Page 1

Fracturing Equipment

Lubrication Kits

Get the Graco Advantage

Because not all oil and gas applications require just one solution, Graco offers multiple levels of advanced control and monitoring

and accessories tailored to your specific budget, conditions and needs.

Page 2

Fracturing Equipment Lubrication Kits

Page

G3™ Pro Grease and MSP Series Progressive – Triplex � � � � � � � � � � � � � � � � � � � � � � 4

™

Pro Grease and MSP Series Progressive – Quintuplex � � � � � � � � � � � � � � � � � � � � 5

G3

™

Max DMS Grease and MSP Series Progressive – Triplex � � � � � � � � � � � � � � � � � � 6

G3

™

Max DMS Grease and MSP Series Progressive – Quintuplex � � � � � � � � � � � � � � � 7

G3

™

Max DMS Grease and GL-1 Injectors – Triplex � � � � � � � � � � � � � � � � � � � � � � � � � 8

G3

™

Max DMS Grease and GL-1 Injectors – Quintuplex � � � � � � � � � � � � � � � � � � � � � � � 9

G3

™

Max DMS Oil and MSP Series Progressive – Triplex � � � � � � � � � � � � � � � � � � � � 10

G3

™

Max DMS Oil and MSP Series Progressive – Quintuplex � � � � � � � � � � � � � � � � � 11

G3

®

Dyna-Star

Dyna-Star

24 VDC Compact Dyna-Star

24 VDC Compact Dyna-Star

24 VDC Compact Dyna-Star

24 VDC Compact Dyna-Star

24 VDC Electric Dyna-Star

24 VDC Electric Dyna-Star

™

G3

Hydraulic Grease and GL-1 Injector – Triplex � � � � � � � � � � � � � � � � � � � � 12

®

Hydraulic Grease and GL-1 Injector – Quintuplex � � � � � � � � � � � � � � � � � 13

®

Grease and GL-1 Injector – Triplex � � � � � � � � � � � � � � 14

®

Grease and GL-1 Injector – Quintuplex � � � � � � � � � � � 15

®

Grease and MSP Series Progressive – Triplex � � � � � � 16

®

Grease and MSP Series Progressive – Quintuplex � � � 17

®

Grease and GL-1 Injector – Triplex� � � � � � � � � � � � � � � � 18

®

Grease and GL-1 Injector – Quintuplex� � � � � � � � � � � � � 19

Pump Enclosure Kits / Accessories / Frac Pump Hose and Fitting Kits � � � � � � � 20

2

graco.com

Page 3

Graco Automatic Lubrication Solutions

Peace of Mind for

Your Bottom Line

Graco automatic lubrication systems deliver benefit-driven solutions

that save you time and money. Perfect for challenging, hazardous and

harsh operating conditions of well services. Whether you need electric,

hydraulic, or pneumatic powered solutions, we’ve got you covered

with multiple levels of control and monitoring.

G3™ Pro

Simple ON/OFF time

control with low-level

sensing and manual

run operation.

G3™ Max

Full control that monitors lube

flow via cycle counts and time.

Monitors machine counts to

match lube flow to machine

use. And monitors low fluid

level. Manual run and DMS

are high value options.

Hydraulic Dyna-Star

Optional Graco controller, level

indicator, pressure switch,

follower plates and drum

covers put you in control of

your system – no more second

guessing. Convenient pressure

and flow control built-in.

Because not all well sites require the same

equipment, Graco offers multiple solutions

to keep your equipment working.

®

Compact Dyna-Star

Optional Integrated Auto-Fill

Shutoff in a robust pump

with a compact footprint.

24 VDC, brushless motor

and zero-maintenance gear

drive deliver lubricants even

in cold temperatures.

®

Electric Dyna-Star

Includes Auto-Fill Shutoff –

mechanical shut off of fill

pump for clean and efficient

refills. Features the Graco

Advantage Drive

duty gear drive which is

lubed for life.

™

®

heavy

Take Control of How You Monitor

You choose the level of control you require – G3™ Pro or G3™ Max. Plus Graco offers our proprietary Data Management System™ (DMS) as an option on

Max control models. You gain a distinct advantage from information that offers accurate time-stamped operation, fault data, and downloadable on/off time

programming. Preferred lube cycle program can be stored and transferred to other G3 pumps in your fleet for quick and accurate repeatability.

G3™ Pump and Control

1

An advanced pump design offers multiple levels of control

and monitoring. Use feedback from MSP blocks and from

your equipment to tailor and monitor the lubrication supply

to critical components. Pumps are IP69K rated so no

enclosure is necessary. Refilling is clean and easy with the

quick connect stud.

MSP Series Progressive Lubrication Blocks

2

Offers time-tested, field proven dependability in the

harshest environments. Flow can be monitored using

a proximity switch and performance indicators so

problems can be pinpointed.

Double Ball Check Valve

3

Ensures lubrication goes into the lube point and

doesn’t get pushed back out. Stops any fluid back

pressure from damaging the lubrication system.

