Page 1

Instructions - Parts List

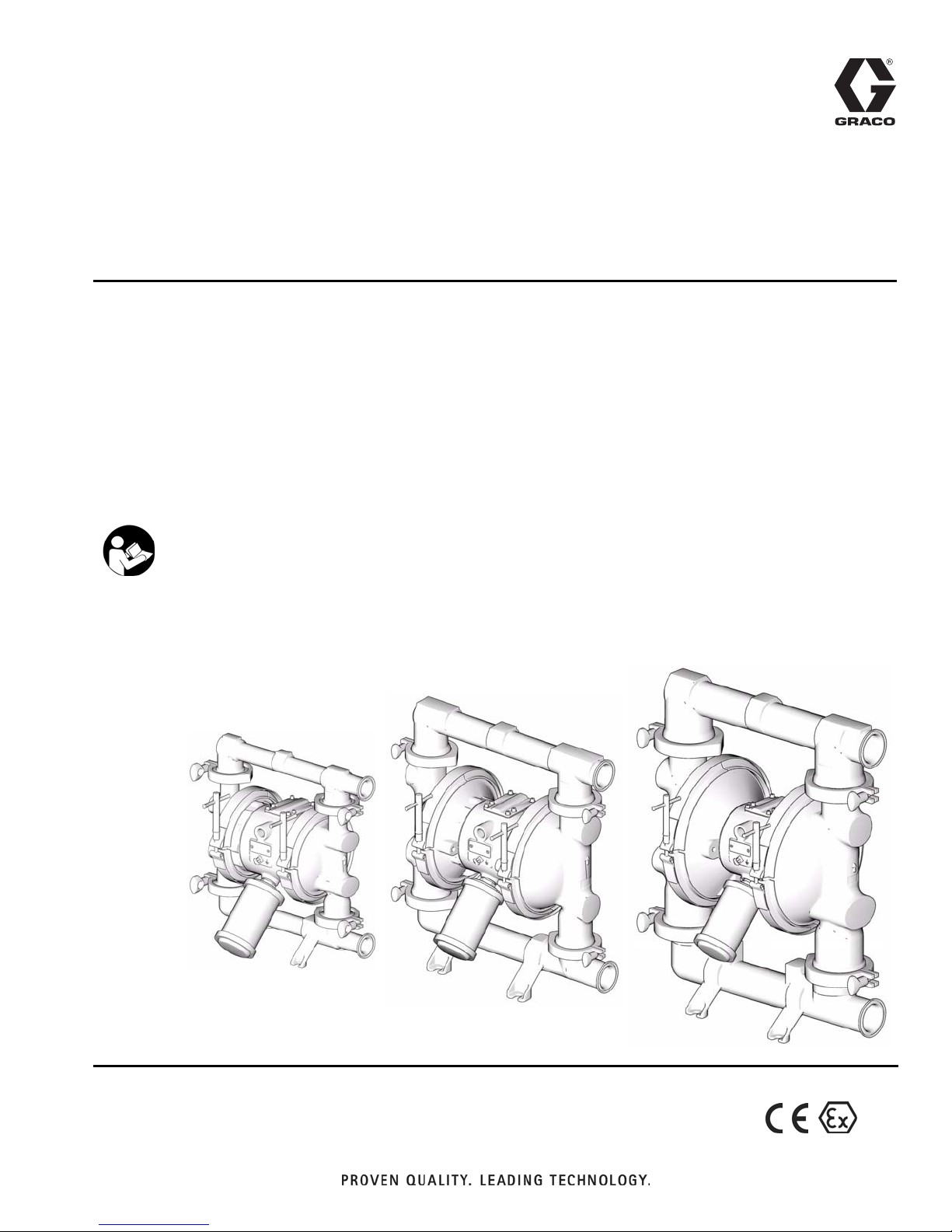

Sanitary Series

FDA-Compliant

Diaphragm Pumps

For use in sanitary applications.

Model FD1___ 1040 FDA

Model FD2___ 1590 FDA

Model FD3___ 2150 FDA

120 psi (0.8 MPa, 8 bar) Maximum Air/Fluid Working Pressure

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

Refer to the appropriate Pump Matrix on page 26, 34, or 42 to

determine the model number of your pump.

311879F

Model 1040

TI8924a

Model 1590

TI8926a

Model 2150

TI8928a

II 2 G

Page 2

Contents

Certificate of Conformance . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Pump Matrix - 1040 . . . . . . . . . . . . . . . . . . . . . . . . 26

Available Configurations . . . . . . . . . . . . . . . . . . 26

Repair Kit Matrix - 1040 . . . . . . . . . . . . . . . . . . . . . 27

Available Configurations . . . . . . . . . . . . . . . . . . 27

Parts - 1040 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Dimensional Drawing - 1040 . . . . . . . . . . . . . . . . . 31

Technical Data - 1040 . . . . . . . . . . . . . . . . . . . . . . 32

Performance Chart - 1040 . . . . . . . . . . . . . . . . . . . 33

Pump Matrix - 1590 . . . . . . . . . . . . . . . . . . . . . . . . 34

Available Configurations . . . . . . . . . . . . . . . . . . 34

Repair Kit Matrix - 1590 . . . . . . . . . . . . . . . . . . . . . 35

Available Configurations . . . . . . . . . . . . . . . . . . 35

Parts - 1590 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Dimensional Drawing - 1590 . . . . . . . . . . . . . . . . . 39

Technical Data - 1590 . . . . . . . . . . . . . . . . . . . . . . . 40

Performance Chart - 1590 . . . . . . . . . . . . . . . . . . . 41

Pump Matrix - 2150 . . . . . . . . . . . . . . . . . . . . . . . . 42

Available Configurations . . . . . . . . . . . . . . . . . . 42

Repair Kit Matrix - 2150 . . . . . . . . . . . . . . . . . . . . . 43

Available Configurations . . . . . . . . . . . . . . . . . . 43

Parts - 2150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Dimensional Drawing - 2150 . . . . . . . . . . . . . . . . . 47

Technical Data - 2150 . . . . . . . . . . . . . . . . . . . . . . . 48

Performance Chart - 2150 . . . . . . . . . . . . . . . . . . . 49

Graco Warranties . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 50

2 311879F

Page 3

Certificate of Conformance

Part Number: All FD1, FD2, FD3 models

Description: FDA-Compliant Diaphragm Pump

Certificate of Conformance

Materials of

Construction: All fluid contacted materials are FDA-

compliant and meet CFR Title 21,

Section 177.

Bradley A. Byron

QMS Management Representative

Graco Inc.

311879F 3

Page 4

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

Warning

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground equipment and conductive objects in work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and

cause serious injury.

• Follow Pressure Relief Procedure in this manual, when you stop operating and before cleaning,

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine Graco

replacement parts only.

• Do not alter or modify equipment.

• For professional use only.

• Use equipment only for its intended purpose. Call your Graco distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not use hoses to pull equipment.

• Comply with all applicable safety regulations.

BURN HAZARD

Equipment surfaces and fluids that are heated can become very hot during operation. To avoid severe

burns, do not touch hot fluid or equipment. Wait until equipment/fluid has cooled completely.

4 311879F

Page 5

Warning

Warning

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

311879F 5

Page 6

Installation

Installation

General Information

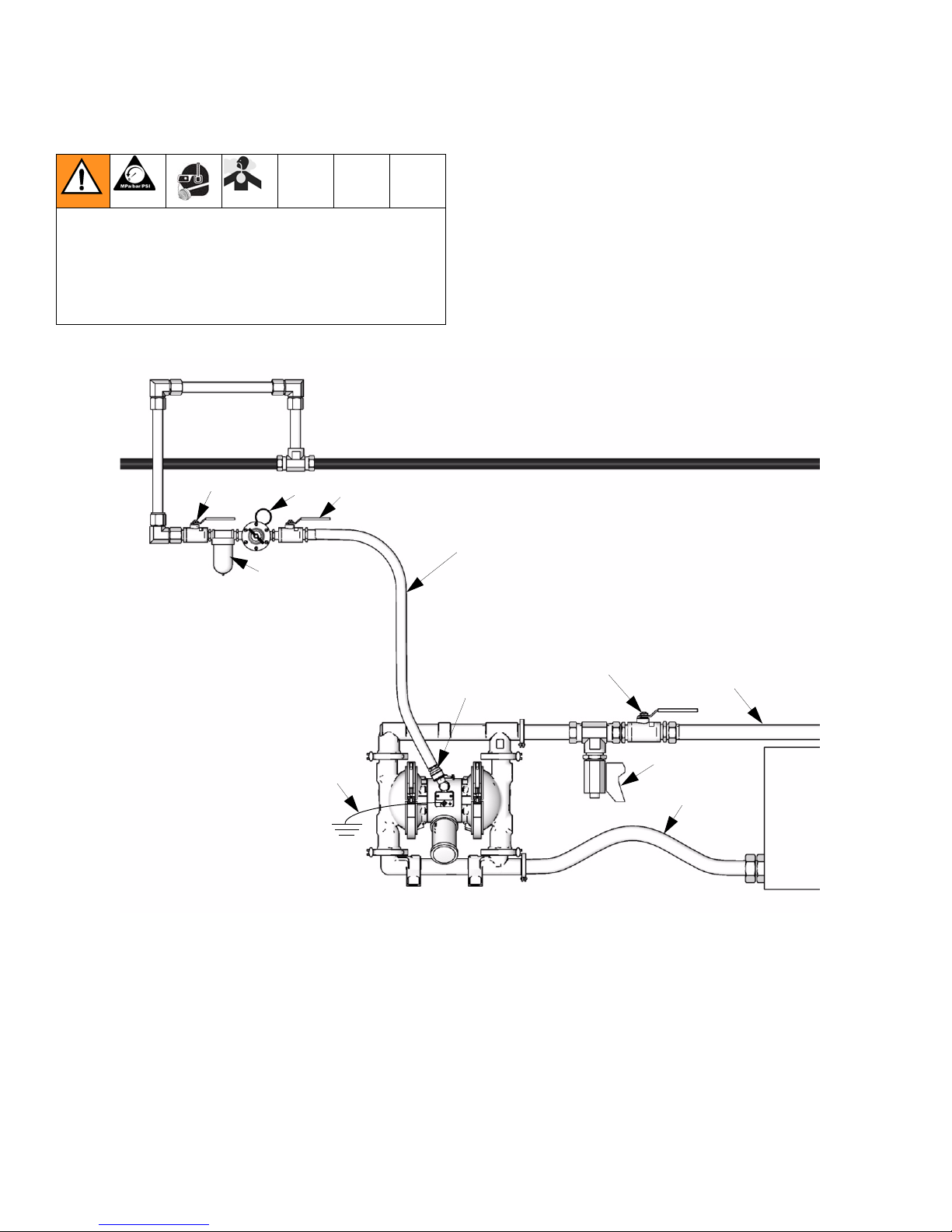

• The typical installations shown in Figs. 2-4 are only

guides for selecting and installing system components. Contact your Graco distributor for assistance

in planning a system to suit your needs.

• Always use genuine Graco parts and accessories.

• Reference numbers and letters in parentheses refer

to the callouts in the figures and the parts lists on

pages 28-30, 36-38, and 44-46.

