Instructions-Parts

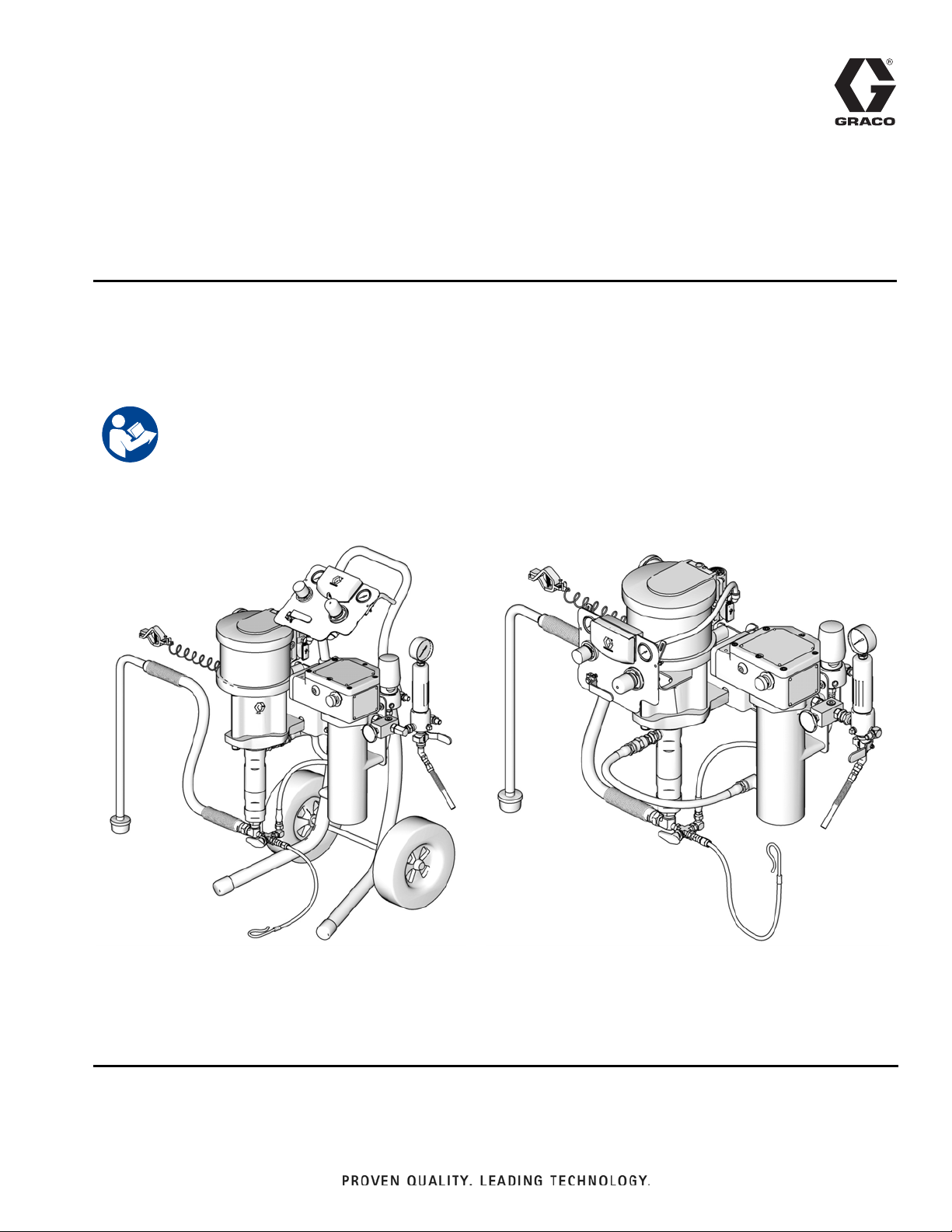

Model

G30W82

Model

G28C18

ti13016b

ti13017a

®

Merkur

Heated

313255T

Spray Packages

For finishing and coating applications requiring heated materials, in hazardous or

non-hazardous locations. For professional use only.

EN

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

See pages 6 to 8 for model information, including maximum working pressures and approvals.