3

2

1

graco.com

3

Page 4

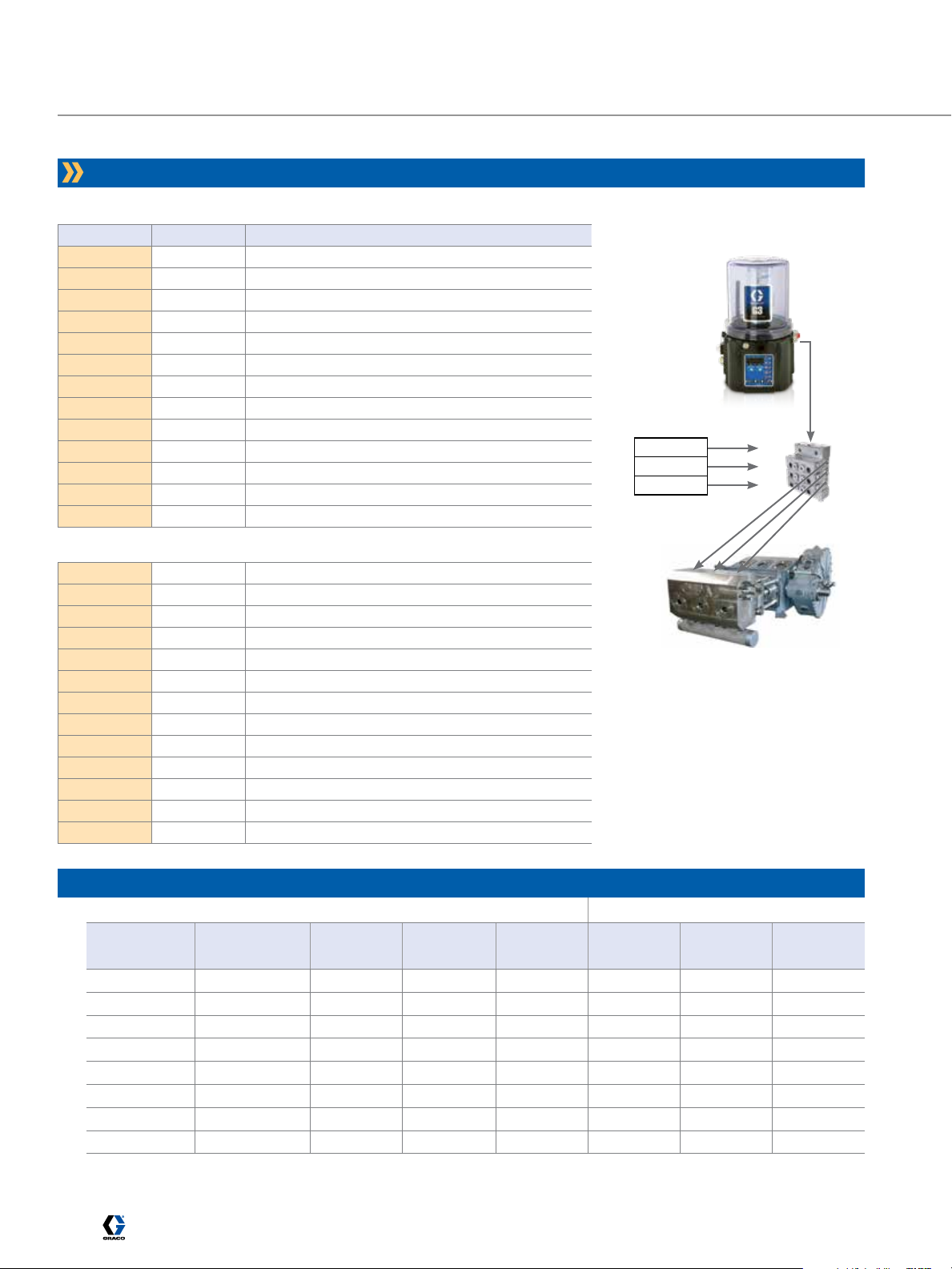

Triplex Frac Kit Selection Guide

G3 Pro Grease and MSP Series Progressive

Time-based

Ordering Information

G3 Pro Grease / MSP Series Progressive 12 V Triplex Kit

Part Number Quantity Description

96G147 1 G3 Pro pump 12 V, 4 liter reservoir, low level and 5 pin CPC

24Z962 1 Protective G3 cover with manual run and reset holes

556420 1 1/4 NPT service tee

563160 1 2,500 psi relief

557874 1 Quick fill stud – 1/4 in NPT

557875 1 Dust cap

563061 3 Check valve, double ball

555453 3 1/4 NPT street elbow

156971 3 1/4 NPT hex nipple

24G485 1 3 section MSP base plate assembly

562713 3 MSP 15S valve assembly

563174 3 2,000 psi relief indicator

563251 1 Visual cycle indicator

Triplex

15S

15S

15S

G3 Pro Grease / MSP Series Progressive 24 V Triplex Kit

96G149 1 G3 Pro pump 24 V, 4 liter reservoir, low level and 5 pin CPC

24Z962 1 Protective G3 cover with manual run and reset holes

556420 1 1/4 NPT service tee

563160 1 2500 psi relief

557874 1 Quick fill stud – 1/4 in NPT

557875 1 Dust cap

563061 3 Check valve, double ball

555453 3 1/4 NPT street elbow

156971 3 1/4 NPT hex nipple

24G485 1 3 section MSP base plate assembly

562713 3 MSP 15S valve assembly

563174 3 2,000 psi relief indicator

563251 1 Visual cycle indicator

Technical Specifications

Triplex Pump (three pistons) MSP Reservoir hours of operation

3

Piston Diameter

2.75 0.340 11.3 5 23 seconds 120 239 479

3 0.371 12.4 5 23 seconds 110 219 439

3.5 0.433 14.4 4 23 seconds 94 188 376

4 0.494 16.5 4 23 seconds 82 165 329

4.5 0.556 18.5 3 23 seconds 73 146 292

5 0.618 20.6 3 23 seconds 66 132 263

5.5 0.680 22.7 3 23 seconds 60 120 239

6 0.742 24.7 2 23 seconds 55 110 219

Notes: 1). Lube rates based on a service factor of 12. 2). G3 pump with one pump element. 3). Please note these are recommended lube rates. Each application should be reviewed to determine optimal rate.