The pump is very heavy (see Technical Data on pages

32, 40, and 48 for specific weights). If the pump must

be moved, follow the pressure relief procedure on

page 11 and have two people to lift the pump by grasping the outlet manifold securely or use appropriate lifting equipment.

Grounding

To reduce the risk of static sparking, ground the pump

and all other equipment used or located in the pumping

area. Check your local electrical code for detailed

grounding instructions for your area and type of equipment.

Read the FIRE AND EXPLOSION HAZARD warnings

on page 4.

• Pump: Connect a ground wire and clamp as shown

in Fig. 1. Loosen the grounding screw (W). Insert

one end of a 12 ga (1.5 mm²) minimum ground wire

(Y) behind the grounding screw and tighten the

screw securely. Connect the clamp end of the

ground wire to a true earth ground. Order Part No.

222011 Ground Wire and Clamp.

Y

Read the TOXIC FLUID OR FUMES HAZARD warn-

ings on page 5.

Read the BURN HAZARD warnings on page 4. To

reduce the risk of serious injury due to burns, insulate

and/or label the pump before pumping fluids above

110°F (43°C).

Tightening Clamps Before First Use

After you unpack the pump, and before you use it for the

first time, check all clamps, and tighten as necessary.

F

W

IG. 1

"

• Fluid hoses: Use only grounded hoses with a maximum of 500 ft. (150 m) combined hose length to

ensure grounding continuity.

• Air compressor: Follow the manufacturer’s recommendations.

• All solvent pails used when flushing: Follow the local

code. Use only metal pails, which are conductive.

Do not place the pail on a non-conductive surface,

such as paper or cardboard, which interrupts the

grounding continuity.

• Fluid supply container: Follow the local code.

6 311879F

Page 7

Mountings

CAUTION

The pump exhaust air may contain contaminants.

Ventilate to a remote area if the contaminants could

affect your fluid supply. See Air Exhaust Ventilation

on page 10.

• Be sure the mounting surface can support the

weight of the pump, hoses, and accessories, as well

as the stress caused during operation.

• For all mountings, be sure the pump is bolted

directly to the mounting surface.

• For ease of operation and service, mount the pump

so the air valve cover (2), air inlet, and fluid inlet and

outlet ports are easily accessible.

Installation

In the step below, do not connect the quick-disconnect

coupler (D) on the air hose to the mating fitting on the

pump until you are ready to operate the pump. Connecting the coupler too early can result in unintentional operation of the pump, leading to serious injury from moving

parts, splashing fluid in the eyes or on the skin, and contact with hazardous fluids.

2. Install a grounded, flexible air hose (A) between the

accessories and the 1/2 npt(f) pump air inlet (N).

See Fig. 5. Use a minimum 3/8 in. (9.5 mm) ID air

hose. Screw an air line quick disconnect coupler (D)

onto the end of the air hose (A), and screw the mating fitting into the pump air inlet snugly.

Fluid Suction Line

Air Line

A bleed-type master air valve (B) is required in the system to relieve air trapped between this valve and the

pump. Trapped air can cause the pump to cycle unexpectedly, which could result in serious injury, including

splashing in the eyes or on the skin, injury from moving

parts, or contamination from hazardous fluids. See F

2.

1. Install the air line accessories as shown in FIG. 2.

Mount these accessories on the wall or on a

bracket. Be sure the air line supplying the accessories is grounded.

a. Install an air regulator (C) and gauge to control

the fluid pressure. The fluid outlet pressure will

be the same as the setting of the air regulator.

b. Locate one bleed-type master air valve (B)

close to the pump and use it to relieve trapped

air. See the WARNING above. Locate the other

master air valve (E) upstream from all air line

accessories and use it to isolate them during

cleaning and repair.

IG.

1. Use flexible, grounded fluid hoses.

2. For best sealing results, use a standard Tri-Clamp®

style sanitary gasket of a flexible material such as

EPDM, Buna-N, fluoroelastomer, or silicon.

3. If the fluid inlet pressure to the pump is more than

25% of the outlet working pressure, the ball check

valves will not close fast enough, resulting in inefficient pump operation.

4. At inlet fluid pressures greater than 15 psi (0.1 MPa,

1 bar), diaphragm life will be shortened.

5. See the Technical Data on pages 32, 40, and 48 for

maximum suction lift (wet and dry).

c. The air line filter (F) removes harmful dirt and

moisture from the compressed air supply.

311879F 7

Page 8

Installation

Fluid Outlet Line

A fluid drain valve (J) is required to relieve pressure in

the hose if it is plugged. The drain valve reduces the

risk of serious injury, including splashing in the eyes or

on the skin, or contamination from hazardous fluids

when relieving pressure. Install the valve close to the

pump fluid outlet. See F

IG. 2.

1. Use flexible grounded fluid hoses (L).

2. For best sealing results, use a standard Tri-Clamp®

style sanitary gasket of a flexible material such as

EPDM, Buna-N, fluoroelastomer, or silicon

3. Install a fluid drain valve (J) near the fluid outlet. See

the WARNING above, and F

IG. 2.

4. Install a shutoff valve (K) in the fluid outlet line.

E

C

F

Key:

A Air supply line

B Bleed-type master air valve

(required for pump)

C Air regulator

D Air line quick disconnect

E Master air valve (for accessories)

F Air line filter

G Flexible fluid suction line

J Fluid drain valve (required)

K Fluid shutoff valve

L Flexible fluid line

Y Ground wire (required; see page

6 for installation instructions)

F

IG. 2 Typical Floor-Mount Installation

B

A

K

D

J

Y

L

G

TI8930a

8 311879F

Page 9

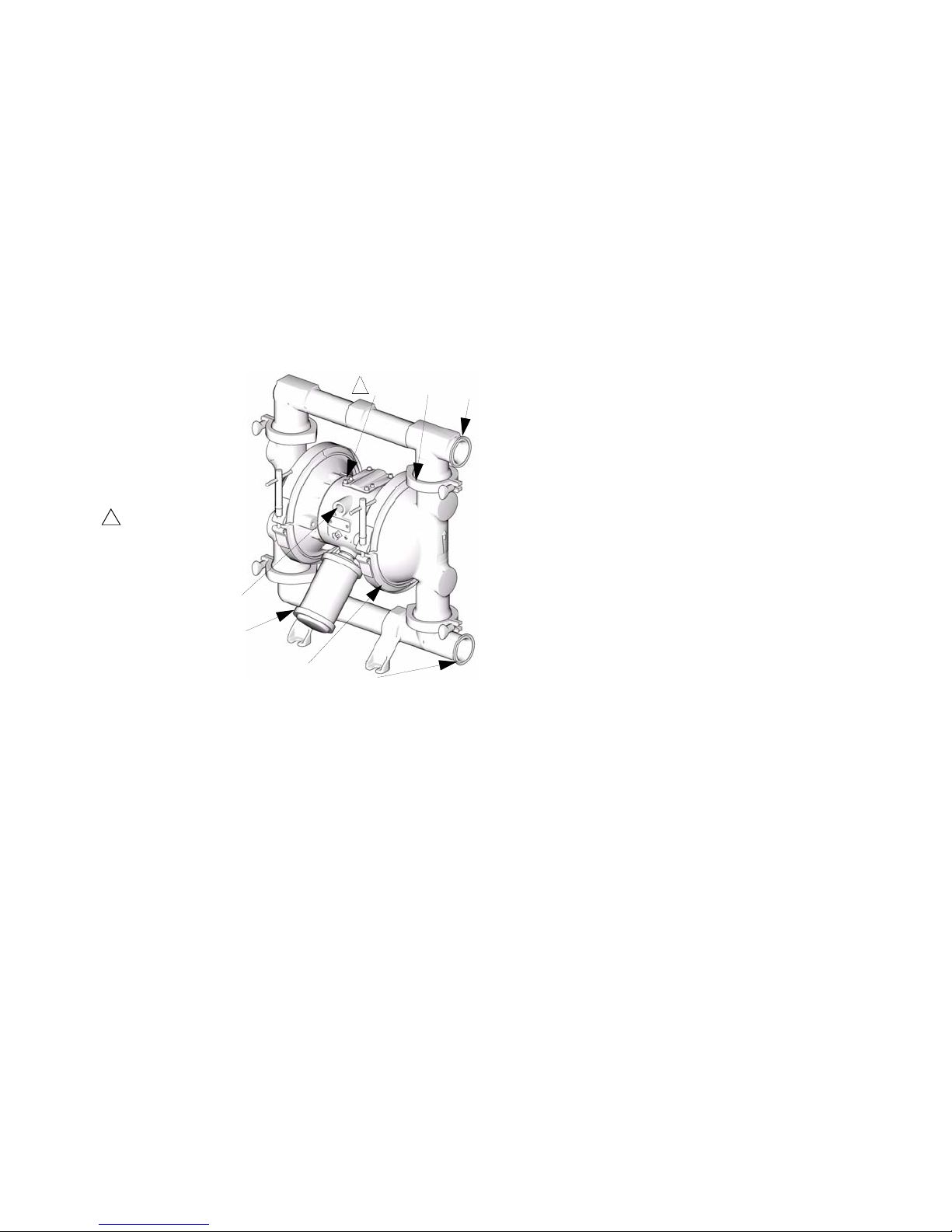

Changing the Orientation of the Fluid Inlet

and Outlet Ports

The pump is shipped with the ports facing the same

direction. To reverse the orientation of the ports:

1. Remove the clamps holding the inlet and/or outlet

manifold to the covers.

2. Reverse the manifold and reattach. Install and

tighten clamps snugly.

Key:

N 1/2 npt(f) air inlet port

P Muffler (air exhaust

port is 3/4 npt(f)

R Fluid inlet port

S Fluid outlet port

113 Manifold clamps

3 Air valve screws

1

3 113

Installation

S

1

Torque to

28-30 in-lb

(3.2-3.7 N•m)

