Page 1

Instructions – Parts List

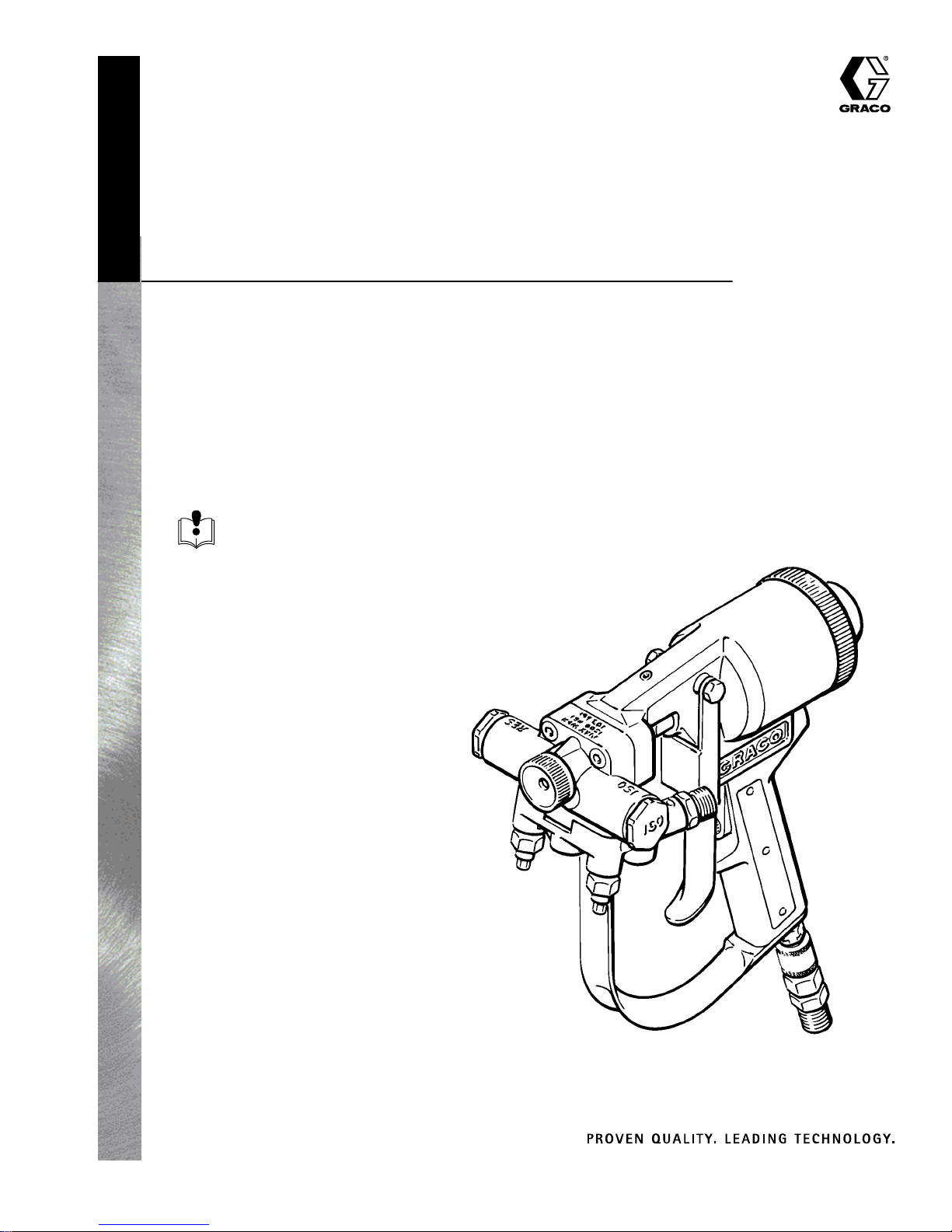

Foam-Catr Foam Gun

1500 psi (10.5 MPa, 105 bar) Maximum Working Pressure

Model 217373, Series E

Order a needle/nozzle kit separately. See page 5.

U.S. Patent No. 4,427,153

U.K. Patent No. 0,116,613

Patented Bréveté 1986 Canada

Other Foreign Patents Pending.

Read warnings and instructions.

See page 2 for Table of Contents.

307546T

GRACO INC.ąP.O. BOX 1441ąMINNEAPOLIS, MNą55440-1441

Copyright 1982, Graco Inc. is registered to I.S. EN ISO 9001

Page 2

Table of Contents

Symbols 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warnings 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spray Nozzle Performance Chart 5. . . . . . . . . . . . . . . . .

Pour Nozzle Performance Chart 5. . . . . . . . . . . . . . . . . .

Installation 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Grounding 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional O-rings 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing a Needle/Nozzle Kit on a New Gun 8. . . . .

Connecting Hoses 10. . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pressure Relief Procedure 11. . . . . . . . . . . . . . . . . . . .

Adjusting Cleanoff Air 12. . . . . . . . . . . . . . . . . . . . . . . .

Spray Pattern Adjustment 13. . . . . . . . . . . . . . . . . . . . . .

Effects of Fluid Temperature and Pressure 13. . . . . .

Observing the Effects of Varying Fluid Temperature

and Pressure 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About Surface Texture 13. . . . . . . . . . . . . . . . . . . . . . .

About Poured Foam Texture 13. . . . . . . . . . . . . . . . . .

Surface Texture Descriptions 14. . . . . . . . . . . . . . . . . . . .

Replacing the Needle/Nozzle Assembly 15. . . . . . . . . .

Cleaning the Nozzle 17. . . . . . . . . . . . . . . . . . . . . . . . . . .

Foam Spraying Nozzles 17. . . . . . . . . . . . . . . . . . . . . .

Foam Pouring Nozzles 17. . . . . . . . . . . . . . . . . . . . . . .

Maintenance 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keeping the Gun Clean While Spraying 18. . . . . . . .

Fluid Buildup on Nozzle 18. . . . . . . . . . . . . . . . . . . . . .

Fluid Buildup on Needle 18. . . . . . . . . . . . . . . . . . . . . .

Cleaning the Fluid Manifold 18. . . . . . . . . . . . . . . . . . .

Shutdown 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flushing 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Needle Valves 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Piston 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Valve 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air Valve 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Nozzle Kit Summary 29. . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Standard Warranty 30. . . . . . . . . . . . . . . . . . . . . .

Graco Information 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 307546

Page 3

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

WARNING

FIRE AND EXPLOSION HAZARD

Improper grounding, poor air ventilation, open flames, or sparks can cause a hazardous condition and

result in a fire or explosion and serious injury.

D Ground the equipment and the object. See Grounding on page 7.

D Provide fresh air ventilation to avoid the buildup of flammable fumes from solvent or the fluid being

dispensed.

D Extinguish all the open flames or pilot lights in the dispense area.

D Keep the dispense area free of debris, including solvent, rags, and gasoline.

D Do not turn on or off any light switch in the dispense area while operating or if fumes are present.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

D Do not smoke in the dispense area.

D Do not operate a gasoline engine in the dispense area.

D If there is any static sparking while using the equipment, stop dispensing immediately. Identify

and correct the problem.

INJECTION HAZARD

Spray from the gun, hose leaks, or ruptured components can inject fluid into your body and cause

extremely serious injury, including the need for amputation. Splashing fluid in the eyes or on the skin

can also cause serious injury.

D Fluid injected into the skin might look like just a cut, but it is a serious injury. Get immediate medi-

cal attention.

D Do not point the gun at anyone or at any part of the body.

D Do not put hand or fingers over the gun nozzle.

D Do not stop or deflect fluid leaks with your hand, body, glove, or rag.

D Be sure the gun trigger safety operates before dispensing.

D Lock the gun trigger safety when you stop dispensing.

D If the nozzle clogs, stop dispensing, lock the gun trigger safety, and follow the instructions of page

17 to clean the nozzle.

D Keep the tip of the nozzle and the nozzle head free of foam buildup. Foam buildup on the nozzle

can cause foam shots to be misdirected and splash foam in the eyes or on the skin.

D Follow the Pressure Relief Procedure on page 11 whenever you: are instructed to relieve pres-

sure; stop dispensing; clean, check, or service the equipment; and install or clean the nozzle.

D Tighten all the fluid connections before operating the equipment.

D Check the hoses, tubes, and couplings daily. Replace worn, damaged, or loose parts immediately.

Permanently coupled hoses cannot be repaired; replace the entire hose.

307546 3

Page 4

INSTRUCTIONS

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture, malfunction, or start unexpectedly and result

in a serious injury.

D This equipment is for professional use only.

D Read all the instruction manuals, tags, and labels before operating the equipment.

D Use the equipment only for its intended purpose. If you are uncertain about usage, call your Graco

distributor.

D Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

D Check the equipment daily. Repair or replace worn or damaged parts immediately.

D Do not exceed the maximum working pressure of the lowest rated system component. See the

front cover or the Technical Data for the maximum working pressure of your gun model.

D Route the hoses away from the traffic areas, sharp edges, moving parts, and hot surfaces.

D Do not use the hoses to pull the equipment.

D Use only Graco approved hoses. Do not remove hose spring guards, which help protect the hose

from rupture caused by kinks or bends near the couplings.