Lube rate (in

hour each piston

) per

Feeder cycles

per hour

G3 Pump

off time setting

in minutes

G3 Pro Pump

on time

2 liter 4 liter 8 liter

4

graco.com

Page 5

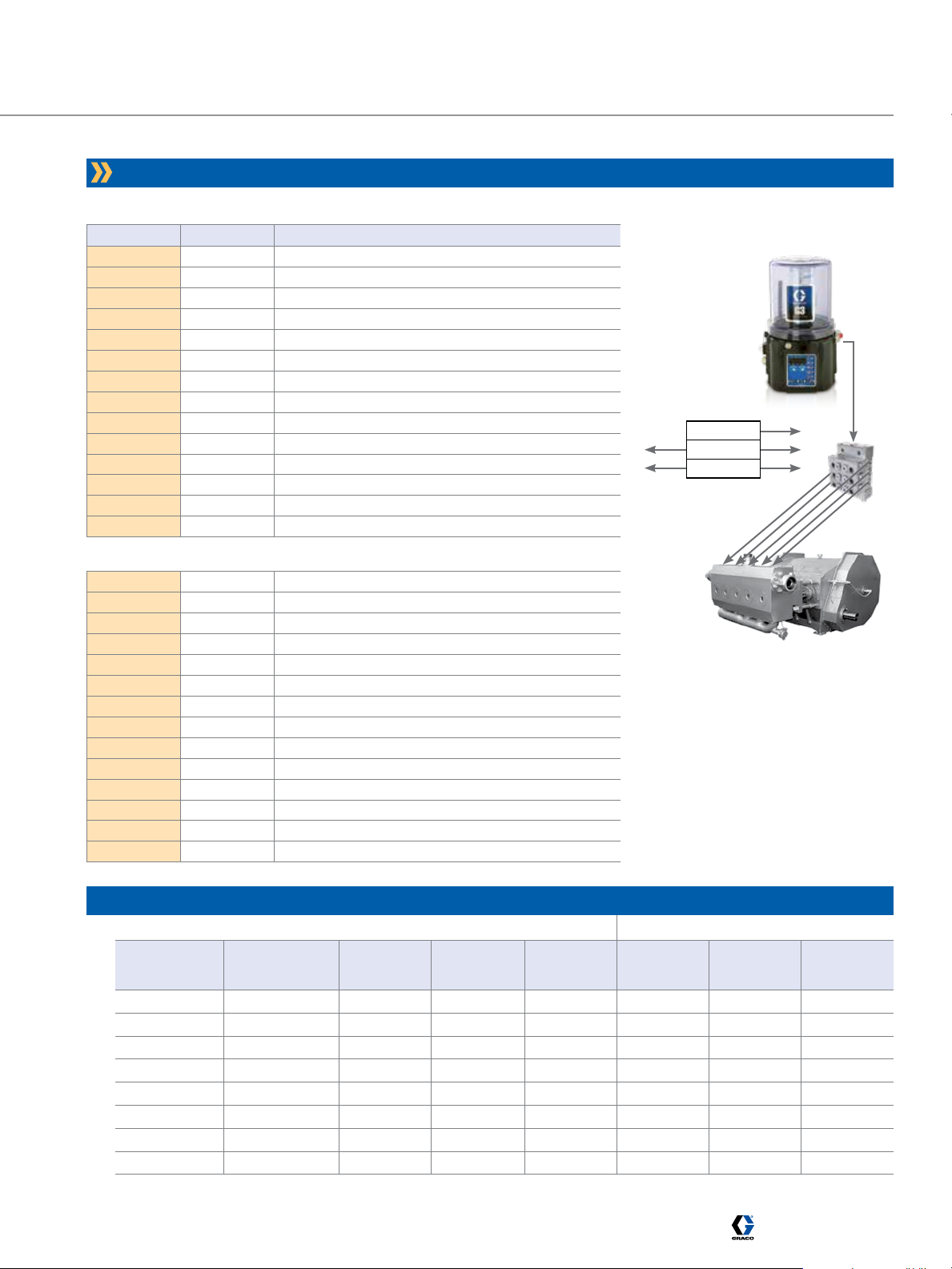

G3 Pro Grease and MSP Series Progressive

Ordering Information

G3 Pro Grease / MSP Series Progressive 12 V Quintuplex Kit

Part Number Quantity Description

96G147 1 G3 Pro pump 12 V, 4 liter reservoir, low level and 5 pin CPC

24Z962 1 Protective G3 cover with manual run and reset holes

556420 1 1/4 NPT service tee

563160 1 2,500 psi relief

557874 1 Quick fill stud – 1/4 in NPT

557875 1 Dust cap

563061 5 Check valve, double ball

555453 5 1/4 NPT street elbow

156971 5 1/4 NPT hex nipple

24G485 1 3 section MSP base plate assembly

562713 1 MSP 15S valve assembly

562725 2 MSP 30T valve assembly

563174 5 2,000 psi relief indicator

563251 1 Visual cycle indicator

Quintuplex Frac Kit Selection Guide

Time-based

Quintuplex

15S

30T

30T

G3 Pro Grease / MSP Series Progressive 24 V Quintuplex Kit

96G149 1 G3 Pro pump 24 V, 4 liter reservoir, low level and 5 pin CPC

24Z962 1 Protective G3 cover with manual run and reset holes

556420 1 1/4 NPT service tee

563160 1 2,500 psi relief

557874 1 Quick fill stud – 1/4 in NPT

557875 1 Dust cap

563061 5 Check valve, double ball

555453 5 1/4 NPT street elbow

156971 5 1/4 NPT hex nipple

24G485 1 3 section MSP base plate assembly

562713 1 MSP 15S valve assembly

562725 2 MSP 30T valve assembly

563174 5 2,000 psi relief indicator

563251 1 Visual cycle indicator

Technical Specifications

Quintuplex Pump (five pistons) MSP Reservoir hours of operation

3

Piston Diameter

2.75 0.340 11.3 5 38 seconds 72 144 287

3 0.371 12.4 5 38 seconds 66 132 263

3.5 0.433 14.4 4 38 seconds 56 113 226

4 0.494 16.5 4 38 seconds 49 99 197

4.5 0.556 18.5 3 38 seconds 44 88 175

5 0.618 20.6 3 38 seconds 39 79 158

5.5 0.680 22.7 3 38 seconds 36 72 144

6 0.742 24.7 2 38 seconds 33 66 132

Notes: 1). Lube rates based on a service factor of 12. 2). G3 pump with one pump element. 3). Please note these are recommended lube rates. Each application should be reviewed to determine optimal rate.

Lube rate (in

hour each piston

) per

Feeder cycles

per hour

G3 Pump

off time setting

in minutes

G3 Pro Pump

on time

2 liter 4 liter 8 liter

graco.com

5

Page 6

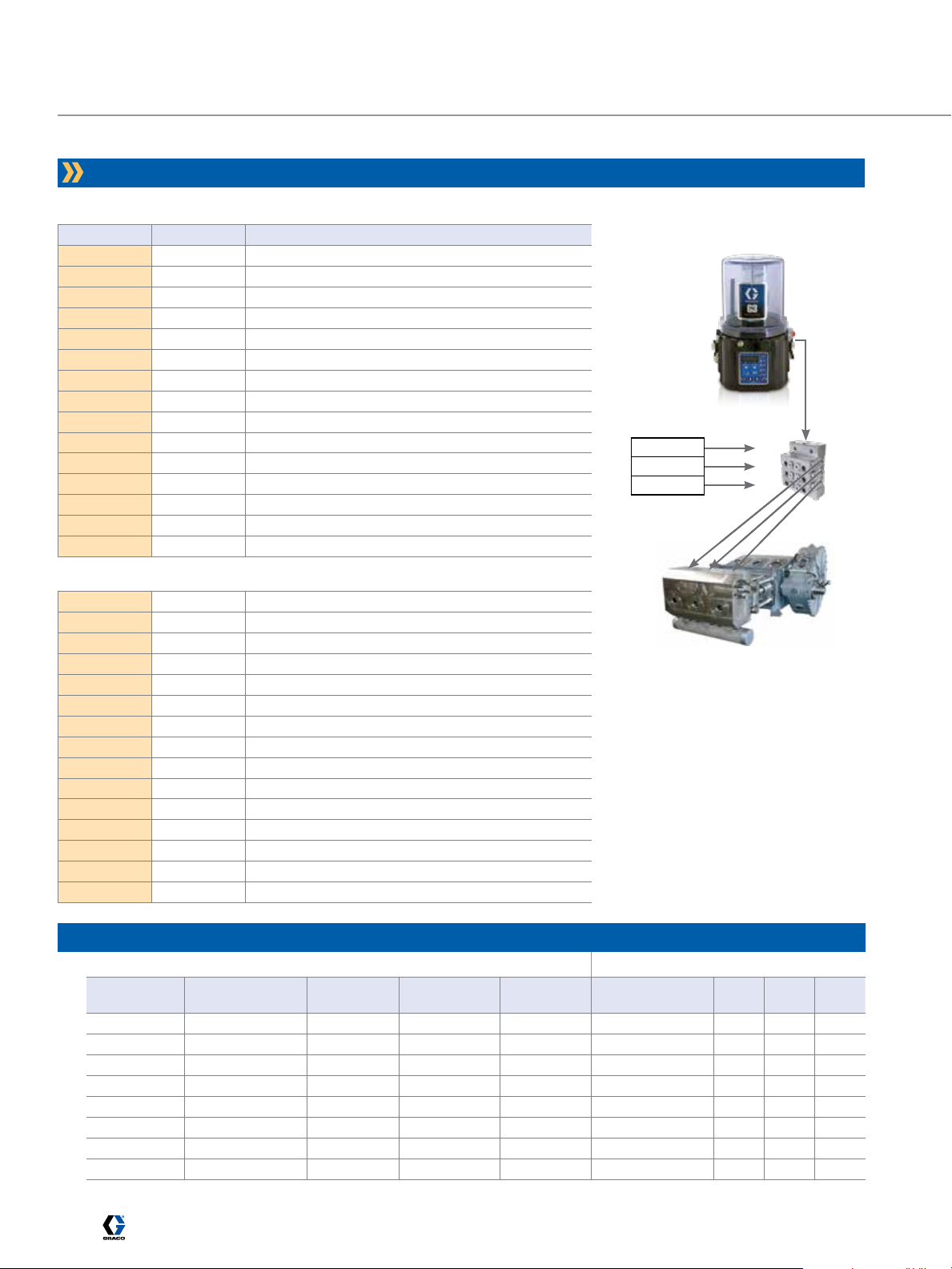

Triplex Frac Kit Selection Guide

G3 Max DMS Grease and MSP Series Progressive

Time-based with monitoring, optional RPM input count, and downloadable system monitoring.