F

IG. 3

N

P

106

R

TI8926a

311879F 9

Page 10

Installation

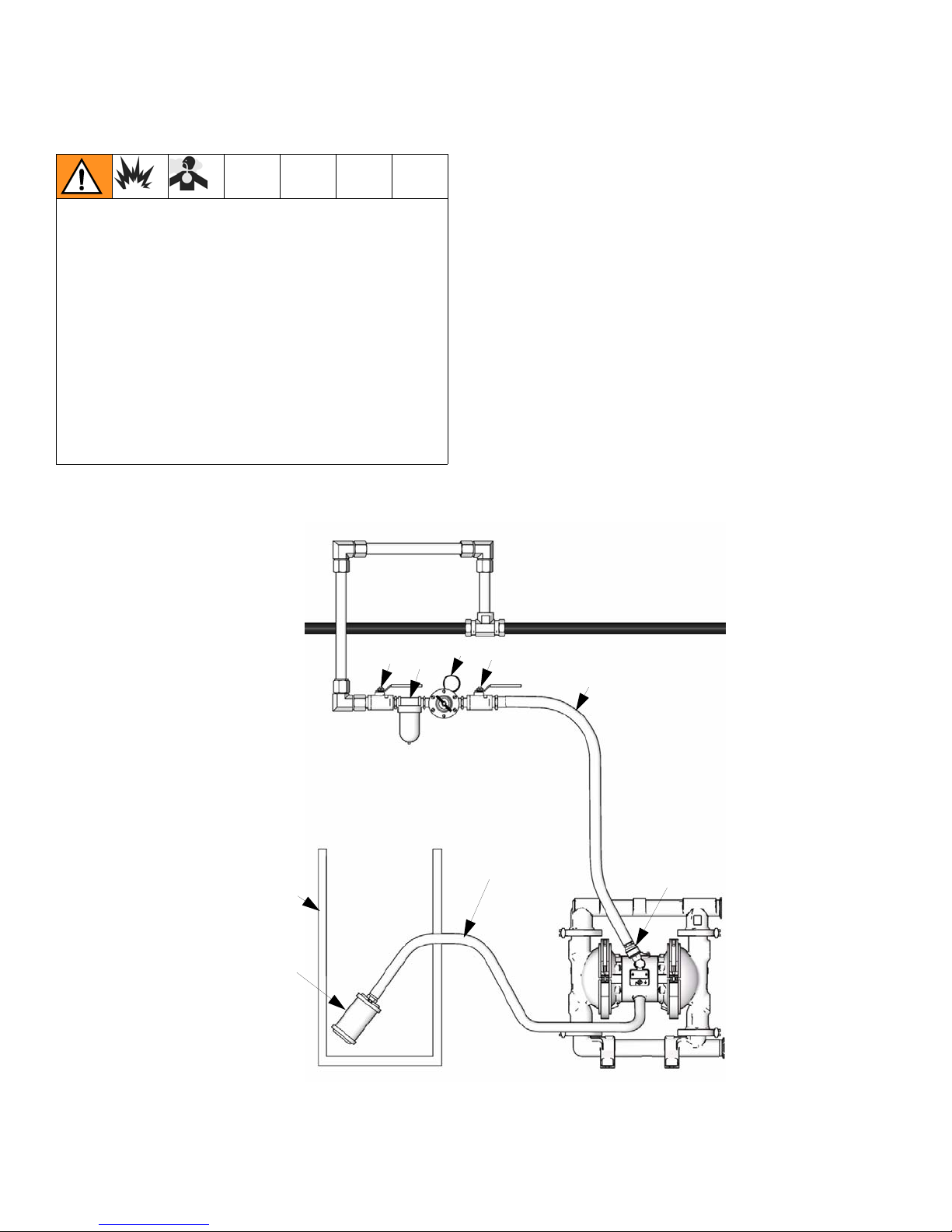

Air Exhaust Ventilation

Read the FIRE AND EXPLOSION HAZARD and

TOXIC FLUID OR FUMES HAZARD warnings on page

5 before operating this pump.

Be sure the system is properly ventilated for your type

of installation. When pumping flammable or hazardous

fluids, you must vent the exhaust to a safe place, away

from people, animals, food handling areas, and all

sources of ignition.

Diaphragm failure will cause the fluid being pumped to

exhaust with the air. Place an appropriate container at

the end of the air exhaust line to catch the fluid. See

F

IG. 4.

The air exhaust port is 3/4 npt(f). Do not restrict the air

exhaust port. Excessive exhaust restriction can cause

erratic pump operation.

To provide a remote exhaust:

1. Remove the muffler (P) from the pump air exhaust

port.

2. Install a grounded air exhaust hose (T) and connect

the muffler (P) to the other end of the hose. The

minimum size for the air exhaust hose is 3/4 in. (19

mm) ID. If a hose longer than 15 ft (4.57 m) is

required, use a larger diameter hose. Avoid sharp

bends or kinks in the hose.

3. Place a container (U) at the end of the air exhaust

line to catch fluid in case a diaphragm ruptures. See

F

IG. 4.

Key:

A Air supply line

B Bleed-type master air valve

(required for pump)

C Air regulator

D Air line quick disconnect

E Master air valve (for accessories)

F Air line filter

PMuffler

T Grounded air exhaust hose

U Container for remote air exhaust

C

E

F

U

P

B

A

T

D

F

IG. 4 Venting Exhaust Air

10 311879F

TI8931a

Page 11

Operation

Operation

Pressure Relief Procedure

Read the PRESSURIZED EQUIPMENT HAZARD

warnings on page 4.

The equipment stays pressurized until pressure is manually relieved. To reduce the risk of serious injury from

pressurized fluid or splashing fluid, follow this procedure whenever you:

• are instructed to relieve pressure

• stop pumping

• check, clean or service any system equipment

1. Shut off the air to the pump.

2. Open the dispensing valve, if used.

3. Open the fluid drain valve to relieve fluid pressure,

having a container ready to catch the drainage.

Sanitize the Pump Before First Use

If fluid inlet pressure to the pump is more than

25% of outlet working pressure, the ball check

valves will not close fast enough, resulting in inefficient pump operation.

4. Place the end of fluid hose (L) into an appropriate

container.

5. Close the fluid drain valve (J).

6. Back out the air regulator (C) knob, and open all

bleed-type master air valves (B, E).

7. If the fluid hose has a dispensing device, hold it

open while continuing with the following step.

8. Slowly increase air pressure with the air regulator

(C) until the pump starts to cycle. Allow the pump to

cycle slowly until all air is pushed out of the lines

and the pump is primed.

Pump Shutdown

It is the user’s responsibility to properly sanitize the

pump before first use. It is up to the user whether this

will include disassembling and cleaning individual parts

or simply flushing pump with a sanitizing solution. As

necessary, follow the steps under Starting and Adjust-

ing the Pump below, under the Service section on

page 16, or under Flushing on page 13.

Read the TOXIC FLUID OR FUMES HAZARD warn-

ings on page 5. Never move or lift a pump under pressure. If dropped, the fluid section may rupture. Always

follow the Pressure Relief Procedure before lifting the

pump.

Starting and Adjusting the Pump

1. Be sure the pump is properly grounded. Refer to

Grounding on page 4.

2. Check connections to be sure they are tight. Tighten

fluid inlet and outlet connections securely.

At the end of the work shift, relieve pressure.

3. Place the suction tube (if used) in fluid to be

pumped.

311879F 11

Page 12

Operation

12 311879F

Page 13

Maintenance

Maintenance

Lubrication

The air valve is designed to operate unlubricated, however if lubrication is desired, every 500 hours of operation (or monthly) remove the hose from the pump air

inlet and add two drops of machine oil to the air inlet.

CAUTION

Do not over-lubricate the pump. Oil is exhausted

through the muffler and could contaminate your fluid

supply or other equipment. Excessive lubrication can

also cause the pump to malfunction.

Flushing

To reduce the risk of serious injury, whenever you are

instructed to relieve pressure, always follow the Pres-

sure Relief Procedure on page 11.

Insert suction tube into cleaning solution. Open air regulator to supply low pressure air to the pump. Run the

pump long enough to thoroughly clean the pump and

hoses. Close the air regulator. Remove the suction tube

from the cleaning solution and drain pump. Place suction tube in the fluid to be pumped.

Tightening Connections

Before each use, check all hoses for wear or damage,

and replace as necessary. Check to be sure all connections are tight and leak-free.

Preventive Maintenance Schedule

Establish a preventive maintenance schedule, based on

the pump’s service history. This is especially important

for prevention of spills or leakage due to diaphragm failure.

Flush the pump often enough to prevent the fluid you

are pumping from drying or freezing in the pump and

damaging it. Flushing schedule will be based on what

the pump is being used for. Use a compatible cleaning

solution and always cycle the pump during the entire

flushing process.

Always flush the pump and relieve the pressure before

storing it for any length of time.

311879F 13

Page 14

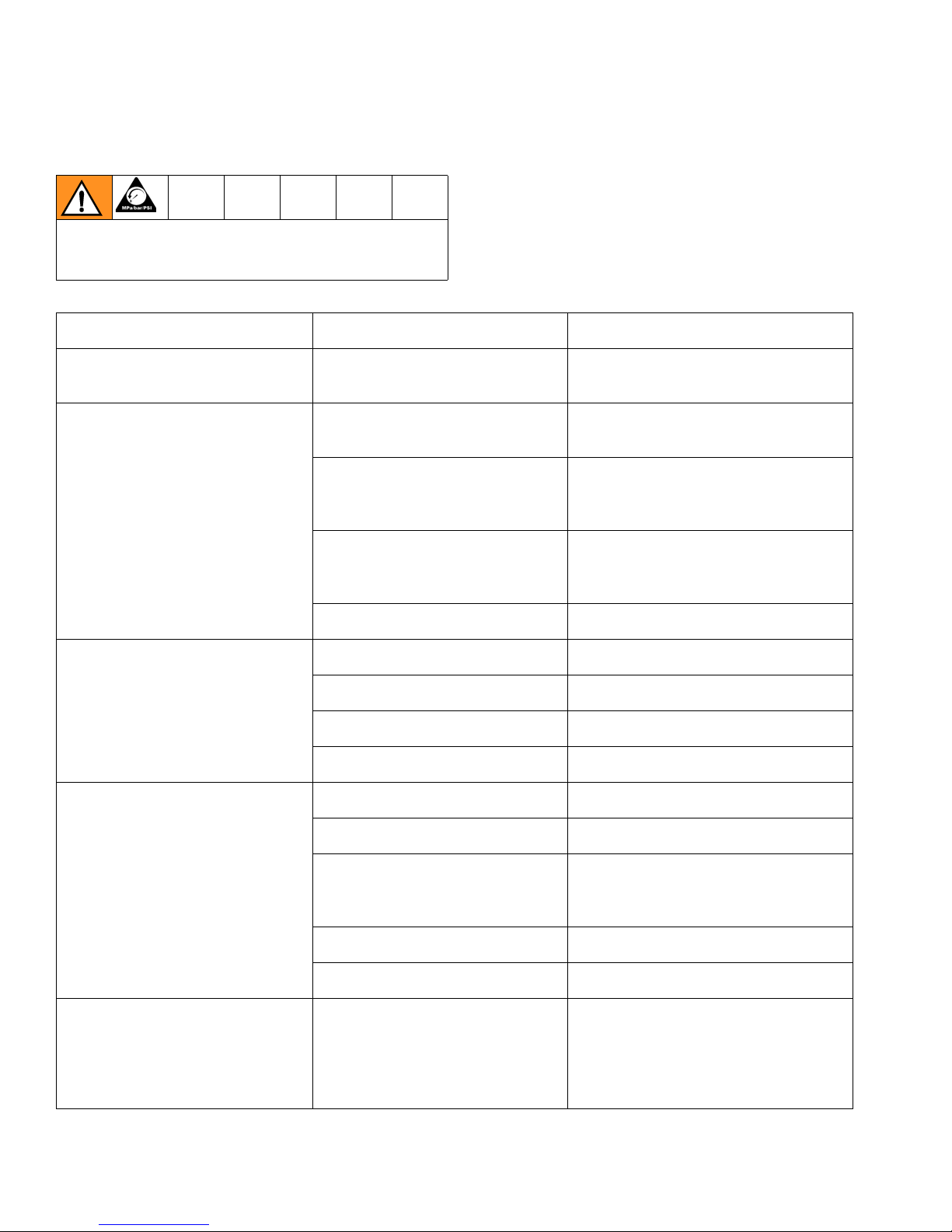

Troubleshooting

Troubleshooting

• Relieve the pressure before checking or servicing

the equipment.

To reduce the risk of serious injury, whenever you are

instructed to relieve pressure, always follow the Pres-

sure Relief Procedure on page 11.

