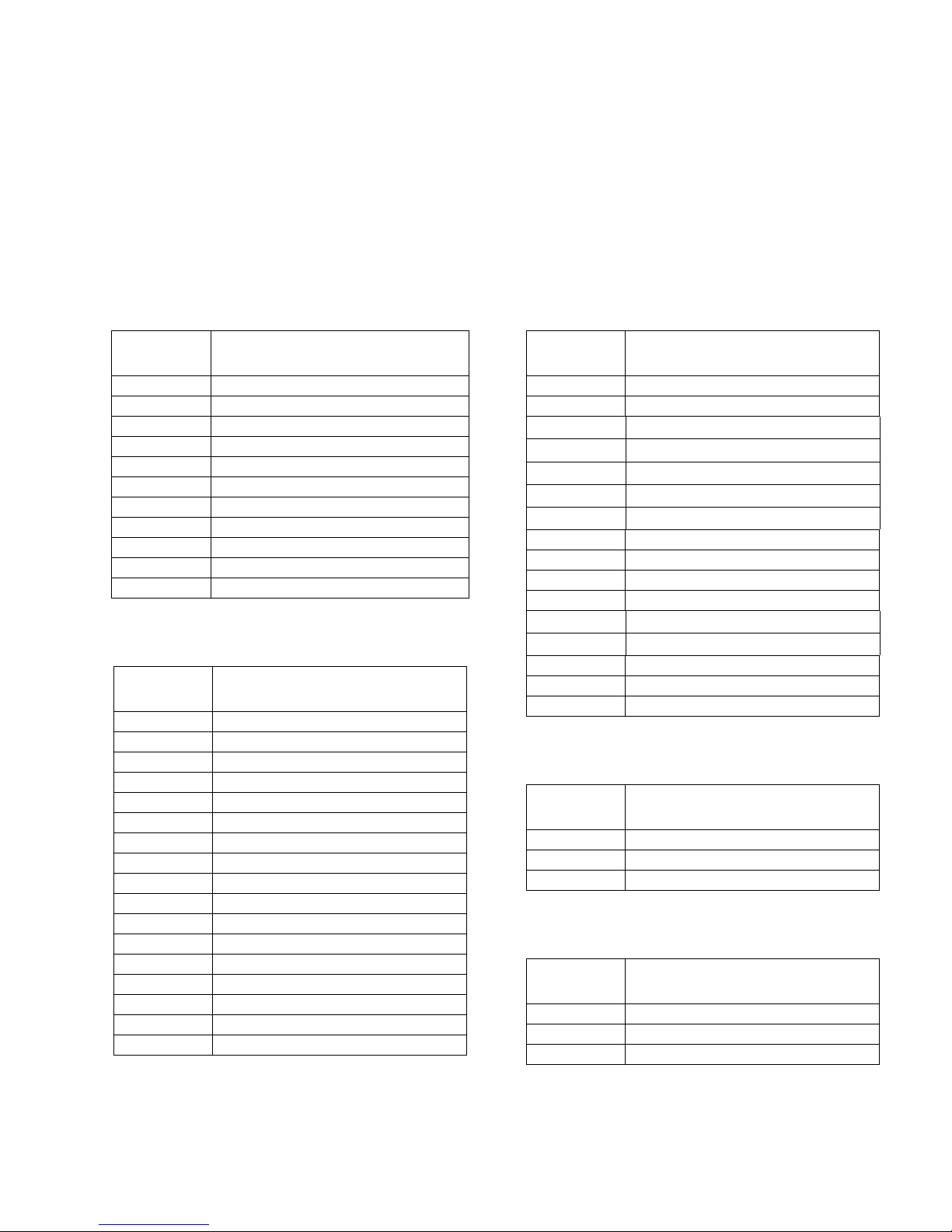

Part / Model Numbers

Part / Model Numbers

The Part Number is a six-digit unique number that is only used to order the G3 Pump. Directly related to this six digit

Part Number is the configured Graco Model Number. This configured number identifies the distinct features of a specific G3 Pump. To help you understand each component that makes up the Model Number see Understanding Your

Model Number, page 4. The tables below shows the relationship between each Part Number and its related Model

Number.

