Page 1

Instructions–Parts List

HIGH PRESSURE

306860S

Back Pressure Regulator

For use in a high pressure spray circulating system to regulate back pressure to gun(s)

and maintain proper pressure for circulation. For professional use only.

Not approved for use in European explosive atmosphere locations.

CARBON STEEL REGULATORS

Part No. 206819, Series F

3000 psi (21 MPa, 207 bar) Maximum Working Pressure

1000–3000 psi (7–21 MPa, 70–207 bar) Regulated Fluid Pressure Range

Part No. 222405, Series B

3000 psi (21 MPa, 207 bar) Maximum Working Pressure

0–1000 psi (0–7 MPa, 0–70 bar) Regulated Fluid Pressure Range

EN

STAINLESS STEEL REGULATOR

Part No. 238926, Series A

3000 psi (21 MPa, 207 bar) Maximum Working Pressure

1000–3000 psi (7–21 MPa, 70–207 bar) Regulated Fluid Pressure Range

Part No. 26A081, Acid Compatible

3000 psi (21 MPa, 207 bar) Maximum Working Pressure

1000–3000 psi (7–21 MPa, 70–207 bar) Regulated Fluid Pressure Range

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

Table of Contents

Symbols 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Phone Number 12. . . . . . . . . . . . . . . . . . . . . . . . . .

06863

Page 2

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

INSTRUCTIONS

D This equipment is for professional use only.

D Read all instruction manuals, tags, and labels before operating the equipment.

D Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

D Do not alter or modify this equipment.

D Check equipment daily. Repair or replace worn or damaged parts immediately.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

D Do not exceed the maximum working pressure of the lowest rated system component. Refer to the

Technical Data on page 11 for the maximum working pressure of this equipment.

D Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the Tech-

nical Data section of all equipment manuals. Read the fluid and solvent manufacturer’s warnings.

D Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose

Graco hoses to temperatures above 180_F (82_C) or below –40_F (–40_C).

D Wear hearing protection when operating this equipment.

D Do not lift pressurized equipment.

D Comply with all applicable local, state, and national fire, electrical, and safety regulations.

2 306860

Page 3

WARNING

INJECTION HAZARD

Spray from the gun, leaks or ruptured components can inject fluid into your body and cause extremely

serious injury, including the need for amputation. Fluid splashed in the eyes or on the skin can also

cause serious injury.

D Fluid injected into the skin might look like just a cut, but it is a serious injury. Get immediate medi-

cal attention.

D Do not stop or deflect leaks with your hand, body, glove or rag.

D Keep your hands away from the end of the drain valve when opening it.

D Lock the gun trigger safety when you stop spraying.

D Follow the Pressure Relief Procedure on page 7 if the spray tip clogs and before cleaning,

checking or servicing the equipment.

D Follow the Pressure Relief Procedure on page 7 before removing the regulator’s adjusting knob.

D Do not pressurize the system when the back pressure regulator’s adjusting knob is removed.

D Tighten all fluid connections before operating the equipment.

D Check the hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

Do not repair high pressure couplings; you must replace the entire hose.

D Use only Graco approved hoses. Do not remove the spring guard that is used to help protect the

hose from rupture caused by kinks or bends near the couplings.

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin,

inhaled, or swallowed.

D Know the specific hazards of the fluid you are using.

D Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state and national guidelines.

D Always wear protective eyewear, gloves, clothing and respirator as recommended by the fluid and

solvent manufacturer.

306860 3

Page 4

Important Acid Catalyst Information

Regulator model 26A081 is designed for acid catalyst (”acid”) currently used in two–component, wood finishing

materials. Current acids in use (with pH levels as low as 1) are more corrosive than earlier acids. More corrosion–

resistant wetted materials of construction are required, and must be used without substitution, to withstand the

increased corrosive properties of these acids.

WARNING

Acid is flammable, and spraying or dispensing acid creates potentially harmful mists, vapors, and

atomized particulates. To help prevent fire and explosion and serious injury:

D Read and understand the fluid manufacturer’s warnings and Safety Data Sheet (SDS) to know

specific hazards and precautions related to the acid.

D Use only genuine, manufacturer’s recommended acid–compatible parts in the catalyst system

(hoses, fittings, etc.). A reaction may occur between any substituted parts and the acid.