D Use fluids or solvents that are compatible with the equipment wetted parts. See the Technical

Data section of all the equipment manuals. Read the fluid and solvent manufacturer’s warnings.

D Comply with all applicable local, state and national fire, electrical and other safety regulations.

PLURAL COMPONENT MATERIAL HAZARD

Before using this equipment, read the material manufacturer’s warnings and determine all facts relating to the materials used, including any of the potential hazards relating to toxic fumes, fires, explosions, reactions times, and exposure of humans to the individual components or their resultant mixtures.

D Wear appropriate protective clothing, gloves, eyewear, face mask, and respirator.

D Know the specific hazards of the fluid you are using. Read the fluid manufacturer’s warnings.

D Graco does not manufacture or supply any of the reactive chemical components that may be used

in this equipment and is not responsible for their effects. Graco assumes no responsibility for loss,

damage, expense or claims for personal injury or property damage, direct or consequential, arising

from the use of such chemical components.

D Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state, and national guidelines.

HOT MATERIAL HAZARD

Heated foam can cause severe burns and can cause equipment surfaces to become very hot. To

avoid a burn or injury from the foam adhering to the skin:

D Wear protective gloves and clothing when operating the equipment in a heated system.

D Do not come in contact with the dispensed material until it has cooled and cured.

D Allow the equipment to cool thoroughly before servicing.

D If you are burned, get emergency medical care at once. Do not pull the foam from your skin.

4 307546

Page 5

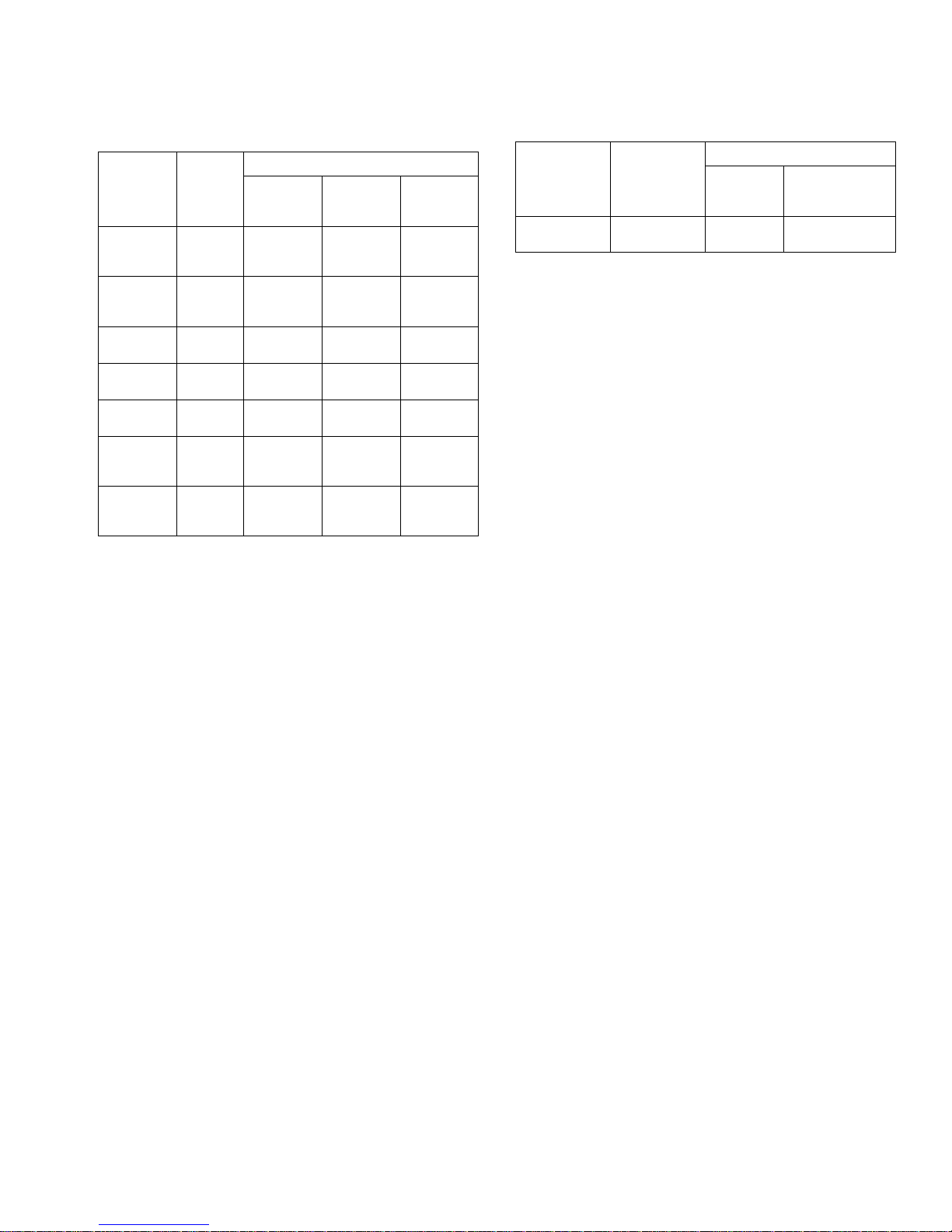

Spray Nozzle

Pour Nozzle

Performance Chart

DELIVERY

Nozzle Kit

No.

217420 0.125

217421 0.114

217423 0.089

217424 0.073

217425 0.083

217426 0.102

217428 0.060

Needle

Diameter

In. (mm)

(3.18)

(2.90)

(2.26)

(1.85)

(2.11)

(2.59)

(1.52)

1

Outlet

Pressure

psi (bar)

1200 (83)

950 (66)

750 (53)

1200 (83)

950 (66)

750 (53)

1000 (70)

750 (53)

1000 (70)

750 (53)

1000 (70)

750 (53)

1200 (83)

950 (66)

750 (53)

1200 (83)

950 (66)

750 (53)

2

Flow Rate

lb/min

(kg/min)

52 (23.4)

45 (20.3)

37 (16.7)

41 (18.4)

35 (15.8)

29 (13.1)

19 (8.6)

15 (6.6)

10.5 (4.7)

8.5 (3.8)

15 (6.8)

12 (5.4)

29 (13.1)

25 (11.3)

21.5 (9.7)

8 (3.6)

6 (2.7)

4 (1.8)

3

Diameter

in. (mm)

20 (508)

18 (457)

17 (432)

12 (305)

16 (406)

17 (432)

9 (228)

Pattern

Performance Chart

DELIVERY

1

Nozzle Kit No.

217427

220616

Needle

Diameter

In. (mm)

0.187 (4.75)

0.073 (1.85)

Outlet

Pressure

psi (bar)

700 (48)

700 (48)

NOTES:

1

Select a nozzle that will not exceed the maximum

recommended flow rate of your foam spray system as

the desired working pressure. Too high a flow rate may

exceed the performance capabilities of the foam

heater and other sprayer components, causing poor

foam development and equipment problems.

2

Flow rate test conditions:

D 2.7 lb (1.22 Kg) foam

D ISO viscosity of 200 cps (200 mPa.s) at 77_F

(25_C)

D RES viscosity of 650 cps (650 mPa.s) at 68_F

(20_C)

2

Flow Rate

lb/min

(kg/min)

16–20 (7–9)

6–8 (2.7–3.6)

D heater and hose temperature of 85–95_F

(29–35_C) for Pour Nozzle Kits 217427 and 220616

D heater and hose temperature of 115_F (43_C) for

all Spray Nozzle Kits

D Pump outlet pressure as indicated in chart

3

At the recommended spraying distance:

D 18–24 in. (457–610 mm) for Pour Nozzle Kits

217427 and 220616

D 30 in. (762 mm) for all Spray Nozzle Kits

307546 5

Page 6

Installation

The Graco Foam-Catr Gun has been designed and

manufactured to withstand rugged use. However, the

interior surfaces and cavities of the gun, and the

needle and nozzle, do require care during installation,

maintenance and service to avoid nicks and scratches.