Ordering Information

G3 Max DMS Grease / MSP Series Progressive 12 VDC Triplex Kit

Part Number Quantity Description

96G161 1 G3 Max DMS pump 12 V, 4 liter reservoir, low level and 5 pin CPC

24Z962 1 Protective G3 cover with manual run and reset holes

556420 1 1/4 NPT service tee

563160 1 2,500 psi relief

557874 1 Quick fill stud – 1/4 in NPT

557875 1 Dust cap

563061 3 Check valve, double ball

555453 3 1/4 NPT street elbow

156971 3 1/4 NPT hex nipple

24G485 1 3 section MSP base plate assembly

562713 3 MSP 15S valve assembly

563257 3 2,000 psi reset performance indicator

17L983 1 Proximity switch, cycle indicator

124300 1 Cable 16 ft for proximity switch

124301 1 Connector for proximity switch cable

Triplex

15S

15S

15S

G3 Max DMS Grease / MSP Series Progressive 24 VDC Triplex Kit

96G162 1 G3 Max DMS pump 24 V, 4 liter reservoir, low level and 5 pin CPC

24Z962 1 Protective G3 cover with manual run and reset holes

556420 1 1/4 NPT Service tee

563160 1 2,500 psi relief

557874 1 Quick fill stud – 1/4 in NPT

557875 1 Dust cap

563061 3 Check valve, double ball

555453 3 1/4 NPT street elbow

156971 3 1/4 NPT hex nipple

24G485 1 3 section MSP base plate assembly

562713 3 MSP 15S valve assembly

563257 3 2,000 psi reset performance indicator

17L983 1 Proximity switch, cycle indicator

124300 1 Cable 16 ft for proximity switch

124301 1 Connector for proximity switch cable

Technical Specifications

Triplex Pump (three pistons) MSP Reservoir hours of operation

3

Piston Diameter

2.75 0.340 11.3 5 1 minute 736 120 239 479

3 0.371 12.4 5 1 minute 670 110 219 439

3.5 0.433 14.4 4 1 minute 566 94 188 376

4 0.494 16.5 4 1 minute 488 82 165 329

4.5 0.556 18.5 3 1 minute 427 73 146 292

5 0.618 20.6 3 1 minute 379 66 132 263

5.5 0.680 22.7 3 1 minute 339 60 120 239

6 0.742 24.7 2 1 minute 306 55 110 219

Notes: 1). Lube rates based on a service factor of 12. 2). G3 pump with one pump element. 3). Please note these are recommended lube rates. Each application should be reviewed to determine optimal rate.

Lube rate (in

hour each piston

) per

Feeder cycles

per hour

G3 Pump off time

setting in minutes

G3 Max cycle

monitor time

Rotations of Frac pump

set point for lube cycle

2 liter 4 liter 8 liter

6

graco.com

Page 7

Quintuplex Frac Kit Selection Guide

G3 Max DMS Grease and MSP Series Progressive

Time-based with monitoring, optional RPM input count, and downloadable system monitoring.

Ordering Information

G3 Max DMS Grease / MSP Series Progressive 12 VDC Quintuplex Kit

Part Number Quantity Description

96G161 1 G3 Max DMS pump 12 V, 4 liter reservoir, low level and 5 pin CPC

24Z962 1 Protective G3 cover with manual run and reset holes

556420 1 1/4 NPT service tee

563160 1 2,500 psi relief

557874 1 Quick fill stud – 1/4 in NPT

557875 1 Dust cap

563061 5 Check valve, double ball

555453 5 1/4 NPT street elbow

156971 5 1/4 NPT hex nipple

24G485 1 3 section MSP base plate assembly

562713 1 MSP 15S valve assembly

562725 2 MSP 30T valve assembly

563257 5 2,000 psi reset performance indicator

17L983 1 Proximity switch, cycle indicator

124300 1 Cable 16 ft for proximity switch

124301 1 Connector for proximity switch cable

Quintuplex

15S

30T

30T

G3 Max DMS Grease / MSP Series Progressive 24 VDC Quintuplex Kit

96G162 1 G3 Max DMS pump 24 V, 4 liter reservoir, low level and 5 pin CPC

24Z962 1 Protective G3 cover with manual run and reset holes

556420 1 1/4 NPT service tee

563160 1 2,500 psi relief

557874 1 Quick fill stud – 1/4 in NPT

557875 1 Dust cap

563061 5 Check valve, double ball

555453 5 1/4 NPT street elbow

156971 5 1/4 NPT hex nipple

24G485 1 3 section MSP base plate assembly

562713 1 MSP 15S valve assembly

562725 2 MSP 30T valve assembly

563257 5 2,000 psi reset performance indicator

17L983 1 Proximity switch, cycle indicator

124300 1 Cable 16 ft for proximity switch

124301 1 Connector for proximity switch cable

Technical Specifications

Quintuplex Pump (five pistons) MSP Reservoir hours of operation

3

Piston

Diameter

2.75 0.340 11.3 5 1 minute 15 seconds 699 72 144 287

3 0.371 12.4 5 1 minute 15 seconds 633 66 132 263

3.5 0.433 14.4 4 1 minute 15 seconds 529 56 113 226

4 0.494 16.5 4 1 minute 15 seconds 451 49 99 197

4.5 0.556 18.5 3 1 minute 15 seconds 390 44 88 175

5 0.618 20.6 3 1 minute 15 seconds 342 39 79 158

5.5 0.680 22.7 3 1 minute 15 seconds 302 36 72 144

6 0.742 24.7 2 1 minute 15 seconds 269 33 66 132

Notes: 1). Lube rates based on a service factor of 12. 2). G3 pump with one pump element. 3). Please note these are recommended lube rates. Each application should be reviewed to determine optimal rate.

Lube rate (in

hour each piston

) per

Feeder cycles

per hour

G3 Pump off time

setting in minutes

G3 Max cycle

monitor time

Rotations of Frac pump

set point for lube cycle

2 liter 4 liter 8 liter

graco.com

7

Page 8

Triplex Frac Kit Selection Guide

G3 Max DMS Grease and GL-1 Injectors

Time-based with monitoring, optional RPM input count, and downloadable system monitoring.