Related Manuals

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Agency Approvals . . . . . . . . . . . . . . . . . . . . . . . . 6

Merkur 28:1 Heated Packages

(G28Wxx and G28Cxx) . . . . . . . . . . . . . . . . 7

Merkur 30:1 Heated Packages

(G30Wxx and G30Cxx) . . . . . . . . . . . . . . . . 7

Merkur 36:1 Heated Packages

(G36Cxx) . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Merkur 48:1 Heated Packages

(G48Wxx) . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

General Information . . . . . . . . . . . . . . . . . . . . . 10

Prepare the Operator . . . . . . . . . . . . . . . . . . . . 10

Prepare the Site . . . . . . . . . . . . . . . . . . . . . . . . 10

Wall Mount Packages . . . . . . . . . . . . . . . . . . . . 10

Ventilate the Spray Booth . . . . . . . . . . . . . . . . . 10

Supplied Components . . . . . . . . . . . . . . . . . . . . 11

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Pressure Relief Procedure . . . . . . . . . . . . . . . . 14

Flush Before Using Equipment . . . . . . . . . . . . . 14

Trigger Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Wet Cup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Prime the Pump . . . . . . . . . . . . . . . . . . . . . . . . 15

Install the Spray Tip . . . . . . . . . . . . . . . . . . . . . 15

Adjust the Atomization . . . . . . . . . . . . . . . . . . . 16

Adjust the Spray Pattern . . . . . . . . . . . . . . . . . . 16

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Preventive Maintenance Schedule . . . . . . . . . . 18

Tighten Threaded Connections . . . . . . . . . . . . . 18

Flush the Pump . . . . . . . . . . . . . . . . . . . . . . . . . 18

Wet Cup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

DataTrak Controls and Indicators . . . . . . . . . . . . 20

DataTrak Operation . . . . . . . . . . . . . . . . . . . . . . . . 21

Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Replace DataTrak Battery or Fuse . . . . . . . . . . 24

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

G28xxx Models . . . . . . . . . . . . . . . . . . . . . . . . . 27

G30xxx Models . . . . . . . . . . . . . . . . . . . . . . . . . 28

G36Cxx Models . . . . . . . . . . . . . . . . . . . . . . . . . 29

G48Wxx Models . . . . . . . . . . . . . . . . . . . . . . . . 30

Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Wall Mount Kit 24A578 . . . . . . . . . . . . . . . . . . . 31

Heated Cart Mount Kit 256427 . . . . . . . . . . . . . 31

Pump and Gun Control Panel Kit . . . . . . . . . . . 32

Pump Only Control Panel Kit . . . . . . . . . . . . . . . 33

DataTrak . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

PTFE Suction Hose Kits . . . . . . . . . . . . . . . . . . 34

California Proposition 65 . . . . . . . . . . . . . . . . . . . 34

Wall Bracket Mounting Dimensions . . . . . . . . . . . 35

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 36

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 36

Related Manuals

Manual Description

312792 Merkur Displacement Pump

312794 Merkur Pump Assembly

312796

312797 Merkur Spray Packages, Ambient

312798 Merkur Electrostatic Spray

3A0149 AA Series Spray Gun (G15, G40, and

2 313255T

™

NXT

Air Motor

Packages, Ambient and Heated

G40 with RAC)

Manual Description

312145

309524

307273 Fluid Outlet Filter

306860 Back Pressure Regulator

307892 Back Pressure Valve

313541 DataTrak Module

™

XTR

5 and XTR™7 Airless Spray Gun

®

Viscon

HP Heater

Warnings

WARNING

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning an d the ha zard symbol re fers to proced ure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammabl e fumes are

present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment until

you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SPECIAL CONDITIONS FOR SAFE USE

Equipment must comply with the following conditions to avoid a hazardous condition which can cause fire

or explosion.

• All label and marking material must be cleaned with a damp cloth (or equivalent).

• The electronic monitoring system is required to be grounded. See Grounding instructions.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric

shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

313255T 3

Warnings

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just a

cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning, checking, or servicing equipment.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See Technical Specifications in all equipment manuals.