2 Liter Models

Part

Numbers

96G000 G3-G-12NC-2L0000-00C00000

96G001 G3-G-24NC-2L0000-00C00000

96G002 G3-G-ACNC-2L0000-0D000000

96G003 G3-G-12NC-2L0A00-L0C00000

96G005 G3-G-24NC-2L0A00-L0C00000

96G006 G3-G-24NC-2LFA00-L0C00000

96G007 G3-G-ACNC-2L0A00-LD000000

96G008 G3-G-ACNC-2LFA00-LD00000

96G050 G3-A-24NC-2L0A00-L0C00000

96G059 G3-A-ACNC-2L0A00-LD000000

96G182 G3-G-24NC-2L0A00-0D00L000

Model Number

4 Liter Models

Part

Numbers

96G038 G3-G-12NC-4L0L00-00C00000

96G040 G3-G-24NC-4L0000-00C00000

96G042 G3-G-ACNC-4L0000-0D000000

96G044 G3-G-12NC-4L0A00-L0C00000

96G048 G3-G-24NC-4L0A00-L0C00000

96G051 G3-A-24NC-4L0A00-L0C00000

96G053 G3-G-24NC-4LFA00-L0C00000

96G055 G3-G-ACNC-4L0A00-LD000000

96G060 G3-A-ACNC-4L0A00-LD000000

96G062 G3-G-ACNC-4LFA00-LD000000

96G173 G3-G-ACNC-4LFA00-0D00L000

96G179 G3-G-ACNC-4LFA00-0D00L000

96G184 G3-G-24NC-4L0A00-0D00L000

96G210 G3-G-24NC-4LAA00-0D00L000

96G180 G3-G-24NC-4L0A02-L0C00000

96G202 G3-G-ACNC-4L0A00-0D00L000

96G204 G3-G-24NC-4LFA00-0D00L000

Model Number

8 Liter Models

Part

Numbers

96G039 G3-G-12NC-8L0000-00C00000

96G041 G3-G-24NC-8L0000-00C00000

96G043 G3-G-ACNC-8L0000-0D000000

96G045 G3-G-12NC-8L0A00-L0C00000

96G049 G3-G-24NC-8L0A00-L0C00000

96G052 G3-A-24NC-8L0A00-L0C00000

96G056 G3-G-ACNC-8L0A00-LD000000

96G061 G3-A-ACNC-8L0A00-LD000000

96G187 G3-G-ACNC-8LFA00-0D00L000

96G189 G3-G-24NC-8L0A00-0D00L000

96G192 G3-G-24NC-8LFA00-L0C00000

96G198 G3-G-24NC-8L0A06-0C000000

96G207 G3-G-ACNC-8LAA00-LD000000

96G213 G3-G-24NC-8LAA00-0D00L000

96G217 G3-G-24NC-8LAA06-00C00000

96G205 G3-G-24NC-8LFA00-0D00L000

Model Number

12 Liter Models