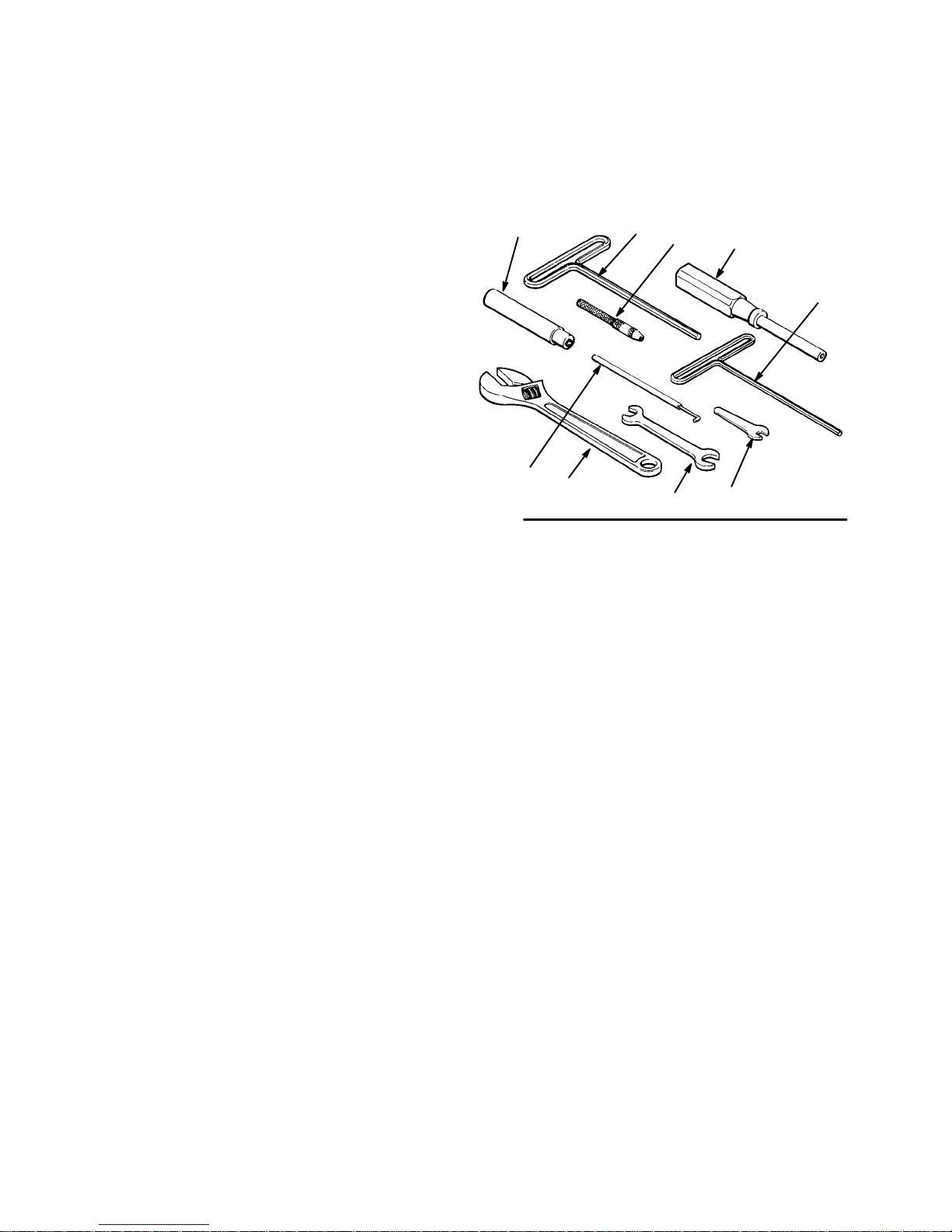

The following tools are supplied with the gun:

D 3/16 in. hex, T–handle hex key wrench (48)

D 3/32 in. hex, T–handle hex key wrench (47)

D 7/16 in. x 1/2 in. open end wrench (53)

D Pin vise (51) for cleaning pin supplied with Needle/

Nozzle Kits

D Nut driver (50)

D 1/4 in. open end wrench (52)

In addition, you will need to purchase an air valve hook

(O) to service the air valve, a pressing tool (P) to

service the piston (see Accessories, page 28), and a

small adjustable wrench (A). See Fig. 1.

You will also need a solvent flushing system to clean

the gun. See page 28 to order an accessory solvent

flush kit.

50

O

A

Fig. 1

48

53

51

50

47

52

6 307546

Page 7

Installation

)

Safety

For your safety, read all of the warnings and instructions in this manual, all system component manuals,

and the chemical manufacturer’s literature before

installing or operating the equipment. The warnings,

cautions and instructions are designed to help all

operators use this equipment with safety and confidence.

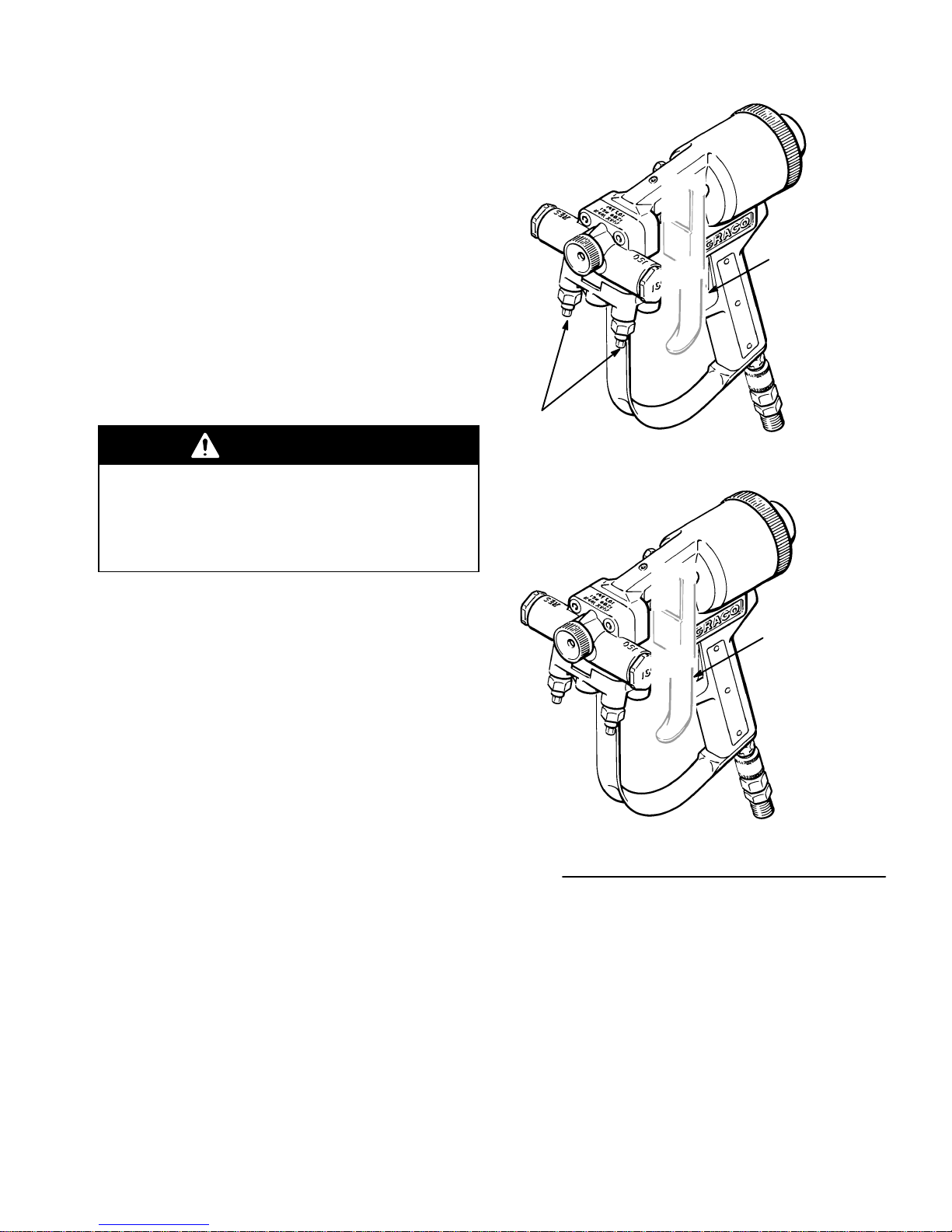

This gun has a trigger safety latch. To engage the

trigger safety latch (ON SAFE) and make the trigger

inoperative, pul out on the trigger safety latch (B) and

turn it so it is perpendicular to the gun body. To disengage the trigger safety latch (OFF SAFE) turn it so it is

parallel to the gun body. See Fig. 2.

WARNING

To reduce the risk of serious bodily injury from

injection of high pressure fluid, always engage the

trigger safety latch (ON SAFE) whenever you stop

spraying and close the needle valves (C) completely with the nut driver (50).

Trigger Safety (B

shown in ON

SAFE position

C

Grounding

When used with Graco Heated Hose, this gun is

grounded through hose connections. For other types of

hoses, be sure the hose you use is static grounded, or

attach a grounding wire between a metal part of the

gun and a true earth ground.

Optional O-rings

This gun is supplied with flourocarbon o-rings (44)

installed in the gun check valves, for use with methylene chloride solvent. A set of silicone o-rings (60) is

also included (not installed) for use with DMF (Dimethyl Formamide) and Cellosolver solvents.