• Do not leave the work area while equipment is energized or un der pressure. Turn off all equipment and

follow the Pressure Relief Procedure in this manual when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

4 313255T

Warnings

WARNING

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

• Read the Safety Data Sheet (SDS) to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when ope rating, servicing, or when in the ope ra ting ar ea

of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic fumes,

burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommend e d by the flu id an d so lven t ma n uf ac tur e r

•Gloves

• Hearing protection

313255T 5

Models

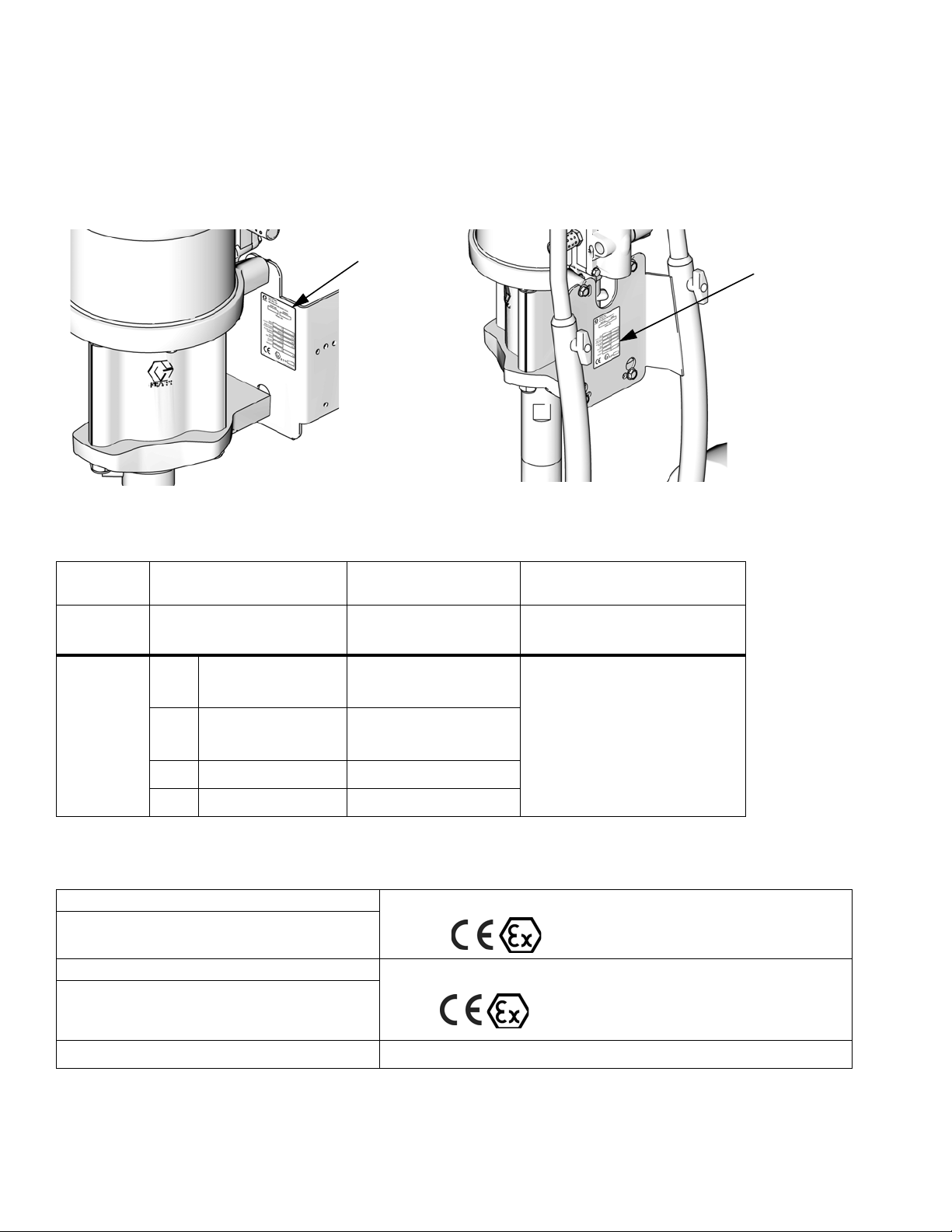

ti12326a

ti12327a

Wall mount

ID

Cart mount

ID

II 2 G Ex db h IIB T4 Gb X

II 2(1) G Ex db h [ia Ga] IIA T3 Gb X

Models

Check the identification plate (ID) for the 6-digit part number of your package. Use the following matrix and tables to

define the components of your package. For example, package number G30W80 represents a Merkur package (G),

with a 30:1 ratio pump (30), wall mounting (W), and the components shown for (80) in the table on page 7.