Ordering Information

G3 Max DMS Grease / GL-1 Injectors 12 VDC Triplex Kit

Part Number Quantity Description

96G099 1 G3 Max DMS pump 12 V, 4 liter reservoir, low level and DIN

24Z962 1 Protective G3 cover with manual run and reset holes

571169 1 Vent valve

571041 1 G3 pump element

557874 1 Quick fill stud – 1/4 in NPT

557875 1 Dust cap

563061 3 Check valve, double ball

555453 3 1/4 NPT street elbow

156971 3 1/4 NPT hex nipple

24P296 1 Two pump union kit

24K414 1 Pressure switch

114903 1 GL-1 injector 3 manifold

17L754 3 Clear, polycarbonate dust cap, GL-1

124300 1 Cable 16 ft for pressure switch

124301 1 Connector for pressure switch cable

G3 Max DMS Grease / GL-1 Injectors 24 VDC Triplex Kit

96G111 1 G3 Max DMS pump 24 V, 4 liter reservoir, low level and DIN

24Z962 1 Protective G3 cover with manual run and reset holes

571170 1 Vent valve

571041 1 G3 pump element

557874 1 Quick fill stud – 1/4 in NPT

557875 1 Dust cap

563061 3 Check valve, double ball

555453 3 1/4 NPT street elbow

156971 3 1/4 NPT hex nipple

24P296 1 Two pump union kit

24K414 1 Pressure switch

114903 1 GL-1 injector 3 manifold

17L754 3 Clear, polycarbonate dust cap, GL-1

124300 1 Cable 16 ft for pressure switch

124301 1 Connector for pressure switch cable

Technical Specifications

Triplex Pump (three pistons) G3 2 pumps and GL-1 injectors set at half �040 cubic inch Reservoir hours of operation

Piston

Diameter

2.75 0.340 8.5 7 2 Minutes 889 60 120 239 235

3 0.371 9.3 6 2 Minutes 801 55 110 219 216

3.5 0.433 10.8 6 2 Minutes 662 47 94 188 185

4 0.494 12.4 5 2 Minutes 558 41 82 165 162

4.5 0.556 13.9 4 2 Minutes 477 37 73 146 144

5 0.618 15.4 4 2 Minutes 413 33 66 132 130

5.5 0.680 17.0 4 2 Minutes 360 30 60 120 118

6 0.742 18.5 3 2 Minutes 315 27 55 110 108

Notes: 1). Lube rates based on a service factor of 12. 2). Please note these are recommended lube rates. Each application should be reviewed to determine optimal rate.

Lube rate (in

hour each piston

3

) per

Feeder cycles

per hour

G3 Pump off

time setting in

minutes

G3 Pump cycle

monitor time (Max)

Rotations of Frac

pump set point

for lube cycle

2 liter 4 liter 8 liter 12 liter

8

graco.com

Page 9

Time-based with monitoring, optional RPM input count, and downloadable system monitoring.

Ordering Information

G3 Max DMS Grease / GL-1 Injectors 12 VDC Quintuplex Kit

Part Number Quantity Description

96G099 1 G3 Max DMS pump 12 V, 4 liter reservoir, low level and DIN

24Z962 1 Protective G3 cover with manual run and reset holes

571169 1 Vent valve

571041 2 G3 pump element

557874 1 Quick fill stud – 1/4 in NPT

557875 1 Dust cap

563061 5 Check valve, double ball

555453 5 1/4 NPT street elbow

156971 5 1/4 NPT hex nipple

24P295 1 Three pump union kit

24K414 1 Pressure switch

114905 1 GL-1 injector 5 manifold

17L754 5 Clear, polycarbonate dust cap, GL-1

124300 1 Cable 16 ft for pressure switch

124301 1 Connector for pressure switch cable

Quintuplex Frac Kit Selection Guide

G3 Max DMS Grease and GL-1 Injectors

G3 Max DMS Grease / GL-1 Injectors 24 VDC Quintuplex Kit

96G111 1 G3 Max DMS pump 24 V, 4 liter reservoir, low level and DIN

24Z962 1 Protective G3 cover with manual run and reset holes

571170 1 Vent valve

571041 2 G3 pump element

557874 1 Quick fill stud – 1/4 in NPT

557875 1 Dust cap

563061 5 Check valve, double ball

555453 5 1/4 NPT street elbow

156971 5 1/4 NPT hex nipple

24P295 1 Three pump union kit

24K414 1 Pressure switch

114905 1 GL-1 injector 5 manifold

17L754 5 Clear, polycarbonate dust cap, GL-1

124300 1 Cable 16 ft for pressure switch

124301 1 Connector for pressure switch cable

Technical Specifications

Quintuplex Pump (five pistons) G3 3 pumps and GL-1 injectors set at half �040 cubic inch Reservoir hours of operation

Piston

Diameter

2.75 0.340 8.5 7 2 Minutes 871 36 72 144 235

3 0.371 9.3 6 2 Minutes 783 33 66 132 216

3.5 0.433 10.8 6 2 Minutes 644 28 56 113 185

4 0.494 12.4 5 2 Minutes 540 25 49 99 162

4.5 0.556 13.9 4 2 Minutes 459 22 44 88 144

5 0.618 15.4 4 2 Minutes 395 20 39 79 130

5.5 0.680 17.0 4 2 Minutes 342 18 36 72 118

6 0.742 18.5 3 2 Minutes 297 16 33 66 108

Notes: 1). Lube rates based on a service factor of 12. 2). Please note these are recommended lube rates. Each application should be reviewed to determine optimal rate.

Lube rate (in

hour each piston

3

) per

Feeder cycles

per hour

G3 Pump off

time setting

G3 Pump on time

(Pro)/cycle monitor

time (Max)

Rotations of Frac

pump set point

for lube cycle

2 liter 4 liter 8 liter 12 liter

graco.com

9

Page 10

Triplex Frac Kit Selection Guide

G3 Max DMS Oil and MSP Series Progressive

Time-based with monitoring, optional RPM input count, and downloadable system monitoring.

Ordering Information

G3 Max DMS Oil / MSP Series Progressive 24 VDC Triplex Kit

Part Number Quantity Description

96G188 1 G3 Max DMS pump 24 V, 4 liter reservoir, low level and 5 pin CPC

24Z962 1 Protective G3 cover with manual run and reset holes

556420 1 1/4 NPT service tee

563160 1 2,500 psi relief

557874 1 Quick fill stud – 1/4 in NPT

557875 1 Dust cap

563061 3 Check valve, double ball

555453 3 1/4 NPT street elbow

156971 3 1/4 NPT hex nipple

24G485 1 3 section MSP base plate assembly

562713 3 MSP 15S valve assembly

563257 3 2,000 psi reset performance indicator

17L983 1 Proximity switch, cycle indicator

124300 1 Cable 16 ft for proximity switch

124301 1 Connector for proximity switch cable

Triplex

15S

15S

15S

Technical Specifications

Triplex Pump (three pistons) MSP Reservoir hours of operation

Piston

Diameter

2.75 0.622 20.7 3 23 seconds/ 1 minute 376 65 131 262

3 0.678 22.6 3 23 seconds/ 1 minute 340 60 120 240

3.5 0.791 26.4 2 23 seconds/ 1 minute 283 51 103 206

4 0.904 30.1 2 23 seconds/ 1 minute 241 45 90 180

4.5 1.017 33.9 2 23 seconds/ 1 minute 207 40 80 160

5 1.130 37.7 2 23 seconds/ 1 minute 181 36 72 144

5.5 1.243 41.4 1 23 seconds/ 1 minute 159 33 65 131

6 1.356 45.2 1 23 seconds/ 1 minute 141 30 60 120

Notes: 1). Lube rates based on a service factor of 12. 2). G3 pump with one pump element. 3). Please note these are recommended lube rates. Each application should be reviewed to determine optimal rate.