D To prevent inhalation of acid mists, vapors, and atomized particulates, everyone in the work area

must wear appropriate respiratory protection. Always wear a properly fitting respirator, which may

include a supplied–air respirator. Ventilate the work area according to instructions in the acid

manufacturer’s SDS.

D Avoid all skin contact with acid. Everyone in the work area must wear chemically impermeable

gloves, protective clothing, foot coverings, aprons, and face shields as recommended by the acid

manufacturer and local regulatory authority. Follow all fluid manufacturer recommendations, including those regarding handling of contaminated clothing. Wash hands and face before eating or

drinking.

D Regularly inspect equipment for potential leaks and remove spills promptly and completely to avoid

direct contact or inhalation of the acid and its vapors.

D Keep acid away from heat, sparks, and open flames. Do not smoke in the work area. Eliminate all

ignition sources.

D Store acid in the original container in a cool, dry, and well–ventilated area away from direct sunlight

and away from other chemicals in accordance with acid manufacturer’s recommendation. To avoid

corrsion of containers, do not store acid in substitute containers. Reseal the original container to

prevent vapors from contaminating the storage space and surrounding facility.

Moisture Sensitivity of Acid Catalysts

Acid catalysts can be sensitive to atmospheric moisture and other contaminants.

Notice

Acid build–up will damage the seals and reduce the performance and life of the regulator. To prevent exposing

acid to moisture:

D Always use a sealed container with a desiccant dryer in the vent, or a nitrogen atmosphere. Never store acids

in an open container.

D Use only moisture–proof hoses compatible with acids.

D Always lubricate threaded parts with an appropriate lubricant when reassembling.

4 306860

Page 5

Installation

The Typical Installations shown in Figs. 1 and 2 are

only guides in designing a system. For assistance in

designing a system to meet your needs, contact your

Graco distributor.

Installing the Back Pressure Regulator

1. Install the back pressure regulator (A) in the spray

gun return line (D). See Figs. 1 and 2.

2. Connect fluid lines to the 1/4 npt(f) inlet and outlets

of choice. Make sure the fluid flow agrees with the

IN and OUT markings on the regulator housing.

3. Install the accessory gauge, if used, in the optional

inlet.

4. If more than one spray station is used, install a

back pressure regulator (A) in the circulating line

(H) after the last spray station to maintain proper

system pressures. Refer to Fig. 2, for multiple

circulating spray stations.

NOTE: The two 1/4–20 tapped mounting holes on the

side of the regulator housing are for mounting the

regulator when flexible fluid lines are used.

306860 5

Page 6

Installation

KEY

A Back Pressure Regulator

B Air Filter/Regulator

C Fluid Supply Line

D Fluid Return Line

E Fluid Regulator

F Air-Assisted Airless Spray Gun

G Air Line

Fig. 1

F

G

C

D

SINGLE CIRCULATING SPRAY STATION

E

B

A

06865

KEY

A Back Pressure Regulator

B Air Filter/Regulator

C Fluid Supply Line

D Fluid Return Line

E Fluid Regulator

F Air-Assisted Airless Spray Gun

G Air Line

H Fluid Circulation Line

G

C

CCH

G

A

F

E

E

G

B

B

A

A

D

D

MULTIPLE CIRCULATING SPRAY STATION

Fig. 2

6 306860

06866

Page 7

Operation

Pressure Relief Procedure

WARNING

INJECTION HAZARD

The system pressure must be manually

relieved to prevent the system from

starting or spraying accidentally. Fluid

under high pressure can be injected through the

skin and cause serious injury. To reduce the risk of

an injury from injection, splashing fluid, or moving

parts, follow the Pressure Relief Procedure

whenever you:

D are instructed to relieve the pressure,

D stop spraying,

D check or service any of the system equipment,

D or install or clean the spray tip.

1. Lock the gun trigger safety.

2. Close the bleed-type master air valve (required in

your system).

5. Lock the gun trigger safety.

6. Open the drain valve (required in your system),

having a container ready to catch the drainage.

7. Leave the drain valve open until you are ready to

spray again.

If you suspect that the spray tip or hose is completely

clogged, or that pressure has not been fully relieved

after following the steps above, very slowly loosen the

tip guard retaining nut or hose end coupling and relieve

pressure gradually, then loosen completely. Now clear

the tip or hose.