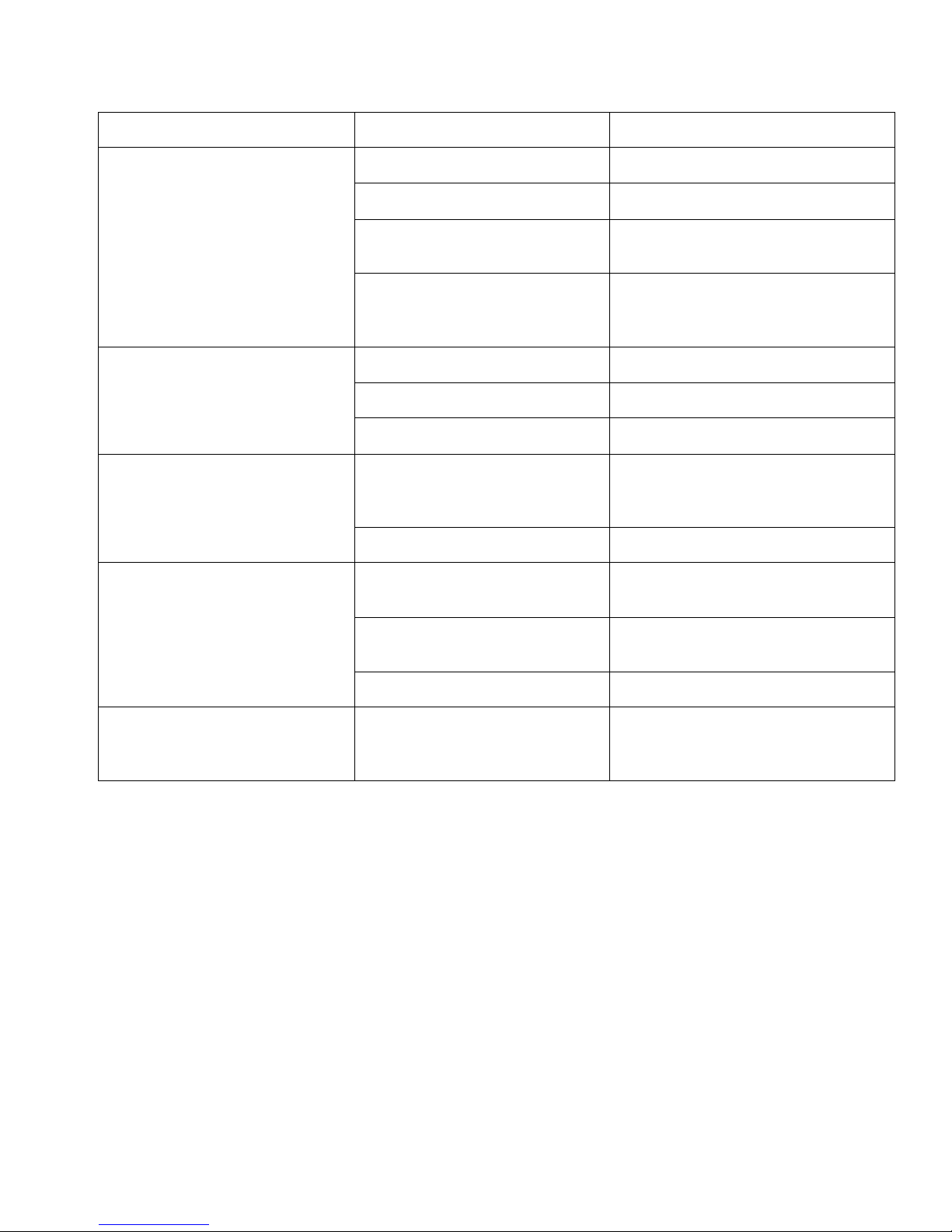

PROBLEM CAUSE SOLUTION

Pump cycles at stall or fails to hold

pressure at stall.

Pump will not cycle, or cycles once

and stops.

Pump operates erratically. Clogged suction line. Inspect; clear.

Worn check valve balls (301), seats

(201) or o-rings (202).

Air valve is stuck or dirty. Disassemble and clean air valve. See

Check valve ball (301) severely

worn and wedged in seat (201) or

manifold (102 or 103).

Check valve ball (301) is wedged

into seat (201), due to overpressurization.

Dispensing valve clogged. Relieve pressure and clear valve.

• Check all possible problems and causes before disassembling the pump.

Replace. See 18.

page 16. Use filtered air.

Replace ball and seat. See page 18.

Install Pressure Relief Valve

(see page 10).

Sticky or leaking balls (301). Clean or replace. See page 18.

Diaphragm ruptured. Replace. See pages 19-21.

Restricted exhaust. Remove restriction.

Air bubbles in fluid. Suction line is loose. Tighten.

Diaphragm ruptured. Replace. See pages 19-21.

Loose inlet manifold (102), damaged seal between manifold and

seat (201), damaged o-rings (202).

Loose diaphragm shaft bolt (107). Tighten or replace (pages 19-21).

Damaged o-ring (108). Replace. See pages 19-21.

Chattering - noisy operation. Check valve balls do not seat prop-

erly/cleanly due to imbalance

between fluid inlet and outlet line

sizing. Noise is accentuated with

light viscosity fluids.

Tighten manifold clamps (113), or

replace seats (201) or o-rings (202).

See page 18.

Reduce size/diameter of inlet line relative to outline line. Outlet line size

should not exceed pump size.

14 311879F

Page 15

PROBLEM CAUSE SOLUTION

Troubleshooting

Leak in inlet or outlet sanitary fit-

Loose sanitary clamp. Tighten clamp.

ting.

Damaged or worn gasket. Replace gasket.

Misalignment of inlet/outlet hose or

pipe.

Use flexible hoses at pump inlet and

outlet.

Gasket does not seal. Use a standard sanitary gasket of flexi-

ble material such as EPDM, Buna-N,

fluoroelastomer, or silicon.

Fluid in exhaust air. Diaphragm ruptured. Replace. See pages 19-21.

Loose diaphragm shaft bolt (107). Tighten or replace. See pages 19-21.

Damaged o-ring (108). Replace. See pages 19-21.

Pump exhausts excessive air at

stall.

Worn air valve block (7), o-ring (6),

plate (8), pilot block (18), u-cups

Repair or replace. See page 16.

(10), or pilot pin o-rings (17).

Worn shaft seals (402). Replace. See pages 19-21.

Pump leaks air externally. Air valve cover (2) or air valve cover

Tighten screws. See page 16.

screws (3) are loose.

Pump leaks fluid externally from

ball check valves.

Air valve gasket (4) or air cover

Inspect; replace. See pages 16, 22-23.

gasket (22) is damaged.

Air cover screws (25) are loose. Tighten screws. See pages 22-23.

Loose manifolds (102, 103), damaged seal between manifold and

seat (201), damaged o-rings (202).

Tighten manifold clamps (113), or

replace seats (201) or o-rings (202).

See page 18.

311879F 15

Page 16

Service

Service

Repairing the Air Valve

Tool Required

• Torque wrench

• Torx (T20) screwdriver or 7 mm (9/32 in.) socket

wrench

• Needle-nose pliers

• O-ring pick

• Lithium base grease

Air Valve Repair Kit 255061 is available. Parts

included in the kit are marked with a symbol, for

example (4†). Use all the parts in the kit for the

best results.

Disassembly

To reduce the risk of serious injury, whenever you are

instructed to relieve pressure, always follow the Pres-

sure Relief Procedure on page 11.

1. Relieve the pressure.

2. With a Torx (T20) screwdriver or 7 mm (9/32 in.)

socket wrench, remove the six screws (3), air valve

cover (2), and gasket (4). See F

3. Move the valve carriage (5) to the center position

and pull it out of the cavity. Remove the valve block

(7) and o-ring (6) from the carriage. Using a needle-nose pliers, pull the pilot block (18) straight up

and out of the cavity. See F

4. Pull the two actuator pistons (11) out of the bearings

(12). Remove the u-cup packings (10) from the pistons. Pull the pilot pins (16) out of the bearings (15).

Remove the o-rings (17) from the pilot pins. See

F

IG. 7.

5. Inspect the valve plate (8) in place. If damaged, use

a Torx (T20) screwdriver or 7 mm (9/32 in.) socket

wrench to remove the three screws (3). Remove the

valve plate (8). See F

IG. 8.

IG. 5.

IG. 6.

7. Clean all parts and inspect for wear or damage.

Replace as needed. Reassemble.

Reassembly

1. If you replaced the bearings (12, 15), reinstall as

explained on page 24. Reassemble the fluid section.

2. Install the valve plate (8) in the cavity, seal down.

Install the three screws (3), using a Torx (T20)

screwdriver or 7 mm (9/32 in.) socket wrench.

Tighten until the screws bottom out on the housing.

See F

IG. 8.

3. Install an o-ring (17†) on each pilot pin (16). Grease

the pins and o-rings. Insert the pins into the bearings (15), narrow end first. See F

IG. 7.

4. Install a u-cup packing (10†) on each actuator piston (11), so the lips of the packings face the narrow

end of the pistons. See F

IG. 7.

5. Lubricate the u-cup packings (10†) and actuator pistons (11). Insert the actuator pistons in the bearings

(12), wide end first. Leave the narrow end of the pistons exposed. See F

IG. 7.

6. Grease the lower face of the pilot block (18†) and

install so its tabs snap into the grooves on the ends

of the pilot pins (16). See F

IG. 6.

7. Grease the o-ring (6†) and install it in the valve

block (7†). Push the block onto the valve carriage

(5). Grease the lower face of the valve block. See

F

IG. 6.

8. Install the valve carriage (5) so its tabs slip into the

grooves on the narrow end of the actuator pistons

(11). See F

IG. 6.

9. Align the valve gasket (4†) and cover (2) with the six

holes in the center housing (1). Secure with six

screws (3†), using a Torx (T20) screwdriver or 7 mm

(9/32 in.) socket wrench. Torque to 52-60 in-lb

(5.6-6.8 N•m). See F

IG. 5.

6. Inspect the bearings (12, 15) in place. See F

The bearings are tapered and, if damaged, must be

removed from the outside. This requires disassembly of the fluid section. See page 24.

16 311879F

IG. 7.

Page 17

Service

2

Torque to 52-60 in-lb

(5.6-6.8 N•m)

FIG. 5

1

2

3

2

4†

Insert narrow end first

2

Grease

3

Install with lips facing narrow end of piston (11)

4

Insert wide end first

10†

3

2

11

4

12

TI9086A

F

IG. 7

2

17†

15

16

TI9089A

1

F

1

See detail at right

2

Grease

3

Grease lower face

IG. 6

2

3

18†

†6

†7

Detail

5

1

Tighten screws until they bottom

out on the housing

1

3

8†

TI9088A

3

1

5

TI9087A

F

IG. 8

TI9090A

311879F 17

Page 18

Service

Ball Check Valve Repair

Tools Required

• O-ring pick

Disassembly

• A Fluid Section Repair Kit is available. Refer

to the Repair Kit Matrix parts section for the

appropriate pump size so that the correct kit

for your pump is ordered. Parts included in

the kit are marked with an asterisk, for example (202*). Use all the parts in the kit for the

best results.

• To ensure proper seating of the balls (301),

always inspect the seats (201) when replacing the balls. Replace seats as necessary if

seating surface shows evidence of wear. Also,

replace the o-rings (202) as necessary. PTFE

o-rings should be replaced every time manifolds are removed.