Trigger Safety (B)

shown in OFF

SAFE position

Fig. 2

307546 7

Page 8

Installation

Installing a Needle/Nozzle Kit on a New Gun

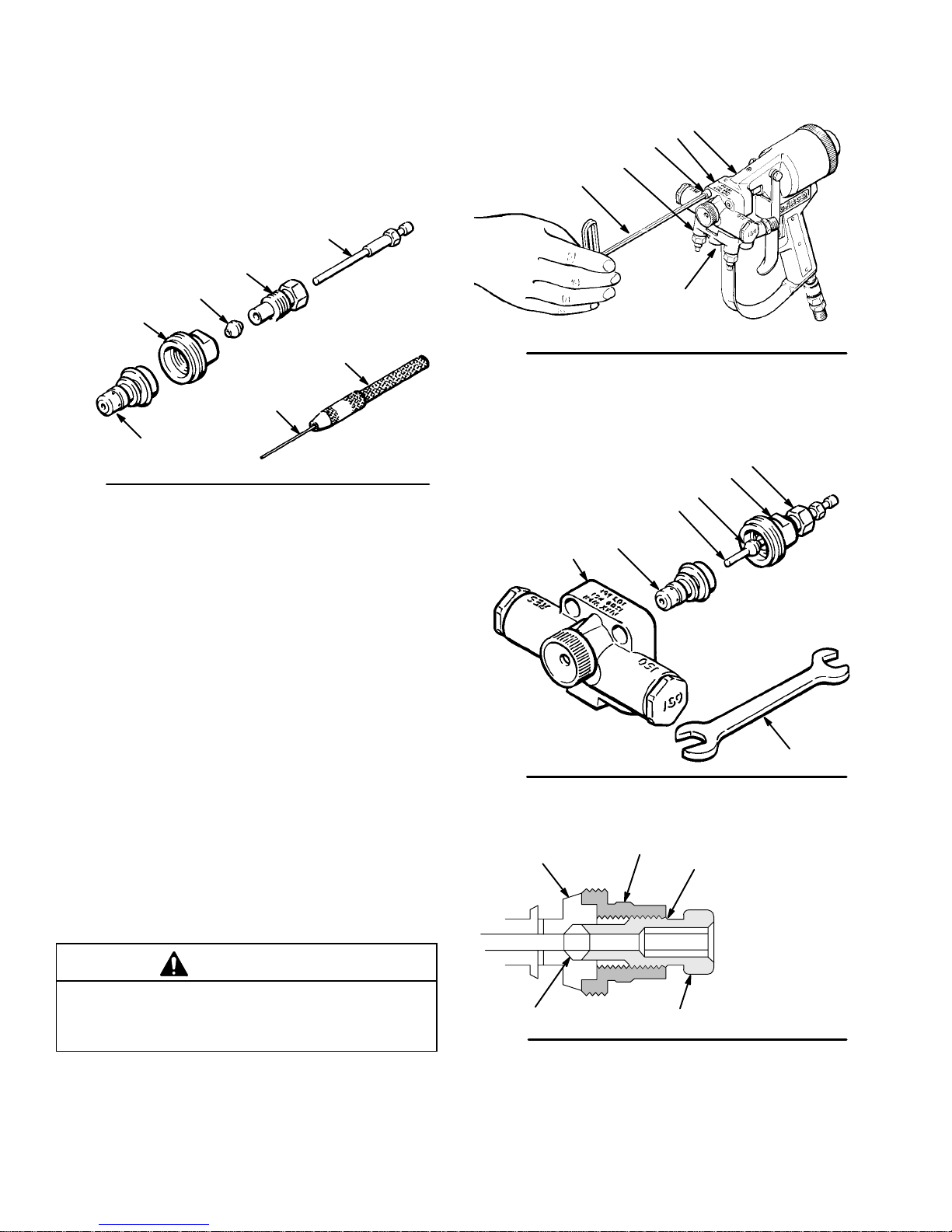

The needle/nozzle kit includes the parts shown in Fig.

3, except the pin vise (51) which holds the cleaning pin

(H), and the nozzle retainer (23).

KEY

23 Nozzle Retainer

51 Pin vise

D Needle

E Nozzle

F Packing

G Packing Nut

G

F

23

H

E

Fig. 3

To install the nozzle kit:

1. Use the 3/16 in. wrench (48) to remove the capscrew (7) from the fluid manifold (26) and to remove

the two capscrews (7) from the nozzle housing (2).

See Fig. 4.

D

51

KEY

1 Gun body

2 Nozzle housing

7 Capscrew

26 Manifold

48 Wrench

48

Fig. 4

KEY

2 Nozzle housing

23 Nozzle retainer

53 Wrench

D Needle

E Nozzle

F Packing

G Packing nut

2

26

1

2

7

7

G

23

F

D

E

2. Trigger the gun, then pull the housing straight off

the gun body (1).

3. Use the 1/2 in. end of the wrench (53) to remove

the nozzle retainer (23) from the back of the

housing (2). Refer to Fig. 5.

4. Insert the nozzle (E), tapered end first, into the

back of the housing. See Fig. 5.

5. Slide the packing nut (G), nozzle retainer (23), and

packing (F) onto the needle (D). Screw the packing

nut (G) into the nozzle retainer (23) until the top

threads of the packing nut is flush with the back of

the retainer. See Fig. 6.

6. Slide the needle assembly through the nozzle and

into the nozzle housing. Refer to Fig. 6.

CAUTION

Do not overtighten the nozzle retainer. This can

compact the nozzle and damage it or cause it to seat

improperly, resulting in spray pattern distortion.

Fig. 5

Fig. 6

53

E

23

F

Top thread of packing nut

(G) must be flush with

back of retainer (23)

KEY

23 Nozzle retainer

E Nozzle

G

F Packing

G Packing nut

8 307546

Page 9

Installation

7. Adjust the needle so it protrudes 1–3/4 in. (44 mm)

from the rear of the housing. See Fig. 7.

Fig. 7

8. Screw the nozzle retainer (23) snugly into the back

of the housing. Tighten using the open end wrench

(53). Torque to 25–35 in-lb (2.8–3.9 NSm).

9. Guide the needle of the nozzle assembly into the

front opening (J) of the gun body (1). The piston

(20) rod has a socket in the side of it which must

face down. Tilt the nozzle assembly up and swing

the ball of the needle (D) into the piston rod

socket. See Fig. 8.

10. Push the nozzle assembly further into the front

opening (J) until the back of the assembly meets

the gun body. Refer to Fig. 8.

11. Use the 3/16 in. wrench (48) to install the two

capscrews (7) firmly into the nozzle housing.

Torque to 40 in-lb (4.5 NSm). Refer to Fig. 9.

WARNING

To reduce the risk of serious bodily injury from fluid

injection, be sure the trigger safety latch (B) is

engaged (ON SAFE) before proceeding. Refer to

Fig. 2 on page 7.

12. Screw on the air cap (24). Connect an air line (K)

to the inlet bushing (9) of the gun. See Fig. 9.

43

7

KEY

1 Gun body

20 Piston

D Needle

J Front opening

Fig. 8

20

1

24

7

25

9

J

D

KEY

7 Capscrew

9 Bushing

24 Air cap

25 Manifold

32 Plug

40 O-ring

K Air line

32

K

Fig. 9

307546 9

Page 10

Installation

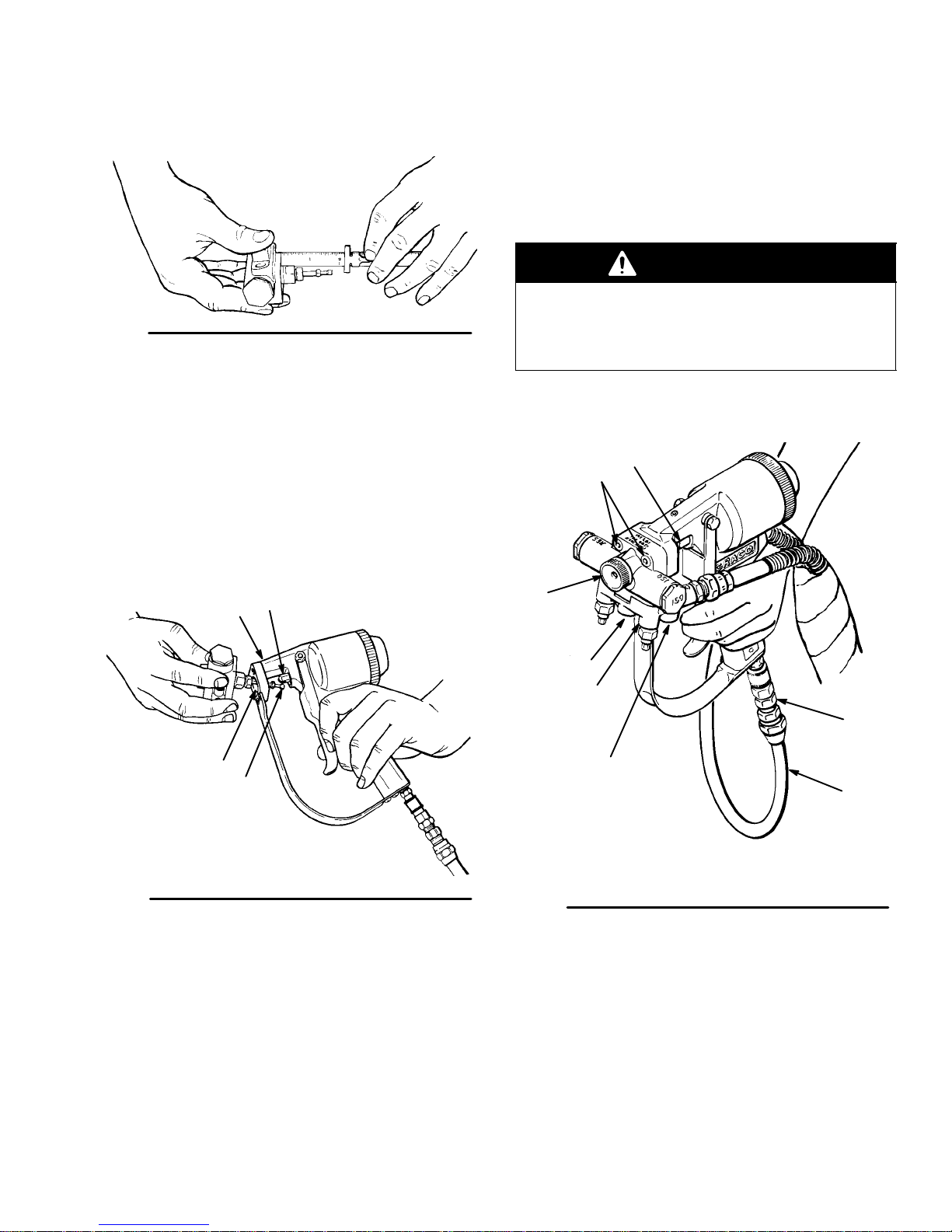

13. Use the 7/16 in. end of wrench (53) to adjust the

packing nut (G) until it is just snug. Don’t overtighten it. See Fig. 10.

