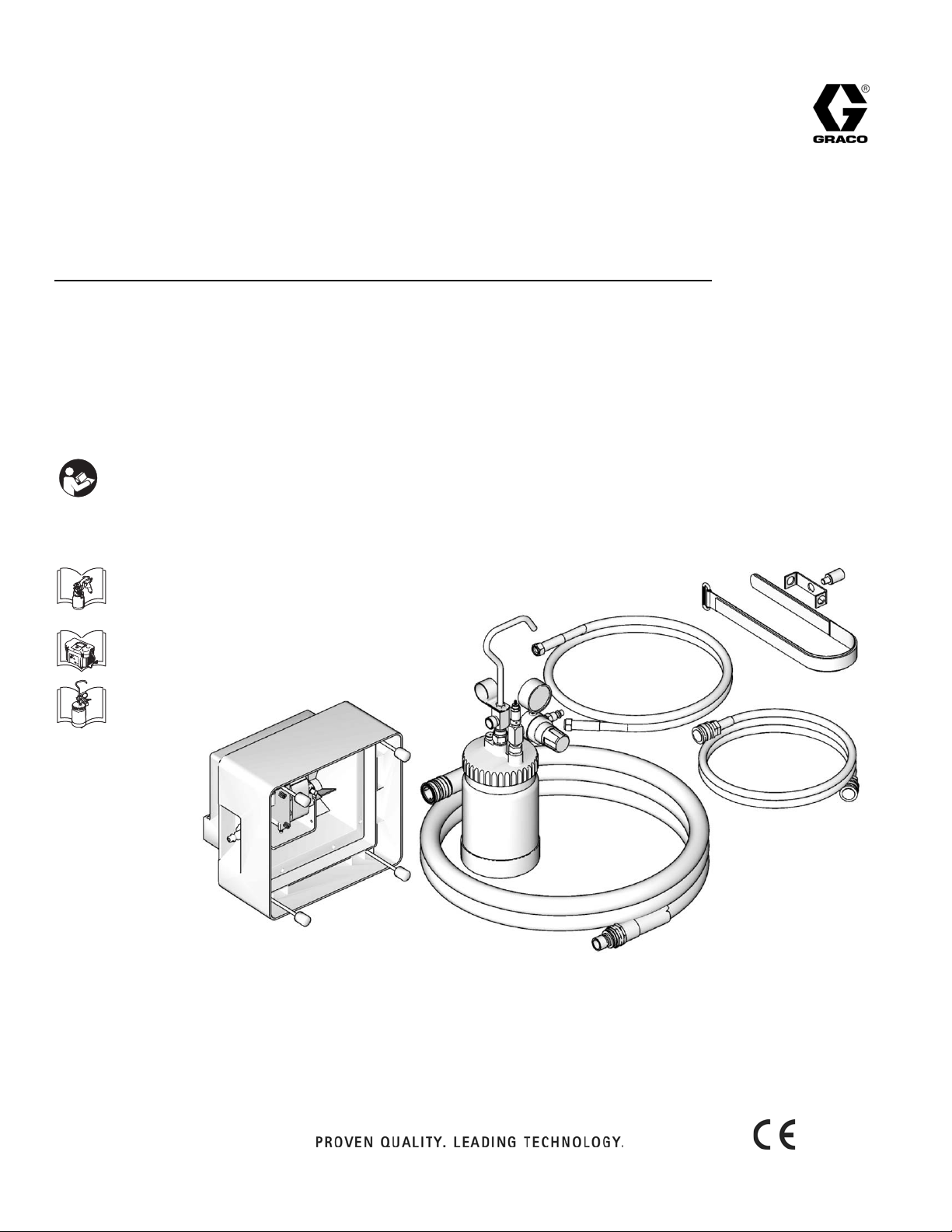

Graco FinishPro CompPack Series, FinishPro CompPack 256850, FinishPro CompPack 25A445, FinishPro CompPack 256854 Repair Manual

Page 1

Repair

ti12757a

FinishPro CompPack Compressor

- For portable spray applications of fine finish coatings -

120 Vac Model: 256850

240 Vac Model: 256854, 25A445

Maximum Working Pressure: 10 psi (0,07 MPa, 0.7 bar)

Important Safety Instructions

Read all warnings and instructions in the sprayer

manual, 313406. Save these instructions.