Adjusting the Regulator

The back pressure regulator controls pressure ahead

of the regulator intake.

To adjust the regulator, first, back the adjusting knob

out until there is no spring pressure. Then, turn the

knob clockwise to increase pressure.

Adjust the pump air pressure and the back pressure

regulator for the best spraying combination and proper

circulation of fluid.

3. Unlock the gun trigger safety.

4. Hold a metal part of the gun firmly to the side of a

grounded metal pail, and trigger the gun to relieve

pressure.

Record the regulator and air pressure settings for

future reference. The regulator cylinder has exterior

markings (set points 1 to 8) for repeat settings.

306860 7

Page 8

Maintenance

WARNING

COMPONENT RUPTURE HAZARD

To reduce the risk of serious bodily injury, including fluid injection or splashing in

the eyes or on the skin, always follow

the Pressure Relief Procedure on page 7 before

adjusting, cleaning, repairing, or removing the regulator from the system.

Never pressurize the system with the back pressure regulator adjusting knob removed.

Never completely remove the adjusting knob when

system pressure is present.

Flushing

Repairing

Reference numbers marked with an asterisk (for

example, 3*) are included in the repair kits, which may

be purchased separately. For Models 206819 and

222405, order Repair Kit 220135. For Model 238926,

order Repair Kit 239000. For Model 26A081, order

Repair Kit 17M564. See page 9.

1. Lubricate the piston packing (9*), piston (13*), and

spring locater (10) with lithium base grease.

2. Place the washer (6) over the pointed end of the

piston (13*).

3. Place the packing (9*), with its lips facing down,

over the pointed end of the piston (13*) and

against the washer (6).

Flush the regulator whenever the rest of the system is

flushed. Before flushing, open the regulator by turning

the adjusting knob counterclockwise until the spring

tension is relieved.

NOTE: Do not allow paint or solvent to set in the

system for a long time. Fluid could dry on the piston,

causing leakage at the piston packing. If leakage

occurs, disassemble and clean the regulator.

Cleaning

Regular cleaning and inspection, and lubrication of the

regulator are necessary to keep the regulator working

properly.

1. Open the regulator and follow the Pressure Relief

Procedure on page 7.

2. Remove the back pressure regulator from the

system.

3. Disassemble the regulator, referring to the parts

drawing on page 9. Clean and inspect all parts.

4. Insert the piston (13*) into the bottom of the cylinder (4) and gently work it into place.

5. Reassemble the remaining parts in reverse order

of disassembly. Make sure the gasket (3*) and

o-ring (7*) are in place. Torque the regulator seat

(12*) into the housing (5) to 175 to 200 in-lb (20 to

22 NSm). Over-tightening could break off the hex

portion of the seat.

CAUTION

Use special care when handling the hard carbide

portions of the piston (13) and seat (12). Damage will

cause poor operation and leakage.

8 306860

Page 9

11

Parts

9*

6

2

1

Install with lips down.

1

2

Torque to 175 to 200 in-lb (20 to 22 NSm).

3

Model and Series stamped on bottom.

Model 206819, Series F

Model 222405, Series B

Ref

No. Part No. Description Qty

1*** 100721 PLUG, pipe; hex socket; 1/4 npt 2

2 101954 RING, int. ret.; 0.75 in. (19 mm)

housing dia.; cadmium plated 1

3* 150670 GASKET, copper 1

4 166982 CYLINDER, regulator 1

5 177124 HOUSING, regulator 1

6 171885 WASHER, back-up; acetal

homopolymer 1

7* 166985 O-RING; PTFE 1

8 166986 SPRING, helical compression;

yellow color-coded

(Model 206819 only) 1

501511 SPRING, helical compression;

blue color-coded

(Model 222405 only) 1

9* 111796 PACKING, “U” type; PTFE 1

10 166988 LOCATOR, spring 1

11 167443 KNOB, adjusting 1

12* 204523 SEAT, regulator 1

13* 238932 PISTON, regulator 1

* These parts are included in Repair Kit 220135,

which may be purchased separately.

** These parts are included in Repair Kit 239000

(Model 238926) and Repair Kit 17M564 (Model

26A081), which may be purchased separately.