14. Install the plastic shield (43) around the exposed

part of the needle assembly to keep foam over

spray from collecting on the needle. See Fig. 10.

15. Connect the fluid manifold (25) to the gun using

the 3/16 in. wrench (48) to tighten the capscrew

(7) firmly. Torque to 40 in-lb (4.5 NSm). See Fig.

10.

KEY

24 Air cap

53 Wrench

G

24

53

G Packing nut

Connecting Hoses

CAUTION

The Graco heated hoses and the fluid manifold (25)

inlets are labeled ISO and RES. Be very careful to

make only ISO to ISO and RES to RES connections.

Crossing fluid can damage the hoses and gun. Refer

to hose manual 307544.

1. The fluid hoses can be connected straight down

from the manifold or straight back from it as shown

in Fig. 10. Plug the manifold inlets that will not be

used with steel plugs (32).

2. Connect the fluid hoses to the manifold inlets. Be

sure the air hose (K) is connected to the gun. See

Fig. 10.

Fig. 10

10 307546

Page 11

Operation

Pressure Relief Procedure

WARNING

INJECTION HAZARD

The system pressure must be manually

relieved to prevent the system from

starting or dispensing accidentally. Fluid

under high pressure can be injected through the

skin and cause a serious injury. To reduce the risk

of an injury from injection, splashing fluid, or moving parts, follow the Pressure Relief Procedure

whenever you:

D are instructed to relieve the pressure,

D stop dispensing,

D check or service any of the system equipment,

D install or clean the nozzle.

1. Engage the spray gun trigger latch.

2. Shut off the air to the feed pumps.

3. Turn off the electric motor switch in a hydraulic

system.

4. Turn off the air to the proportioning system in an

air-powered system.

5. Close the gun manifold needle valves.

6. Disengage the trigger safety latch, trigger the gun

to relieve pressure, and engage the trigger safety

latch again.

7. Open both fluid filter drain valves, having a container ready to catch the draining fluid.

8. If you are working on any part of the heater, shut

off the main electrical power to the heater.

307546 11

Page 12

Operation

1. Adjust cleanoff air as instructed in the next

column. Be sure the needle valves (C) are closed.

See Fig. 11.

2. Adjust the fluid temperature. Most foam fluids

are designed for spraying at 100_ to 140_F (38_ to

60_C). Adjust the heater and hose controls to the

chemical manufacturer’s recommended temperature. If no temperature is specified, start at 115_F

(43_C).

Refer to manual 307543 for specific instructions on

adjusting and operating the Foam-Cat Heater and

Heated Hose Controls.

3. Adjust the pump outlet pressure to 1000 psi (70

bar). This is adequate for most spray applications.

If more fluid flow is needed at that pressure, try

using a larger fluid nozzle. Refer to the Nozzle

Performance Chart on page 5. Increasing the

fluid pressure could distort the spray pattern.

4. Allow the fluid to heat thoroughly. The Graco

Heater and Heated Hose requires 15 minutes

warm up time.

Adjusting Cleanoff Air

Each time the gun’s trigger is released, the needle

purges the nozzle and the cleanoff air blows the

purged foam off the tip of the nozzle. Be sure the

cleanoff air is properly adjusting to avoid a build up of

foam on the nozzle or under the air cap.

WARNING

To reduce the risk of an injection injury, follow this

procedure before adjusting the cleanoff air:

Engage the trigger safety (40), close the needle

valves (64), disengage the trigger safety, and

trigger the gun to relieve the fluid pressure. Engage

the trigger safety again.

1. Screw in the air adjusting setscrew (19) using the

3/32 in. wrench (47), until no air or almost no air is

escaping. See Fig. 11.

2. Regulate the air to the gun to 100 psi (0.7 MPa, 7

bar).

5. Spray for several seconds in cold weather to

bring thoroughly warmed fluid to the gun. Release

the gun trigger safety latch, open the needle

valves (C), and aim the gun at a large piece of

cardboard when testing spraying.

CAUTION

Open the RES side first to help prevent nozzle

damage.

6. Test for proper foam texture. Trigger the gun in

one second intervals to test the spray pattern. A

good spray pattern should be round and well

atomized and it should harden with a fairly smooth

surface. Refer to the chart on page 4 for the

proper size of pattern and spraying distance for the

nozzle being used.

7. Release the gun trigger at least once a minute

while spraying if you use a no–release triggering

method. This actuates the mechanical purger and

avoids fluid buildup on the nozzle tip and air cap.

3. Back off the setscrew two turns as a test setting.

4. If the air appears to affect the spray pattern, screw

in the setscrew another turn. If build up behind the

air cap occurs, back off the setscrew about 1/2

turn at a time.

NOTE: Use the minimum amount of air needed to

clean the nozzle. Too much air could affect the spray

pattern.

KEY

19 Setscrew

47 Wrench

C Needle valves

19

47

CAUTION

Do not nick or scratch the nozzle tip as this could

distort the spray pattern.

12 307546

RES

C

Fig. 11

Page 13

Spray Pattern Adjustment

Effects of Fluid Temperature and Pressure

This section will help you determine how fluid temperature and pressure affect the spray pattern, and what

adjustment can be made to correct a poor spray

pattern. Since fluid temperature and pressure, and the

nozzle, all affect the spray pattern, experimenting will

help you learn how to control these variables.

Changing the fluid temperature affects viscosity and

reaction time of the fluid. Raising the temperature

reduces the viscosity and produces a wider spray

pattern with finer atomization; it has much the same

effect as raising the fluid pressure.

As the fluid temperature gets too high, the pattern

becomes square with less foam in the center. Too high

a temperature can also cause the chemical reaction to

occur before the foam hits the spraying surface, which

causes an undesirable rough surface.

Observing the Effects of Varying Fluid

Temperature and Pressure

It is helpful to observe the effects of varying the fluid

pressure and temperature. Raising the fluid temperature has about the same affect as raising the fluid

pressure.

1. With fluid temperature set at 115_F (43_C), test

the spray pattern at 300 psi (2.1 MPa, 21 bar).

Increase the pressure in 100 psi (0.7 MPa, 7 bar)

increments up to 1000 psi (7 MPa, 70 bar). In the

lower pressure range, the pattern will be narrow

and coarse. As the pressure is raised, the pattern

becomes wider and finer. When the pressure

becomes too high, the pattern becomes square

and light in the middle.

2. Now, lower the fluid pressure and raise the fluid

temperature in 5_ increments up to 135_. Notice

that the spray pattern is affected much the same

by fluid temperature as it is by fluid pressure.

3. To minimize over spray and fogging, always use

the lowest fluid pressure possible to get the

desired spray pattern.

4. The output pressure of both displacement pumps

should be within 150 psi (1.1 MPa, 10.5 bar) of

each other to keep the viscosity of the ISO and

RES similar. To change the pressure in only one

displacement pump, adjust the temperature.

To raise the fluid pressure, decrease the fluid

temperature.

To lower the fluid pressure, increase the fluid

temperature.

About Surface Texture

The quality of foam developed is reflected in its

surface texture. There are several causes of poor

surface texture, including improper equipment adjustments. Descriptions of surface textures and recommendations on how to adjust the equipment to improve

the texture are on the following pages.

About Poured Foam texture

Poured foam should have no dark or soft spots. The

surface should be relatively smooth with only small

ripples. There should be no blow holes larger than 1/4

in. (6 mm) diameter.

307546 13

Page 14

Surface Texture Descriptions

Smooth Surface Texture

Description

Wavy texture.

Equipment Adjustments

None; has good surface texture.

Orange Peel Texture

Description

Fine texture; like the skin of an orange.

Equipment Adjustments

None; has good surface texture.

Coarse Orange Peel Texture

Description

Surface texture has nodules and valleys of similar size

and shape.

Equipment Adjustments

More flow-out time needed before the rise and cream

time.

Atomized material too coarse. Increase fluid pressure.

If condition persists, increase fluid temperature.

Try holding the gun further away from the spray surface.

Popcorn Surface Texture

Description

Linear surface pattern; forms sharp valleys and overhangs.

Equipment Adjustments

More flow-out time needed before the rise and cream

time.

Slow the foam reaction time by lowering fluid temperature; since this increases the viscosity of the chemicals, the fluid pressure must be raised to maintain

good atomization.

This type of surface pattern can also be caused by

spraying a second lift of foam on top of the first lift

while it is still creaming and rising.