313440E

EN

313317

313406

313441

Page 2

Setup

18

17

20

21

ti13061a

35

A

105

17

20

21

35

ti12857a

ti12798a

A

B

C

ti13082a

ti12797a

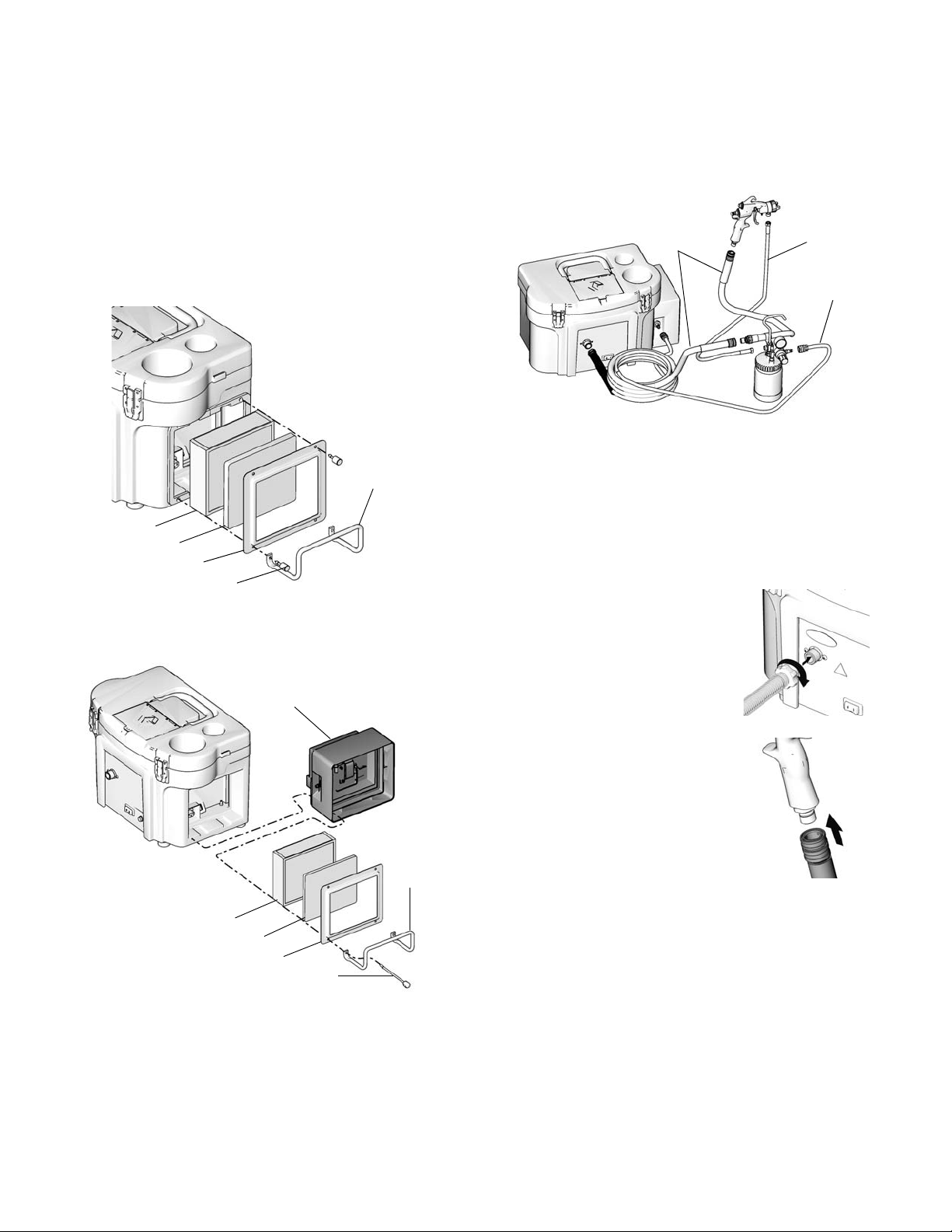

Setup

CompPack Installation

For references (1) - (99), see Parts, manual 313406. For

reference numbers(101) - (199) see Parts, page 7.

1. Turn off and unplug sprayer.

2. Loosen four screws (18), remove hose wrap (35), fil

ter retainer (17), pre-filter (20) and main filter (21).

4. Install main filter (21), pre-filter (20), filter retainer (17)

and hose wrap (35) with four screws (105).

Spray Gun with Optional Remote Cup

The optional remote cup comes with two hoses.

1. Connect the short hoses to their matching long

sprayer hoses.

2. Convert spray gun from siphon cup operation to

remote cup operation. See Convert Gun from

Siphon Cup to Optional Remote Cup.

3. Install CompPack (A) on sprayer.

3. Connect air hose (A) to sprayer.

Hand tighten. Do not connect

whip hose direct to sprayer.

Connect whip hose to gun end of

hose only.

4. Connect air hose (A) from

sprayer to inlet fitting of spray gun.

5. Connect air hose (B) between

CompPack outlet and remote cup

air inlet.