Arrow (A) must point toward outlet manifold (103)

1

Radiused seating surface must face the ball (301).

2

Large chamfer on O.D. must face o-ring.

201

103

113

301*

2

202*

101

To reduce the risk of serious injury, whenever you are

instructed to relieve pressure, always follow the Pres-

sure Relief Procedure on page 11.

1. Relieve the pressure. Disconnect all hoses.

2. Remove the pump from its mounting.

3. Remove the clamps (106) holding the outlet manifold (103) to the fluid covers (101). See F

IG. 9.

4. Remove the o-rings (202), seats (201), and balls

(301) from the manifold (103).

5. Turn the pump over and remove the inlet manifold

(102). Remove the o-rings (202), seats (201), and

balls (301) from the fluid covers (101).

Reassembly

1. Clean all parts and inspect for wear or damage.

Replace parts as needed.

2. Reassemble in the reverse order, following all notes

in F

IG. 9. Be sure the ball checks and manifolds are

assembled exactly as shown. The arrows (A) on the

fluid covers (101) must point toward the outlet manifold (103).

F

IG. 9

A

301*

201

202*

TI8932a

1

2

113

102

18 311879F

Page 19

Standard Diaphragm Repair

If your pump uses heavy-duty diaphragms, see

page 22.

Service

Tools Required

• Torque wrench

• 15 mm socket wrench

• 19 mm open end wrench

• O-ring pick

• Lithium-base grease

Disassembly

A Fluid Section Repair Kit is available. Refer to

page 27, 35, or 43 to order the correct kit for your

pump. Parts included in the kit are marked with an

asterisk, for example (401*). Use all the parts in

the kit for the best results.

106

To reduce the risk of serious injury, whenever you are

instructed to relieve pressure, always follow the Pres-

sure Relief Procedure on page 11.

1. Relieve the pressure.

2. Remove the manifolds and disassemble the ball

check valves as explained on page 18.

3. Remove the clamps (106) holding the fluid covers

(101) to the air covers (23). Pull the fluid covers

(101) off the pump. See F

Arrow (A) must point toward air valve.

1

IG. 10.

1

B

23

IG. 10

F

106

101

A

1

TI9091A

311879F 19

Page 20

Service

4. Loosen but do not remove the diaphragm shaft bolts

(107), using a 15 mm socket wrench on both bolts.

See F

IG. 11.

5. Unscrew one bolt from the diaphragm shaft (24) and

remove the o-ring (108), fluid side diaphragm plate

(105), diaphragm (403), backer (401) used only on

PTFE models, and air side diaphragm plate (104).

See F

IG. 11.

6. Pull the other diaphragm assembly and the diaphragm shaft (24) out of the center housing (1).

Hold the shaft flats with a 19 mm open end wrench,

and remove the bolt (107) from the shaft. Disassemble the remaining diaphragm assembly.

7. Inspect the diaphragm shaft (24) for wear or

scratches. If it is damaged, inspect the bearings (19)

in place. If the bearings are damaged, refer to page

24.

8. Reach into the center housing (1) with an o-ring pick

and hook the u-cup packings (402), then pull them

out of the housing. This can be done with the bearings (19) in place.

9. Clean all parts and inspect for wear or damage.

Replace parts as needed.

d. On PTFE models only, install the backer (401*)

on the bolt. Make certain the side marked AIR

SIDE faces the center housing (1).

e. Install the air side diaphragm plate (104) so the

rounded side faces the diaphragm (401). This

plate is stamped with its part number.

f. Apply medium-strength (blue) Loctite

® or equiv-

alent to the bolt (107) threads. Screw the bolt

into the shaft (24) hand tight.

3. Grease the length and ends of the diaphragm shaft

(24), and slide it through the housing (1).

4. Assemble the other diaphragm assembly to the

shaft as explained in step 2.

5. Hold one shaft bolt (107) with a wrench and torque

the other bolt to 60-70 ft-lb (81-95 N

•m) at 100 rpm

maximum.

6. Align the fluid covers (101) and the center housing

(1) so the arrows (A) on the covers face the same

direction as the air valve (B). Secure covers with the

clamps. See F

IG. 10.

Reassembly

1. Install the shaft u-cup packings (402*) so the lips

face out of the housing (1). Lubricate the packings.

See F

IG. 11.

2. Install the diaphragm assembly on one end of the

shaft (24) as follows:

a. Install the o-ring (108*) on the shaft bolt (107).

b. Install the fluid side diaphragm plate (105) on

the bolt so the rounded side faces the diaphragm (401).

The fluid side diaphragm plate (105) is stainless

steel. This plate is not stamped with its part number. Be sure to install this plate on the fluid side of

the diaphragm.

c. Install the diaphragm (403*). Make certain the

side marked AIR SIDE faces the center

housing (1).

7. Reassemble the ball check valves and manifolds as

explained on page 18.

20 311879F

Page 21

Service

Cutaway view, with

diaphragms in place

1

19

24 104

4 2

402*

401*

3

1

105

2

107

5

24

403*

TI8935a

2

4

104

401*

63

6

3

403*

3

2

105

107

108*

5

TI8934a

1

1

24

4

TI8933a

Lips face out of housing (1).

2

Rounded side faces diaphragm (401).

3

Air side must face center housing (1).

4

Grease.

5

Apply medium strength (blue) Loctite

equivalent. Torque to 60-70 ft-lb (81-95 N•m)

at 100 rpm maximum.

6

Backer used on pumps with PTFE

diaphragms only.

® or

FIG. 11

311879F 21

Page 22

Service

Heavy-Duty Diaphragm Repair

If your pump uses standard diaphragms, see page

19.

Tools Required

• Torque wrench

• 19 mm open end wrench

• O-ring pick

• Lithium-base grease

Disassembly

A Fluid Section Repair Kit is available. Refer to

page 27, 35, or 43 to order the correct kit for your

pump. Parts included in the kit are marked with an

asterisk, for example (401*). Use all the parts in

the kit for the best results.

To reduce the risk of serious injury, whenever you are

instructed to relieve pressure, always follow the Pres-

sure Relief Procedure on page 11.

1. Relieve the pressure.

in place. If the bearings are damaged, refer to page

24.

8. Reach into the center housing (1) with an o-ring pick

and hook the u-cup packings (402), then pull them

out of the housing. This can be done with the bearings (19) in place.

9. Clean all parts and inspect for wear or damage.

Replace parts as needed.

24 104 403*

106

231

2. Remove the manifolds and disassemble the ball

check valves as explained on page 18.

3. Remove the clamps (106) holding the fluid covers

(101) to the air covers (23). Pull the fluid covers

(101) off the pump. See F

IG. 12.

4. Once the fluid covers are removed, the diaphragm

on the side of the pump which was last pressurized

with air will be separated from the center section/air

cover. This allows you to grip the diaphragms.

5. Diaphragms are assembled handtight. To loosen,

grip both diaphragms securely around the outer

edge and rotate counterclockwise. One diaphragm

assembly will come free and the other will remain

attached to the shaft. Remove the freed diaphragm

(403) and air side plate (104).

6. Pull the opposite diaphragm assembly and shaft

(24) out of the center housing (1). Hold the shaft

flats with a 19 mm open end wrench and remove the

diaphragm and air side plate from the shaft.

7. Inspect the diaphragm shaft (24) for wear or

scratches. If it is damaged, inspect the bearings (19)

FIG. 12

101

ti10630a

22 311879F

Page 23

Reassembly

1. Install the shaft u-cup packings (402*) so the lips

face out of the housing (1). Lubricate the packings.

See F

IG. 13.

Service

B

2. Assemble the air side plate (104) onto the diaphragm (403). The wide, radiused side of the plate

must face the diaphragm. Apply medium-strength

(blue) Loctite

® or equivalent to the threads of the

diaphragm assembly. Screw the assembly into the

shaft (24) hand tight.

3. Grease the length and ends of the diaphragm shaft

(24). Determine the orientation of the air valve by

checking which side the pilot pins (16) protrude farthest (see F

IG. 14). This side will be supplied with air

first. Insert the shaft/diaphragm assembly into this

side of the pump. Assemble the fluid cover (101)

and clamp (106) so the arrow (A) on the cover faces

the same direction as the air valve (B). Securely

tighten the clamp.

4. Assemble the other diaphragm assembly to the

shaft as explained in step 2. This diaphragm will be

lifted off the air cover at this point.

5. Set the other fluid cover (101) in place on the diaphragm, so the arrow (A) on the cover faces the

same direction as the air valve (B). Supply the pump

with low pressure air (less than 7 psi [.05 MPa, 0.5

bar]). The diaphragm will very slowly pull onto the

air cover (23). You can support the movement with

your hand by gently pushing on the fluid cover (101).

24 104 403*

231

5

Apply medium strength (blue) Loctite® or

equivalent to bolt (not shown).

FIG. 13

101

5

106

A

ti10631a

CAUTION

Do not deform the diaphragm manually. The diaphragm needs uniform pressure to deform properly.

6. Assemble the fluid cover (101) and clamp (106) so

the arrow (A) on the cover faces the same direction

as the air valve (B). Securely tighten the clamp.

7. Reassemble the ball check valves and manifolds as

explained on page 18.

311879F 23

Page 24

Service

Bearing and Air Gasket Removal

Tools Required

• Torque wrench

• 10 mm socket wrench

• Bearing puller

• O-ring pick

• Press, or block and mallet

Disassembly

Do not remove undamaged bearings.

To reduce the risk of serious injury, whenever you are

instructed to relieve pressure, always follow the Pres-

sure Relief Procedure on page 11.

1. Relieve the pressure.

2. Remove the manifolds and disassemble the ball

check valves as explained on page 18.

3. Remove the fluid covers and diaphragm assemblies

as explained on page 19.

2. The bearings (12, 15, and 19) are tapered and can

only be installed one way. Insert the bearings into

the center housing (1), tapered end first. Using a

press or a block and rubber mallet, press-fit the

bearing so it is flush with the surface of the center

housing.

3. Reassemble the air valve as explained on page 16.

4. Align the new air cover gasket (22) so the pilot pin

(16) protruding from the center housing (1) fits

through the proper hole (H) in the gasket.

5. Align the air cover (23) so the pilot pin (16) fits in the

middle hole (M) of the three small holes near the

center of the cover. Install the screws (25),

handtight. Apply medium-strength (blue) Loctite

® or

equivalent to the threads of the screws (25). See

F

IG. 14. Using a 10 mm socket wrench, torque the

screws oppositely and evenly to 130-150 in-lb

(15-17 N

•m).

6. Install the diaphragm assemblies and fluid covers as

explained on page 19.

7. Reassemble the ball check valves and manifolds as

explained on page 18.

If you are removing only the diaphragm shaft

bearing (19), skip step 4.

4. Disassemble the air valve as explained on page 16.

5. Using a 10 mm socket wrench, remove the screws

(25) holding the air covers (23) to the center housing

(1). See F

IG. 14.

6. Remove the air cover gaskets (22). Always replace

the gaskets with new ones.

7. Use a bearing puller to remove the diaphragm shaft

bearings (19), air valve bearings (12) or pilot pin

bearings (15). Do not remove undamaged bearings.

8. If you removed the diaphragm shaft bearings (19)

reach into the center housing (1) with an o-ring pick

and hook the u-cup packings (402), then pull them

out of the housing. Inspect the packings. See F

IG.