Isocyanate-Rich Surface Texture

Description

Foam is dark in color; does not become tack-free in

the time specified by the chemical manufacturer.

Caused by lack of resin in the foam.

Equipment Adjustments

1. Refill or replace the resin supply.

2. Clean or replace the resin feed pump.

3. Clean the intake filter of the resin proportioning

pump.

4. Clean or repair the resin proportioning pump.

Resin-Rich Surface Texture

Description

Foam has appearance of white shaving cream; does

not become tack-free in the time specified by the

chemical manufacturer. Caused by lack of isocyanate

in the foam.

Equipment Adjustments

1. Refill or replace the isocyanate supply.

2. Clean or replace the isocyanate feed pump.

3. Clean the intake filter of the isocyanate proportioning pump.

4. Resin temperature is too high. Resin is frothing in

the nozzle. Reduce resin temperature.

14 307546

Page 15

Replacing the Needle/Nozzle Assembly

WARNING

PRESSURIZED EQUIPMENT HAZARD

To reduce the risk of serious bodily injury including

fluid injection, splashing in the eyes or on the skin,

follow the Pressure Relief Procedure whenever

you:

D are instructed to relieve the pressure,

D stop spraying,

D check or service any of the system equipment,

D or install or clean the spray nozzle.

1. Have a solvent pail ready to clean the old parts.

2. Solvent flush the gun as instructed in Flushing

steps 1–9 on page 19.

3. Disconnect the solvent manifold.

4. Remove the two capscrews (7) using the 3/16 in.

wrench (48). See Fig. 12. With the air connected

to the gun, hold the gun with the nozzle housing

straight down and briefly trigger the gun to push

the nozzle housing away from the gun body.

Disconnect the air line.

KEY

7 Capscrew

25 Manifold

50 Nut driver

B Safety latch

C Needle valves

Fig. 12

7

25

B

C

50

7

20

5. Tilt the nozzle housing up and disengage the

needle ball from the piston (20) rod. Remove the

housing from the gun. See Fig. 13.

6. Pull the needle out from the rear of the nozzle

assembly. Use the 1/2 in. end of the wrench (53)

to unscrew and remove the nozzle retainer (23).

Remove the air cap (24). Place all parts in the

solvent. Refer to Fig. 5 on page 8.

7. Use your fingers or a soft tool such as pencil

eraser to push on the front of the nozzle (E) and

pop it out the rear of the housing. Place the nozzle

in solvent, being careful to keep it separated from

the other parts to avoid damage. See Fig. 14.

NOTE: If the nozzle impingers holes are blocked, refer

to the section, Cleaning the Nozzle on page 17.

CAUTION

Do not use a sharp tool to remove the nozzle.

Scratches on the edge of the nozzle may distort the

spray pattern. Scratches or nicks on the raised

surfaces prevent the nozzle from sealing properly in

the nozzle housing. An improper seal can result in

fluid crossover which clogs the gun passages.

KEY

20 Piston

Fig. 13

KEY

E Nozzle

Fig. 14

E

307546 15

Page 16

Replacing the Needle/Nozzle Assembly

8. Check the interior surfaces of the nozzle housing

(2). The tapered “steps” inside the nozzle housing

must be free of fluid buildup. Soak the housing in

solvent to soften the foam, then use a soft bristled

brush to gently clean the interior surfaces.

9. Remove the check valve housings (45, 46) and

strainers (34) from the nozzle housing and clean in

solvent. Then reinstall the parts. See page 15.

10. Install the needle/nozzle assembly as instructed in

steps 4–15 on pages 8–10.

11. Reconnect the foam manifold.

46

KEY

2 Nozzle housing

34 Strainer element

45 ISO check valve housing

46 RES check valve housing

Fig. 15

2

34

45

16 307546

Page 17

Cleaning the Nozzle

Foam Spraying Nozzles

Nozzle

Bore Dia.

in. (mm)

0.125 (3.18)

0.114 (2.90)

0.102 (2.54)

0.089 (2.26)

0.073 (1.85)

0.083 (2.11

0.060 (1.52)

Cleaning

Pin Dia.

in. (mm)

0.033 (0.84)

0.029 (0.75)

0.026 (0.66)

0.024 (0.61)

0.018 (0.46)

0.020 (0.51)

0.018 (0.46)

Cleaning Pin

Part No.

106542

106543

106548

106545

106546

106547

106546

Foam Pouring Nozzles

0.187 (4.75)

0.073 (1.85)

1. Solvent flush the gun as instructed in Flushing,

steps 1–9 on page 19. Disconnect the solvent

manifold.

2. Remove the nozzle from the nozzle housing as

instructed on page 15.

3. Insert the correct impinger cleaning pin (H) in the

pin vise (51) so that it protrudes about 1/2 in. (13

mm). Tighten the vise jaws.

0.029 (0.75)

0.020 (0.51)

106543

106547

CAUTION

Each needle/nozzle kit has a specially-sized impinger

cleaning pin (H). Be sure to use the correct pin to

avoid damaging the nozzle. Refer to the tables

above.

4. Clean the rear impinger holes (M) of the nozzle

(E) first. From the tip end of the nozzle, look

through the nozzle while inserting the cleaning pin

(H) into the rear impinger holes. See Fig. 16.

5. Insert the needle (D) through the large end of the

nozzle and push out any debris.

6. Repeat Steps 4 and 5 to be sure the rear impinger

holes are clean.

KEY

51 Pin vise

D Needle

E Nozzle

H Cleaning pin

M Rear impinger holes

N Front impinger holes

51

H

N

M

E

D

Fig. 16

7. Now clean the front impinger holes (N). On the

spray nozzles these impinger holes are not on the

centerline of the nozzle, but are just off center. On

pour nozzles these holes are on the centerline. It is

important that the pin be inserted at the same

angle that the impinger hole is bored in order to

clean it properly.

Look through the nozzle from the tip end. Insert the pin

(H), pushing it through the impinger hole and into the

center of the nozzle. But do not push the pin all the

way through which will scratch the interior of the

nozzle. See Fig. 16.

The rear impinger holes are directly on the centerline

of the nozzle. Push the pin through the impinger hole

and into the middle of the nozzle. Don’t push the pin all

the way through or scratch the interior of the nozzle.

Clean each of the rear holes.

8. Insert the needle (D) through the large end of the

nozzle and push out any debris.

9. Repeat Steps 7 and 8 to be sure the impinger

holes are clean.

307546 17

Page 18

Maintenance

WARNING

PRESSURIZED EQUIPMENT HAZARD

To reduce the risk of serious bodily injury including

fluid injection, splashing in the eyes or on the skin,

follow the Pressure Relief Procedure whenever

you:

D are instructed to relieve the pressure,

D stop spraying,

D check or service any of the system equipment,

D or install or clean the spray nozzle.

Fluid Buildup on Nozzle

A build up of fluid on the nozzle and under the air cap

can cause an irregular spray pattern. If that happens,

follow the Pressure Relief Procedure on page 11.

Then thoroughly clean the air cap and nozzle. Be sure

that the cleanoff air is properly adjusted, also.

Fluid Buildup on Needle

If build up of fluid causes the needle (D) to stick, use

the 1/4 in. open end wrench (52) on the hex of the

needle and rotate to free it.

KEY

43 Needle shield

50 Nut driver

B Safety latch

C Needle valves

C

50

Fig. 17

43

Keeping the Gun Clean While Spraying

Coat it with grease or cover it with a plastic bag. Be

sure the plastic shield (43) is in place around the

exposed area of the needle. See Fig. 17.

A dirty needle can be cleaned by buffing it lightly with

bronze wool or very fine steel wool.

Cleaning the Fluid Manifold

B

Clean the manifold with solvent and a brush whenever

it is removed from the gun to keep fluid from hardening

on it.

Shutdown

WARNING

To reduce the risk of serious bodily injury from fluid

injection or splashing fluid in the eyes or on the

skin, engage the trigger safety latch (B) and close

the needle valves (C) whenever you stop spraying.

See Fig. 2, page 7.

For overnight shutdown:

1. Follow the Pressure Relief Procedure on page

11, and Flushing, steps 1–9 on page 19.

2. Disconnect the solvent manifold and store the gun.

18 307546

Page 19

Flushing

WARNING

PRESSURIZED EQUIPMENT HAZARD

To reduce the risk of serious bodily injury including

fluid injection, splashing in the eyes or on the skin,

follow the Pressure Relief Procedure whenever

you:

D are instructed to relieve the pressure,

D stop spraying,

D check or service any of the system equipment,

D or install or clean the spray nozzle.

CAUTION

Thorough flushing of the nozzle and nozzle housing

is essential each day to reduce fluid buildup which

will quickly ruin the nozzle.

KEY

C Needle valves

R Ground wire and clamp

C

R

Fig. 18

4. Use the lowest possible pressure and hold the gun

firmly to a grounded metal pail when flushing. See

Fig. 18.

5. Flush the gun for 10 seconds.

6. Engage the trigger safety latch.

Graco recommends using a power flushing method,

such as the Solvent Power Flush Kit, Part No.

218669. If you use this kit, refer to instruction manual

307692 for specific flushing procedure.

Use this flushing procedure when a Graco Solvent

Flush Kit is not available.