G30 W 80

Second and Third Digits

First Digit

G

(Merkur

Package)

28

30

36

48

(Ratio)

28:1 C = Cart

30:1 C = Cart

36:1 C = Cart

48:1 W = Wall

Agency Approvals

Merkur Heated Packages No DataTrak

Gxxxx1, Gxxxx3, Gxxxx5, Gxxxx7, Gxxxx9

Merkur Heated Packages with DataTrak

Gxxxx0, Gxxxx2, Gxxxx4, Gxxxx6, Gxxxx8

Fourth Digit

(Mounting Type)

W = Wall

W = Wall

Fifth and Sixth Digit

(Components Included)

See tables, page 7

DataTrak Module

6 313255T

See your DataTrak Kits manual (313541)

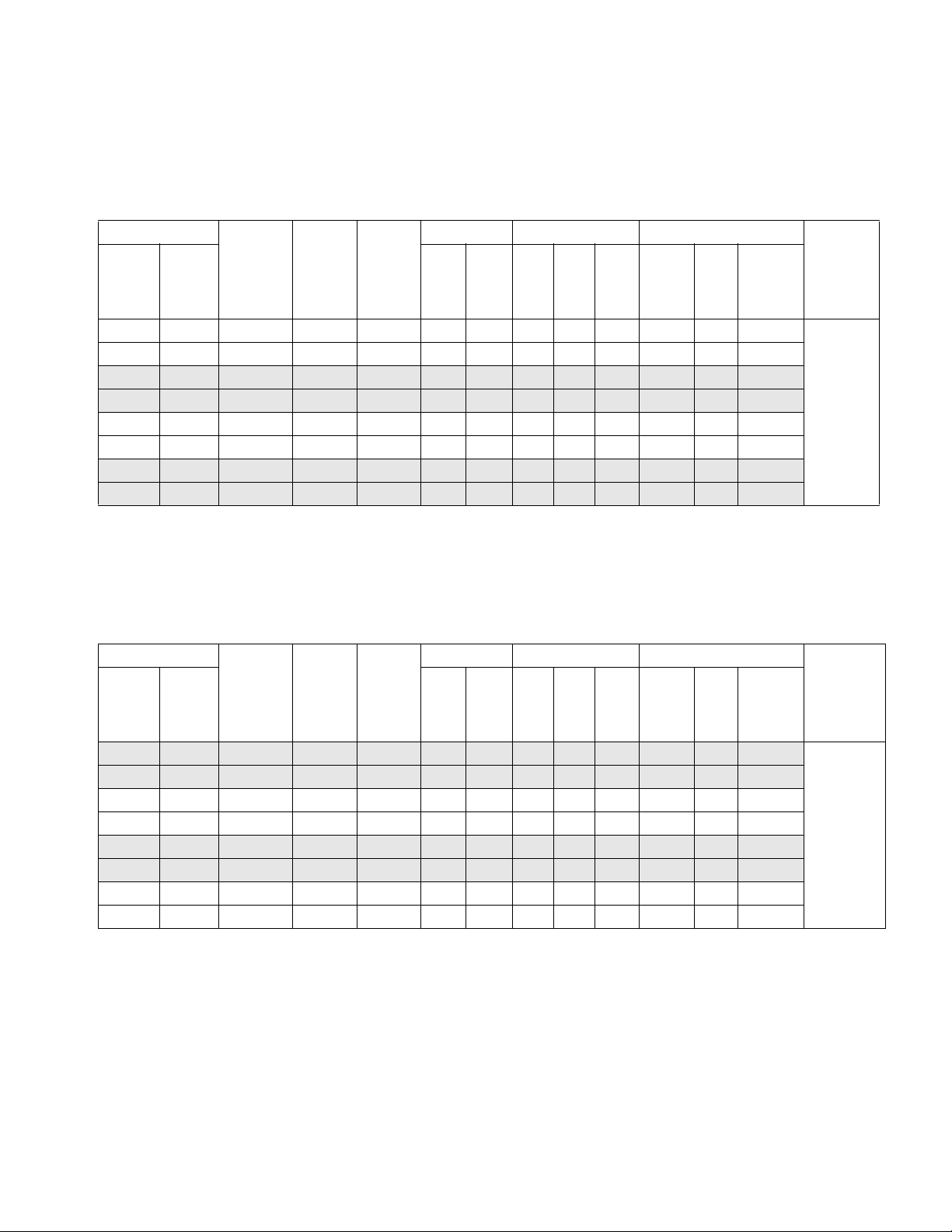

Merkur 28:1 Heated Packages

(G28Wxx and G28Cxx)