Lube rate (in

hour each piston

3

) per

Feeder cycles

per hour

G3 Pump off

time setting in

minutes

G3 Pump on time

(Pro)/cycle monitor

time (Max)

RPM of Frac

pump set point

for lube cycle

2 liter 4 liter 8 liter

10

graco.com

Page 11

Quintuplex Frac Kit Selection Guide

G3 Max DMS Oil and MSP Series Progressive

Time-based with monitoring, optional RPM input count, and downloadable system monitoring.

Ordering Information

G3 Max DMS Oil / MSP Series Progressive 24 VDC Quintuplex Kit

Part Number Quantity Description

96G188 1 G3 Max DMS pump 24 V, 4 liter reservoir, low level and 5 pin CPC

24Z962 1 Protective G3 cover with manual run and reset holes

556420 1 1/4 NPT Service tee

563160 1 2,500 psi relief

557874 1 Quick Fill Stud - 1/4 in NPT

557875 1 Dust Cap

563061 5 Check valve, double ball

555453 5 1/4 NPT street elbow

156971 5 1/4 NPT hex nipple

24G485 1 3 section MSP base plate assembly

562713 1 MSP 15S valve assembly

562725 2 MSP 30T valve assembly

563257 5 2,000 psi reset performance indicator

17L983 1 Proximity switch, cycle indicator

124300 1 Cable 16 ft for proximity switch

124301 1 Connector for proximity switch cable

Quintuplex

15S

30T

30T

Technical Specifications

Quintuplex Pump (five pistons) Reservoir hours of operation

Piston

Diameter

2.75 0.622 20.7 3 38 seconds/1 minute 339 39 78 157 235

3 0.678 22.6 3 38 seconds/1 minute 303 36 72 144 216

3.5 0.791 26.4 2 38 seconds/1 minute 246 31 62 123 185

4 0.904 30.1 2 38 seconds/1 minute 204 27 54 108 162

4.5 1.017 33.9 2 38 seconds/1 minute 170 24 48 96 144

5 1.130 37.7 2 38 seconds/1 minute 144 22 43 86 130

5.5 1.243 41.4 1 38 seconds/1 minute 122 20 39 78 118

6 1.356 45.2 1 38 seconds/1 minute 104 18 36 72 108

Notes: 1). Lube rates based on a service factor of 12. 2). G3 pump with one pump element. 3). Please note these are recommended lube rates. Each application should be reviewed to determine optimal rate.

Lube rate (in

hour each piston

3

) per

Feeder cycles

per hour

G3 Pump off

time setting

G3 Pump on time

(Pro)/cycle monitor

time (Max)

RPM of Frac

pump set point

for lube cycle

2 liter 4 liter 8 liter 12 liter

graco.com

11

Page 12

Triplex Frac Kit Selection Guide

Dyna-Star Hydraulic Grease and GL-1 Injector

Time-based with monitoring and optional RPM input count.

Ordering Information

Dyna-Star Hydraulic Grease / GL-1 Injectors Triplex Kit

Part Number Quantity Description

247574 1 Dyna-Star hydraulic pump, 60 lb reservoir with vent valve

24B591 1 GLC-4400 Controller DC

563061 3 Check valve, double ball

555453 3 1/4 NPT street elbow

156971 3 1/4 NPT hex nipple

24K414 1 Pressure switch

114903 1 GL-1 injector 3 manifold

17L754 3 Dust cap, GL-1

124300 1 Cable 16 ft for pressure switch

124301 1 Connector for pressure switch cable

24K414 1 Pressure switch

114903 1 GL-1 injector 3 manifold

17L754 3 Clear, polycarbonate dust cap, GL-1

124300 1 Cable 16 ft for pressure switch

124301 1 Connector for pressure switch cable

Technical Specifications

Triplex Pump (three pistons) Dyna-Star and GL-1 injectors set at half �040 cubic inch

Piston

Diameter

2.75 0.340 8.5 7 2 Minutes 889 971

3.5 0.433 10.8 6 2 Minutes 662 763

4.5 0.556 13.9 4 2 Minutes 477 593

5.5 0.680 17.0 4 2 Minutes 360 485

Notes: 1). Lube rates based on a service factor of 12. 2). Please note these are recommended lube rates. Each application should be reviewed to determine optimal rate.

12

Lube rate (in3) per

hour each piston

3 0.371 9.3 6 2 Minutes 801 890

4 0.494 12.4 5 2 Minutes 558 668

5 0.618 15.4 4 2 Minutes 413 534

6 0.742 18.5 3 2 Minutes 315 445

Feeder cycles

per hour

GLC-4400 Pump off time

setting in minutes

GLC-4400 Pump cycle

monitor time

graco.com

RPM of Frac pump set

point for lube cycle

Reservoir hours of operation

60 lb (27 kg)

Page 13

Dyna-Star Hydraulic Grease and GL-1 Injector

Ordering Information

Dyna-Star Hydraulic Grease / GL-1 Injectors Quintuplex Kit

Part Number Quantity Description

247574 1 Dyna-Star hydraulic pump, 60 lb reservoir with vent valve

24B591 1 GLC-4400 Controller DC

563061 5 Check valve, double ball

555453 5 1/4 NPT street elbow

156971 5 1/4 NPT hex nipple

24K414 1 Pressure switch

114905 1 GL-1 injector 5 manifold

17L754 5 Clear, polycarbonate dust cap, GL-1

124300 1 Cable 16 ft for pressure switch

124301 1 Connector for pressure switch cable

Quintuplex Frac Kit Selection Guide

Time-based with monitoring and optional RPM input count.

Technical Specifications

Quintuplex Pump (five pistons) Dyna-Star and GL-1 injectors set at half �040 cubic inch

Piston

Diameter

2.75 0.340 8.5 7 2 Minutes 871 971

3.55 0.439 11.0 5 2 Minutes 633 752

4.5 0.556 13.9 4 2 Minutes 459 593

5.5 0.680 17.0 4 2 Minutes 342 485

Notes: 1). Lube rates based on a service factor of 12. 2). Please note these are recommended lube rates. Each application should be reviewed to determine optimal rate.

Lube rate (in3) per

hour each piston

3 0.371 9.3 6 2 Minutes 783 890

4 0.494 12.4 5 2 Minutes 540 668

5 0.618 15.4 4 2 Minutes 395 534

6 0.742 18.5 3 2 Minutes 297 445

Feeder cycles

per hour

GLC-4400 Pump off time

setting in minutes

GLC-4400 Pump cycle

monitor time

RPM of Frac pump set

point for lube cycle

Reservoir hours of operation

60 lb (27 kg)

graco.com

13

Page 14

Triplex Frac Kit Selection Guide

24 VDC Compact Dyna-Star Grease and GL-1 Injector

Time-based with monitoring, optional RPM input count, and downloadable system monitoring.