Part

Numbers

96G057 G3-G-ACNC-120A00-LD000000

96G171 G3-G-24NC-120000-00C00000

96G199 G3-G-24NC-120A00-L0C00000

Model Number

16 Liter Models

Part

Numbers

96G058 G3-G-ACNC-160A00-LD000000

96G172 G3-G-24NC-160000-00C00000

96G220 G3-G-24NC-1600A00-L0C00000

Model Number

332291G 3

Part / Model Numbers

k

m

n

p

h

j

i

g

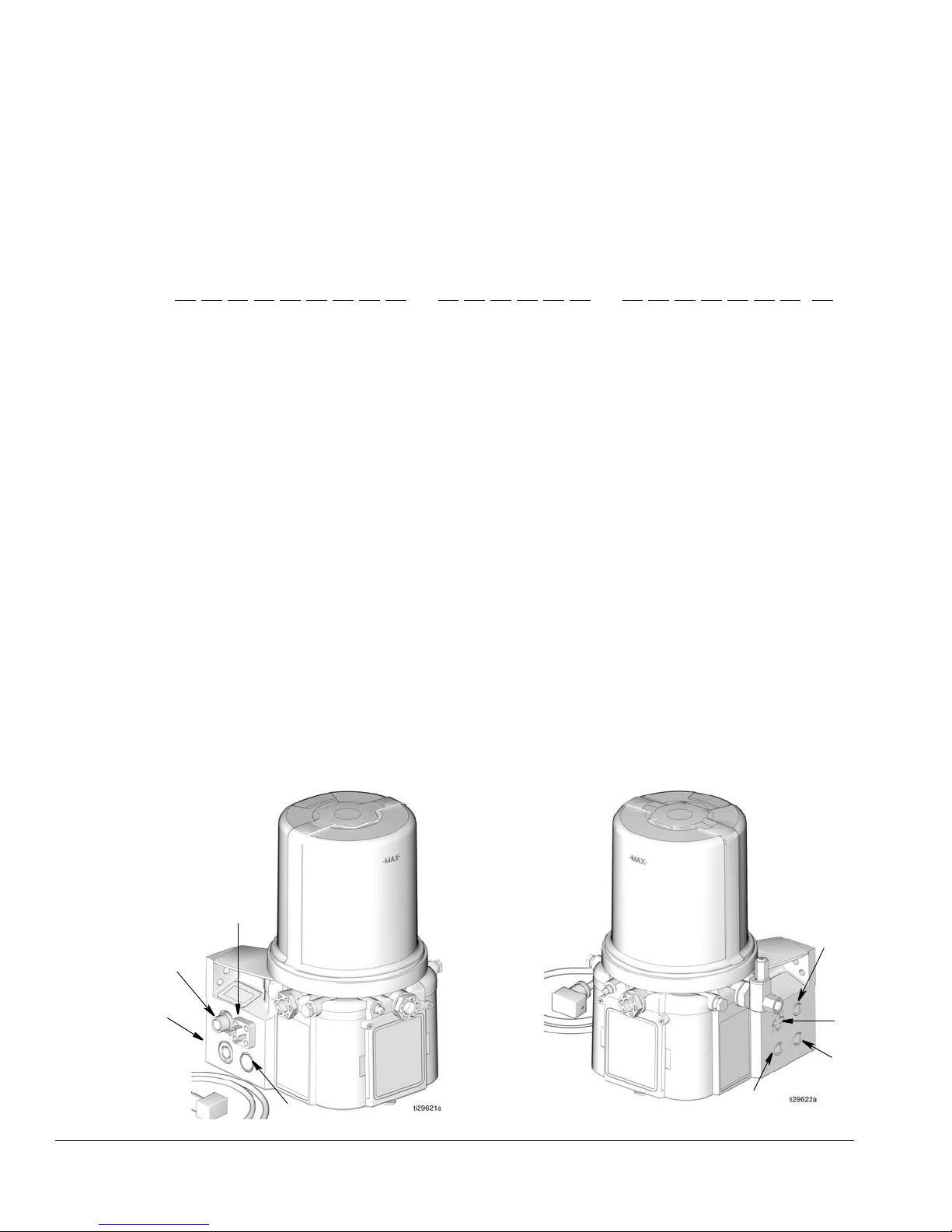

Understanding the Model Number

Use the Code Sample provided below to identify each component’s location in the Model Number. The options for

each component that make up the code are provided on the lists below.

NOTE: Other pump configurations are available that are not documented in this manual. Contact Graco Customer

Service or your local Graco distributor for assistance.

Code Sample: a a b b - c c d e f f - g h i j k m n p

G3 - G = Identifies pump as being a G3; G = Grease

G3 - A = Identifies pump as being a G3; A = Oil

Code aa: Power Source

• 12 = 12 Volts DC

• 24 = 24 Volts DC

• AC = 100 - 240 Volts AC

Code bb: Operation Control

• NC = No Controller

Code cc: Reservoir Capacity (Liters)

• 2L = 2 Liters

• 4L = 4 Liters

• 8L = 8 Liters

• 12 = 12 Liters

• 16 = 16 Liters

Code d: Follower Plate Installed

• F = Follower Plate Installed

• 0 = No Follower Plate

• A = Auto-Fill Shut Off

G3 - G- NC 0 0 0 00 0

Code e: Low Level Option

• A = External Low Level

• 0 = No Low Level monitoring

Code ff: Options

• 00 = No Options

• 06 = Low Level in CPC

Code g, h, i, j, k, m, n, p

NOTE: Codes g - p relate to a specific location on the

G3 pump. See F

•C = CPC

•D = DIN

• L = Low Level

• 0 = Not populated

IG. 1 for these locations.