1. Remove the foam manifold capscrew (7) using the

3/16 in. wrench (68), then disconnect the manifold.

See Fig. 4, page 8.

2. Connect a solvent manifold to the gun; tighten the

capscrew.

3. Open the needle valves (C).

WARNING

7. Turn off the solvent system.

8. Follow the Pressure Relief Procedure on page

11.

46

KEY

34 Strainer element

45 ISO check valve housing

46 RES check valve housing

Fig. 19

9. Remove and clean the check valve housings (45

and 46) and strainers (34) in solvent. See Fig. 19.

10. Remove the solvent manifold and reconnect the

foam manifold.

NOTE: Whenever the foam manifold is removed, clean

it with solvent and a brush.

34

45

To reduce the risk of static sparking which could

result in fire or explosion and serious bodily injury

and property damage:

D Be sure all equipment used in the flushing

operation is properly grounded.

D Never flush gun while standing on or near a

surface where foam has been applied.

CAUTION

Use a solvent which is compatible with the check

valve o-rings. See page 7.

Never immerse the entire gun in solvent.

These steps help prevent damage to the gun o-rings

and seals.

307546 19

Page 20

Troubleshooting

WARNING

To reduce the risk of serious injury, whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 11.

D Relieve the pressure before checking or servicing

the equipment.

D Check all possible problems and causes before

disassembling the pump.

Problem

Coarse atomization Fluid temperature too low. Increase temperature.

Fingering in spray pattern Fluid temperature too low. Increase temperature; use smaller

Square spray pattern with hollow

center

Triangular spray pattern with hollow center

Round spray pattern with hollow

center

Middle of spray pattern dense

Air valve leaks O-rings exposed to solvent. Replace o-rings. See page 24. Do not

Split spray pattern Nozzle impinger hole blocked. Clean nozzle. See page 17.

Distorted, irregular spray pattern Too much cleanoff air. Reduce air. See page 12.

Light-colored foam Too little ISO.

Dark-colored foam Too little RES.

Cause Solution

nozzle.

Fluid temperature too high or fluid

pressure too high.

Fluid temperature too high and a

nozzle impinger hole blocked.

Too much fluid flow. Reduce fluid pressure or tempera-

Fluid buildup on walls of impinger

holes.

Too little fluid flow. Increase fluid flow and/or tempera-

ISO check valve screen blocked. Remove check valve and clean

Decrease temperature and/or reduce

fluid pressure.

Decrease temperature; clean nozzle.

See page 17.

ture.

Clean nozzle. See page 17.

ture.

strainer. See step 9, page 16.

immerse gun in solvent.

Check and clean check valve strainers. See step 9, page 16.

Check and clean proportioning pump

filter screens.

Check and refill ISO fluid supply.

Check proportioning pump ratios.

Check and clean check valve strain-

ers. See step 9, page 16.

Check and clean proportioning pump

filter screens.

Check and refill ISO fluid supply.

Check proportioning pump ratios.

20 307546

Page 21

Troubleshooting

Problem Cause Solution

Gun operates slowly when triggered

Needle won’t pull back when gun

is triggered

Inbound air pressure too low. Increase air, but do not exceed 120

psi (0.8 MPa, 8 bar), since damage to

air valve o-rings may result.

Air valve leaking air. Check for worn, damaged, or over-

compressed o-rings on valve spool

and repair as needed. See pages 24.

Center spacer (12) of air valve compressed.

Air leaking past piston at rear of gun. Check piston o-rings and replace as

Blocked air passages. Check air passages for dried fluid

Foam over spray built up on needle. Clean. See page 18.

Inbound air pressure too low. Increase air, but do not exceed 120

Needle stuck in nozzle. Use 1/4 in. open end wrench to rotate

Piston o-ring (40) damaged, causing

imbalance of pressure between front

and rear chambers.

Check; replace if compressed. See

pages 24.

needed. See page 23.

foam and/or broken o-ring pieces;

clean as needed.

psi (0.8 MPa, 8 bar), since damage to

the air valve o-rings may result.

hex of needle to free. Clean. See

page 18. Check and clean or replace

nozzle.

Check; repair. See page 23.

307546 21

Page 22

WARNING

Service

9. Continue screwing the stem into the housing (28)

all the way to the shoulder.

Follow the Pressure Relief Procedure on page

11, then disconnect the gun from the manifold

before proceeding.

Needle Valves

NOTE: Repair Kit 217360 is available. See page 28.

1. Open the needle valves (C) completely – 3 1/2

turns.

2. Use a wrench (A) to unscrew the valve housing

(28). Refer to Fig. 20.

3. Hold the valve housing with a wrench (A). Turn the

(50) clockwise to free the needle valve stem (29).

See Fig. 21.

4. Use a pick to remove the backup washer (31) and

o-ring (17). See Fig. 22.

5. If needed, soak the valve housing (28) in solvent to

remove fluid buildup.

10. Screw the housing into the manifold (26). Don’t

exceed 80 in-lb (9 NSm) of torque.

11. Finish screwing the stem in gently – it doesn’t

require much torque.

KEY

28 Valve housing

C Needle valve

28

C

Fig. 20

KEY

29 Stem &

seal assembly

50 Nut driver

A Wrench

50

A

29

Fig. 21

6. Install the backup washer (31) on the stem and

screw the stem into the valve housing (28) to

“size” the washer. Unscrew the stem.

7. Install the o-ring (17) on the stem. See Fig. 22.

8. Holding the valve housing, screw the stem

assembly into it. It will require a couple of turns

before it starts to engage in the housing far

enough to use the nut driver.

KEY

17 O-ring

26 Manifold

28 Housing

29 Stem &

seal assembly

31 Backup washer

Fig. 22

26

29

17

31

28

22 307546

Page 23

WARNING

Service

4. Clean all parts thoroughly, replacing parts as

needed, and then reassemble.

Follow the Pressure Relief Procedure on page 11

before proceeding.

Piston (See Fig. 23)

1. Relieve pressure.

2. Remove the nozzle housing assembly as

instructed in Replacing the Needle/Nozzle As-

sembly on page 15.

3. Remove the cylinder cap (21), o-ring (39), spring

(15) and piston (20).

4. If fluid crossover has occurred, remove the bearing

(22) to clean the piston passage as follows: insert

the large end of the accessory pressing tool (P)

through the front end of the gun and press out the

piston rod bearing (22).

5. Replace the o-ring (41), then reinstall the bearing,

if it was removed, through the rear of the gun. Use

the small end of the pressing tool (P) to press it

into place.

KEY

15 Spring

20 Piston

21 Cylinder cap

22 Bearing

39 O-ring

40 O-ring

41 O-ring

P Pressing tool

40

41

22

Fig. 23

46

21

39

15

20

P

6. If the o-ring (40) around the piston shows signs of

wear or damage, replace it. Then reinstall the

piston, spring, o-ring and cylinder cap.

NOTE: The cylinder cap should fit snugly against the

rear of the gun.

Check Valve (See Fig. 24)

1. Relieve pressure.

2. Unscrew the check valve housings (45, 46).

3. If the check valve assembly (61) cannot be

removed easily, insert a pick (such as a dentist’s

pick) into the slot in the check valve housing and

push the seat (36) out of the housing.

KEY

34 Strainer

45 RES Check Valve Housing

46 ISO Check Valve Housing

61 Check Valve Assembly

Fig. 24

34

61

45

307546 23

Page 24

Service

Air Valve (See Fig. 25)

1. Relieve pressure.

2. Remove the nozzle housing assembly as

instructed in Replacing the Needle/Nozzle As-

sembly on page 15.

3. Use the 1/2 in. end of wrench (53) on the flats of

the stem guide (10) to unscrew it.

4. Use your fingers to pull out the valve pin (13).

5. To remove the valve spool (14) and spring (16) tilt

the gun forward and tap the gun against your

hand. The spring is very small – be careful not to

lose it.

NOTE: Use the accessory air valve hook (O) to pull

out the air valve spacers (11,12). To use it, insert the

hook into the valve, hook one of the holes in the

spacer and pull it out.

6. Use the hook (O) to pull the first spacer (11A) out

just 3/32 in. (2.8 mm). Push the spacer back into

the valve and remove the tool. This action will free

the first o-ring (18A). Use the hook to remove the

o-ring.

7. Insert the hook (O) again and remove the first

spacer. Notice the direction this spacer faces.

8. Remove the next o-ring (18B) with the hook.

9. Remove the next spacer (12) by shaking it out or

using the hook if it is stuck.

10. Remove the next o-ring (18C) with the hook.

11. Remove the last spacer (11B) by shaking it out or

using the hook if it is stuck. Again, notice the

direction the spacer faces.

12. Use the hook to remove the last o-ring (18D).

13. If foam has backed up into the air valve cavity,

remove the two setscrews (6, 33) on either side of

the valve cavity and clean the holes with a soft

wooden stick. Never use power tools!

14. Reassemble the air valve using all new o-rings

which have been lubricated with lithium grease.

Use the eraser end of a pencil to guide the o-rings

into the cavity and make sure they seat flatly.

15. Install the first o-ring (18D) and then a spacer

(11B) with the small diameter facing out.

CAUTION

The direction the first and last spacer face out is

critical. Although they are identical spacers, the small

diameters must face each other. See Fig. 24.