Ordering Information

24 VDC Compact Dyna-Star Grease / GL-1 Injectors Triplex Kit

Part Number Quantity Description

CD2221 1 Compact Dyna-Star 24 VDC

25R318 2 Bracket, GLCX and GL1

26A814 1 GLCX Controller

26A883 1 GLC X to CDS 3 ft (1 m) cable

563061 3 Check valve, double ball

555453 3 1/4 npt street elbow

156971 3 1/4 npt hex nipple

114903 1 GL-1 injector 3 manifold

17L754 3 Dust cap, GL-1

Technical Specifications

Triplex Pump (three pistons) Compact Dyna-Star and GL-1 injectors set at half �040 cubic inch

3

) per

Piston

Diameter

2.75 0.340 8.5 7 2 Minutes 889 1,177

3.5 0.433 10.8 6 2 Minutes 662 925

4.5 0.556 13.9 4 2 Minutes 477 719

5.5 0.680 17.0 4 2 Minutes 360 588

Notes: 1). Lube rates based on a service factor of 12. 2). Please note these are recommended lube rates. Each application should be reviewed to determine optimal rate.

14

Lube rate (in

hour each piston

3 0.371 9.3 6 2 Minutes 801 1,079

4 0.494 12.4 5 2 Minutes 558 809

5 0.618 15.4 4 2 Minutes 413 647

6 0.742 18.5 3 2 Minutes 315 539

graco.com

Feeder cycles

per hour

GLC X Pump off time

setting in minutes

GLC X Pump cycle

monitor time

RPM of Frac pump set

point for lube cycle

Reservoir hours of operation

20 liter

Page 15

Quintuplex Frac Kit Selection Guide

24 VDC Compact Dyna-Star Grease and GL-1 Injector

Time-based with monitoring, optional RPM input count, and downloadable system monitoring.

Ordering Information

24 VDC Compact Dyna-Star Grease / GL-1 Injectors Quintuplex Kit

Part Number Quantity Description

CD2221 1 Compact Dyna-Star 24VDC

25R318 2 Bracket, GLCX and GL1

26A814 1 GLCX Controller

26A883 1 GLC X to CDS 3 ft (1 m) cable

563061 5 Check valve, double ball

555453 5 1/4 npt street elbow

156971 5 1/4 npt hex nipple

114905 1 GL-1 injector 5 manifold

17L754 5 Dust cap, GL-1

Technical Specifications

Quintuplex Pump (five pistons) Compact Dyna-Star and GL-1 injectors set at half �040 cubic inch

Piston

Diameter

2.75 0.340 8.5 7 2 Minutes 871 706

3.55 0.439 11.0 5 2 Minutes 633 547

4.5 0.556 13.9 4 2 Minutes 459 432

5.5 0.680 17.0 4 2 Minutes 342 353

Notes: 1). Lube rates based on a service factor of 12. 2). Please note these are recommended lube rates. Each application should be reviewed to determine optimal rate.

Lube rate (in3) per

hour each piston

3 0.371 9.3 6 2 Minutes 783 647

4 0.494 12.4 5 2 Minutes 540 485

5 0.618 15.4 4 2 Minutes 395 388

6 0.742 18.5 3 2 Minutes 297 324

Feeder cycles

per hour

GLC X Pump off time

setting in minutes

GLC X Pump cycle

monitor time

RPM of Frac pump set

point for lube cycle

Reservoir hours of operation

20 liter

graco.com

15

Page 16

Triplex Frac Kit Selection Guide

24 VDC Compact Dyna-Star Grease and MSP Series Progressive

Time-based with monitoring, optional RPM input count, and downloadable system monitoring.

Ordering Information

24 VDC Compact Dyna-Star Grease / MSP Series Progressive Triplex Kit

Part Number Quantity Description

CD2021 1 Compact Dyna-Star 24 VDC

25R318 2 Bracket, GLCX and MSP

26A814 1 GLCX Controller

25T779 1 Wiring harness

563061 3 Check valve, double ball

555453 3 1/4 npt street elbow

156971 3 1/4 npt hex nipple

24G485 1 3 section MSP base plate assembly

562716 3 MSP 30S valve assembly

563258 3 2500 psi reset performance indicator

17L983 1 Proximity switch, cycle indicator

Triplex

30S

30S

30S

Technical Specifications

Triplex Pump (three pistons) Compact Dyna-Star and MSP Series Progressive set at half �040 cubic inch

3

) per

Piston

Diameter

2.75 0.340 5.7 11 20 Seconds 1,531 1,177

3.5 0.433 7.2 8 20 Seconds 1,190 925

4.5 0.556 9.3 6 20 Seconds 913 719

5.5 0.680 11.3 5 20 Seconds 736 588

Notes: 1). Lube rates based on a service factor of 12. 2). Please note these are recommended lube rates. Each application should be reviewed to determine optimal rate.

Lube rate (in

hour each piston

3 0.371 6.2 10 20 Seconds 1,398 1,079

4 0.494 8.2 7 20 Seconds 1,034 809

5 0.618 10.3 6 20 Seconds 816 647

6 0.742 12.4 5 20 Seconds 670 539

Feeder cycles

per hour

GLC X Pump off time

setting in minutes

GLC X Pump cycle

monitor time

RPM of Frac pump set

point for lube cycle

Reservoir hours of operation

20 liter

16

graco.com

Page 17

Quintuplex Frac Kit Selection Guide

24 VDC Compact Dyna-Star Grease and MSP Series Progressive

Time-based with monitoring, optional RPM input count, and downloadable system monitoring.

Ordering Information

24 VDC Compact Dyna-Star Grease / MSP Series Progressive Quintuplex Kit

Part Number Quantity Description

CD2021 1 Compact Dyna-Star 24 VDC

25R318 2 Bracket, GLCX and MSP

26A814 1 GLCX Controller

25T779 1 Wiring harness

563061 5 Check valve, double ball

555453 5 1/4 npt street elbow

156971 5 1/4 npt hex nipple

24G487 1 5 section MSP base plate assembly

562716 5 MSP 30S valve assembly

563258 3 2500 psi reset performance indicator

17L983 1 Proximity switch, cycle indicator

Quintuplex

30S

30S

30S

30S

30S

Technical Specifications

Quintuplex Pump (five pistons) Compact Dyna-Star and MSP Series Progressive set at half �040 cubic inch

Piston

Diameter

2.75 0.340 5.7 11 30 Seconds 1,494 706

3.5 0.433 7.2 8 30 Seconds 1,153 555

4.5 0.556 9.3 6 30 Seconds 876 432

5.5 0.680 11.3 5 30 Seconds 699 353

Notes: 1). Lube rates based on a service factor of 12. 2). Please note these are recommended lube rates. Each application should be reviewed to determine optimal rate.

Lube rate (in3) per

hour each piston

3 0.371 6.2 10 30 Seconds 1,361 647

4 0.494 8.2 7 30 Seconds 997 485

5 0.618 10.3 6 30 Seconds 779 388

6 0.742 12.4 5 30 Seconds 633 324

Feeder cycles

per hour

GLC X Pump off time

setting in minutes

GLC X Pump cycle

monitor time

RPM of Frac pump set

point for lube cycle

Reservoir hours of operation

20 liter

graco.com

17

Page 18

Triplex Frac Kit Selection Guide

24 VDC Electric Dyna-Star Grease and GL-1 Injector

Time-based with monitoring and optional RPM input count.