FIG. 1

4 332291G

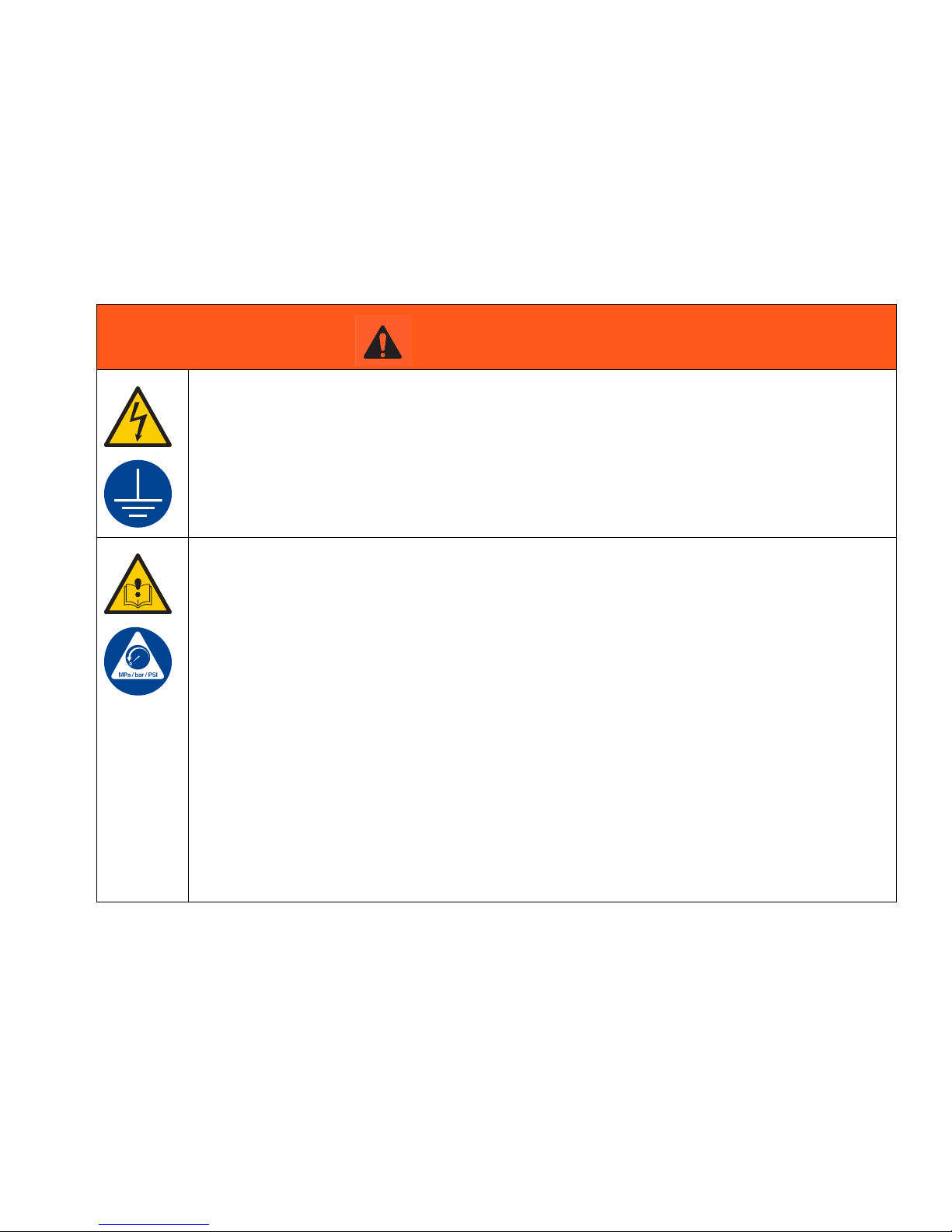

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

WARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause

electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

or installing equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and regulations.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS from distributor or retailer.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

332291G 5

Warnings

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgi-

cal treatment.

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking,

or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

PRESSURIZED EQUIPMENT HAZARD

Over-pressurization can result in equipment rupture and serious injury.

• A pressure relief valve is required at each pump outlet.

• Follow Pressure Relief Procedure in this manual before servicing.

PLASTIC PARTS CLEANING SOLVENT HAZARD

Many solvents can degrade plastic parts and cause them to fail, which could cause serious injury or

property damage.

• Use only compatible water-based solvents to clean plastic structural or pressure-containing parts.

• See Technical Data in this and all other equipment instruction manuals. Read fluid and solvent

manufacturer’s MSDSs and recommendations.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, follow the Pressure Relief Procedure and disconnect all power sources.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes

but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer

6 332291G

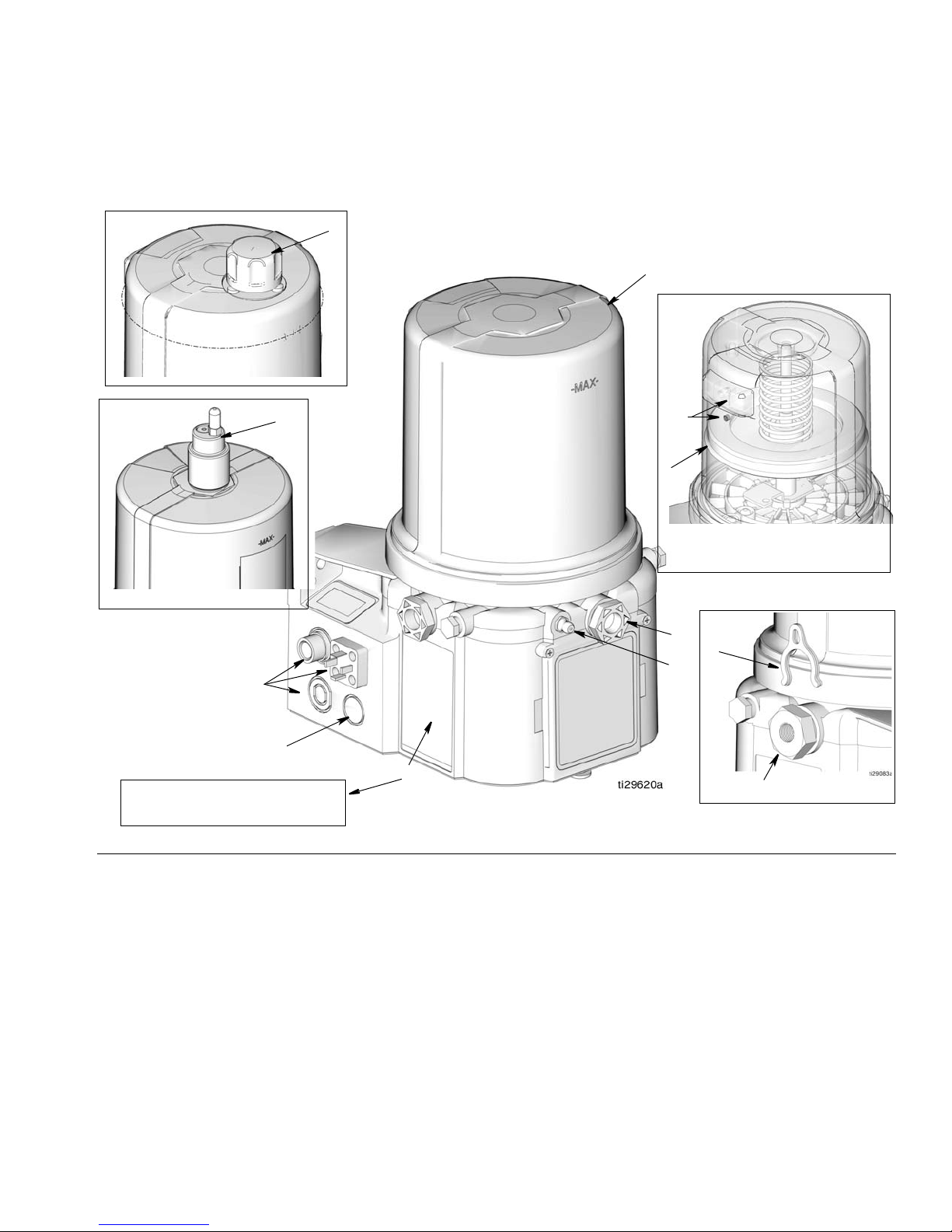

Installation

A

D

H

B

E

J

F

I

G3-G-24NC-2L0A00-L0C00000

Grease Models with Follower

Plate

K

L

96GXXX

Oil Models

M

Grease Models

N

Auto-Fill Shut Off Models

Component Identification

Installation

FIG. 2

Key:

AReservoir

B Adjustable Pump Element (1 included. Can accommodate 3

total)

C Pressure Relief Valve (Not included (not shown) / required for

each outlet - Available from Graco. See Parts, page 32.)

D Zerk Inlet Fill Fitting (1 included / grease models only)

E Pump Outlet Plug (2 included)

F Volume Control Spacers (2 included. More spacers = less

output volume per stroke) (also see F

G Fuse (DC models only - Not included, not shown. Available

from Graco. See Parts, page 32.)

H Power / Sensor Panel (both sides; only one side shown)

I Part Number / Model Number example only shown, (see

J Power Cord (DIN shown)

page 4, Understanding the Model Number, for details)

K Follower Plate (grease models only / not available on all

L Vent Hole for Follower Plate (grease models only / not

M Fill cap (oil models only)

N Auto-Fill Shut Off

IG. 18, page 19)

grease models)

available on all grease models)