16. Install the next o-ring (18C), the U-shaped spacer

(12), another o-ring (18B), the last spacer – with

the small diameter facing in – and the last o-ring

(18A).

17. Gently screw the stem guide (10) into the valve by

hand. Then use the wrench to just snug the stem;

this will stack the o-rings properly.

24 307546

Page 25

CAUTION

Be careful not to wrench the stem guide (10) too

tightly to avoid damage to the air valve.

18. Remove the stem guide and drop in the new

spring (16), making sure it goes all the way into the

hole in the back of the valve cavity.

KEY

10 Stem guide

11 Spacer

12 U-shaped valve spacer

13 Pin

14 Spool

16 Spring

17 O-ring

18 O-ring

57 O-ring

O Pick

O

18A*

17*

Service

19. Install the valve spool (14) and valve pin (13), then

the stem guide (10). Tighten the stem guide until it

is just snug; don’t overtighten.

20. If the setscrews (6,33) were removed from either

side of the valve cavity, reinstall them using

PTFE tape on the threads.

21. Reinstall the trigger.

18D*

18C*

18B*

16

33

11B

6

Small diameter

Fig. 25

57

10

18

13

11A

12

Small diameter

14

NOTE: DO NOT allow o-ring to seat in grooves with passageways

307546 25

Page 26

Ref 25 Manifold Assy.

Includes items 26–32

and two of item 17.

7

24

58

TAP

INTO

PLACE

29

Parts

NEEDLE/NOZZLE DETAIL

See back cover for ordering.

Items 23 and 43 included

2

23

34

35

36

37

38

44 or 60

45 or 46

27

26

with gun only.

43

NEEDLE

PACKING NUT

PACKING

REF 23

NOZZLE

17

31

28

19

33

32

7

21

39*

15

20

4

PRESS FIT INTO GUN BODY (1)

22

40*

41*

5

1

42

54

6

8

9

THE TOOLS SUPPLIED WITH THE GUN

(ITEMS 47 TO 53) ARE PICTURED ON

P AGE 6.

33

16

18*

3

18*

10

57*

26 307546

13

17*

18*

14

11

6

11

12

Air Valve

Includes items

10 to 14, 16,

three of 17,

3 or 18 and 57

Page 27

Model 217373, Series E

Includes items 1 to 61

Parts

REF

NO. PART NO. DESCRIPTION QTY

1 217459 BODY, gun 1

2 178663 HOUSING, nozzle 1

3 178584 TRIGGER 1

4 178682 PIN, trigger 1

5 203953 CAPSCREW, hex hd;

10–24 x 0.375 in. 1

6 102279 SETSCREW, soc hd;

8–32 x 0.188 in. 1

7 101682 CAPSCREW, soc hd;

1/4–20 x 0.625 in. 3

8n 106552 COUPLER, air line 1

9 100030 BUSHING; 1/8 npt(m) x 1/4 npt(f) 1

10 178654 GUIDE, stem 1

11 178653 SPACER, valve 2

12 178652 SPACER, valve, u-shaped 1

13 178650 PIN, air valve 1

14 178651 SPOOL, valve 1

15 178671 SPRING, compression, piston 1

16 106561 SPRING, compression, air valve 1

17* 106560 O-RING; Vitonr 5

18* 106559 O-RING; Viton 5

19 106538 SETSCREW, soc hd;

10–32 x 0.5 in. 1

20 178649 PISTON 1

21 178648 CAP, cylinder 1

22 178647 BEARING, piston 1

23 178646 RETAINER, nozzle 1

24 178642 CAP, air 1

25 221177 MANIFOLD ASSEMBLY; includes

items 26–32 and two of 17 1

26 183598 .MANIFOLD, fluid 1

27 191872 .ADAPTER;

1/4 npsm(f) x 1/8 npt(m) 2

28 178657 .HOUSING, valve 2

29n 218628 .STEM and SEAL ASSEMBLY 2

31 106558 .WASHER, backup; PTFE 2

32 100139 .PLUG, pipe, hdls; 1/8 npt(f) 2

33 100002 SETSCREW, soc hd;

1/4–20 x 0.25 in. 1

REF

NO. PART NO. DESCRIPTION QTY

34n 178585 ELEMENT, strainer; SST; 80 mesh2

35 178660 STEM, check valve 2

36 178659 SEAT, check valve; Delrinr 2

37 106562 SPRING, compression 1

38 178658 RETAINER, spring 1

39* 106557 O-RING; Viton 1

40* 106556 O-RING; Viton 1

41* 106555 O-RING; Viton 1

42 102817 SCREW, drive 3

43 178586 SHIELD 1

44 110188 O-RING; flourocarbon; brown color;

for methylene chloride solvents 2

45 180964 HOUSING, check valve, ISO 1

46 180965 HOUSING, check valve, RES 1

47 106571 WRENCH, hex; 3/32 in. 1

48 106572 WRENCH, hex; 3/16 in. 1

50 106540 TOOL, nut driver 1

51 106550 VISE, pin 1

52 107015 WRENCH, open end; 1/4 in. 1

53 106539 WRENCH, open end;

7/16 in. x 1/2 in. 1

54 178587 PLATE, warning 1

55Y 178695 TAG, warning (not shown) 1

57* 106551 O-RING; Viton 1

58 179716 GASKET, housing 2

59 218756 O-RING KIT, check valve; includes

items 44 and 60 (not installed) 1

60 110189 .O-RING; silicone; rust colored; for

DMF and Cellosolver solvents 2

61 218627 CHECK VALVE ASSEMBLY;

includes items 35–38 1

* These parts are included in Repair Kit 217360,

which may be purchased separately.

n Keep these spare parts on hand to reduce down

time.

Y Replacement Danger and Warning labels, tags, and

cards are available at no cost.

307546 27

Page 28

Must be purchased separately.

Accessories

Foam Flush Kit 218669

120 psi (0.8 MPa, 8 bar) Maximum Working Pressure

For solvent flushing the Foam-Cat gun.

Air Valve Hook 178583

Essential for removing air valve o-rings and spacers.

Pressing Tool 178581

For servicing piston.

Air Valve Repair Kit 217360

Part No. Description Qty.

106560 O-RING; Viton 3

106559 O-RING; Viton 5

106557 O-RING; Viton 1

106556 O-RING; Viton 1

106555 O-RING; Viton 1

106551 O-RING; Viton 1

28 307546

Page 29

Technical Data

N

Packi

Packi

Category Data

Maximum working pressure 1500 psi (10.5 MPa, 105 bar)

Maximum air working pressure 120 psi (0.8 MPa, 8 bar)

Air inlet sizes 1/4 npt(m) with bushing; 1/8 npt(f) without bushing

Fluid inlet sizes 1/4 npsm(m) with adapter; 1/8 npsm(f) without adapter

Strainer element 80 mesh (177 micron)

Wetted parts Stainless steel, Carbon steel, Brass, PTFE, Viton, Delrin,

Fluorocarbon

Vitonr, and Delrinr are registered trademarks of the DuPont Company.

Nozzle Kit Summary

Needle

1

Kit No.

217420* 0.125 (3.18) 217364 178633 178624 178615 106542 0.033 (0.84)

217421* 0.114 (2.90) 217365 178634 178625 178616 106543 0.029 (0.75)

217423* 0.089 (2.26) 217367 178636 178627 178618 106545 0.024 (0.61)

217424* 0.073 (1.85) 217368 178637 178628 178619 106546 0.018 (0.46)

217425* 0.083 (2.11) 217369 178638 178629 178620 106547 0.020 (0.51)

217426* 0.102 (2.59) 217366 178635 178626 178617 106548 0.026 (0.66)

217428* 0.060 (1.52) 217371 178640 178631 178622 106546 0.018 (0.46)

217427{ 0.187 (4.75) 217370 181515 178630 178621 106543 0.029 (0.75)

220616{ 0.073 (1.85) 217368 183117 178628 178619 106547 0.020 (0.51)

* Use for foam spraying applications.

{ Use for pouring applications.

NOTES:

1

Each kit includes a needle, nozzle, packing, packing nut, and cleaning pin. Each part may be ordered separately or as a kit.

2

Select a nozzle that will not exceed the maximum recommended flow rate of your foam spray system at the desired working

pressure. Too high a flow may exceed the performance capabilities of the foam heater and other spray components, causing

poor foam development and equipment problems.

3

The last three digits of the part no. are stamped on the needle, nozzle, and packing nut to help you identify the size.

Diameter

in. (mm)

Part No.

3

ozzle Part

2, 3

No.

ng

Part No.

ng Nut

Part No.

3

Cleaning Pin

Part No.

Diameter

in. (mm)

307546 29

Page 30

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale by an authorized Graco distributor to the original purchaser for use. With the exception of any special, extended, or limited

warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment

determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations.

This warrant y does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non–Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property , o r a ny

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty , and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor, or call one of the following numbers

to identify the distributor closest to you:

1–800–367–4023 Toll Free

612–623–6921

612–378–3505 Fax

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

International Offices: Belgium, Korea, Hong Kong, Japan

PRINTED IN USA 307546 05/1982, Revised 04/2002

30 307546

Sales Offices: Minneapolis, Detroit

www.graco.com

Loading...

Loading...