Maximum Inlet Air Pressure: 100 psi (0.7 MPa, 7 bar)

Maximum Fluid Working Pressure: 2800 psi (19.3 MPa, 193 bar)

Models

Model

Wall

Mount

G28W07 G28C05 W28EAS 120V XTR

G28W08 G28C06 W28EBS 120V XTR

G28W09 G28C07 W28EAS 240V XTR

G28W10 G28C08 W28EBS 240V XTR

G28W17 G28C15 W28EAS 120V G40

G28W18 G28C16 W28EBS 120V G40

G28W19 G28C17 W28EAS 240V G40

G28W20 G28C18 W28EBS 240V G40

Cart

Mount

Pump

Assembly Heater Gun

Air Controls Hoses Options

Pump

Pump

Only

Gun

and

Fluid

Gun

Hose

Merkur 30:1 Heated Packages

(G30Wxx and G30Cxx)

Maximum Inlet Air Pressure: 100 psi (0.7 MPa, 7 bar)

Maximum Fluid Working Pressure: 3000 psi (20.7 MPa, 207 bar)

Model

Wall

Mount

G30W67 G30C59 W30CAS 120V XTR

G30W68 G30C60 W30CBS 120V XTR

G30W69 G30C61 W30CAS 240V XTR

G30W70 G30C62 W30CBS 240V XTR

G30W79 G30C77 W30CAS 120V G40

G30W80 G30C78 W30CBS 120V G40

G30W81 G30C79 W30CAS 240V G40

G30W82 G30C80 W30CBS 240V G40

Cart

Mount

Pump

Assembly Heater Gun

Air Controls Hose Options

Pump

Pump

Only

Gun

and

Fluid

Gun

Hose

Gun

Fluid

Whip

Hose

Gun

Fluid

Whip

Hose

Gun

Air

Hose

Gun

Air

Hose

Siphon

Kit

Siphon

Kit

Fluid

Filter DataTrak

Fluid

Filter DataTrak

Maximum

Fluid Flow

Rate

gpm (lpm)

2.0 (7.5)

Maximum

Fluid Flow

Rate

gpm (lpm)

1.2 (4.5)