332291G 7

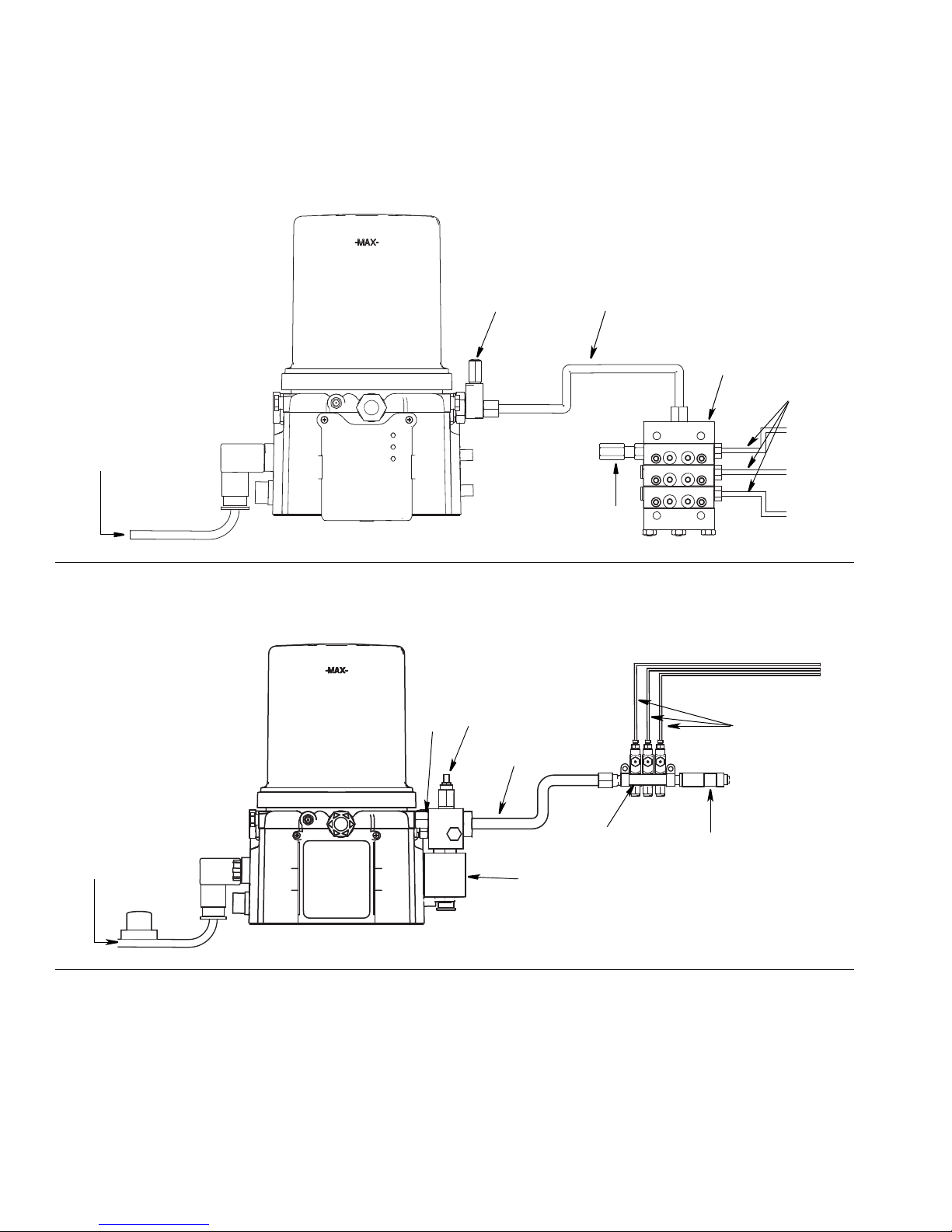

Installation

A

B

D

E

F

C

A

B

D

E

F

H

G

C

Typical Installation

Series Progressive Divider Valve

FIG. 3

Injector Installations

FIG. 4

Key

A Connected to fused power source

B Pressure relief valve (Not included/ required for each out-

let - user supplied. See Parts, page 32)

C Supply Hose (user supplied)

D Series progressive divider valves (Divider Installations)

- Injectors (Injector Installations)

8 332291G

E To lube points

F - Proximity Switch (Divider Installations)

- Pressure switch (Injector Installations)

G Vent valve (Not included / available from Graco. See

Parts, page 33.)