2 313440E

Page 3

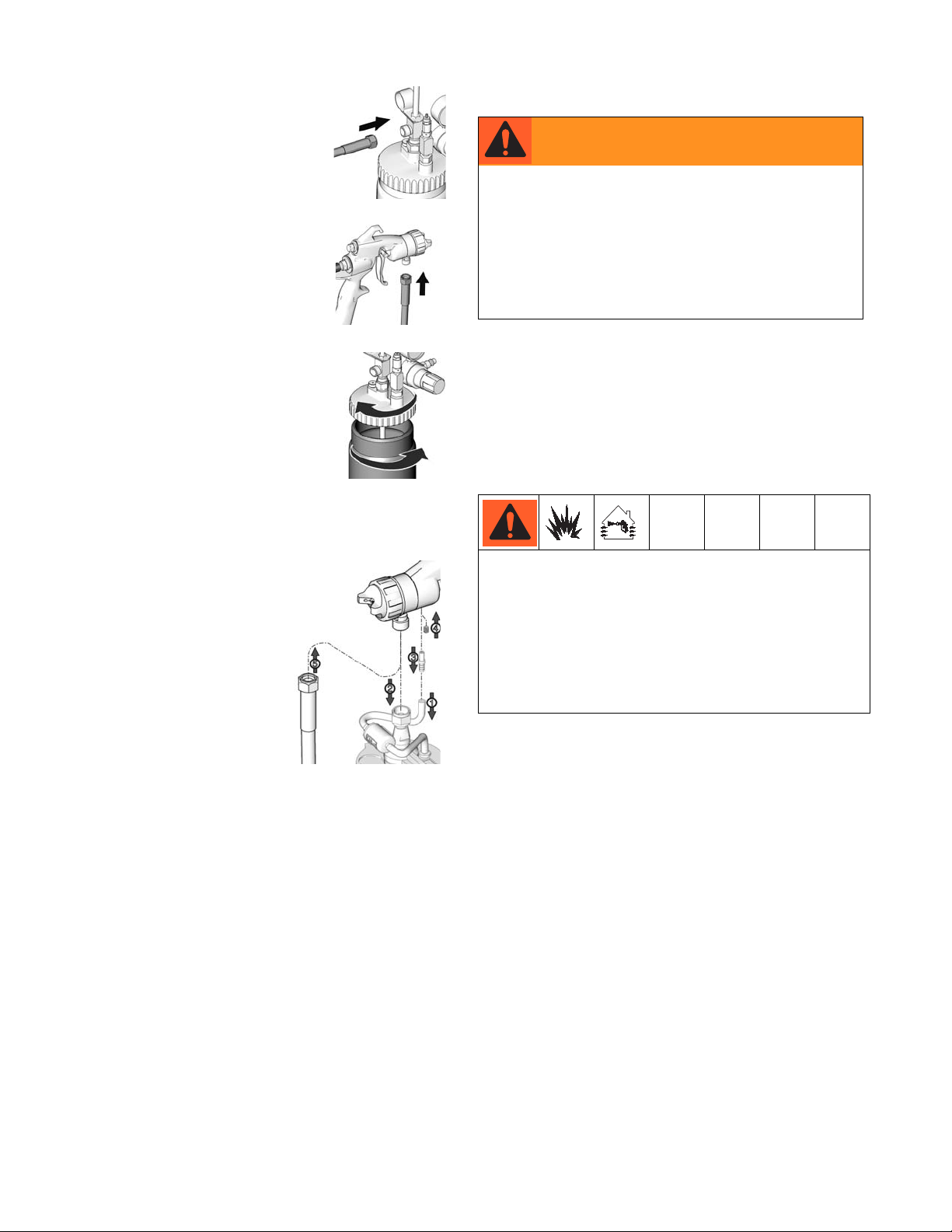

Setup

ti13151a

ti13149a

ti13152a

ti12915a

6. Connect fluid supply hose (C) from

remote cup fluid outlet to spray

gun fluid inlet.

7. Fill cup 3/4 full. Install cover.

Screw remote cup cover to secure

it to remote cup.

8. Refer to spray gun manual 313317

for spraying instructions.

Convert Gun from Siphon Cup to Optional

Remote Cup

Pressure Relief Procedure

WARNING

The optional remote cup remains pressurized

until pressure is manually relieved. To reduce

the risk of serious injury from pressurized fluid

or accidental spray from gun, always relieve

pressure in the remote cup before loosening

or removing the cover. Also, relieve pressure

if the fluid nozzle clogs; and before cleaning,

checking or servicing equipment.

1. Turn off sprayer.

2. Unplug sprayer.

3. Turn out pressure relief knob (113) one turn. Wait

until pressure is completely relieved before removing

cover. Close knob.

Operation Tips

1. Remove air pressure tube

from air stem.

2. Remove siphon cup cover

from gun

3. Remove air stem from gun.

4. Apply medium strength

thread locker to set screw.

Install set screw into gun

flush with gun body.