11.

Reassembly

1. If removed, install the shaft u-cup packings (402*)

so the lips face out of the housing (1). See F

IG. 11.

24 311879F

Page 25

1

Insert bearings tapered end first

2

Press-fit bearings flush with surface of center housing (1)

3

Apply medium strength (blue) Loctite

® or equivalent.

Torque to 130-150 in-lb (15-17 N•m)

Detail of air valve bearings

12

Service

2

1

FIG. 14

TI9093A

1

16

19

2

1

22

M

23

15

1

2

H

3

25

TI9092a

311879F 25

Page 26

Pump Matrix - 1040

Pump Matrix - 1040

1040 FDA-Compliant Stainless Steel Sanitary Pumps

Your Model No. is marked on the pump’s serial plate. To

determine the Model No. of your pump from the following matrix, select the six digits which describe your

pump, working from left to right. The first three digits are

always FD1, designating 1040 SST FDA-compliant

pumps. The remaining three digits define the materials

of construction. For example, a 1040 FDA pump with

FDA- Compliant

Diaphragm

Pump

FD1 - All 1040 Stainless Steel FDA-Compliant pumps.

1040 Stainless

Steel Air Motor

Stainless Steel

Fluid Section

PTFE o-rings, stainless steel seats, PTFE balls, and

PTFE diaphragms is Model

ment parts, refer to the part lists on pages 29-30.

The digits in the matrix do not correspond to the reference numbers in the parts drawings and parts lists.

Seats and

O-rings

1 (316 SST with

PTFE o-rings)

2 (316 SST with

EPDM o-rings)

Balls Diaphragms

1 (PTFE) 1 (PTFE)

2 (Santoprene®) 2 (Santoprene®)

3 (Neoprene

with SST core)

FD1111. To order replace-

3(PTFE

Heavy-Duty)

Available Configurations

•FD1111

•FD1122

•FD1211

•FD1222

•FD1113

•FD1213

•FD1132

•FD1232

26 311879F

Page 27

Repair Kit Matrix - 1040

Repair Kit Matrix - 1040

For 1040 Stainless Steel Sanitary Pumps

Repair Kits may be ordered separately. To repair the air

valve, order Part No. 255061 (see page 28). Parts

included in the Air Valve Repair Kit are marked with a

symbol in the parts list, for example (4†).

ing three digits define the materials of construction.

Parts included in the kit are marked with an asterisk in

the parts list, for example (201*). For example, if your

pump has stainless steel seats, PTFE o-rings, PTFE

balls, and PTFE diaphragms, order Repair Kit

FK1111.

To repair your pump, select the six digits which describe

your pump from the following matrix, working from left to

right. The first three digits are always FK1. The remain-

Diaphragm Pump Null Pump Size Seats and O-rings Balls Diaphragms

FK1 for all 1040 SST FDA-Compliant Pumps.

The digits in the matrix do not correspond to the reference numbers in the parts drawings and parts lists.

1 (316 SST with

PTFE o-rings)

2 (316 SST with

EPDM o-rings)

1(PTFE)

white

2 (Santoprene®)

blue

3 (Neoprene

with SST core)

1(PTFE)

white

2 (Santoprene®)

blue

3(PTFE

Heavy-Duty)

Available Configurations

•FK1111

•FK1122

•FK1211

•FK1222

•FK1113

•FK1213

•FK1132

•FK1232

311879F 27

Page 28

Parts - 1040

*

*

Parts - 1040

Detail of Heavy-Duty Diaphragm

11

†17

16

†18

20

†10

†4

403*

110

▲

104

3

103

2

113

301

201

6†

7†

105

5

108*

107

106

202

3

8†

16

17†

104

12

401*

10†

1

403*

101

11

22

23

25

15

24

402*

1

19

111

1

Used on pumps with PTFE diaphragms only.

*

These parts are included in the Pump Repair Kit which may be purchased

separately. Refer to the Repair Kit Matrix on page 27 to determine the correct

kit for your pump.

†

These parts are included in Air Valve Repair Kit 255061 which may be purchased separately.

▲

Replacement Danger and Warning labels, tags, and cards are available at no

cost.

28 311879F

301*

201

202*

113

102

TI10634a

Page 29

Air Motor Parts List (Matrix Column 2)

Ref. Part No. Description Qty

1 15K009 HOUSING, center; SST 1

2 15A735 COVER, air valve; SST 1

Parts - 1040

3 116344 SCREW, mach, hex flange hd;

M5 x 0.8; 12 mm (0.47 in.)

4† 188618 GASKET, cover 1

5 188855 CARRIAGE; aluminum 1

6† 108730 O-RING; nitrile 1

7† 188616 BLOCK, air valve; acetal 1

8† 15H178 PLATE, air valve; SST 1

10† 112181 PACKING, u-cup; nitrile 2

11 188612 PISTON, actuator; acetal 2

12 188613 BEARING, piston; acetal 2

15 188611 BEARING, pin; acetal 2

16 188610 PIN, pilot; SST 2

17† 157628 O-RING; buna-N 2

18† 188614 BLOCK, pilot; acetal 1

19 188609 BEARING, shaft; acetal 2

20 116344 SCREW, grounding 1

9

22 188603 GASKET, air cover; foam 2

23 15G667 COVER, air, SST 2

24 188608 SHAFT, diaphragm; SST 1

25 112178 SCREW; M8 x 1.25; 25 mm

(1 in.); stainless steel

12

† These parts are included in Air Valve Repair kit 255061 which may be purchased separately.

311879F 29

Page 30

Parts - 1040

Fluid Section Parts List (Matrix Column 3)

Ref. Part No. Description Qty

101 277262 COVER, fluid; SST 2

102 277265 MANIFOLD, inlet; SST 1

103 277266 MANIFOLD, outlet; SST 1

106 15G698 CLAMP, diaphragm 2

110▲ 188621 LABEL, warning 1

111 15G332 MUFFLER 1

113 620223 CLAMPS, sanitary 4

* These parts are included in the Pump Repair Kit which

may be purchased separately. Refer to the Repair Kit Matrix on

page 27 to determine the correct kit for your pump.

▲Replacement Danger and Warning labels, tags, and cards

are available at no cost.

Seat Parts List (Matrix Column 4)

Digit Ref. Part No. Description Qty

1 201 15H824 SEAT; 316 SST 4

202* 15J280 O-RING; PTFE 4

2 201 15H824 SEAT; 316 SST 4

202* 15H827 O-RING; EPDM 4

Ball Parts List (Matrix Column 5)

Digit Ref. Part No. Description Qty

1 301* 112088 BALL; PTFE 4

2 301* 112092 BALL; Santoprene® 4

3 301* 15H832 BALL; neoprene/SST

core

4

Diaphragm Parts List (Matrix Column 6)

Digit Ref. Part No. Description Qty

1 401* DIAPHRAGM; backer;

EPDM

402* 112181 PACKING; u-cup; nitrile 2

403* 188605 DIAPHRAGM; PTFE 2

104 188607 PLATE, air side;

aluminum

105 15C039 PLATE, fluid side; SST 2

107 189044 BOLT; M12 x 1.75;

35 mm (1.38 in.); SST

108* 104319 O-RING; PTFE 2

2 402* 112181 PACKING; u-cup; nitrile 2

403* 188857 DIAPHRAGM; Santo-

prene

104 188607 PLATE, air side;

aluminum

105 15C039 PLATE, fluid side; SST 2

107 189044 BOLT; M12 x 1.75;

35 mm (1.38 in.); SST

108* 104319 O-RING; PTFE 2

3 289224 Kit, heavy-duty diaphragm, PTFE; includes

403 and 104

402* 112181 PACKING; u-cup; nitrile 2

403* 253626 DIAPHRAGM;

Heavy-Duty; PTFE;

includes two dia-

phragms and two pack-

ings (402)

104 15H809 PLATE, air side;

aluminum

* These parts are included in the Pump Repair Kit which

may be purchased separately. Refer to the Repair Kit Matrix on

page 27 to determine the correct kit for your pump.

2

2

2

2

2

2

1

2

30 311879F

Page 31

Dimensional Drawing - 1040

Dimensional Drawing - 1040

IN

MM

!IR%XHAUST

MUFFLERINCLUDED

NPTF

IN

MM

!IR)NLET

NPTF

IN

MM

/VERALL7IDTHINMM

MM

IN

IN/UTLET

3ANITARY&LANGE

IN

MM

IN

MM

IN)NLET

3ANITARY&LANGE

IN

MM

TI9094A

IN

MM

Pump Mounting

Hole Pattern

&OURIN

MM

DIAMETERHOLES

IN

MM

1040 FDA

311879F 31

Page 32

Technical Data - 1040

Technical Data - 1040

Maximum fluid working pressure . . . . . . . . . . . . . . . . . . . 120 psi (0.8 MPa, 8 bar)

Air pressure operating range . . . . . . . . . . . . . . . . . . . . . . 20-120 psi (0.14-0.8 MPa, 1.4-8 bar)

Maximum air consumption . . . . . . . . . . . . . . . . . . . . . . . . 50 scfm

Air consumption at 70 psi/20 gpm . . . . . . . . . . . . . . . . . .

Maximum free-flow delivery . . . . . . . . . . . . . . . . . . . . . . . 41 gpm (159 l/min)

Maximum pump speed . . . . . . . . . . . . . . . . . . . . . . . . . . . 256 cpm

* Gallons (Liters) per cycle . . . . . . . . . . . . . . . . . . . . . . . .

Maximum suction lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum size pumpable solids . . . . . . . . . . . . . . . . . . . . 1/8 in. (3.2 mm)

** Maximum Noise Level at 100 psi, full flow . . . . . . . . . . 92 dBa

** Sound Power Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 dBa

** Noise Level at 70 psi and 50 cpm. . . . . . . . . . . . . . . . . 73 dBa

18 scfm (see chart)

0.16 (0.57)

29 ft (8.83 m) wet, 16 ft (4.87 m) dry

Maximum fluid operating temperature is based on the following maximum diaphragm, ball, and seat temperature

ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air inlet size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid inlet size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 in. sanitary flange

Fluid outlet size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wetted parts

***All fluid contact materials are FDA-compliant and meet the United States Code of Federal Regulations (CFR)

Title 21, Section 177.

Wetted materials on all models . . . . . . . . . . . . . . . . . . . .

Wetted material depending on model. . . . . . . . . . . . . . . .

CAUTION:

Santoprene® may be used only with non-fatty, non-oily foods or alcohols up to 15%.

Non-wetted external parts . . . . . . . . . . . . . . . . . . . . . . . .

Weight

All models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 lb. (24.9 kg)

Santoprene® is a registered trademark of the Monsanto Co.

PTFE 220°F (104.4°C)

Santoprene® 180°F (82.2°C)

EPDM 275°F (135°C)

Neoprene 200°F (93°C)

Stainless steel 250°F (121.1°C)

0.5 in. npt(f)

1.5 in. sanitary flange

316 SST

EPDM, Neoprene, PTFE, Santoprene®

300 series stainless steel, polyester (labels), LDPE foam

(gasket)

Loctite® is a registered trademark of the Loctite Corporation.

* Displacement per cycle may vary based on suction condition, discharge head, air pressure, and fluid type.

** Noise levels measured with the pump mounted to a solid surface. Sound power measured per

ISO Standard 9614-1.