*** Plugs are shipped loose and must be installed in

unused ports. Apply anaerobic pipe sealant prior to

installation.

10

8

13*

12*

2

3*

7*

4

1

5

3

06864

Model 238926, Series A

Model 26A081, Acid Compatible

Ref

No. Part No. Description Qty

1 101970 PLUG, pipe; hex socket; 1/4 npt 2

2 113751 RING, int. ret.; 0.75 in. (19 mm)

housing dia.; stainless steel 1

3** GASKET; acetal homopolymer 1

189817 (Model 238926 only)

17K950 (Model 26A081 only)

4 191840 CYLINDER, regulator 1

5 HOUSING, regulator 1

191841 (Model 238926 only)

17K951 (Model 26A081 only)

6 WASHER, back-up; acetal

homopolymer 1

171885 (Model 238926 only)

121169 (Model 26A081 only)

7** 166985 O-RING; PTFE 1

8 SPRING, helical compression;

yellow color-coded 1

166986 (Model 238926 only)

501511 (Model 26A081 only)

9** 111796 PACKING, “U” type; PTFE 1

10 166988 LOCATOR, spring 1

11 167443 KNOB, adjusting 1

12** SEAT, regulator 1

238933 (Model 238926 only)

17K953 (Model 26A081 only)

13** PISTON, regulator 1

238932 (Model 238926 only)

26A082 (Model 26A081 only)

306860 9

Page 10

Notes

10 306860

Page 11

Accessories

Use Only Genuine Graco Parts and Accessories

Fluid Pressure Gauges

Attaches to optional regulator outlet.

2 in. (51 mm) dial.

102397 0–3000 psi (0–21 MPa, 0–207 bar MPa)

1/4 npt(m) center back fitting

101696 0–1000 psi (0–7 MPa, 0–70 bar)

1/4 npt(m) bottom fitting

17L706 316 sst

0–3000 psi (0–20 MPa, 0–200 bar)

1/4 npt(m) bottom fitting

UHMW Polyethylene U-Type Packing

108317 (included in Repair Kit 220135)

Use instead of 111796 (ref. no. 9), with abrasive fluids.