5. Connect fluid supply hose.

Note: To convert from remote cup to siphon cup, reverse

these instructions.

Connect to Electric Supply

Plug sprayer power cord into grounded o utlet. Grou ndin g

and Electric Requirements, page 4, manual 313406.

Sparks can be expected during normal operation of

motor. These sparks can ignite fumes from flammable

liquids, dust particles, and other flammable sub

stances in the spray area.

• Use additional hose if necessary, and ensure the

sprayer is operated in clean, dry, well ventilated

area.

• Never use sprayer inside spray booth.

• Turn sprayer On a few minutes before spraying to

allow warm-up.

• Ensure sprayer filter is clean before operating. Clean

filter, page 7, manual 313406.

• To adjust spray gun pattern, see HVLP EDGE Gun

manual 313317.

• To get proper adhesion, ensure surface is completely

clean.

• If the remote cup is accidentally tipped over or held at

too great of an angle, fluid may leak into air regulator

and cause damage. Take precautions to avoid this. If

fluid does get into regulator, clean immediately.

• Only hand-tighten remote cup cover. Excessive tight

ening may damage cover gasket.

• Always spray with the least amount of pressure

required to provide the desired spray p attern and rate

of application, typically 10 psi. Spraying at pressures

higher than necessary wastes paint and can result in

an orange peel finish.

• Lightly coat cover threads with petroleum jelly.

313440E 3

Page 4

Repair

A

105

17

20

21

35

ti12857a

107

104

112

111

109

102

B

Repair

Compressor Removal

For references (1) - (99), see Parts, manual 313406. For

reference numbers(101) - (199) see Parts, page 7.

To avoid injury, including electric shock turn off

sprayer and unplug power cord befor e performing any

repair procedures.

1. Remove four thumbscrews (105) hose wrap (35),

remove filter retainer (17), prefilter (20), main filter

(16) and filter gaskets (19).

2. Remove CompPack Compressor (A).

4. Disconnect three spade connectors (B) from back of

inlet plug (102).

5. Remove three screws (104) from compressor box

(112) and remove compressor (111).

3. Remove air tube (107) from quick connector (109)

barb fitting.

Compressor Installation

1. Install compressor (111) in compressor box (112)

with three screws (104).

2. Connect three spade connectors (B) to back of inlet

plug (102).

3. Install air tube (107) on quick connector (109) barb fit

ting.

4. Install CompPack Compressor (A).

5. Install main filter (21), pre-filter (20), filter retainer (17)

and hose wrap (35) with four screws (105).

4 313440E

Page 5

Wiring Diagram

BK

W

G

ti13144a

Wiring Diagram

Technical Data

120 Vac, 60 Hz

Weight lb

Ampere Watts

CompPack

230 Vac, 50 Hz

CompPack

* Sound Power and Sound Pressure are measured at 1 meter per ISO 3744.

1.5 80 5 (2,7) 79.2 dBa 67.2 dBa

Ampere Watts

0,8 80 5 (2,7) 79.2 dBa 67.2 dBa

(kg)

Weight lb

(kg)

Sound

Power*

Sound

Power*

Sound

Pressure*

Sound

Pressure*

313440E 5

Page 6

Parts Drawing

ti12908b

102

101

103

104

Models: 256850, 256854

Parts Drawing

Parts List

Models: 256850, 256854

Ref Part Description Qty

101 15Y858 KIT, compressor box HVLP, 120V 1

102 257098 KIT CUP, 1 qt complete 1

103 240488 COMPRESSOR, hose 1

104 256959 STRAP, remote, cup 1

6 313440E

15Y859 KIT, compressor box HVLP, 240V 1

Page 7

Parts Drawing

103

110

109

107

106

105

102

101

108

ti27709a

Models: 25A445

Parts Drawing

Parts List

Models: 25A445

Ref Part Description Qty

101 15Y859 KIT, compressor 1

102 24Y630 GUN, HVLP, no cup 1

103 240475 HOSE, fluid 1

104 25A433 KIT, repair, 1 qt cup 1

105 17J918 HOSE, air 1

106 17H702 HOSE, air 1

107 257161 HOSE, whip 1

108 114958 STRAP, tie 11

109 240065 VALVE, air control 1

110 M70402 FITTING, female, Q.D. 1

313440E 7

Page 8

Graco Standard Warranty

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in material

and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by

Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non-Graco

component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with structures,

accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or maintenance of structures,

accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of the

claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned to the

original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will be made

at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to the

warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or the

furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the negligence of

Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite de

ou en rapport, directement ou indirectement, avec les procédures concernées.

ADDITIONAL WARRANTY COVERAGE

Graco does provide extended warranty and wear warranty for products described in the “Graco Contractor Equipment Warranty Program”.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2009 Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

8 313440E

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 313440

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised E, November 2015

Loading...

Loading...