Ordering Information

Electric Dyna-Star Grease / GL-1 Injectors Triplex Kit

Part Number Quantity Description

77X202 1 HP EDS pump, 60 lb reservoir, vent valve, tube-in-tube, auto-fill shutoff, low level signal

77X546 1 EDS pump power cable

77X542 1 Remote fill manifold

24B591 1 GLC-4400 controller DC

563061 3 Check valve, double ball

555453 3 1/4 NPT street elbow

156971 3 1/4 NPT hex nipple

24K414 1 Pressure switch

114903 1 GL-1 injector 3 manifold

17L754 3 Clear, polycarbonate dust cap, GL-1

124300 1 Cable 16 ft for pressure switch

124301 1 Connector for pressure switch cable

Technical Specifications

Triplex Pump (three pistons) Dyna-Star and GL-1 injectors set at half �040 cubic inch

3

) per

Piston

Diameter

2.75 0.340 8.5 7 2 Minutes 889 971

3.5 0.433 10.8 6 2 Minutes 662 763

4.5 0.556 13.9 4 2 Minutes 477 593

5.5 0.680 17.0 4 2 Minutes 360 485

Notes: 1). Lube rates based on a service factor of 12. 2). Please note these are recommended lube rates. Each application should be reviewed to determine optimal rate.

18

Lube rate (in

hour each piston

3 0.371 9.3 6 2 Minutes 801 890

4 0.494 12.4 5 2 Minutes 558 668

5 0.618 15.4 4 2 Minutes 413 534

6 0.742 18.5 3 2 Minutes 315 445

graco.com

Feeder cycles

per hour

GLC-4400 Pump off time

setting in minutes

GLC-4400 Pump cycle

monitor time

RPM of Frac pump set

point for lube cycle

Reservoir hours of operation

60 lb (27 kg)

Page 19

Quintuplex Frac Kit Selection Guide

24 VDC Electric Dyna-Star Grease and GL-1 Injector

Time-based with monitoring and optional RPM input count.

Ordering Information

Electric Dyna-Star Grease / GL-1 Injectors Quintuplex Kit

Part Number Quantity Description

77X202 1 HP EDS pump, 60 lb reservoir, vent valve, tube-in-tube, auto-fill shutoff, low level signal

77X546 1 EDS pump power cable

77X542 1 Remote fill manifold

24B591 1 GLC-4400 controller DC

563061 3 Check valve, double ball

555453 3 1/4 NPT street elbow

156971 3 1/4 NPT hex nipple

24K414 1 Pressure switch

114905 1 GL-1 injector 5 manifold

17L754 5 Clear, polycarbonate dust cap, GL-1

124300 1 Cable 16 ft for pressure switch

124301 1 Connector for pressure switch cable

Technical Specifications

Quintuplex Pump (five pistons) Dyna-Star and GL-1 injectors set at half �040 cubic inch

Piston

Diameter

2.75 0.340 8.5 7 2 Minutes 871 971

3.55 0.439 11.0 5 2 Minutes 633 752

4.5 0.556 13.9 4 2 Minutes 459 593

5.5 0.680 17.0 4 2 Minutes 342 485

Notes: 1). Lube rates based on a service factor of 12. 2). Please note these are recommended lube rates. Each application should be reviewed to determine optimal rate.

Lube rate (in3) per

hour each piston

3 0.371 9.3 6 2 Minutes 783 890

4 0.494 12.4 5 2 Minutes 540 668

5 0.618 15.4 4 2 Minutes 395 534

6 0.742 18.5 3 2 Minutes 297 445

Feeder cycles

per hour

GLC-4400 Pump off time

setting in minutes

GLC-4400 Pump cycle

monitor time

RPM of Frac pump set

point for lube cycle

Reservoir hours of operation

60 lb (27 kg)

graco.com

19

Page 20

Frac Kit Selection Guide

G3™ Pump Enclosure Kits / Accessories / Frac Pump Hose and Fitting Kits

Ordering Information

G3 Pump Enclosure Kits

Heavy-Duty G3 Pumps

4-liter G3 Pro or G3 Standard pumps

with 12V or 24V options

Fits Common Configurations

Pre-configured for quintuplex or triplex pumps

Durable Enclosure

Robust fiberglass-reinforced polyester enclosure

Part Number Description

132090 Triplex, 12V, G3 Pro

132091 Triplex, 24V, G3 Pro

132154 Triplex, 24V, G3 Standard

132092 Quintuplex, 12V, G3 Pro

132093 Quintuplex, 24V, G3 Pro

132155 Quintuplex, 24V, G3 Standard

132089 Standalone enclosure with G3/MSP mounting panel

132188 G3/MSP mounting panel

132163 Isolator kit

Accessories

Part Number Description Note

563176 Performance indicator – standard relief to atmosphere Use with the Pro or Max Pump Kit 3 5

563261 Performance indicator – premium re-settable Use with the Max Pump Kit 3 5

563061 Double ball soft seat check valve Used on all pump packages 3 5

563251 LED cycle indicator Used on all pump packages 1 1

125910 L-shaped pump mounting bracket Used on all pump packages 1 1

571162 Manual hand pump used with grease cartridges Used on all pump packages 1 1

247886 Heavy duty hand pump – 35 pound / 5 gallon pail

77X542 Remote fill port manifold with vent Used on all pump packages 1 1

121474 Female coupler Used on all pump packages 1 1

571286 4 liter auto-fill shutoff conversion kit Used on all pump packages 1 1

571287 8 liter auto-fill shutoff conversion kit Used on all pump packages 1 1

563507 Filter, in-line 149 micron, grease Used on all grease pump packages 1 1

563508 Filter, in-line 40 micron, oil Used on all oil pump packages 1 1

17J939 Proximity switch for RPM count Use with the Max Pump Kit 1 1

124333 Cable for RPM count Use with the Max Pump Kit 2 2

557352 5,000 psi pressure gauge Used on all pump packages 1 1

Fits the quick fill stud included in

the pump package

Order Quantity

Triplex Quintuplex

1 1

563251

77X542

Frac Pump Hose and Fitting Kits

Includes Lube Point Check Valves

Part Number Description

556762 #4 JIC, SAE 7/16-20 male x 1/4 in NPT male, straight fitting 4 6

556764 #4 JIC SAE 7/16-20 male x 1/4 in NPT male, elbow fitting 4 6

555749 #4 JIC SAE 7/16-20 male x 1/8 in NPT male, straight fitting 3 5

556773 #4 female JIC 37º swivel, 1/4 in ID hose, field-attachable 8 12

556284 1/4 in ID hose SAE 100R7 construction, 2,750 psi working pressure 1 1

560530 1/8 NPT male x 1/4 NPT female adapter 3 5

555453 1/4 NPT male x 1/4 NPT male adapter 3 5

563061 Double-ball check valve 3 5

©2021 Graco Inc. 352295 Rev. G 1/21 All other brand names or marks

are used for identification purposes and are trademarks of their respective

owners. All written and visual data contained in this document are based

on the latest product information available at the time of publication. Graco

reserves the right to make changes at any time without notice.

20

graco.com

Call 800-533-9655 to speak with a Graco representative,

or visit www.graco.com for more information.

121474

571287

Order Quantity

Triplex Quintuplex

Contact us today!

Loading...

Loading...