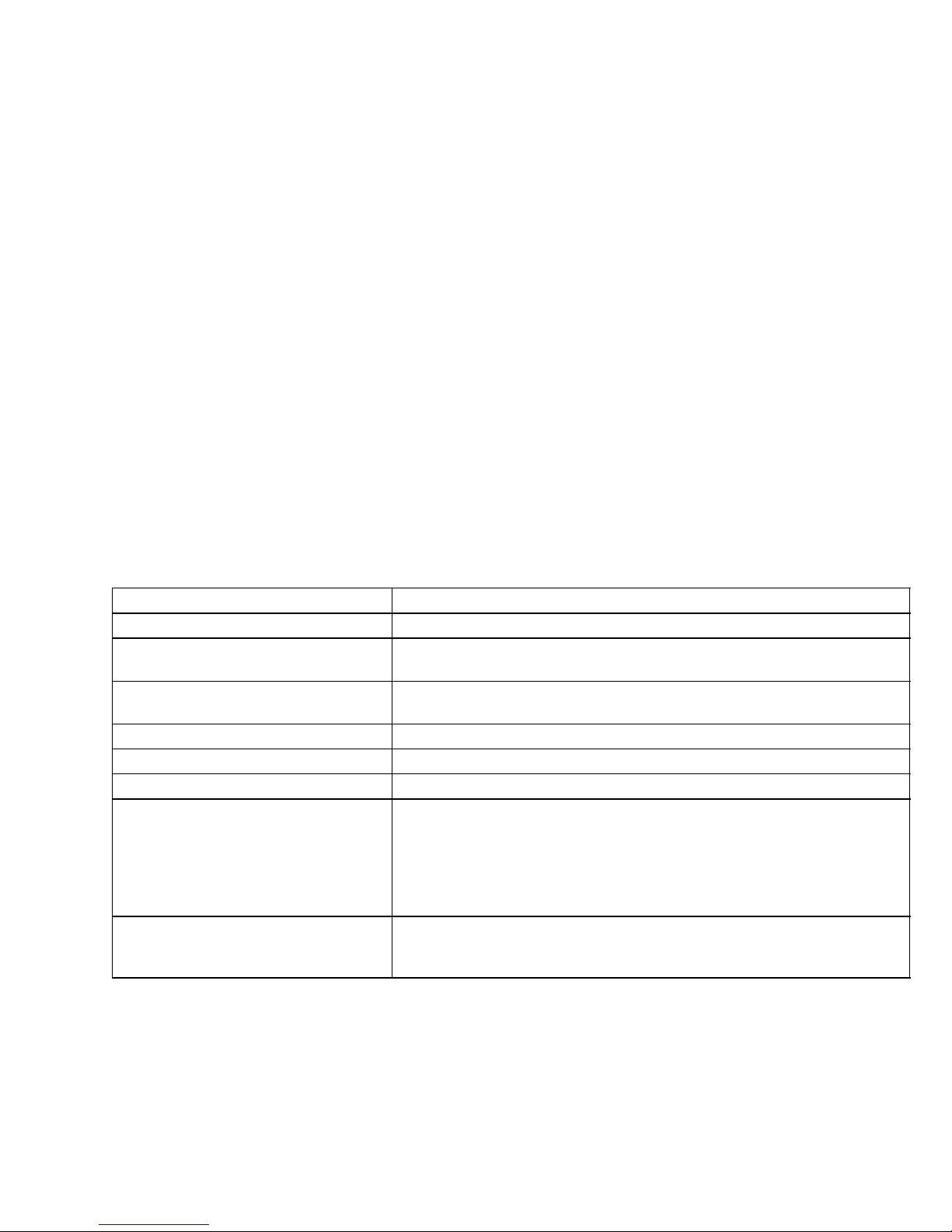

Technical Data

Compression Springs

501510 Converts both models to 1000–2000 psi

(7–21 MPa, 70–138 bar) range.

Red color-coded.

501511 Standard on Model 222405.

Converts Model 206819 to

0–1000 psi (0–7 MPa, 0–70 bar) range.

Blue color-coded.

166986 Standard on Model 206819.

Converts 222405 to 2000–3000 psi

(14–21 MPa, 138–207 bar) range.

Yellow color-coded.

NOTE: Spring 166986 (supplied with Model 206819)

is recommended for 2000–3000 psi (14–21 MPa,

138–207 bar).

Category Data

Maximum Fluid Inlet Pressure 3000 psi (21 MPa, 207 bar)

Regulated Fluid Pressure Range Models 206819 and 238926: 1000–3000 psi (7–21 MPa, 70–207 bar)

Model 222405: 0–1000 psi (0–7 MPa, 0–70 bar)

Normal Factory Preset Range Models 206819 and 238926: 2000–3000 psi (14–21 MPa, 138–207 bar)

Model 222405: 500–1000 psi (3.4–7 MPa, 34–70 bar)

Maximum Flow Rate 3.5 gpm (13.25 liters/min) with 70 centipoise fluid at 75_F (23_C)

Fluid Inlet 1/4 npt(f)

Fluid Outlet (two) 1/4 npt(f)

Wetted Parts Models 206819 and 222405: Tungsten carbide, PTFE,

acetal homopolymer, cadmium and zinc-plated steel, stainless steel, and

chrome-plated stainless steel

Model 26A081: 316 sst 17–4 ph sst, PTFE

Model 238926: Stainless steel, Tungsten carbide, PTFE, acetal

homopolymer

Canadian Registration Number (CRN):

Alberta – 0C04874.52

Ontario – 0C4874.5R1

Models 206819, 238926, and 222405

306860 11

Page 12

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale by an authorized Graco distributor to the original purchaser for use. With the exception of any special, extended, or limited

warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment

determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations..

This warrant y does not cover, and Graco shall not be liable for general wear and tear , or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS W ARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sol e o b l i g a t i o n and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property , o r a ny

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty , and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the distributor closest to you:

Phone: 612–623–6921 or Toll Free: 1–800–328–0211 Fax: 612–378–3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 306860

International Offices: Belgium, China, Japan, Korea

GRACO INC. AND SUBSIDIARIES S P.O. BOX 1441 S MINNEAPOLIS MN 55440–1441 S USA

Copyright 1965, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

12 306860

Graco Headquarters: Minneapolis

www.graco.com

Revision S, November 2017

Loading...

Loading...