H Return to reservoir

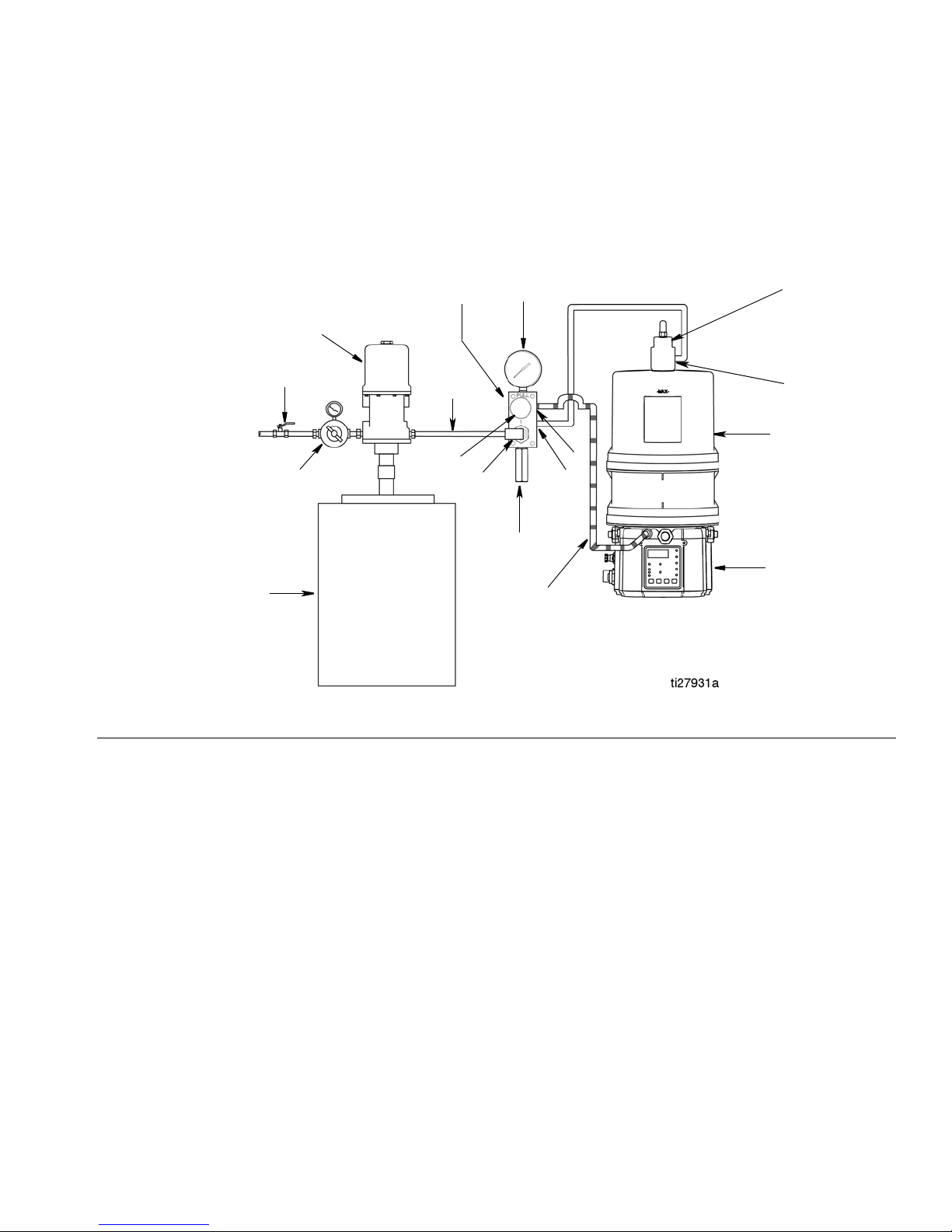

Installation

E

D

C

F

P

N

K

H

J

M

L

A

R

Q

B

S

T

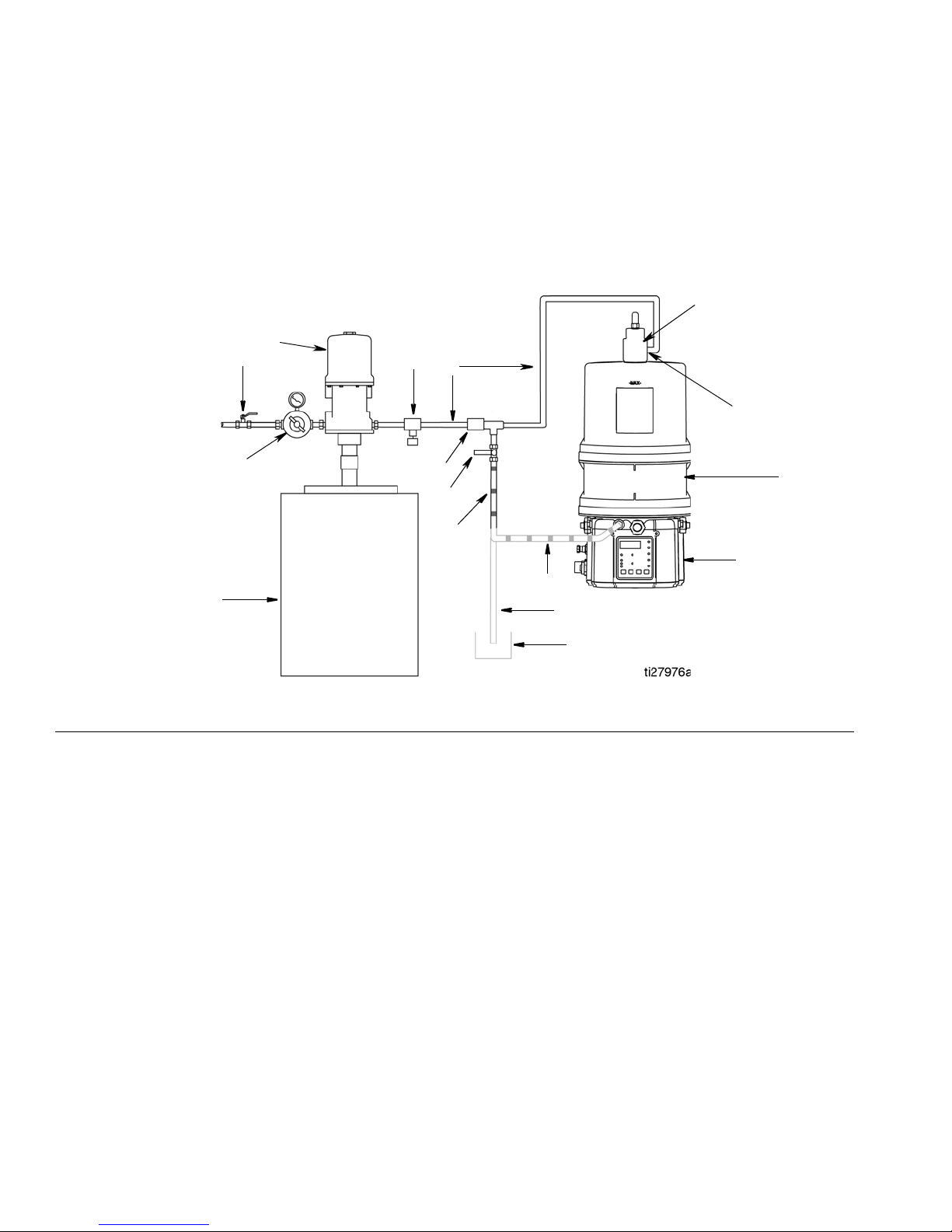

Typical Installation - With Remote Fill Manifold

The installation shown is only a guide for selecting and installing system components. Contact your Graco distributor

for assistance in planning a system to suit your needs.

FIG. 5

Key:

AG3 Pump

B Auto-Fill Shut Off Valve

C Auto-Fill Inlet

D G3 Reservoir

E Remote Fill Reservoir

F Remote Fill Pump

G Supply Hose (user supplied)

H Air Supply to Refill Pump

J Supply Hose (user supplied)

K Pressure Relief Valve

L Drain Hose

M Fill Coupler/Inlet (quick disconnect)

N Fill Manifold

P Fill Manifold Outlet

Q Fill Manifold Vent Port

R Pressure Gauge

S Pressure Regulator and Gauge

T Pressure Relief Knob

To relieve the stall pressure in the fill line a fill manifold

(N) must be installed in the system.

332291G 9

Installation

E

F

J

S

B

C

D

A

L1

H

U

V

L

L2

W

Y

Optional Installation - Without Remote Fill Manifold

The installation shown is only a guide for selecting and installing system components. Contact your Graco distributor

for assistance in planning a system to suit your needs.

NOTE: The remote filling station pump stalls (dead-heads) when the reservoir is full. If the pump does not stall

(dead-head) there is a leak in the system.

FIG. 6

Key:

AG3 Pump

B Auto-Fill Shut Off Valve

C Auto-Fill Inlet

D G3 Reservoir

E Remote Fill Reservoir

F Remote Fill Pump

HRelief Valve

J Supply Hose (user supplied)

LDrain Tube

L1 Option - To reservoir

L2 Option - To overflow container

S Pressure Regulator and Gauge

U Pressure Relief Valve

V Quick Disconnect

W Overflow Container

Y Supply Hose Pressure Relief Valve