*** The pump user must verify that the construction materials meet their specific application requirements.

32 311879F

Page 33

Performance Chart - 1040

)

A

Test Conditions: Pump tested in water with inlet submerged

Fluid Pressure Curves

Performance Chart - 1040

at 120 psi (0.7 MPa, 7 bar) operating air pressure

at 100 psi (0.7 MPa, 7 bar) operating air pressure

at 70 psi (0.48 MPa, 4.8 bar) operating air pressure

at 40 psi (0.28 MPa, 2.8 bar) operating air pressure

o find Fluid Outlet Pressure

psi/MPa/bar) at a specific fluid flow (gpm/lpm) and

perating air pressure (psi/MPa/bar):

1. Locate fluid flow rate along bottom of chart.

. Follow vertical line up to intersection with selected

operating air pressure curve.

. Follow left to scale to read fluid outlet pressure.

Air Consumption Curves

A at 120 psi (0.7 MPa, 7 bar) operating air pressure

B at 100 psi (0.7 MPa, 7 bar) operating air pressure

C at 70 psi (0.48 MPa, 4.8 bar) operating air pressure

D at 40 psi (0.28 MPa, 2.8 bar) operating air pressure

To find Pump Air Consumption

(scfm or m

3

/min) at a specific fluid flow (gpm/lpm) and

operating air pressure (psi/MPa/bar):

1. Locate fluid flow rate along bottom of chart.

2. Read vertical line up to intersection with selected

operating air pressure curve.

3. Follow left to scale to read air consumption.

120

(0.84, 8.4)

100

(0.7, 7)

80

(0.55, 5.5)

60

(0.41, 4.1)

40

psi (MPa, bar)

(0.28, 2.8)

(0.14, 1.4)

(0.41, 4.1)

(0.28, 2.8)

/min)

3

(0.14, 1.4)

scfm (m

20

0

60

40

20

Fluid Outlet Pressure

Air Consumption

0

5

(19)

(19)

10

(38)

15

(57)

20

(76)

25 30

(95) (114)

(133)

Fluid Flow

gpm (lpm)

10

(38)

15

(57)

5

20

(76)

25 30

(95) (114)

Fluid Flow

gpm (lpm)

35

35

(133)

40

(152)

TI8736A

TI8742A

40

(152

TI8737

311879F 33

TI8742A

Page 34

Pump Matrix - 1590

Pump Matrix - 1590

1590 FDA-Compliant Stainless Steel Sanitary Pumps

Your Model No. is marked on the pump’s serial plate. To

determine the Model No. of your pump from the following matrix, select the six digits which describe your

pump, working from left to right. The first three digits are

always FD2, designating 1590 SST FDA compliant diaphragm pumps. The remaining three digits define the

materials of construction. For example, a 1590 FDA

FDA-Compliant

Diaphragm

Pump

FD2 - All 1590 Stainless Steel FDA-Compliant Pumps

1590 Stainless

Steel Air Motor

Stainless Steel

Fluid Section

Available Configurations

pump with a stainless steel motor, stainless steel fluid

section, stainless steel seats, PTFE o-rings, PTFE balls,

and PTFE diaphragms is Model No.

replacement parts, refer to the part lists on pages 37-38.

The digits in the matrix do not correspond to the reference numbers in the parts drawings and parts lists.

Seats and

O-rings Balls Diaphragms

1 (316 SST with

PTFE o-rings)

2 (316 SST with

EPDM o-rings)

1 (PTFE) 1 (PTFE)

2 (Santoprene®) 2 (Santoprene®)

3 (Neoprene

with SST core)

FD2111. To order

3(PTFE

Heavy-Duty)

•FD2111

•FD2122

•FD2211

•FD2222

•FD2113

•FD2213

•FD2132

•FD2232

34 311879F

Page 35

Repair Kit Matrix - 1590

For 1590 Stainless Steel Sanitary Pumps

Repair Kit Matrix - 1590

Repair Kits may be ordered separately. To repair the air

valve, order Part No. 255061 (see page 28). Parts

included in the Air Valve Repair Kit are marked with a

symbol in the parts list, for example (4†).

To repair your pump, select the six digits which describe

your pump from the following matrix, working from left to

right. The first three digits are always FK2. The remaining three digits define the materials of construction.

Diaphragm

Pump Null Pump Size

FK2 - All 1590 SST FDA-Compliant Pumps

Parts included in the kit are marked with an asterisk in

the parts list, for example (201*). For example, if your

pump has stainless steel seats, PTFE o-rings, PTFE

balls, and PTFE diaphragms, order Repair Kit

FK2111.

The digits in the matrix do not correspond to the reference numbers in the parts drawings and parts lists.

Seats and

O-rings

1 (316 SST with

PTFE o-rings)

2 (316 SST with

EPDM o-rings)

Balls Diaphragms

1(PTFE)

white

2 (Santoprene®)

blue

3 (Neoprene

with SST core)

1(PTFE)

white

2 (Santoprene®)

blue

3(PTFE

Heavy-Duty)

Available Configurations

•FK2111

•FK2122

•FK2211

•FK2222

•FK2113

•FK2213

•FK2132

•FK2232

311879F 35

Page 36

Parts - 1590

Parts - 1590

3

Detail of Heavy-Duty Diaphragm

403*

104

110

▲

103

†17

†10

11

16

†18

†4

2

113

*301

5

105

106

108*

6†

107

201

*202

7†

8†

104

3

16

17†

401*

12

1

403*

10†

11

22

23

25

24

402*

101

*301

15

1

19

20

111

1

Used on pumps with PTFE diaphragms only.

*

These parts are included in the Pump Repair Kit which may be purchased

separately. Refer to the Repair Kit Matrix on page 35 to determine the correct

kit for your pump.

†

These parts are included in Air Valve Repair Kit 255061 which may be purchased separately.

▲

Replacement Danger and Warning labels, tags, and cards are available at no

cost.

36 311879F

201

*202

13

113

102

TI8927b

Page 37

Air Motor Parts List (Matrix Column 2)

Ref. Part No. Description Qty

1 15K009 HOUSING, center; SST 1

2 15A735 COVER, air valve; SST 1

Parts - 1590

3 116344 SCREW, mach, hex flange hd; M5

x 0.8; 12 mm (0.47 in.)

4† 188618 GASKET, cover; 1

5 188855 CARRIAGE; aluminum 1

6† 108730 O-RING; nitrile 1

7† 188616 BLOCK, air valve; acetal 1

8† 15H178 PLATE, air valve; SST 1

10† 112181 PACKING, u-cup; nitrile 2

11 188612 PISTON, actuator; acetal 2

12 188613 BEARING, piston; acetal 2

13 103778 PLUG, pipe 2

15 188611 BEARING, pin; acetal 2

16 188610 PIN, pilot; SST 2

17† 157628 O-RING; buna-N 2

18† 188614 BLOCK, pilot; acetal 1

19 188609 BEARING, shaft; acetal 2

9

20 116344 SCREW, grounding 1

22 188603 GASKET, air cover; foam 2

23 15G668 COVER, air; SST 2

24 189245 SHAFT, diaphragm; SST 1

25 112178 SCREW; M8 x 1.25; 25 mm (1 in.);

stainless steel

† These parts are included in Air Valve Repair Kit 255061 which

may be purchased separately.

12

311879F 37

Page 38

Parts - 1590

Fluid Section Parts List (Matrix Column 3)

Digit Ref. Part No. Description Qty

S 101 277263 COVER, fluid; SST 2

102 277267 MANIFOLD, inlet; SST 1

103 277268 MANIFOLD, outlet;

SST

106 15G699 CLAMP, diaphragm 2

110▲ 188621 LABEL, warning 1

111 15G332 MUFFLER 1

113 15D475 CLAMP, sanitary 4

1

Seat Parts List (Matrix Column 4)

Digit Ref. Part No. Description Qty

1 201 15H825 SEAT; 316 stainless

steel

202* 15H830 O-RING; PTFE 4

2 201 15H825 SEAT; 316 stainless

steel

202* 15H828 O-RING; EPDM 4

4

4

Diaphragm Parts List (Matrix Column 6)

Digit Ref. Part No. Description Qty

1 401* DIAPHRAGM; backer;

EPDM

402* 112181 PACKING; u-cup;

nitrile

403* 15K312 DIAPHRAGM; PTFE 2

104 15K448 PLATE, air side;

aluminum

105 189309 PLATE, fluid side; SST 2

107 189410 BOLT; M12 x 1.75;

35 mm (1.38 in.); SST

108* 104319 O-RING; PTFE 2

2 402* 112181 PACKING; u-cup;

nitrile

403* 189426 DIAPHRAGM;

Santoprene®

104 15K448 PLATE, air side;

aluminum

105 189309 PLATE, fluid side; SST 2

2

2

2

2

2

2

2

* These parts are included in the Pump Repair Kit which

may be purchased separately. Refer to the Repair Kit Matrix on

page 35 to determine the correct kit for your pump.

▲ Replacement Danger and Warning labels, tags and cards

are available at no cost.

Ball Parts List (Matrix Column 5)

Digit Ref. Part No. Description Qty

1 301* 112419 BALL; PTFE 4

2 301* 112421 BALL; Santoprene® 4

3 301* 15H833 BALL; neoprene/SST

core

4

107 189410 BOLT; M12 x 1.75;

35 mm (1.38 in.); SST

108* 104319 O-RING; PTFE 2

3 289225 Kit, heavy-duty diaphragm, PTFE;

includes 403 and 104

402* 112181 PACKING; u-cup;

nitrile

403* 253627 DIAPHRAGM;

Heavy-Duty; PTFE;

includes two diaphragms and two

packings (402)

104 15H810 PLATE, air side;

aluminum

* These parts are included in the Pump Repair Kit which

may be purchased separately. Refer to the Repair Kit Matrix on

page 35 to determine the correct kit for your pump.

2

2

1

2

38 311879F

Page 39

Dimensional Drawing - 1590

Dimensional Drawing - 1590

IN

MM

!IR%XHAUST

MUFFLERINCLUDED

NPTF

IN

MM

IN

MM

/VERALL7IDTHINMM

MM

!IR)NLET

NPTF

IN

3ANITARY&LANGE

IN

MM

MM

IN)NLET

3ANITARY&LANGE

IN/UTLET

IN

MM

IN

TI9095a

IN

MM

Pump Mounting

Hole Pattern

&OURIN

MM

DIAMETERHOLES

IN

MM

1590 FDA

311879F 39

Page 40

Technical Data - 1590

Technical Data - 1590

Maximum fluid working pressure . . . . . . . . . . . . . . . . . . . 120 psi (0.8 MPa, 8 bar)

Air pressure operating range . . . . . . . . . . . . . . . . . . . . . . 20-120 psi (0.14-0.8 MPa, 1.4-8 bar)

Maximum air consumption . . . . . . . . . . . . . . . . . . . . . . . . 130 scfm

Air consumption at 70 psi/50 gpm . . . . . . . . . . . . . . . . . .

Maximum free-flow delivery . . . . . . . . . . . . . . . . . . . . . . . 100 gpm (379 l/min)

Maximum pump speed . . . . . . . . . . . . . . . . . . . . . . . . . . . 200 cpm

* Gallons (Liters) per cycle . . . . . . . . . . . . . . . . . . . . . . . .