313255T 7

Models

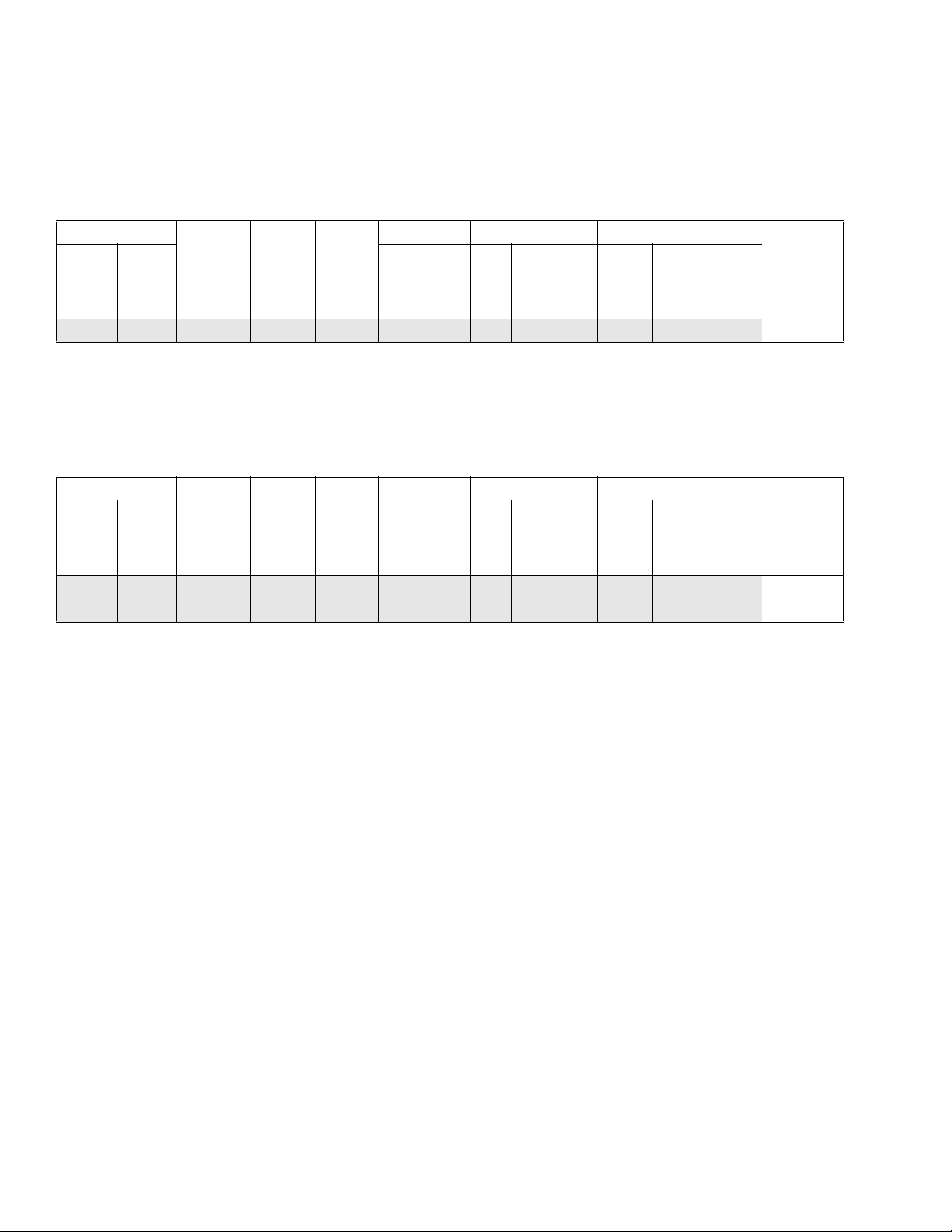

Merkur 36:1 Heated Packages

(G36Cxx)

Maximum Inlet Air Pressure: 100 psi (0.7 MPa, 7 bar)

Maximum Fluid Working Pressure: 3600 psi (24.8 MPa, 248 bar)

Model

Wall

Mount

-------- G36C05 26C180 120V XTR

Cart

Mount

Pump

Assembly Heater Gun

Air Controls Hose Options

Pump

Pump

Only

and

Gun

Gun

Fluid

Hose

Merkur 48:1 Heated Packages

(G48Wxx)

Maximum Inlet Air Pressure: 100 psi (0.7 MPa, 7 bar)

Maximum Fluid Working Pressure: 4800 psi (33.1 MPa, 331 bar)

Model

Wall

Mount

G48W17 ----- W48CAS 120V

G48W18 ----- W48CBS 120V

0

Cart

Mount

Pump

Assembly Heater Gun

Air Controls Hose Options

Pump

Pump

Only

and

Gun

Gun

Fluid

Hose

Gun

Fluid

Whip

Hose

Gun

Fluid

Whip

Hose

Gun

Air

Hose

Gun

Air

Hose

Siphon

Kit

Siphon

Kit

Fluid

Filter DataTrak

Fluid

Filter DataTrak

Maximum

Fluid Flow

Rate

gpm (lpm)

1.6 (6.0)

Maximum

Fluid Flow

Rate

gpm (lpm)

1.2 (4.5)

8 313255T

Installation

A Air Shutoff Valve (optional

accessory)

B Air Filter (optional accessory)

C Air Line Moisture Trap and Drain

Valve (optional accessory)

D Fluid Heater

E Back Pressure Regulator

F Fluid Filter

G Fluid Drain Valve

H Spray Gun

J Gun Swivel

K Fluid Whip Hose

L Electrically Conductive, Air and

Heated Fluid Supply/Return Ho se

M3 Way Valve

N Suction Hose and Tube

P Strainer

R Pump Ground Wire

S Gun Air Pressure Gauge

T Gun Air Pressure Regulator

U Bleed Type Master Air Valve

V DataTrak

W Pump Air Pressure Gauge

X Pump Air Pressure Regulator

Y Insert (for models without

DataTrak)

FIG. 1: Typical Installation (Your package may not include all items shown.)

A

B

C

D

E

F

G

J

H

K

L

MN

P

R

S

T

U

W

X

V

Y

ti13112a

ti13007b

Installation

313255T 9

Installation

General Information

Reference numbers and letters in parentheses in

the text refer to the call-outs in the figures and the

parts drawing.