To relieve the stall pressure in the fill line a ball valve

(Y) must be installed in the system.

10 332291G

Choosing an Installation Location

AUTOMATIC SYSTEM ACTIVATION HAZARD

If the system is equipped with has an automatic timer

(user supplied) that activates the pump lubrication

system when power is connected or when exiting the

programming function, unexpected activation of the

system could result in serious injury, including skin

injection and amputation.

Before you install or remove the lubrication pump

from the system, disconnect and isolate all power

supplies and relieve all pressure.

• Select a location that will adequately support

the weight of the G3 Pump and lubricant, as

well as all plumbing and electrical connections.

• Refer to the mounting hole layouts provided in

the Mounting Pattern section of this manual,

page 35. No other installation configuration

should be used.

Installation

• Use designated mounting holes and provided

configurations only.

• Always mount the G3 oil models upright.

• If the G3 grease model is going to be operated

in a tilted or inverted position for any period of

time, you must use a model that includes a follower plate, otherwise the G3 must be mounted

upright. Refer to your model number to confirm

if a follower plate was installed on your pump.

See page 4, Understanding the Model Number

to identify this character in your model number.

• Use the three fasteners (included) to secure the

G3 to the mounting surface.

• Some installations may require an additional

reservoir support bracket. See Table below for

bracket information

Part No Description

571159 Reservoir bracket and strap

125910 L-Bracket for pump

127665 USP to G-Series mounting bracket

332291G 11

Loading...

Loading...