Maximum suction lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum size pumpable solids . . . . . . . . . . . . . . . . . . . . 3/16 in. (4.8 mm)

** Maximum Noise Level at 100 psi, full flow . . . . . . . . . . 88 dBa

** Sound Power Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95 dBa

** Noise Level at 70 psi and 50 cpm. . . . . . . . . . . . . . . . . 79 dBa

Maximum fluid operating temperature is based on the following maximum diaphragm, ball, and seat temperature

ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

42 scfm (see chart)

0.5 (1.9)

29 ft (8.83 m) wet, 14 ft (4.26 m) dry

PTFE 220°F (104.4°C)

Santoprene® 180°F (82.2°C)

Neoprene 200°F (93°C)

EPDM 275°F (135°C)

Stainless steel 250°F (121.1°C)

Air inlet size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid inlet size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 in. Sanitary flange

Fluid outlet size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wetted parts

***All fluid contact materials are FDA-compliant and meet the United States Code of Federal Regulations (CFR)

Title 21, Section 177.

Wetted materials on all models . . . . . . . . . . . . . . . . . . . .

Wetted material depending on model. . . . . . . . . . . . . . . .

CAUTION:

Santoprene® may be used only with non-fatty, non-oily foods or alcohols up to 15%.

Non-wetted external parts . . . . . . . . . . . . . . . . . . . . . . . .

Weight

All models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89 lb (40.3 kg)

Santoprene® is a registered trademark of the Monsanto Co.

Loctite® is a registered trademark of the Loctite Corporation.

* Displacement per cycle may vary based on suction condition, discharge head, air pressure, and fluid type.

** Noise levels measured with the pump mounted to a solid surface. Sound power measured per

ISO Standard 9614-1.

0.5 in. npt(f)

2.0 in. Sanitary flange

316 SST

EPDM, Neoprene, PTFE, Santoprene®

300 series stainless steel, polyester (labels), LDPE foam

(gasket)

*** The pump user must verify that the construction materials meet their specific application requirements.

40 311879F

Page 41

Performance Chart - 1590

Test Conditions: Pump tested in water with inlet submerged

Fluid Pressure Curves

at 120 psi (0.7 MPa, 7 bar) operating air pressure

at 100 psi (0.7 MPa, 7 bar) operating air pressure

at 70 psi (0.48 MPa, 4.8 bar) operating air pressure

at 40 psi (0.28 MPa, 2.8 bar) operating air pressure

o find Fluid Outlet Pressure

psi/MPa/bar) at a specific fluid flow (gpm/lpm) and

perating air pressure (psi/MPa/bar):

1. Locate fluid flow rate along bottom of chart.

. Follow vertical line up to intersection with selected

operating air pressure curve.

. Follow left to scale to read fluid outlet pressure.

Fluid Outlet Pressure

(0.96, 9.6)

(0.84, 8.4)

(0.7, 7)

(0.55, 5.5)

(0.41, 4.1)

psi (MPa, bar)

(0.28, 2.8)

(0.14, 1.4)

100

140

120

20

Performance Chart - 1590

80

60

40

0

20

(75)

40

(151)

60

(227)80(302)

100

(378)

Fluid Flow

gpm (lpm)

120

(454)

TI8738A

Air Consumption Curves

A at 120 psi (0.7 MPa, 7 bar) operating air pressure

B at 100 psi (0.7 MPa, 7 bar) operating air pressure

C at 70 psi (0.48 MPa, 4.8 bar) operating air pres-

sure

D at 40 psi (0.28 MPa, 2.8 bar) operating air pres-

sure

To find Pump Air Pressure

(scfm or m

3

/min) at a specific fluid flow (gpm/lpm)

and operating air pressure (psi/MPa/bar):

1. Locate fluid flow rate along bottom of chart.

2. Read vertical line up to intersection with selected

operating air pressure.

3. Follow left to scale to read air consumption.

Air Consumption

/min)

3

(0.41, 4.1)

(0.28, 2.8)

scfm (m

(0.14, 1.4)

140

(0.96, 9.6)

120

(0.84, 8.4)

100

(0.7, 7)

(0.55, 5.5)

20

TI8742A

80

60

40

0

20

(75)

40

(151)

60

(227)80(302)

100

(378)

Fluid Flow

gpm (lpm)

(454)

TI8739A

120

311879F 41

TI8742A

Page 42

Pump Matrix - 2150

Pump Matrix - 2150

2150 FDA-Compliant Stainless Steel Sanitary Pumps

Your Model No. is marked on the pump’s serial plate. To

determine the Model No. of your pump from the following matrix, select the six digits which describe your

pump, working from left to right. The first three digits are

always FD3, designating 2150 SST FDA compliant diaphragm pumps. The remaining three digits define the

materials of construction. For example, a pump with an

FDA-Compliant

Diaphragm

Pump

FD3 - All 2150 SST FDA-Compliant Pumps

2150 Stainless

Steel Air Motor

Stainless Steel

Fluid Section

aluminum air motor, stainless steel fluid section, stainless steel seats, PTFE o-rings, PTFE balls, and PTFE

diaphragms is Model No.

ment parts, refer to the part lists on pages 45-46.

The digits in the matrix do not correspond to the reference numbers in the parts drawings and parts lists.

Seats and

O-rings

1 (316 SST with

PTFE o-rings)

2 (316 SST with

EPDM o-rings)

Balls Diaphragms

1 (PTFE) 1 (PTFE)

2 (Santoprene®) 2 (Santoprene®)

3 (Neoprene

FD3111. To order replace-

3(PTFE

with SST core)

Heavy-Duty)

Available Configurations

•FD3111

•FD3122

•FD3211

•FD3222

•FD3113

•FD3213

•FD3132

•FD3232

42 311879F

Page 43

Repair Kit Matrix - 2150

For 2150 Stainless Steel Sanitary Pumps

Repair Kit Matrix - 2150

Repair Kits may be ordered separately. To repair the air

valve, order Part No. 255061 (see page 28). Parts

included in the Air Valve Repair Kit are marked with a

symbol in the parts list, for example (4†).

To repair your pump, select the six digits which describe

your pump from the following matrix, working from left to

right. The first three digits are always FD3. The remaining three digits define the materials of construction.

Diaphragm

Pump

FK3 - All 2150 SST Sanitary Pumps

Null Pump Size

Parts included in the kit are marked with an asterisk in

the parts list, for example (201*). For example, if your

pump has stainless steel seats, PTFE o-rings, PTFE

balls, and PTFE diaphragms, order Repair Kit

FK3111.

The digits in the matrix do not correspond to the reference numbers in the parts drawings and parts lists.

Seats and

O-rings

1 (316 SST with

PTFE o-rings)

2 (316 SST with

EPDM o-rings)

Balls Diaphragms

1(PTFE)

white

2 (Santoprene®)

blue

3 (Neoprene

with SST core)

1(PTFE)

white

2 (Santoprene®)

blue

3(PTFE

Heavy-Duty)

Available Configurations

•FK3111

•FK3122

•FK3211

•FK3222

•FK3113

•FK3213

•FK3132

•FK3232

311879F 43

Page 44

Parts - 2150

Parts - 2150

Detail of Heavy-Duty Diaphragm

403*

110

▲

†10

†17

†18

11

16

†4

104

103

3

2

113

5

6†

*301

105

106

201

108*

3

7†

8†

107

*202

104

17†

16

12

10†

11

401*

1

403*

23

15

1

402*

19

20

22

111

13

1

Used on PTFE models only.

*

These parts are included in the Pump Repair Kit which may be purchased

separately. Refer to the Repair Kit Matrix on page 42 to determine the correct kit for your pump.

†

These parts are included in Air Valve Repair Kit 255061 which may be purchased separately.

▲

Replacement Danger and Warning labels, tags and cards are available at

no cost.

25

24

101

*301

201

*202

113

102

TI8929b

44 311879F

Page 45

Air Motor Parts List (Matrix Column 2)

Ref. Part No. Description Qty

1 15K009 HOUSING, center; SST 1

2 15A735 COVER, air valve; SST 1

3 116344 SCREW, mach, hex flange hd;

M5 x 0.8; 12 mm (0.47 in.)

4† 188618 GASKET, cover 1

5 188855 CARRIAGE; aluminum 1

6† 108730 O-RING; nitrile 1

7† 188616 BLOCK, air valve; acetal 1

8† 15H178 PLATE, air valve; SST 1

10† 112181 PACKING, u-cup; nitrile 4

11 188612 PISTON, actuator; acetal 2

12 188613 BEARING, piston; acetal 2

13‡ 103778 PLUG, pipe 2

15 188611 BEARING, pin; acetal 2

16 188610 PIN, pilot; SST 2

17† 157628 O-RING; buna-N 2

18† 188614 BLOCK, pilot; acetal 1

19 188609 BEARING, shaft; acetal 2

20 116344 SCREW, grounding 1

22 188603 GASKET, air cover; foam 2

23 15H859 COVER, air; SST 2

24 189304 SHAFT, diaphragm; SST 1

25 112178 SCREW; M8 x 1.25; 25 mm

(1 in.); stainless steel

Parts - 2150

9

12

† These parts are included in Air Valve Repair Kit 255061 which may be purchased separately.

311879F 45

Page 46

Parts - 2150

Fluid Section Parts List (Matrix Column 3)

Ref. Part No. Description Qty

101 277264 COVER, fluid; SST 2

102 277269 MANIFOLD, inlet; SST 1

103 277270 MANIFOLD, outlet; SST 1

106 15H513 CLAMP, sanitary, dia-

phragm

110▲ 188621 LABEL, warning 1

111 15G332 MUFFLER 1

113 510490 CLAMP, sanitary 4

2

Seat Parts List (Matrix Column 4)

Digit Ref. Part No. Description Qty

1 201 15H826 SEAT; 316 SST 4

202* 15H831 O-RING; PTFE 4

2 201 15H826 SEAT; 316 SST 4

202* 15H829 O-RING; EPDM 4

* These parts are included in the Pump Repair Kit which

may be purchased separately. Refer to the Repair Kit Matrix on

page 42 to determine the correct kit for your pump.

▲Replacement Danger and Warning labels, tags and cards

are available at no cost.

Ball Parts List (Matrix Column 5)

Digit Ref. Part No. Description Qty

1 301* 112359 BALL; PTFE 4

Diaphragm Parts List (Matrix Column 6)

Digit Ref. Part No. Description Qty

1 401* DIAPHRAGM; backer;

EPDM

402* 112181 PACKING; u-cup;

nitrile

403* 15K313 DIAPHRAGM; PTFE 2

104 189298 PLATE, air side;

aluminum

105 189299 PLATE, fluid side; SST 2

107 189410 BOLT; M12 x 1.75;

55 mm (2.16 in.); SST

108* 104319 O-RING; PTFE 2

2 402* 112181 PACKING; u-cup;

nitrile

403* 189296 DIAPHRAGM;

Santoprene®

104 189298 PLATE, air side;

aluminum

105 189299 PLATE, fluid side; SST 2

107 189410 BOLT; M12 x 1.75;

55 mm (2.16 in.); SST

108* 104319 O-RING; PTFE 2

3 289226 Kit, heavy-duty diaphragm, PTFE;

includes 403 and 104

402* 112181 PACKING; u-cup;

nitrile

2

2

2

2

2

2

2

2

2

2 301* 112361 BALL; Santoprene® 4