Always use Genuine Graco Parts and Accessories,

available from your Graco distributor. If you supply

your own accessories, be sure they are adequately

sized and pressure-rated for your system.

FIG. 1 is only a guide for selecting and installing system

components and accessories. Contact your Graco distributor for assistance in designing a system to suit your

particular needs.

Prepare the Operator

All persons who operate the equipment must be trained

in the operation of all system components as well as the

proper handling of all fluids. All operators must thoroughly read all instruction manuals, tags, and labels

before operating the equipment.

Prepare the Site

Ensure that you have an adequate compressed air

supply.

Bring a compressed air supply line from the air compressor to the pump location. Refer to the performance

charts in your pump assembly manual to find the air

consumption of your pump. Be sure all air hoses are

properly sized and pressure-rated for your system. Use

only electrically conductive hoses. The air hose should

have a 3/8 npt(m) thread. A quick disconnect coupling is

recommended.

Wall Mount Packages

1. Be sure the wall can support the weight of the

pump, bracket, hoses and accessories, as well as

the stress caused during operation.

2. Position the wall bracket about 4–5 ft (1.2–1.5 m)

above the floor. For ease of operation and service,

make sure the pump air inlet, fluid inlet, and fluid

outlet ports are easily accessible.

3. Using the wall bracket as a template, drill 0.4 in.

(10 mm) mounting holes in the wall. Wall mounting

dimensions are shown on page 35.

4. Attach the bracket to the wall. Use 3/8 in. (9 mm)

screws that are long enough to keep the pump fr om

vibrating during operation.

NOTE: Be sure the bracket is level.

Ventilate the Spray Booth

Provide fresh air ventilation to avoid the buildup of

flammable or toxic vapors. Do not operate the gun

unless ventilation fans are operating.

Electrically interlock the gun air supply with the ventilators to prevent gun operation without ventilating fans

operating. Check and follow all National, State, and

Local codes regarding air exhaust velocity requirements.

Keep the site clear of any obstacles or debris that could

interfere with the operator's movement.

Have a grounded, metal pail available for use when

flushing the system.

10 313255T

Installation

Supplied Components

See FIG. 1. Components vary by package ordered.

See tables on pages 7 to 8. Your package may include:

• The red-handled bleed-type master air valve (U) is

required in your system to relieve air trapped

between it and the air motor and gun when the valve

is closed.

Trapped air can cause the pump to cycle unexpectedly, which could result in serious injury from splashing or moving parts.

• The pump air regulator (X) controls pump speed

and outlet pressure by adjusting the air pressure to

the pump.

• The air relief valve (not shown) opens automatically

to prevent overpressurization of the pump.

Do not block access to the valve.

• The 3-way valve (M) allows choice to circulate fluid

back to the pump or return it to the supply container.

• A fluid drain valve (G) relieves fluid pressure in the

hose and gun.

•The fluid heater (D) heats the fluid as it passes

through, to maintain the correct spraying viscosity.

Read and understand all instructions in the supplied

heater manual 309524 before operating the heater.

Heat causes fluid to expand. If the heated fluid is

trapped with nowhere to expand, it can cause component rupture. Be sure to keep the heated fluid circulating (turn the 3-way valve to CIRC). Do not install

a fluid shutoff device between the heater and the

gun.

• The gun air regulator (T) adjusts the air pressure to

the air-assisted spray gun (H).

• The air-assisted or airless spray gun (H) dispenses

the fluid. The gun houses the spray tip (not shown),

which is available in a wide range of sizes for different spray patterns and rates of flow. Refer to gun

manual for tip installation.

• The hose bundle (L) supplies fluid (and air for AA

guns) to the gun, and allows recirculation of fluid

when the gun is not triggered.

• The gun swivel (J) allows for freer gun movement.

• The suction hose (N) with strainer (P) allows the

pump to draw fluid from a 5 gallon (19 liter) pail.

• A fluid filter (F) with a 60 mesh (250 micron) stainless steel element filters particles from fluid as it

leaves the pump.

• DataTrak (V) provides pump diagnostics and material usage information. See page 20.

• The back pressure regulator (E) controls pressure

back to the gun and maintains proper circulation

pressure.

313255T 11

Loading...

Loading...